#which is the no 1 cement in india

Explore tagged Tumblr posts

Text

#which is the no 1 cement in india#rmc concrete#ppc cement#no 1 cement in india#cement supplier#Psc Cement#best cement#cement dump#cement mandate#cement price#cement products#best cement for roof#ready mix concrete plant#rmc plant#Best Cement#Cement Supplier#Cement Manufacturer#Top Cement#Rmc Plant#Cement#Cement Products#Portland Cement#Cement Dump#Best Cement Brand India#Best Cement Company#top 10 best quality cement in india#best cement companies in India#best cement manufacturer

0 notes

Note

bucket here

I’d just like to note that the instant I sent the ask I started writing in the hopes you would say yes and I like actually squeaked I was so happy when you did and also I’ve been writing nonstop since then so bear with me:

*takes deep breath* Safety restrictions were famously lax in F1 until the 1990s. The deaths of Roland Ratzenberger and Ayrton Senna within days of each other at the 1994 Imola GP sparked a huge movement for new safety systems, especially barrier changes. As Senna and Ratzenburger both died in accidents related to the fact that the safety barriers at the edges of tracks were just CEMENT WALLS, this was a huge push for many teams, drivers, and tracks. No one wanted the death of more legends on their hands. These accidents also inspired additions like headrests in 1996 and the HANS system (head and neck support), put in place in 2003. HANS can be seen when drivers get out of the car — it’s that space-age looking neck brace/strap on their shoulders and helmet.

Some safety systems that are much less talked about are things like the accelerometer, first used in 2014 and placed in the drivers ear. This measures the forces during impacts, and its location in the ear allows both for less invasive placement and accurate data on head/neck movement for drivers. This then leads to better safety systems capable of being studied, reasoned for, and implemented. The addition in 2016 of a camera that faces the driver also allows for safety teams to see exactly how the driver is affected during crashes, as well as giving fans a fun camera angle (which I can rant about as well, camera angles in F1 are a huge thing for me).

Rapid fire safety systems (there will be a quiz):

Helmets were first introduced in 1952, but not required until 1977.

Seatbelts/racing harnesses required starting 1972.

Fireproof race suits have been required since 1975.

The safety car didn’t even exist until 1993 (trial runs in 1992, first seen in 1973 Canadian GP)

Pit lane speed limit introduced in 1994. Yes, before this they just ripped through as fast as they could; no, the pit crews didn’t stand any further away.

Wheel tethers introduced in 1999 after an unholy amount of incidents going back to pre-1950 (AKA official F1 start) where the wheels just came off and smacked drivers, marshals, and fans, usually killing them instantly.

The most notable safety system recently is the Halo and VSC (virtual safety car). The halo was put in place in 2018 and will hopefully never leave. It has been the savior of hundreds of lives throughout Formula series, but most well known in Formula 1 were Lewis Hamilton (2021 Monza GP, stopped Max Verstappen's car from becoming a permanent fixture in the side of his head) and Romain Grosjean (2020 Bahrain GP, pushed the crash fencing up away from his head as he hit the barriers), as well as possibly Zhou Guanyu (2022 British GP, flipped upside down and up over tire barriers into catch fencing) and Max Verstappen (2021 British GP, incredibly hard hit into a tire barrier — 51G impact at 160 MPH/257 KPH).

There had been a number of close calls that brought up the possibility of halos, like Fernando Alonso almost having his head removed from this world at Spa in 2012 on lap one, and an incident between Michael Schumacher and Vitantonio Luizzi at Abu Dhabi in 2010 that left Luizzi’s Force India inches from Schumacher’s face.

Unfortunately, it took the horrific death of Jules Bianchi in 2014 at the Japanese GP and a number of junior driver fatalities for the Halo to be finally seriously considered and implimented. Bianchi’s incident also led to the Virtual Safety car, which was put in place in 2015 to keep accidents like his from happening. I can talk more about his incident as well if you’d like. It’s a masterpiece of administrative fuck ups and terrible oversights.

(Ask me about it and camera angles I dare you)

HELLO BUCKET

this is wonderful thank u thank u

i did know a little about the senna crash (tho not the concrete barriers) (i do know that when it happened they were trying to revive the drivers union which is awful) and the bianchi crash (i looked at that quite extensively for update post) but Yeesh yeah the safety stuff is Terrifying. pls. pls tell me about the camera angles.

107 notes

·

View notes

Photo

Solomon

According to biblical tradition (and some say myth), King Solomon was the third and last king in the ancient United Kingdom of Israel. Other faiths, such as Islam and Rastafarianism, also embrace the notion of Solomon as a sagacious king and powerful prophet of Israel. He was renowned for his wisdom, his prolific writings, and his building accomplishments. Born around 1010 BCE, Solomon was the tenth son of King David (the second king of ancient united Israel) and the second son of Bathsheba. Like King Saul and King David, King Solomon reigned for 40 years in one of the highest and most prosperous periods in Israel's history - called by many, “The Golden Age” of Israel.

During his reign, Solomon controlled the trade routes coming out of Edom, Arabia, India, Africa, and Judea; he constructed an elaborate and profitable web of alliances (cemented by an enormous assemblage of hundreds of wives and concubines), and he purportedly built the first Temple of God in Jerusalem, which was destroyed (along with the entire city of Jerusalem) by the Babylonians in 586 BCE. Despite initial sovereign successes, the end of Solomon's rule was marked by several insurrections and attacks from both foreign and domestic enemies, as well as a disintegration of national and religious integrity because of cultural appeasements within Israel, which compromised and weakened the social fabric of the United Kingdom. He died in 931 BCE at age 80, possibly the most prosperous and productive king ever to rule over Israel.

The Traditional Story of King Solomon

The story of King Solomon begins with his father, King David, and his mother, Bathsheba. In the Hebrew scriptures, 2 Samuel 3 states that King David, anointed by the Prophet Samuel before King Saul's demise to be his replacement, officially became King of Judea (1010 BCE). Later, 2 Samuel 5 states that (in 1002 BCE) all the elders of Israel approached him to be their ruler, and “The king made a covenant with them at Hebron before the Lord, and they anointed David king over Israel.” King David's reign lasted 40 years, and like King Saul, it started off better than it ended.

David's initial zeal for God and for ethical integrity paved the way for his early fame and fortune, although being a man of warfare and blood (according to the scriptures), God decided that David was not suitable to be the one to build God's Temple (that would be placed in the hands of his son, Solomon). Moreover, David's illicit affair and subsequent devious actions (leading to the assassination of Uriah the Hittite and its cover-up) complicated the rest of David's reign - along with the rape of Tamar, the murder of Ammon, and the attempted coup of Absalom, among other controversies.

By the end of David's life, he had lost touch with Israelite society and eventually lost political control of it, as well. This led to an attempted coup by his son, Adonijah (whose mother was Haggith, David's fifth wife), who proclaimed himself to be king with the assistance of General Joab and Abiathar the Priest; however, the majority of Israel's institutional agents did not support Adonijah's claim. The Hebrew scriptures state that the Prophet Nathan went first to Bathsheba to alert her to Adonijah's usurpation of the throne, who then went to her husband, King David, to break the troubling news to him. Eventually, the Prophet Nathan joined the two, and King David officially made Solomon his heir apparent. David said, “Assuredly Solomon your son shall be king after me, and he shall sit on my throne in my place” (1 Kings 1).

Continue reading...

33 notes

·

View notes

Text

Pitch for a “The Dark Pictures Anthology” game:

1) The title

“The Thrill of the Hunt”

2) Prologue

1920, British-controlled India. Jaspreet Singh and Sameer Patel, Indian rebels who fought against the British Empire (the false protagonists of the prologue), have been captured by the British Army. Although they’ve been sentenced to execution, they learn that they are actually being transferred to the Kingsley Gentlemen’s Society. From what we can tell of the Society, it’s run by the rich and powerful of British society.

Jaspreet and Sameer then learn the reason why they’ve been transferred. Today is the day of “The Hunt” where the Society members work together to take down the prey in the designated game preserve. And Jaspreet and Sameer are the game.

Since this is the prologue, Jaspreet and Sameer unfortunately end up being killed by the Society.

3) Main story

Present day, Falkland Islands. Five strangers have been brought to the mansion of the Kingsley Gentlemen’s Society. Four of the strangers are there after being invited by the Society while the fifth is there because they are dating one of the Society members. For the invitees, they all have the same goal; join the Society and cement their status as part of the upper class.

But, just like with Sameer and Jaspreet, that’s not the case at all. Today is, once again, the day of “The Hunt”. Since the 1920s, the Society has gotten bored of hunting down people who have already been sentenced to death. To get an extra thrill, the Society now targets the hopeful and wealthy.

In the main villain’s words, “it is far more satisfying to tear down people who are happy and actually have something to lose since you know that it is you who caused their despair”.

As the players, it is up to you to determine if the five strangers can work together as a team to either escape or destroy the Kingsley Gentlemen’s Society. Or end up becoming just another trophy on their shelves…

4) Playable cast

a. Desmond Johnson (ADVENTUROUS, RATIONAL): A highly successful American lawyer whose dream is to become a Supreme Court Justice one day. Desmond becomes the de facto leader of the group. He is played by the celebrity guest actor, Michael B. Jordan.

b. Faye Simmons (NAIVE, INQUISITIVE): A biologist from London who was dating one of the Society members. Much to her horror, she learns that the reason why the Society member wanted to date her was so that he could lure her in and force her to participate in The Hunt.

c. Hiroki Akashi (STERN, OVERBEARING): A high-ranking shareholder of a Japanese corporation. Despite coming off as a little vain and arrogant, he does show a willingness to work with the group since he wants to make it home to his children.

d. Omar al-Ghazi (PARANOID, AMBITIOUS): A Saudi Arabian oil tycoon who has trouble trusting other people. His behavior is a result of numerous business deals that went wrong due to people betraying him, as well as his family becoming estranged to him. Despite this, Omar does take pride in his ambitious nature, even if he ended up alienating his loved ones.

e. Adrianna Reyes (ABRASIVE, LONELY): A Mexican billionaire businesswoman who is currently dealing with a scandal. She reveals to the group that even though she’s married, she had an affair with an unnamed Senator in the Mexican Senate. The reason for the affair was that her current marriage is loveless, only done for political reasons.

5) Bonus poll

#tumblr polls#polls#supermassive games#man of medan#little hope#house of ashes#the devil in me#directive 8020#michael b jordan#dark pictures anthology#dark pictures house of ashes#dark pictures little hope#dark pictures the devil in me#the dark pictures anthology#the dark pictures the devil in me#the dark pictures little hope#the dark pictures house of ashes#the dark pictures man of Medan#until dawn#the quarry#horror games#horror video games#horror ideas#story ideas#game idea#the curator#the dark pictures#video game#video games#gaming poll

12 notes

·

View notes

Text

the second fact (pt. 2)

bucket here

I’d just like to note that the instant I sent the ask I started writing in the hopes you would say yes and I like actually squeaked I was so happy when you did and also I’ve been writing nonstop since then so bear with me:

*takes deep breath*

Safety restrictions were famously lax in F1 until the 1990s. The deaths of Roland Ratzenberger and Ayrton Senna within days of each other at the 1994 Imola GP sparked a huge movement for new safety systems, especially barrier changes. As Senna and Ratzenburger both died in accidents related to the fact that the safety barriers at the edges of tracks were just CEMENT WALLS, this was a huge push for many teams, drivers, and tracks. No one wanted the death of more legends on their hands. These accidents also inspired additions like headrests in 1996 and the HANS system (head and neck support), put in place in 2003. HANS can be seen when drivers get out of the car — it’s that space-age looking neck brace/strap on their shoulders and helmet.

Some safety systems that are much less talked about are things like the accelerometer, first used in 2014 and placed in the drivers ear. This measures the forces during impacts, and its location in the ear allows both for less invasive placement and accurate data on head/neck movement for drivers. This then leads to better safety systems capable of being studied, reasoned for, and implemented. The addition in 2016 of a camera that faces the driver also allows for safety teams to see exactly how the driver is affected during crashes, as well as giving fans a fun camera angle (which I can rant about as well, camera angles in F1 are a huge thing for me).

Rapid fire safety systems (there will be a quiz):

Helmets were first introduced in 1952, but not required until 1977.

Seatbelts/racing harnesses required starting 1972.

Fireproof race suits have been required since 1975.

The safety car didn’t even exist until 1993 (trial runs in 1992, first seen in 1973 Canadian GP)

Pit lane speed limit introduced in 1994. Yes, before this they just ripped through as fast as they could; no, the pit crews didn’t stand any further away.

Wheel tethers introduced in 1999 after an unholy amount of incidents going back to pre-1950 (AKA official F1 start) where the wheels just came off and smacked drivers, marshals, and fans, usually killing them instantly.

The most notable safety system recently is the Halo and VSC (virtual safety car). The halo was put in place in 2018 and will hopefully never leave. It has been the savior of hundreds of lives throughout Formula series, but most well known in Formula 1 were Lewis Hamilton (2021 Monza GP, stopped Max Verstappen's car from becoming a permanent fixture in the side of his head) and Romain Grosjean (2020 Bahrain GP, pushed the crash fencing up away from his head as he hit the barriers), as well as possibly Zhou Guanyu (2022 British GP, flipped upside down and up over tire barriers into catch fencing) and Max Verstappen (2021 British GP, incredibly hard hit into a tire barrier — 51G impact at 160 MPH/257 KPH).

There had been a number of close calls that brought up the possibility of halos, like Fernando Alonso almost having his head removed from this world at Spa in 2012 on lap one, and an incident between Michael Schumacher and Vitantonio Luizzi at Abu Dhabi in 2010 that left Luizzi’s Force India inches from Schumacher’s face.

Unfortunately, it took the horrific death of Jules Bianchi in 2014 at the Japanese GP and a number of junior driver fatalities for the Halo to be finally seriously considered and implimented. Bianchi’s incident also led to the Virtual Safety car, which was put in place in 2015 to keep accidents like his from happening. I can talk more about his incident as well if you’d like. It’s a masterpiece of administrative fuck ups and terrible oversights.

(Ask me about it and camera angles I dare you)

<><><><>

7 notes

·

View notes

Text

Why Indian pharmaceutical companies are among the world’s best

India has emerged as a global leader in the pharmaceutical industry, making significant contributions to healthcare worldwide. With its vast network of pharma manufacturing companies in India, world-class infrastructure, and highly skilled workforce, the country has established itself as a major hub for drug production and innovation. The pharmaceutical industry in India plays a vital role in ensuring affordable and high-quality medicines reach patients across the globe. But what makes pharmaceutical companies in India stand out from the rest? Let us explore the factors that contribute to India's success in this sector.

1. Cost-Effective Manufacturing and High Production Capacity

One of the biggest reasons why pharma companies in India are highly regarded is their cost-effective manufacturing processes. Indian companies have mastered the art of producing high-quality medicines at a fraction of the cost compared to other countries. The medicine manufacturing company in India benefits from lower labor costs, efficient supply chain management, and advanced technological integration.

India is also known for its massive production capacity. Whether it is generic medicines, vaccines, or complex biologics, pharmaceutical companies in India produce a significant percentage of the world’s pharmaceutical products. This high-volume production capability allows India to meet global healthcare demands efficiently.

2. Strong Research and Development (R&D) Capabilities

India is home to some of the top pharmaceutical companies in India that invest heavily in research and development. The country has numerous state-of-the-art research facilities that focus on drug discovery, formulation development, and biosimilars.

Moreover, Indian pharma firms collaborate with global research institutions to develop innovative treatments for life-threatening diseases. This commitment to innovation has helped India stay ahead in the competitive pharmaceutical landscape.

3. Leadership in Generic Medicines

India is often referred to as the “Pharmacy of the World” due to its dominance in the generic drug market. The best Indian pharma industry supplies more than 50% of the global demand for generic medicines. Generic drugs offer the same therapeutic benefits as branded medications but at much lower prices, making healthcare more affordable for millions worldwide.

The ability of pharma manufacturing companies in India to produce high-quality generics at competitive prices has helped many developing and underdeveloped nations improve their healthcare systems. This stronghold in the generics market has cemented India’s position as a leading player in the pharmaceutical industry.

4. Regulatory Compliance and Global Certifications

Indian pharmaceutical companies adhere to stringent quality control standards and obtain regulatory approvals from leading global authorities such as the U.S. FDA, EMA (European Medicines Agency), and WHO-GMP. These certifications validate the high-quality standards maintained by medicine manufacturing company in India, enabling them to export medicines to over 200 countries.

The strict compliance with international regulations ensures that Indian pharmaceutical products meet global safety and efficacy standards. This commitment to quality has helped Indian pharma companies build trust among healthcare professionals and patients worldwide.

5. Growing Biopharmaceutical and Vaccine Industry

While India is well known for generic drugs, it has also made significant advancements in biopharmaceuticals and vaccine production. The country is home to leading vaccine manufacturers like Serum Institute of India, which played a crucial role in supplying COVID-19 vaccines globally.

The best pharmaceutical industry in India continues to invest in biopharmaceutical research, aiming to develop advanced biologics and biosimilars. With increasing government support and private sector investments, India's biopharma industry is set to achieve new milestones in the coming years.

6. Availability of Skilled Workforce and Advanced Infrastructure

India’s pharmaceutical success is backed by a vast pool of skilled professionals, including scientists, pharmacists, engineers, and regulatory experts. The country produces thousands of pharmacy and life sciences graduates every year, ensuring a steady supply of talent for the industry.

Additionally, top pharmaceutical companies in India have invested in state-of-the-art manufacturing facilities that integrate automation, artificial intelligence, and data analytics to enhance production efficiency. The combination of skilled labor and modern infrastructure has helped Indian pharmaceutical companies maintain their global competitiveness.

7. Strong Export Market and Global Presence

Indian pharmaceutical companies have a significant global presence, exporting medicines to countries across North America, Europe, Africa, and Asia. The best pharma company in India contributes to over 20% of the global supply of generic drugs, making India the largest exporter of pharmaceutical products by volume.

The country’s ability to provide affordable and effective medicines has strengthened its reputation as a trusted supplier in the global pharmaceutical industry. With continued investment in research, innovation, and quality control, top pharma companies in India are expected to expand their reach further.

8. Government Support and Policy Initiatives

The Indian government has played a crucial role in supporting the growth of the pharmaceutical sector. Various policy initiatives such as the Production Linked Incentive (PLI) Scheme and Make in India program have encouraged domestic manufacturing and research.

Moreover, the government has eased regulatory processes and provided financial incentives to boost pharmaceutical exports. These measures have helped pharma companies in India scale up their operations and compete with global pharmaceutical giants.

9. Focus on Emerging Therapeutic Areas

Indian pharmaceutical companies are increasingly focusing on emerging therapeutic areas such as oncology, neurology, and rare diseases. With the rise in chronic and lifestyle diseases, the demand for specialized treatments is growing. Many top pharma companies in the world are partnering with Indian firms to develop innovative therapies that address these healthcare challenges.

The shift towards high-value and niche segments showcases India's potential to lead in advanced drug discovery and personalized medicine.

Conclusion

The best pharmaceutical industry in India has earned its place among the top pharma companies in the world through its cost-effective manufacturing, strong research capabilities, regulatory compliance, and global reach. As the pharmaceutical industry in India continues to evolve, it is set to play an even more significant role in shaping the future of global healthcare.

With continuous innovation, government support, and a skilled workforce, pharmaceutical companies in India are well-positioned to remain at the forefront of the global pharmaceutical landscape. Whether it is generic medicines, vaccines, or cutting-edge biopharmaceuticals, India’s pharma industry is poised for continued growth and success in the years to come.

#Pharma manufacturing companies in India#Medicine manufacturing company#Top pharmaceutical companies in India#Pharma companies in India#Pharmaceutical companies in India#Top pharma companies in the world#Best pharmaceutical industry in India#Best pharma company in India#Pharmaceutical industry in India#Medicine manufacturing company in India#Best Indian pharma industry#Top pharma companies in India#Healthcare#Hospitals#Diagnostics#Pharmacy#Prescription Medications

4 notes

·

View notes

Text

The Most Expensive Stock in India:

A 73,600x increase in just two days

Elcid Investments, the Most Expensive Stock in India: From ₹3 to ₹2,36,250

A 73,600x increase in just two days

The share price of Elcid Investments started off only at ₹3.21. However, shortly after being relisted on the BSE on October 29, 2024, its share value increased to 225,000 rupees before closing 5% up at 236,250 rupees. Not only did this increase boost the profile of Elcid Investments, but it also made it the highest priced share in India, overtaking MRF Ltd that had its shares trading at 122,576.50 rupees on that day.

What is Elcid Investments and who owns it?

Elcid Investments is an NBFC incorporated with the Reserve Bank of India that is engaged in the business of investing in equities, bonds, mutual funds and other related securities. The business is also parent to two firms, Suptaswar Investments & Trading Company Limited and Murahar Investments & Trading Company Limited. Each of these subsidiaries are also registered with RBI as NBFCs.

75% of the Mumbai based non banking finance company Elcid is owned by the owners of Asian Paints whereas Hydra Trading and 3 A Capital Services owns 9.04% and 3.34% of the company respectively.

Business Overview

Excluding the managing director, only three people remained in the full employment category with the firm. In financial Year 24 which is the year in which Elcid Investments company’s net profits climbed by 139 % to 176 crores rupees.

The balked share capital rose in its sales more than two-folds to 236 crores in the year under review. There were only 200,000 shares issued and outstanding at the end of September 2024, 75 percent of which are promoters. There were 241 traded stocks at the centre(s) BSE on Tuesday against the average volume of 100 days of five shares.

What made the price of shares for Elcid Investments outrun other stocks?

The company's re-list on the BSE on 29 October 2024 raised the stock price which led the shareholders to immense profit. The company's capital now stands at rupees 4725 crores.

There was no delay in the selling of that particular share which was later followed up by a high frequency of buying due to mistakes from shareholders.

In June, the market regulator, Sebi, advised stock exchanges to conduct special call options for a few of the investment holding companies or holdco, whose shares are being offered at an extreme discount to the book value of the stocks.

It also issued a framework allowing some of the holding companies to bid for such price discovery. Holding companies hold interests in other assets including shares of listed companies without running any business activity on their own.

Consequently, the first of such call options developed on October 28 to discover prices and in two sessions, elcid shares increased Rs 236246.47.

What’s more puzzling is the fact that shares of Elcid stock were available at only Rs 3.53 till last week.

The book value of the stock was about Rs 5,84225 as at the end of March 2024, the last week price of Rs 3.53 was that of a Friday, which is the reason for the spike in the price. Even with this sudden spike, the company's book value has already been 2.5 times more than the Tuesday price of 236,250.

On Tuesday, Elcid investments closed shares at Rs 2, 32, 250 each, whereas shares in MRF were at Rs 1, 22, 577.

Another important reason for its high price is due to the ownership of Elcid Investments, which is around 8,500 crores and cited as owning more than 2,83,13,860 equity shares or a 2.95% stake in Asian Paints Ltd.

India’s Most Expensive Stocks

Other than Elcid Investments, there are just 30 companies in India whose shares trade more than Rs10,000 apiece. Some stocks that stand out in this group include MRF, Page Industries, Honeywell Automation India, Shree Cement, 3M India, Abbott India, Nestle India, Bosch,Procter & Gamble Hygiene, and Lakshmi Machine Works. Investors engage with these stocks because they have a trustworthy return on investment and have proven to be sound investments that perform well over the long term.

2 notes

·

View notes

Text

5 Popular Women GMs That Will Inspire Every Girl Child

Time and again women have proved that they are a force to be reckoned with in every sphere of life. And the chess world is no exception. From not being allowed to play, to having separate tournaments specially for women — it has been a long journey!

Despite facing challenges and pressure from society, women have excelled in chess and will only keep getting better from here on.

The pioneers of this change are undoubtedly the women Grandmasters all over the world. They beat stereotypes and play neck and neck with men in international tournaments.

Let us take a look at some of the popular women Grandmasters in Chess –

1. Nona Gaprindashvili

This list won’t get its deserved start if we do not mention the first woman to ever receive the International Grandmaster title from FIDE. Born in 1941, this Georgian (then Soviet) player has played in numerous international tournaments and won several of them.

She was the Women’s World Champion from 1962 to 1978! She participated in the Women’s Chess Olympiad for the Soviet Union many times between 1963 to 1990 and for Georgia in 1992. She contributed immensely to the team in these olympiads and won many gold medals along the way! She has also won the Women’s World Senior Championship several times between 1995 to 2019.

Nona Gaprindashvili has given more to the field of chess than words can express. She was the flagbearer of women’s chess and gave hope and inspiration to many young girls to work hard and achieve the Grandmaster title.

2. Judit Polgar

Popularly referred to as the strongest woman chess player of all time, Grandmaster Judit Polgar needs absolutely no introduction! She was known for her aggressive, tactical and fierce playing style. But here’s something that has cemented her fierce reputation amongst the chess world. She is the only woman to have played in the men’s candidates tournament and to have crossed the 2700 elo mark in the history of chess!

In her long and successful chess career, she has won games against fellow legends like GM Anatoly Karpov, GM Garry Kasparov, GM Magnus Carlsen, GM Viswanathan Anand, GM Vladimir Kramnik, GM Veselin Topalov and many more in either rapid or classical formats.

She is the only woman to be ranked among the top 10 of all chess players, her peak ranking being 8th in 2004.

She has been a source of inspiration for countless women chess players. And she truly has broken many gender stereotypes people have about women playing chess.

3. Koneru Humpy

The highest ranked Indian woman player and one of the finest Grandmasters of our country, Koneru Humpy has been a sensation since her childhood days. She achieved the title of Grandmaster in 2002, at the young age of 15 years and 1 month – a feat not achieved by any other Indian woman so far!

GM Koneru has won many world youth championships and in 2001 she won the coveted World Junior Girls Championship. Interestingly, she participated in the boys’ section of the World Junior Championship in 2004 and tied for 5th place which is an extremely amazing achievement!

In 2019, she won the Women’s World Rapid Championship. In 2020, she was a crucial part of the gold medal winning Indian team for the Online Chess Olympiad.

She is also the recipient of the honorable Padma Shri Award and Arjuna Award for her contribution to the field of chess. In 2020, she received the BBC Indian Sportswoman of the year award.

If Vishy Anand has influenced India to take up chess, GM Koneru Humpy has done the same for young Indian girls.

4. Alexandra Kosteniuk

Popularly known as the chess queen, Russian GM Alexandra Kosteniuk is one of the finest female Grandmasters in the history of chess. She was the Women’s World Chess Champion from 2008 to 2010. She is also the first person to win the Chess960 Women’s World Championship. In 2013, she became the first woman to win the men’s Swiss Chess Championship.

She has won numerous gold medals while playing for team Russia in the Women’s Chess Olympiad, Women’s World Chess Team Championship and Women’s European Chess Team Championship.

GM Kosteniuk is known to play aggressively and quickly, often creating pressure over her opponent with her speed. She has been one of the top women grandmasters in Russia for many years and has even won the Women’s World Cup in 2021.

5. Hou Yifan

A chess prodigy, GM Hou Yifan has taken the chess world by storm since her debut. She is the youngest female to achieve the Grandmaster title and the second highest rated female chess player after GM Judit Polgar.

Between 2010 to 2017, she has won the Women’s World Chess Championship 4 times!

Currently ranked no.1 in active players, she has held that streak since September 2015!

Many regard her as the best active female chess player and her track record only proves her capabilities.

Apart from being a successful chess player, she’s also given equal importance to academics and completed her degree from University of Oxford. She is now working as a professor at Shenzhen University.

WGMs - a humble gratitude

Women have had to face many obstacles in their respective careers over the years. Despite that, they have strongly overcome these hurdles and established themselves firmly.

The female Grandmasters mentioned in this article and many others have done the same in the field of chess. They have broken barriers and set new records and fought neck and neck with their male competitors. They are a constant source of inspiration for many young girls to take up chess professionally.

To such exceptional female personalities, we extend our humble gratitude!

#chessclasses#chess#chessgame#chessclassesforkids#onlinelearning#chessboard#onlinechess#chess club#onlineeducation#chessonline

3 notes

·

View notes

Text

HOW NEHRU CAN TRULY BE CALLED 'THE ARCHITECT OF INDIA'S BIMARU ECONOMIC STRUCTURE'. ................................................................................. - HOW NEHRU INCOMPETENTLY, & PER MANY HISTORIANS, MALICIOUSLY, RUINED EASTERN INDIAN ECONOMIES, LIKE BENGAL, BIHAR, JHARKHAND, MADHYA PRADESH, CHHATTISGARH, & ORISSA, BY HIS ONE SIDED (SUBSIDIZED/EQUALIZED FREIGHT COST OF RAW MATERIAL ONLY & NOT FOR FINISHED GOODS) FREIGHT EQUALIZATION POLICY. - HOW NEHRU IN THE GARB OF A SOCIALIST INDIA, MANAGED TO CREATED A REGRESSIVELY CAPITALISTIC INDIA INSTEAD.

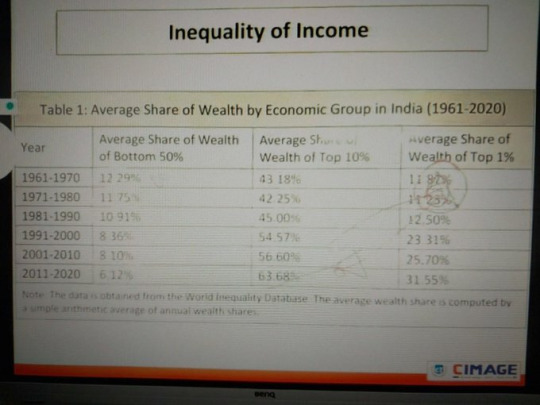

Here are India's 60 yr Share of Wealth stats, from 1961-2020, taken from the 'World Inequality Database'.

Looking at which, most would be forced to ask, why is it that in a wholly socialized state like India (& heavily publicized so at that for 60 yrs)....that our Top 1% 's share in wealth goes up 3 times, Top 10%'s share goes up 1.5 times, BUT SHARE OF THE BOTTOM 50% IS LITERALLY HALVED?

The answer to this lies largely in one man, Nehru, & his policies, either incompetently unintentional or maliciously intentional, policies directly responsible for creating a deeply disparate & heavily lopsided yet overall non-flourishing economic structure, for the entire first half century of the 'Dominion (of Britain) India'.

And the biggest mishap-causing misadventure, being 1951's infamous FREIGHT EQUALIZATION POLICY.

👇

https://en.wikipedia.org/wiki/Freight_equalisation_policy#:~:text=Freight%20equalisation%20policy%20was%20adopted,subsidised%20by%20the%20central%20government.

☝

Above is the Russian Govt+military reaction, to Indian 'independence' in mid 1947. This article was published in the Russian central military newspaper 'Red Star' on July 31, 1947, just 2 weeks before the official date of India's so-called Independence.

"Chief economic positions still remain in British hands–railways,marine transport,port economy,irrigation systems,finance,basic part of jute,industry,almost whole mining industry etc"

“The defence of economic positions and interests is not possible without political power. That power will be secured in the person of the capitalists, landowners and businessmen who are dependent upon British capital.”

“The partition, does not affect the feudal power of the Princes who have always supported British domination.”

"The British Govt plans to artificially separate industrial from agricultural areas,turning it to a agrarian & raw material appendage of Britain."

Exactly what Nehru's Freight Equalization Policy achieved 4 yrs later!

And to add to what y'all I assume would already have read from above, as to it's evil designs & effects, it created a reverse-reward scenario, whereby all the resource-rich states were essentially penalized for their natural advantages, by taking away all incentive for processing-industries & final transportation industries, that are a logical next step from the extraction industries, to germinate & set base in these places. Thereby creating a scenario where the South-western & western coastal states like Maharashtra, Gujarat & Tamil Nadu, & parts of Punjab in North India, were able to find logical easy base for all the processing & transportation industries in their states, for industries like steel, cement, heavy manufacturing, & power, all enabled via raw materials from the other far-off states, like iron ore, coal, limestone, bauxite, copper etc, even w/o any personal natural resources to rely on themselves, merely by virtue of being easy locations to set up ports in for exports, & w/o industries having to compromise on higher transportation & value-added processing costs, that cost aspect equalized & protected for all distances from the resource point. All this, with resource states not finding even some respite in terms of return benefits from any possibly subsidized finished product costs, finished goods not covered by this policy!

These 4-5 states effectively thus became the parasites, for atleast 7 of the traditionally god-gifted states of today like Bihar, Jharkhand, Madhya Pradesh, Chhattisgarh, Orissa, Bengal & Uttar Pradesh, killing all their hope at industrial development & economic progress, & where there is economic (or lotsa times attached) spiritual hopelessness, springs leftism in all it's devious forms, giving birth to intense communism & it's shameful offsprings of caste-divide & gang-culture, literally turning these states HOUSING HALF OF INDIA'S POPULATION, into the pot-holes of the Indian Union -the BIMARU (for Bihar, Madhya Pradesh, Rajasthan, Uttar Pradesh) states of India.

Now in all of this, it's not as if the above-mentioned coastal states were turning themselves into heavens of prosperity either, merely relatively well-off & with a hopeful disposition of the future, that in itself enough to attract large-scale migration from the above BIMARU states, particularly Maharashtra with a more traditionally Hindi-friendly ambience, but also in TN, creating a new urban housing problem, giving birth anew to Mumbai's infamously gargantuan chawl (dingy hutment) lifestyle.

And the reasons for these states, given all these special privileges, not able to take off well enough, aren't directly visible, yet that we can now, on basis of our analysis of Nehru & his so-called Independent India, over innumerable blogs prior, safely interpret, to be an India yet functioning in 1950s & till mid-1960s as some sort of a vassal state of Britain. Only natural then for a supreme state in such a relationship, to not be assumed to desire nations other than itself any sorta economic or strategic base in it's territory, thus curtailing more robust foreign economic to-and-fro.

A utterly class-subservient bent, not seen just for the British race, but per historians, eg Kanchan Gupta, in his hateful sense of complex & hatred of dark-skinned & skinny Bengali community, even worse passionate Hindu Durga-lovers, & per many, all largely borne of his hatred for Bose.

And thus ends yet another inglorious chapter from the life of the self-confessed Last British Ruler of India.

The Tale of the Internal Destruction of India, & it's Premier at it.

2 notes

·

View notes

Text

Trusted Cardiac Diabetic Franchise Company in Baddi for Quality Growth

1. A Heartbeat for Innovation: The Rise of Cardiac Lifecare

In the realm of pharmaceuticals, few names echo as profoundly as Cardiac Lifecare. A company forged from a vision to revolutionize healthcare accessibility, Cardiac Lifecare has consistently set industry benchmarks in the cardiovascular and diabetic segments. As lifestyle diseases rise globally, the need for dedicated healthcare solutions is more pressing than ever—and Cardiac Lifecare answers this call with precision and purpose.

Based in the pharmaceutical hub of Baddi, the company has emerged as a symbol of trust, quality, and innovation. Known for being a cardiac diabetic franchise company in Baddi, Cardiac Lifecare has leveraged location, expertise, and vision to become a formidable force in India’s healthcare landscape.

2. Rooted in Baddi: A Strategic Stronghold

Nestled in the Solan district of Himachal Pradesh, Baddi has grown into one of India’s largest pharmaceutical manufacturing bases. Cardiac Lifecare’s presence here is more than geographical; it is strategic. With access to state-of-the-art infrastructure and a skilled workforce, Baddi empowers the company to meet large-scale demands while ensuring top-notch quality.

Moreover, the region’s supportive regulatory environment and proximity to northern Indian markets further bolster the company’s reach. For aspiring entrepreneurs looking to partner with a cardiac diabetic franchise company in Baddi, Cardiac Lifecare presents unmatched logistical and economic advantages.

3. Crafting Care: The Science Behind Every Tablet

Every capsule, tablet, or injection that leaves the Cardiac Lifecare facility is the result of meticulous research and stringent quality control. The company’s R&D team constantly works on formulating new treatments that cater to evolving patient needs, especially for cardiac and diabetic conditions, which require nuanced and long-term care.

Stringent adherence to WHO-GMP standards, ISO certifications, and a focus on zero-defect manufacturing ensures that each product is safe, effective, and reliable. This commitment to excellence cements Cardiac Lifecare's reputation as a top-tier player in the pharmaceutical space.

4. Cardiac and Diabetic Care: The Twin Pillars

What truly distinguishes Cardiac Lifecare is its focused specialization. While many pharmaceutical companies attempt to cover a wide therapeutic spectrum, Cardiac Lifecare zeroes in on cardiac and diabetic treatments—two of the world’s most pressing healthcare challenges.

With an aging population and sedentary lifestyles becoming the norm, conditions like hypertension, arrhythmia, type 2 diabetes, and heart failure are on the rise. Cardiac Lifecare responds to this epidemic with a range of innovative, affordable, and accessible treatments that prioritize both prevention and long-term disease management.

5. Franchise with a Future: Empowering Entrepreneurs

Cardiac Lifecare isn’t just about manufacturing; it’s about empowering. As a leading cardiac diabetic franchise company in Baddi, it offers a golden opportunity for aspiring pharma professionals and entrepreneurs to enter the healthcare industry with confidence.

The company’s franchise model is designed for success. With extensive marketing support, monopoly rights, prompt product delivery, and a wide product portfolio, franchise partners are equipped with everything they need to thrive. It’s not just a business partnership—it’s a shared mission to improve lives.

6. Innovation at Its Core: R&D That Drives Results

In a dynamic industry like pharmaceuticals, standing still is not an option. Cardiac Lifecare’s robust R&D division is a hub of innovation, constantly exploring novel formulations, improved delivery systems, and bioequivalent generics. The goal is clear: enhance patient outcomes while keeping treatments affordable.

Whether it's the introduction of fixed-dose combinations for better compliance or extended-release tablets for improved efficacy, Cardiac Lifecare stays ahead of the curve. This dedication to research ensures that franchise partners always have access to cutting-edge solutions that set them apart in the market.

7. The Human Touch: Customer-Centric Healthcare

Behind the complex chemical formulations and high-tech machinery lies a simple truth—Cardiac Lifecare cares. Its approach is deeply human-centric. The company believes that every patient, regardless of location or income, deserves access to quality treatment. This belief drives its pricing strategies, distribution models, and after-sales support.

For its franchisees, this ethos translates into strong brand loyalty and repeat prescriptions. Doctors and patients alike trust Cardiac Lifecare, not just for the science, but for the sincerity behind it. It’s this emotional equity that often makes all the difference in a crowded marketplace.

8. Sustainability Matters: Green Pharma for a Healthy Planet

While saving lives is a noble pursuit, Cardiac Lifecare understands that preserving the planet is equally vital. The company integrates eco-friendly practices into its operations—from energy-efficient manufacturing to responsible waste management and green packaging.

In a world increasingly leaning towards conscious consumption, being a sustainable business is not just good ethics—it’s smart economics. Franchisees can proudly associate with a brand that doesn’t just heal people but also helps heal the planet.

9. Testimonials That Talk: Voices of Trust

Nothing speaks louder than the voices of those who’ve experienced the Cardiac Lifecare journey. Across India, franchise partners and healthcare providers share stories of support, success, and satisfaction. From Tier-II towns to metropolitan hubs, the brand’s reputation precedes itself.

Doctors commend the product quality and consistency, while franchise owners highlight timely supplies, excellent margins, and unmatched support. It’s these real-world endorsements that solidify Cardiac Lifecare’s standing as a premier cardiac diabetic franchise company in Baddi.

10. The Road Ahead: A Vision for Global Wellness

Cardiac Lifecare’s journey is far from over. With plans to expand internationally, launch new divisions, and deepen its digital presence, the company is ready to embrace the future of healthcare. Telemedicine, AI-driven diagnostics, and personalized medicine are all on the horizon, and Cardiac Lifecare aims to lead these transformations.

Franchise partners can expect even greater opportunities as the brand expands its reach and influence. For those seeking to align with a future-ready, impact-driven, and ethically rooted pharmaceutical company, the path is clear—and it beats strongly at the heart of Cardiac Lifecare.

In Conclusion:

Cardiac Lifecare is not just a pharmaceutical company—it is a movement toward accessible, ethical, and innovative healthcare. As a dedicated cardiac diabetic franchise company in Baddi, it combines local strength with global ambition, scientific rigor with human compassion, and tradition with technology. Whether you’re a healthcare professional, an aspiring entrepreneur, or a patient, Cardiac Lifecare is a name you can trust—because when it comes to matters of the heart, only the best will do.

0 notes

Text

Reliable Centrifugal Blowers Manufacturers in India | Custom Sizes Available

In moving air or gases, centrifugal blowers are vital for the processes within an industry. These machines find applications in factories, plants, and ventilation systems. Many Centrifugal Blowers Manufacturers exist in India, and Aerotech fans is among the most trusted. This company has been making blowers of good quality for a long time and has acquired a very good reputation for reliability, performance, and customer satisfaction. Their products are utilized by many of the industries in the country.

Aerotech Fans Products Are Superior Quality

Aerotech Fans makes its centrifugal blowers with tough materials and modern techniques. All blowers are designed to perform well in tough operating conditions. They are tested for quality before they are sent to the customer and therefore a customer gets a product that lasts, operates very smoothly, and demands very little service. Also, there are Aerotech Fans blowers, which promise energy savings and thus reduce the cost of consuming electricity while providing air with great power. That is the reason why Aerotech Fans is remembered as long-lasting by the companies in India.

Wide-Ranging Applications

Centrifugal blowers manufactured by Aerotech Fans are employed in a myriad of industries. They are useful nearly anywhere one needs to move, cool, or clean air. When it comes to textiles, they'd work for dust and heat removal; drying and ventilation in food; dust collection and gas handling in cement and chemicals; for air supply and exhaust in HVAC. Aerotech Fans knows these requirements and thus offers blowers for various applications, sizes, and power ratings.

As far as service reliability and customer service are concerned

At Aerotech Fans, the company's philosophy is product, service, and market. The experienced team is able to assist customers in specifying the right blower design for their application. Similarly, they help with installation, along with rendered services for full technical support as requested. The company believes much more in nurturing long-term relationships with its customers, responding promptly to the service requests never leaving a stone unturned for their satisfaction. This very supportive network is the reason Aerotech Fans stands out within the supplier category for industrial buyers deploying blower manufacturers on India.

Top most Position in the Centrifugal Blowers Manufacturers in India

Aerotech Fans is now a household name in India for centrifugal blowers, thanks to years of hard work. It has earned this reputation due to its focus on quality, performance, and service in a fiercely competitive market. They continually improve their designs and adopt modern technology for better solutions. If you are looking forward to trusting centrifugal blower manufacturers in India, beyond any doubt, you can depend on Aerotech Fans. Products manufactured in India, built to last, and competitively priced-The perfect partner for powerful and reliable air movement systems-Aerotech Fans.

visit- https://www.aerotechfans.in/centrifugal-blowers/ Address- Plot No. 189, Ecotech Extensions-1, Kasana Greater Noida-201301, (Near Asian Paint) Uttar Pradesh, India

1 note

·

View note

Text

In the realm of modern construction, Ready-Mix Concrete (RMC) has emerged as a game-changer, offering unparalleled convenience, quality, and efficiency. As a leading cement brand in India, Kamdhenu Cement is at the forefront of this revolutionary shift in construction practices. In this blog, we delve into the world of RMC concrete, exploring its benefits, applications, and why it's becoming the preferred choice for builders and contractors alike.

Understanding RMC Concrete

What is RMC Concrete?

Ready-Mix Concrete, commonly referred to as RMC concrete, is a specialized form of concrete that is manufactured in a batching plant according to a set recipe and then delivered to the construction site in a ready-to-use condition. Unlike traditional on-site mixing, where raw materials are mixed manually, RMC concrete offers a standardized and quality-controlled alternative.

How is RMC Concrete Produced?

The production process of RMC concrete begins with the careful selection and proportioning of raw materials, including cement, aggregates, water, and additives. These ingredients are precisely measured and mixed in a centralized batching plant using sophisticated equipment and techniques. Once mixed, the concrete is transported to the construction site in specialized vehicles, such as transit mixers, to ensure freshness and workability.

Advantages of RMC Concrete

1. Consistent Quality

One of the primary advantages of RMC concrete is its consistent quality. By adhering to strict production standards and quality control measures, RMC manufacturers like Kamdhenu Cement ensure that each batch of concrete meets the required specifications, resulting in uniform strength, durability, and performance.

2. Time Savings

With RMC concrete, time is of the essence. By eliminating the need for on-site mixing, RMC offers significant time savings, allowing construction projects to proceed more efficiently. This accelerated construction pace translates into faster project completion times and reduced labor costs, making RMC an attractive option for builders and developers.

3. Cost Efficiency

While the initial cost of RMC concrete may be slightly higher than traditional concrete, its long-term cost benefits far outweigh the initial investment. The streamlined production process, reduced material wastage, and enhanced construction efficiency result in overall cost savings for construction projects of all scales.

4. Enhanced Workability

RMC concrete is engineered for optimal workability, ensuring smooth placement, consolidation, and finishing on the construction site. Its consistent composition and controlled properties make it easier to handle and manipulate, thereby improving construction productivity and reducing labor requirements.

5. Environmental Sustainability

In an era where environmental sustainability is paramount, RMC concrete offers several eco-friendly advantages. By minimizing material wastage, reducing carbon emissions associated with on-site mixing, and optimizing transportation logistics, RMC contributes to a more sustainable and environmentally responsible construction industry.

Applications of RMC Concrete

Residential Construction

From individual homes to multi-story apartment complexes, RMC concrete is widely used in residential construction projects of all scales. Its consistent quality, time-saving benefits, and ease of use make it the preferred choice for builders and homeowners alike.

Commercial Projects

In the realm of commercial construction, where speed and efficiency are paramount, RMC concrete shines. Whether it's office buildings, shopping malls, or industrial facilities, RMC concrete offers the durability, strength, and versatility required for modern commercial projects.

Infrastructure Development

RMC concrete plays a crucial role in infrastructure development, including roads, bridges, dams, and airports. Its high strength, durability, and resistance to environmental factors make it an ideal choice for critical infrastructure projects that require long-term performance and reliability.

Conclusion

In conclusion, RMC concrete represents a paradigm shift in the construction industry, offering unmatched quality, efficiency, and sustainability. As a leading cement brand in India, Kamdhenu Cement is proud to be at the forefront of this innovation, providing high-quality RMC concrete solutions that meet the evolving needs of builders, contractors, and developers. Whether it's residential, commercial, or infrastructure projects, RMC concrete offers a host of benefits that are reshaping the way we build for the future.

Experience the difference with Kamdhenu Cement's RMC concrete – the cornerstone of modern construction. Contact us today to learn more about our RMC concrete solutions and how they can elevate your next construction project to new heights of excellence and efficiency.

#best cement#no 1 cement in india#which is the no 1 cement in india#cement price#rmc concrete#ppc cement#Psc Cement#cement mandate#ready mix concrete plant#rmc plants#cement#cement products#best cement for roof#cement supplier#cement dump#portland cement#cement manufacturer#Top Cement#rmc ready mix concrete

0 notes

Text

Guide To Premier Concrete Solid Block Manufacturer in Navi Mumbai – Saibuildcast Blocks

When it comes to construction, the foundation of any structure relies heavily on the quality of building materials used. Concrete solid blocks are one of the most essential components in modern construction due to their strength, durability, and cost-effectiveness. If you're looking for a reliable Concrete Solid Block Manufacturer in Navi Mumbai, Saibuildcast Blocks stands out as a trusted name in the industry.

At Saibuildcast Blocks, we specialize in manufacturing high-quality concrete solid blocks that meet industry standards and cater to diverse construction needs. Whether you're working on residential, commercial, or industrial projects, our products ensure superior performance and longevity.

Why Choose Saibuildcast Blocks as Your Concrete Solid Block Manufacturer in Navi Mumbai?

1. Superior Quality Materials

We use premium-grade cement, fine aggregates, and precise water ratios to produce concrete solid blocks that offer exceptional compressive strength. Our manufacturing process adheres to IS 2185 (Part 1) standards, ensuring durability and resistance to weathering, moisture, and structural stress.

2. High Strength & Durability

Our concrete solid blocks are known for their high load-bearing capacity, making them ideal for constructing strong walls, foundations, and pavements. Unlike traditional bricks, these blocks provide better thermal insulation and soundproofing, enhancing the comfort of buildings.

3. Cost-Effective & Eco-Friendly

Concrete solid blocks are more economicalcompared to conventional bricks due to their larger size, which reduces the need for excessive mortar and labor. Additionally, they are environmentally friendly, as they minimize construction waste and reduce the carbon footprint.

4. Customizable Sizes & Shapes

We offer standard and customized sizes to meet specific project requirements. Whether you need 4-inch, 6-inch, or 8-inch blocks, we provide tailored solutions for different construction applications.

5. Timely Delivery & Pan-India Supply

As a leading Concrete Solid Block Manufacturer in Navi Mumbai, we ensure on-time delivery across Navi Mumbai, Thane, Mumbai, and other regions in Maharashtra. Our efficient logistics network guarantees that your project stays on schedule.

Applications of Concrete Solid Blocks

Our high-density concrete solid blocks are widely used in:

✔ Residential Buildings (Houses, Apartments, Villas) ✔ Commercial Complexes (Offices, Malls, Hotels) ✔ Industrial Structures (Warehouses, Factories, Godowns) ✔ Infrastructure Projects (Bridges, Retaining Walls, Pavements)

Advantages of Using Saibuildcast Concrete Solid Blocks

✅ Fire-Resistant – Enhances building safety. ✅ Low Maintenance – Long-lasting with minimal upkeep. ✅ Termite-Proof – Prevents pest infestations. ✅ Faster Construction – Larger size reduces laying time.

Why Navi Mumbai Prefers Saibuildcast Blocks?

Navi Mumbai is a rapidly growing hub for real estate and infrastructure development. Builders and contractors in the region prefer Saibuildcast Blocks because:

Local Manufacturing Facility – Reduced transportation costs.

Strict Quality Control – Every batch is tested for strength & consistency.

Competitive Pricing – Affordable without compromising quality.

Expert Technical Support – Guidance on block selection & usage.

Frequently Asked Questions (FAQs)

Q1. What is the compressive strength of your concrete solid blocks?

Our blocks have a compressive strength ranging from 4 MPa to 7 MPa, depending on the mix design and application.

Q2. Do you supply concrete solid blocks outside Navi Mumbai?

Yes, we deliver across Mumbai, Thane, Pune, and other parts of Maharashtra.

Q3. How do concrete solid blocks compare to clay bricks?

Concrete blocks offer better strength, thermal insulation, and durability compared to traditional clay bricks. They also require less mortar, reducing construction costs.

Q4. Can I get customized block sizes?

Absolutely! We provide tailor-made solutionsbased on project specifications.

Q5. What is the lead time for bulk orders?

We maintain sufficient stock for quick dispatch, and bulk orders are processed with minimal lead time.

Choose Saibuildcast Blocks for Unmatched Quality!

When you need high-performance concrete solid blocks in Navi Mumbai, Saibuildcast Blocks is your go-to manufacturer. With a commitment to quality, affordability, and sustainability, we support your construction projects with the best materials available.

Contact Us Today!

📞 Phone: +91 8796181821, 7021596847 📍 Address: Office No. 805, Crown Building, Sector 15, Near D Mart, Kharghar, Navi Mumbai 410210 📧 Email: [email protected] 🌐 Website: https://saibuildcastblocks.com

Build stronger, smarter, and more efficiently with Saibuildcast Blocks – Your Trusted Concrete Solid Block Manufacturer in Navi Mumbai.

0 notes

Text

Calcined Lime Powder Applications | Choose the Right Manufacturer in Jodhpur

In industrial and chemical processes, one material that consistently proves its value is calcined lime powder. Known for its high reactivity and purity, calcined lime—also referred to as quick lime—serves multiple sectors such as metallurgy, construction, water treatment, and agriculture. However, the performance of this compound hinges significantly on the quality delivered by its manufacturer. If you’re sourcing lime products, especially in Rajasthan, choosing the right partner among top Jodhpur lime manufacturers is crucial.

This blog explores the vast applications of calcined lime powder and highlights why the choice of hydrated lime manufacturers in Jodhpur or quick lime manufacturers in India can directly impact your operations.

What is Calcined Lime Powder?

Calcined lime powder is produced by heating limestone (calcium carbonate) in a kiln to a temperature above 900°C, which drives off carbon dioxide and leaves behind calcium oxide (CaO). This product, when ground into fine powder, becomes a high-performance compound used in a wide range of industries.

While it is often referred to as quick lime, it differs from hydrated lime (calcium hydroxide), which is produced by adding water to quick lime. Both variants are used in distinct industrial applications, and their usage often overlaps in integrated processes.

Key Industrial Applications of Calcined Lime Powder

1. Steel and Metallurgical Industry

In steelmaking, calcined lime plays a critical role in removing impurities such as sulfur and phosphorus during the refining process. It also helps in slag formation and improves metal purity. Major steel plants rely heavily on high-grade lime from reputed quick lime manufacturers in India to maintain quality and efficiency.

2. Chemical Manufacturing

Calcined lime is a primary raw material in the production of chemicals like calcium carbide, sodium alkali, and bleaching powder. Its high reactivity allows for rapid chemical conversions, making it a cornerstone for several industrial chemical processes.

3. Water Treatment

Municipal and industrial wastewater plants use calcined lime to adjust pH levels and precipitate heavy metals. It also helps in softening water and neutralizing acidic effluents. Sourcing from trustworthy hydrated lime manufacturers in Jodhpur ensures consistent reactivity and purity for these sensitive applications.

4. Construction and Building Materials

Calcined lime is an essential component in making mortar, plaster, whitewash, and even certain types of cement. Its strong binding properties improve durability and moisture resistance in buildings. Choosing the right Jodhpur lime manufacturers guarantees high-strength material suitable for long-lasting infrastructure.

5. Paper and Pulp Industry

In paper production, lime is used in the causticizing process during pulping. It helps in converting sodium carbonate into sodium hydroxide. Quality is key here, as any variation can affect the quality and texture of paper products.

6. Sugar Industry

Quick lime is widely used in sugar refining to remove impurities and clarify sugar juice. It enhances the yield and quality of sugar production, making consistent product delivery essential from the lime supplier’s end.

7. Environmental and Agricultural Uses

Calcined lime helps in treating acidic soils, reducing pest populations, and balancing soil pH for better crop production. For environmental applications like flue gas desulfurization, only high-purity, reactive lime is effective. Leading quick lime manufacturers in India often cater to both the agricultural and environmental sectors.

Why Manufacturer Choice Matters

When it comes to calcined lime, not all products are made equal. Here’s why selecting a reputable manufacturer—particularly in Jodhpur—is a game changer.

1. Consistency in Quality

The chemical composition and particle size of calcined lime significantly affect its reactivity. Jodhpur lime manufacturers who follow standardized production processes ensure consistency, reducing risks in your industrial applications.

2. Compliance with Industry Standards

Top manufacturers comply with BIS (Bureau of Indian Standards) and international norms for purity and quality. This ensures you receive lime that meets regulatory requirements, particularly important in food, pharma, and water treatment sectors.

3. Advanced Production Facilities

Trusted hydrated lime manufacturers in Jodhpur and quick lime suppliers invest in high-temperature kilns, automated systems, and robust quality control processes. This translates to higher efficiency, better yield, and safer handling.

4. Technical Support and Customization

Many industries require lime with specific properties, like high reactivity, low silica content, or particular fineness. Established quick lime manufacturers in India offer tailored solutions and lab-tested batches to meet your precise needs.

5. Reliable Supply Chain

Inconsistent supply or delays can severely hamper operations. Well-known manufacturers from Rajasthan often maintain strong logistics networks, ensuring timely and uninterrupted supply of lime products.

Why Choose Jodhpur as Your Lime Hub?

Jodhpur, situated in the mineral-rich state of Rajasthan, is a recognized center for limestone reserves and lime production. Here’s why it’s often the first choice for sourcing calcined lime powder:

Abundant Raw Material: Jodhpur is surrounded by high-grade limestone mines, making it cost-effective and sustainable for lime production.

Skilled Workforce: Generations of experience in lime manufacturing ensure expertise in product handling and delivery.

Reputed Manufacturers: Many leading hydrated lime manufacturers in Jodhpur and calcined lime producers have earned trust nationally and internationally for their superior quality.

Infrastructure and Connectivity: Proximity to road, rail, and port facilities ensures smooth logistics for bulk shipments across India and beyond.

Conclusion: Go Beyond Price—Choose Proven Excellence

While cost is an important factor, the true value of calcined lime powder lies in its consistent performance and quality. Whether you're in steelmaking, water purification, or agriculture, choosing the right manufacturer can dramatically enhance your productivity and reduce waste.

If you’re exploring quick lime manufacturers in India, or narrowing your search to trusted Jodhpur lime manufacturers, look for companies with a strong track record, strict quality assurance, and end-to-end support. The right manufacturer is not just a supplier but a strategic partner in your growth.

#hydrated lime manufacturers in jodhpur#quick lime manufacturers in india#limestone suppliers in india

0 notes

Text

The Role of Calcite Powder Manufacturers in India in Driving Innovation Across Multiple Industries

India-based manufacturers of calcite powder contribution to fueling innovation in other industries

In the fast-emerging industries of today, it is more important than ever to get the right raw materials. One such essential material is calcite powder. It is being used in a wide range of industries like paint, plastic, rubber, construction, and even agriculture. But the true heroes of providing this mineral in the best possible quality are the Calcite Powder Manufacturers in India.

These companies not only help to make companies better but also help keep the cost low and the quality of the production higher. In this article, we are going to discover what such companies do and how Chanda Minerals is doing an excellent job.

What is Calcite Powder

Calcite powder is the natural form of calcium carbonate (CaCO₃). Calcite powder is white, fine in nature, and is used by various industries. It is processed through grinding and crushing limestone. Calcite powder is highly sought after because of its whiteness, purity, and fine texture.

It is used in:

Paints and Coatings – to provide luster and whiteness

Plastics – to enhance material strength as well as reduce costs

Construction – to reinforce cement, concrete, and tiles

Rubber – to make them tougher and more flexible

Agriculture – to counteract soil pH and promote plant growth

Why Calcite Powder Manufacturers in India Are So Important

India is blessed with colossal natural limestone reserves, from which calcite powder is mined. It is because of this fact that Indian Calcite Powder Manufacturers are capable of providing high-quality products at affordable prices. But what they need to do is far more comprehensive than the work of simple mining and selling.

Some of the ways they strive towards innovation are as follows:

1. Quality Material for Better Products

A quality producer supplies pure, uniform, and high-grade calcite powder. This helps the organization to improve the end product quality of the paint, plastic, or construction material.

2. Customized Solutions

Different industries have different needs. Some may need very fine powder, whereas others need a coarser powder. Quality producers manufacture special grade and mesh sizes that meet each buyer's requirement.

3. Ensuring Cost Effectiveness

By utilizing calcite powder as filler, more expensive materials are reduced. This ensures companies have little cost without affecting functionality.

4. On-Time Supply

There needs to be urgency in terms of innovation. Great manufacturers ensure timely supply and consistency, which enables companies to work harmoniously without manufacturing disconnect.

5. Sustainable Practices

Many producers these days focus on sustainable mining and processing methods. This way, companies obtain environmental compliance while still acquiring the material they need.

Chanda Minerals – A Reliable Calcite Powder Producer in India

One of the companies that surpass Calcite Powder Manufacturers in India is Chanda Minerals. Chanda Minerals, based in Rajasthan, has been a regular supplier of calcite powder for 30 years now. They sell their product to various industries within India and are renowned for the quality and customer satisfaction.

What Sets Chanda Minerals Apart?

High Purity Products: They use nothing less than high-grade limestone to prepare pure and sparkling calcite powder.

Advanced Machinery: Chanda Minerals uses high-quality machines to grind and process the powder based on precise size and quality requirements.

Tailor-Made Orders: They offer you multiple mesh sizes and packaging to fit your business needs.

Timely Delivery: Their strong logistics system guarantees that you get your product on time, wherever you are based in India.

Excellent Service: The team at Chanda Minerals hears and assists you right from order right up to delivery.

To organisations in the quest for long term supply and assured quality, the name of one company immediately comes to mind — that is Chanda Minerals.

Impact of Calcite Powder on Real Life as well as Industries

Let us give a little more heed to numerous ways plain calcite helps in the development of industries:

Paint Industry: Calcite powder is finer, more colors, and provides paint with improved durability.

Plastic Industry: As a filler, cost-saving and making plastic products more durable.

Construction Sector: Used in tiles, cement, and wall putty to improve quality and reduce cracks.

Rubber Products: Makes rubber more hardy and elastic which is utilized in tires, pipes, and seals.

Agriculture: When used in soil, it increases the pH level so that plants grow better.

These benefits show how a single mineral, when used to its maximum capacity, can aid in growth and development in one way or another.

Choosing the Right Manufacturer for Your Company

After you have decided to include calcite powder in your products, you need the correct manufacturer. Here's what you need to note:

Experience: Choose a company that has decades of experience. They will best know how to work for you.

Product Range: A good quality manufacturer provides multiple grades, mesh sizes, and packaging options.

Quality Control: Make sure the company has a quality control procedure for checking the quality of each batch.

Customer Support: Your supplier must be available and ready to provide assistance if anything goes awry.

Safe and Reliable Delivery: Supply delays might impact your company. Choose one that has an effective delivery system.

Final Words

In the contemporary era, where businesses never stop searching for smarter, better, and cheaper ways of manufacturing their product, raw material like calcite powder plays a significant role. But it is the Indian Calcite Powder Manufacturers who see to it that this happens with quality, reliability, and innovation too.

Chanda Minerals, being experienced, customer-oriented, and well-facilitated, continues to serve industries with the best calcite powder across the country. To grow your business and upgrade your products, it is a wise move to partner with a good manufacturer like Chanda Minerals.

0 notes

Text

Laser Welding Machine Market Drivers Showcase Demand Across Medical Devices, Aerospace, and Manufacturing Sectors

Laser Welding Machine Market have steadily emerged as a transformative force across industries, revolutionizing how materials are joined with precision and efficiency. These high-tech systems are increasingly favored over traditional welding methods due to their speed, accuracy, automation capabilities, and ability to weld difficult materials. As industries like automotive, aerospace, electronics, and medical devices push for cleaner, stronger, and more efficient joining methods, the demand for laser welding machines continues to rise.

1. Growing Demand in Automotive and Aerospace Industries

The automotive and aerospace sectors are primary consumers of laser welding machines. The constant push for lighter, more fuel-efficient vehicles drives the need for precision welding techniques capable of working with lightweight alloys and complex geometries. In automotive manufacturing, laser welding enables high-speed processing and produces consistent, strong joints that are essential for structural integrity. Likewise, the aerospace industry values the ability to weld materials such as titanium and nickel alloys, where exactness is critical. These requirements make laser welding machines indispensable in modern assembly lines.

2. Technological Advancements and Innovation

Recent advancements in laser technologies—such as fiber lasers, hybrid laser systems, and real-time monitoring tools—have dramatically enhanced the efficiency, adaptability, and cost-effectiveness of laser welding machines. Smart manufacturing and Industry 4.0 trends are also propelling the integration of AI and IoT features into welding systems. These innovations allow for automation, predictive maintenance, quality assurance, and real-time data analytics, all of which optimize production and reduce downtime. As manufacturers seek greater operational intelligence, these high-tech capabilities drive market growth.

3. Rising Adoption in Medical Device Manufacturing

Miniaturization and precision are critical in medical device manufacturing. Laser welding meets these demands by providing non-contact, sterile, and micro-welding solutions, essential for assembling devices like pacemakers, surgical tools, and catheters. The growing global healthcare demand and medical device innovation pipeline are prompting manufacturers to invest in advanced welding systems that ensure both accuracy and regulatory compliance. As the medical device market expands, so does the laser welding machine market.

4. Shift Towards Electric Vehicles (EVs)

The global transition from internal combustion engines to electric vehicles has introduced new welding requirements. EVs rely heavily on battery packs, which require intricate and robust welds. Laser welding is ideal for battery module assembly because it offers the precision and thermal control necessary for working with sensitive materials and intricate designs. Additionally, the rising focus on sustainability and energy efficiency further cements the role of laser welding in the EV ecosystem.

5. Increased Focus on Automation and Labor Cost Reduction