#warehouse safety

Explore tagged Tumblr posts

Text

Maximizing Warehouse Safety with Global Shutter USB Cameras for Obstacle Detection

Efficiency and safety are critical in the hectic world of warehouse operations. As the use of robotics and automated systems grows, it is essential to make sure that these devices can safely navigate their surroundings. The global shutter USB camera is useful in this situation. These cameras greatly improve obstacle detection capabilities by offering real-time, high-quality imaging, which lowers the chance of accidents and raises operational safety standards. We'll look at how global shutter USB cameras can be essential for optimizing warehouse security in this blog post.

Improved detection of obstacles using global shutter technology

Global shutter technology allows for the simultaneous capture of an entire scene, eliminating motion blur that can occur with traditional rolling shutter cameras. This feature is especially beneficial in dynamic environments like warehouses, where forklifts, automated guided vehicles (AGVs), and other machinery are constantly in motion.

Key Benefits:

Clarity in Motion: Global shutter USB cameras capture sharp images without distortion, enabling precise detection of obstacles in real time.

Rapid Response: With clearer visuals, robots can react faster to obstacles, reducing the chances of collisions and accidents.

Increased Reliability: These cameras maintain consistent performance under various lighting conditions, ensuring that obstacle detection remains effective even in low light.

Integrating global shutter USB cameras into warehouse robotics

Integrating global shutter USB cameras into warehouse robotics can significantly enhance the capabilities of automated systems. These cameras can be strategically placed on robots, forklifts, and other equipment to improve their navigation and operational safety.

Key Benefits:

Seamless Integration: Global shutter USB cameras are easily integrated into existing robotic systems, enhancing their functionality without requiring significant overhauls.

Enhanced AI Training: High-quality imaging data collected from these cameras can be used to train AI algorithms for better decision-making and obstacle recognition.

Adaptability: The versatility of global shutter USB cameras allows them to be used in various applications, from AGVs to robotic arms, ensuring that safety is prioritized across all equipment types.

Real-Time Monitoring for Improved Safety Protocols

One of the standout features of global shutter USB cameras is their ability to provide real-time video feeds, enabling operators to monitor warehouse activities closely. This capability allows for immediate identification and resolution of potential hazards.

Key Benefits:

Proactive Safety Measures: Real-time monitoring helps in quickly identifying unsafe conditions or practices, allowing for immediate corrective actions.

Data-Driven Decisions: The visual data captured can be analyzed to refine safety protocols and operational strategies continuously.

Incident Documentation: In the event of an accident, high-quality footage can serve as documentation for investigations, helping organizations improve their safety standards.

Improving Operational Efficiency Through Visual Feedback

Global shutter USB cameras not only enhance safety but also contribute to operational efficiency in warehouses. By providing clear visuals, these cameras can improve workflow and productivity.

Key Benefits:

Optimized Workflow: Clear visuals allow workers and robots to navigate more effectively, minimizing delays caused by miscommunication or unclear signals.

Enhanced Training: New employees can benefit from recorded footage showing the correct way to navigate the warehouse, making training more effective and practical.

Reduced Downtime: With better obstacle detection and navigation, the likelihood of accidents decreases, leading to less downtime for repairs and incident resolution.

The Future of Warehouse Safety with Global Shutter USB Cameras

As technology continues to evolve, the role of global shutter USB cameras in enhancing warehouse safety will only grow. Future advancements may include improved AI integration, better connectivity options, and enhanced features for even more accurate obstacle detection.

Key Benefits:

Innovative Solutions: Continuous advancements in global shutter technology will lead to even more efficient safety solutions tailored to the unique needs of warehouses.

Scalability: As businesses expand, the scalable nature of global shutter USB cameras ensures that safety measures can grow alongside operations.

Sustainable Practices: With improved safety and efficiency, businesses can reduce waste and enhance sustainability efforts, creating a safer workplace for everyone.

Are you prepared to deploy state-of-the-art technology to increase warehouse safety? Read more of our material to see how global shutter USB cameras may revolutionize your business. For the most recent information, sign up for our newsletter, or get in touch with us right now to find out how we can assist you in putting these creative solutions into practice at your establishment!

0 notes

Text

Improve Warehouse Safety with SharpEagle Forkview Camera System

Forklifts are operated mainly in the manufacturing, logistics and cargo dealing industries. Due to their extensive use of forklifts, warehouses are on a priority docket for all forklift safety procedures. Industrialists pay particular attention to the technologies used for safety procedures at warehouses. The implementation of safety procedures leads to significant advantages, such as, higher employee satisfaction & increased productivity.

The latest trend is the use of the Forkview camera system for forklifts. Installing a forkview camera on a forklift provides an operator with a view down the fork for optimal positioning with the monitor placed on the forklift for the operator. It is designed to perform under the most severe conditions, which often arises during cargo and weighing processes.

At present, SharpEagle offers two major variants of forkview cameras - wired and wireless forkview cameras. You can opt for either camera system, depending on your warehouse requirements for lifting high loads and securing cargo.

Wireless fork view camera

Wired fork view camera

You can use either a wired or a wireless forklift camera system, depending on your requirements. As both, the variants make it easier to lift high loads and secure cargo.

Benefits of Forkview Camera System

The Forkview camera system offers several benefits over traditional forklifts, making material handling more efficient and safer. It is important to notice that the primary goal that a forkview camera system fulfils is that of better security. But there are many more benefits, as follows:

Improved Visibility: The ForkView camera system provides a wide view of the forklift's surroundings, eliminating blind spots and improving visibility. This enhances the operator's ability to manoeuvre in tight spaces, reducing the risk of accidents and increasing productivity.

Increased Safety: With improved visibility, this Forklift Fork camera system enhances the forklift operator's situational awareness, reducing the risk of collisions with other equipment, structures, or pedestrians. The system's intelligent software also provides alerts when the forklift approaches potential hazards, further increasing safety.

Reduced Downtime: Accidents and collisions can cause significant downtime in material handling operations. By reducing the risk of accidents, the forkview camera system helps to minimise downtime and keep operations running smoothly.

Improved Productivity: This forklift safety product enables operators to work more efficiently, reducing time to complete tasks. With improved visibility, operators can move loads more accurately and quickly, reducing the need for rework and increasing productivity.

Reduced Maintenance Costs: The forkview camera system can reduce maintenance costs by providing operators with better visibility of the forklift. This enables them to identify potential issues early on, preventing them from turning into more significant and costly problems.

Lower Insurance Premiums: The forkview camera system can also lower insurance premiums by providing evidence of safe operation. With a reduced risk of accidents, businesses may be eligible for lower insurance rates, resulting in cost savings.

Improved Employee Satisfaction: With the forkview camera system, operators can work more confidently and productively, knowing they have the latest technology to help them navigate safely and efficiently. This can lead to improved employee satisfaction and morale, positively impacting the operation's success.

How does the Forkview Camera System make Material Handling Efficient?

Material handling is critical in any manufacturing, construction, or warehousing operation. It involves the movement of raw materials, goods, and finished products from one location to another, and it can be a challenging and complex task, especially in environments where space is limited and safety is a top priority.

One of the critical parts of equipment in material handling is the forklift. Forklifts are used to lift, move, and transport heavy loads, and they play a crucial role in making material handling processes efficient and productive. However, forklifts can also be dangerous, especially in busy warehouses and construction sites.

SharpEagle’s forkview camera system specifically designed for forklifts. The forkview camera system is a state-of-the-art technology that enhances the forklift operator's visibility, allowing them to see their surroundings more clearly and avoid accidents.

Forkview Camera Technology Significantly Enhances Warehouse Safety

Forkview cameras are designed with advanced technology incorporating features to improve safety at the warehouse. SharpEagle has designed a safety framework of forkview camera, including features like:

Remote monitor system:

It's an essential framework of a forkview camera system, as it provides the driver a view of the forklift while loading. It will facilitate the complete view of the loading region of a warehouse in the monitor itself which will help in proper loading as well as prevent any mishap, thereby making a safe & secure environment for workers.

Rechargeable battery:

It is easy to operate the forkview camera as per the cargo schedule, eliminating the dependency on a power system. Thus, making it available to the driver at the time of necessity.

Front & Rear View camera:

During loading, poor visibility is the primary cause of accidents & damage. But with the forkview camera system, this problem gets sorted as both the wireless forkview camera system & wired one provides a driver with the proper front as well as the rear view of the surroundings. So, the forkview camera makes the operator aware of the position of loads from the height, and the presence of the pedestrian in the vicinity. In a way, the forkview camera system helps in increasing the efficiency of loading and enhances security.

SharpEagle Technologies is a leading end-to-end safety consultant for your overall warehouse safety. Beside forklift cameras, we have also designed forklift safety lights to target specific visibility and forklift-related fatalities in modern workspaces. Partner with us to create workplaces that meet OSHA-recommended standards of safety while maximising crew safety and operator’s efficiency in forklift operations. Visit our website to know more about our forklift safety solutions or connect with our experts for a free consultation call today!

#Forkview Camera System#Warehouse Safety#fork view camera#Wired fork view camera#warehouse security camera

0 notes

Text

How to Reduce Product Damage in the Warehouse with Plastic Pallets

How to Reduce Product Damage in the Warehouse? Every warehouse manager knows the pain of seeing damaged goods. It causes lower profits, slows operations, and can even harm your reputation in the market. But this damage can be managed simply by using the right plastic pallets.

Plastic pallets offer a major advantage over traditional wooden pallets when protecting your products. Here’s how they can significantly reduce damage in your warehouse:

In the dynamic world of warehouse management, minimizing product damage is key to sustained success. Plastic pallets offer a modern solution many facilities embrace, effectively reducing damage and enhancing efficiency. Let’s explore how plastic pallets are used with their durability and functional versatility to improve warehouse operations and protect valuable goods.

Check The Merits of Plastic Pallets Plastic pallets have become a preferred choice in warehouses for transportation and storage due to several advantages. These include Reduced product damage, Ease of cleaning, customizable designs, and enhanced durability with reinforced steel rods, these factors help businesses to reduce product damage.

Plastic Pallets are highly Durable Plastic pallets are durable and don’t break during their movement while in transportation and storage. They won’t splinter, split, or break under heavy loads, ensuring your products stay safe during handling and transportation. With its durable nature pallets can resist the harsh conditions of warehouse settings, such as frequent handling, and make your transportation operation smooth.

Maintain Proper Hygiene Plastic pallets are especially useful in areas like food and pharmaceutical sectors that have strict hygiene rules. Plastic pallets are beneficial in this sector because they are so easy to clean and wash and easy to maintain hygiene.

Lightweight Construction of Pallets Lightweight Plastic pallets making them simpler to handle and decreasing warehouse worker accidents. Despite their low weight, they are extremely durable, providing a dependable storage solution for a wide range of products.

Enhanced Stability Plastic pallets excel in offering superior stability owing to their uniform construction and interlocking design. This stability mitigates the risk of pallets tipping over or collapsing, thereby preventing products from shifting or falling during transportation.

Impact Resistance Designed to withstand impacts and rough handling, plastic pallets remain resilient without sustaining damage. They absorb shocks and evenly distribute weight, This feature is particularly beneficial for fragile items or goods that are sensitive to vibrations and shocks, such as electronics, glassware, or pharmaceutical products.

Moisture Resistance Plastic pallets do not absorb moisture or hold humidity, they are the perfect option for storing goods in moist or humid conditions while maintaining product quality.

Cleanliness The plastic pallets are not complex in cleaning and washing to minimize dirt and dust. It helps keep the items safe at the warehouse.

Customization Options Plastic pallets offer flexibility in design and customization. They can be tailored to specific industry requirements, such as reinforced corners and anti-slip surfaces giving a personal touch to meet your specific transportation and storage needs. These modifications not only improve pallet performance but also reduce the risk of product damage, allowing for smooth operations and peace of mind.

Conclusion plastic pallets present a robust solution for minimizing product damage in warehouse operations. Swift’s Plastic pallets are the better option, especially when it comes to less product damage in the warehouse. Their hygienic qualities, stability, longevity, and customization possibilities make them valuable resources for companies looking to boost productivity and protect expensive stock. Warehouses may successfully reduce product damage, and speed up processes.

#plastic pallets#rackable plastic pallets#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic#swifttechnoplast#swifttechnoplastprivatelimited#plastic pallets manufacturer#plastic pallet supplier#warehouse safety#HDPE plastic pallets#plastic pallets near me#pallets near me#export pallets

0 notes

Text

The Role of Advanced Inspection and Measurement Systems in Industrial Operations

In the realm of industrial operations, precision and safety are paramount. Inspection and measurement systems form the backbone of quality control, ensuring that products meet stringent standards and that processes adhere to the highest safety norms. Among these systems, vision systems, automated light curtains, and muting photocells are critical components that enhance efficiency and…

View On WordPress

#Automated Testing#Inspections and measurement systems#Real-time data collection#Vision systems#warehouse processes#warehouse safety

0 notes

Text

Simple Ways to Increase Warehouse Efficiency

1. How to Increase Warehouse Productivity

our Facility

Make it easy for your employees to improve their productivity. There are many ways to increase productivity. You cannot expect your employees to do more to manage their jobs and increase their labor productivity for incentives if you haven't done anything.

You can cut down on time by organizing your warehouse so that workers don't need to travel as far to pick up the right products and then deliver them to the loading dock. To reduce productivity, workers must take many steps.

You can place items strategically. Place items that you use most often on shelves or racks near the dock. You should keep rarely shipped items in more accessible places.

Cross docking is a way to make sure that every product you receive arrives at your dock doesn't need to be stored. Cross-docking makes it easy to quickly ship out products that have just arrived. This latest warehouse improvement technique will help you save time and money.Take a look at the tasks your employees do in your facility. Are they able to make improvements that will increase their productivity? Your employees should be able to work more efficiently and encouraged to do so.

Reduce Time Waste in YNo matter how efficient your warehouse is, there are ways to improve its efficiency. You will need to pay attention to several areas. Arvist offers the best Warehouse Productivity Improvement service. To reduce waste and increase efficiency, you need to consider the productivity of your warehouse workers, warehouse operations, warehouse costs, and distribution costs. These areas will help maximize your return on investment in warehouse operations.

Get feedback from your employees: Ask them where they think there is room for improvement. This information can help you to improve your facility and make employees' jobs easier.

Safety: Workers who are safe won't be injured at work will not need to miss any time. You can also increase safety at work to improve productivity and loyalty.

Workstation organization: Make sure that tools are clearly labeled and kept in well-organized areas. Regularly inspect all tools for wear by employees. Items that are damaged should be removed until they are fixed. Your employees will be able to reach for a quality tool, such as a scanner and trust it will work. It will save you time and frustrate workers by not having to return to their workstations to replace tools.

Training managers: Increase productivity by training managers. This will help you identify areas that can be improved in your warehouse.

Incentivize Your Workers

Your employees are likely to have half the control of picking and packing. These workers should be given incentives to reach production goals. You can increase your worker's productivity by offering them monetary incentives for performance improvements.

2. How to improve warehouse operations

It is more than just reducing wasted time in the warehouse. You must also ensure that your inventory is up to date and you keep track of it. It is easier for workers to locate products in the warehouse and pull them out when they are needed. You can prevent theft and damage from your inventory by tracking it.

Use technology to track inventory

It is too time-consuming and laborious to track products manually in modern warehouses. Radio frequency identification (RFID), and barcodes allow you to track your products in a warehouse. RFID allows you to track inventory from the moment it enters your warehouse until it departs. These tags contain more information than barcodes and are more secure. The radio component of RFID tags can also be used to broadcast the information or require a reader.

Barcodes can also be used to save time and increase accuracy, as they reduce the amount of effort required by workers to identify the product. Barcodes are less expensive to purchase and take up less space. Although many companies are moving to RFID technology, barcodes will continue to be a cost-effective way to track inventory in warehouses.

Warehouse Management Systems: Take Advantage

Scanners collect information about the products in your warehouse. This information is stored by your warehouse management software (WMS). WMS software is a great way to plan layout, workflow, and other aspects of efficiency that you couldn't have imagined with manual calculations and observations.

Warehouse management systems are able to create the most efficient way of picking inventory. It can also relay lists to direct workers to the most efficient route to order products. You may have product tracking, which allows inventory management. This can be combined with scanning technology to help reduce loss. These are just a few ways WMS can tighten your operations. This software can help you save time and improve your facility.

3. How to Lower Warehouse Costs

Labor and operations are both part of the cost of operating your facility. Reduced time and productivity on operations are two ways to reduce storage costs. There are other ways you can make your warehouse more affordable.

Increase Energy Efficiency

You are missing a key opportunity to lower warehouse costs by not evaluating your facility's energy consumption and finding ways to reduce it. Natural lighting is best. Natural lighting will help reduce your dependence on electricity. It will also draw the warmth of the sun into your warehouse in winter, which will lower your heating bills. Motion-sensitive lighting can be used to automatically turn off the lights when the room is empty. These light controls can help reduce the amount of electricity required to keep darkened rooms lit.

Heating and cooling costs are another area that your facility could improve. Insulation is key to controlling the temperature in the facility. Your workers will feel more comfortable in summer heat and winter cold if there is an insulation barrier. You can reduce the impact that open bay doors have on your workers' comfort by keeping docking bays separate from the rest.

Your facility's electrical motors draw large amounts of energy. Up to 65 percent of the electricity used by your facility goes towards industrial engines. Your motors will run at the same efficiency using less power with gear reducers. Upgrade any equipment you have. Make sure you get the most efficient devices possible. The energy savings you'll see over time will offset any extra costs.

Reduce labor costs without reducing your workforce

Cross-training workers is a great way to make the most of the time workers spend on the floor. A diverse workforce will make it easier for you to find a replacement if an employee becomes sick. A trained workforce will allow you to expand your warehouse's capacity during peak demand times. You can also pull workers from other areas of the warehouse to pick products during holiday shipping seasons. It will help you save money as you won't have to train and hire seasonal workers. Your workers will be more productive and loyal to your company.

Keep your equipment in good condition

Regular maintenance is required for lift trucks and other equipment used in warehouses. Breakdowns during use are costly and time-consuming. Establish a schedule for regular maintenance to ensure that machines are always available. This will ensure that you have reliable equipment for your workers whenever they need it. Regular maintenance will also save you money on emergency repairs and replacements.

You can choose to store used items

You could save up to 40% by purchasing reclaimed storage containers instead of buying new ones. Second-hand is not just for bags and boxes. As well as quality, pre-owned parts, pallets, boxes and shelves liners can be found at a number of places. These storage options can be used to organize your warehouse for a better price.

4. How to Lower Distribution Costs

Distribution costs are the time, effort, and money that you spend to get products into and out of your warehouse. The delivery cost is only one component of total distribution costs. Distribution costs include the cost of shipping, loss due to product expiration or poor storage, and operating costs at your facility. You can reduce shipping costs by looking at how to improve all aspects of distribution.

Shipment Value

Higher product prices mean higher distribution costs. You may need to pay more for insurance and additional care. These areas should not be compromised. Instead, you should be focusing on protecting your valuable cargoes from loss or damage.

Loss from Improper Storage or Expiration

You may need to store products in a specific temperature range depending on what you store or ship. These products should be kept within the temperature range regardless of external conditions. Find a way to cool your products in the event of delays at the shipping dock. For a better long-term solution, have a refrigerator or freezer storage area near the loading dock to store temperature-sensitive products. This can help prevent product loss.

To prevent theft at any stage of the supply chain, make sure you keep track of your inventory. You can increase the security of your warehouse if necessary. In the event of a break in, alarm systems can be installed to notify local authorities. Verify the amount of insurance that you have to protect against theft and other product losses. Always report theft to the police. You may need this report to file an insurance claim.

Always ship products using methods that are guaranteed to get them there before they expire. For fresh produce, this time can be as short as a few days or as long for consumer goods such home furnishings.

Shipping costs

It is possible that land and sea transport will be cheaper than air travel. Compare prices with shippers, as prices can vary. It is important to compare the delivery times of different shipping methods in order to save money and protect products. Although longer shipping times might be more expensive, they can cause inventory to expire and cost you less.

Never let an empty truck leave your warehouse to reduce shipping costs. To maximize your shipping costs, fill empty trucks with friendly products. Your loading dock should be staffed with enough people to move goods around the day. Reusable bags can also be used to reduce the size of storage containers and increase product delivery. Bags can be shaped to fit the product inside. This reduces the shipping space. Bagged products take up less space, which allows you to fit more product into your truck. This reduces the cost of shipping and lowers your travel costs.

How our bags can be part of your warehouse improvement plan

These warehouse improvement ideas may require major changes to your facility. It is important to assess where your operations are in relation to your expectations. You can identify areas that you can cut costs and decrease the time your workers spend doing tasks. These are the areas you should start looking at when creating your facility improvement plan.

You can increase efficiency by making the best use of what space you do have and reducing storage costs. Saving space in your warehouse will help you make more money. Bulk storage bags, unlike boxes, can be shaped to fit the product inside. The packaging shape reduces the space required for goods to be stored in bags. You will save every inch of warehouse space you use, and you'll add it to the available space for other products, increasing your efficiency, profits, and profitability.

#Warehouse Software#Warehouse Safety#Warehouse Operations#Warehouse Productivity Improvement#Warehouse Productivity Software#AI for warehouse management

1 note

·

View note

Text

one thing about mcu peter is that he's a little TOO polite. he should've held the fact that tony repossessed his suit against him for the rest of time. he should've told him to eat shit at the avengers compound.

#like when tonys yelling at him in infinity war about coming with#'thats so funny i dont remember you being worried about my safety when i was buried alive under a warehouse 🫵🤨 but whatever!!'

56 notes

·

View notes

Text

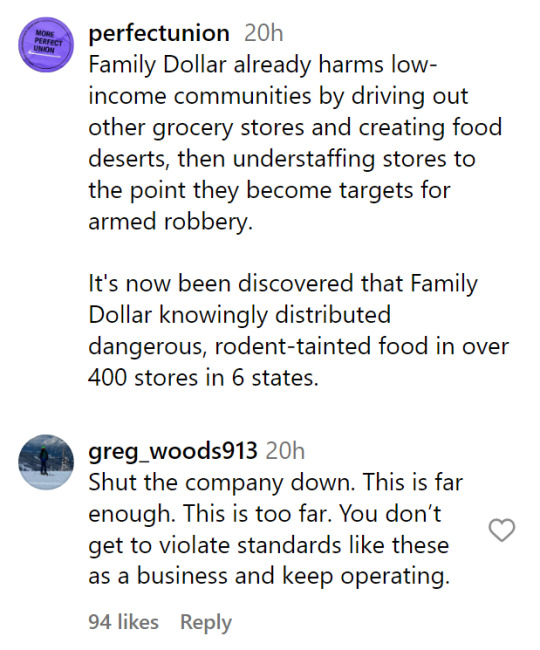

A Senate probe found Amazon manipulated injury data to make warehouses appear safer. It's twice as high as other warehouse jobs.

#senate#probe#amazon#manipulated#injury#data#fraud#warehouse#occupational health and safety#boycott amazon#fuck amazon#anti amazon#ausgov#politas#auspol#tasgov#taspol#australia#fuck neoliberals#neoliberal capitalism#anthony albanese#albanese government

24 notes

·

View notes

Text

Everyone wants to talk about workplace safety until you point out that dirt buildup is a slipping hazard and time should be set aside for all the floors to be thoroughly swept at least once a month. Then suddenly everyone wants to talk about deadlines and profit margins

#my job has this workplace safety incentive by which they mean 'what more difficult or time consuming steps can YOU as employees take'#'that might theoretically reduce the risk of some wildly impausible happenstance possibly involving a herd of wild pigs jn the warehouse'#'wearing tophats and bowties and carrying shotguns for how likely it is to actually happen. we the company will not be doing anything'

9 notes

·

View notes

Note

Hi! Okay so don't answer if this is too personal but outside of this blog do you get recognised as a lesbian by other gay women? Like... when seeing recent selfies of u we are given suggestions of other selfies of you from before T, and obviously then you could potentially be hit on and seen by lesbians, still with the short hair and masc style pre-T, but now? Like you pass as a whole ass man. Depending on the pics you could be perceived by randos as a straight or gay man but anyway always a cis one. But maybe that's my perception? If you pass that well that sapphics don't see u as a lesbian then how do u deal with that? Isn't it alienating in a way ? Or is that not a problem at all for you? Thanks

Hi anon, butches on T and butches with facial hair have existed for a while so while sometimes it might feel lonely, as being a butch often does, I’m always comforted by my brothers, sisters, and predecessors.

While I sometimes am able to pass as a cis man, I often find myself still being flirted w sapphics wherever I go, I live in a very gay city, a very trans city, and I’m grateful for my community

#when I do pass as a cis man it has its perks#better work dynamics sometimes (warehouse work) and added safety when camping/traveling with my partner#I hope you figure yr self out anon#wasn’t even a month ago I found myself in a sapphic boiler room with my partner having to fight ppl away haha#ask#anon

8 notes

·

View notes

Text

#regulatory enforcement#warehouse conditions#dollar store practices#corporate accountability#public health concerns#food safety regulations#corporate fines#health inspections#family Dollar#family Dollar store

14 notes

·

View notes

Text

New workplace downside: as we are tearing down old electronics and there's everything in the air..... My snot is black (they do regular medical checks on us to make sure there aren't bad levels of toxins like lead or whatever building up in us)

#i feel so dry#i need to drink more water#they give me so many breaks here too#an unpaid half hour and THREE paid 15min#it's a ten hour day but still#it's crazy#but when it's not a break it's kinda hard to get away to pee or whatever so i don't wanna drink too much#plus i can only drink on the breaks bc we can't have our drinks out in the warehouse#bc of chemicals and stuff in the air that we would then ingest after it gets on our bottles#they're very safety oriented and it's crazy to me#I'm like traumatized by my two previous workplaces

2 notes

·

View notes

Text

Listen. I don’t ever complain about being a short king. It’s just part of life.

I also don’t usually complain about receiving product at my store because I love it.

But if I ever meet the motherfucker at the warehouse who decided to put a fifty pound box of Johnny Cash at the top of a stack already taller than the average human, it’s on sight.

He’ll have to look down because he has to be a goddamn giant, but when he does, on sight. 📜🗡🤌

#I’m not even that short#despite lifting books all day#i have no upper body strength#when the job asked if I could lift 50 pounds repeatedly#i didn’t know they meant I had to climb to do it#there is no safety here#abandon all hope#the warehouse is the worst during the holidays man

2 notes

·

View notes

Text

How To Increase Warehouse Safety With Forklift Safety Lights

The convergence of heavy machinery and pedestrians within warehouses frequently leads to catastrophic outcomes. Sharp Eagle's unwavering commitment revolves around discovering innovative methods to enhance workplace safety for both humans and machines, and that's why we deal with forklift safety lights.

These lights for forklifts can be tailored to suit individual preferences and serve as an effortless means to prevent collisions in any kind of setting. By embracing safety lights, we can embrace a straightforward and effective approach to ensure a safer environment for all!

So let's see what those lights are, what makes them a perfect safety solution, and what kind of forklift lights you can get with us.

What Are Safety Lights?

These lights emit visual warnings near forklifts or other machinery to convey vital information to nearby workers. By projecting strong lights, these devices enhance safety by indicating the direction of travel for the machine.

Furthermore, they establish a protective zone around the equipment, enabling pedestrians to steer clear of potential hazards effortlessly. In noisy environments, visual warnings excel as they effectively capture attention, eliminating concerns about important alerts being pushed to the background by ambient noise, which is a common issue encountered with auditory systems like backup alarms.

Characteristics of Great Forklift Safety Lights

When it comes to enhancing forklift safety in a warehouse, selecting appropriate safety lights holds great significance. To ensure that your warehouse or work environment reaps the advantages, your forklifts need to have certain "qualities":

Brightness: An effective forklift safety light must possess sufficient brightness to remain visible even in low light or high glare conditions. It should serve as a prominent warning signal, effectively alerting pedestrians and nearby workers to the presence of the forklift.

Durability: Given the demanding nature of warehouse settings, forklift safety lights often undergo rough handling and exposure to harsh environmental factors. Therefore, a reliable safety light should exhibit durability, capable of withstanding such conditions without succumbing to breakage or malfunction.

Energy efficiency: Optimal forklift safety lights prioritise energy efficiency by employing low-power LED technology. This not only minimises battery drain but also reduces the frequency of battery replacements, contributing to cost savings and sustainability.

Versatility: A commendable forklift safety light should offer versatility and adaptability to diverse settings and environments. It should have the capacity to withstand various weather conditions, ensuring seamless functionality both indoors and outdoors.

With careful selection of forklift safety lights, you can establish a safe and productive warehouse environment for both workers and operators. Understanding how these safety lights contribute to a better and safer work setting is vital for fostering a culture of workplace well-being.

Ease of Use

Another significant characteristic of these safety devices is that they should be as easy to use as possible! And it holds for our lights — the installation process for these forklift safety lights is straightforward. They can be easily mounted directly onto the front, back, and sides of the forklift or other machinery.

In most cases, forklifts are equipped with pre-drilled holes specifically designed for mounting warning lights and work lights. However, safety lights also provide brackets that securely attach to the forklift without the requirement for any drilling. This hassle-free installation method ensures convenience and saves valuable time during the setup process.

Different Types

The forklift safety lights offer a range of models and functions, each projecting a distinct shape:

Spot: Spotlights are commonly utilised in warehouses, providing focused illumination.

Arrow: Arrows are gaining popularity due to their added functionality of clearly indicating the direction in which the machine is moving, facilitating effective communication.

Arc: Mounted on the rear of the machine, arc lights visually emphasize the safety zone at the back through an illuminated arc, ensuring heightened awareness.

Side-mounted forklift safety lights play a crucial role in a comprehensive safety system. They project a line alongside the machine, working in conjunction with lights on the front and back. Combining these lights establishes a complete safety zone, enabling individuals to easily gauge the necessary distance to maintain a safe position away from potential risks.

Some lights project different shapes to enhance safety measures. For instance, triangle-shaped lights serve as recognizable symbols reminiscent of traffic signs. When passers-by encounter a triangle light, they instinctively comprehend the need to yield to the machine, as they are already familiar with this shape from their experiences driving on roads.

Incorporating these diverse shapes and models of forklift safety lights amplifies safety measures, contributing to a more secure work environment! Let's see what kind of lights we have in store for you.

Products You Can Get With SharpEagle

Forklift ARC Lights

Forklift ARC lights are designed with a robust aluminium alloy casing and a flexible rubberized wire, enabling them to function flawlessly in the most demanding environments. Their powerful LEDs emit a beam of light that extends to the ground!

Constructed to endure anything we subject them to, these lights are equipped with tempered glass protection, making them resistant to water, dust, and shocks. They meet the ingress IP-67 protection standard, guaranteeing their reliability and performance.

Therefore, whether you're embarking on an arduous adventure or require dependable illumination for your daily activities, rest assured that these lights will leave a lasting impression!

Red Danger Lights

Say hello to the Forklift Red Danger Light, an ideal answer to enhance pedestrian safety. Encased in a sturdy aluminium die-cast housing, this light showcases high-powered LED security lights that can withstand even the most extreme temperatures. Emitting a vivid red glow, it sends an unmistakable signal to pedestrians. Crafted with dependable construction and top-notch materials, this danger light is specifically designed to endure and overcome any obstacles it encounters.

Forklift Blue Spot Light

This safety device is crafted to effectively warn pedestrians about approaching vehicles. This light is the perfect choice for signalling the presence of a forklift, particularly around corners.

Designed to endure even the most perilous surroundings, this blue light emitter boasts 100% resistance to dust, water, and shocks, guaranteeing its dependability in any environment. Furthermore, its aluminium alloy housing is specially engineered to minimise the impact of heat and fire, providing an additional layer of safety.

Elevate the safety standards in your facility by incorporating the Forklift Blue Spot Light. It's time to prioritise pedestrian awareness and establish a secure environment.

Blue Arrow Lights

Prepare to be captivated by these attention-grabbing devices that swiftly communicate warnings to both pedestrians and warehouse personnel! Specifically engineered for placement at the rear of a reversing forklift, these lights showcase powerful 3W LED lights encased within an aluminium housing that effectively dissipates heat.

But wait, there's more! The light's double-insulated rubberized wire and stainless steel bracket are meticulously constructed to withstand extremely high or low temperatures, assuring its resilience in any setting.

Elevate your safety protocols with the Forklift Blue Arrow Light and let its unmistakable illumination command attention and enhance awareness throughout your premises!

Warning Lights

Ensure accidents are kept at bay and foster a secure working environment with these indispensable power tools. Featuring high-powered LED lights, forklift warning light seizes attention while being shielded by a robust glass cover, ensuring enduring protection. And here's the cherry on top – it arrives with a two-year warranty from SharpEagle, offering complete peace of mind.

This exceptional light flaunts a quakeproof, waterproof, and dustproof body, rendering it resilient in every circumstance. Its aluminium alloy casting facilitates efficient temperature regulation, guaranteeing optimal performance even in extreme environments.

Why Blue and Red

When it comes to projection warning lights, the most prevalent colour preferences among users are red and blue. Wondering why?

Well, red lights possess an inherent association with danger, triggering a response of heightened attention and vigilance. Blue lights offer exceptional visibility on concrete surfaces, making them effortlessly noticeable in a warehouse setting. However, it's worth noting that these forklift safety lights are also available in alternative colours, such as green.

The choice of colour is entirely at the user's discretion rather than being dictated by specific standards. This safety system is fully customizable to cater to each user's and workplace's unique requirements.

Conclusion

The bustling day of heavy machinery and pedestrians in warehouses often leads to catastrophic outcomes. However, SharpEagle is dedicated to finding innovative methods to enhance workplace safety for both humans and machines, which is why we offer a range of forklift safety lights.

These lights can be customised to individual preferences and provide a simple yet effective way to prevent collisions in any environment. We can create a safer working environment for everyone involved by embracing safety lights.

Acquire your own with us!

You can call us at +971-4-454-1054 or mail us at [email protected]

#"Forklift Safety Lights#warehouse safety#forklift safety light#forklift safety lighting#Forklift camera system price#360 degree camera for forklift#Forklift camera kit#Forklift Safety Camera System#Fork truck camera#Reach truck camera#forklift camera systems uk#Forklift Truck Camera & Monitor System#forklift explosion proof camera UAE

0 notes

Text

after yesterday if my job genuinely doesnt think im not going to go out of my way and stir the pot and make Problems amongst their staff theyre fucking stupid as hell

#how very catholic of the organization to pretend its all about health and safety#and treat me like a stupid idiot child for asking forna functional fan inna warehouse where the inside temps reach 90+#everyone is stoked on me. ive done this before. i clear out more than half of a joann’s staff before#i’ll fucking do it again

4 notes

·

View notes

Text

shout out to fuckn. chemist warehouse adelaide street for not giving me my renewed script . found this out 2day when i tried to get more testosterone

#ps i am not in thst state anymore hashtag internet safety#but like ueah. love chemist warehouse they are not at allll transphobic#they tried to get out of giving it to me too xx

3 notes

·

View notes

Text

roofing supply services

Enhance safety and productivity on your job site with the newly redesigned TriRex mobile fall protection unit! Garza Supply is at the forefront of safety innovation. – Fall Arrest Capacity: Supports up to 3 workers; Fall Restraint Capacity: Accommodates 2 workers. – Concrete Applications: Designed for 2 workers in both fall arrest and restraint scenarios. – New Features: Equipped with flat-free tires, a spacious 20 cf job box with double doors, a material rack, and an optional 12 cf job box along with the Raptor Alert system. – Updated Design: Features a streamlined frame, closed guide loops, fork pockets, and a newly enhanced braking system. – User-Friendly: No assembly needed, OSHA compliant, and engineered to minimize tripping hazards. Perfect for any job site, this unit adheres to fall protection standards and is tested across various substrates. For more information, visit our website: TriRex at GarzaSupply.com.

#garza roofing#roofing supply#roofing equipment#roofing supply company chicago#roofing tools#roofing company#roofing supply near me#roofing chicago#roof safety equipment#chicago roofing supply#roofing material#roofing supply company near me#roofing supply store#roofing supply company#roofing store near me#roofing supply specials#roofing supply business#roofing supply services#roofing company near me#roofing products#roofing felt#roofing warehouse#roofing supply store near me#best roofing supply#roof safety#commercial roofing supply near me#roofing shop near me#roofing material near me#quality roofing supply#cheap roofing material

0 notes