#Ac Pcb

Explore tagged Tumblr posts

Text

A Comprehensive Guide to Circuit Card Assembly

Introduction

Circuit Card Assembly (CCA) is a critical process in the electronics manufacturing industry, involving the assembly of electronic components onto a printed circuit board (PCB). This process transforms a bare PCB into a fully functional electronic assembly, enabling the operation of various devices across numerous applications.

Key Components of CCA

Printed Circuit Board (PCB):

The foundation of the assembly, a PCB consists of a non-conductive substrate with conductive pathways etched onto it, connecting different components.

Soldering Techniques:

Different methods are employed to attach components to the PCB:

Hand Soldering: Used for small-scale or repair work.

Wave Soldering: Suitable for through-hole components; the board passes over a wave of molten solder.

Surface Mount Technology (SMT): Allows for the mounting of components directly onto the surface of the PCB, facilitating high-density assemblies.

The CCA Process

1. Design and Layout:

The assembly begins with the design of the PCB using Computer-Aided Design (CAD) software. This step involves laying out the components and their interconnections.

2. Component Placement:

Once the PCB is fabricated, components are placed on the board. Automated pick-and-place machines are commonly used to ensure precision and efficiency.

3. Soldering:

After placement, components are soldered to the PCB using one of the aforementioned techniques. Proper soldering is essential to create reliable electrical connections.

4. Inspection:

The assembled boards undergo inspection to check for defects, misalignments, or soldering issues. Techniques such as automated optical inspection (AOI) are often used.

5. Testing:

Functional testing is performed to verify that the assembly meets design specifications. This may include in-circuit testing, where each component's functionality is checked, and final functional tests to assess overall performance.

Quality Assurance

Quality assurance is paramount in CCA, involving rigorous testing and inspection processes to ensure that assembled boards meet industry standards. Common practices include:

ISO Certification: Many manufacturers adhere to ISO standards to ensure quality management.

Environmental Testing: Assemblies may undergo thermal cycling, humidity, and vibration tests to simulate real-world conditions.

Reliability Testing: Long-term tests assess the durability and performance of the assembly over time.

Applications of Circuit Card Assembly

CCAs are used in a wide range of industries, including:

Consumer Electronics: Smartphones, tablets, and home appliances.

Industrial Equipment: Robotics, automation systems, and control panels.

Medical Devices: Diagnostic equipment, monitoring devices, and surgical tools.

Telecommunications: Network devices, routers, and communication systems.

Automotive: Control units, infotainment systems, and safety features.

Conclusion

Circuit Card Assembly is a fundamental process in electronics manufacturing, bridging the gap between design and functionality. By transforming raw PCBs into operational assemblies, CCA plays a crucial role in the performance and reliability of electronic devices. As technology advances, innovations in assembly techniques and quality assurance continue to enhance the efficiency and capabilities of CCAs across diverse applications.

1 note

·

View note

Text

Capacitor blocks DC

and

Inductor blocks AC

4 notes

·

View notes

Text

PCB Repair for Industrial Machinery

Printed Circuit Boards (PCBs) are the heart and soul of modern industrial machinery. They control the operation of various components, ensuring seamless functioning. However, PCBs can malfunction due to various factors, leading to downtime and operational inefficiencies. When it comes to PCB repair for industrial machinery, choosing a reliable and experienced service provider is crucial. Shreemeera Electronic Services, based in Pune, offers comprehensive PCB repair solutions for all types of industrial machinery, including AC DC, Servo, and VFD drives repair services.

Common PCB Failures in Industrial Machinery

PCBs in industrial machinery can fail due to several reasons, including:

Component failures: Individual components on the PCB, such as resistors, capacitors, transistors, and integrated circuits, can malfunction or fail.

Open circuits: Breaks or disconnections in the conductive traces on the PCB can prevent current flow.

Short circuits: When conductive traces come into contact with each other, it can cause excessive current to flow, leading to damage.

Corrosion: Exposure to moisture, chemicals, or high temperatures can cause corrosion on the PCB, affecting its conductivity.

Physical damage: Accidental drops, impacts, or mishandling can cause physical damage to the PCB, leading to fractures or broken traces.

The Importance of Timely PCB Repair

PCB failures can have significant consequences for industrial operations. Downtime caused by faulty PCBs can lead to production losses, increased costs, and decreased efficiency. Therefore, it is essential to address PCB issues promptly to minimize disruptions and maintain optimal performance.

Shreemeera Electronic Services is a leading provider of industrial machine PCB repair services in Pune. With years of experience and expertise, they offer comprehensive solutions to address a wide range of PCB problems. Their team of skilled technicians is equipped with state-of-the-art equipment and diagnostic tools to accurately identify and rectify PCB failures.

Services Offered by Shreemeera Electronic Services

PCB repair and replacement: Shreemeera Electronic Services can repair damaged PCBs or replace faulty components to restore functionality.

PCB inspection and testing: They conduct thorough inspections to identify potential issues and perform diagnostic tests to pinpoint the root cause of problems.

PCB cleaning and maintenance: Regular cleaning and maintenance can help prevent PCB failures and extend their lifespan.

PCB reverse engineering: For obsolete or hard-to-find PCBs, Shreemeera Electronic Services can reverse engineer the board to create a replacement.

Emergency PCB repair: They offer emergency repair services to minimize downtime and ensure rapid restoration of operations.

Why Choose Shreemeera Electronic Services?

Expertise and experience: Their team of technicians has extensive experience in PCB repair for industrial machinery.

State-of-the-art equipment: They use advanced diagnostic tools and equipment for accurate diagnosis and repair.

Quick turnaround time: Shreemeera Electronic Services strives to provide timely repairs to minimize downtime.

Quality assurance: They adhere to strict quality standards to ensure the reliability and performance of repaired PCBs.

Competitive pricing: They offer competitive pricing without compromising on quality.

By choosing Shreemeera Electronic Services for your industrial machine PCB repair needs, you can be confident in their ability to provide reliable and efficient solutions. Their expertise and commitment to customer satisfaction make them a trusted partner for businesses across various industries.

#ac dc drives repair services in pune#industrial machine pcb repair services in pune#pcb repair services in pune#shreemeera electronic services

1 note

·

View note

Text

The Ultimate Guide to Buying an Air Conditioner

Hitachi Cooling & Heating India is a distinguished name in the air conditioning industry. Air conditioners from the brand blend cutting-edge technology with a promise of an unmatched user experience. The air Home Inverter series with ‘Yoshi’ and ‘IZen’ range are equally highly rated on aspects of aesthetics and par excellence in cooling performance. Yoshi, a 5-star inverter ac series, iZen, a 3-star inverter ac series are equipped with features that cater user’s air conditioning requirements.

Here are some of the advanced features and technologies offered by Hitachi ACs:

Ice Clean Feature Powered by Frost Wash Technology

This feature eliminates dust, mold, viruses and bacteria with Freeze-Melt-Dry process to promote clean air throw. The revolutionary Frost Wash technology enhances air quality but also prolongs the lifespan of the air conditioner, offering unmatched reliability.

Xpandable+ Feature

Hitachi ACs come with Xpandable+ feature that adjusts the rotation per minute as per the ambient conditions and the load requirement inside the room. This allows the indoor unit to maintain the set temperature inside the room, while also reducing the humidity level.

Long air throw Feature

The Long air throw feature in Hitachi ACs allows the indoor unit to cool the room faster with less energy consumption. As the air throw bounces back from the wall and gets filled in every nook and corner of the room maintaining the set temperature across the room.

Air Cloud Go, Wi Fi- enabled ACs

With features such as air Cloud Go and Smart-Fence, consumers gain unparalleled control over temperature settings, on/off timer, etc. from a single app through their smartphone, digital device, or voice assistant on their mobile for conveniently managing temperature.

Conclusion

In summary, Hitachi Cooling & Heating's technologically advanced air conditioners stand out in the market due to their innovative features. The ice Clean feature powered by Frost Wash technology ensures clean and fresh air, while the Xpandable+ functionality provides adaptive cooling for superior performance. Moreover, the Long air throw feature ensures wide coverage and even cooling in large rooms. By incorporating these advanced features, Hitachi Cooling & Heating has reimagined the air conditioning experience, offering efficient cooling, flexibility in installation, and a cleaner environment for ultimate comfort.

#air conditioner pcb price in india#1.25 ton ac#ac online india#air conditioner 2 ton price#air conditioner amc price#air conditioner price 1 ton#best 3 star air conditioner#air conditioner 1.5 ton 5 star online#air conditioner 2 ton 5 star

0 notes

Text

1 note

·

View note

Text

AC REPAIRING COURSE | AC REPAIRING COURSE IN TILAK NAGAR DELHI

Learn the art of AC and PCB repair with our comprehensive AC Repairing Course in Tilak Nagar, Delhi at AC PCB Repairing Institute! This course is tailored towards anyone interested in repairing air conditioners (ACs) and printed circuit boards (PCBs), including AC troubleshooting and repair as well as PCB soldering and testing. All essential topics will be covered - everything from AC troubleshooting and repair through soldering/testing for testing purposes to soldering/tuning the components themselves!

Experienced instructors teach this course and will equip you with all of the knowledge and tools to become a successful AC repair technician. After taking this course, you will be able to, Troubleshoot and repair ACs of All Kinds, Solder PCBs with Soldering Machine, AC Compressor Repair Service Utilize test equipment to diagnose AC and PCB problems. This course is the ideal way to begin or advance a career in AC repairing so register now in our comprehensive AC Repairing Course in Tilak Nagar Delhi to take your first step toward becoming a certified technician! The institute also provide the online mode education so anyone can join the course & learn from anywhere at anytime in the world according to his schedule.

#AC PCB Repairing Course#Ac PCB Repairing Institute in Delhi#AC PCB Repairing Training#AC Repairing Course in Tilak Nagar Delhi#AC PCB Repair Repairing Course#Air Conditioner Repair#AC Repairing Technician#AC Repairing Training#AC Repairing Course#AC Repairing Certification#AC Repairing Jobs#AC Repairing Business

1 note

·

View note

Text

Get the job AC Technician Course in Dubai || AC Mechanic Course in Dubai

#ac repair#pcb repairing course#ac technician#ac mechanic near me#ac mechanic course#ac repairing institute#hvac repair

0 notes

Text

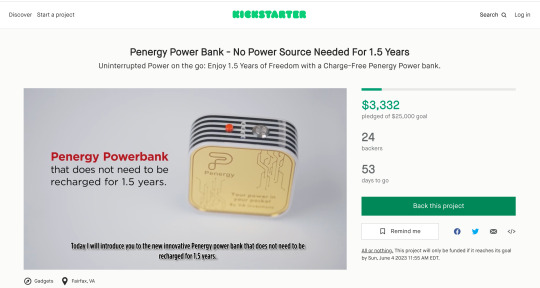

I just found my new favorite Kickstarter scam. It becomes more efficient by switching to the triangle.

"The Alternating Current (AC) produced in the generator is being rectified into Direct Current (DC) through the PCB. There, it becomes more efficient by switching to the Triangle*."

IT BECOMES MORE EFFICIENT BY SWITCHING TO THE TRIANGLE

IT BECOMES MORE EFFICIENT BY SWITCHING TO THE TRIANGLE

17K notes

·

View notes

Text

schottky diode smd - PCB Antenna

A diode is a two-terminal electronic component that allows current to flow in one direction while blocking it in the other direction. It is a semiconductor device made up of a p-type material and an n-type material, which are joined together to form a p-n junction.

Diodes are commonly used in electronic circuits for a variety of purposes, such as rectification (converting AC to DC), voltage regulation, and signal modulation. They are also used in power supply circuits, lighting circuits, and electronic displays.

#pcb components#diodes#types of pcb components#types of diodes#pcb components in os#zener diodes#pcb component adhesive#schottky diodes#pcb component assembly#light emitting diodes#pcb component antenna#laser diodes#pcb active components#diodes and transistors#ac pcb components#diodes and triodes#adhesive for pcb components#diodes basics#pcb components buy#"#diodes circuits#pcb board components#diodes cost#pcb basic components#diodes company#pcb buried components#diodes capacitors resistors

0 notes

Text

Top Hitachi Inverter AC Pcb Price

Need to find the top hitachi inverter ac pcb price near store. The price of an Inverter AC PCB (Printed Circuit Board) can vary depending on the brand, model, and specific requirements. Browse the website for more info.

0 notes

Text

The Composition of E-Waste

Electronic waste, also known as e-waste, is made up of a wide variety of different materials. The category of waste can include everything from toys and consumer electronics to medical equipment to telecommunications equipment, all of which have differing amounts of nearly every type of common materials (plastics/polymers, glass, metals, ceramics, semiconductors, etc.). By weight, iron, plastics, aluminum, and copper make up the majority of many e-waste materials. Looking at value, though, precious and scarce metals make up most of the cost (such as gold, silver, and palladium, or selenium, tantalum, and germanium).

Beyond that, many forms of electronic waste contain toxic or hazardous chemical such as arsenic, lead, mercury, or chromium:

Batteries and cathode ray tubes often contain lead

Mercury can be found in thermostats and sensors, in gas discharge lamps and many printed circuit boards (PCBs)

Liquid crystal displays and printer inks and toners should be treated separately and chlorofluorocarbons, hydrochlorofluorocarbons, and hydrofluorocarbons can be found in electronics such as refrigerators with insulating foams

To give an example for all these facts, let's look at mobile/cell phones:

Phones are said to contain ~40 different elements

Of the most common materials by weight, phones are ~43% plastic, 7% iron, 3% aluminum, and 13% copper

Looking at precious metals, phones are ~3000ppm silver, 320ppm gold, and 120ppm palladium (approximated as over 90% of the value of the phone in terms of raw materials)

Rare earth metals can be found in many places in a phone, include the screen, circuitry, and speakers. Vibrating cell phones are usually thanks to neodymium, dysprosium, and/or praseodymium.

Phone batteries are typically lithium-ion but older phones especially can have nickel-metal-hydride or nickel-cadmium batteries

The plastic casing is typically polycarbonate and/or acrylonitrile butadiene styrene

Chargers are mostly copper and plastic, but can contain flame retardants that can include gold, cadmium, or bromine

Sources/Further Reading: (Image source - 2018 article) (2014 article) (2013 article) (ACS) (CompoundChem) (WEForum)

26 notes

·

View notes

Text

The bros, during exams

Yudhishthira

Has prepared notes

disapproves cheating

sleep deprived as usual

is giving tuitions to others even at this point

Bhima

unaware of the syllabus till the last moment

tries to study, but fails

but hey, he has home science, so who is the real winner here

"hey guys, I was wondering about the taste of potassium nitrate, should I go taste some?-"

Arjun

can and will ace this test

leaves everything behind to study #chidiyakiaankh

but still sobs to Krishna about his troubles

says that he will fail ends up scoring 99%

Nakul

spends time in making chits instead of studying

has a whole book ready about methods of cheating

cheats and ends up scoring higher than the one from whom he cheated

"why should I study when I will become a celebrity?" *flips hair*

Sahadeva

wonders why he took PCB should have pursued astronomy instead

makes all sorts of coffees before exams

aces the practicals

dutifully organizes study sessions with Yudi

#mahabharat#mahabharata#memes#mahabharat memes#yudhishthira#bhima#arjun#sahadeva#nakula#exam season is near :(((((((((#me will disappear soon T_T

35 notes

·

View notes

Text

When an iron rod is inserted between the coils the magnetic flux through coils increases. This happens because iron is a ferromagnetic substance and it lets more number of magnetic lines of force to pass through it.

1. Since, flux increases, the induced emf also increases, hence, the deflection of the galvanometer also increases.

2. Since flux increases, the inductance also increases which means that Inductive reactance of the inductor in an ac circuit will also increase. This will cause decrease in current through the circuit and hence brightness of bulb in series with inductor, will decrease.

#ac circuits#alternating current#inductance#engineering#engineering prep#physics#pcm#pcb#jee#jee 2023#neet#cbse#daily padhai updates#stressed desi high schooler content

1 note

·

View note

Text

#AC DC Drives repair services in Pune#Industrial machine PCB repair services in Pune#pcb repair services in Pune#Shreemeera Electronic Services

0 notes

Note

Sorry if you've already answered this but being a bit of a tech nerd I have to ask: how do the in-card-pacitators "scientifically" work?

okay, oh boy, my moment is here! /j

I'm sorry it took me so long to answer, I started working on a reply, saved it as a draft, and then it got buried 🥲 but I got a shovel and started digging, so here I am, several months later, with an answer!

It's long, so I put it under a read more ^^

Before I go into it, I am very much an electronics amateur and it's been a minute since I studied circuits in school, so a lot of the gaps in the "science" I filled with magic, so. Take it with a grain of salt.

The basic concepts behind the in-card-pacitators were inspired by two things: those pens that were really popular at one point that allowed you to "draw" circuits and PCBs on paper with electrically conducive ink; and static shock. I like the fan theory that ectoplasm conducts electricity really well, and since Danny has drawn sigils with ectoplasmic paint, I figured he could marry science and sigils again with the cards. If ectoplasm conducts electricity well, it seemed logical to conclude that ectoplasm is full of ions.

The show doesn't really go into how overshadowing "works", so I came up with my own explanation. When a ghost tries to overshadow someone, they have to extend their 'ectoplasmic field' and take over the electric synapses of the person's brain they're trying to control. Assuming ectoplasm operates on a different layer of reality, the electromagnetic field is an area of overlap between 'ghost stuff' and 'not ghost stuff'.

One more thing that has been touched on but not thoroughly explained in IYGABAB-verse is that: 1)ectoplasm is ectophilic; unbound ectoplasm is prone to sticking to larger sources (like: ghost cores, ectoplasm rifts, sigils, etc); and 2) ecto-ice is particularly attractive to ectoplasm; it has a "purifying" effect, but in practice this means it acts like an ecto-magnet. (important to note that although ice and ecto-ice share many qualities, like being cold and being less dense than the liquid state, ecto-ice is not actually ice, and therefore possesses qualities that ice does not have)

Okay. So all that is base level. Going back to the cards and how they work, the most important question is: how are they 'powered'? Where does the shock come from?

The idea here is inspired by static shock and what causes it. I know it's different from AC/DC electricity, so that's where ectoplasm does the heavy lifting. Because most humans don't have their own ecto-field, they wouldn't generate ecto-static (which in this case would be the transfer of ions from one ectoplasmic object to another when they rub against each other, like socks and carpet. But ghost!). Basically, the "capacitors" in the cards are made of ecto-ice, which collect these negatively charged ions, and when a ghost tries to exert their ecto-field on a person holding the card, the circuit connects and the ions jump to the ghost. Boom. They're shocked. Not unlike when you touch two charged capacitors together (to anyone reading this who doesn't know: don't do that. It's dangerous)

So that's basically how they work, and any gaps that make that not make sense scientifically....well no one really understands how magnets work, right? Blame the magnets.

#answered asks#iygabab#batburger au#in-card-pacitators#if you're thinking 'does this mean the cards are rechargeable through ambient ecto-static' the answer is you're gosh darn right they are

14 notes

·

View notes

Text

Upgrade your lighting with our LED 2835 Strip 120LEDs/m—a versatile and energy-efficient solution that offers exceptional brightness and durability. Designed for both indoor and outdoor use, this IP67 waterproof rope lighting is suitable for various applications, from outdoor decoration, false ceiling lights, architectural and decorative lighting to emergency pathway illumination. These lights work on AC 220V so can be directly plugged in without a driver, It comes with connector attached to the rope. It can also be cut every 1m and powered using unique lead free connector plug.

Note: The open and end part of the lights need to be concealed using a tape, heat shrink or silicone glue as it runs on high voltage 220v can cause issue or shock if PCB is touched directly.

2 notes

·

View notes