#aluminum profile

Explore tagged Tumblr posts

Text

Discovering the Aluminum Profiles Versatility

Aluminum billets are heated and forced through a die's curved aperture to create an Aluminum profile, often referred to as aluminum extrusions, which have consistent cross-sectional geometries. It is possible to create complex designs with exact proportions using this approach. These profiles are appropriate for a variety of applications as they may be made in an extensive array of sizes, forms, and finishes.

Utilization of Aluminum Profiles

Building: A lot of aluminum profiles are utilized in buildings for curtain walls, windows, doors, frame systems, and structural elements. They are perfect for architectural projects because of their lightweight design, resistance to corrosion, and tolerance to extreme weather conditions.

Automobile: Aluminum profiles are used in engine components, heat exchangers, body frames, and chassis constructions in the automobile sector. Their excellent strength-to-weight ratio contributes to improved performance, increased fuel economy, and weight reduction of the vehicle.

Electronics: Aluminum profile China dissipates heat produced by electronic components by acting as heat sinks in electronic equipment. Because of its superior thermal conductivity, heat is dissipated effectively, minimizing overheating and prolonging the life of electronic equipment.

Aluminum profiles are used in aerospace applications for fuselage panels, interior parts, and aircraft structures. Aluminum is a desirable material in aircraft manufacture because of its lightweight characteristics, which also allow for increased cargo capacity and fuel savings.

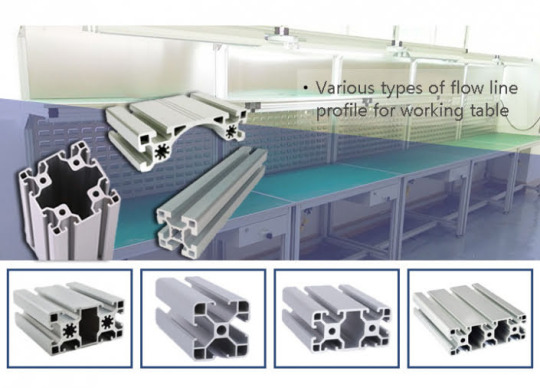

Industrial Machinery: Conveyor systems, assembly lines, robotic equipment, and other pieces of machinery are made using aluminum profiles. Their adaptability enables machine frames and structural supports to be tailored to individual needs.

Aluminum Profile Benefits

Lightweight: Compared to steel or other metals, aluminum profiles are lighter due to their excellent strength-to-weight ratio. This feature lowers total costs by streamlining the handling, installation, and shipping procedures.

Corrosion Resistance: Due to its inherent corrosion resistance, aluminum can endure exposure to air, moisture, and chemicals. This characteristic guarantees resilience and endurance in many settings.

Formability: Aluminum profiles are easily extruded into intricate combinations and forms, enabling accurate measurements and bespoke designs. This formability makes applications across several sectors more versatile.

Aesthetic Appeal: Anodizing, powder coating, painting, and other surface treatments by Aluminum profile Manufacturer can be applied to aluminum profiles to improve their look and offer more resistance to wear and corrosion.

#Aluminum profile Manufacturer#Aluminum profile Company China#Aluminum profile Company#Aluminum profile Process#Aluminum profile China#Aluminum profile

2 notes

·

View notes

Text

Aluminium Profile Sheets – The Versatile Solution for Contemporary Construction and Design

Aluminium profile sheets are an important material used in many industries, especially construction, architecture and manufacturing. These sheets are a multipurpose solution for all kinds of applications, such as facades, roofing, interior designs and partitions with durability, lightweight & aesthetics.

Corrosion resistance is one of the fundamental features of aluminium profile sheets. In contrast with steel, aluminium instantly creates a protective oxide layer that makes it extremely safe and also prevents rust and wear. Furthermore, its resistance to corrosion over time, even in extreme weather conditions, allows aluminium sheets to ensure they keep their integrity and appearance for years.

Moreover, other than being strong, aluminium is also extremely light weight and thus can easily be handled and installed without risking rigidity during the structure.Its flat and long form also lends itself to shaping into various profiles, for bespoke applications, where needed. Aluminum profile sheets can be fashioned to suit industrial, commercial, or residential applications and allow for flexibility in design, size, and functionality.

In addition, aluminium is one of the most sustainable materials around as it is 100 per cent reusable without compromising on its properties. With this being an eco-friendly option for modern building, sustainability is becoming a priority.

Thus, aluminium profile sheets offer practicality and aesthetics, making them perfect alternatives for various projects while being reliable and budget-friendly.

0 notes

Text

5 Amazing Ways Aluminium Profiles Shape Modern Construction

In the world of construction, aluminium profiles, aluminium extrusion, and aluminium extrusion profiles have become irreplaceable. Lightweight, resistant, and versatile, the metal is the preferred choice in innovative designs and sustainable solutions. From towering skyscrapers to intricate interiors, let's explore five remarkable ways aluminum is transforming construction. 1. Structural Support with Aluminium Profiles This has made aluminum the material for frameworks because of its good strength-to-weight ratio. Further, aluminum extrusion profiles serve in beams, columns, and supports, while availing strength with flexibility in design. These lightweight structures reduce the overall load on buildings, making it ideal to use in multi-story buildings and big infrastructural projects. 2. Modern and Resilient Building Facades Aluminum profiles are indispensable for modern building facades. Resistant to corrosion, these provide a long life to the facades exposed to harsh weather conditions. Architects use aluminum because it can combine strength with slim, modern appearances that create striking and low-maintenance facades. 3. Eco-Friendly Doors and Windows In building with energy efficiency, there is no match for aluminum. Aluminum extrusion profiles provide exact fits in doors and windows for improved insulation and reduced energy leakage. Besides, it is fully recyclable, hence sustainable for projects that take into consideration ecological concerns. 4. Versatile Roofing and Cladding Systems From roofing panels to external cladding, no other metal competes with the flexibility that aluminium provides. In an extruded form, the metal offers tough and light panels whose installation and maintenance techniques are simple. The panels insulate well against harsh weather conditions like UV radiation, wind, and rain; therefore, their application suits both commercial and residential areas. 5. Interior Design and Decorative Features Indoors, aluminium is used inside buildings for its versatility and contemporary appearance. It is used to manufacture partition walls, ceiling systems, and decorative elements. Designers use the aluminium extrusion profile to develop bespoke luminaire, trims, and furniture that add elegance to any room. Why Aluminium is So Important in Building and Construction

Aluminium is a popular metal used in building and construction due to several underlying reasons. Some of the key reasons include: Strength : Provides low construction load with high strength. Design Versatility: Allows for creative and detailed designs. Corrosion Resistance: Ensures durability for several environmental conditions. Sustainability: It is 100% recyclable, reducing its environmental footprint. Cost-Effectiveness: Long-lasting with very limited maintenance needs. The Future is Aluminium , As building requirements are changing, so the aluminium profiles and aluminium extrusion keep pace with them. Not only do they satisfy the technological demands of a newly created building but also ecological ones, turning them into an integral part of every building process in the world. Upgrade your next construction project to the unequalled benefits offered by using aluminum.

0 notes

Text

The advantage of anodized aluminum plate and anodized aluminum facade

(1) Good processability: anodized aluminum plate/anodized aluminum facade has strong decorative properties, moderate hardness, and can be easily bent into shape for continuous high-speed stamping, making it convenient to directly process into products without the need for complex surface treatment, greatly reducing product production cycle and production costs.

(2) Good weather resistance: The anodized aluminum plate with a standard thickness oxide film (3 μ m) will not change color, corrode, oxidize, or rust after long-term indoor use. The anodized aluminum plate with a thickened oxide film (10 μ m) can be used outdoors and can withstand long-term exposure to sunlight without changing color.

(3) Strong metallic feel: The anodized aluminum plate has a high surface hardness, reaching gem level, good scratch resistance, no paint coverage on the surface, retains the metallic color of the aluminum plate, highlights modern metallic feel, and improves product grade and added value.

#anodizedaluminum#anodized aluminum facade#wallnova#aluminum profile#aluminum baffle panel#aluminum ceiling

0 notes

Text

youtube

We manufacture wood grain heat transfer films/papers

what's APP:+86 13672690566

Email:[email protected]

1 note

·

View note

Text

Aluminum Profile CNC Machining Service

youtube

1 note

·

View note

Text

The Modern Workplace: Enhancing Aesthetics and Functionality with Office Glass Door

The design and functionality of office spaces have a significant impact on productivity, employee satisfaction, and the culture of the workplace as a whole in today's fast-paced business environment. The office glass door is one design element that has gained a lot of popularity. This cutting-edge feature not only looks good, but it also has a lot of useful benefits that can make any workplace better.

Aesthetics and Elegance :

Glass office doors give any workspace a sleek, modern appearance. Because of their transparency, even the smallest offices can be made to appear larger and more inviting. The perfect lines and moderate plan of glass entryways add to an expert and cleaned climate, which can dazzle clients and guests the same. Additionally, glass entryways can be tweaked with glazed or scratched examples, logos, or coloring to improve security while as yet keeping an exquisite appearance.

Energy Efficiency and Natural Light :

One of the most notable advantages of office glass door is their capacity to maximize natural light. Dissimilar to conventional wooden or metal entryways, glass entryways permit daylight to infiltrate further into the workplace, diminishing the requirement for counterfeit lighting during the day. This not only saves money on energy, but it also makes the workplace healthier and more enjoyable. Natural light is a valuable asset in any office because it has been shown to improve mood and productivity.

Collaboration and Communication :

Open correspondence is a foundation of an effective business, and office glass entryways cultivate a climate of straightforwardness and cooperation. Workers are more open and noticeable to each other, which can energize unconstrained conversations and collaboration. Glass entryways can likewise assist bosses and chiefs keep a visual association with their groups, working with better oversight and more prompt criticism.

Privacy without Isolation :

Despite their openness, glass doors do not compromise privacy. Glazed or colored glass choices can give the fundamental caution to gatherings and confidential discussions. Acoustic glass can also aid in noise reduction while safeguarding confidential information. This harmony among transparency and protection is significant in keeping an expert and agreeable work environment.

Durability and Maintenance :

Contrary to common misconceptions, contemporary office glass doors are constructed to be long-lasting and low-maintenance. Produced using treated or overlaid glass, they are impervious to breaking and can endure the afflictions of a bustling office. Cleaning and keeping up with glass entryways is clear, requiring just ordinary cleaning with proper cleaning answers for keep them looking unblemished.

Final Thoughts :

In conclusion, incorporating office glass doors into the design of your workplace is a smart move that improves both functionality and aesthetics. The advantages of glass doors are numerous, ranging from enhancing natural light and energy efficiency to fostering collaboration and maintaining privacy. As organizations keep on developing, embracing such present day plan components can assist with making a more powerful, effective, and engaging office climate.

0 notes

Text

SLIM PROFILE

Size

10ftUsage/Application

ConstructionDesign

As per requirementMaterial

Aluminium 6063 GradeSurface Finishing

As per requirementsPosition

Interior

Aluminium Slim Profile sections available for Sliding in different types of surface finishes as per your needs

1 note

·

View note

Text

0 notes

Text

This summer, let your home shine. It is brilliant to have bifold doors in the summer for those summer events and activities because they let in the fresh air and help you cool off. Use high-quality aluminum and glass products when installing a bifold door. Slim profile sections of the BF73 system minimize the visible framework and maximize the glass area. Let us help you create your dream home

#door installation#window installation#aluminum profile#aluminum products#canopy#Brooklyn windows#window installation nyc#window repair nyc#SkyWindows & Aluminum Products

0 notes

Text

Innovative Uses of Aluminum Profiles in Home Architecture

Aluminum is one of the most versatile materials used in modern home architecture. Its strength, lightweight nature, and resistance to rust make it an excellent choice for various applications. Aluminum profiles, which are specially designed extrusions of aluminum, offer innovative solutions for both interior and exterior home designs. In this blog, we explore some creative and practical ways aluminum profiles are transforming home architecture.

1. Modern and Stylish Windows

Windows are essential in any home, providing natural light, ventilation, and aesthetic appeal. Aluminum profiles are widely used to create sleek and modern window frames. Unlike traditional wooden or steel frames, aluminum profiles offer better durability and require minimal maintenance.

Aluminum windows can be designed with thin frames, allowing for larger glass panels that maximize the view and natural light. They also provide excellent insulation when combined with energy-efficient glass, making homes more comfortable and reducing energy bills.

2. Durable and Elegant Doors

Aluminum profiles are perfect for making strong yet stylish doors. Sliding doors, French doors, and bi-fold doors made with aluminum frames add a modern touch to homes. These doors are lightweight, easy to operate, and resistant to warping or rotting, unlike wooden doors.

Aluminum sliding doors are particularly popular for connecting indoor and outdoor spaces. Their slim yet strong frames allow for larger glass panels, creating a seamless transition between the interior and exterior of a home.

3. Innovative Room Partitions

Open-plan living is a popular trend in modern homes. However, homeowners often need flexible partitions to divide spaces when needed. Aluminum profiles are used to create stylish and lightweight room dividers.

Glass partitions with aluminum frames allow for separation while maintaining an open and airy feel. These partitions can be designed as sliding, folding, or fixed panels, offering functional and aesthetic benefits.

4. Stylish Kitchen Cabinets and Shelving

Aluminum profiles are widely used in kitchen designs to create durable and modern cabinets. Traditional wooden cabinets can be heavy and prone to damage from moisture and heat. Aluminum-framed cabinets, on the other hand, are resistant to these issues and offer a contemporary look.

Additionally, aluminum profiles are used to build open shelving units. Their sleek and minimalist design makes them ideal for modern kitchens, providing both functionality and elegance.

5. Strong and Lightweight Stair Railings

Aluminum profiles are commonly used in stair railings due to their strength, durability, and modern appeal. They provide a sleek, contemporary alternative to traditional wooden or iron railings.

Aluminum railings can be combined with glass panels for a stylish, open look that enhances the beauty of staircases. They are also resistant to corrosion, making them ideal for both indoor and outdoor staircases.

6. Energy-Efficient Curtain Walls

In modern home architecture, curtain walls made from aluminum profiles and glass are becoming increasingly popular. These walls allow for maximum natural light while providing excellent insulation.

Aluminum curtain walls are commonly used in high-rise apartments and luxury homes. They enhance the aesthetics of a building while improving energy efficiency by reducing heat loss and keeping interiors comfortable.

7. Outdoor Pergolas and Sunshades

Aluminum profiles are also used for outdoor structures such as pergolas, sunshades, and patio covers. These structures provide shade and protection from the elements while maintaining a stylish and contemporary appearance.

Unlike wooden pergolas, aluminum structures do not rot, warp, or require frequent maintenance. They can also be customized with retractable roofs or sliding panels for added functionality.

8. Security and Decorative Grilles

Aluminum profiles are widely used in designing window grilles and security doors. These grilles provide protection while maintaining a sleek and modern look. Unlike traditional iron grilles, aluminum grilles are lightweight, corrosion-resistant, and require minimal maintenance.

Decorative aluminum grilles can also be customized with various patterns, adding an artistic touch to windows and doors.

Conclusion

Aluminum profiles have transformed modern home architecture by offering innovative, stylish, and durable solutions. Whether used for windows, doors, partitions, railings, or outdoor structures, aluminum enhances the functionality and aesthetic appeal of homes.

For homeowners looking for high-quality and modern solutions, Aluminium Window Grille and Sliding Door and Windows are excellent choices that combine strength, beauty, and efficiency.

0 notes

Text

Exploring the Aluminum Profile Processing Intricacies

Aluminum profile is unique among components used in modern production because of their versatility and necessary nature. Applications for these extruded forms may be found in a wide range of sectors, including consumer products, electronics, automotive, and construction. A thorough grasp of material qualities, technical innovation, and precise engineering are all required in the exciting process of creating aluminum profiles.

Aluminum Profiles Significance

Because of their many benefits, aluminum profiles are the material of choice for a wide range of applications:

Lightweight

Power and Sturdiness

The corrosion free

Flexibility

The Procedure for Processing Aluminum Profiles

Design and Development of Die: Engineers develop the ideal profile form and proportions during the process's first design step. A unique die, or mold, is made after the design is complete in order to extrude the metal into the required shape.

Heating the billet: To prepare it for extrusion, aluminum billets, which are usually formed from primary or recycled aluminum, are heated to a particular temperature. In order to guarantee consistency and malleability, this preheating phase is critical.

Extrusion: Using mechanical or hydraulic pressure, the heated aluminum billet is pushed through a specifically made die. The metal takes on the shape of the profile as it goes through the die and emerges as a continuous length of extruded aluminum.

Quenching and Cooling: To maintain its shape and characteristics, the extruded aluminum profile is quickly cooled with either water or air. In order to achieve the appropriate mechanical characteristics and avoid distortion, this quenching procedure is essential.

Cutting and Finishing: Using precision saws or shears, the extruded aluminum profile is trimmed to the necessary lengths once it has cooled. The profile may also be modified by using additional machining techniques like punching, drilling, or milling to add holes or features. Lastly, surface treatments like powder coating or anodizing can be used to improve corrosion resistance and appearance.

Quality Control: Strict quality control procedures are followed during the whole Aluminum profile Process to guarantee that the final aluminum profiles have the required mechanical qualities, surface polish, and tolerances. To find any flaws or irregularities, this may entail visual inspections, mechanical testing, and dimensional inspections.

#Aluminum profile#Aluminum profile China#Aluminum profile Process#Aluminum profile Company#Aluminum profile Company China#Aluminum profile Manufacturer#Aluminum profile supplier

2 notes

·

View notes

Text

WALLNOVA ARCHITECTURAL PRODUCTS CO., LTD ALUMINUM KNOWLEDGE-2

The Advantage Application of Aluminum in Green Buildings-2

Durability Aluminum alloy building materials are resistant to weathering, corrosion, and can also shield the harmful effects of ultraviolet radiation. Aluminum alloy building materials always maintain ideal performance over a long period of use. Customized aluminum alloy building materials have more outstanding corrosion resistance. Therefore, aluminum alloy profiles can be used for a long time even under harsh conditions, without the need for expensive maintenance and repair.

Diversity Aluminum has strong machinability, therefore, the design potential of aluminum products is almost endless. Aluminum can be formed, welded, rotary cut, or cut into dynamic three-dimensional shapes. With the help of extrusion technology, a variety of aluminum materials can be obtained, so designers can integrate a large number of functions into a single aluminum profile product. Calendered products can be made of sheet metal, curved surfaces, processed into box shapes, or used as interlayers with other materials. In addition, aluminum materials can be sawed, drilled, riveted, rotary cut, bent, and welded in workshops or construction sites.

0 notes

Text

#T-SLOT ALUMINIUM PROFILES AND ACCESSORIES MANUFACTURER IN INDIA#Welcome to Aluminium Profiles#a leading source for top-tier T-slot Aluminium profiles and accessories in India. Our commitment to excellence is reflected in our extensiv#KEY FEATURES:#Anodized Aluminium extrusion profiles with a thickness of 10 to 12 microns for superior quality.#Standard sizes include 2020#2040#3030#3060#4040#4080#4590#6060#8080#and 9090.#Special profiles like half-round corner aluminium profiles 3030R#4040R#and 4545R are also available.#Custom profiles can be requested#although they may require additional delivery time.#DISCOUNT SALES ON T-SLOT ALUMINUM EXTRUSION PROFILES:#Take advantage of our ongoing discount sales on all T-slot Aluminum extrusion profiles. As a trusted manufacturer#exporter#wholesaler#supplier#dealer#and distributor since 2014#we serve customers all over India#catering to diverse project requirements.

0 notes

Text

Your Trusted Custom Aluminium Extrusion Supplier for Automation Needs

When it comes to precision, durability, and innovation, Dhaatu Fabex is a name you can trust. As a leading custom aluminium extrusion supplier and Automation Aluminum Extrusions Supplier, we provide tailored solutions that align perfectly with the unique needs of various industries. Whether you’re looking to optimize your automation systems or require high-quality aluminum for specific applications, Dhaatu Fabex delivers unmatched products and services.

Why Dhaatu Fabex is the Right Choice

Customised Aluminium Extrusions for Every Project Every industry has distinct requirements, and at Dhaatu Fabex, we specialise in creating custom aluminium extrusions to meet your precise specifications. From intricate components to robust frameworks, our customisation options ensure that your vision becomes a reality.

Uncompromising Quality and Durability Quality is the hallmark of our manufacturing process. Using advanced technology and premium-grade aluminium, we ensure our extrusions are durable, reliable, and built to withstand demanding conditions, making them ideal for both small-scale and large-scale automation projects.

Tailored for Automation Excellence As an Automation Aluminum Extrusions Supplier, we understand the unique challenges of automated systems. Our extrusions are designed to improve efficiency, minimise downtime, and enhance the overall performance of your automation setups, whether in industrial assembly lines, robotic systems, or conveyor mechanisms.

Eco-Friendly and Sustainable Practices Aluminium is a recyclable material, and Dhaatu Fabex is committed to sustainable manufacturing. By choosing our products, you not only ensure exceptional quality but also contribute to reducing environmental impact, aligning your business with global eco-friendly initiatives.

Industry Applications and Expertise

Dhaatu Fabex has been at the forefront of providing high-performing aluminium solutions for a wide range of applications. Our extrusions find their place in industries such as automotive, construction, electronics, and manufacturing automation. With a dedicated team of experts, we ensure that every product we deliver meets the rigorous demands of modern industries while maintaining cost-efficiency.

Partnering with Dhaatu Fabex

Our partnership approach sets us apart from others. We don’t just provide aluminium extrusions; we collaborate with you to understand your challenges and requirements, offering comprehensive support from design consultation to timely delivery. This commitment makes us a preferred supplier for businesses looking to achieve excellence in their projects.

Conclusion

Dhaatu Fabex is more than just a supplier—it’s your partner in driving innovation and efficiency. With our expertise in custom aluminium extrusions and a deep understanding of automation requirements, we empower businesses to succeed in today’s competitive market. Trust Dhaatu Fabex to deliver precision-engineered solutions that exceed expectations while supporting sustainable growth.

Ready to elevate your projects? Visit Dhaatu Fabex today and explore how our expertise can transform your vision into reality. Let’s shape a smarter, more efficient future together!

#custom aluminium extrusion supplier#Automation Aluminum Extrusions Supplier#best aluminium company in india#aluminium construction profiles#Industrial aluminium providers

0 notes

Text

Efficient Heat Dissipation with Premium Aluminum Heatsinks When performance and reliability matter, trust our high-quality aluminum heatsinks to keep your electronic devices cool. Engineered for optimal thermal management, our heatsinks deliver superior heat dissipation, extending the life of your components and improving overall system efficiency.

1. Superior Heat Dissipation: Designed to efficiently transfer heat and maintain optimal performance. 2. Lightweight & Durable: Made from high-grade aluminum for strength and long-lasting reliability. 3. Customizable Sizes & Shapes: Tailored to fit your specific cooling requirements. 4. Versatile Applications: Ideal for power electronics, LED lighting, automotive systems, and more. 5. Eco-Friendly & Cost-Effective: Sustainable design that offers both performance and value. Keep your electronics running cooler and longer. Choose our aluminum heatsinks for your next project!

If you have more specific details about your product (like custom features or target industries), let me know and I can tailor the copy further!

You will find more heat sinks on www.glarysh.com

#led heatsink#led cooler#aluminum profiles#cooler#led light#heatsink#radiator#led lighting#led lights#extrusion

0 notes