#Agricultural chemicals manufacturers in India

Explore tagged Tumblr posts

Text

The Future of Agricultural Chemicals Innovations and Trends

The agricultural sector is undergoing a significant transformation, driven by advancements in technology, sustainability practices, and evolving market demands. Agricultural chemicals, which play a crucial role in enhancing crop productivity and protecting plants from pests and diseases, are at the forefront of this transformation. Let's explore the future of agricultural chemicals, focusing on the innovations and trends that are shaping the industry.

Innovations in Agricultural Chemicals

Biopesticides and Biofertilizers As concerns about the environmental impact of synthetic chemicals grow, the demand for biopesticides and biofertilizers is rising. These products, derived from natural sources such as plants, bacteria, and fungi, offer a sustainable alternative to traditional chemicals. They not only reduce the chemical load on the environment but also promote soil health and biodiversity.

Precision Agriculture Precision agriculture is revolutionizing the way farmers apply agricultural chemicals. Utilizing technologies like GPS, drones, and IoT sensors, farmers can apply chemicals more accurately and efficiently. This reduces waste, minimizes environmental impact, and ensures that crops receive the optimal amount of nutrients and protection.

Nanotechnology Nanotechnology is making waves in the agricultural chemicals sector. By using nanoparticles, manufacturers can create more effective and targeted chemical formulations. These nanoparticles can deliver active ingredients directly to the plants, improving absorption and reducing the overall quantity of chemicals needed.

Genetically Modified Organisms (GMOs) Advances in genetic engineering are leading to the development of crops that require fewer chemical inputs. GMOs can be engineered to be more resistant to pests, diseases, and environmental stresses, reducing the need for external chemical applications.

Trends in the Agricultural Chemicals Industry

Sustainability and Environmental Responsibility There is a growing emphasis on sustainability within the agricultural chemicals industry. Agricultural chemicals manufacturers are investing in research and development to create products that are less harmful to the environment and human health. This includes the development of eco-friendly packaging and the reduction of greenhouse gas emissions during production.

Regulatory Changes Governments around the world are tightening regulations on the use of agricultural chemicals. This is driving companies to innovate and develop safer, more effective products. In India, regulatory bodies are implementing stricter guidelines to ensure the safety and efficacy of agricultural chemicals.

Digital Agriculture The integration of digital technologies in agriculture is transforming how agricultural chemicals are managed and applied. Digital platforms and apps are providing farmers with real-time data and analytics, helping them make informed decisions about chemical usage. This trend is expected to grow, leading to more efficient and sustainable farming practices.

Collaborations and Partnerships Collaboration between agrochemical companies, research institutions, and technology providers is becoming more common. These partnerships are fostering innovation and enabling the development of cutting-edge solutions that address the challenges faced by modern agriculture.

The Role of Agricultural Chemicals Manufacturers in India

India is home to a burgeoning agricultural chemicals industry, with numerous companies leading the charge in innovation and sustainability. Agricultural chemicals manufacturers in India are investing heavily in research and development to create products that meet the needs of modern farmers while adhering to strict environmental standards. These companies are also focusing on expanding their global footprint, making India a key player in the international agrochemical market.

Conclusion

The future of agricultural chemicals is marked by exciting innovations and evolving trends that promise to make agriculture more sustainable, efficient, and productive. As the industry continues to evolve, agricultural chemicals manufacturers, especially those in India, will play a pivotal role in driving this transformation. By embracing new technologies and prioritizing sustainability, these companies are ensuring a brighter future for agriculture and the environment.

0 notes

Text

Produce High-Quality Agriculture Crops, Organic and Handicraft Products Manufacturer and Exporter in Telangana, India

#Fruits and Vegetables#Cereals and Pulses#Dried Products#Handicrafts#Chemical Products#Avenue Plants#Coconut Products#Agriculture Product#Exporter in Telangana#Manufacturer in India

0 notes

Text

Growth Strategies Adopted by Major Players in Turf Protection Market

In the dynamic landscape of the turf protection industry, key players like Syngenta Crop Protection AG (Switzerland), UPL Limited (India), Corteva Agriscience (US), Nufarm (US), Bayer AG (Germany), and BASF SE (Germany) are at the forefront of innovation and market expansion. These industry leaders are driving growth through strategic initiatives such as partnerships, acquisitions, and cutting-edge product developments, solidifying their positions as influential forces in shaping the future of the turf protection industry. Their efforts not only enhance their global presence but also set new benchmarks for industry standards and customer expectations. The global turf protection market size is estimated to reach $8.1 billion by 2028, growing at a 4.9% compound annual growth rate (CAGR). The market size was valued $6.4 billion in 2023.

Top Global Turf Protection Leaders to Watch in 2024

· Syngenta Crop Protection AG (Switzerland)

· UPL Limited (India)

· Corteva Agriscience (US)

· Nufarm (US)

· Bayer AG (Germany)

· BASF SE (Germany)

· SDS Biotech K.K. (Japan)

· AMVAC Chemical Corporation (US)

· Bioceres Crop Solutions (Argentina)

· Colin Campbell (Chemicals) Pty Ltd (Australia)

· ICL Group Ltd. (US)

Investments and Innovations: Key Strategies of Top Turf Protection Companies

🌱 Syngenta Crop Protection AG: Leading the Way in Integrated Pest Management

Syngenta Crop Protection AG, a global agribusiness based in Switzerland, operates prominently in the crop protection and seeds markets. The company offers a comprehensive range of herbicides, insecticides, fungicides, and seed treatments, helping growers worldwide enhance agricultural productivity and food quality. With a presence in over 90 countries, Syngenta’s reach is truly global. In October 2020, Syngenta further strengthened its position by acquiring Valagro, a leading biologicals company. Valagro’s strong presence in Europe, North America, Asia, and Latin America complements Syngenta’s existing crop protection chemicals. This acquisition allows Syngenta to offer more integrated pest management strategies that reduce reliance on synthetic chemicals, while Valagro’s expertise in plant nutrition promotes healthier turfgrass growth and improved soil health.

Know about the assumptions considered for the study

🌍 UPL Limited: Innovating Turf Management Solutions Globally

UPL Limited, formerly known as United Phosphorus Limited, is a global agrochemical company based in India, providing a wide range of agricultural solutions, including crop protection products, seeds, and post-harvest solutions. UPL is a key player in turf management, offering innovative solutions for golf courses, sports fields, and other turf areas. Their product portfolio includes herbicides, fungicides, insecticides, and plant growth regulators, all designed to enhance turf quality and health while effectively controlling pests and diseases. Operating in over 130 countries across North America, South America, Europe, and Asia Pacific, UPL has 28 manufacturing sites worldwide, solidifying its position as a leader in the global turf protection market.

🏆 Bayer AG: Streamlining for a Focused Future in Turf Protection

Bayer AG, a multinational pharmaceutical and life sciences company headquartered in Leverkusen, Germany, operates across three business segments: Pharmaceuticals, Consumer Health, and Crop Science. The company’s Crop Science division caters to the turf protection market, offering products such as herbicides, insecticides, and fungicides. With operations in over 90 countries, including regions like North America, South America, Europe, the Middle East, Africa, and Asia Pacific, Bayer maintains a strong global presence. In March 2022, Bayer sold its Environmental Science Professional business, which includes turf protection products, to private equity firm Cinven for USD 2.6 billion. This strategic divestment is part of Bayer’s ongoing efforts to streamline its portfolio and concentrate on core businesses, ensuring a more focused approach to its future operations.

16 notes

·

View notes

Text

Bottling and Packaging Line Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Bottling and Packaging Line Solution in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. A Bottling and Packaging Line Solution is an integrated system designed to streamline the entire process of filling, capping, labeling, inspecting, and packaging bottles. It is used across industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals, ensuring that liquid and semi-liquid products are efficiently packaged for distribution. These automated systems help businesses reduce production time, minimize human error, and ensure high-quality standards for every product. Similar Name of Bottling and Packaging Line Solution: Automated Bottling and Packaging System, Bottle Filling and Packing Line, Integrated Packaging and Bottling Solution, Liquid Packaging Line System, Complete Bottling Line Setup, Turnkey Packaging and Bottling Solutions, Customizable Bottling and Packaging Equipment, Automated Beverage Bottling Line, Filling and Packaging Machinery Solutions, Industrial Bottling and Packaging System. Why Choose Bottling and Packaging Line Solutions? Increased Efficiency: Automation minimizes manual labor, reducing human error and increasing throughput. Consistency and Quality Control: Advanced systems ensure uniform filling, sealing, and packaging. Scalability: Modular designs allow you to upgrade or expand systems as your business grows. Cost Savings: Streamlined processes reduce waste, energy use, and operational costs. Compliance and Safety: Modern solutions adhere to strict regulatory standards, safeguarding consumer health and brand reputation. Applications of Bottling and Packaging Line Solution: Food and Beverage Pharmaceuticals Cosmetics and Personal Care Chemicals Agricultural Products What is a bottling and packaging line solution? A bottling and packaging line solution encompasses machinery and processes designed to automate the filling, sealing, labeling, and packaging of liquid products. How do I determine the right capacity for my production line? Capacity depends on your current production volume and future growth projections. Consulting with a professional provider can help you determine the optimal configuration. Shiv Shakti Machtech is a Bottling and Packaging Line Solution and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, and Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#BottlingandPackagingLineSolution#BottlingandPackagingLineSolutioninGujarat#BottlingandPackagingLineSolutioninIndia#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad

2 notes

·

View notes

Text

Acetic Acid Market - Forecast(2024 - 2030)

Acetic Acid Market Overview

Acetic Acid Market Size is forecast to reach $14978.6 Million by 2030, at a CAGR of 6.50% during forecast period 2024-2030. Acetic acid, also known as ethanoic acid, is a colorless organic liquid with a pungent odor. The functional group of acetic acid is methyl and it is the second simplest carboxylic acid. It is utilized as a chemical reagent in the production of many chemical compounds. The major use of acetic acid is in the manufacturing of vinyl acetate monomer, acetic anhydride, easter and vinegar. It is a significant industrial chemical and chemical reagent used in the production of photographic film, fabrics and synthetic fibers. According to the Ministry of Industry and Information Technology, from January to September 2021, the combined operating revenue of 12,557 major Chinese garment companies was US$163.9 billion, showing a 9% increase. Thus, the growth of the textile industry is propelling the market growth for Acetic Acid.

Report Coverage

The “Acetic Acid Market Report – Forecast (2024-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Acetic Acid industry.

By Form: Liquid and Solid.

By Grade: Food grade, Industrial grade, pharmaceutical grade and Others.

By Application: Vinyl Acetate Monomer, Purified Terephthalic Acid, Ethyl Acetate, Acetic Anhydride, Cellulose Acetate, Acetic Esters, Dyes, Vinegar, Photochemical and Others

By End-use Industry: Textile, Medical and Pharmaceutical, Oil and Gas, Food and Beverages, Agriculture, Household Cleaning Products, Plastics, Paints & Coating and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (the UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America) and the Rest of the World (the Middle East and Africa).

Request Sample

Key Takeaways

The notable use of Acetic Acid in the food and beverages segment is expected to provide a significant growth opportunity to increase the Acetic Acid Market size in the coming years. As per the US Food and Agriculture Organization, world meat production reached 337 million tonnes in 2019, up by 44% from 2000.

The notable demand for vinyl acetate monomer in a range of industries such as textile finishes, plastics, paints and adhesives is driving the growth of the Acetic Acid Market.

Increase in demand for vinegar in the food industry is expected to provide substantial growth opportunities for the industry players in the near future in the Acetic Acid industry.

Acetic Acid Market Segment Analysis – by Application

The vinyl acetate monomer segment held a massive 44% share of the Acetic Acid Market share in 2021. Acetic acid is an important carboxylic acid and is utilized in the preparation of metal acetates and printing processes, industrially. For industrial purposes, acetic acid is manufactured by air oxidation of acetaldehyde with the oxidation of ethanol, butane and butene. Acetic acid is extensively used to produce vinyl acetate which is further used in formulating polyvinyl acetate. Polyvinyl acetate is employed in the manufacturing of plastics, paints, textile finishes and adhesives. Thus, several benefits associated with the use of vinyl acetate monomer is boosting the growth and is expected to account for a significant share of the Acetic Acid Market.

Inquiry Before Buying

Acetic Acid Market Segment Analysis – by End-use Industry

The food and beverages segment is expected to grow at the fastest CAGR of 7.5% during the forecast period in the Acetic Acid Market. Acetic Acid is also known as ethanoic acid and is most extensively used in the production of vinyl acetate monomer. Vinyl acetate is largely used in the production of cellulose acetate which is further used in several industrial usage such as textiles, photographic films, solvents for resins, paints and organic esters. PET bottles are manufactured using acetic acid and are further utilized as food containers and beverage bottles. In food processing plants, acetic acid is largely used as cleaning and disinfecting products. Acetic acid is extensively used in producing vinegar which is widely used as a food additive in condiments and the pickling of vegetables. According to National Restaurant Association, the foodservice industry is forecasted to reach US$898 billion by 2022. Thus, the advances in the food and beverages industry are boosting the growth of the Acetic Acid Market.

Acetic Acid Market Segment Analysis – by Geography

Asia-Pacific held a massive 41% share of the Acetic Acid Market in 2021. This growth is mainly attributed to the presence of numerous end-use industries such as textile, food and beverages, agriculture, household cleaning products, plastics and paints & coatings. Growth in urbanization and an increase in disposable income in this region have further boosted the industrial growth in this region. Acetic acid is extensively used in the production of metal acetates, vinyl acetate and vinegar which are further utilized in several end-use industries. Also, Asia-Pacific is one of the major regions in the domain of plastic production which provides substantial growth opportunities for the companies in the region. According to Plastic Europe, China accounted for 32% of the world's plastic production. Thus, the significant growth in several end-use industries in this region is also boosting the growth of the Acetic Acid Market.

Acetic Acid Market Drivers

Growth in the textile industry:

Acetic Acid, also known as ethanoic acid, is widely used in the production of metal acetate and vinyl acetate which are further used in the production of chemical reagents in textiles, photographic films, paints and volatile organic esters. In the textile industry, acetic acid is widely used in textile printing and dyes. According to China’s Ministry of Industry and Information Technology, in 2020, textile and garment exports from China increased by 9.6% to US$291.22 billion. Also, according to the U.S. Department of Commerce, from January to September 2021, apparel exports increased by 28.94% to US$4.385 billion, while textile mill products rose by 17.31% to US$12.365 billion. Vinyl acetate monomer is utilized in the textile industry to produce synthetic fibers. Thus, the global growth in demand for textiles is propelling the growth and is expected to account for a significant share of the Acetic Acid Market size.

Schedule a call

Surge in use of vinegar in the food industry:

The rapid surge in population along with the adoption of a healthy and sustainable diet has resulted in an increase in demand for food items, thereby increasing the global production level of food items. As per US Food and Agriculture Organization, in 2019, global fruit production went up to 883 million tonnes, showing an increase of 54% from 2000, while global vegetable production was 1128 million tonnes, showing an increase of 65%. Furthermore, world meat production reached 337 million tonnes in 2019, showing an increase of 44% from 2000. Acetic acid is majorly used in the preparation of vinegar which is further widely utilized as a food ingredient and in personal care products. Vinegar is used in pickling liquids, marinades and salad dressings. It also helps to reduce salmonella contamination in meat and poultry products. Furthermore, acetic acid and its sodium salts are used as a food preservative. Thus, the surge in the use of vinegar in the food industry is boosting the growth of the Acetic Acid Market.

Acetic Acid Market Challenge

Adverse impact of acetic acid on human health:

Acetic Acid is considered a strong irritant to the eye, skin and mucous membrane. Prolong exposure to and inhalation of acetic acid may cause irritation to the nose, eyes and throat and can also damage the lungs. The workers who are exposed to acetic acid for more than two or three years have witnessed upper respiratory tract irritation, conjunctival irritation and hyperkeratotic dermatitis. The Occupational Safety and Health Administration (OSHA) reveals that the standard exposure to airborne acetic acid is eight hours. Furthermore, a common product of acetic acid i.e., vinegar can cause gastrointestinal tract inflammatory conditions such as indigestion on excess consumption. Thus, the adverse impact of Acetic Acid may hamper the market growth.

Buy Now

Acetic Acid Industry Outlook

The top 10 companies in the Acetic Acid Market are:

Celanese Corporation

Eastman Chemical Company

LyondellBasell

British Petroleum

Helm AG

Pentoky Organy

Dow Chemicals

Indian Oil Corporation

Daicel Corporation

Jiangsu Sopo (Group) Co. Ltd.

Recent Developments

In March 2021, Celanese Corporation announced the investment to expand the production facility of vinyl portfolio for the company’s acetyl chain and derivatives in Europe and Asia.

In April 2020, Celanese Corporation delayed the construction of its new acetic acid plant and expansion of its methanol production by 18 months at the Clear Lake site in Texas.

In October 2019, BP and Chian’s Zhejiang Petroleum and Chemical Corporation signed MOU in order to create a joint venture to build a 1 million tonne per annum Acetic Acid plant in eastern China.

Key Market Players:

The Top 5 companies in the Acetic Acid Market are:

Celanese Corporation

Ineos Group Limited

Eastman Chemical Company

LyondellBasell Industries N.V.

Helm AG

For more Chemicals and Materials Market reports, please click here

#Acetic Acid Market#Acetic Acid Market Share#Acetic Acid Market Size#Acetic Acid Market Forecast#Acetic Acid Market Report#Acetic Acid Market Growth

2 notes

·

View notes

Text

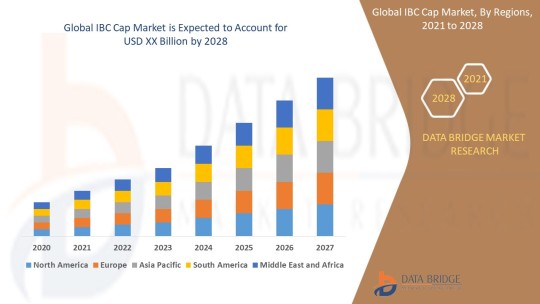

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Lowest Price GI Flanges in Assam

Assam, with its rich natural resources and vibrant culture, is becoming increasingly significant in India's industrial landscape. The state is home to a variety of industries, including agriculture, oil and gas, and manufacturing. As businesses in Assam continue to expand, the need for reliable and high-quality industrial components is more critical than ever. At Udhhyog, we offer the lowest price GI flanges in Assam, ensuring that your operations can flourish without straining your budget.

GI flanges play a vital role in ensuring the integrity of piping systems across various applications. Their durability and corrosion resistance make them ideal for use in challenging environments, including oil refineries, chemical processing plants, and water supply systems. By choosing quality GI flanges, businesses can minimize risks related to leaks and failures, enhancing safety and efficiency in their operations.

At Udhhyog, we recognize the unique challenges that micro, small, and medium enterprises (MSMEs) face in Assam. Our commitment to providing the lowest price GI flanges ensures that businesses of all sizes can access high-quality materials without compromising their financial stability. We partner with reputable manufacturers to guarantee that our products meet stringent quality standards, allowing you to make informed procurement decisions.

Our user-friendly platform streamlines the purchasing process, enabling customers to easily find the GI flanges they need. With just a few clicks, businesses can browse our extensive range, compare prices, and place orders efficiently. This simplicity saves valuable time and allows businesses to focus on their core activities, driving growth and innovation.

In addition to our competitive pricing, Udhhyog provides flexible credit options tailored to the needs of Assam’s MSMEs. This financial flexibility empowers businesses to manage their budgets more effectively while still acquiring essential materials. Our reliable supply chain ensures prompt delivery, helping you keep your projects on track and within budget.

#GIFlanges#AssamIndustry#IndustrialSupplies#LowestPrice#MSMEs#Procurement#GalvanizedIron#PipingSolutions#Udhhyog#SupplyChain#CorrosionResistant#QualityProducts#BusinessGrowth#CostEffective#ReliableSupplies#AssamManufacturers#EfficientProcurement#IndustrialApplications#TrustedSupplier#ManufacturingExcellence

2 notes

·

View notes

Text

The Role of Agrochemicals in Global Agriculture: Opportunities for Exporters

Agriculture is the backbone of the global economy, feeding billions of people worldwide. As the world’s population continues to grow, there is an ever-increasing demand for higher food production. Agrochemicals, which include fertilizers, pesticides, herbicides, and fungicides, play a pivotal role in meeting this demand by improving crop yields and ensuring food security. This has opened up significant opportunities for exporters, especially those in India, a country that has emerged as a key player in the agrochemical industry.

In this blog, we’ll explore the role of agrochemicals in global agriculture and discuss the promising opportunities for exporters. We’ll also highlight the importance of global imports and exports in the agrochemical market and examine how companies can capitalize on this thriving sector.

The Importance of Agrochemicals in Modern Agriculture

The global agricultural industry is facing immense challenges, including climate change, soil degradation, and water scarcity. These issues threaten the ability of farmers to produce enough food to meet the world’s growing needs. Agrochemicals are essential in mitigating these challenges.

Fertilizers enhance soil fertility by replenishing essential nutrients, thus ensuring healthy and robust crop growth.

Pesticides protect crops from pests, insects, and diseases that could significantly reduce yields.

Herbicides control the growth of unwanted weeds that compete with crops for water and nutrients.

Fungicides help prevent fungal diseases that can decimate crops.

By increasing productivity, agrochemicals have become indispensable in modern agriculture. Their role in improving crop efficiency and food security cannot be overstated.

Global Demand for Agrochemicals

The demand for agrochemicals is driven by the growing global population, estimated to reach nearly 10 billion by 2050. This means the world will need to produce 70% more food than it currently does. As more countries look to expand their agricultural output, the demand for agrochemicals continues to rise.

Countries with large agricultural sectors, such as the United States, Brazil, and China, are the largest consumers of agrochemicals. However, developing countries are also experiencing increased demand as they strive to modernize their farming practices and increase productivity.

This growing demand presents a golden opportunity for companies involved in global imports and exports of agrochemicals. Exporting these chemicals to countries with emerging agricultural markets is one of the key strategies for sustaining growth in the agrochemical industry.

India: A Leading Player in the Agrochemical Export Market

India has emerged as a major player in the global agrochemical market. With its robust agricultural sector and a growing manufacturing base, the country is home to some of the top 10 exporters in India in the agrochemicals industry. Indian agrochemical companies have built a strong reputation for producing high-quality and cost-effective products that meet international standards.

There are several reasons why India has become a leader in agrochemical exports:

Cost-effective production: India’s relatively low manufacturing costs make its agrochemical products highly competitive in the global market.

Large production capacity: India has a well-established chemical industry, and its agrochemical companies benefit from large-scale production, enabling them to meet the growing global demand.

Strong research and development (R&D): Indian agrochemical companies invest heavily in R&D to develop innovative products and meet the specific needs of international markets.

Strategic location: India’s geographic position offers easy access to important markets in Asia, Africa, and the Middle East.

As a result, Indian companies are well-positioned to capitalize on the growing global demand for agrochemicals. The best export companies in India are expanding their reach into new international markets, helping farmers around the world enhance their productivity.

Global Imports and Exports in the Agrochemical Market

The agrochemical industry is characterized by a complex web of global imports and exports. Developing countries with growing agricultural sectors rely heavily on imports of agrochemicals to boost their production. This makes international trade in agrochemicals a crucial component of the industry.

Exporters, particularly those from India, are benefitting from this dynamic. Indian agrochemical companies export a wide range of products, including insecticides, herbicides, fungicides, and fertilizers, to more than 100 countries. Major export destinations include the United States, Brazil, Australia, China, and African nations.

Exporters must also navigate a range of challenges, including regulatory compliance, quality standards, and competition from other countries. By focusing on quality, innovation, and competitive pricing, Indian companies have established themselves among the top 10 exporters of the agrochemicals industry, securing their place in the global market.

Opportunities for Agrochemical Exporters

The increasing global demand for agrochemicals creates numerous opportunities for exporters. Here are some key areas where companies can capitalize:

1.�� Expanding to Emerging Markets

Developing countries with growing agricultural sectors represent significant opportunities for agrochemical exporters. Countries in Africa, Latin America, and Southeast Asia are modernizing their farming practices and adopting advanced agrochemical solutions to improve their yields. Exporters can tap into these emerging markets by providing affordable, effective agrochemical products tailored to local needs.

2. Sustainable Agrochemicals

There is growing global awareness of the need for more sustainable agricultural practices. Exporters can take advantage of this trend by offering environmentally friendly agrochemical solutions that minimize the impact on soil, water, and ecosystems. Sustainable agrochemicals, such as bio-based pesticides and organic fertilizers, are gaining traction in both developed and developing countries.

3. Focus on Innovation

Innovation is crucial to staying competitive in the agrochemical industry. Exporters can invest in R&D to develop new formulations that are more effective, longer-lasting, and safer for the environment. Offering customized solutions that address specific crop needs or climate conditions can help exporters differentiate themselves in the global market.

4. Building Strong Partnerships

Establishing partnerships with local distributors and retailers is key to entering new markets. Exporters can work closely with distributors in target countries to ensure that their products are accessible to farmers and comply with local regulations. For instance, Indian exporters have successfully partnered with distributors in Africa and Latin America, helping them establish a strong foothold in these regions.

5. Leveraging Government Support

Exporters can benefit from various government schemes and incentives aimed at promoting international trade. In India, government initiatives such as the “Make in India” campaign and export subsidies for agrochemical companies have contributed to the industry’s growth. By leveraging these opportunities, exporters can scale their operations and increase their presence in global markets.

Conclusion: Agrochemicals and Export Growth

Agrochemicals are vital to feeding the world’s growing population, ensuring that farmers can maximize their yields and meet increasing demand. As global agriculture continues to modernize and expand, the need for high-quality agrochemicals will only intensify.

For Indian companies, the agrochemical industry presents a golden opportunity to capitalize on their strengths in production, innovation, and cost-effectiveness. Indian exporters have already made a mark as some of the top 10 exporters in the agrochemicals industry, and there is immense potential to grow further by entering new markets and investing in sustainable practices.

As one of the best export companies, focusing on quality, innovation, and partnerships will allow Indian agrochemical exporters to continue driving growth and contributing to global agricultural success.

#Pharmaceuticals exporter in Gujarat#Best exporter in India#Best exporter of pharmaceuticals#Global imports and exports#Top 10 exporters in India in the agrochemicals industry#Best export company#Top 10 exporters of agrochemicals industry#Largest exporter of spices in world#international trade imports and exports#import and export products#Food import export companies#food import and export#top Indian export import companies

2 notes

·

View notes

Text

Exploring the Chemistry: How Ammonium Heptamolybdate Benefits Various Ind

Ammonium Heptamolybdate, a versatile chemical compound with the formula (NH₄)₆Mo₇O₂₄·4H₂O, plays a crucial role in several industrial applications. Known for its excellent catalytic and chemical properties, this compound is essential in various sectors, including agriculture, ceramics, and analytical chemistry. Palvi Chemical Industries Limited, a leading Ammonium Hepta Molybdate manufacturer in India, has been at the forefront of producing and supplying high-quality Ammonium Heptamolybdate to meet the growing demands of different industries. As a prominent exporter, we also cater to the needs of clients in the UAE and other regions.

#Ammonium Hepta Molybdate manufacturer in India#Ammonium Hepta Molybdate#Exporter UAE Ammonium Hepta Molybdate

2 notes

·

View notes

Text

What is Bagging Machine? - Payper India

A bagging machine is a type of industrial equipment used to automate the process of filling and sealing bags with various products. These machines are widely used in different industries, such as food, pharmaceuticals, chemicals, and agriculture, to efficiently package goods ranging from powders and granules to liquids and solids.

Image Ref : What is Bagging Machine — Payper India

Key Functions of Bagging Machines:

Filling: The machine accurately dispenses a pre-set amount of product into each bag. This can be achieved through various mechanisms, such as volumetric fillers, auger fillers, or weigh scales, depending on the nature of the product being packaged. Click here for Ref : www.payperindia.com

Sealing: After the bag is filled, the machine seals it to ensure the product is contained and protected. Sealing methods can include heat sealing, ultrasonic sealing, or using adhesive tapes, depending on the bag material and the product requirements. Click here for Ref : www.payperindia.com

Cutting/Trimming: Some bagging machines also trim excess material from the sealed bags to ensure a neat and uniform appearance. Click here for Ref : www.payperindia.com

Types of Bagging Machines:

Valve Bagging Machines: Designed for heavy-duty products such as cement, sand, or chemicals, these machines fill bags through a valve and then seal the valve to prevent leakage. Click here for Ref : www.payperindia.com

Open-Mouth Bagging Machines: Used for bulk products like grains, animal feed, or fertilizers, these machines fill pre-made bags that are manually or automatically positioned under the filling spout. Click here for Ref : www.payperindia.com

FIBC- Jumbo Bagging Machine: A jumbo bagging machine, or bulk bag filling machine, is designed to fill large bags (500–2000 kg) with bulk materials.

Why Payper ?

Payper India develops and manufactures bagging machines for all types of bulk solids such as powders or granulates. Other important product lines are palletizers and complete lines.

Our customers come from many different sectors, e.g., Chemical Industry, Agro-food Industry, Mining Industry and Building Industry. Payper India offers a comprehensive solution for each sector.

No need or demand is too small neither too big for us. We supply bagging machines for smaller industries with low volume requirements. We also provide complete turnkey projects for customers with high demands as to capacity and speed.

What matters to us is that our customer is comfortable and satisfied with the solution we have developed for them

Visit Payper at — https://www.payperindia.com/

Business LinkedIn -http://bit.ly/45Y1xMQ

Twitter — https://twitter.com/PayperIndia

Instagram — https://www.instagram.com/payperindia/

#payper#payperindia#baggingmachines#manufacturer#industry#machinery#robotics#palletisers#jumbobaggingmachine

2 notes

·

View notes

Text

Petrochemical Solutions – Optimizing Performance and Sustainability in Oilfield Operations

Introduction

In the dynamic and demanding landscape of oilfield operations, finding innovative and sustainable solutions is paramount. As a leading player in the petrochemical sector, Imperial Chemical (ICPL) is at the forefront of providing cutting-edge petrochemical solutions that not only optimize performance but also contribute to the sustainability of oilfield operations. This blog will delve into the significance of petrochemical products, the role of petrochemical companies in Gujarat, and ICPL's commitment to being a premier petrochemical solutions provider in India.

The Petrochemical Industry in India

India's petrochemical industry plays a pivotal role in the country's economic growth. It encompasses the production of a wide range of chemicals derived from petroleum and natural gas, serving as the backbone for various sectors, including agriculture, manufacturing, and energy. As one of the fastest-growing economies globally, India relies heavily on petrochemical products to meet its ever-expanding industrial demands.

Petrochemical companies in Gujarat, with its strategic location and robust infrastructure, have emerged as key contributors to India's petrochemical landscape. Gujarat's proactive policies, state-of-the-art facilities, and access to key resources position it as a hub for petrochemical manufacturing. Imperial Chemical, headquartered in Gujarat, takes pride in being a frontrunner among petrochemical companies, offering comprehensive solutions to cater to the diverse needs of the industry.

Imperial Chemical: A Petrochemical Solutions Provider in India

Imperial Chemical (ICPL) stands tall as a leading petrochemical solutions provider in India. With a commitment to innovation, sustainability, and customer satisfaction, ICPL plays a vital role in shaping the future of the petrochemical sector. Let us explore how ICPL's petrochemical products and solutions contribute to optimizing performance and promoting sustainability in oilfield operations.

Diverse Range of Petrochemical Products:

ICPL boasts a diverse portfolio of petrochemical products designed to meet the specific requirements of oilfield operations. From specialty chemicals to essential components used in extraction and refining processes, our product range is tailored to enhance efficiency and performance.

Advanced Technology and Research:

Innovation is the driving force behind ICPL's success. Our state-of-the-art research and development facilities are dedicated to exploring new technologies and formulations. This commitment to innovation ensures that our petrochemical solutions remain at the cutting edge, providing our clients with the latest advancements in the industry.

Sustainability at the Core:

Recognizing the global shift towards sustainable practices, ICPL integrates environmental responsibility into every aspect of our operations. Our petrochemical solutions are designed to minimize environmental impact while maximizing operational efficiency. This includes the development of eco-friendly additives, cleaner extraction processes, and sustainable packaging solutions.

Customized Solutions for Oilfield Challenges:

Oilfield operations are multifaceted, with unique challenges requiring tailored solutions. ICPL collaborates closely with clients to understand their specific needs and challenges. Our team of experts then develops customized petrochemical solutions that address these challenges effectively, ensuring optimal performance and resource utilization.

Stringent Quality Control:

Quality is non-negotiable at ICPL. Our petrochemical products undergo rigorous testing and quality control measures to meet and exceed industry standards. This commitment to quality ensures that our clients receive reliable and high-performance solutions for their oilfield operations.

Petrochemical Solutions in Gujarat: A Regional Perspective

Gujarat has emerged as a key player in India's petrochemical sector, housing some of the most significant petrochemical companies in the country. The state's strategic location, well-established infrastructure, and business-friendly policies have attracted investments, making it a vibrant hub for petrochemical manufacturing.

Imperial Chemical, with its headquarters in Gujarat, is proud to contribute to the state's reputation as a petrochemical powerhouse. Our presence in Gujarat allows us to leverage the region's resources, collaborate with local talent, and actively participate in the state's economic growth. As a responsible corporate citizen, ICPL is committed to upholding the highest standards of environmental stewardship and community engagement in Gujarat.

Sustainable Practices in Petrochemical Operations

Sustainability is a cornerstone of ICPL's philosophy. As a responsible petrochemical solutions provider in India, we are dedicated to incorporating sustainable practices into every aspect of our operations. Here's how ICPL contributes to sustainability in oilfield operations:

Reduced Environmental Impact:

ICPL focuses on developing petrochemical products and solutions that minimize environmental impact. This includes the reduction of emissions, efficient use of resources, and the development of sustainable alternatives to traditional petrochemical products.

Energy-Efficient Processes:

Our manufacturing processes prioritize energy efficiency, reducing the carbon footprint associated with our operations. By adopting advanced technologies and energy-efficient practices, ICPL strives to contribute to the overall sustainability of the petrochemical sector.

Waste Minimization and Recycling:

ICPL implements waste minimization and recycling initiatives to reduce the generation of waste and promote a circular economy. By reusing and recycling materials, we aim to minimize the environmental footprint of our petrochemical operations.

Community and Stakeholder Engagement:

ICPL actively engages with local communities and stakeholders to foster a collaborative approach to sustainability. Through community outreach programs, education initiatives, and transparent communication, we aim to build lasting relationships that benefit both the industry and the communities we serve.

Conclusion

In the ever-evolving landscape of oilfield operations, the role of petrochemical solutions cannot be overstated. Imperial Chemical (ICPL), as a leading petrochemical solutions provider in India, is dedicated to optimizing performance and promoting sustainability in the oilfield sector. With a diverse range of petrochemical products, advanced technology, and a commitment to sustainable practices, ICPL is poised to shape the future of the petrochemical industry in Gujarat and beyond. As the industry continues to grow and adapt, ICPL remains at the forefront, delivering innovative solutions that drive efficiency, performance, and environmental responsibility. Contact us today to explore how ICPL's petrochemical solutions can elevate your oilfield operations to new heights of success.

#Petrochemical products#Petrochemical companies in Gujarat#Petrochemical industry in India#Petrochemical solutions provider in India#Petrochemical sector#Oil and gas industry#Oil and gas companies in Vadodara#oil and gas pipelines#oil and gas product solution provider in India#Oil and gas sector#oil and gas services companies in india#India#Gujarat#Tamilnadu#Kerala#Andhrapradesh#ICPL

6 notes

·

View notes

Text

The Future of Agricultural Chemicals Innovations and Trends

The agricultural sector is undergoing a significant transformation, driven by advancements in technology, sustainability practices, and evolving market demands. Agricultural chemicals, which play a crucial role in enhancing crop productivity and protecting plants from pests and diseases, are at the forefront of this transformation. Let's explore the future of agricultural chemicals, focusing on the innovations and trends that are shaping the industry.

Innovations in Agricultural Chemicals

Biopesticides and Biofertilizers As concerns about the environmental impact of synthetic chemicals grow, the demand for biopesticides and biofertilizers is rising. These products, derived from natural sources such as plants, bacteria, and fungi, offer a sustainable alternative to traditional chemicals. They not only reduce the chemical load on the environment but also promote soil health and biodiversity.

Precision Agriculture Precision agriculture is revolutionizing the way farmers apply agricultural chemicals. Utilizing technologies like GPS, drones, and IoT sensors, farmers can apply chemicals more accurately and efficiently. This reduces waste, minimizes environmental impact, and ensures that crops receive the optimal amount of nutrients and protection.

Nanotechnology Nanotechnology is making waves in the agricultural chemicals sector. By using nanoparticles, manufacturers can create more effective and targeted chemical formulations. These nanoparticles can deliver active ingredients directly to the plants, improving absorption and reducing the overall quantity of chemicals needed.

Genetically Modified Organisms (GMOs) Advances in genetic engineering are leading to the development of crops that require fewer chemical inputs. GMOs can be engineered to be more resistant to pests, diseases, and environmental stresses, reducing the need for external chemical applications.

Trends in the Agricultural Chemicals Industry

Sustainability and Environmental Responsibility There is a growing emphasis on sustainability within the agricultural chemicals industry. Agricultural chemicals manufacturers are investing in research and development to create products that are less harmful to the environment and human health. This includes the development of eco-friendly packaging and the reduction of greenhouse gas emissions during production.

Regulatory Changes Governments around the world are tightening regulations on the use of agricultural chemicals. This is driving companies to innovate and develop safer, more effective products. In India, regulatory bodies are implementing stricter guidelines to ensure the safety and efficacy of agricultural chemicals.

Digital Agriculture The integration of digital technologies in agriculture is transforming how agricultural chemicals are managed and applied. Digital platforms and apps are providing farmers with real-time data and analytics, helping them make informed decisions about chemical usage. This trend is expected to grow, leading to more efficient and sustainable farming practices.

Collaborations and Partnerships Collaboration between agrochemical companies, research institutions, and technology providers is becoming more common. These partnerships are fostering innovation and enabling the development of cutting-edge solutions that address the challenges faced by modern agriculture.

The Role of Agricultural Chemicals Manufacturers in India

India is home to a burgeoning agricultural chemicals industry, with numerous companies leading the charge in innovation and sustainability. Agricultural chemicals manufacturers in India are investing heavily in research and development to create products that meet the needs of modern farmers while adhering to strict environmental standards. These companies are also focusing on expanding their global footprint, making India a key player in the international agrochemical market.

Conclusion The future of agricultural chemicals is marked by exciting innovations and evolving trends that promise to make agriculture more sustainable, efficient, and productive. As the industry continues to evolve, agricultural chemicals manufacturers, especially those in India, will play a pivotal role in driving this transformation. By embracing new technologies and prioritizing sustainability, these companies are ensuring a brighter future for agriculture and the environment.

0 notes

Text

#Fruits and Vegetables#Cereals and Pulses#Handicrafts#Chemical Products#Avenue Plants#Coconut Products#Agriculture Product#Exporter in Telangana#Manufacturer in India

1 note

·

View note

Text

Fbd Bag Manufacturers

Makpol Industries is one of the reputed Fbd Bag Manufacturers in India. Fbd stands for Fluidized bed dryer which is used to dry the granules in pharmaceuticals. We are using best quality products to make these bags. We never compromise with quality because customer satisfaction is our aim. The applications of the Fbd Bag in the Chemical industry, Pharmaceutical industry, Agricultural industry and Processing industry. For more details, you can visit our website.

Address : 56, Ist Floor, Hariniwas Market, Panchwati Colony, Ghaziabad- 201001, Uttar Pradesh Email Id : [email protected] Contact No: +91-9871525385 , +91-9999175385 Website : https://www.makpolindustries.com/fluid-bed-dryer-filter.html

2 notes

·

View notes

Text

Filling Line - End to End Packaging Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Filling Line - End to End Packaging Solution in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Filling lines are advanced, automated systems that optimize packaging efficiency for various industries, such as food and beverages, pharmaceuticals, chemicals, and cosmetics. From product filling to capping, labeling, and sealing, these systems provide a seamless, end-to-end packaging solution. Process of Filling Lines: Filling lines follow a systematic, step-by-step process to ensure efficient product packaging: Product Feeding: The raw material or liquid is fed into the system, often from bulk storage tanks. Filling: The system accurately measures and dispenses the product into containers or bottles. Capping: The system automatically places and tightens caps or lids onto the filled containers. Sealing: The system seals containers using heat or adhesives to ensure product integrity. Labeling: The system applies custom labels to containers for branding and regulatory compliance. Inspection: The system conducts quality checks to ensure that the packaging meets standards. Cartoning & Palletizing: The system groups, boxes, and prepares packaged items for shipping. Applications of Filling Lines: Food & Beverage Industry Pharmaceutical Industry Cosmetics & Personal Care Chemical Industry Agricultural Products What is a filling line? A filling line automates the process of filling containers with liquids, powders, or granules. It can include processes like capping, labeling, and packaging for a complete solution. What industries use filling lines? Industries like food and beverage, pharmaceuticals, cosmetics, and chemical manufacturing commonly use filling lines. Can a filling line handle multiple product types? Yes, our filling lines are versatile and can handle various product types, including liquids, semi-liquids, powders, and viscous materials. Shiv Shakti Machtech is a Filling Line - End to End Packaging Solution and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad#Chile#Colombia#Congo

2 notes

·

View notes

Text

Best Manufacturer of Aromatherapy products in India

Aromatherapy is an alternate plant based treatment one can opt for and improve health of the body, mind and spirit. Any goods like diffusers, inhalers, body oils, massage oils, hot and cold compresses, etc. are appropriate since aromatherapy primarily relies on the sense of smell hence are quite popular and preferred.

Aadhunik Ayurveda vitals is the best manufacturer of aromatherapy products because all the aromas like lavender, chamomile, sweet lime, orange, lemongrass, juniper, camphor, eucalyptus, peppermint, spearmint, rosemary, curry leaf, basil etc. are made at Aadhunik Ayurveda's own distillery using the conventional steam distillation method. These smells are more than just the aroma; they are also the plant's potent volatile chemicals, which can stimulate the body to heal itself.

Best Essential oil Manufacturer in India - We produce the top notch quality as was produced in ancient India. You can select to obtain essential oils that are completely pure and natural and that have been painstakingly extracted in a sophisticated distillation facility in Himalayan foothills, India. We use steam distillation to prepare the variety we provide using freshly gathered flowers. This is due to the numerous advantages and applications of the essential oil created by Aadhunik Ayurveda, including -

Essential oils were first utilized as antibiotics by allopath's

.Because it is edible, it can be used as a natural and healthy aromatic and flavoring agent in foods and beverages such cakes, kheer, salads, soups, and curries.

Since it is made from plants and doesn't include any chemicals, it has excellent medicinal effects when inhaled.

Topical application, or application to the skin's surface, aids in skin hydration and healing.

This essential oil has only been steam distilled hence it is highly therapeutic.

The greatest quality essential oil is produced through a time- and labor-intensive procedure that involves obtaining raw materials, such as fresh or semi-dried herbs, directly from farmers and transporting them to Aadhunik Ayurveda's internal distillery. The best recognized method of steam distillation is used by Aadhunik Ayurveda to manufacture more than 40 different types of essential oils.

We are aware that the medicinal value and safety of essential oils depend on their quality. Nonetheless, we use tried-and-true techniques, procedures, and activities to create premium essential oils. All of our items undergo a rigorous quality check before being handed to customers.

A team of quality assurance specialists carefully examines the elements, such as plant species, processing, packaging, and storage, that may have an impact on the quality of essential oils. Highly recommended for use in aromatherapy and medicine as these are ISO-certified goods.

Custom formulation Aromatherapy products - We can distill any herb of your choice using our world-class facility and on-site distillery to provide you a distinct competitive edge in the market. Working with us is quite easy; from comprehending the requirements to moving on to prototype creation, doing compatibility and performance tests, to working on packing, designing, and labelling.

The leading manufacturer of skin care, health, and wellness products is Aadhunik Ayurveda Vitals, which has a sophisticated network for obtaining top-notch agricultural input from farmers to produce top-notch products. At Aadhunik Ayurveda, everything is done to ensure that the items you receive are of the highest quality and are free from adulteration. Get in touch with us through our email [email protected]

#Top Quality Manufacturer#top wholesaler#top supplier#top exporter#Natural#Herbal#Organic#Aromatherapy products manufacturer

5 notes

·

View notes