#Aerospace Parts Manufacturing Market Demand

Explore tagged Tumblr posts

Text

Aerospace Parts Manufacturing Market Trends, Growth, Scope, Opportunities and Future Outlook Till 2034: SPER Market Research

Aerospace parts are specialized components created and produced for use in airplanes, spacecraft, and associated systems. Along with complex items like engines, avionics, navigation systems, and propulsion units, these parts also comprise structural features like fuselage panels, wings, and landing gears. Aerospace components are designed to endure harsh environments, including high altitudes, abrupt pressure changes, and temperature fluctuations, guaranteeing their performance, safety, and dependability. In order to create lightweight and long-lasting designs, they are made with cutting-edge materials including titanium, aluminum alloys, and composites. Their production requires exacting manufacturing methods, stringent quality requirements, and thorough testing procedures. Aerospace components are essential to space exploration and aviation's operation and safety, which spurs industry innovation.

According to SPER Market Research, ‘Aerospace Parts Manufacturing Market Size- By Product type, By Application, By End User- Regional Outlook, Competitive Strategies and Segment Forecast to 2034’ states that the Global Aerospace Parts Manufacturing Market is estimated to reach USD 1315 billion by 2033 with a CAGR of 5.21%.

Over the coming years, the market for manufacturing aerospace parts will grow gradually. Massive backlogs of aircraft orders with manufacturers and the growing size of the global fleet of commercial aircraft are the main drivers of the market. In order to create intricate and customized parts, some of the market's players are concentrating on developing 3D printing technologies, which is also anticipated to drive the market forward throughout the course of the forecast year. Because commercial aviation is growing in many major countries of the world, there is a huge increase in demand for aircraft parts. Numerous developing nations are seeing rapid economic expansion and have become profitable aviation markets.

A number of barriers confront the market for manufacturing aeronautical parts: The strong demand from the sector forces manufacturers to deal with escalating raw material costs. They are also up against fierce competition from other suppliers of parts. Regulatory agencies' stringent safety and quality requirements raise production costs. Export markets and supply networks have been impacted by ongoing trade disputes and protectionism. Furthermore, the industry is highly reliant on major aircraft manufacturers, which exposes parts manufacturers to the cyclicality of orders from a select few clients. Aerospace parts might have drawn-out and intricate certification and approval procedures. For manufacturers' components to satisfy the necessary standards and requirements, they must go through stringent testing, validation, and verification processes.

Request a Free Sample Report: https://www.sperresearch.com/report-store/aerospace-parts-manufacturing-market.aspx?sample=1

The demand for aeronautical materials has suffered as a result of COVID-19. Manufacturers of aircraft components are forced to operate at partial capacities due to supply chain disruptions that cause delays or non-arrival of raw supplies, interrupt financial flows, and increase production line worker absenteeism. Due to the travel limitation, air traffic has drastically decreased, which has had a negative impact on the aerospace industry by lowering demand for and deliveries of new aircraft. The demand for aerospace materials has decreased as fewer aircraft have been delivered. Because of restrictions on foreign travel, the pandemic had a negative impact on the aviation sector. Major revenue-generating firms were forced to close as a result of the imposed lockdown.

The market for aerospace components manufacturing will be concentrated in North America driven by the growing need for innovative aircraft and the increased need for fixed-wing aircraft, which will promote market expansion. Some of the key players are - Boeing Company, Dassault Aviation, GENERAL ELECTRIC, Honeywell International Inc.

For More Information, refer to below link: –

Aerospace Parts Manufacturing Market Growth

Related Reports:

Fishing Drones Market Growth, Size, Trends Analysis - By Type, By Payload Capacity, By Application, By End User - Regional Outlook, Competitive Strategies and Segment Forecast to 2034

Drones for Emergency Responders Market Growth, Size, Trends Analysis - By Drone Type, By Application, By Level of Autonomy, By End User - Regional Outlook, Competitive Strategies and Segment Forecast to 2034

Follow Us –

LinkedIn | Instagram | Facebook | Twitter

Contact Us:

Sara Lopes, Business Consultant — USA

SPER Market Research

+1–347–460–2899

#Aerospace Parts Manufacturing Market#Aerospace Parts Manufacturing Market Growth#Aerospace Parts Manufacturing Market Size#Aerospace Parts Manufacturing Market Trends#Aerospace Parts Manufacturing Market Share#Aerospace Parts Manufacturing Market Revenue#Aerospace Parts Manufacturing Market Demand#Aerospace Parts Manufacturing Market Challenges#Aerospace Parts Manufacturing Market Competition#Aerospace Parts Manufacturing Market Report#Aerospace Parts Manufacturing Market Segmentation#Aerospace Parts Manufacturing Market Future Outlook

0 notes

Text

The new tariffs imposed by the U.S. on China, Mexico, and Canada will have widespread effects on American goods and services. Here’s how they are likely to impact different aspects of the economy:

1. Higher Costs for Businesses and Consumers

Many American businesses rely on imported materials, components, and products from these countries. Tariffs increase the cost of these imports, forcing companies to either absorb the costs (reducing profits) or pass them on to consumers.

Industries such as automotive, electronics, manufacturing, and retail will see price hikes, making everyday goods more expensive for American consumers.

2. Inflationary Pressure

Tariffs function like a tax on imported goods, leading to higher prices across the board.

If companies pass increased costs to consumers, inflation could rise, making goods and services more expensive and potentially prompting the Federal Reserve to reconsider interest rate policies.

3. Supply Chain Disruptions & Business Uncertainty

Companies that rely on raw materials, electronics, and auto parts from these countries may face delays and shortages, forcing them to find alternative suppliers or move production, which takes time and money.

Some businesses might restructure their supply chains by sourcing materials from other countries or increasing domestic production, but this transition isn't immediate and could further increase costs.

4. Retaliation from Trading Partners

Canada, Mexico, and China have signaled that they may impose their own tariffs on U.S. exports, which could hurt American industries that depend on international trade, such as agriculture, aerospace, and manufacturing.

Farmers, in particular, could face declining demand for crops like soybeans, corn, and dairy products, which were previously targeted in retaliatory tariffs during the Trump-era trade war.

5. Impact on the Stock Market & Business Investment

Investors dislike uncertainty. If businesses anticipate lower profits due to higher costs or potential trade disruptions, stock markets may react negatively.

Companies may delay hiring or expansion plans due to concerns over higher operational costs and shifting trade dynamics.

6. Possible Job Losses in Affected Industries

If businesses face significantly higher costs and declining demand due to retaliatory tariffs, some industries could see layoffs or reduced hiring.

Manufacturing and export-dependent sectors, such as automotive, steel, and agriculture, may be hit the hardest.

Potential Silver Linings

Some industries, like domestic manufacturing and steel production, could see short-term gains if companies decide to shift production back to the U.S. instead of relying on imports.

The government may use tariff revenues to invest in domestic industries or subsidies, potentially offsetting some negative effects.

Bottom Line

The new tariffs will likely increase costs for businesses and consumers, contribute to inflation, and create uncertainty in financial markets and supply chains. While some domestic industries might benefit, the risk of retaliatory tariffs and economic slowdown poses a challenge for the broader U.S. economy.

13 notes

·

View notes

Text

Green and Eco-Friendly Blasting Media: Current Development, Trends, and Future Challenges

——An In-Depth Industry Analysis for Manufacturing Managers and Environmental Engineers

Introduction: The Revolution of Blasting Technology in the Era of Environmental Transformation

As global environmental regulations tighten (e.g., EU REACH, U.S. EPA standards) and the ESG (Environmental, Social, Governance) concept gains traction, the manufacturing industry is increasingly demanding sustainable surface treatment technologies. Traditional blasting media, such as silica sand and steel grit, are under scrutiny due to dust pollution, high energy consumption, and health risks. In contrast, green and eco-friendly blasting media are emerging as a core breakthrough for industry transformation. This article combines the latest market data and technological trends to analyze the current development and future challenges in this field, providing strategic insights for decision-makers.

I. Market Status: Policy-Driven Growth and Technological Advancements

1. Market Size and Growth Potential

According to Grand View Research, the global blasting media market reached $5.2 billion in 2023, with the share of eco-friendly media rising from 12% in 2018 to 28% in 2023, achieving a compound annual growth rate (CAGR) of 9.7%. By 2030, the market share of green media is expected to exceed 45%, with the Asia-Pacific region (especially China and India) becoming a growth engine due to manufacturing upgrade demands.

2. Mainstream Eco-Friendly Media Types

Plant-Based Materials (walnut shells, corn cobs): Biodegradable, low dust emission (70% less than silica sand), suitable for precision parts.

Synthetic Ceramic Particles (alumina, silicon carbide): High hardness, reusable 5-8 times, reducing long-term costs.

Ice/Dry Ice: Zero-residue technology, with over 40% penetration in the aerospace sector.

Recycled Glass Beads: Made from waste glass, reducing carbon emissions by 65% compared to traditional processes.

3. Policy and Industry Standards Driving Adoption

The EU Circular Economy Action Plan aims to increase industrial waste recycling to 70% by 2030.

China’s 14th Five-Year Plan tightens blasting dust emission limits to 10mg/m³ (previously 20mg/m³).

Automotive giants (e.g., Toyota, Volkswagen) have incorporated "green blasting certification" into supply chain standards.

II. Technological Advantages and Business Value: Why Choose Green Media?

1. Environmental Benefits

Dust Control: Plant-based media reduce dust concentration to <2mg/m³ (compared to 15-20mg/m³ for silica sand), lowering the risk of silicosis.

Carbon Reduction: Each ton of recycled glass beads reduces CO₂ emissions by 1.2 tons compared to new steel grit.

Waste Management: 95% of synthetic ceramic media can be recycled, reducing landfill costs.

2. Economic Breakthroughs

Lower Lifecycle Costs: In the automotive industry, switching to ice media reduced annual maintenance costs by 18% per production line (source: Frost & Sullivan).

Improved Efficiency: High-precision ceramic particles increase blasting speed by 30% and reduce rework rates.

III. Future Challenges: Technological Bottlenecks and Industry Collaboration

1. Technical Pain Points

Material Limitations: Plant-based media have low hardness (Mohs 2-3), making them unsuitable for hard substrates like high-strength steel.

Cost Barriers: Green media prices remain 20-50% higher than traditional materials, hindering adoption by SMEs.

Lack of Recycling Systems: Only 35% of global companies have media recycling equipment, relying on third-party processing.

2. Industry Collaboration Challenges

Lack of Standardization: Differing definitions of "eco-friendly media" across countries create barriers to cross-border procurement.

Insufficient R&D Investment: SMEs lack funding for new material testing (single certification costs exceed $50,000).

IV. Solutions: Innovation and Ecosystem Building

1. Technological Breakthrough Paths

Composite Material Development: For example, "bio-resin + ceramic" hybrid media balancing hardness and biodegradability.

Smart Blasting Equipment: AI algorithms optimize media usage, reducing waste.

Cryogenic Plasma Technology: A zero-media alternative to physical blasting (currently in the lab stage).

2. Industry Ecosystem Recommendations

Policy Subsidies: Governments should offer tax credits for green media procurement (e.g., U.S. IRA Act).

Industry Alliances: Establish cross-company recycling networks to share regeneration facilities.

Customer Education: Use Life Cycle Assessment (LCA) reports to quantify long-term benefits and boost decision-maker confidence.

V. Conclusion: Green Blasting—A Must for Sustainable Manufacturing

Eco-friendly blasting media are not just a compliance requirement but a strategic choice for cost reduction, efficiency improvement, and brand value enhancement. To overcome the dual challenges of technological evolution and market education, innovation, policy coordination, and industry collaboration are essential to transition this field from an "optional solution" to an "industry standard."

Keywords: Green blasting media, eco-friendly surface treatment, sustainable manufacturing, blasting technology trends, industrial carbon neutrality, ESG compliance

Data Sources: Grand View Research, Frost & Sullivan, European Environment Agency, China Ministry of Ecology and Environment. Further Reading:

2024 Global Surface Treatment Technology White Paper

Pathways to Carbon Neutrality in Manufacturing: Starting with Blasting Processes

2 notes

·

View notes

Text

Songshun Steel Rod Supplier: Provides Various High Quality Steel Rods

Steel rod is a common rod-shaped steel material made of metal materials, it is widely used in machinery, ships, construction, engineering, manufacturing and other fields. Steel rods are one of the indispensable materials in the steel market and are in high demand, so steel rod suppliers play a pivotal role in the steel market. Songshun Steel, as a high-quality steel rod supplier in China, can provide various high-quality steel rod materials to the world. It not only has rich varieties and sufficient inventory, but also ensures that the quality, service, price, etc. can satisfy you. This article will introduce the steel rods and advantages provided by Songshun steel rod supplier.

Steel Rod Types Songshun Steel, as a steel rod supplier with a wide range of steel materials, provides steel bar materials of various materials. Our steel rod types are as follows:

(1) Classified by process, it can be divided into hot-rolled, forged and cold-drawn steel bars; (2) Classified by material, steel rods can be divided into alloy steel rods, Ordinary carbon steel rods, stainless steel rods, tool steel rods, high-speed steel rods, aluminum alloy rods, synthetic fiber steel rods, etc.; (3)Classified by shape, it can be divided into solid steel rods, round steel rods, square steel rods, hexagonal steel rods, wire rods, etc.

Steel Rod Properties High quality steel rod supplier, offering a wide range of high performance steel rods. As a reliable steel rod supplier in China, Songshun Steel provides steel rods with the following properties:

Excellent wear resistance, corrosion resistance and high temperature resistance Better electrical and thermal conductivity High strength and rigidity Good solderability and stability Good plasticity and toughness

Uses Of Steel Rods As a professional steel rod supplier, we have an in-depth understanding of steel rods and clearly understand the purposes for which our customers purchase steel rods. Below are some of our customers’ applications for steel rods in various fields.

Construction field: Steel rods are often used to reinforce concrete structures, and are also used to support structures such as beams, columns, bridges, and columns.

Automobile manufacturing field: Steel rods are used to manufacture various engine parts, rods, brake calipers, exhaust pipes, connectors, support columns, door beams, roof frames, etc.

In the manufacturing of electronic and electrical equipment, steel rods are often used to make wires for electromagnetic coils, transformers and generators. They are also used as heat-conducting elements in air conditioners, refrigerators, and other appliances, among other things.

In the manufacturing field, it is often used to manufacture various mechanical parts, tools, cutters, drill bits, planers, etc.

In addition to the above fields, steel rods are also used in aerospace, energy and power transmission, oil and gas industry, shipbuilding, chemical and heavy industry, home furnishing and decoration, etc.

Steel Rod Supplier In addition to the above points, as a high-quality and reliable steel rod supplier, Songshun can not only provide a variety of high-performance, multi-purpose and types of steel rods, but also has advantages in quality, professionalism, service, price, etc.

We ensure the quality of steel rods, provide various testing services, provide products in strict accordance with international production standards and customer requirements, and provide steel rods with the best performance and quality to customers.

Songshun has an experienced team that studies various steel rod materials and provides customers with one-stop solutions and technical support.

Whether it is processing, pre-sales or after-sales service, we are professional and can ensure that your project is completed smoothly and perfectly.

Competitive prices, abundant inventory, and ability to deliver on time.

Understand industry policies, market demand, international trade, etc., and be able to make reasonable strategies to adjust industrial structure, optimize product quality, improve operational efficiency, and promote innovative development according to market changes in a timely manner.

Adhere to the path of sustainable development, adhere to the goal of achieving win-win development with customers, adhere to treating every customer with sincerity, adhere to customer-centeredness, and meet customer needs.

In summary, Songshun Steel can become a reliable steel rod supplier, not only providing high-quality steel rod materials, but also having other advantages. In the future, we are committed to becoming your preferred steel rod supplier, constantly moving forward, and providing you with better steel products.

2 notes

·

View notes

Text

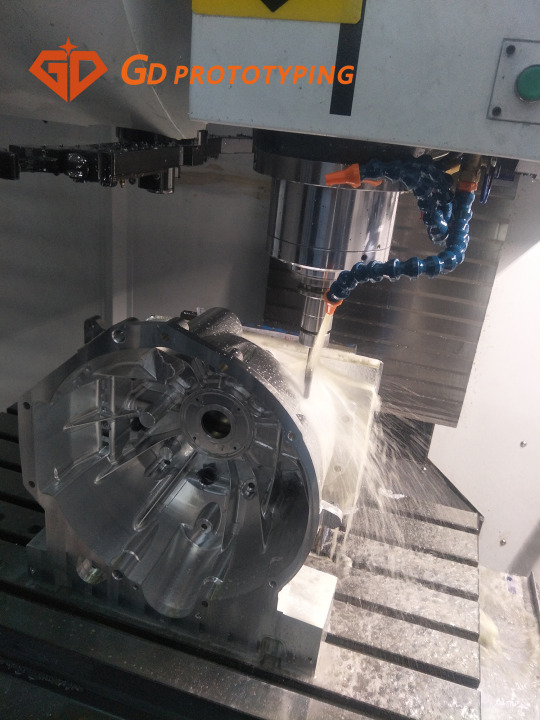

CNC Machining for Aerospace Products

Precision CNC machining of aeronautical parts, as an indispensable part of the modern aeronautical industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous progress of science and technology and the rapid development of the aviation industry, precision CNC machining technology is also constantly optimised and innovated to meet the more demanding aerospace parts machining needs.

Why is CNC important in the aerospace industry?

There is very high and even demanding requirements in aerospace industry for structural design, functionality, performance, product quality and reliability. A large number of new materials and structures were first applied to aircraft components. National defence needs and market competition require a significant reduction in the development and production cycles of space products. In addition, the average cost of the final product needs to be constantly reduced, thus placing higher demands on the aerospace manufacturing industry and requiring advanced manufacturing technologies. Modern CNC machining is a key part of advanced manufacturing technology and has become a decisive key technology, especially in aerospace manufacturing. The following advantages of CNC machining services make them important in the aerospace industry: ①It is the process of synthesising a variety of advanced technology types, including computer technology, communication technology, modern manufacturing technology, digital control technology and so on. ②During CNC machining, the development of a new product and the machining of another batch can be realised by simply changing the settings and parameters of the CNC machine, greatly increasing automation and flexibility. ③Multiple CNC machining can be done automatically on a single machine or in a single clamping, greatly reducing machining time and production cycle time, as well as increasing efficiency. ④CNC machining technology improves the accuracy and precision of aerospace products, reduces or minimises manufacturing errors and results in CNC aircraft parts of higher quality and durability. ⑤Most materials for aerospace components need to be cut and machined during the manufacturing process.

CNC Aircraft Part Features and Application

What are aerospace products? Aircraft can be classified by structure into fuselage, engines, on-board equipment and components, including wings, large wall and tail frames, casings, valve bodies, hydraulic valves, optical tubes, rotor blades, fasteners, connectors, etc. ①Aircraft engine parts: Aircraft engine is one of the core components of the aircraft, the machining accuracy and performance of its parts directly affect the performance and safety of the entire aircraft. ②Fuselage Structural Components: Structural components are the backbone of the aircraft and are subject to a variety of complex loads. Precision CNC machining technology enables high-precision machining of fuselage structural parts, such as beams, frames, plates and other components, to ensure the stability and reliability of their dimensions and shapes. ③Avionics equipment parts: With the continuous development of avionics technology, avionics are more and more widely used in aircraft. Precision CNC machining technology enables high-precision machining of avionics parts, such as circuit boards, connectors and other components, to ensure their accuracy and reliability.

The main features of CNC machining of aerospace parts are as follows:

①High performance: use of new hard-to-machine materials such as titanium ②High Precision: Aerospace parts require a high degree of precision, and any small error may affect the performance and safety of the entire aircraft. Precision CNC machining technology meets the aerospace industry's need for high precision by machining in the micron level of accuracy, ensuring that the size and shape of the part is exactly as designed. ③High Efficient: Precision CNC machining technology can greatly improve productivity by automating and controlling the machining process. After one programming, the CNC machine can run continuously, reducing manual intervention time and increasing production speed. ④Flexibility: Parts in the aerospace industry are varied and complex in shape. Precision CNC machining technology can be quickly adapted to the machining needs of different parts by changing tools and adjusting the programme, without the need for cumbersome manual adjustments, and is suitable for small batch and multi-species production modes. ⑤Lightweight: Extensive use of thin-walled structures. ⑥Consistency: In mass production, part consistency is critical. Precision CNC machining technology ensures that the machining parameters of each part are exactly the same, avoiding quality fluctuations caused by human factors, thus ensuring product consistency and stability. ⑦Reliability and economy: Increasingly stringent quality and cost controls. ⑧Environmental protection and energy saving: The future of precision CNC machining of aerospace parts will pay more attention to environmental protection and energy saving. Adopting more energy-saving and environmentally friendly materials and processes to reduce resource waste and environmental pollution and realise green manufacturing.

In summary, precision CNC machining of aviation parts, as one of the important technologies in the modern aviation industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous innovation and progress of technology, the future of precision CNC machining of aviation parts will move towards the direction of intelligence, automation, high-speed and high-precision, multi-axis and environmental protection and energy saving, injecting a new impetus for the development of the aviation industry.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#cnc precision machining#aerospace parts#cnc precision#machining parts#aerospace#aviation#aircraft

2 notes

·

View notes

Text

Boeing US plant workers strike after 96% vote for walkout

Workers at a Boeing plant on the US west coast left their jobs after overwhelmingly rejecting a contract deal, according to Reuters.

The growing crisis hit Boeing shares and prompted a management coup. The company’s shares fell 3.4 per cent in pre-market trading in the US on Friday.

New CEO Kelly Ortberg is facing a battle between unions and management just weeks after being invited to restore faith in the aircraft manufacturer. He offered a deal including a 25 per cent pay rise over four years, well below what 40 per cent of workers demanded.

About 30,000 members of the International Association of Machinists and Aerospace Workers (IAM), which produces the 737 MAX and other Boeing jets in Seattle and Portland, voted for the first full-fledged contract in 16 years. In a two-part vote, 96 per cent rejected it and favoured industrial action.

Back to negotiating table

A protracted strike could severely hit Boeing’s finances facing $60 billion in debt. Boeing said Thursday night that the vote sent a clear message that the tentative agreement reached with IAM management was unacceptable to members.

We remain committed to resetting our relationship with our employees and the union, and we are ready to get back to the table to reach a new agreement.

The proposed deal also included a $3,000 signing bonus and a promise to build Boeing’s next commercial aircraft in the Seattle area, provided the programme is launched within four years of the contract.

Jon Holden, who headed the negotiations for Boeing’s largest union, stated:

We’re going to get back to the table as quickly as we can. This is something that we take one day at a time, one week at a time.

If the strike lasts, it will also put pressure on airlines that depend on that manufacturer’s planes and suppliers that make parts and components for its planes.

A 50-day strike could cost Boeing between $3bn and $3.5bn in cash, according to a TD Cowen pre-vote note. The last strike by Boeing workers in 2008 shut down plants for 52 days, resulting in a $100 million a day drop in revenue.

Read more HERE

#world news#news#world politics#usa#usa news#usa politics#united states#americans#america#boeing#strike against boeing

4 notes

·

View notes

Text

Shaping the Future: The Rise of Stainless Steel Components Manufacturers in India

In recent years, India has emerged as a powerhouse in the manufacturing sector, particularly in the production of stainless steel components. This surge can be attributed to various factors, including technological advancements, evolving market demands, and a skilled workforce. Stainless steel components play a crucial role in numerous industries, including automotive, construction, and aerospace, due to their durability, corrosion resistance, and aesthetic appeal.

One of the key drivers behind the growth of stainless steel components manufacturing in India is the country's abundant availability of raw materials, particularly stainless steel. With the government's emphasis on initiatives like "Make in India," there has been a significant push to boost domestic manufacturing and reduce dependency on imports. This has led to the establishment of numerous stainless steel component manufacturing units across the country, catering to both domestic and international markets.

Amidst this growth, companies like Meck Industries have played a pivotal role in shaping the landscape of stainless steel component manufacturing in India. Established in 1990, Meck Industries has carved a niche for itself as a leading provider of precision turned parts. Specializing in CNC machining and automatic screw machines, Meck Industries has earned a reputation for its commitment to quality, reliability, and innovation.

With a state-of-the-art facility located in G.I.D.C. Makarpura, Vadodara, Meck Industries is well-equipped to meet the diverse needs of its clientele. The company's skilled workforce, coupled with its investment in cutting-edge technology, has enabled it to deliver superior stainless steel components to various industries, including electrical, automotive, and sheet metal.

Moreover, Meck Industries' dedication to customer satisfaction and continuous improvement has been instrumental in driving its growth and success. By adhering to stringent quality standards and embracing innovative manufacturing processes, Meck Industries has positioned itself as a trusted partner for stainless steel component requirements, both domestically and internationally.

Looking ahead, Meck Industries remains committed to pushing the boundaries of excellence in stainless steel component manufacturing. With a focus on leveraging technology, fostering innovation, and expanding its global footprint, Meck Industries is poised to continue shaping the future of the industry and contributing to India's manufacturing prowess on the world stage.In conclusion, the rise of stainless steel components manufacturers in India, exemplified by companies like Meck Industries, underscores the country's growing dominance in the global manufacturing arena. With a blend of tradition, innovation, and excellence, Indian manufacturers are poised to lead the way in shaping the future of stainless steel component manufacturing worldwide.

1 note

·

View note

Text

Revolutionizing Manufacturing: Top Trends to Watch in 2023

The manufacturing industry faced several challenges in 2022, including disruptions in the supply chain, transportation difficulties, worker shortages, and inflation. As a manufacturing company, it is essential to stay informed about the emerging industrial developments to prevent the issues that plagued the industry last year.

However, one thing we can tell you for sure is, having the right technology in place can bring you closer to gaining a competitive edge and adapting to the changing industry dynamics. To help manufacturing businesses gain this edge, we offer next generation SAP ERP solution.

What are some technological trends the manufacturing industry can expect in 2023?

Industry 4.0 and Digital Transformation

Industry 4.0 and digital transformation will continue to be major drivers of innovation in the manufacturing industry in 2023. With the rise of the Internet of Things (IoT), Artificial Intelligence (AI), and other advanced technologies, manufacturers will have unprecedented access to real-time data, which will enable them to optimize their operations and improve efficiency. By integrating digital technologies across the entire supply chain, manufacturers will be able to achieve greater flexibility, agility, and responsiveness to changing market demands.

Advanced Robotics and Automation

As the cost of robotics and automation technology continues to decrease, we can expect to see an increased adoption of these technologies in the manufacturing industry. Robotics and automation can help manufacturers reduce labor costs, improve quality and consistency, and increase productivity. With the advent of more advanced robotics and automation systems, we can expect to see greater levels of collaboration between human workers and robots, as well as the development of more complex and sophisticated automation systems.

Sustainability and Green Manufacturing

As the world becomes increasingly aware of the impact of climate change, sustainability and green manufacturing will become more important in 2023. Manufacturers will need to find ways to reduce their environmental impact, including the use of renewable energy sources, the reduction of waste and emissions, and the adoption of sustainable materials and processes. Customers are also becoming more conscious of their environmental impact, which means that manufacturers who prioritize sustainability will be more competitive in the marketplace.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a rapidly growing technology that is changing the way manufacturers design, prototype, and produce products. In 2023, we can expect to see an increased adoption of additive manufacturing technologies, particularly in industries such as aerospace, healthcare, and automotive. With the ability to produce highly complex parts and components on-demand, additive manufacturing will enable manufacturers to achieve greater levels of customization and flexibility.

Reshoring and Nearshoring

The COVID-19 pandemic has highlighted the risks of global supply chains and the importance of resilience and agility in manufacturing. In 2023, we can expect to see more manufacturers exploring reshoring and nearshoring strategies to reduce their reliance on overseas suppliers and improve their ability to respond to changing market conditions. By bringing production closer to home, manufacturers can reduce lead times, improve quality control, and reduce transportation costs.

In conclusion, the manufacturing industry is set to undergo significant changes in 2023, driven by digital transformation, advanced robotics and automation, sustainability, additive manufacturing, and reshoring and nearshoring. Manufacturers who stay ahead of these trends will be better equipped to compete in an increasingly complex and competitive global marketplace.

If you want to transform your business by implementing latest solutions, get in touch with the team of Techscope Technologies.

Source: https://techscope.co.in/revolutionizing-manufacturing-top-trends-to-watch-in-2023/

3 notes

·

View notes

Text

Digital Twin Market to Witness Remarkable Growth from 2021-2030

Allied Market Research, titled, “Digital Twin Market," The digital twin market was valued at $6.5 billion in 2021, and is estimated to reach $125.7 billion by 2030, growing at a CAGR of 39.48% from 2021 to 2030.

A virtual machine that offers a real-time online version of a physical object or process is called a "digital twin." The performance of industrial assets is profiled, predicted, and optimised using simulation models, data, and intelligence. Because it enables automatic vehicle control and monitoring of industrial assets and processes like product development, design & manufacturing planning, investment performance management, business & operation optimization, and more, the digital twin is a crucial part of the Industrial Internet of Things.

The automotive and transportation industries' increasing demand for digital twin technology is anticipated to fuel market expansion over the forecast period. The digital twin, which facilitates continuous communication between product developers & designers, end users, and a number of other stakeholders in order to provide creative and efficient vehicles which can be digitally automated, is principally responsible for this increase. In the upcoming years, it is anticipated that these reasons would hasten the market's expansion for digital twins. Additionally, the prospective applications of the industrial internet of things are anticipated to increase demand for digital twin technology and propel digital twin market growth.

The use of digital twin as an advanced technology is anticipated to gain traction. Manufacturers in the industry currently require actual visibility across company boundaries and all the way back down the supply side chain. This is made possible by digital twin technology. The digital twin serves as a strong digital shadow. They collect all the interrelated data sources from an asset's entire lifecycle as semantically clearly delineated, information virtualization. A digital twin could be used to create twins of individual elements, assemblies, people, or a whole manufacturing facility. Such technological advancements may further lead to lucrative market opportunities in the market in the upcoming years.

The global digital twin market size is segmented on the basis of type which has been divided into system digital twin, product digital twin, and process digital twin. By industry, the market has been divided into aerospace & defense, automotive & transportation, home & commercial, healthcare, energy & utilities, oil & gas, agriculture, telecommunication, and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Some of the leading digital twin market players are ABB Group, ANSYS Inc., Accenture PLC, Bentley systems corporation,AVEVA Inc, Bosch, Oracle Corporation, Siemens AG, Rockwell Automation Inc, and Schneider Electric..

The report offers a comprehensive analysis of the global digital twin market trends by thoroughly studying different aspects of the market including major segments, market statistics, market dynamics, regional market outlook, investment opportunities, and top players working towards the growth of the market. The report also sheds light on the present scenario and upcoming trends & developments that are contributing to the growth of the market. Moreover, restraints and challenges that hold power to obstruct the market growth are also profiled in the report along with the Porter’s five forces analysis of the market to elucidate factors such as competitive landscape, bargaining power of buyers and suppliers, threats of new players, and emergence of substitutes in the market.

Key Findings of the Study

Based on type, the system digital twin sub-segment is expected to have the dominant share during the forecast period.

By industry, the automotive & transportation industries had the largest digital twin market share and are expected to grow by 2030.

By region, Asia-Pacific is forecasted to be the fastest-growing region during the forecast period.

The report provides an in-depth study of the digital twin market analysis.

0 notes

Text

Smart Investment: Navigating the Cost of CNC Lathe Machines

Understanding the cost of CNC lathe machines is critical for manufacturers aiming to balance upfront expenses with long-term ROI. The High-Speed Drilling and Tapping Center Series Lathe Machine T600-21T offers a strategic solution, combining advanced automation, precision engineering, and durability to minimize total ownership costs for TOC clients in the automotive, aerospace, and medical industries. Designed for high-volume production and complex prototyping, this machine delivers rapid payback through reduced labor, material waste, and downtime.

Key Factors Influencing the Cost of CNC Lathe Machines

Automation Level: Programmable toolpaths and multi-axis control reduce manual labor by up to 60%, lowering long-term operational costs.

Material Versatility: Adjustable spindle speeds (20–4000 RPM) and adaptive feed mechanisms handle materials from aluminum to titanium, minimizing the need for multiple machines.

Durability: A rigid cast-iron bed and heat-resistant components ensure 24/7 reliability, reducing maintenance expenses over time.

Applications Maximizing ROI

Automotive Component Production: Mass-produce shafts, bushings, or engine parts with ±0.005mm tolerances, reducing scrap rates by 25%.

Medical Device Manufacturing: Achieve micron-level precision for surgical tools or implants, avoiding costly rework.

Aerospace Machining: Machine high-strength alloys for turbine components with minimal tool wear, extending cutter lifespan.

Technical Advantages Reducing Total Cost

12-Tool Turret: Eliminates frequent tool changes, cutting setup time by 50% and labor costs.

Energy Efficiency: Optimized power consumption reduces energy bills by 15–20% compared to conventional models.

Predictive Maintenance Alerts: Real-time diagnostics prevent unplanned downtime, safeguarding production schedules.

Strategic Investment for Competitive Manufacturing

While the initial cost of CNC lathe machines varies, the T600-21T ensures value through:

Faster Cycle Times: High-speed drilling and tapping capabilities slash production time by 30–40%.

Scalability: Compatible with CAD/CAM software, adapting to evolving design demands without costly upgrades.

Resale Value: Industrial-grade construction retains market value for future resale or trade-in.

Optimize Your Budget with Precision Engineering

The High-Speed Drilling and Tapping Center Series T600-21T transforms the cost of CNC lathe machines into a competitive advantage. Its blend of automation, accuracy, and durability ensures rapid ROI while future-proofing your operations.

Request a Customized Cost-Benefit Analysis Today Contact us to explore financing options, bulk discounts, or tailored configurations—equip your facility with technology designed to maximize efficiency and minimize the cost of CNC lathe machines!

0 notes

Text

Precision Machined Components: Advancing Manufacturing Excellence

Importance of Precision-Machined Components

Precision-machined components are critical to modern manufacturing, ensuring high accuracy, durability, and efficiency in various industries. These components are produced using advanced machining techniques such as CNC (Computer Numerical Control) milling, turning, and grinding. Industries like aerospace, automotive, medical, and electronics depend on precision machining to maintain stringent quality standards. The ability to produce intricate and highly detailed parts with tight tolerances has made precision machining a cornerstone of industrial progress.

Accuracy and Reliability

One key advantage of precision-machined components is their exceptional accuracy. Unlike traditional machining, which may involve manual processes and inconsistencies, precision machining uses automated technology to achieve micron-level tolerances. This level of precision enhances product performance, reduces material waste, and ensures seamless integration into larger assemblies. As a result, manufacturers can achieve greater consistency and reliability in their production lines.

Versatility in Material Selection

In addition to accuracy, precision machining is another significant benefit. Components can be made from various materials, including aluminum, stainless steel, titanium, plastics, and composites. Components can be made from multiple materials, including aluminum, stainless steel, titanium, plastics, and composites. These components can be made from various materials, including metals such as aluminum, stainless steel, and titanium, as well as plastics and composites. This flexibility allows industries to select the most suitable materials based on strength, weight, conductivity, or resistance to environmental conditions. The adaptability of precision machining enables manufacturers to create components that meet exact design and functional requirements.

Efficiency and Cost-Effectiveness

Furthermore, advancements in precision machining technology have led to increased efficiency and cost-effectiveness. Modern CNC machines are equipped with automation features that reduce human intervention and minimize production errors. High-speed machining, multi-axis capabilities, and computer-aided design (CAD) integration further enhance productivity. These innovations not only improve turnaround times but also reduce overall manufacturing costs, making precision machining a preferred choice for large-scale production.

The Future of Precision Machining

The future of precision-machined components looks promising, with continued advancements in digital manufacturing and Industry 4.0 technologies. Innovations such as AI-driven predictive maintenance, additive manufacturing integration, and real-time quality monitoring are set to revolutionize the industry. Companies investing in these technologies will gain a competitive edge by improving efficiency, reducing downtime, and delivering superior-quality components to the market.

Conclusion

Precision-machined components play an indispensable role in modern manufacturing by offering unmatched accuracy, versatility, and efficiency. As technology continues to evolve, industries will benefit from improved production methods that drive innovation and quality. The demand for high-performance components will keep precision machining central to manufacturing excellence and drive future industrial advancements.

0 notes

Text

The Growing Strength of Manufacturer Malaysia in the Global Market

The Rise of Manufacturing in Malaysia

Malaysia has emerged as a strong player in the global manufacturing sector. Over the past few decades, the country has transformed from an agrarian economy into an industrial powerhouse. Its strategic location, skilled workforce, and supportive government policies have played a crucial role in this transformation. With advancements in technology and infrastructure, Malaysia has attracted investments from multinational corporations looking for reliable and cost-effective production hubs. The government has also implemented policies to encourage local businesses to grow and compete globally. Today, the country is known for manufacturing a wide range of products, including electronics, automotive parts, and consumer goods. The steady growth of industrial zones and free trade agreements has further strengthened Malaysia’s position in the global supply chain. The country's ability to adapt to global trends and implement modern industrial strategies has made it a key destination for companies seeking high-quality manufacturing services.

Key Industries Driving the Manufacturing Sector

Malaysia’s manufacturing industry is diverse, covering various key sectors that contribute significantly to its economy. The electronics and electrical (E&E) sector is one of the largest, with multinational companies setting up production plants to manufacture semiconductors, integrated circuits, and consumer electronics. The automotive industry is also a significant contributor, with major car manufacturers and suppliers establishing operations in the country. In addition to these, Malaysia is a hub for medical device production, rubber and palm oil processing, and aerospace manufacturing. The government has introduced incentives to attract foreign direct investments (FDI) in these sectors, providing tax benefits and infrastructure support. Manufacturer Malaysia has also seen a rise in automation and Industry 4.0 initiatives, enabling factories to increase efficiency and reduce costs. These factors have made Malaysia a competitive destination for businesses looking to manufacture products at a global scale.

Government Support and Policies

The Malaysian government has played an essential role in strengthening the manufacturing sector. Through initiatives like the National Policy on Industry 4.0 (Industry4WRD), businesses are encouraged to adopt automation, digitalization, and smart manufacturing practices. Various agencies such as the Malaysian Investment Development Authority (MIDA) provide support to investors by offering grants, incentives, and assistance in setting up manufacturing operations. Additionally, Malaysia has signed multiple free trade agreements (FTAs) with countries worldwide, facilitating smooth trade and reducing tariffs. The focus on sustainability and green manufacturing has also gained traction, with efforts to promote eco-friendly production methods. With a clear roadmap for industrial growth, the country has positioned itself as an attractive destination for companies seeking a stable and business-friendly environment. Manufacturer Malaysia continues to benefit from these progressive policies, ensuring sustained growth and competitiveness in the global market.

Technological Advancements in Manufacturing

The integration of advanced technology has played a crucial role in Malaysia’s manufacturing growth. Companies are increasingly investing in smart manufacturing, automation, and artificial intelligence to enhance productivity and efficiency. The adoption of robotics and the Internet of Things (IoT) has enabled businesses to streamline production processes and reduce human error. Moreover, 3D printing and precision engineering have revolutionized product design and customization, providing manufacturers with more flexibility in meeting market demands. Research and development (R&D) initiatives are also gaining momentum, allowing businesses to innovate and produce high-quality products. The digital transformation in manufacturing is supported by strong government backing and partnerships between industries and academic institutions. With these advancements, Malaysia is well on its way to becoming a global leader in smart manufacturing. The rise of technology-driven production has further reinforced the country’s status as a preferred manufacturing destination, offering world-class solutions to international markets.

Conclusion

The manufacturing sector in Malaysia has witnessed tremendous growth due to its robust industrial policies, technological advancements, and a favorable business environment. With continuous support from the government, increasing foreign investments, and the adoption of modern industrial practices, Malaysia has positioned itself as a global manufacturing hub. The country’s ability to adapt to new market trends and technological innovations ensures long-term sustainability and competitiveness. As the demand for high-quality and cost-effective production continues to rise, Malaysia remains a top choice for businesses worldwide. For more insights into the country's industrial capabilities and opportunities, visit [mention the manufacturermalaysia.com].

1 note

·

View note

Text

American Industrial Supplies: Global Procurement Solutions with KTB Europe

American Industrial Supplies: Reliable Global Procurement with KTB Europe

The Demand for American Industrial Supplies in Global Markets

Industries across the globe rely on high-performance equipment and parts to maintain efficient and safe operations. In this space, American industrial supplies are often preferred for their exceptional quality, engineering precision, and durability. From manufacturing to aerospace, energy to pharmaceuticals, U.S.-made products are trusted to meet the strictest international standards.

For companies operating outside the United States, sourcing these components can pose challenges due to supplier limitations, shipping complexity, and customs regulations. That’s where a global procurement partner like KTB Europe becomes essential.

What Are American Industrial Supplies?

American industrial supplies refer to products designed and manufactured in the United States to support industrial operations. These include:

Maintenance, Repair, and Operations (MRO) items

Electrical and mechanical components

Automation controls, sensors, and drives

Pneumatics, hydraulics, and filtration systems

Tools, fasteners, and safety equipment

These supplies are critical for maintaining machinery, supporting production lines, and ensuring uninterrupted operations.

Challenges in Sourcing U.S.-Made Industrial Supplies Internationally

While the quality of U.S. industrial products is undisputed, sourcing them from abroad comes with unique challenges:

Complex Import Processes: Managing customs, documentation, and international logistics can be time-consuming.

Supplier Fragmentation: Companies often have to deal with multiple U.S.-based vendors, complicating procurement.

Lead Time Issues: Delays in international shipping can lead to unexpected downtime.

Price Variations: International buyers may face inconsistent pricing without centralized negotiation.

To overcome these hurdles, businesses need an experienced procurement company that understands both American manufacturing and global sourcing logistics.

KTB Europe – Your Link to American Industrial Supplies

KTB Europe has been connecting global industries to American industrial supplies since 1976. With decades of experience in MRO procurement and industrial automation sourcing, the company simplifies the international supply process—helping manufacturers, engineers, and maintenance teams get the right parts, on time, at the right price.

Centralized Procurement with Global Reach

Headquartered in Germany and with branches in the USA, Mexico, Brazil, China, and more, KTB Europe operates as a global procurement partner. Whether you’re sourcing parts for a production plant in Argentina, a facility in Mexico, or a factory in Eastern Europe, KTB ensures your access to American-manufactured industrial supplies.

Services Tailored to International Buyers

KTB Europe provides end-to-end procurement solutions to businesses worldwide looking for U.S.-made industrial components.

Strategic Sourcing

Through established relationships with leading American manufacturers and distributors, KTB Europe can source high-quality items across multiple product categories—including automation parts, mechanical components, and electrical systems.

Procurement Consolidation

Tired of managing dozens of U.S. suppliers? KTB Europe acts as a single point of contact, consolidating orders from multiple vendors and reducing administrative tasks.

Logistics & Delivery Coordination

KTB manages all shipping and customs procedures, ensuring that your American industrial supplies are delivered where and when you need them.

Quality Assurance

All products are quality-checked before shipment, ensuring compliance with your project’s standards and certifications.

Multi-Currency & Tax-Friendly Invoicing

KTB Europe provides invoicing in local currencies and handles VAT and tax compliance based on your region.

Why Choose KTB Europe for American Industrial Supplies?

1. Decades of Experience

With nearly 50 years of experience, KTB understands the technical and logistical needs of global industries sourcing U.S.-made parts.

2. Global Fulfillment Network

With fulfillment hubs across North America, Europe, and Latin America, KTB delivers quickly and reliably, reducing downtime risk.

3. Access to Leading U.S. Brands

KTB Europe sources directly from reputable American brands in automation, electrical, pneumatic, and mechanical sectors.

4. Procurement Efficiency

Consolidated purchasing reduces transaction costs, paperwork, and unnecessary delays.

5. Local Support, Global Access

Multilingual support teams and account managers across continents provide the local understanding your business needs with global reach.

Industry Applications

KTB Europe supplies American industrial components to companies in:

Aerospace and Aviation

Automotive Manufacturing

Food and Beverage Processing

Pharmaceuticals and Biotech

Steel and Mining

Power and Renewable Energy

Textiles and Packaging

Water Treatment Facilities

Each industry requires specific products and certifications. KTB Europe works closely with clients to ensure the right items are sourced to meet technical requirements and compliance standards.

Future Outlook – American Supplies & Global Demand

The global demand for American industrial supplies is expected to grow as industries prioritize reliability, compliance, and performance in their supply chains. With the rise of smart manufacturing and automation, U.S.-made automation controls, robotics components, and high-precision parts will continue to be in high demand.

KTB Europe is investing in digital tools, real-time order tracking, and predictive sourcing systems to better serve international clients seeking American components.

Conclusion

Whether you're maintaining a production line, upgrading industrial automation, or building new infrastructure, sourcing from the U.S. gives you access to some of the world’s most reliable industrial products. But navigating international procurement isn’t always easy.

That’s where KTB Europe comes in—your strategic partner for sourcing American industrial supplies with global reach and local understanding. From procurement to logistics and beyond, KTB ensures you get the parts you need, exactly when you need them.

📍 For more information, visit https://www.ktb-europe.com/en/

#american industrial supplies#industrial parts#industrial automation parts#mro procurement services#mro procurement#procurement company#international procurement company

1 note

·

View note

Text

Quickparts: Transforming Ideas into Reality with Rapid Prototyping 🚀

Introduction 🌍

In today's fast-paced world, businesses need solutions that can keep up with the speed of innovation. This is where Quickparts steps in, offering rapid manufacturing 3D printing and rapid prototyping services to transform ideas into reality. Whether you’re a startup testing a new concept or a large enterprise streamlining production, Quickparts provides cutting-edge rapid prototyping services that ensure efficiency, accuracy, and speed.

What is Rapid Prototyping? 🤔

Rapid prototyping is an advanced manufacturing technique that allows businesses to quickly create physical prototypes of their designs. By leveraging 3D printing and other advanced technologies, companies can:

✅ Test and validate designs before mass production ✅ Reduce development costs ✅ Speed up time-to-market ✅ Improve product quality through iterative design

At Quickparts, our rapid prototyping services cater to various industries, including automotive, aerospace, healthcare, consumer goods, and more. Our expertise in rapid manufacturing 3D printing ensures that you get precise, high-quality prototypes in record time. ⏳

Quickparts: Your Trusted Rapid Prototyping Company 🏆

As a leading rapid prototyping company, Quickparts provides a seamless experience from design to production. Our state-of-the-art facilities and expert engineers deliver superior rapid prototype services, ensuring that your product development process is efficient and cost-effective.

Why Choose Quickparts? 💡

✅ Cutting-Edge Technology: We use the latest 3D printing and CNC machining for accurate and high-quality prototypes. ✅ Fast Turnaround: Our rapid prototyping services ensure you get your prototypes quickly, reducing development cycles. ✅ Custom Solutions: We offer tailored rapid manufacturing 3D printing solutions to meet your specific needs. ✅ Expert Support: Our team of professionals provides guidance at every stage of the prototyping process.

Services Offered by Quickparts 🔧

1. 3D Printing Prototyping 🖨️

Our rapid manufacturing 3D printing solutions include:

Stereolithography (SLA): Ideal for high-detail and smooth surface finish prototypes.

Selective Laser Sintering (SLS): Best for durable, functional prototypes.

Fused Deposition Modeling (FDM): Great for cost-effective, rapid prototyping.

Multi Jet Fusion (MJF): Provides excellent strength and detail in prototypes.

2. CNC Machining ⚙️

For high-precision prototypes, our CNC machining services offer:

Aluminum, steel, and plastic machining

Tight tolerances and superior finishes

Ideal for functional testing and low-volume production

3. Urethane Casting 🏗️

For low-volume production and high-quality prototypes, our urethane casting service delivers:

High durability and fine details

Wide range of material options

Ideal for market testing and pre-production runs

4. Injection Molding 🏭

Our injection molding services help scale up production quickly:

Cost-effective for mass production

High repeatability and consistency

Perfect for end-use parts

Industries We Serve 🌎

With expertise in rapid manufacturing 3D printing, Quickparts serves a wide range of industries:

🚗 Automotive – Rapid prototyping for vehicle components and testing. ✈️ Aerospace – High-precision prototypes for aircraft and space exploration. 🏥 Healthcare – Medical device prototyping and anatomical models. 📱 Consumer Electronics – Fast-tracked development of new gadgets and devices.

How Quickparts Enhances Your Product Development Process 🔄

🔹 Step 1: Submit Your Design – Upload your CAD files on our platform. 🔹 Step 2: Choose Your Manufacturing Process – Select from our rapid prototyping services. 🔹 Step 3: Production Begins – Our advanced machines start bringing your prototype to life. 🔹 Step 4: Quality Check & Delivery – We ensure every prototype meets high standards before shipping.

The Future of Rapid Manufacturing 🚀

The demand for rapid manufacturing 3D printing is growing exponentially, and Quickparts is at the forefront of this revolution. With continuous advancements in rapid prototyping services, we help businesses innovate faster and smarter.

Are you ready to take your product development to the next level? Contact Quickparts, the industry-leading rapid prototyping company, and let’s turn your ideas into reality. 💡✨

📞 Contact Us Today! 📧 Visit our website for a free quote!

#RapidManufacturing #3DPrinting #RapidPrototyping #Quickparts #Innovation

1 note

·

View note

Text

The Evolution of the Metal Powder Market: Key Innovations and Applications

Rising Adoption in Additive Manufacturing, Automotive, and Aerospace Industries Fuels Growth in the Metal Powder Market.

The Metal Powder Market size was USD 6.9 billion in 2023 and is expected to reach USD 12.3 billion by 2032 and grow at a CAGR of 6.7% over the forecast period of 2024-2032.

The Metal Powder Market is driven by increasing applications in 3D printing, automotive, aerospace, medical, and industrial manufacturing. Metal powders are finely powdered metals used in various industries for powder metallurgy, coatings, and additive manufacturing (AM). The shift toward lightweight, high-strength materials, along with advancements in powder-based production techniques, is fueling market expansion. Key metal powders include iron, aluminum, copper, titanium, nickel, and tungsten, with growing adoption in industries focused on efficiency, customization, and sustainability.

Key Players in the Metal Powder Market

Sandvik AB (Stainless Steel Powder, Powdered Metal)

Carpenter Technology Corporation (Carpenter Additive, Custom Metal Powders)

Hoganas AB (Hoganas Powder, Atomized Iron Powder)

GKN Plc. (High-Performance Powder, Powder Metallurgy Products)

Rio Tinto (Titanium Powder, Aluminum Powder)

Allegheny Technologies Incorporated (Titanium Alloys, Powder Metallurgy Products)

American Chemet Corporation (Copper Powder, Zinc Powder)

Carl Schlenk AG (Aluminum Powder, Bronze Powder)

Hitachi Chemical Co., Ltd. (Copper Powder, Silver Powder)

Metaldyne Performance Group Inc. (Automotive Powdered Metal Parts, High-Strength Steel Powder)

Future Scope of the Market

The Metal Powder Market is expected to grow significantly due to:

The rising demand for metal-based additive manufacturing (3D printing).

Expanding use of metal powders in the automotive and aerospace sectors for lightweight components.

Increasing applications in medical implants and prosthetics.

Growing adoption of sustainable powder metallurgy to reduce material waste.

Advancements in atomization technologies for high-purity metal powders.

Emerging Trends in the Metal Powder Market

The market is evolving with a focus on high-performance metal powders for precision manufacturing and sustainability. The adoption of additive manufacturing (AM) in industries like aerospace and healthcare is driving the need for advanced metal powders with superior mechanical properties. Additionally, recycled metal powders are gaining popularity as part of the circular economy, reducing environmental impact. Innovations in gas atomization and plasma atomization technologies are improving the quality and consistency of metal powders, further boosting their applications in industrial manufacturing. With automakers and aerospace firms investing in metal powder-based production, the market is set for substantial expansion.

Key Points:

3D printing and additive manufacturing driving demand for high-quality metal powders.

Automotive and aerospace industries using metal powders for lightweight, high-strength parts.

Growing focus on sustainable and recycled metal powders to reduce waste.

Advancements in atomization technology enhancing metal powder purity and efficiency.

Increasing medical applications for metal powders in implants and prosthetics.

Conclusion

The Metal Powder Market is on a strong growth trajectory, fueled by technological advancements and expanding applications across multiple industries. As 3D printing, powder metallurgy, and sustainable manufacturing continue to evolve, the demand for high-performance and eco-friendly metal powders will rise. With key players investing in innovation and strategic collaborations, the market is set to play a crucial role in shaping the future of manufacturing, automotive, aerospace, and healthcare sectors.

Read Full Report: https://www.snsinsider.com/reports/metal-powder-market-1467

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Metal Powder Market#Metal Powder Market Size#Metal Powder Market Share#Metal Powder Market Report#Metal Powder Market Forecast

0 notes

Text

Desktop 3D Printer Market Growth: How Innovation and Affordability Are Shaping the Future

The desktop 3D printer market has witnessed remarkable growth in recent years, driven by technological innovations and an increased demand for affordable and accessible 3D printing solutions. From hobbyists and educational institutions to small businesses and industries, desktop 3D printers are now recognized for their potential to revolutionize how products are designed, prototyped, and even produced. As the market continues to evolve, two key factors—innovation and affordability—are significantly shaping its future.

1. Technological Innovation Driving Market Growth

Technological advancements in 3D printing have opened up new possibilities for desktop 3D printers, making them more powerful, efficient, and versatile. In the early days of 3D printing, the technology was primarily used by large corporations or research institutions due to the high cost and complex operation. Today, innovations in hardware and software are making desktop 3D printers more user-friendly and accessible to a wide range of industries.

Key Technological Advancements:

Improved Print Quality: The latest models of desktop 3D printers are capable of producing highly detailed and accurate prints. With better resolution, precision, and faster printing speeds, users can create more complex designs with greater ease.

Enhanced Materials: Desktop 3D printers now support a variety of materials beyond just plastic, such as metal, resin, and even biodegradable filaments. These innovations allow industries like healthcare, aerospace, and automotive to adopt 3D printing for functional prototypes, tools, and end-use parts.

Advanced Software: Along with hardware, 3D printing software has evolved to provide better design flexibility, error correction, and easier integration with digital manufacturing workflows. Software advancements have helped streamline the design-to-production process, reducing the complexity for users and enabling more efficient workflows.

Multi-material and Multi-color Printing: Some of the latest desktop 3D printers offer the ability to print using multiple materials or colors in a single print job, further expanding the potential for creating more intricate, customized products.

These innovations make desktop 3D printers not only more efficient but also more applicable across a broader range of industries. As technology continues to improve, the market will likely see even more powerful and specialized 3D printers entering the mainstream.

2. Affordability Driving Market Accessibility

Another critical factor fueling the growth of the desktop 3D printer market is the significant drop in prices over the past few years. Once limited to high-end industrial machines, 3D printers are now more affordable and accessible to small businesses, educational institutions, and even individual consumers. As the cost of hardware, materials, and software decreases, the adoption of desktop 3D printers has skyrocketed.

Factors Contributing to Affordability:

Mass Production and Increased Competition: As 3D printing technology became more widely adopted, manufacturers began producing more machines to meet demand. The rise in competition among printer manufacturers has led to lower prices, as companies seek to differentiate themselves by offering more affordable options.

Open-Source Platforms: Many companies have embraced open-source models, where users can modify and customize 3D printer designs. This model has significantly reduced the cost of hardware and software, making it easier for users to build their own printers or purchase low-cost models with high-quality performance.

Consumer Market Growth: With the increasing use of 3D printers in the consumer market, there is a larger supply of affordable desktop models designed for home use, hobbyists, and small businesses. This has opened up new avenues for entrepreneurs and makers to create prototypes, models, and even finished products without the need for expensive equipment.

Cost-effective Materials: The availability of low-cost filament and material options has made 3D printing more affordable for users. Today, materials like PLA, PETG, and ABS filaments are readily available at a fraction of the cost of earlier, specialized materials, further decreasing the overall cost of ownership.

As 3D printing becomes more affordable, businesses and individuals alike can take advantage of this technology to streamline product design, enhance prototyping, and even produce small batches of customized products on-demand.

3. Impact of Affordability and Innovation on Various Sectors

The convergence of affordability and technological innovation is paving the way for widespread adoption of desktop 3D printers across several sectors. Some of the most notable applications include:

Manufacturing and Prototyping: Small businesses are increasingly using desktop 3D printers for rapid prototyping and small-scale manufacturing. The ability to quickly iterate designs and produce low-cost prototypes accelerates the product development cycle, enabling faster time-to-market for new products.

Education: Educational institutions, from high schools to universities, are adopting desktop 3D printers to teach students about design, engineering, and manufacturing. This technology is empowering students to create tangible models of their ideas, fostering creativity, and developing critical skills in emerging technologies.

Healthcare and Medical Devices: Desktop 3D printers are finding growing applications in the healthcare sector, particularly in the creation of custom prosthetics, implants, and medical models. The affordability of 3D printers enables healthcare providers to create cost-effective, patient-specific solutions.

Arts and Design: The creative industries are also benefiting from desktop 3D printing, with designers using the technology to create intricate sculptures, jewelry, and art pieces. 3D printing allows for greater design freedom and the production of complex forms that would be difficult or impossible to achieve with traditional manufacturing methods.

Consumer Products and Customization: As more individuals gain access to desktop 3D printers, there is an increased demand for customized products. From personalized jewelry and home décor to custom phone cases and toys, 3D printing is enabling consumers to create unique, tailor-made products to meet their individual preferences.

4. Future Outlook of the Desktop 3D Printer Market

The desktop 3D printer market is expected to continue growing as innovations and affordability further lower the barriers to entry for businesses and consumers alike. As industries increasingly recognize the benefits of 3D printing—whether for rapid prototyping, customized production, or design freedom—the adoption rate is likely to rise.

The integration of AI and machine learning in 3D printing will also likely improve the precision, speed, and cost-effectiveness of printers. This, coupled with the development of new materials and the continuing trend toward personalization, will drive market expansion in the coming years.

Conclusion

The future of the desktop 3D printer market is undeniably bright, as ongoing innovation and decreasing costs are making the technology more accessible and powerful. Whether for manufacturing, healthcare, education, or personal use, 3D printing is transforming the way we design and produce goods. As the technology continues to evolve, we can expect to see even more applications across industries, shaping a future where desktop 3D printing becomes an integral part of everyday life and business operations.

0 notes