#Aerospace casting manufacturers India

Explore tagged Tumblr posts

Text

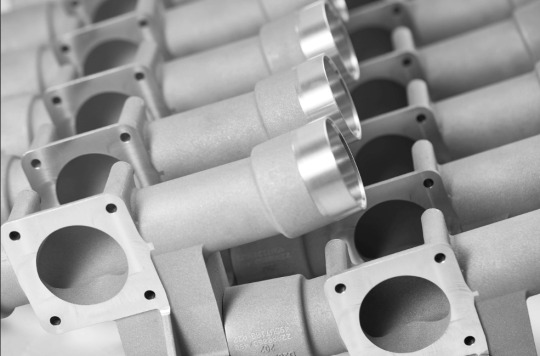

Uni Tritech Pioneering Aerospace & Defence Castings in India

In the realm of Aerospace and Defence, where the precision and reliability of components are paramount, India has been rapidly advancing with its foundry capabilities. Among the leaders in this sector is Uni Tritech, a company that has been setting benchmarks in quality and innovation. As one of the premier Aerospace & Defence investment casting foundries in India, Uni Tritech has a proven track record of providing cutting-edge solutions that meet the complex demands of these industries.

What sets Uni Tritech apart is its relentless pursuit of excellence. The foundry employs state-of-the-art technology to produce castings that adhere to the most stringent aerospace standards. Their investment casting process is fine-tuned to deliver components with unparalleled accuracy and material integrity, crucial for aerospace and defence applications.

Moreover, Uni Tritech's facilities are tailored to cater to the intricate needs of the Aerospace & Defence sectors, offering a vast array of alloys and comprehensive testing to ensure each part withstands the toughest conditions. With certifications and approvals that attest to their quality and processes, Uni Tritech stands as the best platform to buy Aerospace & Defence investment casting foundries in India. Their commitment to excellence and customer satisfaction propels them to the forefront, making them the ideal partner for clients seeking nothing less than the best in the industry.

#Aerospace casting manufacturers India#Defence investment foundries India#Indian foundry aerospace defence#Uni Tritech precision casting

0 notes

Text

Excellence in Non-Ferrous Forging & Casting in India

Non-ferrous forging and casting have emerged as critical processes in the manufacturing landscape, contributing significantly to India's industrial prowess. With a focus on metals like aluminum, copper, brass, and bronze, the country's expertise in non-ferrous forging and casting has reached new heights. Let's explore the excellence that India brings to these essential metallurgical processes.

Non-ferrous forging in India is marked by precision and skill, as manufacturers leverage advanced techniques to shape metals into components with superior mechanical properties. The forging process involves applying heat and pressure to mold metals into desired forms, enhancing their strength and durability. Indian forging facilities are equipped with state-of-the-art technology, ensuring the production of high-quality components that meet international standards.

Casting, another integral part of non-ferrous metal processing, is equally impressive in India. Foundries across the country use advanced casting methods to create intricate and complex shapes from molten non-ferrous metals. The attention to detail in the casting process is evident in the precision components that are vital to various industries.

Industries such as automotive, aerospace, and electronics in India benefit significantly from the excellence in non-ferrous forging and casting. The automotive sector, for instance, relies on these processes for manufacturing engine components, transmission parts, and lightweight structural elements. The use of non-ferrous metals contributes to fuel efficiency and sustainability, aligning with global trends.

In the aerospace industry, where precision and reliability are paramount, non-ferrous forging and casting play a crucial role. Components like aircraft engine parts and structural elements are crafted with meticulous attention to detail, ensuring the highest standards of performance and safety.

The electronics industry in India also reaps the rewards of non-ferrous forging and casting. The superior thermal conductivity of non-ferrous metals makes them ideal for applications such as heat sinks and connectors. The corrosion resistance of these metals ensures the longevity of electronic components in various environments.

As India continues to position itself as a global manufacturing hub, the excellence in non-ferrous forging and casting becomes a cornerstone of its industrial success. The commitment to quality, technological advancement, and sustainability places India at the forefront of non-ferrous metallurgy, contributing to the growth and competitiveness of its industries on the world stage. The journey of excellence in non-ferrous forging and casting in India is undoubtedly a testament to the nation's capabilities in shaping the future of manufacturing.

2 notes

·

View notes

Text

Vessels Supplier in Madhya Pradesh

Amma En-fab Is a leading Supplier of Vessels in Madhya Pradesh, India. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. Amma En-Fab manufactures Storage Vessels / Reactors with capacities ranging from 50 liters to 180,000 liters, suitable for various applications and equipped with the following accessories and attachments. Amma En-Fab is a leading manufacturer and supplier of pressure vessels for diverse applications and industries. A designer designs a sealed container to hold gases or liquids at pressures different from the ambient pressure, making it a pressure vessel. Pressure vessels are essential in various industries, including oil and gas, chemical production, power generation, and pharmaceuticals. Specialized pressure vessels in chemical and petrochemical industries facilitate chemical reactions and are called reactors. These reactors are designed to withstand high temperatures and pressures and may include internal components such as agitators, baffles, or coils. Applications of Pressure Vessels: Oil and Gas Chemical Processing Food and Beverage Pharmaceutical Aerospace Power Generation Petrochemica What is the difference between a cooking vessel and a storage vessel? Designers design cooking vessels, such as pots and pans, to handle heat for preparing food, while they make storage vessels to keep items fresh or protected from external factors. Storage vessels don’t need to withstand high temperatures. What materials are best for cooking vessels? Stainless steel, cast iron, and ceramic are popular choices for cooking vessels due to their heat resistance, durability, and even heat distribution. Non-stick coatings are also commonly used for easy food release and cleaning. Amma En-fab Is a leading Vessels Supplier in Madhya Pradesh, India Including Agar, Malwa, Alirajpur, Anuppur, Ashoknagar, Balaghat, Barwan, Betul, Bhind, Bhopal, Burhanpur, Chhatarpur, Chhindwara, Damoh, Datia, Dewas, Dhar, Dindori, East Nimar, Guna, Gwalior, Harda, Hoshangabad, Indore, Jabalpur, Jhabua, Katni, Mandla, Mandsaur, Morena, Narsinghpur, Neemuch, Niwari, Panna, Raisen, Rajgarh, Ratlam, Rewa, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri, Sidhi, Singrauli, Ujjain, Umaria, Vidisha, West Nimar. If you have any questions or need more information, feel free to reach out to us. View Product: Click Here Read the full article

0 notes

Text

High precision casting is a manufacturing process used to create intricate metal parts with exceptional accuracy. It involves pouring molten metal into a mold to form components with precise dimensions and minimal imperfections. This technique is widely used in industries like aerospace, automotive, and medical devices, where high-quality, durable components are crucial for performance and reliability.

0 notes

Text

10 Reasons to Choose Top Foundry Manufacturers

India is home to some of the world’s top foundry manufacturers, leading the industry with innovation, quality, and cutting-edge technology. For businesses seeking the best casting solutions, choosing a top foundry manufacturer is crucial. These manufacturers provide reliable and durable products essential for industries ranging from automotive to semiconductor manufacturing. In this article, we’ll explore the top 10 reasons why choosing the best foundry in India is the smartest decision for your business.

H2: 1. Superior Quality Standards

When you work with top foundry manufacturers, you can expect products that adhere to superior quality standards. The best foundry manufacturers in India maintain stringent quality checks throughout the casting process, ensuring that every product meets or exceeds industry standards. Whether you need steel casting, iron casting, or alloy casting, these manufacturers leverage the latest technologies to produce high-quality components that offer exceptional performance and longevity.

H2: 2. Advanced Technological Capabilities

Top foundry companies in India continually invest in advanced technologies to stay ahead of the competition. These manufacturers are equipped with state-of-the-art machinery, automation, and AI-powered systems, enabling them to produce complex castings with remarkable precision. This commitment to technology ensures that you receive casting solutions that meet exact specifications, especially important for sectors requiring precision, such as the aerospace and semiconductor industries.

H2: 3. Cost-Effective Production

India’s top foundry manufacturers offer a balance of high quality and cost-effectiveness. Foundries in India leverage efficient production processes and skilled labor to produce castings at a competitive price. This cost advantage does not compromise on quality, allowing businesses to access premium products without the high price tag. Companies looking for a cost-effective casting foundry in India benefit from reliable services that fit their budgets while still receiving exceptional quality.

H2: 4. Expertise in Diverse Casting Types

One of the key advantages of working with the best foundries in India is their expertise across a broad range of casting types. Whether you require sand casting, die casting, or investment casting, these top foundry manufacturers have the expertise and equipment to deliver. This versatility means you can rely on them for various applications, including automotive components, heavy machinery parts, and even parts for semiconductor foundry companies, ensuring a single partner for multiple casting needs.

H2: 5. Customized Solutions

Every industry has unique requirements, and top foundry manufacturers understand this well. These foundries specialize in providing customized solutions tailored to meet specific needs. From designing castings that match exact dimensions to recommending the right alloy composition, top foundry companies in India offer flexibility that caters to diverse industrial requirements. This customizability makes them the best choice for clients looking for unique and optimized solutions.

H2: 6. Strong Commitment to Sustainability

In today’s business environment, sustainability is a key consideration. The best foundry manufacturers in India are committed to sustainable practices, minimizing waste, and adopting environmentally friendly production processes. By choosing a foundry that prioritizes eco-friendly operations, you align with green initiatives that enhance your brand image. Many of these foundries are certified in sustainable manufacturing processes, making them a responsible choice for environmentally conscious companies.

H2: 7. Skilled Workforce and Expertise

Top foundry manufacturers in India employ a skilled and experienced workforce adept at handling intricate casting processes. From design engineers to skilled labor, the expertise of these professionals is unmatched. Their in-depth knowledge ensures high-quality results, even in challenging casting requirements. With a skilled workforce, the best metal foundry in India is able to meet tight deadlines and complex specifications, providing an edge to businesses that demand reliability.

H2: 8. Compliance with International Standards

India’s top foundry manufacturers adhere to international standards, ensuring that their products meet global quality and safety norms. Compliance with standards such as ISO, ASTM, and other quality certifications makes these foundries a trusted source for industries worldwide. By choosing a foundry that meets these stringent standards, businesses can rest assured of receiving products that are safe, durable, and of the highest quality.

H2: 9. Efficient Delivery and Supply Chain Management

Top foundry manufacturers have well-established supply chains and logistics systems, ensuring timely delivery of products. The best foundry companies in India understand the importance of on-time delivery in maintaining business continuity. By streamlining production and logistics processes, they can meet urgent requirements without compromising on quality. For businesses that rely on a steady supply of casting components, this efficient delivery is invaluable.

H2: 10. Proven Track Record in the Industry

India’s top foundry manufacturers have a proven track record of serving diverse industries. From automotive giants to semiconductor foundry companies, these manufacturers have built a reputation for reliability and excellence. A strong portfolio and history of successful projects make them a trusted partner for businesses seeking long-term casting solutions. This track record of success provides confidence to clients that they are working with an experienced and capable team.

H2: Choosing the Right Foundry for Your Business Needs

In summary, working with top foundry manufacturers provides access to high-quality, reliable, and sustainable casting solutions. From meeting stringent quality standards to offering cost-effective services, these foundries deliver value that meets the unique requirements of various industries. When selecting a foundry, consider factors such as quality, technology, expertise, and sustainability. The best foundries in India offer these benefits and more, positioning them as the preferred choice for businesses globally.

Sigma Malleable is a leading foundry manufacturer known for delivering top-quality casting solutions across various industries. With advanced technology and a commitment to excellence, Sigma Malleable produces reliable, durable castings tailored to meet unique business needs. Whether you need automotive components, heavy machinery parts, or custom solutions, Sigma Malleable offers unmatched expertise and precision. For more information or to discuss your specific requirements, contact us today to experience the best in foundry manufacturing.

#Top Foundry Manufacturers#top foundry companies in India#Best Foundry in India#Casting foundry in India#Best metal foundry in India#foundries in India#Foundry Manufacturers#Semiconductor foundry companies

0 notes

Text

From Manufacturing To Application: The Complete Journey Of Round Bars

Round bars play a crucial role in a multitude of industries, from construction to automotive, owing to their strength, versatility, and wide range of material options. In this article, we will explore the complete journey of round bars from their manufacturing processes to their application in various sectors, focusing on how their design and material composition meet the diverse demands of modern industries.

1. Round Bars

Round bars are cylindrical metal rods typically used as a basic material in manufacturing, construction, and mechanical applications. Their simple, versatile form allows them to be shaped into various components, including shafts, fasteners, and structural supports. Historically, round bars have evolved in terms of material composition and manufacturing techniques, making them indispensable across different industrial applications.

2. Types of Round Bars

There are several types of round bars, each suited to specific uses and industries:

Stainless Steel Round Bars: Known for their corrosion resistance, these bars are ideal for applications in harsh environments such as chemical plants, food processing units, and marine installations.

Carbon Steel Round Bars: These bars offer excellent strength and are used in construction, heavy machinery, and other high-stress environments.

Alloy Steel Round Bars: Alloyed with other elements to enhance mechanical properties, these are often used in aerospace and automotive industries.

Aluminum, Copper, and Other Round Bars: These bars are lightweight and corrosion-resistant, making them ideal for specialised applications in electronics, marine, and architectural industries.

3. Materials Used in Round Bar Manufacturing

The choice of material for round bars depends on the specific requirements of the application. Common materials include:

Stainless Steel: Offers excellent corrosion resistance and strength, suitable for both high and low temperatures.

Carbon Steel: Provides high strength and durability, making it a popular choice for construction and manufacturing.

Aluminum: Lightweight and resistant to corrosion, widely used in aerospace and automotive industries.

Copper: Known for its electrical conductivity, copper round bars are used in electrical and thermal applications.

The material properties, such as tensile strength, corrosion resistance, and temperature tolerance, determine the suitability of round bars for specific tasks.

4. Manufacturing Process of Round Bars

The production of round bars involves several key steps to ensure the material’s quality and dimensional accuracy:

Raw Material Procurement: Raw metal is sourced in the form of billets or ingots.

Melting and Casting: The metal is melted and cast into a cylindrical shape.

Hot Rolling and Cold Rolling: Depending on the desired strength and surface finish, the bar is either hot-rolled (for general applications) or cold-rolled (for precision).

Precision Machining: The round bars are machined to specific dimensions, ensuring accuracy in length, diameter, and surface finish.

5. Heat Treatment and Finishing of Round Bars

To improve mechanical properties and durability, round bars undergo heat treatment:

Annealing: Softens the metal for easier machining.

Quenching and Tempering: Enhances strength and toughness for high-stress applications.

Polishing and Coating: Surface treatments improve corrosion resistance and appearance, making the bars suitable for exposed applications.

Round Bar Exporters In India: A Full Overview For Industry And Trade

With Indian round bar exporters being well-known worldwide for their superior goods, Nippon Alloys Inc. has emerged as a major force in the steel sector. Round bars are crucial structural and equipment elements that are used extensively in the industrial, automotive, and building sectors. To meet the varied needs of customers throughout the world, our exporters provide a broad range of round bars made of alloy steel, carbon steel, and stainless steel. They have established a strong reputation in markets across Europe, Asia, and the Middle East because of their dedication to affordable prices and strict quality standards.

Round bars are cylindrical, long goods used in a wide range of sectors, including construction, automobile manufacture, heavy machinery, and infrastructure development. These round bars manufactured from a number of materials, including stainless steel, carbon steel, alloy steel, and copper, among others. Round bars are vital in contemporary manufacturing and construction because to their strength, durability, and adaptability.

Another important market for round bars is the automobile sector. India, one of the biggest automakers in the world, had an exponential increase in demand for premium round bars for usage in axles, chassis, and engine parts. Large amounts of round bars were also needed for the building of train stock, signalling equipment, and tracks in the nation's expanding railway network.

For More Detail

Website: nipponalloys.com

Product: Round Bar Exporter in India

Other Product: Alloy Round Bar Supplier in India, Monel Round Bar Importer in India.

#Round bar Supplier in India#Round bar Supplier#Round bar#Alloy Round Bar Supplier in India#Monel Round Bar Importer in India

0 notes

Text

India’s Top Inoculant Wire Feeder Producer | Superior Manufacturing

India’s metallurgical and foundry industries have experienced tremendous growth, particularly in the production of essential materials like inoculant wire feeders. These feeders play a crucial role in enhancing the quality of metal casting, especially in industries like automotive, aerospace, and heavy machinery.

Indian producers have earned a reputation for delivering top-notch products with a focus on precision, innovation, and reliability. In this article, we’ll explore why these feeders are important for industries reliant on metal casting, how Indian manufacturers have emerged as global leaders, and the unique qualities that set them apart in terms of production excellence.

Importance of Inoculants in Metal Casting

Inoculants play a vital role in the casting of metals such as cast iron and steel. They are added in small quantities to molten metal to modify its microstructure, which enhances its mechanical properties and reduces defects. In particular, inoculants help to control the solidification process, resulting in finer grain structures and improved overall performance of the cast product.

One of the most efficient ways to introduce inoculants into molten metal is through feeder systems, which ensure controlled and accurate dosing. This precise addition improves the quality of the metal, minimizes waste, and increases the efficiency of the casting process. The result is a more cost-effective production method and a higher-quality end product.

Key Benefits of Using These Systems:

Enhanced Material Strength: Inoculants help refine the grain structure of the metal, leading to stronger and more durable castings.

Reduction in Defects: By preventing the formation of carbides and other unwanted phases, inoculants help reduce common casting defects such as porosity and shrinkage.

Process Optimization: The accurate delivery of inoculants ensures uniformity in the final product, reducing the need for rework and lowering production costs.

Improved Surface Finish: Better solidification control leads to a smoother and more consistent surface on cast components.

Leading Indian Producers Inoculant Wire Feeders

Several Indian companies have become prominent producers in this field, gaining recognition for their advanced production processes and commitment to quality. These companies supply domestic and international markets with feeders that meet stringent industry requirements, contributing to the high performance of critical cast components in various industries.

1. Elkem India Pvt. Ltd.

A subsidiary of the global industry leader Elkem, Elkem India has built a strong presence in the Indian market by providing reliable and advanced solutions. The company’s commitment to research and development enables it to stay ahead of technological trends, offering efficient systems that improve the quality of castings in automotive, construction, and other industries.

2. Ferroglobe India

Ferroglobe India is known for producing a wide range of silicon-based products, including inoculants that enhance the quality of steel and iron castings. The company’s high-performance feeders are designed to meet the demands of industries requiring precision and consistency. With cutting-edge technology and a focus on sustainability, Ferroglobe India is a leader in this field.

3. IFGL Refractories Ltd.

IFGL Refractories Ltd. has established itself as a trusted name in India’s metallurgical industry. The company produces a variety of products for the foundry sector, with its feeders recognized for their role in optimizing casting processes. By focusing on customer satisfaction and consistent product quality, IFGL has earned a strong reputation both in India and abroad.

4. Simco Group

Simco Group is a prominent Indian manufacturer and exporter of advanced casting systems. Their products are widely used in industries that require high-performance materials, such as automotive and heavy machinery. Simco’s dedication to technological advancement and rigorous quality control ensures that its solutions meet the highest international standards.

5. Tata Steel Advanced Materials

Tata Steel, one of India’s largest and most respected companies, has expanded into producing advanced materials, including feeder systems. Known for its innovation and sustainability practices, Tata Steel’s products are designed to enhance the efficiency of casting operations, ensuring high-quality output with minimal environmental impact.

Why Indian Manufacturers Stand Out

Indian producers have gained a competitive edge in the global market for several reasons, positioning themselves as top suppliers in the casting industry for both feeder systems and alloys ferro silicon magnesium in India:

1. Advanced Manufacturing Technology

India’s leading manufacturers have invested in modern production facilities that allow for high-precision manufacturing. By incorporating automation and cutting-edge technologies into their processes, these companies ensure that their products meet the strict quality standards required by industries worldwide.

2. Innovation and R&D

Innovation is a key driver for success in the Indian alloy industry. Leading producers are continually developing new solutions that improve casting efficiency and product quality. By focusing on research and development, these companies stay ahead of industry trends, offering customized solutions that meet the unique needs of their customers.

3. Customization and Flexibility

Indian manufacturers are known for their ability to provide tailored solutions. Industries that require specific compositions or designs can rely on Indian companies to meet their exact requirements. This flexibility, combined with a strong focus on customer satisfaction, has helped Indian producers build long-term relationships with clients around the world.

4. Cost-Effectiveness

One of the key advantages Indian producers offer is the ability to provide high-quality products at competitive prices. By streamlining production processes and leveraging economies of scale, Indian manufacturers can offer cost-effective solutions without sacrificing quality. This makes them attractive suppliers for industries looking to optimize their production costs.

5. Sustainability Initiatives

Environmental responsibility is becoming increasingly important in the manufacturing industry, and Indian producers are leading the way in adopting sustainable practices. Many companies have implemented measures to reduce energy consumption, minimize waste, and use renewable resources, ensuring that their products are not only high-quality but also eco-friendly.

Global Reach and Future Prospects

The success of India’s leading manufacturers has extended far beyond the domestic market. These companies have established strong export networks, supplying high-quality products to industries around the world. As global demand for efficient and precise casting systems continues to rise, Indian producers are well-positioned to meet these needs, ensuring consistent growth and further expansion in the future.

Conclusion

India’s top inoculant wire feeder producers have earned their place in the global metallurgical industry through superior manufacturing practices, innovation, and a commitment to quality. By investing in advanced technologies and focusing on customer satisfaction, Indian manufacturers continue to meet the growing demand for high-performance inoculant wire feeders in industries worldwide. Their ability to provide cost-effective and sustainable solutions makes them the go-to choice for businesses seeking reliable and high-quality products.

#inoculant wire feeder#ferro silicon magnesium in india#ferro silicon magnesium#magnesium cored wire injection system#cored wire#manufacturers

0 notes

Text

Comprehensive Guide to Stainless Steel Round Bar Manufacturing in India

Introduction

Stainless steel round bars are major components in various industries, be it construction or manufacturing. India hosts a variety of manufacturers who specialize in the production of high-quality stainless steel round bars to cater for a multitude of applications. This piece takes a look at what stainless steel round bars are, their manufacturing process, their usages, and considerations while purchasing them.

What are Stainless Steel Round Bars?

Stainless steel round bars also known as stainless steel rods are cylindrical bar made of stainless steel. The latter exhibits many outstanding corrosion resistance properties and various strength levels as compared to some other steel grades. Generally, these bars are available in various diameters and lengths. Therefore, they are used for various purposes. The widely used grades of round bars include 304 and 316 stainless steel having different properties and can be applied in specific environments.

How are Stainless Steel Round Bars Manufactured?

Manufacturing stainless steel round bars involves several key steps:

Melting: This process begins through melting raw materials by using an electric arc furnace where the fusible material at very high temperatures is combined with iron and alloying elements.

Casting: The molten steel is cast into slabs or billets, which are cooled to become solid steel.

Rolling: Cold steel is heated and passed through the rolling mills to impart the necessary diameter. Hot rolling enhances the mechanical properties of the material.

Finishing: After the process of rolling, bars are subjected to various finishing processes like pickling and passivation so that the surface quality improves and gets resistive to corrosion as well.

What is the Use of Stainless Steel Round Bars?

The application of stainless steel round bars also keeps on being very versatile and in great demand, and these include :

Building: They are primarily used in the building of column, beams, and reinforcement rods in concrete.

Engineering: Round bars are part of the many engineering applications for making various parts of machinery, shafts, among other many uses.

Automobile: These bars are used in the manufacturing of the axles, gears, and other components of the engine since they too, have known strength and durability features.

Aerospace: These bars are useful for use in aircraft and other aerospace applications due to their lightweight strength structure.

Key Considerations When Sourcing Stainless Steel Round Bars

The following points are to be considered in case of importing stainless steel round bars from India:

Quality Standards: The ISO certification by the respective manufacturer will ensure that the products are provided in accordance with the international standards. This will definitely ensure the reliability of the products.

Grade Selection: The choice of the stainless steel grade must be carried out as per the desired application to obtain maximum performance.

Customization: The manufacturer should provide options for customization. Especially, the dimensions and finishing processes shall be put as customization options.

Supplier Reputation: It should check its reputation, customer reviews, and years of experience in the industry to ensure the best supply chain.

Conclusion

Stainless steel round bars are utilized in a very wide range of applications across many different kinds of industries. If you wish to understand how it is manufactured and its applications along with the salient points to ponder during procurement, then it would serve the business well in terms of better decision-making. You can rely on quality stainless steel round bars from a good stainless steel roundbar manufacturer in India.

#stainless steel roundbar manufacturer in India#stainless steel roundbar manufacturer#stainless steel roundbar manufacturers#stainless steel roundbar

0 notes

Text

Innovations and Sustainability in the Aluminum Castings Market: A 10-Year Outlook

The aluminum castings market is poised for substantial growth in the coming decade, driven by the increasing demand for lightweight and durable materials across various industries. Aluminum castings are widely utilized in automotive, aerospace, construction, and consumer goods sectors due to their excellent mechanical properties, corrosion resistance, and cost-effectiveness. As industries focus on reducing weight to enhance energy efficiency and performance, the preference for aluminum castings continues to rise.

The aluminum castings industry was valued at US$ 41.5 billion in 2023 and is projected to grow at a CAGR of 6.6% from 2024 to 2034, reaching an estimated US$ 83.4 billion by the end of 2034. This growth can be attributed to the expanding automotive sector, where aluminum castings are increasingly being used to manufacture engine components, transmission housings, and structural parts. Additionally, the aerospace industry's shift toward lightweight materials is further propelling market expansion.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/aluminum-casting-market.html

Market Segmentation

The aluminum castings market can be segmented based on several factors:

By Service Type

Manufacturing Services: Includes custom and standard manufacturing of aluminum castings.

Design and Engineering Services: Encompasses the design and engineering of aluminum casting solutions to meet specific requirements.

By Sourcing Type

In-house Sourcing: Companies that produce aluminum castings within their facilities.

Outsourcing: Companies that outsource aluminum casting production to specialized manufacturers.

By Application

Automotive: Engine blocks, transmission cases, wheels, and structural components.

Aerospace: Aircraft components, landing gears, and other structural parts.

Consumer Goods: Kitchenware, furniture, and decorative items.

Industrial: Machinery parts, pumps, and valves.

By Industry Vertical

Automotive: The largest segment due to the extensive use of aluminum in vehicle manufacturing.

Aerospace: Rapidly growing as manufacturers seek to reduce weight and improve fuel efficiency.

Construction: Increasing demand for lightweight structural components.

Electronics: Use of aluminum castings in electronic housings and components.

By Region

North America: Significant market share due to a robust automotive and aerospace industry.

Europe: Strong demand for lightweight materials in automotive manufacturing.

Asia-Pacific: The fastest-growing region, led by countries like China and India, where industrialization and infrastructure development are driving demand.

Latin America and the Middle East & Africa: Emerging markets with growing construction and automotive sectors.

Regional Analysis

North America holds a significant share of the aluminum castings market, primarily due to the presence of major automotive and aerospace manufacturers. The region's focus on advanced manufacturing techniques and sustainable practices further enhances market prospects. Europe is also a key player, with stringent regulations promoting the use of lightweight materials in transportation.

In the Asia-Pacific region, rapid industrialization, urbanization, and increasing automotive production are expected to propel market growth significantly. Countries like China and India are investing heavily in infrastructure and automotive sectors, leading to a surge in aluminum casting demand.

Market Drivers and Challenges

Drivers

Lightweight Materials Demand: The push for fuel-efficient and lightweight vehicles drives the need for aluminum castings.

Technological Advancements: Innovations in casting techniques enhance the quality and performance of aluminum castings.

Sustainability: The recyclability of aluminum aligns with the global shift toward sustainable manufacturing practices.

Challenges

Cost Fluctuations: The volatility in aluminum prices can impact production costs and profitability.

Competition from Alternative Materials: The rise of composites and other lightweight materials poses a challenge to aluminum casting demand.

Manufacturing Constraints: The need for specialized equipment and skilled labor can limit production capabilities for some manufacturers.

Market Trends

Increasing Adoption of 3D Printing: 3D printing technologies are gaining traction in aluminum casting, enabling the production of complex geometries and reducing lead times.

Focus on Automation: Automation in casting processes is enhancing efficiency, reducing labor costs, and improving product consistency.

Growing Electric Vehicle Market: The rise of electric vehicles (EVs) is creating new opportunities for aluminum castings in battery enclosures and other lightweight components.

Future Outlook

The aluminum castings market is expected to witness significant growth through 2034, driven by the expanding automotive and aerospace industries' shift towards lightweight materials. As technological advancements continue to shape the manufacturing landscape, companies that invest in innovative casting techniques and sustainable practices will likely lead the market. Additionally, emerging economies in the Asia-Pacific region will play a crucial role in driving demand for aluminum castings.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=31241<ype=S

Key Market Study Points

Continuous investment in research and development for innovative aluminum casting solutions.

Strategic partnerships and collaborations among manufacturers to enhance production capabilities.

Monitoring of regulatory changes and sustainability initiatives impacting the aluminum industry.

Competitive Landscape

The aluminum castings market is characterized by a mix of established players and emerging companies. Key players include:

Alcoa Corporation: A leader in aluminum production and casting, focusing on innovation and sustainability.

Rio Tinto Group: Engaged in aluminum production with a strong emphasis on environmental responsibility.

Nemak S.A.B. de C.V.: Specializes in lightweight castings for the automotive industry.

Casting Technologies International: Provides advanced casting solutions for various industries.

These companies are investing in technology, expanding their product offerings, and enhancing operational efficiency to gain a competitive edge.

Recent Developments

Sustainability Initiatives: Many companies are adopting greener practices, including recycling and reducing carbon emissions in aluminum casting processes.

Expansion Plans: Major players are expanding their manufacturing facilities in emerging markets to cater to growing demand.

Collaborations: Strategic alliances between aluminum producers and technology firms to develop advanced casting solutions.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

The Stainless Steel Sheet Manufacturing Industry: A Comprehensive Overview

United Stainless LLP is a leading Stainless Steel Sheet Manufacturer in India. Stainless steel sheet manufacturing is a cornerstone of modern industry, providing a material that is highly versatile, durable, and corrosion-resistant. From construction to automotive, household appliances to aerospace, stainless steel sheets are used in countless applications due to their unique properties. In India, the demand for stainless steel continues to rise, as manufacturers focus on delivering high-quality materials that meet international standards. This blog will explore the Stainless Steel Sheet Manufacturer industry, its process, key players in the market, and the growing demand for stainless steel in India.

Overview of Stainless Steel

Stainless steel is an alloy composed primarily of iron, with at least 10.5% chromium. This chromium content forms a thin, protective oxide layer on the surface of the steel, preventing corrosion and rust. Other elements such as nickel, molybdenum, and nitrogen are often added to enhance specific properties like formability, strength, or corrosion resistance.

The unique characteristics of stainless steel make it an ideal material for various industrial applications. It is durable, recyclable, resistant to heat and chemicals, and has an attractive appearance. These qualities make stainless steel sheets an indispensable material in industries that require strength, hygiene, and long-term durability.

The Manufacturing Process of Stainless Steel Sheets

The SS Sheet Manufacturer in India begins with the melting of raw materials such as iron ore, nickel, and chromium in an electric furnace. The furnace heats the raw materials to extremely high temperatures (up to 1500°C) to melt them together. Once the materials are thoroughly melted and mixed, they are cast into slabs or ingots.

The next stage involves hot rolling the slabs, which reduces the thickness of the steel and shapes it into a sheet. During this process, the slabs are passed through a series of rollers at high temperatures. Once the desired thickness is achieved, the hot-rolled sheet is cooled and annealed (a heat treatment process that increases the material's ductility and reduces its hardness). After annealing, the stainless steel sheet undergoes cold rolling, which refines the surface finish and increases the strength of the material.

Finally, the sheets are cut to size, polished, and undergo surface treatments such as pickling or passivation to remove any impurities or scale from the surface. The result is a high-quality stainless steel sheet that is ready for use in various applications.

Applications of Stainless Steel Sheets

The versatility of stainless steel sheets makes them suitable for a wide range of industries. Some of the major sectors that rely heavily on stainless steel sheets include:

Construction and Architecture: Stainless steel is used in building facades, roofing, cladding, and interior applications. Its corrosion resistance and aesthetic appeal make it a popular choice in modern architectural designs.

Automotive Industry: Stainless steel sheets are used in exhaust systems, catalytic converters, and structural components of vehicles due to their strength, heat resistance, and lightweight properties.

Aerospace Industry: Aircraft components, engine parts, and structural components are made from stainless steel sheets because of their durability and ability to withstand extreme temperatures.

Food and Beverage Industry: Stainless steel sheets are used in the manufacture of equipment such as tanks, sinks, and tables, thanks to their hygienic properties and resistance to corrosion.

Medical Industry: Surgical instruments, hospital equipment, and pharmaceutical equipment are often made from stainless steel due to its ability to be easily sterilized.

Household Appliances: Stainless steel sheets are widely used in the production of refrigerators, ovens, dishwashers, and other household appliances because of their sleek appearance, durability, and resistance to staining and rust.

Countries We Supply Stainless Steel Sheet

Stainless Steel Sheet Manufacturer in Vietnam

Stainless Steel Sheet Manufacturer in Taiwan

Stainless Steel Sheets Manufacturers USA

Stainless Steel Sheet Suppliers in UAE

Stainless Steel Sheet Suppliers in Srilanka

Stainless Steel Sheet Suppliers in Qatar

Growing Demand for Stainless Steel Sheets in India

India’s growing industrialization and urbanization have led to an increased demand for stainless steel sheets. Industries such as construction, automotive, and infrastructure are driving this demand, especially as the government invests heavily in infrastructure projects like roads, bridges, and airports. Additionally, the automotive industry’s shift towards electric vehicles is creating new opportunities for SS Sheet Manufacturer.

The rising awareness of sustainability and recycling is also contributing to the demand for stainless steel, as it is 100% recyclable. Furthermore, stainless steel’s long lifecycle and minimal maintenance requirements make it a cost-effective solution for various industries.

Conclusion

Stainless Steel Sheet Supplier in India is a dynamic and growing industry in India, supported by a strong industrial base and increasing demand across multiple sectors. With advancements in technology and a focus on sustainability, manufacturers are continuously improving the quality of stainless steel sheets to meet global standards. As industries expand, the Stainless Steel Sheet Supplier industry will continue to play a pivotal role in supporting India's economic growth and infrastructure development.

#Stainless Steel Sheet Manufacturer in India#ss sheet manufacturer in india#Stainless Steel Sheet Manufacturer#Stainless Steel Sheet

0 notes

Text

Nickel 200 Flanges Stockists

Nickel 201 Flanges are an integral component in many industrial applications due to their extraordinary resistance to corrosion and stability at high temperatures.

1) Overview: Understanding Nickel 200 Flanges Basics

Nickel 200 is a commercially pure form of nickel with exceptional mechanical properties, making it ideal for various industrial applications. Nickel 200 flanges are widely used in chemical processing, aerospace, marine, and energy sectors due to their high resistance to corrosive environments, especially acids and alkalis. These flanges are crucial components in piping systems, providing secure connections for pipes, valves, and other equipment. Manilaxmi Industrial, a leading manufacturer and supplier, offers top-quality Nickel 200 flanges, which are essential for industries requiring materials with excellent heat and corrosion resistance.

Key Features of Nickel 200 Flanges:

High thermal and electrical conductivity

Superior resistance to various corrosive media

High ductility and toughness even in extreme temperatures

Exceptional weldability and machinability

2) Current Trends in Nickel 200 Flanges

With growing emphasis on sustainable solutions and the need for high-performance materials in harsh environments, the demand for Nickel 200 flanges is on the rise. The global industrial shift toward energy-efficient and environmentally friendly processes has led to increased utilization of these flanges in chemical and petrochemical plants. In India, the infrastructure boom and the expansion of industries such as oil & gas, fertilizers, and pharmaceuticals have further boosted the demand for Nickel 200 flanges.

Moreover, advanced manufacturing techniques, such as precision casting and 3D printing, are enhancing the production quality and customization options for flanges, making it easier for companies to meet specific industry requirements.

3) Impact in the Industry

Nickel 200 flanges play a vital role in ensuring the safety and efficiency of industrial systems. Their resistance to aggressive chemicals, high-temperature environments, and corrosive conditions makes them invaluable in sectors like chemical processing and power generation. The robust nature of these flanges ensures longevity, reducing the need for frequent replacements, thereby contributing to cost savings and uninterrupted operations.

Manilaxmi Industrial, with its advanced manufacturing capabilities, ensures that their Nickel 200 flanges meet the highest industry standards, further enhancing the reputation of Indian manufacturers globally.

4) Implications and Future Prospects

The future of Nickel 200 flanges in India looks promising, driven by the increasing demand for high-performance materials in critical sectors. As industries strive for more sustainable and energy-efficient solutions, Nickel 200 flanges will continue to gain importance, especially in renewable energy projects and green chemical processing.

Furthermore, the rapid adoption of advanced technologies like Industry 4.0 and smart manufacturing will lead to better quality control and customization of these flanges. With India emerging as a global manufacturing hub, the export potential of Nickel 200 flanges is set to grow, positioning Manilaxmi Industrial as a key player in the global market.

5) Summary & Recommendations

Nickel 200 flanges are indispensable in industries requiring high levels of corrosion resistance and durability, making them a crucial component in sectors like chemical processing, oil & gas, and power generation. Manilaxmi Industrial stands out as a trusted supplier of these flanges, providing products that meet international quality standards.

Recommendations:

For Industrial Buyers: Opt for Nickel 200 flanges from reputable suppliers like Manilaxmi Industrial to ensure product longevity and superior performance in harsh environments.

For Engineers & Designers: Consider Nickel 200 flanges for applications where resistance to extreme temperatures and corrosive materials is critical.

For Exporters: Given the growing global demand for high-quality industrial materials, exporting Nickel 200 flanges from India offers lucrative business opportunities.

By investing in Nickel 200 flanges from Manilaxmi Industrial, companies can enhance the safety, reliability, and efficiency of their operations.

#Nickel 201 Flanges#Nickel 201 Flanges Manufacturers#Nickel 201 Flanges Suppliers#Nickel 201 Flanges Stockists#Nickel 201 Flanges Exporters#Nickel 201 Flanges Manufacturers In India#Nickel 201 Flanges Suppliers In India#Nickel 201 Flanges Stockists In India#Nickel 201 Flanges Exporters In India

1 note

·

View note

Photo

Are you looking for the best quality tool steel, die steel, and mold steel suppliers for your engineering work in India?

As one of India’s leading special steel suppliers, #ViratSpecialSteels can supply the following industries requirement of steel practically off-the-shelf.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Forging Industry - Forging is a process in which metal is being shaped using compressive forces with a Hammer or a press. Forging are classified into Cold forging, warm forging or hot forging. Mainly material used: Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343(H11).

Pressure Die Casting – Die casting is performed by forcing molten metal under high pressure into a mold cavity & the cavity (mold cavity) is manufacture by using two hardened tool steel dies & perform similar to an injection mold. Mainly material used: Hot die steel i.e. DIN 1.2344(H13), DIN 1.2343(H11), and DIN 1.2581(H21).

Aluminum Extrusions - In Extrusion process material is pushed through a die to the desired cross section & in this manufacturing process it creates very complex cross section. The parts are being formed with an excellent surface finish. Mainly material used: - Hot die steels i.e. DIN 1.2344 (H13) grade.

Automotive Industry - Automotive industry are wide range of companies is mainly involved in manufacturing, design, development, of motor vehicles. Mainly material used: - Din 1.2714(DB6), DIN 40NiCrMo84(EN24), DIN 3343(M2), 16Mncr5, 20Mncr5.

Plastic industry - Polymer materials are manufactures in plastic industry and offers services to aerospace, building, construction, electronics, packaging and transportation. Mainly material used: - DIN 2738 (P20+ Ni), DIN 2311(P20).

Railways - They are involves mainly in manufacturing railways components i.e. Railway gear holder, Railway bogie cast parts, Railways axles, railways Sets of pins, Ground lever frame, adjustable crank, Compressor pistons, Compressor bearings. Mainly material used:-Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343 (H11), DIN 40NiCrMo84(EN24), 20NiCrMo5(EN353).

Oil & Gas - Oil & Gas they supply more than 60 percent of our nation’s energy. Natural gas also helps generate the electricity that powers our daily lives.

They also have a fully equipped quality assurance and process examination facility that conducts tests such as hardness and analyses of grain structure.

Find us: Website: https://www.viratsteels.com/ Email us: [email protected] Call Us Now: +91-9814021775

#viratspecialsteels#viratsteelsindia#viratsteels#2714steel#h13steel#din2714#din2738#db6steel#din2344#diesteel#mouldsteel#mouldsteelstockist#tool steels#toolsteelsupplier#delhincr#gurugram#ludhiana#gurgaon#pune#india#forging#metalworking#steel#alloy steel#cold work steel#high speed steel#hot work steel#manufacturing#construction#iso9001

3 notes

·

View notes

Text

Motilal Oswal's Strategic Investment in PTC Industries: A Significant Boost as the Company Raises ₹700 Crore via QIP

In a significant financial move, PTC Industries Limited, a key player in the manufacturing and technology sectors, has successfully raised ₹700 crore through a Qualified Institutional Placement (QIP). This fundraising effort marks a crucial milestone in the company’s growth strategy, with a notable investment of over ₹210 crore coming from the prominent financial services firm Motilal Oswal. This investment highlights the growing confidence in PTC Industries' business prospects and its strategic importance in the market.

The QIP, which saw the issuance of 5.3 lakh equity shares, was conducted at an issue price of ₹13,199.7 per share. This price represented a 5% discount to the floor price, making it an attractive opportunity for institutional investors. The significant participation of Motilal Oswal underscores the firm's belief in the long-term potential of PTC Industries. Specifically, Motilal Oswal’s Large and Midcap Fund acquired 1 lakh shares, while its Long Term Equity Fund purchased an additional 59,236 shares. This combined acquisition, totaling 1.59 lakh shares, amounted to an investment of just over ₹210 crore, effectively giving Motilal Oswal a 30 percent stake in the total QIP issue.

The participation of Motilal Oswal in the QIP is not only a vote of confidence in PTC Industries' current operations but also a strategic move that aligns with the fund’s long-term investment objectives. Alongside Motilal Oswal, other significant players in the financial sector, including HSBC and Societe Generale, also participated in the QIP. HSBC invested ₹130 crore, while Societe Generale contributed ₹60 crore, further diversifying the investor base and adding to the financial strength of PTC Industries.

PTC Industries is known for its extensive manufacturing capabilities, particularly in the production of earth-moving equipment, fork and machine tools, pumps, and spare parts. The company is also a significant exporter of stainless steel castings and non-ferrous alloys, supplying critical components to various industries worldwide. This diverse portfolio has positioned PTC Industries as a reliable supplier in both domestic and international markets.

The timing of this QIP is particularly noteworthy given the current performance of PTC Industries' stock. At the time of the QIP announcement, the stock was trading at ₹14,470.70 per share on the National Stock Exchange (NSE), reflecting a marginal increase of 0.31 percent. The company’s stock has been on an impressive upward trajectory, rising by 72.47 percent over the last six months. Moreover, in 2024 alone, PTC Industries has delivered a remarkable 118.04 percent return on the Bombay Stock Exchange (BSE), solidifying its status as a multibagger stock. Over the past year, the stock has appreciated by 141.72 percent, demonstrating the company’s robust financial performance and the market’s positive sentiment towards its future growth.

PTC Industries’ recent success is not limited to financial achievements. In June 2024, the company announced a strategic partnership with leading defense entities under the Defence Testing Infrastructure Scheme (DTIS). This collaboration is part of the Indian government’s 'Make in India' initiative, aimed at bolstering domestic production capabilities in the defense and aerospace sectors. As part of this initiative, PTC Industries is developing a state-of-the-art greenfield defense testing facility at the Lucknow Node of the Uttar Pradesh Defence Industrial Corridor. This facility is expected to play a crucial role in enhancing India’s defense manufacturing infrastructure, further positioning PTC Industries as a key contributor to the nation’s strategic objectives.

The successful QIP, coupled with strategic investments and partnerships, places PTC Industries on a strong footing for future growth. The infusion of ₹700 crore will likely be used to expand the company’s manufacturing capabilities, invest in new technologies, and explore new market opportunities. For investors, the strong performance of PTC Industries’ stock, combined with its strategic initiatives, makes it a compelling investment opportunity.

As PTC Industries continues to build on its successes, the involvement of institutional investors like Motilal Oswal will be crucial in supporting the company’s long-term vision. With its diverse portfolio, strategic partnerships, and robust financial performance, PTC Industries is well-positioned to continue its upward trajectory in the competitive landscape of manufacturing and technology.

0 notes

Text

Aluminium Die Casting Manufacturers: Taural India’s Impact and Expertise

Aluminium die casting has become a crucial part of the modern manufacturing industry, especially in sectors that require durable, lightweight, and cost-effective components. One company that stands out in this space is Taural India, an industry leader with expertise in producing high-quality aluminium die-cast parts for various applications. Operating with a focus on precision, efficiency, and sustainability, Taural India has earned a strong reputation among aluminium die casting manufacturers worldwide. This blog explores the essential role of Taural India in the aluminium die casting industry, the processes they employ, and the industries they serve.

1. An Overview of Aluminium Die Casting

Aluminium die casting is a manufacturing process where molten aluminum is injected into steel molds, or “dies,” under high pressure. The process allows for complex, highly detailed designs with excellent accuracy and consistency. Aluminium die casting is favored across industries for its unique properties:

Lightweight Strength: Aluminium has a high strength-to-weight ratio, which is invaluable in industries such as automotive and aerospace.

Corrosion Resistance: Aluminium’s natural resistance to corrosion enhances the durability of parts in various applications.

Cost Efficiency: Once a die is created, the casting process is repeatable, making it cost-effective for large production runs.

Recyclability: Aluminium is 100% recyclable, making it an environmentally friendly choice.

2. Taural India: A Leader in Aluminium Die Casting

Taural India has grown into one of the most respected aluminium die casting manufacturers in India. With a commitment to quality, innovation, and sustainability, Taural India delivers die-cast components that meet the high standards required by diverse industries. They leverage state-of-the-art technology and a team of skilled engineers to manufacture precision parts for their clients across the globe.

Quality Assurance at Taural India

Quality is at the core of Taural India’s mission. Every step of their production process, from material sourcing to final inspection, adheres to stringent quality standards. Taural India invests in advanced technology, such as high-pressure die-casting machines, CNC machining, and automated inspection tools. This ensures that every product meets both the customer’s specifications and global industry standards.

Their commitment to quality also extends to maintaining high standards in testing and certification, enabling Taural India to meet the stringent requirements of industries such as automotive, aerospace, and electronics.

Precision Engineering and Advanced Technologies

To achieve high precision and accommodate complex designs, Taural India employs advanced engineering techniques. Using computer-aided design (CAD) and computer-aided manufacturing (CAM), they can achieve intricate part geometries with minimal tolerances. Additionally, Taural India’s use of sophisticated simulation software helps in predicting and mitigating potential issues in the casting process, ensuring a higher yield of defect-free components. This use of technology also allows for flexibility in producing both large and small parts with consistent accuracy and durability.

Sustainability Initiatives and Environmental Responsibility

In line with global shifts toward sustainable practices, Taural India prioritizes environmental responsibility. Aluminium, being highly recyclable, aligns with this commitment as it can be reused without compromising quality. Taural India minimizes waste by recycling aluminium scrap and optimizing energy consumption across their operations. By focusing on sustainable manufacturing practices, Taural India not only contributes to a greener environment but also attracts clients who value eco-conscious suppliers.

3. Industries Served by Taural India

The versatility of aluminium die casting has enabled Taural India to supply high-quality components to a wide array of industries, meeting specific requirements for each.

a) Automotive Industry

The automotive industry is a primary consumer of aluminium die-cast parts due to the lightweight and durable properties of aluminium. Taural India provides critical components such as engine parts, transmission casings, and structural parts that reduce vehicle weight, improve fuel efficiency, and enhance performance. With vehicles moving toward electrification, Taural India’s parts are essential in creating lightweight structures that accommodate the added weight of electric power systems.

b) Aerospace Industry

In aerospace, precision and weight reduction are crucial. Aluminium’s lightweight properties are perfect for components like fuselage frames, support brackets, and engine housings. Taural India’s expertise in high-quality die casting enables them to meet the stringent safety and performance standards required by the aerospace sector, delivering reliable and precise components that withstand extreme conditions.

c) Electronics and Telecommunications

Electronics manufacturers benefit from aluminium die-cast parts due to aluminium’s excellent thermal conductivity and shielding capabilities. Taural India produces housings and enclosures that protect sensitive electronic components from electromagnetic interference (EMI) and heat. These parts are commonly used in applications like telecommunication devices, LED lighting systems, and computer hardware, providing durability, heat dissipation, and protection from environmental hazards.

d) Industrial and Heavy Machinery

Taural India’s aluminium die-cast parts are essential for various industrial machinery applications. They produce parts like pump housings, motor covers, and hydraulic components that require strength, durability, and resistance to corrosion. The precision casting techniques ensure that these components meet the high demands of heavy machinery, allowing for efficient and reliable performance under rigorous conditions.

4. Taural India’s Competitive Advantage

Taural India’s competitive edge lies in its unwavering commitment to innovation, quality, and customer satisfaction. Their key advantages include:

State-of-the-Art Facilities: Equipped with the latest die casting technology, Taural India can handle high-volume production runs with consistent quality.

Dedicated Research and Development (R&D): Taural India invests significantly in R&D to continuously improve their processes and materials. This enables them to stay ahead of industry trends and provide solutions for emerging market demands, such as lightweight electric vehicle parts.

Customization and Flexibility: Taural India is known for its ability to cater to specific customer needs, offering custom casting solutions and collaborating closely with clients to meet unique specifications.

5. The Future of Aluminium Die Casting with Taural India

As industries evolve, so do the demands for aluminium die-cast components. Taural India is prepared to meet these evolving needs by continuing to innovate, enhance sustainability, and expand their capabilities.

a) Emphasis on Electric Vehicles (EVs)

With the global push for electric vehicles, the demand for lightweight, energy-efficient parts has surged. Taural India is at the forefront of this movement, producing parts that not only reduce vehicle weight but also enhance battery life and energy efficiency. By partnering with automotive companies focused on EV development, Taural India is positioned to be a key supplier of aluminium die-cast parts for the electric mobility industry.

b) Increased Automation and Smart Manufacturing

Taural India is leveraging automation and digital technology to streamline operations, reduce lead times, and enhance product quality. The incorporation of automation in their production lines and the use of real-time monitoring systems allow them to minimize defects and improve efficiency. This smart manufacturing approach ensures that Taural India remains competitive and responsive to market changes.

c) Commitment to Green Manufacturing

In addition to recycling, Taural India is exploring ways to reduce its carbon footprint further. This includes investing in cleaner energy sources, optimizing energy use in their facilities, and exploring new eco-friendly alloys. Taural India’s commitment to green manufacturing aligns with the sustainability goals of many of its clients, further strengthening its market position.

Conclusion

Taural India has established itself as a leader among aluminium die casting manufacturers, offering quality, innovation, and sustainability to its clients. Their dedication to producing precise, durable, and eco-friendly aluminium die-cast parts has made them a preferred partner across multiple industries. With a future-focused approach that embraces sustainability, automation, and customization, Taural India is set to play a pivotal role in shaping the aluminium die casting landscape. For industries that require high-performance, lightweight components, Taural India remains a trusted name, delivering reliable solutions that meet the demands of a fast-changing world.

0 notes

Text

Why Industries Rely on Metal Casting Manufacturers for Success.

Metal casting has long been a cornerstone of industrial production providing the foundation for manufacturing components used in a vast array of industries. Metal casting manufacturers have a vital position to play in industries across the board, from car and aerospace to agriculture and heavy machinery, continually making sure that these sectors are provided with pinnacle-notch components with which they could characterize. Here is a list of reasons why industries rely on precision in casting and the benefits they can get by collaborating with the best metal foundry in India.

The Importance of Metal Casting in Industrial Applications

Metal casting is the process of creating metal components by pouring molten metal into a mold and allowing it to cool and solidify. This method is crucial for producing components that are durable, precise, and cost-effective. Industries, such as automotive, aerospace, agriculture, and heavy machinery, require specialized components that can withstand extreme conditions, such as heat, pressure, and wear. Casting manufacturers have the expertise to create customized solutions that meet these needs, making metal casting a vital part of these industries.

The metal casting procedure allows for the introduction of complicated shapes that can often be impossible or expensive to achieve through other production techniques. As a result, industries rely on metal casting manufacturers in India to deliver precision components that meet their unique requirements. The potential to create such tricky and sturdy elements is why metal casting companies in India are in excessive demand throughout numerous sectors.

Precision and Quality in Metal Casting Manufacturing

One of the primary reasons why industries trust metal casting manufacturers is the precision and quality they bring to the manufacturing process. Whether producing small components for electronics or large parts for industrial equipment, the level of accuracy achieved by metal casting is unmatched. This precision ensures that the final product functions optimally, leading to improved performance and reduced risk of failure, which is crucial in industries where safety and reliability are non-negotiable.

When working with great best metal casting manufacturers, industries can expect a rigorous best control method that ensures each factor meets the specified specs. This attention to elements is vital in sectors where safety and reliability are non-negotiable. By partnering with metallic casting producers in India, corporations can get the right of entry to a wealth of enjoyment and understanding in generating additives that meet the highest enterprise standards.

Cost Efficiency and Scalability with Metal Casting

In addition to precision and quality, casting manufacturers offer cost-effective solutions that help industries manage their production costs. Metal casting is an economical method of production, especially in relation to mass production. The ability to produce large quantities of components at a lower cost per unit empowers industries economically, making metal casting an attractive alternative for industries looking to scale their operations.

Moreover, the adaptability of metal casting companies in India allows them to provide components in numerous sizes and quantities, supplying flexibility to companies as their needs evolve. This scalability is critical for industries that experience fluctuations in demand because it ensures they can always meet production targets without compromising on quality or performance.

Why Choose the Best Metal Foundry in India?

India has become a hub for steel casting, with numerous metal casting companies in India imparting modern facilities and technology to meet the desires of industries worldwide. The best metal foundry in India combines modern technology with years of experience, ensuring industries that their components are synthetic to the very best requirements.

Choosing a metal casting manufacturer in India not only ensures access to quality products but also provides companies with a competitive edge. The cost of production in India is lower compared to other countries, without compromising quality. This combination of affordability and excellence makes Indian metal casting manufacturers in India a reliable and attractive choice for industries seeking dependable, cost-effective solutions.

Versatility Across Industries

One of the key reasons why casting manufacturers are so important to industries is their versatility. Metal casting can be used to produce components for a wide range of industries, including automotive, aerospace, agriculture, manufacturing, and energy.Each of these sectors has unique requirements, and metal casting manufacturers have the ability to customize their processes to meet the specific needs of each industry, providing reassurance about its applicability.

For example, in the automobile sector, metel casting manufacturers in India produce engine blocks, transmission components, and brake components.. In aerospace, they devise lightweight but strong components able to withstand extreme situations. This versatility permits metel casting manufacturers to function as crucial partners to industries that depend on specialized elements for their success.

Meeting Industry Standards with the Best Metal Casting Manufacturers

Industries regularly function below strict regulatory guidelines, and assembly of those standards is non-negotiable. This is where the best metal casting manufacturers shine. These manufacturers have an intensive knowledge of the regulatory requirements and make sure that their casting strategies follow country-wide and international standards.

When operating with a metal casting manufacturer in India , industries may be confident that their products are not only brilliant but also meet the essential compliance and certification requirements. This reduces the hazard of product failure, legal challenges, or reputational damage, making metal casting manufacturers indispensable to industries where compliance is paramount.

Innovation and Technological Advancement in Metal Casting

The landscape of metal casting has advanced notably. Modern metal casting companies in India leverage progressive techniques, such as 3D printing, computer-aided layout (CAD), and automatic molding, to enhance precision, reduce waste, and accelerate manufacturing times. These technologies enable metal casting producers to live ahead of the curve, imparting industries' present-day answers that beautify productiveness and performance.

Industries benefit from these improvements as they gain access to better-performing components, faster manufacturing cycles, and decreased lead times. Partnering the best metal casting manufacturers' approach keeps them at the forefront of technological advancements, which is crucial in modern-day fast-paced commercial surroundings.

Environmental Sustainability and Metal Casting

In recent years, environmental sustainability has become a primary challenge for international industries. Fortunately, metallic casting manufacturers in India are making strides in adopting more sustainable practices. Many casting manufacturers use recycled materials, reduce power consumption throughout the casting technique, and implement green waste control practices.

These sustainable efforts help industries lessen their carbon footprint while still maximizing the use of excellent, long-lasting steel components. Metal casting companies in India that prioritize sustainability are increasingly appealing to industries seeking to align with international environmental requirements and company social responsibility projects.

Global Competitiveness of Indian Metal Casting Manufacturers

The Indian metal casting industry has established itself as a worldwide competitor, with metal casting manufacturers in India exporting products to nations around the world. The mixture of professional exertions, contemporary generation, and aggressive pricing has made India a pass-to destination for industries seeking superb metallic castings.

Industries worldwide rely upon the pleasant best metal casting manufacturers in India to offer components that meet their specifications, regardless of how complicated. This international recognition for excellence continues to develop as more businesses apprehend the benefits of partnering with metal casting manufacturers based entirely in India.

Conclusion

In conclusion, metal casting manufacturers play a vital role in the achievement of industries by supplying precision, excellent performance, and scalability. From automotive to aerospace, agriculture to heavy equipment, industries rely upon metal casting manufacturers in India to supply components that meet their genuine needs. The versatility and innovation of casting manufacturers make them integral partners for companies looking to live competitively in the contemporary, rapid-paced industrial panorama.

Choosing the best metal foundry in India guarantees that industries now not only receive remarkable additives but also benefit from modern-day technological advancements and sustainable practices. As the global demand for remarkable metallic components continues to grow, metal casting manufacturers in India are well-positioned to guide the way, offering the expertise, reliability, and aggressive parts that industries need for long-term success.

Sigma Malleable stands as a premiere foundry devoted to turning in advanced metallic merchandise, setting the benchmark within the industry as one of the leading Metal Casting Manufacturers. With a focal point on precision, exceptionality, and innovation, Sigma Malleable provides a diverse range of steel components tailor-made to meet the wishes of various industries. Our advanced casting techniques and commitment to excellence make sure that we constantly produce high-overall performance, long-lasting products, making us a trusted companion inside the international steel casting market.

#Metal casting#metal casting manufacturers#metal casting companies in India#best metal foundry in India

0 notes

Text

From Production to Application: Exploring the Journey of Grade 660 Round Bar