#welding equipments

Explore tagged Tumblr posts

Text

Unlocking Precision Welding: High-Tech Equipment Trends and Industry Insights

The global welding equipment, accessories, and consumables market is on a trajectory of substantial growth. It's not just about welding; it's about precision welding. From 2021 to 2026, this market is projected to expand from USD 25.9 billion to an impressive USD 32.5 billion, at a CAGR of 4.6% during the forecast period. What's driving this surge, you might wonder? It's a blend of innovation, technology, and a growing demand in the automotive industry.

We'll dive into the exciting world of precision welding, exploring the high-tech equipment trends and industry insights that are transforming the landscape. And we'll do it without the jargon, in a way that resonates with businesses seeking convincing reasons to embrace these innovations.

Meeting Growing Demands

The automotive industry is changing significantly as it adapts to the shifting needs of the customer. Modern drivers anticipate more from their cars than simply dependability; they want vehicles with revolutionary safety features, better fuel economy, and stylish looks. Manufacturers are increasingly using precision welding techniques to satisfy these needs.

The increasing need for welding materials, accessories, and equipment is an outcome of the increasing need for precisely set up, high-quality components. Businesses are driving the worldwide welding market as they strive to provide their clients cutting-edge solutions.

The Power of Innovation

Innovation is at the heart of this industry's growth. The constant evolution of welding technology is a testament to the commitment to delivering top-notch products. New equipment is designed with efficiency, precision, and ease of use in mind.

One significant trend is automation. Advanced welding robots are making their way into production lines, ensuring consistent, high-quality welds. These robots are not only precise but also increase productivity, making them a valuable addition for businesses seeking to meet rising demands.

Sustainable Solutions

In today's world, sustainability is not just a buzzword; it's a way of life. This ethos extends to the welding industry as well. Welding equipment and consumables are becoming more eco-friendly, aligning with global environmental goals.

Businesses that embrace sustainable welding solutions not only contribute to a healthier planet but also benefit from reduced costs and enhanced brand reputation. It's a win-win situation.

Download PDF Brochure :

APAC: A Hotspot for Growth

The Asia-Pacific (APAC) region is leading the charge when it comes to growth in the welding equipment market. Why? A combination of factors plays into this, including a booming population, favorable investment policies, robust economies, and government initiatives aimed at promoting electronics and automobile industries.

For businesses looking to expand their reach and tap into new markets, APAC is a region ripe with opportunities. The growing demand for precision welding is met with enthusiasm here, offering a promising market to explore.

The Path Forward

One thing becomes evident as we go more into the field of precision welding: innovation and technology are what will shape this sector's future. Adapting to the latest developments in high-tech equipment is essential for businesses seeking to build a name for themselves or for well-established companies hoping to stay competitive.

The global market for welding equipment, consumables, and accessories is about more than just statistics; it's about satisfying changing customer needs and ensuring a sustainable future. The key is to identify prospects in areas such as Asia-Pacific and establish tactical alliances that have the potential to provide exceptional expansion.

In a world where precision is more important than ever, utilizing the capabilities of cutting-edge welding technology is vital to being competitive. So, get ready to embrace the future, to drive innovation, embracing the future, and meet the needs of a world that is changing. This is the start of your journey into precision welding.

0 notes

Text

Leading Contract Manufacturer with over 100 years of Trusted Technology

Electric Energy, Power Transmission & Distribution, Generation & Motors, Material Handling, Brick & Ceramics, Furnaces & Kilns, Steelmaking, and other specialist sectors are among the industries we serve. Forged Steel Wheels and Assemblies, NEMA Enclosures and Weldments, Tunnel Kiln Cars, and Powder Coat Painting are some of our specialties. Rockett employs "Best Practice" production and management approaches to provide our clients with flexibility and value. Rockett is ready to service your production requirements by combining a devoted and experienced workforce with contemporary equipment and large facilities. To know more visit https://www.rockettinc.com/capabilities/equipment-list/

#fabrication equipments#fabrication tools#metal fabrication tools#machine fabrication#welding equipments#welding supplies#powder coating equipment#powder coating machine#powder coating system

1 note

·

View note

Text

Discovering Hobart Welding Products: Unleashing Top-Quality Performance

When it comes to industrial tools and welding supplies, one name stands out among the rest - Hobart Welding Products. With a legacy of excellence and innovation, Hobart has been at the forefront of providing top-quality welding consumables and equipment to professionals and enthusiasts alike. Let's dive into what makes Hobart Welding Products a trusted choice for welders across the globe.

#Industral tools and equipment#welding equipments#industrial tools and welding supplies#welding tools

0 notes

Text

Experience the Future of Welding with Translas' Cutting-Edge MIG Welding Fume Extraction Technology!

Are you looking to take your welding operations to the next level of safety and efficiency? Look no further than Translas, the renowned Dutch manufacturer at the forefront of welding equipment innovation. Say goodbye to hazardous welding fumes with our state-of-the-art MIG Welding Fume Extraction system, engineered to create a clean and healthy work environment for welders and bystanders alike.

With Translas' MIG Welding Fume Extraction solutions, you can ensure that your workspace remains free from harmful particles and airborne contaminants. Don't compromise on safety or air quality any longer. Join the Translas family and witness the future of welding with our exceptional MIG Welding Fume Extraction technology.

1 note

·

View note

Text

manifest, manifest

#kinda was like ‘what if jack actually wore proper welding equipment’#take ‘proper’ with a grain of salt because i didnt even put effort into researching it past a ref#chickened out of drawing his actual welding helmet in the show because its one am#jack spicer#xiaolin showdown#eyestrain cw#eyesore

100 notes

·

View notes

Text

If there is one thing I’m sure of in life, it’s that I am not a welder.

#personal garbage#despite my father being a welder for longer than I’ve been alive#he taught me how to drive and use equipment as a wee lad but never how to weld

4 notes

·

View notes

Text

In 1964, Rajiv Machine Tools provided products and services in Welding and Cutting Equipment, Consumables, and Accessories. It has served clients for 60 years in the manufacturing and fabrication industry. Today, Rajiv Machine Tools deals in 1,100+ products, has 500+ clients, and has a 100+ dealer network across Gujarat in diverse markets and sectors. Our product range includes Welding & Cutting Equipment, Consumables, Accessories, Winding Wires, Flexible Wires, and Cables.

2 notes

·

View notes

Note

Which one is Phineas and which one is Ferb

31 notes

·

View notes

Text

Xtreme Precision Engineering Ltd, based in Gloucester, Gloucestershire, is your go-to solution for various engineering services, catering to your specific project needs with highly skilled engineers. Our comprehensive offerings include advanced technologies such as welding safety equipment, CNC pipe cutters, CNC DXF digitising systems, CNC plasma cutting, r-tech p100 CNC accessories, CNC plasma tables, and both mig and tig welding machines, along with essential welding supplies. Known for our quick and efficient service, we pride ourselves on producing high-quality products, from prototypes to full-scale manufacturing. Our central location enables prompt services and fast product delivery nationwide. With our expertise in CNC technologies, we can bring precision engineering directly to your production space, providing technical support during regular working hours. For engineering solutions and to discuss your needs, contact Xtreme Precision Engineering Ltd today or visit our website for an extensive overview of our services. We are dedicated to assisting you from initial consultation to the final delivery, ensuring your engineering project exceeds expectations.Xtreme Precision Engineering Ltd

Website: https://xtremeplasma.com

Address: Unit 1 Capitol Park, Pearce Way, Gloucester, Gloucestershire, GL2 5YD

Phone Number: 01452 739025

Contact Email ID: [email protected]

Business Hours: Monday - Friday : 08:30 am - 04.00 pm Saturday : 09:00 am - 01:00 pm Sunday : Appointment Only

2 notes

·

View notes

Text

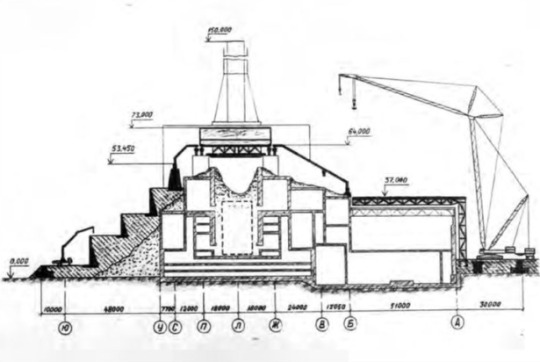

The collapsed northern wall of the reactor building of Chernobyl Reactor 4.

A cross section diagram of the final design of the Sarcophagus.

The Cascade Wall (seen on the left of the diagram above) was one of the most difficult sections of the Sarcophagus to build, but it was one of the most important. It covered the partially collapsed northern wall of the reactor building, as well as the pile of highly radioactive debris left by the explosion. The wall was composed of four stepped tiers, and topped out at 54 meters above the ground.

This was the first part of the Sarcophagus to begin construction. To begin, the men of Sredmesh Unit US-605 installed "Pioneer Walls" (I will make a post on these later) to lessen the gamma radiation at the site. They then filled the space between the Pioneer Walls and the reactor with concrete. On top of this base, they placed huge prefabricated metal wall sections, like the one seen below.

Demag 21 prepares to lift a section of the Cascade Wall into place.

The first tier of the Cascade Wall during installation.

Once the wall sections were all in position, remote controlled concrete pump trucks (seen on the left of the above image) filled the space between the wall and the reactor building, in a similar manner to the area between the Pioneer Walls and the reactor building. This process was repeated until the Cascade Wall was completed.

Crews help to position a section of the third tier of the Cascade Wall before it is lifted into place by crane. These sections weighed more than 120 tons.

Note the white cabin on the crane. These were built similarly to the bathyscaphes used to survey the reactor building during construction of the sarcophagus, with air filters and thick lead sheeting.

The first and second halves of the fourth and final tier of the Cascade Wall, on the left and right respectively.

The men of Sredmash Unit US-605 Shift Four, who installed the fourth tier of the Cascade Wall.

I could not find their names, but I felt compelled to share this photo in their honor.

Without the Cascade Wall, radiation levels would have remained dangerously high and radioactive debris would have been left exposed to the atmosphere. Additionally, it shored up the collapsed northern wall of the reactor building, which had to support some of the weight of the roof section of the Sarcophagus. The men who participated in the project are some of the worst affected amongst the liquidators in terms of sickness.

Men of US-605 fourth shift celebrate the completion of the Cascade Wall with a ceremonial flag raising.

[Image descriptions:

First image: This black and white photo shows the partially destroyed northern wall of the reactor building. Twisted metal and piles of concrete rubble sit on various ledges within the collapsed wall. A network of pipes is visible about three fourths of the way up the wall. The main circulation pumps of the reactor sit partially covered by rubble at the bottom of the wall. Burns cover much of the concrete. An even gravel surface makes up the foreground of the photo, and a large crane is on the right. The striped circular stack of the plant rises in the top left of the image.

Second image: A cutaway diagram of the sarcophagus viewed from the west side of the reactor building. It shows the original structure of the power plant and the plans for the structure of the sarcophagus. From left to right it consists of the four steps of the Cascade Wall, then a slight incline up to the roof section over the reactor hall, then another more gradual slope down to the section covering the turbine hall.

Third image: A black and white photo showing a large crane on the right preparing to lift a large section of metal wall on the ground in front of it. The wall has a small section to help it stand on its own protruding at ninety degrees at its bottom, with angular pipes bracing it against the wall. The crane is lifting it via its hook, which is attached in the shape of an uppercase A. A large metal brace holds the two halves of the lifting section apart above the wall section.

Fourth image: A black and white photo showing the early construction of the cascade wall. The collapsed northern wall sits above the newly placed first section of the cascade wall. The wall is on a raised embankment, below which sit a concrete pump truck sticking its spindly white boom into the wall to add concrete and help build the structure.

Fifth image: The same large crane is lifting another section of the cascade wall just off of the ground. The first and second tiers of the wall can be seen in place in the background of the photo. Nine men, dwarfed by the section of wall they are working on, pull on ropes attached to the wall to angle it correctly for placement on top of the previous sections. The heavy protective cabin of the crane can be seen mounted on the crane chassis, a large white metal box with thick windows to protect the driver from radiation.

Sixth and seventh images: these twin images show the lifting of the two final sections of the cascade wall into place. These sections are both shown in the air on the way to their destination.

Eighth image: A group photo of about forty men in front of the destroyed reactor during the construction of the cascade wall. The wall is only partially finished, but the men are posing in two rows for a photo (crazy!). The men are dressed in dark khaki/deep blue clothes, and white sanitary caps that cover their hair and prevent contaminated. Some of them are also wearing masks or respirators.

Ninth image: this color image shows another gathering of liquidators around a blue concrete pump with a red banner attached to the end of its pump arm. The arm is fully extended about a hundered feet into the air. The group is a lot more informal. The cascade wall is seen fully completed behind the men, but several white and orange concrete pumps still work on other parts of the Sarcophagus. The large yellow crane used to lift the wall sections into place sits idle on the right of the image. Also in this image is the iconic red and white striped chimney of the plant.

#chernobyl#chernobyl hbo#nuclear#nuclear power#radiation#accidents and disasters#history#reactor#autism#disaster#concrete#remote control#concrete pump#construction equipment#construction#welding#heavy lifting#chernobyl disaster#collapse#explosion#cleanup#soviet#soviet union#ussr (former soviet union)#ussr#ussr history#reactor 4#sarcophagus#chnpp#nuclear disaster

8 notes

·

View notes

Text

My face got sunburned enough today that when I scratch an itch my fingers leave a white line for like three minutes afterwards 😬

#kee speaks#i also tired this has been such a long week#i only just got home like twenty minutes ago and it's 10 PM now#and i have to be up to go get parts at 8 AM and then go jump in a tractor#i feel like I'm officially reaching my fulltime farmer era#the last five years we've had enough people to run the farm side of things that I've been the designated shop person#so i was always working on welding projects or being the Go-For for everyone else#and i was really only involved during harvest time when its all hands on deck#but we're down a person this year so I'm learning how to run the planting equipment which is a new experience for me#i haven't even ridden along on this equipment since i was a kid and technology has changed by leaps and bounds since then#so it's a little intimidating#but it also means i dont get 9-5 Mon-Fri weeks anymore#more like 730A-10P Mon-Sat#which means not much time for viddy games :c#i was so excited that Survivor got pushed back so that it didnt release while i was in school#but now that its out im like. idk when I'll get to play#i have an appointment in the city next week though so I'll be able to pick it up at least#and have it for a rainy day#oh but also rainy days means my basement leaks AARRGGHH#BEING AN ADULT SUCKS AND I DIDN'T SIGN UP FOR THIS

2 notes

·

View notes

Text

HD-400B welding monitor: accurate monitoring, leading the new benchmark of welding quality control

In the welding industry, welding quality directly affects the reliability and safety of products. As the "smart eye" of the welding process, the welding monitor can monitor welding parameters in real time to ensure stable and reliable welding quality. Among many welding monitors, Huandian HD-400B welding monitor stands out with welding detector's excellent performance and innovative functions, becoming the industry's leading welding quality control solution.

Accurate monitoring, comprehensive coverage of welding parameters

Compared with other welding monitors on the market, Huandian HD-400B has significant advantages in monitoring accuracy and parameter coverage. Welding analyzer equipment can monitor welding current, voltage, power, power-on time, pressure, displacement, temperature, air pressure and other key parameters in real time to ensure the comprehensive control of the welding process. In contrast, some manufacturers' monitors only support the monitoring of basic parameters such as current and voltage, which cannot meet the needs of high-precision welding.

Intelligent judgment, real-time warning of unqualified products

The HD-400B is equipped with advanced welding quality judgment function. Users can set the upper and lower limits of parameters such as current, voltage, power, pressure, displacement, etc. Once unqualified welding is detected, the system will immediately issue an abnormal alarm and automatically detect unqualified products. This function significantly reduces the defective rate, while some manufacturers' monitors only provide data recording function and lack real-time warning capabilities.

Powerful database, support efficient quality traceability

The HD-400B has a built-in powerful database that can record detailed data and historical alarm information for each welding, with a storage capacity of up to millions of items. Data supports USB flash drive export and generates table files for quality traceability and analysis. In contrast, some manufacturers' monitors have limited data storage capacity, and the export function is not convenient enough to meet the needs of large-scale production.

User-friendly and easy to operate

The HD-400B uses an 8-inch high-definition touch screen, an intuitive user interface and a simple operation process, so even novices can quickly get started. At the same time, welding detector also supports remote monitoring and management, which allows users to understand the welding status anytime and anywhere. However, the monitors of some manufacturers are complicated to operate, lack remote management functions, and have poor user experience.

Conclusion

The HD-400B welding monitor of Huandian has become a leader in the field of welding quality control with its precise monitoring, intelligent judgment, powerful database and user-friendly design. Whethere welding testing equipment is to improve welding quality, increase production efficiency, or support quality traceability, HD-400B has demonstrated excellent performance and reliability. Choosing the HD-400B of Huandian means choosing a smarter and more efficient way of welding quality management.

#welding monitor#welding detector#welding testing equipment#welding checker#welding monitoring device

0 notes

Text

Welding Electrodes Equipments in India

It is impossible to overstate the importance of better electrodes and equipment in the welding industry. Parag Traders, now known as Parag Weld, was founded in 1980 and has led the way in offering top-notch welding electrodes and equipment to a variety of sectors. Mr. Parag Mashruwala founded Parag Weld at GIDC, Vatva, Ahmedabad, to meet the increasing need for welding solutions in the fabrication, machine shop, forging, and castings sectors.

The Role of Welding Electrodes in Quality Welding?

The quality, strength, and longevity of welds are guaranteed by welding electrodes. The quality of the electrode has a direct effect on the welding job's success since these electrodes operate as the filler material that forms a connection between two metals. Because we at Parag Weld recognize the importance of high-performance welding electrode equipment, we provide goods that are especially made to satisfy the demands of different sectors.

Why Choose Parag Weld for Your Welding Electrodes Needs?

Having worked for many years, Parag Weld has established a solid reputation as one of India's top providers of welding electrode equipment. Our products are built to last under the most demanding welding situations, guaranteeing their performance, longevity, and affordability. We provide a large selection of welding electrodes that may be used for everything from simple replacements to complicated industrial operations. We deliver electrodes that offer excellent arc strength, low spatter, and improved weld appearance, regardless of your industry fabrication, casting, or machine shop.

Commitment to Quality and Customer Satisfaction?

At Parag Weld, quality is key to all we do. We have always focused on offering goods that satisfy the highest industry requirements since our founding in 1980. Our committed staff works directly with customers to learn about their unique requirements and suggest the best welding electrode equipment for their uses. We have gained the confidence of several industries in Ahmedabad and around India by putting the needs of our customers first.

Conclusion

India's Premier Source for Welding Electrode Equipment

To sum up, for more than 40 years, Parag Weld has been an established name in the welding sector. We are pleased to provide the Best Welding Electrodes Equipment in India, having established a solid reputation for dependability and quality. Our selection of welding electrodes, which vary from mild steel to stainless steel welding, is made to satisfy the demands of machine shops, casting, and fabrication sectors. Parag Weld offers the appropriate welding supplies and machinery to help your company, regardless of how big or small your workshop is. For all of your welding electrode needs, Parag Weld continues to be a trusted resource because of our vast expertise, a constant commitment to quality, and solid focus on client satisfaction.

For More Info : 9824099621, [email protected], https://www.paragweld.com/

0 notes

Text

Global Welding Equipment Market Insights: Key Players and Industry Trends Shaping the Future

The global welding equipment market is anticipated to reach USD 27.77 billion by 2030 and is anticipated to expand at a CAGR of 5.1% from 2024 to 2030, according to a new report by Grand View Research, Inc. The demand for welding equipment is fueled by growing consumer preference for automated devices such as robotic welding equipment and laser welding techniques in comparison to manual ones. The majority of the demand for welding equipment is associated with end-use industries such as automotive, aerospace, transportation, and construction, which are also experiencing operational difficulties owing to macro-economic factors.

According to HIS Markit, new vehicle sales accounted for 82.4 million globally in 2022, which is up by 3.7% in 2021. The continually increasing demand for automobiles worldwide is anticipated to increase the demand for tools and robots in the automotive industry. This, in turn, is expected to boost the demand for welding equipment over the projected period.

Heavy industries, building & construction, and transportation are among the important end-use industries of welding equipment. In the transportation sector, welding equipment is commonly utilized to fabricate various vehicle body components. According to the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2022, the worldwide output of vehicles was 81,628,533 units. Innovations and technical advancements, such as automation, robotics, IIoT, and others, in the automotive sector to meet rising customer demand are anticipated to increase the demand for welding equipment. In addition, the increasing sales of electric vehicles are expected to further propel the adoption of the welding equipment industry in the coming years.

The rise in construction activities globally, coupled with swift urbanization in developing nations like China, India, Brazil, and those in the Middle East and Africa, is poised to propel the expansion of the construction sector. Increased disposable incomes and enhanced consumer spending capabilities are expected to drive investment in new building construction. Furthermore, government initiatives emphasizing urban planning and infrastructure development in multiple countries are likely to provide additional momentum to the growth of the construction sector. Consequently, the positive trajectory of the construction industry is anticipated to have a favorable impact on the expansion of the market.

Welding Equipment Market Report Highlights

In 2023, automatic welding equipment dominated the global market, accounting for 56.4% of the total revenue share. This dominance is attributed to its capacity to enhance productivity, reduce cycle duration, and improve efficiency in welding processes. The widespread adoption of automatic welding equipment on a global scale has surged in recent years, driven by its ability to achieve rapid weld cycle times, deliver high output, and substantially lower welding costs

In 2023, the arc welding technology segment held the largest share of the global revenue in 2023. The growing prevalence of arc welding technology can be attributed to its inherent characteristics, including flexibility and adaptability to diverse conditions. Notably, continuous advancements in robotic arc welding play a pivotal role in propelling the growth of the arc welding segment within the welding equipment market

The aerospace end-use segment is projected to witness growth at the fastest CAGR from 2024 to 2030 owing to the growing applications in aerospace manufacturing, including heating elements, circuit board traces, electronic components, actuators, fine ribbon welding, inductors, mesh welding, and hybrid micro-weld devices

Asia Pacific dominated the global market on account of the robust automotive industry. Increasing demand for electric and hybrid cars is expected to benefit the demand for welding equipment

In February 2023, Miller Electric Mfg. LLC launched the miller Deltaweld 852, Deltaweld 402, Deltaweld 602, welding machines in Southeast Asia. These machines specifically cater

Welding Equipment Market Segmentation

Grand View Research has segmented the welding equipment market based on technology, type, end-use and region:

Welding Equipment Technology Outlook (Revenue, USD Billion; 2018 - 2030)

Arc Welding

Shielded Metal/Stick Arc Welding

MIG

TIG

Plasma Arc Welding

Others

Resistance Welding

Laser Beam Welding

Oxy-Fuel Welding

Others

Welding Equipment Type Outlook (Revenue, USD Billion; 2018 - 2030)

Automatic

Semi-Automatic

Manual

Welding Equipment End-use Outlook (Revenue, USD Billion; 2018 - 2030)

Aerospace

Automotive

Building & Construction

Energy

Oil & Gas

Marine

Others

Welding Equipment Region Outlook (Revenue, USD Billion; 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Italy

Spain

Asia Pacific

China

India

Japan

Australia

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

South Africa

Saudi Arabia

List of Key Players

The Lincoln Electric Company

ACRO Automation Systems, Inc

Miller Electric Mfg. LLC

Ador Welding Limited

Mitco Weld Products Pvt. Ltd.

voestalpine Böhler Welding Group GmbH

Carl Cloos Schweisstechnik GmbH

OTC DAIHEN Inc.

Illinois Tool Works Inc.

Panasonic Industry Co., Ltd.

Coherent, Inc.

ESAB

Polysoude S.A.S.

Kemppi Oy.

Cruxweld Industrial Equipments Pvt. Ltd.

Recent Developments

In February 2023, Miller Electric Mfg. LLC launched the Copilot Collaborative Welding System in February 2023. It is a cobot with advanced capabilities intended for welders and shops new to robotic welding who are looking for solutions to keep up with demand.

In March 2023, voestalpine Böhler Welding Group GmbH launched Böhler Welding`s Crane & Lifting Full Welding Solution. The product helped the company to achieve 50% faster welding speed.

Order a free sample PDF of the Welding Equipment Market Intelligence Study, published by Grand View Research.

0 notes

Text

Hiring for the Oil & Gas Industry in Abu Dhabi! Interviews on: Mark this Date: 28/01/2025 - Chennai +91 93637 51845 | +91 99942 93267 [email protected]

#Surveyor Civil#Technical Engineer Civil / Building#Contracts Engineer#Quantity Surveyor Civil#Electrical Supervisor#Road Safety#MEP Engineer#Project Engineer#Costing Engineer#Welding Engineer#Planning Engineer Lead#Senior Quantity Surveyor (Mechanical)#Quantity Surveyor (Equipment)#Senior Quantity Surveyor (Equipment)

0 notes

Text

Discover Welding Supplies That Boost Efficiency and Quality

At First Choice Industrial, we offer a premium range of welding supplies designed to enhance your efficiency and deliver exceptional results. From durable tools to high-quality materials, our products cater to both professionals and DIY enthusiasts. Discover innovative solutions tailored to meet your project needs. Shop now to find top-notch welding supplies that ensure precision and reliability every time.

#hardware tools#hardware store#hardware#industrial equipment#construction#welding supplies#welding#welding equipment#welding machine#welding electrode

1 note

·

View note