#3d Scanner Manufacturers

Text

Precision in Minimal Access Laparoscopic Surgery: 3D Printing Custom SILS Ports

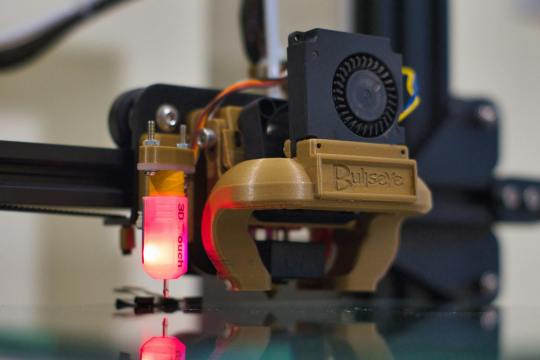

Altem Technologies Pvt Ltd's assistance proved invaluable to Victoria Hospital in Bangalore, as Altem worked together with Dr. Prem Kumar A and Dr. Nikhil S Reddy to address challenges with conventional SILS ports in laparoscopic surgery. These ports posed issues such as fixed sizes, close placement causing instrumentation difficulties, and leaks in periportal sites. Using advanced tools like the Artec 3D Space Spider 3D Scanning machine and Geomagic Design X software, they scanned and modified the ports, allowing for customization on a Stratasys 3D Printer with Polyjet Technology to ensure optimal flexibility during surgery.

This innovative collaboration between Victoria Hospital and ALTEM pioneers a new approach to rectal conditions including live surgeries, the Polyjet 3D Printer model proved successful, marking a groundbreaking achievement in laparoscopic surgery.

#3d printing#3d printing india#additive manufacturing#stratasys#3d scanner#prototyping#polyjet technology#altem

0 notes

Text

3D Printing: From Prototypes to Organ Transplants

In the last decade, the landscape of manufacturing, medical science, and even the arts have been fundamentally transformed by the advent of 3D printing technology. Once a niche tool used for the creation of simple prototypes, 3D printing has burgeoned into a revolutionary force that stands at the forefront of innovation across numerous sectors. This article delves into the journey of 3D printing,…

View On WordPress

#3D ink#3D models#3D printed organs#3D printing#3D scanners#Additive manufacturing#Aerospace#Artificial organs#Automotive#Bioengineering#Bioink#Biomaterials#Bioprinting#Biotechnology#CAD#Cellular structures#Ceramics#Creative tech#Custom-made#customization#Dental devices#Design#Design thinking#Development#Digital fabrication#Digital manufacturing#Digital models#Disruptive tech#Donor organs#efficiency

1 note

·

View note

Text

Astronomics Game Art : Designing Mining Equipment! Pt 2

Brainstorming and feedback loops

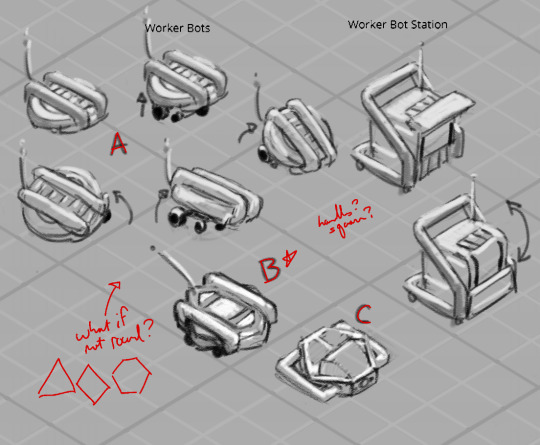

One of the first steps of designing is always brainstorming -- sometimes this starts before research, sometimes I research first, and often I go back and forth, letting brainstorming push me to the limits of my current knowledge and then taking to the internet to open up new territory. For the equipment for Astronomics (demo on steam right now!), while the design team had a few key assets they were looking for, they were also still brainstorming and so we were all kind of discovering what the equipment part of the game could be as a whole.

For me, that brainstorming usually looks like a LOT of very rough drawings. I usually have my research sketches open nearby for reference, and I try and draw small enough that i can see all my brainstorming and seek out possibility spaces between ideas.

Above is my first VERY rough brainstorming page, and on it you can see art from two passes - the softer, lighter drawings are the open-ended thinking; the darker clear lines are the second pass, where I start filtering, choosing which pieces to take to the rest of the team to start conversations with.

You can see how we would collect feedback above - i would write notes and do additional drawing on top of the submitted artwork as we went through things in screenshared video meetings, and then have these with me as I iterated further.

One thing you might notice is that these are all drawn with straight lines -- Astronomics is a low-poly 3D style game, and it was fun to think about simplifying the shapes right from the beginning. While I didn't do all my drawing like this, it was a fast and quick way to get clean linework that had some connection to the style of the game long before we really knew anything about said style!

Speaking of style...

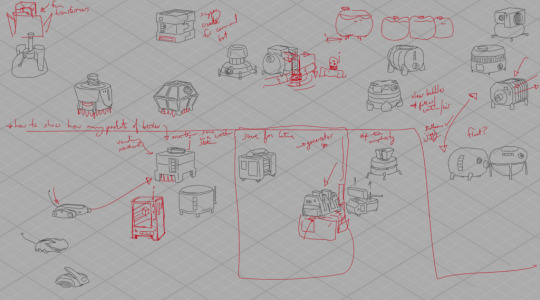

Next up, we had to make some big decisions. Astronomics has a lot of equipment with a big range of functions and scales and the most important thing was making sure it all read like equipment from the same manufacturer - that being CubeCorp, as you'll see in the demo. I narrowed it down to three possibilities:

I went in three directions -- "Star Wars" style, all panel lines and chamfered edges and a sense of overall complexity; "Safety" style, with safety bars and frames around everything, focusing otherwise on simple, chunky shapes; and "Modern" style, exploring simple silhouettes with hidden complexity.

(none of these are official names for known styles, eg, the star wars style didn't actual aim for matching the style in those films particularly -- these names were more mnemonic devices to help me quickly sum up what I was thinking in a punchy way, and help my coworkers refer to the styles more easily in conversation while we discussed an debated direction together.)

In the end, what we chose was mostly Safety-styled, but elements from both other directions made their way in too!

And here was my first sheet ft a pass on the drill, pump and vaccuum, containers for solids, liquids and gasses, a worker bot, a worker bot home, and a robust scanner machine.

A few things we were thinking about: we wanted there to be a sense of a unit of size that everything fit into - CubeCorp, remember? - and so even our most complicated equipment needed to pack down into that cube. That meant that we were going to be animating equipment essentially unfolding, so I tried even at this stage to think about what that could mean for the drill and pump and vaccuum, and you can see packed and unpacked states up there for each design.

They also were likely to be carried around by our little darling worker bots -- so everybody needed feet the bots could squeeze between to get underneath. Speaking of, they probably went through the most designs of everything, and what's in the demo does not appear in these pages at all, haha, but here, a few more passes:

In fact, you might not be able to find any of these exact designs in the demo -- that's just the nature of concept art in games! What the game needed then and what it needed later -- as the game design itself was developed -- well, it changed, as it often can! I think it can be easy from the outside to assume that everything anyone thought of was eventually brought to life, but that rarely ever happens. Concept art is a process, and so even if these designs didn't make it into the game, they were an important step along the path towards designs that did, and they taught us a lot about what we did and didn't want Astronomics to look like!

Read the full article

8 notes

·

View notes

Text

offscreen post

//(note: set a few days ago, shortly before this post. mostly under the cut because this got kinda long)

[Concordia knocks on the door to an apartment in Nimbasa. “Be good, Cartwright," she says softly. The phone in her hand beeps in response.

The door is opened by a man with warm brown skin, blue hair, and a cane. He gives a sunny smile. “Connie! Hello! You brought the Porygon?” She holds up the phone and he says, “Good, good. Come inside!”

Connie follows him into a warmly-lit apartment. A Tynamo and a Bronzor watch her curiously. “Sit down for a moment, okay?” Tam says. “I just need to finish cleaning this up.” He gestures to a table where some kind of mechanical device sits, partially disassembled.

Connie sits on the couch, goes to open her texts, then thinks the better of it and sets her phone down.

“Any luck finding manufacturers?” Tam asks.

“No, I am afraid not. I have been somewhat busy these past few days.”

“Huh. You heard what’s been going on in Castelia?”

Unexpectedly to both of them, Concordia bursts into tears.

“Oh, dear Palkia, are you alright?”

“I’m—sorry, sorry, I should not be crying…”

“No, I…think that’s reasonable to be upset about, actually. Can I…” Connie nods, and Tam sits down on the couch next to her.

“I’m sorry,” Connie says again. “I just…everyone I know is terribly upset about this, I have spent two days answering phone calls and trying to comfort people and talking them down from arson—most of my friends are former Plasma members, we are not exactly known for making rational decisions when it comes to Pokémon welfare—my siblings are furious, and I have to keep reminding them to eat and sleep—” Connie puts her head in her hands. “I am so tired, Tam. Everyone needs me to be strong, but I am so tired. And it seems that every time I look away Minskt escalates things to new heights of corruption, and I have to start all over again…”

“Do you, um…do you need a hug?”

Connie nods miserably and lets him wrap his arms around her.

After a moment they break apart. Connie stands up, face a little red.

“We, um. We should get to work on the Porygon thing…”

“Right…right.” Tam stands up as well, rubbing the back of his head. “The scanner’s right back through here… You said you don’t have her Pokéball, right?”

“Yeah, N couldn’t find it…”

A stream of electric light comes out of Connie’s phone and congeals into the form of Cartwright the Porygon. She chirps curiously as Tam leads them into a room lined with worktables and machinery. A 3d printer hums away in one corner.

Tam goes to one of the machines and starts flipping switches. “Arright. My machine’s not connected to the PC network, so we can check her registration data, but if we alter it, it’ll glitch out next time she links to the network. It’s a whole mess and I spend a lot of time sorting out reg data corruption for clients who thought they could change their traded ‘mon’s nickname at home…”

“You can release her, though, right?”

“Oh, yeah, that’ll be no trouble if that’s what you want. Sort of in a legal gray area, but—her trainer’s dead, yeah? And she doesn’t want to go back to the company he worked for?”

“Yeah.”

“Alright, Porygon, come sit here,” Tam says, pressing some buttons on one of his machines. Cartwright hovers down to sit on the table next to it. Tam presses another button, and a beam of light flashes out to scan her. A few seconds later, the machine’s screen lights up with the scanned information. “…Um.”

Connie leans over curiously to see the screen. “Um what?”

“Connie, this Pokémon is legally owned by the company, not by the trainer. I’m all for Pokémon autonomy, but—”

“We cannot send her back," Connie says quickly. "She says they are going to erase her memory if she goes back.”

“I know, I wasn’t going to say we should—” Tam stops. “Erase her memory? That’s awful!”

“Exactly.”

“I—yeah, okay, this is very justified, I just…you understand this is super illegal, right? Are you sure you want to do this, like, right after Castelia’s law enforcement pulls that?”

“We already have the Porygon,” Connie points out. “Might as well be in for an Ampharos as for a Mareep, no? And they will be distracted. This new change will cause more chaos in their ranks than anything.”

“Okay. Yeah, okay.” Tam takes a deep breath and pushes his glasses up. “Pory, you got anything you want to save from your reg data before we delete it?”

Cartwright shakes her head, then vanishes into the machine for a moment. She types across the screen, “Status: ready rready ready! Begin procedure,” and then rematerializes onto the table.

“Okay. Here goes nothing… Wiping registration data now.”]

#werepersian arc#electric dreams arc#and tangentially#jammer tech hunt#offscreen post#pkmn irl#pokeblogging#pokemon irl#//to steal a tagging convention from ao3: no beta. we die like sada and turo

11 notes

·

View notes

Link

It can be unlocked with wet hands The top-end flagship smartphone Xiaomi 14 Ultra will receive an ultrasonic fingerprint sensor and will become the only smartphone in the line with such a solution. This was reported by insider Digital Chat Station. Judging by previously published information, Xiaomi14 Ultra should use an ultrasonic under-display fingerprint scanner manufactured by Goodix, and not a Qualcomm solution. Compared with traditional optical fingerprint solutions, pulses emitted by ultrasonic sensors can recognize unique fingerprints to generate 3D depth data, thereby achieving higher accuracy. When ultrasonic waves identify fingerprints, the screen does not need to be turned up to high brightness. More importantly, smartphones with ultrasonic fingerprint sensors can be unlocked with wet hands. Traditional phones with optical fingerprints will not unlock in such cases. Xiaomi 14 Ultra will be the only smartphone in this flagship [caption id="attachment_85486" align="aligncenter" width="780"] Xiaomi 14 Ultra[/caption] Previously, the same source reported that the main camera will support a variable aperture that can be adjusted from F/1.6 to F/4.0, fixing the amount of light entering the image sensor. The 50-megapixel sensor of the main camera of Xiaomi 14 Ultra will be Sony LYT900. This sensor is an optimized version of the Sony IMX989 and has an optical format of 1 inch. It is also stated that Dual Conversion Gain technology will improve image quality by reducing the amount of noise. It is expected that Xiaomi 14 Ultra will be equipped with the Qualcomm Snapdragon 8 Gen3 mobile platform and will receive up to 1 TB of flash memory. It will be released in the first quarter of next year. Digital Chat Station was the first to accurately report the specifications and release dates of the Redmi K60 and Xiaomi 14.

#Android#battery_life#camera_features#device_release#Display#Gaming#MIUI#Mobile_communication#mobile_device#mobile_device_launch.#mobile_technology#phone_features#photography#processor#smartphone#smartphone_specifications#tech_specifications#Xiaomi#xiaomi_14_ultra#Xiaomi_14_Ultra_price#Xiaomi_14_Ultra_review#xiaomi_phone

2 notes

·

View notes

Text

3D Technologies for dental process

As mentioned above, 3D technologies should be able to provide greater precision and reduce manufacturing times. But what are the new steps to follow when creating 3D printed dental devices? Oliver Bellaton explains, “The physical impression will be replaced by a 3D digital impression taken by the dentist with an intra-oral scanner (meaning a camera will reconstruct in 3D and in real time the surface of the teeth and gums). This 3D file can then be sent over to the dental laboratory through a secure web platform. The laboratory will review the digital impression and model the morphology of the crown in its design software (CAD), taking into account the limits of the gum, interference with other digitised teeth and even the shape of the patient’s smile with a face scanner. In case of doubt, a quick exchange by split screen with the dentist allows to validate the shape of the crown. The 3D file of the crown can then be sent to a 3D printer for manufacturing. In the near future, the dentist could have the 3D printer directly in the office for simple manufacturing. All digital flow configurations are possible. The process may take only a few hours, which in some cases means that the patient could only be brought in to the practice once.” The result is reduced logistics flows and production times, a personalised system that is much more adapted to the patient’s morphology.

Dentists and dental technicians will therefore have to equip themselves with 3D scanners or printers but also with CAD software, an obstacle for many professionals today. Nicolas Klaus, Dental Product & Business Development at Formlabs explains, “The essential pillars of these new working methods are 3D scanners, CAD software and 3D printing. Generally, there is a point of resistance in the software on which training is not obvious”.

Future of dental 3D printing?

While 3D technologies have significant advantages for the sector, their adoption may frighten some practitioners because it requires a new work logic, training in software, scanners and printers and a certain amount of confidence in these innovative processes. Today, for example, more than 50% of French laboratories have equipped themselves with 3D scanners and machine tools and 20% with 3D printers. These players recorded a 70% increase in turnover, proof that they represent real gains for dental professionals. Anton from EnvisionTEC added, “Most practitioners are very receptive and open to new digital technologies. It is simply a matter of asking clinicians and dental industry professionals to understand and trust the new digital technology and its benefits for themselves, their company and their patients. And of course, education and training play an important role. This is why many manufacturing companies are investing in this field to better understand the technology and its clinical applications“.

For more details on our products and services, please feel free to visit us at: 3d printed dental models Idaho, 3d printed dental model Idaho, orthodontic laboratory, dental lab & digital dentistry.

Please feel free to visit us at: https://www.3ddentalprints.com/

2 notes

·

View notes

Text

Can you provide examples of real-world applications of 3D laser scanning?

I’ve always been fascinated by technology that allows us to see the world in new ways. But nothing quite compares to my experience with 3D laser scanning. As I’ve come to learn, it’s not just a cool tool—it’s transforming industries all around us. From construction to archaeology, 3D laser scanning is opening doors to possibilities I couldn’t have imagined. Today, I’d like to take you through some real-world applications I’ve encountered that have solidified my belief in this technology's incredible potential.

1. Architecture and Construction: Precision Like Never Before

When I first delved into the world of 3D laser scanning, architecture and construction were the fields that jumped out at me. Initially, I had thought this technology was just a high-tech version of traditional surveying, but after seeing it in action, I realized that 3D laser scanning is reshaping the entire industry.

In construction, precision is everything. During my first project in Montreal, we were tasked with renovating a large commercial space that had undergone several modifications over the years. Blueprints were outdated, and manually measuring the site was time-consuming. That's when I was introduced to 3D laser scanning, which enabled us to create an exact digital replica of the building in minutes.

The scan provided millions of data points, creating a point cloud that we could use to model the structure down to the tiniest details. Not only did it save time, but it also allowed for accuracy that manual methods simply couldn’t achieve. This digital model helped us avoid costly mistakes during the renovation and provided a solid foundation for the project’s timeline and budget. I quickly saw that what I had thought of as just “another tool” was really an indispensable resource for any modern construction project.

2. Historical Preservation: Safeguarding the Past

As someone passionate about history, the use of 3D laser scanning in preserving heritage sites blew me away. I remember working on a project at an ancient church in Quebec, where the primary goal was to create digital records of the architecture before any restoration work began. I realized then that this technology wasn’t just about convenience—it was about preserving history for future generations.

The church had delicate carvings and stonework that could have been damaged during restoration. By using 3D laser scanning, we captured the structure in such minute detail that we could recreate exact replicas of its design, if necessary. The technology’s ability to document these fragile historical sites in a non-invasive way is changing the way we approach preservation.

youtube

In fact, I’ve seen instances where, after a natural disaster, historical buildings that were destroyed were digitally reconstructed thanks to earlier 3D scans. This is history brought back to life—allowing people to experience it as it once was, even if the physical structure no longer stands.

3. Manufacturing and Quality Control: Raising the Standards

Another domain that left a strong impression on me was manufacturing. I visited a factory where 3D laser scanning was being used for quality control in product design. The factory produced highly specialized mechanical components for aerospace companies, where even a fraction of a millimeter inaccuracy could be catastrophic.

In this highly precise world, traditional methods for measuring the components had their limitations. That's when I realized the critical role 3D laser scanning plays here. The laser scanner was used to create detailed 3D models of each part, allowing engineers to compare these models with the original design specifications. The scan ensured that every component was exactly as it should be, catching any flaws before they reached the assembly line.

What amazed me most was the speed with which the scanning system could check for errors. It was a perfect example of how 3D laser scanning not only elevates the quality of manufacturing but also reduces costs by eliminating the need for rework.

4. Archaeology: Uncovering Hidden Secrets

Perhaps one of the most fascinating applications I’ve come across is 3D laser scanning in archaeology. I’ve always imagined archaeology to be a field where people painstakingly dig and brush dirt away from ancient ruins. While that’s still a huge part of the job, 3D laser scanning has made a significant impact on how archaeologists work.

One of my colleagues worked on a dig in Central America, where they used 3D laser scanning to map ancient ruins buried under dense vegetation. The scanners penetrated the thick jungle, capturing the hidden structures in stunning detail. It was mind-boggling to me to think that technology could uncover ruins that might otherwise have taken decades to discover by hand.

Additionally, 3D laser scanning allows archaeologists to document and share their findings with researchers worldwide. Even sites that are difficult to access or are degrading over time can be scanned and preserved digitally, allowing researchers to study them long after physical access is no longer possible. It’s a perfect example of how modern technology can work hand-in-hand with the ancient world, revealing its secrets.

5. Healthcare: Transforming Patient Care

I was surprised when I learned that 3D laser scanning was being used in healthcare, but the more I dug into it, the more I understood its life-changing potential. In the field of prosthetics and orthotics, for instance, doctors are using 3D scanning technology to create custom devices for patients. Instead of using plaster molds or manual measurements, doctors scan the patient’s body, creating a highly accurate model from which they can design the perfect prosthetic limb.

It’s not just about precision, either. The whole process is faster and less invasive, making it more comfortable for patients. I’ve heard stories of patients receiving prosthetic limbs that fit better and function more naturally than ever before, thanks to the accuracy of 3D laser scanning.

Beyond prosthetics, this technology is also being used in surgery planning. Doctors can create 3D models of a patient’s organs, allowing them to visualize and practice complex surgeries before ever making the first incision. It’s incredible to think how much safer and more efficient these procedures can become with this technology at the forefront.

Conclusion: A World of Possibilities

After witnessing these real-world applications, I can’t help but marvel at the versatility of 3D laser scanning. Whether it's shaping the future of construction, preserving history, elevating manufacturing standards, uncovering ancient mysteries, or transforming healthcare, this technology is paving the way for innovation in ways I never imagined.

As I look back on my journey, I see 3D laser scanning as more than just a tool—it’s a bridge between the physical and digital worlds, offering solutions to problems we didn’t even know we had. And as more industries begin to embrace it, the possibilities truly seem endless. I can’t wait to see where 3D laser scanning will take us next.

Contact us :

iScano Connecticut

Randolph Place, Cos Cob, CT 06807

(917) 383-3456

https://iscano.com/3d-laser-scanning-connecticut/

#laser scanning#laser scanners#laser scan#3d laser#scanning services#3d laser scanner for buildings#3d construction scanner#3d scanning services#3d scanning#3d laser scanning services connecticut#Youtube

0 notes

Text

Benefits of 3D Scanning in MRO

Precision and Accuracy: 3D scanners capture detailed geometries, allowing for precise measurements that can enhance fit and function in repairs and replacements.

Time Efficiency: Scanning can significantly reduce the time needed for inspections and measurements compared to traditional methods.

Data Visualization: Scanned data can be used to create detailed models, enabling better visualization and understanding of complex components.

Documentation: 3D scans serve as a reliable documentation method for components, aiding in quality assurance and compliance.

Reverse Engineering: Scanning allows for accurate reproduction of parts, facilitating repairs for obsolete or hard-to-find components.

Applications in MRO

Component Inspection: Scanning can detect wear and tear on parts, ensuring timely maintenance and preventing failures.

Assembly Verification: 3D models can be used to verify that assemblies are correct and meet design specifications.

Custom Part Fabrication: Using scanned data, organizations can create custom parts through additive manufacturing or machining.

Training and Simulation: Scanned models can be used in training programs to help technicians learn about complex systems without the risk of damaging actual equipment.

Historical Preservation: In industries like aviation and heritage conservation, 3D scanning helps preserve the history of equipment or structures.

Challenges

Cost: Initial investment in scanning technology and software can be high.

Data Management: Handling and processing large amounts of data from 3D scans can be complex.

Integration: Incorporating 3D scanning into existing workflows may require adjustments and training.

In summary, 3D scanning is a valuable tool in MRO, enhancing accuracy, efficiency, and overall operational effectiveness.

0 notes

Text

Benefits of Using Industrial 3D Scanners for Reverse Engineering and Product Development

In today's fast-paced industrial landscape, precision, efficiency, and innovation are key drivers of success. Whether in automotive, aerospace, or manufacturing, companies are constantly seeking new technologies to improve product development processes and ensure high-quality output. One such technology making waves in these industries is the industrial 3D scanner, a tool that has become indispensable for reverse engineering and product development.

Reverse engineering—the process of deconstructing a product to understand its design and functionality—is often crucial in industries where improving, replicating, or enhancing existing products is required. With the rise of industrial 3D scanners, reverse engineering has become faster, more accurate, and highly efficient. In this article, we will explore the benefits of using industrial 3D scanners for reverse engineering and product development.

1. Precision and Accuracy in Capturing Complex Geometries

One of the most significant advantages of using industrial 3D scanners in reverse engineering is their ability to capture complex geometries with high precision. Unlike manual measurements, which are prone to human error, 3D scanners use advanced laser or structured light technologies to create highly accurate digital models of physical objects.

This high level of accuracy is crucial for industries like aerospace and automotive, where even the smallest deviation in a part's dimensions can lead to performance issues or safety risks. Industrial 3D scanners can capture intricate details, such as curves, angles, and edges, with a level of accuracy down to microns, making it easier to replicate or improve upon existing designs.

By creating precise 3D models of physical objects, engineers and designers can make informed decisions about product development and identify areas for improvement in existing products.

2. Faster and More Efficient Reverse Engineering

Traditionally, reverse engineering involved time-consuming processes such as manual measurement, drawing, and CAD modeling, which could take days or even weeks. Industrial 3D scanners significantly reduce the time required to reverse engineer a product by automating the process of capturing an object’s dimensions.

With a 3D scanner, the entire shape of an object can be scanned in a matter of minutes, and the data is automatically converted into a digital model that can be manipulated in CAD software. This not only speeds up the process but also reduces the labor involved in reverse engineering, freeing up engineers to focus on more complex tasks.

For industries where time-to-market is critical, the ability to reverse engineer products quickly and efficiently gives companies a competitive edge. Faster reverse engineering leads to shorter product development cycles and allows businesses to respond more rapidly to customer demands or changes in market trends.

3. Enhancing Product Development with 3D Scanning Technology

Product development is a multi-stage process that often involves prototyping, testing, and refining a design before it reaches the production stage. Industrial 3D scanners play a vital role in this process by allowing designers and engineers to create accurate digital models of prototypes, parts, or even competitor products.

These digital models can then be analyzed, modified, and tested in virtual environments before physical prototypes are produced. This reduces the need for multiple iterations of physical prototypes, saving both time and material costs. Moreover, it enables designers to experiment with different design elements and make improvements to product performance, aesthetics, or functionality without the need for costly retooling or adjustments to production machinery.

Additionally, industrial 3D scanners allow for seamless integration with CAD and other product development software, making it easier to incorporate scanned models into existing design workflows.

4. Cost Savings in Manufacturing and Design

Another major benefit of using industrial 3D scanners for reverse engineering and product development is the potential for cost savings. By streamlining the reverse engineering process, reducing the need for physical prototypes, and improving the accuracy of designs, companies can lower overall production costs.

For example, 3D scanning allows manufacturers to detect design flaws or potential issues early in the development process, reducing the risk of expensive modifications during production. Furthermore, it enables efficient use of materials by optimizing part design for manufacturing, leading to fewer material waste and lower production costs.

In industries where precision and reliability are essential, such as automotive or aerospace, these cost savings can be substantial, as errors or inefficiencies in the design process can lead to costly recalls or reworks.

5. Improved Quality Control and Assurance

Quality control is another area where industrial 3D scanners excel. By creating highly accurate 3D models of products, engineers can compare the scanned models to the original CAD designs, ensuring that manufactured parts meet the required specifications.

This capability is particularly valuable in industries with stringent quality standards, where even the smallest deviations can have significant consequences. For instance, in the aerospace industry, where components must meet strict safety regulations, 3D scanning can detect imperfections or inconsistencies that might go unnoticed through traditional inspection methods.

In addition, industrial 3D scanners allow for non-contact measurement, meaning parts can be scanned without risk of damaging them, which is especially useful for delicate or complex components.

Conclusion

Industrial 3D scanners are transforming the fields of reverse engineering and product development by providing highly accurate, fast, and cost-effective solutions. Their ability to capture complex geometries, enhance product design, and improve quality control makes them an indispensable tool in industries ranging from automotive and aerospace to manufacturing.

For companies looking to stay competitive and innovative, investing in industrial 3D scanning technology can lead to significant improvements in product development cycles, cost savings, and overall product quality. As 3D scanning technology continues to evolve, its role in shaping the future of reverse engineering and product design will only grow.

0 notes

Text

Sheet Metal Forming: Enhancing Precision with 3D Scanning and Reverse Engineering

Reverse Engineering

Sheet metal forming is a vital manufacturing process used to create metal components for industries such as automotive, aerospace, and heavy machinery. This process involves shaping metal sheets into various forms using techniques like bending, stamping, and drawing. While traditional methods are still widely used, the integration of 3D scanning and reverse engineering technologies has revolutionized sheet metal forming, making it more efficient and precise than ever before.

How 3D Scanning is Transforming Sheet Metal Forming

One of the main challenges in sheet metal forming is ensuring that the final product meets exact design specifications. In traditional setups, this requires manual inspections and measuring, which can be time-consuming and prone to human error. 3D scanning has changed this landscape by enabling manufacturers to capture detailed and accurate 3D models of metal components. These models allow for precise analysis and ensure that parts are produced to exact measurements.

With high-precision 3D metrology, manufacturers can significantly reduce material wastage, minimize errors, and streamline the overall production process. This not only improves efficiency but also cuts down on costs related to rework and rejected parts.

Reverse Engineering in Sheet Metal Forming

Reverse engineering is another critical tool that complements 3D scanning in sheet metal forming. It allows manufacturers to recreate or modify existing parts when original designs or documentation are unavailable. Using reverse engineering, companies can scan a physical part, analyze its geometry, and generate digital models that can be used for redesign or reproduction.

This process is particularly useful when working with legacy equipment or when making design improvements to existing parts. Reverse engineering enables manufacturers to optimize designs for better performance, durability, and ease of production. Additionally, it plays a crucial role in quality control and inspection services, ensuring that every piece of metalwork aligns with the required standards.

Benefits of 3D Scanning and Reverse Engineering in Metal Forming

The integration of 3D scanning and reverse engineering into the sheet metal forming process offers numerous advantages:

Accuracy: Both technologies ensure high precision, reducing errors and improving product quality.

Cost Efficiency: Faster inspections and reduced material waste lower production costs.

Speed: Digital models from 3D scanners accelerate the prototyping and production process.

Quality Control: Inspection using 3D data allows for comprehensive analysis, ensuring that all parts conform to design specifications.

Future of Sheet Metal Forming

As manufacturing technologies continue to advance, 3D scanning, reverse engineering, and related digital tools will play an even more significant role in shaping the future of sheet metal forming. The ability to produce accurate, high-quality parts with minimal error will become an industry standard, ensuring that manufacturers stay competitive in an increasingly digital world.

By leveraging 3D scanning, reverse engineering, and other advanced technologies, businesses can improve the efficiency and accuracy of their sheet metal forming operations, leading to enhanced production processes and better end products.

0 notes

Text

Buy Best 3D Printer for Reverse Engineering Solutions

For those in need of reverse engineering solutions, 3D Monotech offers the best 3D printers and scanners on the market. Buy the best 3D printer that suits your engineering needs with precision and efficiency. Our 3D printing solutions are trusted by professionals across industries like manufacturing and healthcare for unparalleled accuracy and quality.

Contact Us :-

Phone:-+91 99401 85761

Email :[email protected]

Website :-https://3dmonotech.in/

0 notes

Text

Dimensional Inspection: The Key to Perfecting Precision in Modern Manufacturing

In the world of modern manufacturing, precision is not just a goal—it's a necessity. As industries such as aerospace, automotive, medical devices, and consumer goods evolve, their requirements for accuracy and quality have surged. Meeting these demands involves more than just ensuring that parts fit together; it's about adhering to strict tolerances, avoiding costly mistakes, and complying with industry standards. This is where dimensional inspection comes into play.

Dimensional inspection is a critical process in manufacturing that ensures parts are built exactly to specification. From the earliest stages of development to final product approval, dimensional inspection offers detailed measurement data, reducing errors, enhancing quality control, and speeding up the production process. Whether you're producing prototypes or scaling to mass production, precision inspection is the linchpin that keeps projects on track.

What Is Dimensional Inspection?

Dimensional inspection involves measuring the physical dimensions of a manufactured part to ensure it meets specific tolerances. This isn't just about checking the length, width, and height. Advanced dimensional inspection covers intricate measurements such as angles, curvature, thickness, and surface texture.

Dimensional inspection techniques can be applied to products in various stages of manufacturing, such as:

First Article Inspection (FAI): The first prototype is thoroughly inspected to verify that it matches design specifications.

Ongoing Quality Control: During the production process, routine inspections are carried out to ensure consistency.

Final Product Inspection: Before the product is delivered to the market, a final check guarantees all dimensions are within acceptable tolerance levels.

Dimensional inspection services often use sophisticated tools and technologies like Coordinate Measuring Machines (CMM), laser scanners, and computed tomography (CT) scanning to capture detailed, highly accurate data.

Why Is Dimensional Inspection Critical for Manufacturers?

1. Avoid Costly Errors:

Manufacturing errors are not only expensive but can lead to significant delays. Errors that go undetected in the design or prototyping phase can multiply during mass production, leading to faulty products, expensive recalls, or even legal ramifications. Dimensional inspection mitigates this by catching errors early.

For example, a company producing medical devices must meet stringent regulatory requirements. Dimensional inspection allows manufacturers to verify each component's accuracy before moving forward with production, preventing potential non-compliance issues.

2. Ensure Product Functionality:

Parts that don’t meet required dimensions can cause products to malfunction or fail entirely. Dimensional inspection provides engineers and manufacturers with accurate measurements to ensure parts function as intended, improving product safety and performance.

In industries like automotive and aerospace, where precision is vital to safety, dimensional inspection ensures that parts like engine components or turbine blades meet exact specifications for both form and function.

3. Streamline Product Development:

Dimensional inspection accelerates the product development process by offering precise data quickly. This allows engineers to adjust designs on the fly, reducing time spent on trial and error. With advanced tools like 3D scanning and CT scanning, inspection reports are delivered within days instead of weeks, helping companies hit production milestones without unnecessary delays.

Key Tools Used in Dimensional Inspection

1. Coordinate Measuring Machines (CMM):

CMMs are used to measure the exact geometry of objects by sensing discrete points on the surface with a probe. The machine then calculates the coordinates and checks them against the intended design.

2. 3D Scanning:

3D scanners are commonly used for capturing the exact shape and surface detail of a part. Technologies such as blue-light laser scanners can generate accurate digital representations of objects, allowing for in-depth analysis and comparisons with CAD models.

3. Industrial CT Scanning:

Computed tomography (CT) scanning is increasingly being used for dimensional inspection, especially for complex or internal features that are hard to measure with traditional tools. CT scanning provides a 3D image of the part's internal and external structures, enabling precise inspection without disassembling or damaging the part.

Applications Across Industries

Dimensional inspection services cater to a wide variety of industries:

Medical Devices:

Dimensional inspection is crucial for ensuring that medical components like implants, drug delivery systems, and surgical instruments are produced to exact specifications, preventing patient harm.

Automotive:

In the automotive sector, precision is vital for the performance of components like engines, transmissions, and safety systems. Dimensional inspection ensures these parts are made to the highest standards.

Aerospace:

Aerospace components must meet stringent tolerances to guarantee safety and performance at high altitudes and extreme conditions. Dimensional inspection provides the necessary accuracy to meet these demands.

Consumer Products:

Whether it's packaging, electronics, or sporting goods, dimensional inspection helps ensure that products are manufactured consistently and meet consumer expectations.

The Role of Accreditation in Dimensional Inspection

When outsourcing dimensional inspection, choosing a laboratory accredited to international standards like ISO/IEC 17025 is critical. This accreditation ensures that the lab operates competently, consistently producing valid results. Accredited labs follow strict procedures and maintain equipment that is regularly calibrated to meet global standards of precision.

Accredited labs also provide traceability, ensuring that all measurements can be traced back to a recognized standard. This is particularly important for industries like medical devices and aerospace, where regulatory compliance is essential.

Conclusion: The Future of Dimensional Inspection

As manufacturing continues to evolve with new technologies and materials, the demand for dimensional inspection services will only grow. Tools like CT scanning, 3D metrology, and CMM systems allow for faster, more accurate inspections, giving manufacturers a competitive edge. Whether for small-scale prototyping or large-scale production, precision measurement plays a pivotal role in ensuring product quality, safety, and compliance.

With its ability to prevent costly errors, streamline product development, and ensure functionality, dimensional inspection is a cornerstone of modern manufacturing excellence.

For more information on how dimensional inspection can improve your manufacturing processes, visit Nel PreTech's Dimensional Inspection Services.

ChatGPT can make mistakes. Check important info.

0 notes

Text

Precision in Manufacturing: The Role of Measuring Machines in Quality Control

In today’s fast-evolving manufacturing landscape, precision and accuracy are not just desirable—they are essential. Whether it’s producing components for aerospace, automotive, or medical industries, even the smallest deviations from design specifications can lead to serious issues. This is where measuring machines come into play. As the unsung heroes of quality control, measuring machines ensure that parts and products meet exacting standards, contributing to both safety and efficiency in production processes.

What is a Measuring Machine?

A measuring machine is a specialized piece of equipment used to assess the dimensions, geometry, and surface quality of manufactured parts. These machines are essential for verifying that components are within specified tolerances—parameters set by engineers that dictate acceptable levels of variation in size, shape, and position. By comparing the actual part against its design specifications, measuring machines help maintain consistent quality and ensure parts perform as intended.

There are several types of measuring machines used in different industries, including coordinate measuring machines (CMMs), optical measurement systems, and laser-based devices. Each type has its strengths and is designed to meet the needs of specific applications, ranging from microscopic inspections to large-scale measurements.

Types of Measuring Machines

Coordinate Measuring Machines (CMMs):

CMMs are one of the most widely used and versatile measuring machines in modern manufacturing. They consist of a probing system that moves along three axes (X, Y, Z) to take precise measurements of the part. The probing system can either touch the surface (contact measurement) or use lasers and optical sensors (non-contact measurement) to capture dimensional data. CMMs are essential for ensuring that parts adhere to tight tolerances, especially in industries where accuracy is critical, such as aerospace and automotive.

Optical Measuring Machines:

Optical measuring machines use cameras, lasers, or other light-based systems to measure parts without making physical contact. These machines are ideal for inspecting delicate components, complex geometries, or soft materials that might deform under pressure. By using high-resolution imaging and software algorithms, optical systems can capture and analyze thousands of data points in seconds, providing quick, non-invasive measurements.

Laser Scanners and 3D Measurement Systems:

Laser scanners use laser beams to create a detailed 3D map of a part’s surface. These systems are especially useful in reverse engineering, prototyping, and inspecting parts with intricate designs. Laser measuring systems are known for their speed and accuracy, making them valuable in high-volume production environments where rapid inspections are necessary.

Surface Roughness Testers:

Surface roughness testers, also known as profilometers, are specialized machines that measure the texture or finish of a part’s surface. Surface quality is important in industries like automotive and electronics, where friction, wear, and aesthetics play a significant role. These testers use a stylus or laser to scan the surface and detect any irregularities or deviations from the desired smoothness.

Why Are Measuring Machines Important?

Ensuring Accuracy and Precision:

Measuring machines are critical in verifying that parts conform to their design specifications. Manufacturing processes often involve high levels of complexity and tiny tolerances, where even a minor error can lead to product failure. Measuring machines help catch any deviations early, allowing manufacturers to correct issues before they lead to costly defects or rework.

Maintaining Consistent Quality:

In high-volume production, ensuring the consistency of every part is a challenge. Measuring machines allow manufacturers to monitor and control quality throughout the production process, ensuring that every component meets the same standards. By providing objective data on part dimensions and surface finishes, these machines help maintain consistency across batches, which is vital for industries like automotive, where interchangeable parts are essential.

Reducing Costs and Waste:

Detecting defects early in the manufacturing process saves both time and money. If a defective part makes it through multiple stages of production, the costs of scrapping or reworking it can be significant. Measuring machines help identify issues before they escalate, reducing waste and preventing the production of non-compliant parts.

Supporting Compliance and Certification:

Many industries, especially those involving safety-critical components like aerospace and medical devices, require strict adherence to regulatory standards. Measuring machines provide the data needed to ensure compliance with these standards, helping companies meet regulatory requirements and maintain certifications. This data is often critical for audits, customer requirements, and quality management systems.

Increasing Efficiency:

Modern measuring machines are often automated, allowing them to perform inspections faster and with fewer errors than manual measurement methods. Automated systems can operate around the clock, increasing the speed of quality control without sacrificing accuracy. This leads to improved throughput, shorter lead times, and faster production cycles.

How Measuring Machines Fit Into the Smart Manufacturing Revolution

As manufacturing moves towards greater automation and smart factories, measuring machines are becoming more integrated with Industry 4.0 technologies. This includes:

Data-Driven Manufacturing:

Measuring machines are now equipped with advanced sensors and connected to cloud-based systems, making them integral to data-driven manufacturing. By collecting, analyzing, and storing measurement data in real time, manufacturers can monitor trends, predict potential issues, and continuously improve production processes.

Real-Time Quality Control:

Some modern measuring machines are embedded directly into production lines, providing real-time feedback and allowing for immediate adjustments to the manufacturing process. This integration helps prevent defects from reaching the final stages of production, minimizing downtime and boosting efficiency.

Predictive Maintenance:

By analyzing measurement data over time, manufacturers can identify wear patterns in machinery and tooling. This enables predictive maintenance, where parts are replaced or repaired before they fail, reducing unplanned downtime and improving overall equipment effectiveness (OEE).

Digital Twins:

Measuring machines play a role in creating digital twins, virtual replicas of physical products that allow manufacturers to simulate and analyze performance under various conditions. By capturing precise data on a product’s dimensions and characteristics, measuring machines help engineers create more accurate digital models, improving design and production processes.

Future Trends in Measuring Machines

As technology continues to advance, the capabilities of measuring machines are also evolving. Future trends include:

AI and Machine Learning:

The integration of AI and machine learning into measuring machines will allow for smarter, more autonomous systems. AI algorithms can help analyze measurement data, identify patterns, and even make decisions about when to flag a part for rework or further inspection.

Portable and Wearable Devices:

Portable and handheld measuring devices are becoming more common, providing flexibility in quality control. These devices allow for on-the-spot measurements in the factory or field, making it easier to inspect parts in real-world conditions.

Higher Precision and Resolution:

As industries demand tighter tolerances and more complex geometries, measuring machines will continue to improve in terms of precision and resolution. Advances in sensor technology and materials science will enable even more accurate measurements at microscopic scales.

Conclusion

Measuring machines are indispensable in today’s precision-driven manufacturing landscape. From ensuring compliance and reducing waste to supporting the future of smart manufacturing, these machines play a vital role in maintaining the quality and reliability of products across industries. As technologies such as AI, automation, and data integration continue to advance, the role of measuring machines in ensuring precision will only become more critical.

With their ability to provide real-time insights, support continuous improvement, and adapt to the ever-growing complexity of manufacturing processes, measuring machines are a key player in the future of quality control and production efficiency.

Key Takeaways:

Measuring machines are essential for ensuring precision, accuracy, and quality in manufacturing.

Different types of measuring machines, such as CMMs and optical systems, are used to inspect dimensions, geometries, and surfaces.

They reduce costs, maintain consistency, and support compliance with regulatory standards.

Integration with smart manufacturing and Industry 4.0 technologies is driving new capabilities for real-time quality control and predictive maintenance.

0 notes

Text

Unlocking Precision: The Power of 3D Laser Scanning

In today’s world of advanced technology, 3D laser scanning has become an indispensable tool across multiple industries. From construction and architecture to manufacturing and heritage preservation, this cutting-edge technology allows for detailed and accurate digital representations of objects and environments. In this article, we will delve into the fundamentals of 3D laser scanning, its applications, and how it is transforming various sectors by enhancing precision, efficiency, and overall productivity.

What is 3D Laser Scanning?

3D laser scanning is a process that captures the shape of physical objects or environments through laser beams. The technology operates by emitting laser pulses towards a surface and measuring the time it takes for the laser to bounce back. The result is a collection of data points, known as a point cloud, that forms a precise 3D representation of the scanned object or area.

The scanners can capture intricate details, from the complex textures of small objects to expansive environments like construction sites or entire buildings. Unlike traditional surveying methods, 3D laser scanning is fast, non-intrusive, and highly accurate, making it a go-to solution for many industries seeking exact measurements.

Key Applications of 3D Laser Scanning

Architecture and Construction

One of the most significant applications of 3D laser scanning is in the field of architecture and construction. The technology is used to create highly accurate digital models of buildings, construction sites, and other structures. These models assist architects, engineers, and construction teams in design, planning, and renovation processes. By scanning existing conditions, teams can reduce errors, ensure precise alignment, and avoid costly rework.

Moreover, construction sites benefit from continuous monitoring through 3D laser scans, allowing project managers to track progress, inspect quality, and ensure adherence to design plans. It also helps identify any discrepancies between the actual site and design models, reducing delays.

Manufacturing and Quality Control

In manufacturing, precision is critical, especially when dealing with complex parts and systems. 3D laser scanning helps manufacturers assess whether components meet design specifications by comparing them to digital models. It is also widely used in reverse engineering, where existing parts or products are scanned to create a 3D model for reproduction or modification.

Quality control processes also benefit from 3D laser scanning, as it allows for the detection of defects, deformities, or inconsistencies in products. This ensures that only high-quality components make it to market.

Heritage Preservation

For historical preservation, 3D laser scanning plays a vital role in documenting and conserving cultural heritage. This technology enables precise digital reconstructions of ancient structures, artifacts, and monuments, many of which may be at risk of deterioration due to time or environmental factors. The scanned models can be used for restoration projects, virtual exhibitions, or educational purposes, ensuring that historical treasures are preserved for future generations.

Oil and Gas Industry

In the oil and gas sector, 3D laser scanning is used for plant and facility management, as well as maintenance. Detailed 3D scans of oil rigs, pipelines, and refineries help engineers plan upgrades or repairs while minimizing downtime and avoiding hazards. Additionally, the scans assist in monitoring the wear and tear of equipment, ensuring safety and compliance with regulations.

Benefits of 3D Laser Scanning

The advantages of 3D laser scanning go beyond its ability to produce accurate digital models. Its non-invasive nature ensures minimal disruption to the surrounding environment, whether it’s a bustling construction site or a delicate archaeological dig. The speed at which it captures data drastically reduces the time needed for surveys and inspections, making it a cost-effective solution in the long run.

Furthermore, 3d Laser Scan To Cad promotes better collaboration between different stakeholders by providing an exact visual reference, which can be shared digitally. This improves communication and reduces the likelihood of misunderstandings during project execution.

0 notes

Text

The Role of Technology in Orthodontic Treatment

Have you ever wondered how technology has transformed the orthodontics field? Technological advancements have introduced a variety of innovative treatments that have revolutionized the methods used to straighten teeth and correct bites. Modern orthodontic treatments have significantly benefited from technological innovations, leading to improved patient outcomes, enhanced comfort, and more efficient procedures. Here are some of the key ways technology has transformed orthodontic treatment:

Digital Imaging and 3D Scanning

One of the most significant changes in orthodontics is the use of digital imaging and 3D scanning technologies, such as cone-beam computed tomography (CBCT) and intraoral scanners, which allow orthodontists to create highly accurate models of a patient’s teeth and jaw structure. This detailed technology allows for more precise and efficient treatment and better communication between the orthodontist and the patient.

Clear Aligners Technology

Clear aligner systems like Invisalign have gained popularity due to their convenience and aesthetics. Invisalign Orthodontist in HSR Layout provides aligners which are custom-made using advanced 3D printing technology, providing a nearly invisible alternative to traditional braces. Aligner systems use computer-aided design and manufacturing (CAD/CAM) to create a series of aligners that gradually move teeth into their desired positions, ensuring predictable and precise results.

3D Printing and Custom Appliances

3D printing technology allows for the creation of custom orthodontic appliances, such as retainers, brackets, and even braces. These appliances are tailored to fit each patient’s unique dental anatomy, improving comfort and effectiveness. 3D printing technology can produce detailed structures necessary for orthodontic appliances, ensuring that each bracket or aligner exerts the correct amount of pressure on specific teeth as planned. The use of 3D printing in orthodontics speeds up the production process, allowing for quicker delivery of custom appliances and reducing overall treatment times.

Teledentistry and Remote Monitoring

Teledentistry platforms enable patients to have virtual consultations with their orthodontists, making it easier to receive expert advice and guidance without the need for in-person visits. Advanced apps and devices allow orthodontists to remotely monitor patient’s progress, ensuring that treatments are on track and making adjustments as needed. This technology enhances convenience and accessibility for patients.

As technology continues to evolve, the field of dentistry, especially orthodontics, will likely see even more innovative solutions, further improving outcomes for patients seeking a perfect smile. For those looking for the best orthodontic care, Braceport Dentistry is the best Dental Clinic in HSR Layout, offering range of dental treatments and exceptional dental patient care. If you’re looking for a modern orthodontic solution, consider us for the perfect blend of advanced technology and personalized care. Contact us today for more information.

0 notes

Text

Safety Considerations for 3D Laser Scanning Projects in Montreal

When I first embarked on using 3D laser scanning technology in Montreal, I was captivated by its potential to revolutionize how we capture spatial data. The precision, efficiency, and sheer depth of information this technology offers are unparalleled. But as I delved deeper into various projects, I quickly realized that while the technology itself is cutting-edge, the importance of safety considerations cannot be overstated. Ensuring the safety of both the team and the environment is paramount, especially in a bustling city like Montreal, where the mix of historic architecture and modern infrastructure presents unique challenges.

Understanding the Environment: The First Step to Safety

One of the first lessons I learned was that every project begins with a thorough understanding of the environment. In Montreal, this is especially critical. The city’s eclectic mix of old and new, combined with its unpredictable weather, means that no two scanning sites are alike. Before setting up any equipment, I make it a point to conduct a comprehensive site assessment.

This involves identifying any potential hazards—be it uneven surfaces, nearby traffic, or even the presence of historical artifacts that must be preserved. In some cases, I’ve had to liaise with local authorities to understand any site-specific regulations, especially when working near heritage sites or in high-traffic areas. Understanding these environmental factors helps in planning the project more effectively and ensures that the team is well-prepared to tackle any challenges that might arise.

Equipment Safety: Ensuring Reliability and Accuracy

The safety of the equipment itself is another crucial aspect. 3D laser scanners are sophisticated pieces of technology, and ensuring their proper functioning is vital—not just for the accuracy of the data, but also for the safety of the team. I always ensure that all equipment is regularly maintained and calibrated according to the manufacturer’s specifications.

Before starting a project, I run a series of checks to confirm that the scanner, tripods, and other associated equipment are in perfect working order. This includes checking for any loose connections, ensuring that the tripod is stable on the surface, and verifying that the scanner’s laser is functioning correctly. In Montreal, where weather conditions can change rapidly, I also ensure that all equipment is protected from the elements, whether that means using weatherproof covers or scheduling scans during optimal weather windows.

youtube

Team Safety: Training and Awareness

Perhaps the most critical aspect of safety in 3D laser scanning projects is the well-being of the team. Over the years, I’ve come to appreciate the importance of comprehensive safety training. Every member of the team, from the most experienced to the newest recruit, undergoes rigorous training on how to handle the equipment, recognize potential hazards, and respond to emergencies.

In Montreal, this training often includes specific modules on working in urban environments, where the risk of encountering pedestrians, vehicles, and other obstacles is higher. We also cover the safe handling of the laser itself. While 3D laser scanners are generally safe, it’s essential to understand the proper procedures to avoid any risk of exposure to the laser beam, especially when working in close quarters.

I also make it a point to conduct regular safety briefings before the start of each project. These briefings are an opportunity to go over the specific safety protocols for the site, review the day’s tasks, and ensure that everyone is aware of their responsibilities. In a city like Montreal, where the landscape can change from one block to the next, these briefings are crucial for keeping the team informed and prepared.

Public Safety: Minimizing Disruption in Urban Settings

Working in a city as dynamic as Montreal means that public safety is always a consideration. When conducting 3D laser scanning in public or semi-public spaces, minimizing disruption and ensuring the safety of bystanders is a top priority. One of the strategies I’ve found effective is setting up clear signage around the scanning area. This not only informs the public about the work being conducted but also helps keep them at a safe distance from the equipment.

In some cases, especially in high-traffic areas, it’s necessary to cordon off sections of the sidewalk or street. This requires careful coordination with local authorities to ensure that we’re compliant with city regulations and that the disruption to the public is minimized. On several occasions, I’ve had to schedule scans during off-peak hours or even at night to avoid interfering with pedestrian or vehicular traffic. This approach has proven effective in maintaining a safe environment for both the team and the public.

Environmental Safety: Protecting Montreal’s Heritage

Montreal is a city steeped in history, and many of the projects I’ve worked on involve scanning historic buildings or sites. In these cases, environmental safety takes on an added dimension. It’s not just about ensuring that the scanning process is safe for the team, but also about protecting the integrity of the structures being scanned.

I’ve learned to work closely with preservationists and architects to ensure that the scanning process does not damage any part of the building or site. This often involves using non-invasive techniques and taking extra care when setting up equipment on delicate surfaces. In some cases, we’ve had to modify our scanning approach to accommodate the unique requirements of a historic site, whether that means using smaller, more portable scanners or adjusting the scanning angle to avoid contact with fragile surfaces.

Adapting to Montreal’s Unique Challenges

Montreal presents its own set of unique challenges when it comes to 3D laser scanning, and adapting to these challenges is key to ensuring safety. For instance, the city’s cold winters and hot summers mean that I need to be prepared for extreme temperatures that can affect both the equipment and the team. I’ve had to implement specific protocols for working in these conditions, such as using heated or cooled storage for equipment and ensuring that the team is adequately dressed and hydrated.

In addition, Montreal’s bilingual environment means that all safety protocols, signage, and briefings need to be available in both French and English. This ensures that everyone, from the team to the public, can understand the safety measures in place.

Conclusion: Safety as a Core Value

As I reflect on my experiences with 3D laser scanning in Montreal, it’s clear to me that safety is not just an add-on—it’s a core value that underpins every project. By prioritizing safety at every stage, from planning and equipment checks to team training and public awareness, I’ve been able to carry out successful scanning projects that not only deliver accurate and valuable data but also protect the well-being of everyone involved.

In a city like Montreal, where the stakes are high and the environment is constantly changing, maintaining a strong focus on safety is the key to success. Whether you’re a seasoned professional or just starting out, making safety a priority will ensure that your 3D laser scanning projects are not only efficient and effective but also safe for everyone involved.

Contact us:

iScano | Montreal 3D Scanning Services

357 Rue Square-Sir-George-Étienne-Cartier, Montréal, QC H4C 3A3, Canada

(647) 773-1341

https://iscano.com/3d-laser-scanning-montreal/

#3d laser#3d laser scanning services montreal#laser scan#laser scanners#scanning services#laser scanning#3d scanning services#3d laser scanning services#3d construction scanner#3d laser scanner#Youtube

0 notes