#Acrylic Bending and Bonding

Explore tagged Tumblr posts

Text

Detailed List of popular Acrylic Bending Tools

Acrylic is a beautiful, versatile material. It can be used to make everything from jewelry to furniture to architectural models. There are several different methods of bending acrylic that has proven effective from time to time when working with this material:

Fabric steamer

Fabric steamers are handheld devices that use steam to soften acrylic. They can be used for a variety of things, including bending acrylic to make curved edges and corners, as well as forming plastic sheets into different shapes.

Heat gun

A heat gun is a tool that uses heat to bend acrylic. Heat guns are used in the construction industry, for example, to bend PVC pipes.

Hot air welder

A hot air welder is a tool that can be used to weld or glue acrylic together. It uses heated air to melt the pieces of acrylic into one piece of plastic. The process works by using high heat from an electric heating element in the nozzle of the tool and then sending that heat through tubes to a tip that melts both sides of the plastic together. The melted plastic becomes smooth, shiny, and clear again after cooling down.

Laser cutter

Laser cutters are machines that use a laser to cut materials. The process of laser cutting is called "laser engraving". A laser beam is focused on the material and the material heats up, melts, or vaporizes and the surface of it gets lifted away from surrounding areas creating a hole or an opening in the material. The process can be used to create objects from plastic, wood, and metal by removing parts of those materials with heat to create a design.

The oven method

If you are looking for a way for acrylic bending and bonding that is easy, then the oven method is your best option. This technique requires heat, which can be accomplished by using a heat gun or by placing the acrylic in an oven set at 350 degrees Fahrenheit for about 10 minutes. Once your project has been heated to the appropriate temperature, use a heat gun (or another tool) to bend it into its desired shape.

Thermoforming

A Thermoforming bending machine is a machine that uses heat and pressure to mold acrylic sheets into shapes. It's perfect for making signs or trophies, but can also be used to create other small items like jewelry boxes.

CNC router Takeaway:

CNC routers are used to cut, carve and engrave 3D objects. CNC routers are used to make custom signs, nameplates, and trophies. These machines can be used to cut out shapes in a variety of materials like wood, plastic, and metal. In the end, you should choose the method that best fits your project. There are many tools available to help you achieve prismatic acrylic bending. Get the knowledge of these tools deeply before planning to use any.

0 notes

Text

SFW ALPHABET HEAD-CANNONS —.✦ RAFE CAMERON

A — Admiration ⟢ What do they admire about you?

Rafe admires the way you hold yourself, he admires the fact the amount of kindness in your heart and the way you see the good in everyone! — But he won’t deny that he always will admire you physically

B — Bonding ⟢ What’s their favorite bonding activity?

Rafe loves taking you to the country club, showing you off in your little tennis skirt showing you off to all the other business men. He loves looking back before taking a hit on the golf course and seeing you either chatting with some of your girl friends or seeing you sit in the golf cart scrolling on your phone with a pout on your face.

C — Cuddling ⟢ How do they like to cuddle?

Rafe is 100% the big spoon, he loves holding you, wrapping your legs around him, feeling your head on his chest and your acrylic nails drawing shapes on his arms.

D — Dates ⟢ What are date nights like?

When Rafe chooses date nights it varies from dinner at the country club, a night on the yacht, or taking you outside Outer Banks to an upper class restaurant! (And he books a night at a fancy hotel)

E — Emotions ⟢ How do they express their emotions?

Rafe has never been one to show their emotions, it takes him a while to slowly express his emotions and when he does it’ll take him a minute. He usually shows his emotions through his body language whether it’s a clenched jaw or his knuckles turning white.

F — Future ⟢ How do they see their future with you?

Rafe sees himself marrying you and living the “all american dream” living in the mansion of Tannyhill, and he’ll be the CEO and the man of the house. All he wants is to come home to his beautiful wife dressed in a pretty sundress making dinner and their two kids playing around the house.

G — Gifts ⟢ How do they feel about gift giving?

Rafe is a huge gift giver! He absolutely loves to take you on shopping sprees, picking out clothes (especially lingerie) for you to try on, for you he doesn’t mind spending a good ten thousand dollars if it makes you smile.

H — Holding Hands ⟢ How do they hold hands?

I don’t think Rafe is a big hand holder but when he does, is hand is on top engulfing yours, gently squeezing your hand when you zone out.

I — Injury ⟢ How would they react if you got hurt?

His protective mode is on! He’ll set you down on the nearest surface and bend down to your level asking you “What happened? Did someone hurt you?” best believe if someone hurt you he will grab his gun and deal with it.

J — Jealousy ⟢ How jealous do they get?

Very!!! Rafe is a jealous and possessive man, he sees a man just talking to you and you best believe he is seething! He can’t help it, he doesn’t like seeing what’s his being around someone else!

K — Kisses ⟢ How do they like to kiss you?

It depends, it goes between him giving you a soft kiss, he usually gives these when he’s in a rush in the morning for a meeting or he’s busy trying to get a perfect shot on the golf course, but for the most part he kisses you with passion, putting his large hands around your neck bending down and picking you up, never stopping the kiss. (Sometimes the kisses get quite sloppy)

L — Love ⟢ What’s their love language?

I’d say Rafes love language is both physical touch and acts of services. He loves having a hand on you at all times, it helps him feel grounded when he feels your skin on his, plus it’s a way to show you off. Rafe loves doing things for you, it makes him feel manly and proactive, sometimes it’s him making sure you don’t bump into anything or him bringing you breakfast after a long night!

M — Morning ⟢ How are mornings spent with them?

Mornings are usually spent tangled between each other on the kings side bed, sometimes Rafe is already in the shower when you wake up and sometimes he’s on the balcony porch overlooking the backyard, he’ll be sitting on one of the couches dressed in just his grey sweatpants manspreading his legs and patting his thigh for you to join.

N — Nightmare ⟢ What is their worst fear?

Rafes worst fear is losing you, he’s so afraid that you’ll see him as he sees himself. He doesn’t want you to leave him, he can be insecure and it’ll lead him to trying to get you to be co-dependent on him sometimes.

O — Obvious ⟢ How obvious is their love to you?

It can be obvious in some cases, he isn’t the type to pull a Patrick Verona stunt and sing you a song in front of everybody, he gives subtle hints. He will drop off large bouquets of your favorite flowers and he’ll give you his overprotective nature to show you that he loves and cares for you.

P — Pet Names ⟢ What do they call you?

In public it goes between “Doll” “Sweetheart” “Baby” but he’ll say it in a bit of a condescending way! (But to preface his pet names are very different in private)

Q — Quirk ⟢ What is one of their quirks?

Rafe is a neat freak! He does not tolerate messes, it overstimulates him. Rafe can not deal with his bed being messed up or his clothing all over the floors.

R — Romance ⟢ How romantic are they?

Rafe can be romantic, like I said he doesn’t go over the top in a show off way, but in private he will. He doesn’t feel the need to show his love to you for the purpose of others but he will do anything you ask! You want to go shopping? He’s already in the car, you want to go on a vacation? He’s already preparing the private jet!

S — Show Off ⟢ Do they like to show you off?

Rafe absolutely loves it! Like I said he’s a possessive guy, so nothing feels better than to walk around Outer Banks with his hand on your lower back as you cling to his arm dressed in a cute dress and kitten heels! Oh boy does he love the way the other guys look at the two of you with faces of jealousy and envy!

T — Time ⟢ How quickly do they fall in love with you?

I think Rafe knew the moment you moved to the Outer Banks that you were the one for him, however it did take him a minute to admit it out loud.

U — Upset ⟢ How do they comfort you?

Rafe isn’t the best at comforting people but he tries for you, he’ll ask you to talk about it but he just ends up threatening whoever upsets you so now he approaches these situations by pulling you onto his lap and asking if he can do anything to help.

V — Value ⟢ What do they value most about you?

A better question is what doesn’t he value about you? Rafe finds value in everything when it comes to you, even if that value annoys the hell out of him. But overall Rafe values your sweet and loving personality, it’s a comforting and warm feeling to be around.

X — X-Ray ⟢ How easily can they read you?

Rafe can read right through you, he can tell your upset by the pout on your face and the crossed arms and the way you stomp your foot on the ground like a little bunny! He may tease you at first but just know he will always be there for you.

Y — Yearning ⟢ How easily do they miss you?

As much as Rafe tries to make you co-dependent on him, he definitely has his co-dependcy issues when your away. Even when your just gone for the day going shopping or to the spa, you best believe Rafe is constantly checking on you through messages, instagram, and even your location.

Z — Zzzz ⟢ What are nights like with him?

It depends on the nights, sometimes Rafe comes home late from work and he’ll see you cuddling his pillow waiting for his arrival, but on a normal night you two eat dinner and sometimes you’ll watch a movie and fall asleep in each others arms. (Rafe refuses to go to sleep before you do, just in case something happens!)

#cameronsbabydoll ⋆. 𐙚 ˚#rafe cameron ۶ৎ#rafe cameron#rafe x reader#rafe cameron prompt#rafe cameron x reader#rafe cameron blurb#rafe cameron fanfic#rafe cameron headcanons#rafe cameron fluff#outer banks 。𖦹°‧#rafe obx#outer banks x reader#sfw alphabet#rafe cameron x female reader#rafe cameron x you#rafe cameron x yn

178 notes

·

View notes

Text

I finished the UV Acrylic scorpions!

I designed them in cardboard and had my friend Gil_the_vlogsmith cut them with the CnC machine (thank you so much!!!)

Then, I used a heat gun to bend the back end of the body and the two tail pieces so they look more dynamic.

Then assembled each tab joint with UV cure resin for a strong bond. Plus it won't be a different color of florescent just in the joints.

They glow really well!!!

I think they look pretty good for my first time designing such a thing. 👍✨️

I'll know for next time that the claw arms need more room. I had to glue them up towards the mouth area more just so they wouldn't hit the first set of legs 😅

6 notes

·

View notes

Text

⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹

The Sin of Gluttony

⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹⊰⊹

➥ Name: Lanre Garcia-Rubio

↓ Age:

> 16 (Pre-Dionysus Complex)

> 18 (Dionysus Complex, some AUs)

> 19 (Current Hands of Misanthropy canon)

> 24 (Other)

➥ Gender: Bigender

➥ Pronouns: He/She

➥ Job: Tailor and Brand owner of Saccharine Sweet online.

➥ Where are they from: Punta Cana, Dominican Republic

➥ Where do they live: Ithaca, New York

↓ Height:

> 6’0 (Pre-Dionysus Complex)

> 6’3 (Dionysus Complex)

> 6’4 (Other)

➥ Birthday: September 23rd.

↓ Star signs:

> Libra Sun

> Pisces Moon

> Taurus Rising

↓ Likes:

╰┈➤ Music

╰┈➤ Food

╰┈➤ Partying

╰┈➤ Alcohol

╰┈➤ Designing Outfits

╰┈➤ Creating Things for People

╰┈➤ Playing Rough

╰┈➤ Amusement Parks

↓ Dislikes:

╰┈➤ Boring Things

╰┈➤ Work

╰┈➤ Chlorine

╰┈➤ Responsibilities

╰┈➤ Elitists

╰┈➤ Romance Films

╰┈➤ Long acrylics

╰┈➤ Fleece

Extra details

➥ Public personality: Lanre is well-regarded in social spaces for being “that loud guy”- he’s always playing or goofing off and taking things on the chin with a grin when they’re unpleasant. He’s open to most people who meet him, greeting strangers with a warm familiarity that encourages the growth of friendships. Lanre tends to resort to picking on people and bantering with people he may not entirely see eye to eye with as a way to bond with them. Others may describe him as careless, but he’d much prefer the word carefree- a life without its shackles of responsibilities is the life Lanre lives and idealizes. Alas, the world does not bend for him, so he simply deals with having to do menial responsibilities or the “less fun” portions of managing his tailoring business online.

CURRENT REFERENCES: (first by WillowOkami on discord and second by me!)

1 note

·

View note

Text

How Non-Ionic Softeners Reduce Static and Increase Flexibility in Fabrics

Textile manufacturing and finishing involve processes that significantly influence the quality, performance, and comfort of fabrics. One critical aspect is the use of fabric softeners to enhance the hand feel, reduce static electricity, and improve flexibility. Among various types of softeners, non-ionic softeners stand out for their effectiveness, versatility, and eco-friendliness.

In this article, we explore how non-ionic softeners help reduce static and enhance flexibility in fabrics, and why they are a preferred choice in the textile industry.

What Are Non-Ionic Softeners?

Non-ionic softeners are textile auxiliaries that lack ionic charge. Unlike cationic or anionic softeners, non-ionic softeners interact with fabric fibers through physical adsorption rather than chemical bonding. This makes them highly versatile and compatible with a wide range of fabrics, including natural, synthetic, and blended materials.

The non-ionic nature ensures that these softeners work effectively without causing adverse reactions with dyes, finishes, or other chemical treatments, making them an ideal choice for post-treatment applications in textiles.

Static Electricity in Fabrics: The Problem

Static electricity in fabrics occurs due to the accumulation of electrical charges on the surface. This is common in synthetic materials like polyester, nylon, and acrylic, which are poor conductors of electricity. Factors contributing to static build-up include:

Friction: Generated during manufacturing, washing, or wear.

Low Humidity: Dry air exacerbates charge accumulation.

Insulation: Synthetic fabrics do not dissipate charges effectively.

Static electricity not only causes discomfort—such as clinginess and minor shocks—but also makes fabrics harder to handle during production.

How Non-Ionic Softeners Reduce Static Electricity

Non-ionic softeners combat static electricity through the following mechanisms:

Reducing Friction Non-ionic softeners form a thin lubricating layer on the surface of the fabric fibers. This layer reduces the friction between fibers, minimizing the generation of static charges during movement or wear.

Moisture Retention These softeners enhance the moisture-retention properties of fabrics by introducing hydrophilic (water-attracting) elements. Increased moisture content dissipates static charges, as water conducts electricity more effectively than dry air.

Neutral Interaction Unlike cationic or anionic softeners, which can introduce additional charges, non-ionic softeners remain electrically neutral. This neutrality helps stabilize the fabric’s charge balance, preventing excessive charge build-up.

Improved Conductivity By altering the fiber surface properties, non-ionic softeners slightly improve the material's ability to conduct charges, further mitigating static build-up.

Flexibility in Fabrics: Why It Matters

Flexibility in textiles refers to the ease with which a fabric can bend, stretch, or drape. It directly impacts the fabric’s comfort, durability, and suitability for specific applications. Stiff or rigid fabrics can feel uncomfortable to wear, restrict movement, and lose their aesthetic appeal.

How Non-Ionic Softeners Improve Flexibility

Fiber Lubrication Non-ionic softeners create a smooth coating on the fibers, reducing internal friction. This allows the fibers to move more freely, enhancing the overall flexibility of the fabric.

Softening Effect These softeners alter the fiber’s mechanical properties, making them softer and more pliable. This effect is particularly noticeable in coarser materials, such as denim or heavy cotton.

Stress Absorption By improving fiber elasticity, non-ionic softeners help fabrics absorb and distribute mechanical stress more effectively. This reduces the likelihood of tears or permanent deformation under stress.

Uniform Fabric Drape Non-ionic softeners enhance the draping quality of fabrics, ensuring they fall smoothly and conform to body movements or shapes without appearing stiff or bulky.

Applications of Non-Ionic Softeners

The versatility of non-ionic softeners makes them suitable for various applications, including:

Textile Finishing: Used as a final treatment to improve the hand feel, flexibility, and anti-static properties of fabrics.

Garment Manufacturing: Enhances the comfort and wearability of finished garments.

Blended Fabrics: Ideal for treating synthetic-natural blends, maintaining a balance of softness and performance.

Industrial Textiles: Improves handling and performance of technical fabrics, such as those used in upholstery or automotive interiors.

Advantages of Non-Ionic Softeners

Compatibility: Suitable for all fiber types, including natural and synthetic.

Eco-Friendliness: Often biodegradable, reducing environmental impact.

No Interference: Do not react with dyes, finishes, or other treatments.

Enhanced Durability: Provide long-lasting softness and anti-static properties, even after multiple washes.

Conclusion

Non-ionic softeners play a vital role in enhancing fabric performance by reducing static electricity and improving flexibility. Their neutral charge and hydrophilic properties make them an excellent choice for textile manufacturers looking to improve product quality without compromising compatibility with other treatments. As the demand for high-quality, comfortable, and versatile fabrics continues to grow, non-ionic softeners remain a cornerstone in textile finishing processes.

0 notes

Text

Experience the art of crafting bespoke transparent acrylic handbags! Our precision bending and bonding techniques ensure top-quality custom products for your brand." ✨👛

#acrylichandbag#custommanufacturing#oemservices#acrylicdesign#handcraftedquality#bespokeproducts#industrialcraftsmanship#transparentdesign#acrylicfabrication#precisionengineering#manufacturingexcellence#qualitycraftsmanship#innovation#customsolutions#madeintheusa

0 notes

Text

High-Quality Channel Letter Trim Caps in Bangalore: Elevate Your Brand Identity

Introduction

In Bangalore's vibrant urban landscape, where businesses vie for attention, the importance of captivating signage is undeniable. Channel letter signs, synonymous with modern advertising, provide a unique visibility and brand recognition advantage. The channel letter trim cap is central to these impactful signs and is essential for durability and aesthetic appeal. This guide delves into channel letter trim caps, uncovering their manufacturing process, benefits, and the unparalleled craftsmanship of Channel Letter Trim Cap Manufacturers in Bangalore.

Understanding Channel Letter Trim Caps

Channel letter trim caps serve as the border for individual letters in channel letter signage, providing structural integrity and defining the letters' shape. Crafted from high-quality materials such as aluminum, these trim caps offer resilience against environmental elements while maintaining a sleek appearance. In Bangalore, manufacturers specialize in producing channel letter trim caps that adhere to stringent quality standards, catering to the diverse needs of businesses across various industries.

The Manufacturing Process

Precision and attention to detail are paramount in Bangalore's thriving manufacturing sector. Channel letter trim caps are meticulously fabricated using advanced machinery and techniques to ensure flawless results. The process typically involves cutting aluminum coils to specific dimensions and shaping and bending them to form the desired profiles. Advanced welding and bonding methods seamlessly join the trim cap components, creating a cohesive and visually appealing product.

Advantages of Channel Letter Trim Caps

Enhanced Durability

One of the primary benefits of channel letter trim caps is their exceptional durability. Constructed from corrosion-resistant materials, such as aluminum with protective coatings, these trim caps withstand exposure to harsh weather conditions, UV radiation, and other external factors. As a result, businesses can rely on channel letter signage to maintain its integrity and visibility for years to come.

Customization Options

Channel Letter Trim Cap Manufacturers in Bangalore provide customization options for channel letter trim caps, enabling businesses to tailor their signage to match their brand identity and aesthetic preferences. From various colors and finishes to bespoke detailing, the versatility of trim caps empowers businesses to craft eye-catching signage that connects with their target audience.

Seamless Integration

Channel letter trim caps seamlessly integrate with other components of channel letter signage, such as LED modules and acrylic faces, to create a cohesive and visually impactful display. Whether illuminated or non-illuminated, channel letter signs adorned with meticulously crafted trim caps exude professionalism and sophistication, leaving a lasting impression on customers.

Applications Across Industries

Channel letter signage adorned with precision-engineered trim caps finds widespread use across diverse industries in Bangalore and beyond. From retail stores and restaurants to corporate offices and healthcare facilities, these signs serve as practical marketing tools, guiding customers to their destinations while reinforcing brand identity. With customizable options and unparalleled craftsmanship, channel letter trim caps cater to the unique requirements of each industry, ensuring maximum impact and visibility.

Choosing a Reliable Manufacturer

When choosing among Channel Letter Trim Cap Manufacturers in Bangalore, several factors come into play. It's essential to partner with a company that boasts a proven track record of excellence, adheres to industry standards, and prioritizes customer satisfaction. By selecting a reputable manufacturer, businesses can ensure that their channel letter signage meets the highest quality and craftsmanship standards, enhancing their brand presence and attracting attention in the competitive market.

FAQs (Frequently Asked Questions)

What are channel letter trim caps?

Channel letter trim caps are bordering components used in channel letter signage to provide structural support and define the shape of individual letters. They are typically made from durable materials like aluminum and play a crucial role in enhancing the appearance and longevity of signage.

How are channel letter trim caps manufactured?

Channel letter trim caps are manufactured using advanced machinery and techniques. This process involves cutting aluminum coils to specific dimensions, shaping, bending, welding, and bonding to create the desired profiles. The result is a meticulously crafted trim cap that meets stringent quality standards.

What are the benefits of using channel letter trim caps?

Channel letter trim caps offer several benefits, including enhanced durability, customization options, and seamless integration with other signage components. They withstand harsh weather conditions, allow for personalized branding, and contribute to the overall professional appearance of signage.

In which industries are channel letter trim caps commonly used?

Channel letter trim caps find widespread use across various industries, including retail, hospitality, corporate, healthcare, and more. They serve as practical marketing tools, guiding customers to establishments while reinforcing brand identity and enhancing visibility.

How can businesses choose a reliable manufacturer for channel letter trim caps?

When selecting a manufacturer, businesses should consider several factors, including their reputation, track record of excellence, industry standards adherence, and customer satisfaction commitment. By partnering with a reputable manufacturer, businesses can ensure top-tier trim caps that reflect their brand identity and meet their signage needs.

Conclusion

In conclusion, channel letter trim caps are pivotal in creating visually stunning and durable signage solutions. With their exceptional durability, customization options, and seamless integration, trim caps offer businesses in Bangalore a distinct advantage in enhancing their brand visibility and attracting customers. By partnering with reputable Channel Letter Trim Cap Manufacturers in Bangalore, companies can access top-tier trim caps that reflect their brand identity and leave a lasting impression on their target audience.

#trimcaplettermanufacturerinbangalore, #channellettertrimcapmanufacturerinbangalore, #trimcapforsignsmanufacturerinbangalore, #trimcapsignagemanufacturerinbangalore,

#trimcaplettermanufacturerinbangalore#channellettertrimcapmanufacturerinbangalore#trimcapforsignsmanufacturerinbangalore#trimcapsignagemanufacturerinbangalore

0 notes

Text

What is FPC (Flexible Printed Circuit)?

1 Overview

FPC, also known as flexible printed circuit, is favored due to its lightweight, thin thickness, free bending and folding, and other excellent characteristics. With the rapid development of the electronics industry, circuit board design is increasingly moving towards high precision and high density. Traditional manual inspection methods can no longer meet production needs, and automatic defect detection of FPC has become an inevitable trend in industrial development.

Flexible printed circuit (FPC) is a technology developed by the United States in the 1970s to develop aerospace rocket technology. It is made of polyester film or polyimide as a substrate, with high reliability and good flexibility. By embedding circuit designs on flexible thin plastic sheets, a large number of precision components can be stacked in narrow and limited spaces to form flexible circuits. This circuit can be bent and folded at will, with light weight, small volume, good heat dissipation, and convenient installation, breaking through traditional interconnection technologies. In the structure of flexible circuits, materials include insulating films, conductors, and adhesives. Flexible printed circuits are the only solution that meets the requirements of miniaturization and mobility of electronic products. Flexible printed circuits can greatly reduce the volume and weight of electronic products, making them suitable for the development of electronic products towards high density, miniaturization, and high reliability.

2 FPC Composite Materials

Insulation Film:

Insulation films form the base layer of the circuit, and adhesives bond the copper foil to the insulation layer. In multi-layer designs, it is bonded to the inner layers. They are also used as protective covers to protect the circuit from dust and moisture and reduce stress during bending. Copper foil forms the conductive layer.

In some flexible circuits, the use of rigid elements made of aluminum or stainless steel can provide dimensional stability, provide physical support for the placement of components and wires, and eliminate stress. Adhesives bond the rigid elements and flexible circuits together. In addition, another material sometimes used in flexible circuits is the bonding layer, which is formed by applying adhesive to both sides of the insulation film. The bonding layer provides environmentally friendly and electrical insulation functions and can eliminate one layer of film, with the ability to bond multiple layers with a small amount of layers.

There are many types of insulation film materials, but the most commonly used are polyimide and polyester materials. Nearly 80% of all flexible circuit manufacturers in the United States use polyimide film materials, and about 20% use polyester film materials. Polyimide materials are non-flammable, geometrically stable, have high tear strength, and withstand welding temperatures. Polyester, also known as polyethylene terephthalate (PET), has physical properties similar to those of polyimide, has a lower dielectric constant, absorbs less moisture, but is not resistant to high temperatures. The melting point of polyester is 250°C, and the glass transition temperature (Tg) is 80°C, which limits their use in applications that require a large number of terminal welds. In low-temperature applications, they exhibit stiffness. However, they are suitable for mobile phones and other products that do not need to be exposed to harsh environments. Polyimide insulation films are usually combined with polyimide or acrylic adhesives, and polyester insulation materials are generally combined with polyester adhesives.

Conductors:

Copper foil is suitable for use in flexible circuits. It can be electroplated (ED) or electroplated. One side of the electroplated copper foil has a glossy surface, while the other side of the processed surface is dull. It is a flexible material that can be made in many thicknesses and widths. The matte surface of ED copper foil is often specially treated to improve its adhesion capacity. Forged copper foil, in addition to being flexible, also has the characteristics of rigidity and smoothness. Suitable for applications requiring dynamic deflection.

Adhesives:

Adhesives not only bond the insulation film to the conductive material but can also serve as a cover layer, as a protective coating, and as a cover coating. The main difference between the two lies in the application method used. The cover layer bonds with the cover insulation film to form a circuit with a laminated structure. Screen printing technology is used for the coverage and coating of adhesives. Not all laminate structures contain adhesives, and laminate structures without adhesives form thinner circuits and greater flexibility. Compared to adhesive-based laminate structures, it has better thermal conductivity. Since the thin structure of the non-adhesive flexible circuit and the elimination of the thermal resistance of the adhesive improve thermal conductivity. It can be used in working environments where adhesive-based laminate structures cannot be used.

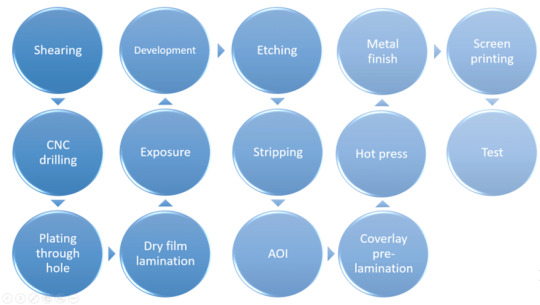

#3 FPC production process

#4 Advantages of Flexible Printed Circuits

Flexible printed circuit boards are printed circuits made of flexible insulating substrates, which have many advantages that rigid printed circuit boards do not have:

Flexible printed circuit boards Can bend freely, coil, fold, can be arranged according to any space layout requirements, and can move and expand in three-dimensional space.

The use of FPC can greatly reduce the volume and weight of electronic products, making them suitable for the development of electronic products towards high density, miniaturization, and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communication, notebook computers, computer peripherals, pdas, digital cameras and other fields or products.

FPC also has good heat dissipation and weldability, is easy to assemble, and has overall low cost advantages. The combination of soft and hard design also compensates to some extent for the slight lack of component carrying capacity of flexible substrates.

#5 FPC soldering operation steps

Before soldering, apply soldering flux to the pads and treat them with a soldering iron to prevent poor tin plating or oxidation of the pads from causing poor soldering. Chips generally do not require processing.

Use tweezers to carefully place the PQFP chip on the PCB board to avoid damaging the pins. Align it with the pad and ensure that the chip is placed in the correct direction. Adjust the temperature of the soldering iron to above 300 degrees Celsius, apply a small amount of solder to the tip of the soldering iron, press down the aligned chip with a tool, and add a small amount of solder to two diagonal pins. Hold the chip down and solder the pins at the two diagonal positions to secure the chip in place. After soldering the diagonals, recheck the alignment of the chip position. If necessary, adjust or remove and readjust the position on the PCB board.

When starting to solder all the pins, add solder to the tip of the soldering iron and apply soldering flux to all the pins to keep them moist. Touch the end of each pin of the chip with the tip of the soldering iron until you see the solder flowing into the pin. When soldering, the tip of the soldering iron should be parallel to the soldering pin to prevent overlapping due to excessive soldering.

After soldering all the pins, moisten all the pins with flux to clean the solder. Suck up any excess solder to eliminate any shorts or overlaps. Finally, use tweezers to check for misaligned soldering. After checking, remove the solder from the circuit board, soak a stiff brush in alcohol, and carefully wipe along the pin direction until the solder disappears.

SMD resistor-capacitor components are relatively easy to solder. You can first place it on the pad, then place one end of the component on it, use tweezers to hold the component, and then solder one end before checking if it is placed correctly. If it is already aligned, then solder the other end.

Click here for more information:https://fpcway.com/

0 notes

Text

Kapoor Plastics: Your Best Supplier of Acrylic Sheets and Panels

Welcome to your ultimate source for premium acrylic solutions. Whether you're seeking vibrant coloured acrylic sheets, durable acrylic boards, or crystal-clear acrylic panels, Best Supplier of Acrylic Sheets offers the best deals and quality you can rely on. As an authorized dealer of Acrylic Sheets, we provide an extensive range of acrylic products tailored to meet the demands of both creative projects and commercial applications.

Unmatched Variety of Acrylic Sheets

Top distributors of Acrylics sheets offer a diverse range of acrylic products, including both coloured acrylic sheets and acrylic boards. Coloured acrylic sheets come in a spectrum of hues, perfect for a variety of applications, from creative projects to commercial displays. Each sheet promises vibrant color, durability, and excellent light transmission.

Why Choose Kapoor Plastics?

Authorized Dealer Excellence: As an authorized dealer, we provide not only top-quality clear acrylic sheets but also personalized customer service that helps you find the perfect product for your needs.

Proximity and Convenience: Searching for an "acrylic sheet near me"? Our strategically located stores ensure that you have quick and easy access to our products no matter where you are.

Best Deals Guaranteed: Kapoor Plastics is recognized for offering competitive prices without compromising on quality. Our tagline, 'Kapoor Plastics best dealer of clear acrylic sheet,' isn't just a claim—it's a promise.

Applications of Acrylic Panels

Acrylic panels are versatile and can be used in numerous settings. Their impact resistance and clarity make them ideal for construction projects, signage, and even as protective barriers in today's health-conscious environment. They are easy to work with, whether you are cutting to size, bending, or bonding, making them suitable for both professionals and DIY enthusiasts.

Visit Us Today

To explore our full range of products and take advantage of the best deals, visit our website or stop by one of our locations. At Kapoor Plastics, we are committed to providing not just acrylic sheets but complete solutions that cater to all your acrylic needs.

Conclusion

Whether you are a seasoned contractor or a creative individual, Kapoor Plastics is your go-to supplier for all things acrylic. With our commitment to quality, variety, and customer satisfaction, we are here to support your projects with the best materials in the market. Visit us today and experience why we are the top supplier of acrylic sheets and Panels.

Source: https://kapoorplastics.jigsy.com/entries/business/kapoor-plastics-your-best-supplier-of-acrylic-sheets-and-panels

#coloured acrylic sheets#Acrylic Sheets#acrylic sheet near me#Acrylic panels#acrylic sheets and Panels

0 notes

Text

Introduction of material for touch screen OCA optical bonding

With the development of technology, more and more of our electronic devices, especially the development of touch screens, are getting higher and higher for the optical materials for the structure of optical bonding, which are required to have colorless transparency, light transmittance of more than 98%, good bonding strength, can be cured at room temperature or medium temperature, and have the characteristics of small curing shrinkage, this adhesive is called optical adhesive. Optical adhesives made of different materials such as silicone, acrylic resin, unsaturated polyester, polyurethane, epoxy resin, etc.

1. What is OCA

OCA (Optically Clear Adhesive) is a double-sided adhesive tape without matrix material obtained by making optical acrylic glue into no substrate material, and then laminating a layer of release film on the upper and lower layers.

2. Advantages of OCA

High cleanliness, high light transmittance, low haze; The thickness of the adhesive layer is uniform and the flatness is high; High adhesion and high bonding strength after lamination; Soft to soft, soft to hard, hard to hard can be fitted, and the fit material has a wide applicability.

3. OCA manufacturer

3M and TESA are the main ones, and the 3M production capacity is mainly occupied by traditional LCD manufacturers for a long time, and basically occupies the highest-end market; Mitsubishi and Nitto Denko from Japan, South Korea is LG Chemical and SKC from South Korea.

4. What is OCR

OCR (Optical Clear Resin) is a kind of optical glue, because the glue is in a liquid state, it is also known as liquid optical glue, optical water glue or LOCA. After curing, the glue is colorless and transparent, with a light transmittance of more than 98%, and has the characteristics of small curing shrinkage and yellowing resistance. In the field of optical lamination, compared with traditional OCA tapes, OCR has unique advantages in large size, curved surfaces, harsh environments and other fields.

5. Advantages of OCR/LOCA

1) Strong applicability, one glue can correspond to a variety of laminating products;

2) Liquid glue has strong fluidity, is not sensitive to ink thickness, and has good gap filling;

3) It is suitable for large-size lamination, and there is no restriction on the size of the laminating product;

4) It is suitable for surface lamination or complex structure lamination;

5) High lamination yield and good rework performance;

6) Chemical bonding, the bonding is less affected by temperature, and the bonding stability is strong.

6. OCR/LOCA production companies are: Wacker, Henkel, Momentive, DuPont;

SAEF Technology is committed to providing complete solutions for functional materials for the smart and touch industries, and has developed high-sensitivity silicone OCR products for touch screens that are used in the optical lamination process of display components such as cover glass, touch sensors and LCD modules. The combination of silicone OCR and A/R glass perfectly solves the problem of light loss in the air layer between the touch screen and the display panel, which can increase the contrast by 400% in sunlight and improve the visibility of the touch screen inside and outside. Silicone OCR for high-sensitivity touch panels can be used for a long time in the range of -50-200°C, which improves the reliable performance of the display and thus extends the life of the display product. Compared with frame-mounted components, silicone OCR/LOCA for high-sensitivity touch screens can also reduce the impact of external impacts, improve impact resistance and bending strength, and increase the reliability of touch screens. Liquid silicone OCR enables a wide range of product adhesion thicknesses, better fills gaps between inks and coatings, and enables thinner designs.

Source URL: https://www.lcdoleddisplay.com/introduction-of-material-for-touch-screen-oca-optical-bonding/

0 notes

Text

Membrane Switch

Membrane Switch

A membrane switch or more precisely a standard membrane switch assembly is comprised of several flexible layers that make up a complete switch package. This assembly can have as few as one active area (key or button) to several dozen active areas. A custom membrane panel switch is an interface between man and machine, which enables an operator to communicate with equipment, instrumentation, or machinery. Subsequently, this allows the operator to communicate with the device, issuing commands and/or performing other operations. The operator presses the membrane control panel when he or she wants to control the device.

Why choose our membrane switch?

Construction of Membrane Switch

Graphic Overlay – PET/PC is usually the overlay material of choice due to its fantastic chemical resistance and flex property. Komkey offers membrane switch customized design services such as digital printing, screen-printing, or apply both methods to ensure you get the right colors, textures and finish your membrane switch design requirements.

Adhesive Overlay – This adhesive layer sticks the membrane switch overlay to the top circuit layer, and is usually an acrylic adhesive. The material is the same as the fourth layer. Only the thickness is maybe different according to the actual situation.

Top Circuit Layer – The material of this layer is specific. It is a 0.1mm thickness thermostable PET film printed with conductive silver ink and also dielectric oil, which used for fastening metal domes.

Circuit Spacer – This layer separates the top circuit from the bottom circuit so that the touch membrane remains normally break until the membrane switch keypad is pressed. The circuit spacer is a polyester spacer with adhesive on both sides.

Lower Circuit Layer – This layer is a 0.1mm-0.25mm thickness thermostable PET film printed with conductive silver ink and also dielectric oil. This layer terminates as a flexible tail that serves as an interconnector to controller PCBs or other IC.

Rear Adhesive – This adhesive layer bonds the entire membrane switch to the product surface, housing, or to a rigid support panel. Komkey, one of the membrane switch keypad suppliers, can use the proper adhesive type and thickness to bond your membrane switch to your equipment.

Membrane Switch Specification

Mechanical Properties:

Life Expectancy

Flat type ≥ 5 million times,

Tactile type ≥ 1 million times

Operation Force

Flat Type 57-284g ,Tactile Type 170-397g

Dome Rebound Time

≤6ms

Tail Bending Performance

≤180°

Switch Stroke

Flat 0.1~0.5mm,Tactile 0.6~1.5mm

Vibration

20G's max.

Thickness

0.7~1.5 mm

Electrical Properties:

Rated Voltage

≤50V DC

Rated Current

≤ 100mA

Operating Power

≤1W

Insulation Resistance

≥100MΩ (250V DC)

Loop Resistance

10Ω~2kΩ

(Depending on the design)

Contact Resistance

0.5 ~ 5Ω

(Depending on wire length and the materials)

Wire Lead Resistance

<1Ω/cm

Base Material Voltage Withstand

1500V DC

Environmental Properties:

Operation Temperature

-40°C to +80°C (-40°to 176°F)

Storage Temperature

-40°C to +85°C (-40°to 185°F)

Atmospheric Pressure

86 ~ 106 kPa

Humidity

+40°C, 90%~95%RH for 240 Hours

Why Choose Our Membrane Switch?

Our Membrane Switch Pad Advantages

Beautiful appearance, Variety color printing.

Small size, light in weight, good tactility, Long life span.

moisture-proof, dustproof, waterproof, anti-corrosion, and erosion of harmful gases proof.

Easy to operate, intuitive, safe and reliable

Cost-effective, convenient installation

Komkey is one of the reliable membrane keyboard suppliers offering custom membrane keypad design service

Customized specification is available, the Smaller volume can be accepted.

Customized logo/Brand/Contact way can be printed in the overlay for advertisement.

https://www.kom-key.com/membrane-switch/

0 notes

Link

We are one of the leading companies in Acrylic Product Manufacturers and Suppliers in Dubai. Our Expert team is indulged in providing outstanding Acrylic Fabrication services in UAE.

#Acrylic Moulding and Bending Supplier in Dubai#Acrylic Fabrication in Dubai#Acrylic Fabricators in Dubai#Acrylic Moulding and Bending Dubai#Acrylic Supplier in Dubai#Acrylic Moulding and Bending#Acrylic molding in dubai#Acrylic Company in Dubai#Acrylic Display Stand Dubai#Acrylic Dubai#Acrylic UAE#Acrylic Fabrication#Acrylic Bending and Bonding#Acrylic Custom Painting#Acrylic Engraving

1 note

·

View note

Text

Paul Lewin Art

‘Messages in the Roots’ ….Acrylic on wood 24” x 30”.

Guided by the Sun and the interconnectedness of all things

She bends light towards the ancestral

Deciphering ancient transmissions hidden in genetic pathways

Strengthening bonds….

Fortifying the roots.

1 note

·

View note

Text

Six Factors to Be Considered While Manufacturing Flexible Circuit Boards for the First Time

Flexible printed circuit boards are equally popular as their rigid counterparts. When compared with rigid PCBs, the flexible printed circuit boards assure major cost savings in terms of weight and small footprint. Although the technique of flexible circuit board manufacturing has evolved over the years, there are certain factors that you need to address while building your first PCB. What are these factors? How do they contribute to the functioning of the PCBs? Read this post to know the answers.

Absolute Electronics Services provides PCB assembly rework for your existing printed circuit boards. Our service is custom to fit all your industrial needs.

Top 6 Factors That You Need to Address During the Manufacturing of Flexible Circuit Boards

There are several minute details that you need to address and take care of while designing a printed circuit board. However, these six factors are quite important because the performance of your PCBs will be influenced by them.

Address the Flexibility and Bendability: Although flexible PCBs are bendable and flexible, they may impose limitations in certain applications. These limitations may result in breakage of the PCB or jeopardizing the performance of the electronic circuit. To avoid this, it is important to address the flexibility and bendability of the PCB. You need to determine the number of times, the PCBs will flex or bend. Based on this, you can decide in favor of the dynamic or static boards. Generally, the static boards can be bent only at the time of installation and they can withstand bending up to 100 times during their entire lifetime. Against this, dynamic boards can support flexing and bending the unlimited number of times. These dynamic boards are considered perfect for PCBs used in mission-critical applications.

Know the Material to Be Used: Polyimide is used for both coverlay layers as well as flexible core layers. This material maintains uniform thickness throughout the PCB. The polyimide flex cores comprise rolled annealed copper or electro-deposited copper, which is quite thin. This makes it suited for static and dynamic applications. You can find two types of flexible polyimide materials – an adhesive-based material where the copper is bonded to the polyimide using an acrylic adhesive, and an adhesive-less material where the copper is cast directly on the polyimide. Each of these materials possesses their advantages and disadvantages, so you need to choose them wisely.

Address the Flex Trace Routing: The layout of the circuit plays a key role in the functioning of the PCB. It can make or break a PCB. You can choose between angular traces and curved traces. Curved traces are considered better over angled ones because they cause less stress to the board. It is recommended to reduce I-beaming or avoid it altogether to minimize the stress on the boards.

Protect the Flexible Layers: The flexible layers of flexible circuit boards can be protected by placing them at the center of the stack-up. This helps avoid exposure of the layer to the plating of the outer layer. This placement of a flexible layer in the middle of the stack-up also helps simplify the overall manufacturing procedure, as well as improve control and impedance.

Secure the Vias: Several reasons lead to the failure of flexible PCBs, and the presence of vias is one of them. It is known to tear down the PCB design. To avoid this, it is always recommended to use tear-dropped vias.

RF and EMI Shielding Options: Flexible circuit boards may be subjected to emitting or receiving radio frequency (RF) and electromagnetic (EM) waves. To avoid this, additional external copper layers are added. They can be added as cross-hatched or solid hatched planes, which are connected to the ground, and signal layers are sandwiched between them. You can also use shielding films and silver ink shield layers to minimize RF and EMI interferences. Each of these components has their own benefits and disadvantages, which need to be understood and the right decision must be made.

By now you may have realized how different factors contribute to the performance of these flexible circuit boards. You can get these factors right by partnering with a trusted and experienced PCB manufacturer. Owing to the popularity of these components, today, it is quite easy to find PCB manufacturers and assemblers specializing in PCB assembling; however, all may not serve your purpose. Twisted Traces is one of the leading manufacturers of flexible circuit boards in the US and has been serving clients across industries like medical, military, and defense, and commercial electronics by offering them performance-driven PCBs. The company also provides rigid and rigid-flex PCBs. The experts at the company will guide you on these important factors irrespective of whether you are building the PCB for the first time or nth time.

1 note

·

View note

Text

Something There - Nick Burkhardt

Pairing: Nick Burkhardt x reader

Requested: Yes!

Warnings/notes: Some Nick fluff for Anon, although I failed miserably in including the fluff. xD It kinda sucks and the title is even worse, but I hope it’s readable, anyways. Feel free to request more Nick imagines because I kinda feel like I need to make up for this crap. xD

Wordcount: 2215

Summary: You and Nick have been friends for years, and have had an unspoken bond just as long. On a night out at a bar with Juliette and Rosalee, he turns up and saves you from getting hit on by a sleaze.

”I don’t get why you don’t just get it over and done with!” Juliette groaned for probably the hundredth time that evening, slapping your arm and jumping slightly in her seat like a child would when not getting their way.

Her childish antics made you roll your eyes, before letting them swipe over the busy room. Right and left men and women were mingling, shouting, singing and making out. Ignoring your friend, you lazily sipped your mojito.

If you were going to get through this night without pushing her off her barstool, you were going to need a stronger drink.

“Aw, she’s ignoring us now.” Rosalee then joined in from the other side of you, leaning forward on the bar, her chin resting on the palm of her hand.

You scoffed, letting the black straw slip out of your mouth. “Yeah, because you’ve been nagging me about the same thing since we got here. And we’ve been here for over an hour.”

“Hey, don’t be like that.” Juliette smiled, nudging your side with her elbow. “We’re just having a bit of fun.”

“The sexual tension between you two is insane, everyone but the two of you can see it.”

Your hand came to slap your face in annoyance at Rosalee’s words, wanting nothing more in the world than for this conversation to be over and done with already.

“Why are you two so hell-bent on me getting with Nick? You’re his ex, and him and I work together. Us getting together is not something that would end well.” You questioned, taking another sip of your drink, although this time you were more pissed than annoyed.

Juliette snorted. “We went out on two dates, we didn’t even kiss so I most definitely wouldn’t call him my ex. You need to get laid, (Y/N) and like Rosalee said, the sexual tension between you and Nick is out of this world and frankly, it’s starting to get on everyone’s nerves that neither of you are doing anything about it. So, who better fit for the job of taking your innocence away?”

You raised an eyebrow at this, turning to look at Juliette with an unimpressed look. “I’m twenty-nine, you do know I’m not a virgin, right?”

“I mean, you might as well be. You haven’t been with anyone in two and a half years.” She snorted.

“Neither have you, so you’re one to talk.” You scoffed back, bending your head down to once again capture the straw between your lips. When greeted with silence, however, you left your previous task at hand and turned your head to look between your two friends, who both awkwardly avoided your eyes.

Your eyes widened as they set on Juliette innocently sipping her own drink. “Are you serious?” You asked. “You slept with someone and you told Rosalee, but not me? Your best friend since practically diapers?”

“It happened just before you were shot on that one case, I was on my way calling you when Rosalee turned up to tell me you were in the hospital, so I just ended up telling her on the way and then it slipped my mind.” Juliette defended quickly, eyes widening to match your own.

You glared at her, but nonetheless grumbled understandingly. “Who was it then?”

Juliette opened her mouth to speak, but before she could utter a word, Rosalee spoke from the other side. “Your captain.” She giggled.

You whipped around to look at the Fuchsbau, eyes wide, before turning back to Juliette, whose cheeks were now tinted bright red. “Are you serious?!”

Juliette opened her mouth once again, but no words came out, allowing you the silence you needed to break into a fit of laughter, head falling backwards in the process. You clapped your hands in joy, surely earning you the attention of a few people close by, but you couldn’t care less.

“Oh, this is golden.” You laughed, eyes twinkling in amusement. “Was it good?”

The redhead choked on her drink at the question, hand coming to slap gently on her chest. “W-what?”

“Was he good?” You repeated, a teasing smirk now resting on your bright red lips as you awaited the answer. However, before she could form the words, a rather buff body squeezed its way in between the barstools you and Juliette were seated at.

Looking up, you were met with the face of an alright-looking guy in his mid-30’s. Or well, had it not been for the nasty grin he wore on his bearded face you’re sure he would’ve been rather easy on the eyes, but that was not the case.

Raising an eyebrow, you turned in your seat to better be able to look at him. “Yes? Can I help you?”

The man smirked and held his hand out for you to shake which you grabbed in your own, against your better judgement, while he spoke. “I’m Mark. You were looking kind of bored with your company, so I’d thought come over and relieve you.”

The second the words left his mouth your other eyebrow shot up in surprise, and as Rosalee and Juliette both poked their heads around to join the conversation with an “Excuse me?” each, you pulled your hand out of his grip, proceeding to wipe it on your blouse for extra effect.

“If the first thing you’re going to do is insult my friends, then you can go try your luck elsewhere, though I doubt you’ll get lucky no matter where you go.” You spoke, giving him a smile as fake as the acrylic nails on your fingers.

The smile was instantly wiped of Mark’s face at the sound of your strained and rude words, instead being replaced by a glare. “That’s not a nice thing to say.” He stated, his hand shooting out to grab a hold of your bare arm.

Your eyes narrowed at the feeling of his dirty fingers against your skin, and Rosalee and Juliette exchanged a look from either side of you and Mark. God help anyone who dared put a hand on (Y/N)(Y/L/N) without her permission.

Lucky for the guy, a hand suddenly came to remove his from your arm, before you had the chance to do it yourself.

“Is there a problem here?”

Thank God.

Nick stepped up to your side, arm coming to rest around your waist protectively. You sucked in a breath at the feeling of his hand squeezing your side softly, your stomach starting to flutter at the sensation, cheeks warming up both from the proximity with Nick and the anger you were currently feeling toward Mark.

Mark looked between the two of you with narrowed eyes, before raising a finger to point between you. “You her boyfriend?”

The question threw Nick off, and he stumbled on his words, glancing at you briefly. Suddenly you felt his grip on your waist tighten, causing a small smile to tug on the corners of your lips.

While Nick was still struggling to form words, Mark continued. “Because if you’re not, I’m not leaving until I have her on my arm so I would appreciate it if you went back to wherever you came from.”

You rolled your eyes, and over the sound of the music you could barely make out the sound of Rosalee and Juliette’s offended swearing as they desperately attempted to give him a piece of their minds.

“Well, that’s just fine with me.” Nick finally answered with a calm smile as he reached his other hand into his jacket, pulling out his badge and holding it up for Mark to see. “But you’d be coming with me.”

Mark’s tough façade faltered slightly at the sight of the police badge, but only a second later a glare settled on his face. “On what charges?”

Much to your disappointment, Nick’s arm then left your waist, the detective stepping closer to Mark and getting into his face. He scanned his face for a moment, the same teasing smile he always wore resting on his lips, before he spoke. “I don’t need any.”

Mark narrowed his eyes into slits, before waving his hand in the air. “Whatever, she’s too fat, anyways.”

At the sound of that, your body moved out of your chair out of instinct, hands reaching out to land a hit on the filthy excuse of a man. But once again, Nick was there to save his ass from a not so pleasant encounter.

Nick held you down on your stool as you watched the man walk away in silence, each with different expressions on your faces. Yours was one out of pure anger, Nick’s one of mild irritation and something you couldn’t quite determine, and as you looked behind Nick at Rosalee and Juliette, you were met by suggestive hip motions and sexual faces.

You quickly adverted your eyes, heat creeping up your neck. Nick, taking note of your sudden movements and wide eyes started turning around. Not wanting him to see what the two females were doing, you brought your hand up to his cheek and turned his head to face you.

“Wha-“ Nick stuttered as his head was whipped to the side violently. When coming face to face with your wide-eyed expression, he chuckled fondly. “What are you doing?”

You smiled awkwardly. “Nothing, I, uh, I was just…” You faltered slightly at the feeling of a hand squeezing your side. Only then did you notice he was still holding your waist after holding you back from going off on that sleazebag.

You couldn’t help the small smile rising on your lips. You glanced down at his hand quietly, biting down on the inside of your lower lip. “You’re, uh, you’re still holding me. You can let go now; I think I’m calm enough to restrain myself.” You chuckled.

“Oh.” Nick’s eyes flashed down to his hand on your waist, the realization hitting him. But he didn’t remove his hand, instead just giving you a smile. “I don’t think I want to let go, though.” His other hand came to rest on the other side of your waist carefully, testing out the waters.

Your chest fluttered at the feeling and you couldn’t keep your breath from wavering. “Oh?” You asked, before looking around briefly. “Where did you come from, anyways?”

“We didn’t have any work left to do at the precinct, so we picked up Monroe and just thought it’d be fun to join you. Monroe, Wu and hank are over there getting drinks.” He filled you in, all while getting closer to your face. “We can go if you guys want to be alone.”

You offered him a half-flirty smile, your hand gingerly coming to ghost over his that still rested on your hips. “No, you can stay.” You chuckled. “I have to admit, though. This is not the Nick I’m used to.”

He froze at that, and shook his head as if shaking himself out of a trance, and the next second you felt his hands begin to lose their grip on your waist. “Sorry. I just… Seeing you get hit on, although very poorly, by that guy, made me feel some kind of way.”

He paused, looking down at you. “Look, I know it and you know it, there’s something going on between us. But I understand if you want to take things slow, seeing as we’ve been friends for over ten years. It would be a pretty big change and-”

Your hands shot out to catch his as he moved them away from you, causing him to fall quiet mid-sentence. With firm motions, you moved his hands right back to where they had rested a few seconds before.

He spared your touching hands a glance with a nervous chuckle, before looking back up to your face, almost feeling like he was melting inside at the look you were giving him.

“I don’t think I want to go slow, though.” You smirked up at him, imitating his previous statement and letting your hands travel up his to rest on his chest once you had secured his hands at your sides.

He grinned back, eyes twinkling with amusement. “Good.” And with that, he pulled you closer by your waist, hands sliding slightly further down to rest at the small of your back as he bent his head down and captured your lips with his.

Your hands grabbed onto the front of his maroon button-up shirt, fisting the fabric gently as he pushed you into his body.

“Go, Nick!” Monroe’s voice then came from somewhere in the room, causing the two of you to quickly break apart wide-eyed.

Turning to face the direction of their friend’s yell, you were met with the sight you had been forced to put up with all night: Rosalee and Juliette making suggestive faces at the two of you, while Hank and Monroe was cheering Nick on with big grins and Wu was watching quietly from the side with a knowing smirk.

You weren’t surprised in the slightest at your girlfriends’ actions, and usually, you weren’t one to be embarrassed. But when Nick noticed their antics, and you noticed him getting embarrassed, you couldn’t help but become so yourself.

And there went the supposed, all too real, sexual tension, right out the window.

For now.

401 notes

·

View notes

Text

The Future is Replicated - A Vorik Drabble

Fandom: Star Trek: Voyager Ship: Ensign Vorik x OC Words: 1,061 words Rating: General Warnings: I like mixing updated tech with the old Trek stuff whenever I imagine it, so forgive me for having holograms, also it’s such short self-indulgent fluff, you guys. Don’t @me

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

I had known Vorik had been watching me over his PADD as I worked, a dubious expression firmly in place, from where he sat in a chair across the table from me. The Vulcan was silent as I pulled up an ancient recipe and transferred it from my PADD to the larger holographic kitchen display. He hadn’t said anything as I began replicating ingredients from the list and arranged each bowl according to the order it would be mixed. The last straw, however, had been when I began scrolling the display to double check my recipe before adding my dry ingredients together.

“You do realize that if you wanted this ‘banana bread’ so badly, it would have been far easier to simply replicate the finished product, as opposed to all its individual components.”

I smiled to myself. I’d been waiting for something like this and I was a little surprised it had taken Vorik so long to inform me I was being nonsensical. Again. “I’m willing to bet anything that it tastes different when you bake it from scratch. Most things do.”

“You replicated all the ingredients,” he said reasonably, gesturing to the sea of bowls in front of him. “The finalized product shall be the exact same. The only variable you have introduced will be your own ability, which when compared to that of a replicator, will most certainly be found lacking.”

I threw him a half-hearted dirty look and stuck my tongue out and started mixing my dry ingredients. Where to even begin? “I like baking. I’m good at it and I miss doing it. A replicator can’t emulate the heart and soul a good baker will put into this bread—”

“It couldn’t burn it either,” he said, but I ignored him and finished loudly:

“—Or the love that’s passed on through homemade things.”

Vorik sighed and rolled his eyes. “Must you humans always do that? You insist on giving everything more meaning than it needs. It’s a very telling display of your species’ highly illogical need to pack bond with everything.”

“It’s not illogical, it helped us survive,” I reasoned as I mashed perfectly overripe bananas.

“At the beginning of your species’ development, perhaps. Pack bonding with other humans, certainly. Not now and with inanimate objects like food.”

I couldn’t help but chuckle at him. “Don’t Vulcans have any notion of pouring their hearts and souls into things they do? Beautiful things?”

“Fine art, music... Not food. Not inanimate objects that are simply necessary. Food is for sustenance and energy. It shouldn’t be romanticized.”

I laughed, and I shook my head at him. “Oh, I know Vulcans don’t romanticize their food. I’ve eaten it before.” I looked up from my mixing bowl and spatula to wink at him.

“Ha. Ha.” He tapped the end of his stylus to his PADD and shook his head back at me. Illogical creature, I could practically hear the echo of it in my mind.

I smiled to myself and switched arms to stir my thickening batter. “You’ll see, corazón. One day when we’re off this ship, I’ll make you your favorite food with all fresh and natural ingredients just for you with love from me and then you’ll understand.”

Vorik graced me with a raised brow but resumed reading his report without further comment.

There didn’t seem to be more to say. Though, I did consider trying to explain. Maybe he would understand it brought me closer to home. Maybe he’d understand if told him it reminded me of my childhood and coming home from school to freshly baked bread and a glass of milk. Maybe he’d understand if I tried to explain it felt good to use my hands to create something or that I found pleasant quiet in the monotonous task of following a recipe’s directions. But then, maybe, at the end of the day, I would still be a silly Human from the past who insisted too hard on sticking to it, however illogical it might be.

Whatever I could have said, I let it go and let the easy contentment from making things settle in my heart. A small smile spread across my face; Vorik glanced up at me from time to time as I worked.

I greased my loaf pan and meticulously spooned out thick batter until my largest glass bowl was empty. Baking was simple work, with high rewards, I thought about saying to him. For me, just imagining the smell of fresh banana bread wafting through our quarters as I sipped tea and studied warp cores was enough to make me giddy. It was a good feeling, making something from scratch, and one that I didn’t think had an equal; no matter how illogical Vorik might think it was. It was his loss, really.

Satisfied with myself, I straightened out the cricks in my back from bending over the table and wiped my fingers on the hand towel draped over my shoulder. I glanced around behind me for the oven when it struck me. Shit, had I even preheated it at all? I always forgot to do that first and now I’d have to wait for it to be ready before I could sit down. Every time.

“I had meant to ask before you began,” Vorik piped up in a strange restrained sort of voice, “but you were so adamant about baking ‘from scratch’ that I didn’t wish to spoil your carefully laid out plans with logic.”

Inwardly, I groaned and turned back to him. His eyes sparkled with something like barely concealed amusement and the corners of his lips twitched. I leaned over the table and drummed my fingers on the acrylic.

“Yes?” I prompted when Vorik didn’t continue, just kept looking annoyingly smug.

The Vulcan pushed his PADD aside with a slow, deliberate hand, and interlaced his fingers on the now empty space in front of him. Even as I dreaded the inevitable bad news he was about to drop on me, I could hardly keep the stupid smile from jumping to my lips. The penchant for the dramatic could hardly be deemed logical, and yet...

He arranged his face and fixed me with an innocent look from beneath his long lashes and delivered his lethal blow:

“How were you planning on baking your bread when conventional ovens no longer exist?”

#Star Trek: Voyager#Vorik#Ensign Vorik#Vorik x OC#Star Trek#Voy#unabashed domestic fluff#okay it's a little abashed#look I just want short sweet things okay don't @me#anyway here's the thing I promised#I have a shit ton more and I guess I am sorry#lol#post-pon farr#otp: Never Tear Us Apart#Fiend writes

35 notes

·

View notes