#Advance Pillow Packing Machines

Explore tagged Tumblr posts

Text

Innovations like the pillow packing machine have completely changed the packaging industry. These devices have swiftly integrated themselves into contemporary packaging procedures because of their numerous beneficial qualities.

#Pillow Packing Machines#Pillow Packing Machines Price#Advance Pillow Packing Machines#Pillow Packaging Machines in India#Pillow Packing Machines Manufacturer

0 notes

Text

Miyu's Confidant

(last updated 11/21/24!)

This post documents the fully filled-in information on Miyu Sahara gained through progressing her Confidant! It contains things that could be considered spoilers for her Confidant, as part of the information is a summary of its story.

Miyu is available in the evenings most days, when it isn’t rainy. Her Confidant is tied to the Kindness social stat, and level 17 Kindness is required to fully complete it.

Her Confidant also requires changing a heart (technically two hearts, with one fight) in Mementos.

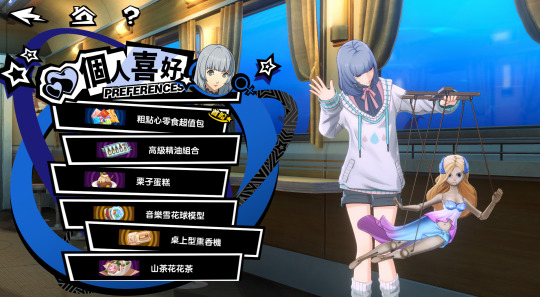

Favorite Presents

(An asterisk (*) marks the special presents added with (and unlocked through) Miyu’s own Confidant, which are liked by all Confidants currently in the game.)

Collector's Edition Complete Collection of Fairytales A collector's edition collection of masterpieces by world-renowned fairytale authors.

Dress-Up Doll Beautifully packaged ball-jointed dress-up doll that can be freely outfitted with clothing.

Cartoon Apron Apron with a cute pattern, made from a fabric that can effectively block kitchen oil stains.

Premium Fragrance Combination A classic home fragrance set with a soft scent.

Collected Set of Psychology Essays A collection of select classic works by famous psychologists. It's not only suitable for collectors, but also works as teaching material or for studying.

Cartoon-Shaped Pillow This round pillow in the shape of a popular cartoon character is very popular among girls because of its cuteness.

Advanced Custom Dollhouse A cute high-end dollhouse. Though not very big, the interior is well-designed and it has a warm atmosphere.

The Latest Drone The latest model of civilian drone. It's small in size, with a longer battery life, and can be modified as needed.

Mini Speaker A compact desktop speaker. It's easy to carry, supports multiple connections, and has specially installed custom color lights.

Limited-Edition Keychain* This keychain has a unique shape, and is well-made, but there weren’t many of it produced. It has a certain collector’s value.

Bulk Snacks Value Pack* A combo pack containing a variety of traditional snacks that will remind people of the taste of childhood.

Advanced Essential Oil Combination* A value-for-money set of essential oils, with multiple functions to help you relax your mind and body.

Chestnut Cake* Fragrant chestnut cake with mild sweetness to suit most people’s tastes.

Musical Snow Globe* A snow globe that plays music, and can be shaken gently to make snow fall inside.

Desktop Incense Machine* A household incense machine that is small in size, so it can be placed anywhere.

Camellia Flower Tea Tea leaves made from dried camellias. They still retain the beautiful color of the flowers, and emit an elegant aroma as they are brewed.

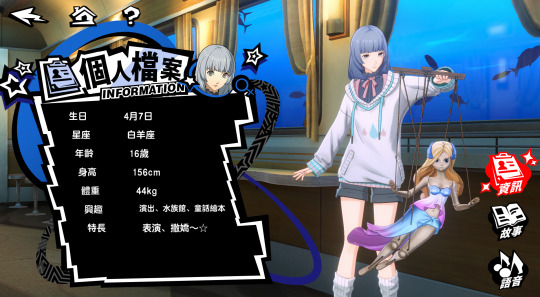

Personal Information

Birthday: April Zodiac Sign: Aries Age: 16 years old Height: 156 cm Weight: 44 kg Interests: Performances, aquariums, fairytale picture books Features: Acting, behaving coquettishly~☆

Story

Character Details A girl who performs her puppet show on the streets, and looks to be about the same age as me. She always avoids talking about herself, and seems to be hiding many secrets...

Personal Data 1 Miyu was a girl performing on the street when I visited Shinjuku. Her puppet show "The Little Mermaid" attracted many people's attention. After the performance, she was questioned by the police. She seemed to be struggling to deal with this, so I helped her out as I was passing by, and we got to know each other and became friends. She seems to like to call me "brother"... it's a bit much.

Personal Data 2 Miyu didn't seem to know much about the street conditions in Shinjuku, and was almost blackmailed by some gangsters. Fortunately, I secretly called the police and helped Miyu drive away the gangsters. The two times I've helped her made her trust me more, so she promised to find an opportunity to tell me the truth of her situation.

Personal Data 3 After the trouble last time, Miyu was ready to move from Shinjuku to another location to perform. But before that, Miyu hoped to fulfill her promise and tell me her actual situation. As she explained, I learned that she wanted to escape the control of her parents, and chose to run away from home and live alone... Miyu's persistence and hard work are admirable, but it's really difficult to live off of french fries. Is she okay?

Personal Data 4 After a series of preparations, Miyu was ready to start performing again, in Kichijoji. As this was her first performance, she asked that I accompany her. The performance went smoothly, but the audience's comments about the fate of the Little Mermaid made Miyu fall into deep thought... Perhaps it's because of their similarity that Miyu's able to perform The Little Mermaid so vividly.

Personal Data 5 Miyu's performances are becoming more and more successful, and larger and larger audiences are attracted. However, during one performance, Miyu was suddenly attacked by a man of unknown origin in a black suit. Fortunately, we responded in time and Miyu was not injured... but this man in a black suit seems to have been lurking around Miyu for a while. Who is he...?

Personal Data 6 The Tokyo Street Performers Festival event is coming up, and as a street performer herself, Miyu also wants to participate, so she began to actively prepare for it. But the man in a black suit who spies on everything from a short distance still makes people feel a bit uneasy...

Personal Data 7 A disaster happened... During a performance in Kichijoji, the man in a black suit suddenly appeared and stole Miyu's luggage and puppet. Miyu and I tried our best to catch up, but we still couldn't stop him from breaking her puppet... Although Miyu successfully made him confess the masterminds who hired him- her parents- the puppet was seriously damaged. Miyu tried hard to pretend to be strong, but in the end she couldn't help but cry... how can she make her parents understand her? Miyu wants to know the answer.

Personal Data 8 In order to lift her spirits and re-prepare for the festival, Miyu and I planned to go shopping together to relax. Looking at the fish in the aquarium, Miyu gradually confessed her true feelings to me...

Personal Data 9 Seeking to stop Miyu, her parents didn't hesitate to use their resources, and got the venue permit for the Street Performers Festival cancelled. Miyu didn't want everyone to suffer because of her, so she was going to agree to return home... but seeing how Miyu has been working hard all this time, none of us wanted her to give up. We persuaded Miyu not to, and began to search for another place to host the event. Miyu was uplifted by everyone and decided to try as well. Maybe... now's also the time for the Phantom Thieves to try something, too.

Personal Data 10 Miyu's parents had a change of heart, and the event was allowed to be held as originally planned. In order to prepare, Miyu came to the stage to practice. She happily performed her puppet show before the crowd. Not far away, her parents stood secretly watching her... They seemed to gradually understand Miyu more, and let her choose her path based on her own wishes. The future is still far off and requires a lot of hard work, but I believe Miyu will be able to use her own legs to move forward.

Voice Lines

Japanese VA: Kana Ichinose | Chinese VA: YiLei Liu

(As I can only add up to ten audio files per post, I’ll only include the Japanese lines below! Feel free to ask for the Chinese ones, though.)

I'm Miyu Sahara! I do street performances with marionettes. Please support me~

Because I didn't want my parents to decide my future, I ran away from home. Since this is the path I chose for myself, no matter how difficult it gets, I won't give up!

My dream is to become a performer everyone knows, and one day travel the whole world... Hahahaha!

My father and mother just want an obedient daughter. They want to decide my education, career, and even who I marry... I will never accept a life like that.

People think of the Little Mermaid as a helpless girl... but she gave me courage. She gave up her pristine life and proud voice, and pursued love on her own legs... don't you think that's amazing?

I'm an only child, so though my parents took care of me, I always wished I had an older brother to protect me. Ah, but please don't get the wrong idea! I wouldn't be happy with just anyone. My big brother could only be you!

If I were the Little Mermaid, what role would my brother have? The prince isn't wrong, but he's also a bit like a wizard. He gave me beautiful legs, and brought me from the sea to land. He's a very kind, magic-using prince. Ah, hehe! It's a bit greedy, but this will definitely have a happy ending!

Confidant-Specific Bonuses

Rank 1 Tips for People-Pleasing: Unlocks the Limited-Edition Keychain and Bulk Snacks Value Pack for purchase at stores.

Rank 5 Warm Tolerance: The points earned from gifting favorite presents is increased by 15%.

Rank 9 Brother, Please Give Me Some Advice: Unlocks the Advanced Essential Oil Combination and Chestnut Cake for purchase at stores.

Rank 13 Can I Act Coquettishly?: Unlocks the Musical Snow Globe and Desktop Incense Machine for purchase at stores.

Rank 17 Brother is So Cunning: The points earned from gifting non-favorite presents is increased by 15%.

7 notes

·

View notes

Text

A not-so-simple relocation, day 2/3

Last time, we arrived safely in "Bergen?" as the sign at the airport says, much to my eternal delight. It was a long trip, made longer by airport and airplane screwups. I had three friends in tow and my partner waiting for me at the apartment. The rest of the day was basically for rest.

Day 2 - Why does everything have to be uphill?

Day 2 started by me realizing... I had very little clean clothing. In fact, I had no clean underwear, no clean pants, and only dress shirts clean and actually present. While the baggage handler at the Bergen airport said it would arrive the same day I did... Oslo never got their shit together on a Sunday and I had to make do for an unknown amount of time.

This day was marked by reconnaissance. I needed to learn more about my new apartment to figure out what is needed, figure out the Bergen bus system, figure out the grocery stores, and so on.

The apartment itself is... weird, to me. One of my friends described it as the set to a cocaine druglord's apartment and... yeah, that matches. The view is breathtakingly gorgeous, the decor is super bright and white, and it seems to be missing a few things that don't really make a lot of sense.

Like a freezer.

Or a washing machine.

Or pillows (plural - it had one).

So, that means heading out of the house being super uncomfortable in my clothing, exhausted from the trip, and dealing with a recurring gout attack (along with other physical ailments that are a bit too gross to state). Four of us went - my partner, two of our friends, and myself, with the last friend staying behind with the cats.

A brief aside, at this point Zoan was still hiding in the master bedroom. Issun had started exploring.

Now, keep in mind - I had been exploring Google Maps around my apartment for a while. The apartment itself is very new, so most of the maps just show a hole in the ground where it is, with a couple of angles showing the buildings under construction. I had never been to the apartment and hadn't even been in this region of Bergen before. So all I really had to go on were photos of the area, which looked quite nice.

The apartment is about fifteen minutes by foot away from the closest bus stop, which happens to be right next to the two local grocery stores. A fifteen minute walk for me is pretty easy, even in my gout-addled state. I absent-minded pace for longer distances than that.

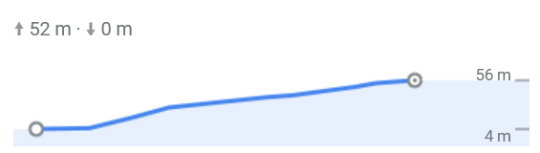

A fifteen minute walk where the entire walk is uphill for 52 meters / 170 feet? That's just a bit rougher. My legs were screaming at me at the 1/4th point, let alone for the rest of the walk. The object of this trip was to go to the mall a couple of bus stops away, buy some pillows and plug adapters*, get some lunch, come back, stop by the grocery store, then head home.

Did you see that asterisk? I had prepped for this well in advance - the price difference between buying a plug adapter in the US and buying one in Norway was huge, so I bought a large 12-pack of them to supplement the three I already had. Problem being, I think the movers packed it up for the slow boat shipment, so I had nothing.

Anyway, after a grueling 20 minute walk (because I kept needing to stop; how the hell people think walking uphill is anywhere near as easy as walking long distances, I haven't a clue), made it to the bus, head out for our shopping. We needed to make it back by the delivery window for @kriatyrr's delivery of some much needed supplies (such as more power cords).

Made it back to the apartment. We had to go out and back a second time for some food, which involved me whining the entire way of course, made it back... to find a courier dropping off all of my luggage. Everything arrived! HOORAY!

Kriatyrr's packages, however, didn't arrive during the delivery window. Turns out, they were stuck in Oslo due to delays on a Sunday. Remember that quote from earlier from the baggage handler, "Oslo needs to get their shit together on Sundays"?

Day 3 - Bus adventures

Day 3 is the first day that I specifically had something I had to do - I had a meeting with the Norwegian police. As an incoming immigrant to Norway, one of the requirements was a police interview. They want to meet you in person to take photos, fingerprints, and presumably ensure you're actually real. I had scheduled this a few weeks in advance, with the idea that I should be (mostly) on a normal sleep schedule by Day 3.

The interview location was in Fyllingsdalen, a separate borough from both downtown Bergen and the borough I live in. Technically it is one of the two in between, but due to geography I actually travel through Årstad to downtown Bergen (Bergen-hus) first before basically turning around, going back through Årstad and finally to Fyllingsdalen. This sounds way more complicated than it is; I'm already used to Madison buses where I had to circle my own neighborhood before I arrive at the closest stop to my house; this at least makes sense due to mountains being in the way.

I used the bus a bit the prior day, but this was my first real bus trip.

Transit side-note

Transit in Bergen is controlled primarily through a smartphone app. You buy the ticket on the app before you board and it is good for 90 minutes after. Buses are on the testing system; 99% of the time it is on the honor system with no one checking, 1% of the time they inspect for bus passes and give you large fines for skipping the pass. While I haven't seen anyone checking in Bergen so far, I have seen the same thing in Oslo during a visit.

Bus passes cost 40kr for a trip, 105kr for a day, 235kr for a week, 755kr for a month, and 3775kr for a half-year. In USD at the time of this posting, that's $3.60 / $9.44 / $21.13 / $67.90 / $339.48 for each of those passes. I budgeted assuming those half-year passes, but I haven't bothered with one yet. Once I'm more in the swing of things, I'll figure out how I want to handle bus passes. It also technically includes a parking pass (for those that park-and-ride), but since I don't drive that part is irrelevant to me. Bergen also has light rail (same bus pass system), but the area I live in isn't convenient to use the light rail for.

Buses come frequently by the bus stop next to the grocery store. That stop has seven bus routes stopping there, three routes going from the mall (mentioned the previous day) to the Bergen bus station. The result is that I have service roughly every 5-10 minutes during weekdays, 15 minutes on Saturdays, 30 minutes on Sundays (not that the latter matters... insert ominous foreshadowing here).

In my mind, anything going every fifteen minutes or sooner is, "just get to the bus". Anything 30 minutes or later is, "schedule your trip to make sure you don't miss the bus". It is a huge difference in mentalities, and I repeatedly lambasted Madison for depriving my old neighborhood of enough bus service to fulfill the former. If I missed a bus there, I'm an hour or two late, and taking a bus early means arriving an hour or two early. Whereas arriving at the previous bus here puts me around ten minutes earlier than expected.

Side-note over, back to the day

Anyway, our group decide on a trip that morning. Myself and my partner heading to Fyllingsdalen, two of our friends heading to Bergen-hus for some exploration, the last friend staying at home again. We'd all get off the bus at the same spot and split up from there - us to the bus transfer, them to wandering. Our stop in Fyllingsdalen was just a few stops down another bus route and would take a total of 45 minutes to get there (including the 15 minute walk uphill, which took me 23 minutes this time).

Kriatyrr and I arrived at the police station around ten minutes early... and left before the scheduled appointment time. Turns out, they really did just need to take a photo, get my fingerprints, and ask me for my address and signature. There was nothing else. After that, we spent time shopping for some housewares. I get a text from my friends mentioning that they were going to head back at this point. We decide to try to grab food (and failing - seriously, why do restaurants open so late around here, don't people eat lunch?) before heading back.

We arrived at the bus, took it down one stop, and saw our friends there, who had accidentally taken the wrong bus and just so happened to turn around and take our bus back. We made it back, rested, then head out to the mall again to buy more things. This time it was myself, the friend that kept staying at home, and the friend that kept heading out with me; Kriatyrr stayed home waiting on that package from the previous day.

This part was fairly uneventful except for one small thing. To explain that, I need to explain international banking. I'm absolutely going to put this in a video when I started recording these.

Credit Card side-note

You know how credit/debit card usage in the US requires you to occasionally sign a piece of paper, but otherwise seems super duper insecure? Yeah, the entire rest of the world thinks so as well. The chip located on a credit card is a part of a system used by EMV cards to increase security. The US migrated to it back in October of 2015, doing away with swipe-based transactions (more that the CC companies shifted fraud liability to any merchant using a swipe, and they're not going to want to deal with that).

In Europe? The same shift happened in 1993.

EMV cards are a part of a chip-and-PIN system; basically, you stick your chip into the terminal, put in a PIN, and that authorizes the transaction. It follows two-factor security, basically, as it contains something you have (the card with the chip) and something you know (your PIN) for authorization. In the US, debit cards use the same mechanism now at an ATM or a terminal supporting debit.

The US uses chip-and-signature for credit cards (as well as debit cards being used as a credit card). This is... definitely not two-factor. It combines something you have (the card with the chip) and... something no one bothers to even look at (the signature). That's one-factor, just like the strip. Europeans have been endlessly baffled when I mention this to them, and for good reason - this system is awful and useless.

Tapping to pay for things with your credit card effectively works the same way as the chip-and-signature system, only it works for values under a certain amount. Even Europe does that one, they just keep the limits super low so liability isn't really a big deal.

Unfortunately for us, this system follows us wherever we go. If you use a US credit card in Norway, for instance, sometimes the receipt will print out a slip that you have to sign. If the person at the register doesn't realize this, it'll look like a receipt and send you on your way... which is a problem, as that means you haven't technically paid for your goods.

Trouble in Clas Ohlson

Which leads me to my situation. I was at a shop called Clas Ohlson - a Swedish-based chain of general stores. For a comparison point to us Americans, I'd call it like a hybrid of Home Depot and Best Buy, but far smaller. You want to go to one store to buy food containers, socks, power cords, hand tools, a tablet PC, and a printer? Clas Ohlson to the rescue.

I had a bunch of things I was picking up, went through the store, tapped to pay my bill for a couple thousand kroner / couple hundred dollars, was handed the receipt, and walked out.

The person at the cash register looked down, realized that the register said the transaction was still waiting, and booked it to chase after me.

This one mistake took an hour to fix.

This is what life will be like for me for the foreseeable future, as not only can I not get a Norwegian credit card until two years after I have a Norwegian bank account, but I can't even get a Norwegian bank account at the moment until I receive my national ID (which was what the police started the process for).

Welcome to Norway!

Previous post:

5 notes

·

View notes

Text

How a Potato Chips Packing Machine Enhances Efficiency and Quality in Snack Packaging

In the fast-paced snack food industry, packaging plays a crucial role in maintaining the freshness, quality, and shelf life of products like potato chips. The introduction of automated solutions such as the Potato Chips Packing Machine has revolutionized the way snack manufacturers package their products. These machines have become indispensable in modern production lines, offering speed, consistency, and cost-efficiency.

What is a Potato Chips Packing Machine?

A Potato Chips Packing Machine is an automated device designed specifically to package potato chips into bags or pouches. It is capable of handling various packaging formats, including pillow bags, standing pouches, and gusset bags, ensuring that the chips are securely packed without compromising their crispiness or freshness. The machine typically includes features such as portion control, sealing, labeling, and date printing.

Benefits of Using a Potato Chips Packing Machine

Speed and Efficiency One of the most significant advantages of using a Potato Chips Packing Machine is the increased speed and efficiency in the packing process. These machines can fill and seal multiple pouches per minute, reducing manual labor and increasing overall productivity. This allows manufacturers to meet high demand and maintain a constant supply.

Precise Portion Control With automated portion control systems, these packing machines ensure each pouch receives the correct amount of chips. This reduces waste, minimizes the chances of human error, and ensures consistency across all packed bags. This precision is vital for manufacturers who want to maintain the uniformity of their product and meet specific weight standards.

Enhanced Product Freshness The packaging process is critical to preserving the freshness and crispiness of potato chips. A high-quality Potato Chips Packing Machine uses advanced sealing technology that locks in freshness, protects the chips from moisture and air, and ensures that they stay crunchy for longer periods. This is particularly important in maintaining the snack’s shelf life and ensuring customer satisfaction.

Reduced Labor Costs By automating the packing process, manufacturers can significantly reduce the number of workers needed on the production line. The machine's high-speed capabilities enable the efficient use of time and resources, ultimately lowering labor costs while maintaining high output levels.

Customization Options Many modern Potato Chips Packing Machines offer a variety of customization options for packaging size, bag style, and branding. This flexibility allows manufacturers to cater to different market demands, from single-serving bags to large family-sized packs. Additionally, these machines can print production dates, batch numbers, and other essential information directly on the packaging.

Improved Hygiene and Safety Automated packing machines help to reduce the risk of contamination that can occur in manual packing processes. They are designed with hygiene in mind, featuring materials that are easy to clean and maintain. This ensures that the packaging process adheres to industry standards and regulations, reducing the risk of contamination and enhancing the overall safety of the product.

How Does a Potato Chips Packing Machine Work?

A typical Potato Chips Packing Machine consists of the following key components:

Feeding System: Chips are conveyed to the packing machine via an automatic feeding system. The chips are gently handled to avoid breaking or crushing during the transfer process.

Filling System: The chips are then accurately measured and dispensed into pre-formed pouches or bags. Depending on the machine, this could be done using a volumetric filler or a weight-based system.

Sealing: Once the chips are packed into the pouch, the machine seals the opening using heat or other sealing methods to ensure that the package is airtight and tamper-proof.

Labeling and Printing: The machine can print batch numbers, expiry dates, and other important product details on the bags, ensuring compliance with regulatory standards and adding branding elements.

Output: Finally, the packed bags are conveyed to the collection point, ready for distribution.

Types of Potato Chips Packing Machines

Vertical Form Fill Seal (VFFS) Machines These machines create pouches from a roll of film, fill them with chips, and then seal them. VFFS machines are highly versatile, making them suitable for different sizes and types of packaging.

Horizontal Form Fill Seal (HFFS) Machines HFFS machines operate similarly to VFFS but work horizontally. These machines are often used for larger packaging formats, such as family-sized bags of chips.

Automatic Pouch Filling Machines These machines are designed to fill pre-formed pouches with chips. They are commonly used in high-speed production environments where quick, efficient packing is essential.

Choosing the Right Potato Chips Packing Machine

When selecting a Potato Chips Packing Machine, manufacturers should consider factors like:

Production Capacity: Choose a machine that can handle the volume of your production line without compromising speed or quality.

Packaging Type: Ensure the machine is compatible with the packaging formats you need, such as stand-up pouches or pillow bags.

Customization: Consider machines that offer customization options, such as the ability to adjust portion sizes or print branding and production details.

Maintenance and Support: Choose a machine that is easy to maintain and comes with reliable technical support.

Conclusion

The Potato Chips Packing Machine is a game-changer for snack manufacturers looking to streamline their production lines while ensuring consistent quality and freshness. With benefits ranging from increased speed and efficiency to enhanced product hygiene and longer shelf life, investing in a high-quality packing machine is an essential step toward maintaining competitiveness in the snack food industry. For manufacturers aiming to stay ahead of the curve, automating the packing process with a Potato Chips Packing Machine is a smart choice.

For more information on how our Potato Chips Packing Machines can improve your packaging process, contact Munky Packaging Machines today!

1 note

·

View note

Text

Automatic Pouch Packing Machine- A Game-Changer for Packaging Solutions By Munky

In today’s competitive manufacturing landscape, efficiency, accuracy, and speed are paramount to staying ahead of the curve. Packaging, a crucial element in the supply chain, can significantly impact product quality, safety, and overall customer satisfaction. With advancements in technology, the packaging industry has seen a shift towards automated solutions that streamline processes and reduce human error. One such innovation is the Automatic Pouch Packing Machine, an indispensable asset for businesses looking to optimize their packaging operations. Munky Packaging Machines, a leading name in the industry, offers cutting-edge solutions tailored to meet the needs of various sectors.

What is an Automatic Pouch Packing Machine?

An Automatic Pouch Packing Machine is an advanced packaging system designed to fill and seal pouches efficiently and accurately. Whether it’s powders, granules, liquids, or snacks, these machines offer an automated approach to filling pre-formed pouches with the right amount of product and then sealing them securely. The automation eliminates the need for manual labor, increasing productivity and minimizing errors.

At Munky Packaging Machines, we specialize in designing high-performance automatic pouch packing machines that cater to diverse industries such as food and beverage, pharmaceuticals, cosmetics, and more.

Key Features of Munky Packaging Machines' Automatic Pouch Packing Machine

Precision Weighing and Filling One of the core features of our automatic pouch packing machines is the high level of precision they offer. Equipped with advanced multi-head weighers or volumetric filling systems, our machines ensure that each pouch contains the exact amount of product. This feature reduces product waste, ensuring that manufacturers get the most out of their raw materials while maintaining consistent product quality.

Versatility Across Products Our automatic pouch packing machines are designed to handle a wide range of products. Whether you’re packing powders like flour and spices, liquids such as sauces and juices, or snacks like chips and popcorn, Munky Packaging Machines can provide a tailored solution. The machines can be customized to suit the product’s specific requirements, ensuring seamless operation regardless of the type of product being packed.

High-Speed Operation In industries where time is of the essence, the speed of packaging can make a significant difference. Munky Packaging Machines offers high-speed automatic pouch packing machines that can fill and seal pouches in rapid succession, making them ideal for large-scale production environments. These machines can significantly increase production output without compromising on accuracy or product quality.

Durable and Hygienic Design Our machines are built to last. Made from high-grade stainless steel, they are not only durable but also easy to clean and maintain. This makes them perfect for food and pharmaceutical applications where hygiene is critical. Additionally, the user-friendly design ensures minimal downtime for cleaning and maintenance, allowing businesses to maximize their uptime and productivity.

Sealing Perfection One of the most important aspects of pouch packaging is the sealing process. A properly sealed pouch not only preserves the freshness and quality of the product but also ensures its safety. Munky Packaging Machines ensures perfect sealing every time, using advanced sealing technology that is reliable and consistent across all types of pouches, whether they are pillow pouches, stand-up pouches, or gusseted bags.

Nitrogen Flushing for Extended Freshness For perishable products like snacks and food items, retaining freshness is essential. Our machines come with optional nitrogen flushing capabilities. By replacing the oxygen inside the pouch with nitrogen, this feature helps extend the shelf life of products, ensuring they remain fresh and crisp for longer periods.

Advantages of Automated Pouch Packing Machinery

Increased Efficiency Manual packaging processes are not only time-consuming but also prone to errors. With an automatic pouch packing machine, manufacturers can automate the entire packaging process, from weighing and filling to sealing. This results in faster production rates, fewer errors, and ultimately, cost savings.

Consistent Quality Maintaining consistent product quality is crucial for brand reputation. An automatic pouch packing machine ensures that each pouch is filled with the exact amount of product, and the sealing is done uniformly. This consistency is key to maintaining high product quality, reducing the likelihood of customer complaints.

Labor Cost Reduction Automating the pouch packing process can significantly reduce labor costs. With minimal human intervention required, businesses can allocate their workforce more efficiently and reduce the need for manual labor in the packaging process.

Reduced Product Waste With precise weighing and filling mechanisms, our automatic pouch packing machines help minimize product waste. This is especially beneficial for manufacturers dealing with expensive raw materials, as the machines ensure that the exact quantity is packed every time.

Improved Hygiene and Safety By automating the packaging process, businesses can improve hygiene and safety standards in their production lines. This is especially important in industries such as food and pharmaceuticals, where contamination risks are high. Our machines are designed with food-grade materials and are easy to clean, ensuring that hygiene standards are always maintained.

Why Choose Munky Packaging Machines?

At Munky Packaging Machines, we have been at the forefront of packaging technology for over a decade, offering innovative solutions to businesses across various sectors. Our Automatic Packing Machines are designed to meet the specific needs of each client, ensuring optimal performance and reliability. With a focus on precision, speed, and quality, we have built a reputation as one of the most trusted names in the packaging industry.

#pouch packaging machines#Automated Pouch Packing Machinery#Automatic Packing Machines#Automatic Pouch Packing Machine

0 notes

Text

Our DBF-001 Dog Bed Pillow Filling Machine and DBP-001 Stuffing Machine are here to revolutionise your production process. Featuring advanced VGI carding technology, reverse drive functionality, and overload protection, these machines are designed for efficiency and safety. With various capacities and a user-friendly interface, For more details, visit- https://www.multipromachines.com/product/dog-bed-filling-packing-machine

0 notes

Text

The PFM Pearl Horizontal Flow Wrapper: Revolutionizing Packaging for Australian Businesses

In today's competitive Australian market, presentation is key. Consumers are drawn to products that not only look appealing but are also securely packaged. This is where Emrich, a leading supplier of packaging machinery, steps in with the PFM Pearl Horizontal Flow Wrapper – a game-changer for businesses seeking efficient and versatile packaging solutions.

Beyond Aesthetics: Unveiling the Power of the PFM Pearl

The PFM Pearl isn't just about creating visually pleasing pillow-pack styles. It's a powerhouse of functionality designed to streamline your packaging process and elevate your product presentation. Here's what sets this horizontal flow wrapper apart:

Versatility Meets Efficiency: The PFM Pearl utilizes a flat reel of film, allowing you to package a wide range of products, from food items like biscuits and confectionery to non-food items like stationery and pharmaceuticals.

Dual Sealing Power: This innovative machine offers both heat sealing and cold sealing capabilities. This flexibility ensures you can choose the most appropriate sealing method for your specific product, maximizing its shelf life and integrity.

Food-Safe Packaging: The PFM Pearl prioritizes food safety. All parts that come in contact with your products are made from high-quality, food-grade plastic or stainless steel, ensuring your food items remain untouched by harmful contaminants.

Export-Ready Packaging: The PFM Pearl creates robust and secure packages, ideal for protecting your products during transportation, even for export purposes. This allows you to confidently expand your market reach without compromising on product quality.

Designed for Smooth Operation and Efficiency

Emrich understands that efficiency is paramount for businesses. The PFM Pearl is designed with user-friendliness and streamlined operation in mind:

Compact Design: This space-saving machine is perfect for businesses with limited floor space. Its compact footprint allows for optimal utilization of your production area.

Complete Automation: From feeding the film to sealing the package, the PFM Pearl automates the entire flow wrapping process. This minimizes manual intervention, increases production speed, and reduces labor costs.

User-Friendly Controls: The PFM Pearl features a user-friendly color touchscreen interface. This intuitive system allows for easy operation and parameter adjustments, even for new users. Operators can quickly learn to manage machine settings and optimize packaging for different products.

Advanced Technology: The PFM Pearl boasts an axis motion controller and brushless servomotors. This advanced technology translates to smooth, precise operation and minimal downtime, ensuring consistent and reliable performance.

Optimizing Your Packaging Process with Emrich

Emrich goes beyond simply providing machinery. They offer comprehensive support to ensure you get the most out of your PFM Pearl:

Expert Consultation: Their knowledgeable team can assess your specific packaging needs and recommend the ideal PFM Pearl configuration for your products.

Seamless Installation: Emrich's technicians handle the installation process meticulously, ensuring the machine is properly set up and integrated into your existing production line.

Training and Support: They provide comprehensive training for your staff on operating and maintaining the PFM Pearl effectively. Emrich's ongoing support ensures you can continue to utilize the machine to its full potential.

The PFM Pearl: A Boon for Australian Businesses

By investing in the PFM Pearl Horizontal Flow Wrapper, Australian businesses can unlock a multitude of benefits:

Enhanced Product Presentation: Create eye-catching pillow-pack styles that grab customer attention and elevate your brand image.

Increased Efficiency: Streamline your packaging process with automated operations and achieve higher production outputs.

Reduced Costs: Minimize labor costs through automation and potentially reduce material waste with optimal film utilization.

Improved Food Safety: Ensure your food products remain safe and fresh with secure packaging and food-grade materials.

Export Readiness: Confidently expand your market reach with packaging that protects your products during transportation.

Emrich: Your Partner in Packaging Innovation

Emrich's PFM Pearl Horizontal Flow Wrapper is a testament to their commitment to providing Australian businesses with advanced and versatile packaging solutions. With its efficient operation, user-friendliness, and focus on food safety, the PFM Pearl empowers you to present your products in the best light while ensuring their protection. Contact Emrich today and explore how the PFM Pearl can revolutionize your packaging process and elevate your brand in the Australian market.

Contact- Web - https://www.emrich.com.au/pfm-pearl-horizontal-flow-wrapper-machine/ Ph - 1800 801 243 / +61 3 9540 0255 Address - 1/14-18 Venture Court, Dandenong South VIC 3175, Australia.

0 notes

Text

Flowing Smoothly: Mastering Your Oil Packaging Machine Efficiency

Bangladesh's oil industry has been experiencing unprecedented growth, driven by changing consumer preferences and market dynamics. In this dynamic landscape efficiency is a necessity. With consumers looking for quality and convenience, mastering the efficiency of your oil packaging machine is extremely important.

As a leading provider of packaging machines, Nichrome is at the forefront of this transformation. Our oil bottle-filling machines and automatic liquid pouch packing machines are revolutionizing the way oil products are packaged and distributed.

This is because an oil packaging machine isn't just a piece of equipment; it's the cornerstone of your production line. At Nichrome Bangladesh, we understand the significance of seamless packaging operations to ensure timely delivery and customer satisfaction. We offer a comprehensive range of oil packaging machines designed to cater to the diverse needs of the industry. Whether it's soybean oil, cooking oil, or any liquid variant, our oil-filling packaging machines are engineered to deliver unmatched performance.

Let's delve into how you can streamline your oil packaging process with our cutting-edge solutions.

Innovative Technology - Nichrome takes pride in offering the fastest oil packaging solutions in Bangladesh. Our oil packaging machines are equipped with advanced features that ensure higher speed, accuracy, and control. The Nichrome Filpack Servo SMD stands out as a prime example, offering innovative packaging solutions that include the highly efficient 3-sided seal Pillow Pouch format, among other packaging options.

Versatility and Adaptability - In this fast-paced world of soybean oil packaging machines, versatility is key. Nichrome's oil packaging machines are designed to adapt to various packaging requirements seamlessly. Whether you need automatic sachet packing machines for small portions or bottle filling machines for larger volumes, we have you covered. Our machines offer unparalleled flexibility to meet your evolving needs.

Speed, Accuracy, and Control - Nichrome takes pride in offering the fastest oil packaging solutions, ensuring timely delivery and customer satisfaction. The Filpack Servo SMD stands out with its exceptional speed, delivering a packaging process that is not only swift but also precise. The automatic liquid pouch packing machines are designed to handle a variety of oils, including soybean oil, with utmost accuracy.

Automated Excellence - Gone are the days of manual filling and packaging processes. Our automatic sachet packing machines and bottle filling machines are equipped with advanced technology to automate your production line, reducing human error and increasing throughput. With Nichrome's automated solutions, you can significantly enhance operational efficiency while maintaining the highest quality standards.

Sealing the Deal with Secondary Packaging - Efficiency isn't just about the primary packaging process; it extends to secondary packaging as well. Nichrome understands the importance of presentation and protection. Our liquid pouch packing machine facilitates secondary packaging with precision, ensuring that your products reach consumers in pristine condition, while also enhancing brand visibility.

Conclusion

In conclusion, mastering the efficiency of your oil packaging machine is essential for success in the competitive landscape of the oil industry in Bangladesh. With Nichrome as your partner, you can elevate your packaging operations to new heights of excellence. From liquid filling machines to packaging technology, we offer comprehensive solutions tailored to your specific needs for liquid filling machines in Bangladesh.

That’s because Nichrome isn't just a packaging machine supplier in Bangladesh; we are pioneers in the field of packaging technology. With decades of industry experience and a commitment to innovation, we have earned the trust of leading brands across the globe. Our liquid packaging machines are engineered to exceed expectations, setting new benchmarks for efficiency and reliability.

So next time you require a liquid packaging machine supplier in Bangladesh, connect with Nichrome and experience the difference with your trusted partner for all your packaging needs.

0 notes

Text

Dry cleaning

Black N White Laundry is the No.1 Service for both Domestic and Business Customers in Kochi with Free Home Pick-up/Delivery. We offer laundry,dry clean, dying and darning services at affordable rates. This is a fully mechanized unit with highly advanced Machines and well experienced staffs. We treat your fabrics like Celebrity with the Best available Equipment and Good Quality Chemicals. The technology of Steam Pressing gives more Finishing for your Fabrics. Special Care and Speed Delivery for your Garments, Curtains, Carpets, Bed sheets, Blankets, Quilts, Comforts, Sofa/Pillow Covers etc. We also have Industrial Laundry Services for Hotels, Hospitals, Beauty Parlor, Saloon, Spa etc. On Demand Door Step Service, Vertical Delivery, Express Delivery and Wrinkle free Packing are our Specialties

youtube

1 note

·

View note

Text

Migraine Remedies 101

I recently posted about Red Light Therapy, but that is not the first light for me to try this out with-I also have been using a Green Light one for Migraines. I realized I did not have a post about Migraines, and I needed to right that wrong right away.

My Background:

I like to start with my background on these kinds of posts. I am 32 years young when I write this post. My grandmother, on my mothers side, has bad migraines. Her mom? In the early 1900's she had them worse, and medicine was far less advanced than it was now. Great Grandma had them, Grandma has them, mom has them-the writing for that trait was on the wall for me. The thing is, they should of started in my 20's or 30's. When did they start? When I was 2 or 3, how? I was sick from something, not sure as early parts of my story are lost to me, and my mom decided to give me a spinal tap to determine the cause. I was told, that she was told not to put a pillow under my head the night of the procedure, and she thought I looked uncomfortable so she went against that. I have dealt with migraines on a daily ish basis since I was 3 years old.

Growing up, my father has a steady job with the union so anytime we needed to go the doctor, we could. At one point, I saw a neurologist and he told me to try watching my sleep, caffeine, and diet/food allergies. Beyond that, which I still use to this day-my great grandma's remedies have been way more helpful. There are some doctors that I talk to about what I do and use, and they tell me they are JUST NOW teaching it in medical school. So I know what I am talking about.

Where Matters:

I wish I could of found a better visual for this, but location of the pain will tell you a lot in how you handle it. Keeping your triggers in mind, attack your pain with an informed strategy.

Remedies:

Sleep: Keep a consistent sleep schedule, and wind down before bed with no electronics

Caffeine: Try watch how much you have. You can try a caffeine pill, but there are some foods that have it too.

Diet: I watch what I eat in general but I also avoid MSG, Yellow #40, Red#40, and Blue#40.

Vitamins: D3 and Coq10 are prenatal vitamins that are also great migraine prevention. I had way less migraines when pregnant, however brief.

Ice: Ice pack on the location of the pain spot. I would always suggest wrapping the ice pack in a rag.

Migraine Glasses: This is kind of new, the eyes of someone who has migraines tends to work harder to be "normal" and focus so there are lenses that have the eye work less. Otherwise in general, glasses that help with the blue light glare of electronics helps eyes. One of the worst symptoms of migraines is light sensitivity.

Massage: Gently with fingers or a small machine, bringing blood flow to the area helps the body to heal itself.

Darkness/Nap: Your body can heal itself if you let it shut down other functions and focus on the task at hand.

Relax: Hard to imagine you can do when it seems like your head is pounding, but the sooner you can do it, the better you will be.

Green Light Therapy: You can find this on Amazon. I find this to be very helpful. It is better if you use it more often, not just when its really bad.

Medicine: General migraine medicine usually can do the trip, but if it is hormonal then you need a premysn (or something like that). Sinus issues? Take a sinus med, its a sinus headache. Medicine is a last resort, one I will use to stay productive or avoid the ER.

I might try Foot Reflexology one time as a possible remedy. Cupping or acupuncture could be good too, but I am not the person to do that. I have heard of Botox helping? But have never done that. I hope this helps! What would you add to this list?

#rant#pixabay#health#lifestyle#headache#migraine#green light therapy#sleep#caffeine#vitamins#d3#coq10#ice#migraine lens#massage#blue light glasses#light sensitivity#darkness#nap#medicine#cupping#acupuncture#botox#foot reflexology

1 note

·

View note

Text

At Terron India, we are dedicated to advancing packaging solutions with cutting-edge innovations in pillow packing machine technology. These machines have transformed the packaging industry, ensuring efficiency and precision.

#Pillow Packing Machine#Pillow Packing Machine in India#Best Pillow Packing Machine#Pillow Packing Machines Suppliers#Pillow Packing Machines Manufacturers#Pillow Packing Machines Price#price#pillow packing machine manufacturer#pillow packing machine in India#pillow packing machines#pillow packaging machine;

0 notes

Text

Sleep Soundly Anywhere: A Guide to Traveling with Your CPAP Machine

Traveling with a CPAP machine can be a daunting task for those who rely on it for a good night's sleep. However, with the right preparation and knowledge, you can ensure a restful sleep no matter where you go. In this guide, we will explore the essential tips and tricks to make your travel with cpap experience seamless and stress-free.

Understanding the Importance of Traveling with CPAP

For individuals with sleep apnea, a CPAP machine is a lifeline. It helps maintain a continuous flow of air pressure, keeping the airways open during sleep. This ensures uninterrupted breathing and prevents the occurrence of apneas or pauses in breathing. When traveling, it is crucial to bring your CPAP machine along to maintain the same level of therapy and ensure a good night's sleep.

Choosing the Right CPAP Machine for Travel

When it comes to traveling with a CPAP machine, portability is key. Many manufacturers offer travel-friendly CPAP machines that are lightweight and compact, making them easy to carry. Look for machines that have a travel mode or come with a travel bag for added convenience. Additionally, consider investing in a battery pack or a power adapter that can be used internationally, ensuring you have power wherever you go.

Preparing Your CPAP Machine for Travel

Tips for Traveling with CPAP

Traveling with a CPAP machine can be made easier with a few simple tips:

Carry your CPAP machine as a carry-on item to avoid the risk of damage or loss.

Inform the airline in advance about your medical equipment to ensure a smooth security check process.

Consider using a travel-sized CPAP pillow for added comfort during your journey.

Research the voltage requirements of your travel destination and bring the necessary adapters or converters.

By following these tips, you can ensure a hassle-free travel experience with your CPAP machine.

Traveling with a CPAP machine should not hinder your ability to explore the world. With proper planning and the right equipment, you can sleep soundly anywhere. Remember to always prioritize your sleep health and make the necessary arrangements to continue your therapy while on the go. Happy travels!

0 notes

Text

private labelling in india

In the ever-evolving landscape of the spice industry in India, one company stands out as a pioneer in delivering both purity and innovation - Swani Spice. With a constant commitment to providing the highest degree of purity in spices, Swani Spice has ventured into the world of private labelling in india , redefining the way we perceive spices and their packaging.

In a world where consumer trends change rapidly, building a competitive edge is crucial for gaining better bargaining power over other suppliers. Private labelling allows us to create cost-effective leadership and offer better margins with wider price options for our clients. This, in turn, leads to increased customer loyalty.

One of the critical aspects of delivering pure spices is ensuring their quality remains untarnished from the moment they are packed until they reach the client. Swani has taken a leap into the future by investing in advanced packaging machines that not only save floor space but also enhance product sterility and quality.

Fill, Seal (FFS) Machines have four vertical forms, each designed to cater to specific packaging requirements:

FFS Machines with Dual Feeding System - Precision in packaging is assured, providing a competitive edge.

Multi-head Filling System - Ideal for packing whole products, it ensures the spices' freshness remains intact.

Auger Filling System - Perfect for powders, this system preserves the texture and flavour of the spices.

Pouch Orientation - Versatile options like pillow pouches with three-sided seals meet varied packaging needs.

Packaging is not merely about aesthetics; it plays a pivotal role in preserving the quality of spices throughout their shelf life. Swaniconsiders packaging a top priority, offering a wide array of options to cater to diverse products and sizes.

Depending on the physical characteristics of a product, different packaging requirements need to be met. Swani is fully equipped to meet these demands, offering a wide range of packaging options:

Plain Laminated Print -

A simple yet effective solution with stickers or print directly on the pouch for quick identification.

Generic Printed Film –

Featuringprinting of product names and batch codes for efficiency and accuracy.

Product-Specific Printed Laminated Films –

Customized packaging highlights the uniqueness of each spice, enhancing brand identity.

Sustainability and Beyond

Swanis’ commitment extends beyond delivering purity; it's about sustainability too. The emphasis on organic and sustainable cultivation ensures that our spices are free from synthetic pesticides, herbicides, and other chemical fertilizers.

By partnering with local farmers, we support sustainable agriculture while promoting the economic well-being of farming communities. Swani’sjourney encompasses the entire lifecycle of spices, creating a cycle of purity and sustainability.

private labelling in india has become an essential aspect of the business landscape in India. It allows companies to differentiate themselves from their competitors, offer better margins, and build their brand identity. At Swani, we understand the importance of private labelling and have taken steps to ensure that our products meet the highest quality standards while offering a wide range of packaging options to our clients.

You can reach out to us with just a click on the link and enquire more.

0 notes

Text

Flow Pack Machine Market CAGR, Trends, Top Players, Analysis, Industry Size - Forecast 2032

The flow pack machine market is anticipated to US$ 4.8 Bn in 2022 and is projected to reach US$ 6.8 Bn by 2032, at a CAGR of 3.4% from 2022 to 2032. Sales in the market are expected to increase at a steady rate on the back of growing adoption of automatic machines in diverse industries such as food & beverage, personal care, and others.

The Flow Pack Machine Market is a segment within the packaging machinery industry that specializes in the production and distribution of flow pack machines. Flow pack machines, also known as horizontal flow wrappers or flow wrapping machines, are used for high-speed packaging applications in various industries. Here's an overview of the Flow Pack Machine Market:

Market Significance:

The Flow Pack Machine Market is vital for industries requiring efficient and high-speed packaging, such as food, pharmaceuticals, personal care, and household products.

These machines are essential for packaging products in airtight and tamper-evident wraps.

Flow Pack Machine Functionality:

Flow pack machines automate the process of wrapping products with a continuous film, creating a tightly sealed package around the product.

They are suitable for packaging items of different shapes and sizes, making them versatile for various industries.

Get Sample Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-15590

Types of Products Packaged:

Flow pack machines are used for packaging products like bakery goods, confectionery, fresh produce, frozen foods, medical devices, and more.

Key Features of Flow Pack Machines:

High Speed: Flow pack machines are known for their high-speed packaging capabilities, making them ideal for mass production.

Sealing Quality: They provide consistent and high-quality sealing, ensuring product freshness and safety.

Customization: These machines can be adjusted for different packaging formats, including pillow packs, gusseted bags, and more.

End-Use Industries:

The Flow Pack Machine Market caters to various industries, including food and beverages, pharmaceuticals, cosmetics, personal care, and non-food items.

Materials Used:

Packaging materials include plastic films (such as polyethylene and polypropylene), laminates, and specialty films with barrier properties.

Eco-friendly and sustainable materials are gaining traction due to environmental concerns.

Benefits of Flow Pack Machines:

Efficiency: High-speed packaging lines are cost-effective for large-scale production.

Product Protection: Flow pack packaging provides excellent protection against moisture, contaminants, and physical damage.

Tamper-Evident: The tightly sealed packages provide tamper-evident features for safety and security.

Regulatory Compliance:

Flow pack machines and packaging materials must adhere to regulatory standards, particularly in the food and pharmaceutical industries.

Technological Advancements:

Ongoing research and development efforts focus on improving machine efficiency, automation, and sustainability.

Impact of COVID-19: - The pandemic influenced packaging preferences, with increased demand for single-serve and convenience packaging, aligning with the capabilities of flow pack machines.

The Flow Pack Machine Market is an integral part of the packaging machinery sector, offering efficient and versatile solutions for packaging a wide array of products. Its high-speed capabilities and adaptability to various industries make it a vital component in modern packaging processes, meeting the demands of both manufacturers and consumers for convenience and reliability.

For More Info: https://www.futuremarketinsights.com/reports/flow-pack-machine-market

0 notes

Text

Snacks Packing Machine: Elevating Packaging Efficiency with Munky Packaging Machines

In today’s fast-paced world, the demand for ready-to-eat snacks is continuously rising. Whether it’s potato chips, popcorn, or namkeen, snack manufacturers are under constant pressure to meet the increasing consumer demand while ensuring the quality and freshness of their products. To address these challenges, Munky Packaging Machines offers state-of-the-art snacks packing machines that are designed to streamline and optimize the packaging process.

Why Choose Munky Packaging Machines for Snack Packaging?

At Munky Packaging Machines, we understand the critical role packaging plays in product quality, shelf life, and brand reputation. Our snack packing machines are engineered to provide precision, speed, and reliability, making them the ideal solution for businesses of all sizes in the snack industry.

Here are some key features and benefits of using our snacks packing machines:

1. Automated Solutions for Consistent Performance

Our snacks packing machines are fully automated, allowing for efficient and precise packaging. The automation reduces human errors and minimizes product waste, ensuring that each pack contains the exact amount of product. With Munky’s machines, you can guarantee uniform packaging across all batches, which is essential for maintaining quality standards.

2. High-Speed Weighing and Filling

Accuracy is crucial in the snack industry, especially when dealing with high-volume production. Our machines come equipped with our Made in India linear weighers that ensure each pack contains the precise weight of the snack, whether it's light and airy popcorn or denser snacks like namkeen. Once weighed, the products are transferred seamlessly to the filling station for swift and accurate filling into pouches or containers.

3. Reliable Sealing Technology

The sealing process is critical to preserving the freshness of snacks. Our machines use cutting-edge sealing technology to ensure that the packages are airtight, keeping the product crispy and fresh. From pillow pouches to stand-up pouches, the machine can handle a variety of packaging styles. Additionally, the inclusion of nitrogen flushing is an optional feature that further prolongs shelf life by replacing oxygen inside the package with nitrogen, which prevents oxidation and spoilage.

4. Versatility Across Snack Types

One of the standout features of our snacks packing machines is their versatility. They can efficiently handle a wide range of snack types, including:

Potato Chips

Popcorn

Namkeen

Roasted Dry fruits

Extruded snacks This versatility makes our machines a perfect fit for manufacturers producing multiple snack varieties under one roof.

5. Easy to Operate and Maintain

Our machines are user-friendly and come with intuitive interfaces that require minimal training for operators. This ensures smooth day-to-day operations with minimal downtime. Additionally, the machines are designed for easy maintenance, with readily accessible parts and a robust build that ensures longevity.

The Three-Step Packaging Process of Munky Snack Packing Machines

Our snacks packing machines follow a three-step process to deliver perfectly packed products every time:

Weighing The machine accurately measures the desired weight of the product before it’s packaged. This ensures consistency in every pouch, reducing wastage and maintaining cost efficiency.

Filling After weighing, the product is transferred to the filling station, where it is filled into the selected pouch or container. The filling process is smooth and precise, handling even fragile products like chips without damage.

Sealing The filled pouches are then sealed to protect the product from air and moisture. Our machines use advanced sealing technology that ensures a secure and airtight closure, maintaining the product's crunch and flavor for an extended period.

Customizable Solutions for Your Business

At Munky Packaging Machines, we know that no two businesses are alike. That’s why we offer customizable solutions to meet your specific production needs. Whether you need a machine that can handle high-volume production or one that’s capable of handling different types of snacks, we’ve got you covered. Our team works closely with clients to deliver tailor-made solutions that align with their goals.

0 notes

Text

Packing Tips for a Smooth Move, ensure a smooth and organized moving process.

Packing Tips for a Smooth Move, ensure a smooth and organized moving process.

Packing and moving is need of all peoples in the today life. Because today, lifestyle is very busy and stress-full. All peoples are running for better lifestyle. So when they promoted different place for job location or as a promotion then they need to be moved from where with all belongings for new location. In this process, all peoples need professional packers and movers Bangalore. Whose take all responsibility for safe and reliable packing and moving services Bangalore.

Welcome to professional Packers and movers Bangalore company, Bangalore. Whose very famous and most popular in Bangalore for moving services, relocation services, and new home shifting services. When we need any relocation services than we check professional packers and movers Bangalore with license and all documents. And whose providing insurance coverage for our belongings and heavy machine, car and other expensive tools etc.

Prism Lead India is a moving service providing company. Whose one of the most popular companies in the Bangalore. All peoples are like their services and gives good reviews. Their services too reliable and trustable for customers. Because this company provide professional packers and movers Bangalore. Their behavior are too good from customers, and they have only one goal that getting customers trust and positive response.

We provide safe, reliable, affordable and timely services. We use only the best packing materials, equipment and the latest technology to provide these services. Likewise, we have everything you need for a successful relocation. Prism Lead India packers and movers Bangalore can handle everything from packing to transportation. Professional packers and movers Bangalore objective is 100% customer satisfaction, And professional packers and movers Bangalore work hard to achieve it.

Here are some packing and moving tips for a smooth move

Start early: Begin packing well in advance to avoid last-minute rush and stress.

Create a packing plan: Organize your belongings into categories and label boxes accordingly to make unpacking easier.

Declutter: Get rid of items you no longer need or use. Donate, sell, or discard them to reduce the number of things you have to move.

Use quality packing materials: Invest in sturdy boxes, packing tape, bubble wrap, packing paper, and other materials to protect your items during the move.

Pack room by room: Focus on one room at a time to stay organized and ensure everything ends up in the right place in your new home.

Pack essentials separately: Pack a separate box with essentials like toiletries, important documents, a change of clothes, and basic kitchen items for the first few days in your new place.

Take photos: Before disassembling furniture or electronics, take photos to help you remember how to reassemble them later.

Label clearly: Clearly label each box with its contents and the room it belongs to. This will make unpacking much smoother.

Pack fragile items carefully: Wrap delicate items in bubble wrap or packing paper, and use cushioning materials to prevent breakage.

Use bags for soft items: Use suitcases or large bags for items like clothing, bedding, and pillows, as they are easier to carry and transport.

0 notes