#palletisers

Explore tagged Tumblr posts

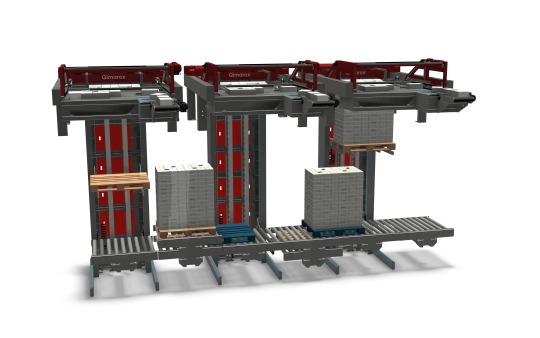

Photo

The Crossrunner palletising system is a patented solution which makes it possible to put several palletisers next to eachother while using just one central pallet conveyor system. This saves a lot of floor space and the reliability of the system increases a lot.

0 notes