#vacuum forming equipment for sale

Explore tagged Tumblr posts

Text

Find Top-Quality Vacuum Forming Equipment for Sale | GoBelovac

Looking for durable vacuum forming equipment for sale? Visit GoBelovac to explore our BV E-Class 53" x 103" machine & elevate your production process today!

0 notes

Text

Ethylene Oxide Sterilizer

Labtron Ethylene Oxide Sterilizer is a vertical, constant temperature heating box type sterilizer cabinet with manual door opening offers 120 L of capacity, 50 ℃ sterilization temperature, -60 kPa work pressure. it has Automatic ventilation with Sealed wear parts an Simple and convenient operation with long service life for more information visit our website https://www.labtron.uk/

0 notes

Text

the destiny of cooking oils: an creation to commercial oil press machine.

commercial oil press can be used for multi -plant oils inclusive of mustard, cottonseed, soybean, peanuts, tung seeds, oil sunflower, sunflower seeds and different oil seeds. business oil press gadget integrates an automatic temperature manipulation device. the device can alter the proper temperature to reap one of a kind uncooked substances, clean functions, and simplify the complexity of fried seeds. subsequent, benteng machinery will introduce the functions of commercial oil press machine.

on this basis, our agency released the new and bloodless dual -use multi -beneficial industrial oil press machine. the device has the feature of processing a spread of raw substances. on the equal time, the system is equipped with infrared heating, micro -power control and exquisite filter tool. squeezing oil, the raw additives are right away poured into the device and squeezed it out. it's miles filtered with well -filtered oil. it may be consumed immediately. the gadget is the first to apply 220 luo molybdenum carbon steel, this is more potent than ordinary manufacturers' carbon metallic machines. lifestyles is long, smooth to restore, easy to carry out, robust in response, and high oil output.

commercial oil press is a multifunctional spiral pre -squeezing machine composed of compacting, feeding device, spiral leader, faculty cake mechanism, equipment container and motor. the developments of the spiral pre-squeezing tool are that the hengli tielong works simultaneously, the squeezing is axial phase, and the shell is fixed with the middle thing of the single bolt of the tail tail bolt. warmth form cooling. industrial oil urgent system spirals are segmented structures. a maze -type sealing pads are used among the spiral and the band, which is prepared on the aspect of the spiral. this gadget has a novel design, low priced shape, and a feature of automatic manual college desserts. it can not forestall the hollow of the bore to clean up and update the dearth of harm. the processing amount is large, the energy consumption is small, the land is small, and the rate is low.

commercial oil pressing machines are mainly managed with the aid of automated electric powered manipulate, infrared heating, vacuum filtration, and the host makes use of materials. its processing and production improves the oil output price and the performance reaches the house degree. for all customers who purchase a multi -realistic oil press, all unfastened set up schooling, deliver elements all year spherical, lifelong protection, welcome new and vintage clients. multi -sensible industrial oil -filled oil press is suitable for gadgets and small oil factories, but moreover for people to squeeze present sale and outdoor processing.

our agency mainly produces business oil press machine, its collection of products, and a entire oil manufacturing line. we advise different machines in line with the particular needs of customers. unique raw materials, one of a kind outputs require exceptional varieties of oil press. we will offer you with exclusive customized services and intimate after -sales provider.

you're welcome to get in touch with us and inform us your requirement on oil mill!

2 notes

·

View notes

Text

How a Sanitary Napkin Incinerator Promotes Health and Sustainability

Proper disposal of menstrual wastes is quite an issue in this modern time. The sanitary napkin incinerator fulfills eco-friendly as well as hygienic purposes by safe disposal of used sanitary napkins. This machine is designed in such a way that it burns menstrual waste at very high temperatures, reducing it to ash while maintaining almost zero environmental hazard. This is an important device used in schools, offices, and even some public spaces where menstrual hygiene management is needed.

What is a Sanitary Napkin Incinerator?

The sanitary napkin incinerator is a specifically designed procedure that incinerates the waste sanitary napkins in a controlled environment. This machine houses vacuum technology which ensures an efficient but safe combustion process while following strict environmental safety standards. The risks of health as well as environmental issues that go along with the poor disposal methods of menstrual wastes can therefore be solved by the invention of this device.

Key Features of a Sanitary Napkin Incinerator

High-temperature combustion: It burns pads at between 600 degrees and 800 degrees.

Compact design: Available in wall-mounted and self-standing models for easy installation.

Power Efficiency: Operates on a very low power consumption cost.

Low Emissions: Equipped with filters in the emissions, thus ensuring eco-friendly operations.

User-friendly Interface: Simple with easy operations for easy co-operation.

Durable Construction: Made from heat-resistant materials ensuring reliability as well as longevity.

Applications of Sanitary Napkin Incinerators

Schools and Colleges: Installing a sanitary napkin incinerator serve for a school promoting menstrual hygiene and helps prevent improper disposal in classrooms and restrooms.

Offices and Workplaces: Encourages hygienic waste in a professional environment.

Open Spaces: Public restrooms; thus, ensure clean and safe disposal options for women.

Hospitals and Healthcare Facilities: Essential for managing large quantities of menstrual wastes in a sanitary manner.

Benefits of Using a Sanitary Napkin Incinerator

Environmental impact: Reduces landfill waste by addressing the problem of non-biodegradable sanitary products.

Hygienic Disposal: Prevents the dissemination of infection and foul odor due to improper waste management.

Ease of use: Requires little effort and forms an easy and fast disposal method.

Cost Saving: Eliminates recurring expenditure of outsourced waste disposal services.

Sustainability: Gives way for stronger waste management practices in communities.

Choosing the Right Sanitary Napkin Incinerator Machine

There are various factors you can consider when selecting a machine for incinerating sanitary napkins, such as:

Volume: Choose the machine according to the volume expected to be generated by waste.

Consumption of Energy: Go in for energy-efficient models, which should cut down operational costs.

Regulatory: The machine should live up to the environmental and safety standards.

Warranty and Support: Service after-sales and aftercare options must be checked.

Challenges in Implementing Sanitary Napkin Incinerators

Awareness: Organizing programs on proper menstrual hygiene subjected to communities.

Initial Investment: High purchase costs of the machines are considered hurdles for small organizations.

Maintenance: Servicing the machines regularly is necessary for the proper functioning of the machine.

The Future of Sanitary Napkin Incineration

As much as knowledge and practice about managing the menstrual hygiene and sustainability matter, they increase the demand for sanitary napkin incinerators. Emerging innovative ideas like solar-powered machines and more efficient emission controls will further the development of greener solutions. If used broadly, these machines can greatly improve public health and environmental conditions.

Conclusion

The sanitary napkin incinerator by EnvCure Technocrat LLP is not just a waste management device, but a step toward hygienic, dignified and sustainable living. These machines are not just present in schools, workplaces or public areas; they are extremely important in addressing the challenges of menstrual waste disposal. Such an incinerator, chosen right by organizations, can lead to a cleaner environment and a healthier society.

0 notes

Text

Sunkaier vertical powder dryer is a type of equipment designed specifically for the drying of powders in industries such as pharmaceuticals, polymers, and chemicals. This type of dryer typically operates under vacuum conditions, which can help to reduce the temperature required for drying and minimize thermal degradation of sensitive materials.

Shaftless Helix Scraper Mixer:

A shaftless agitator is designed to mix and process powders or bulk solids without the need for a central shaft. This design helps in reducing the potential for material buildup, bridging, or clogging that can occur around a traditional shaft. Since there is no central shaft, there are fewer obstructions for the powder to flow around. This reduces the likelihood of blockages forming, especially with sticky or cohesive materials.

Characteristics Features:

This jacketed and vacuum rated version is an ideal conical mixer, vertical dryer, and reactor.

Spiral tools, arms and shaft are jacketed and heated.

This vertical dryer guarantees quick and gentle drying results.

It can be used for moist powder, wet suspensions as well as liquids, paste and dough.

If the drying process requires deagglomeration, high-speed cutting rotors may be installed.

The mixing device is driven from the top, using only a single top bearing.

The shaftless mixer-dryer meets all industry standards for surface finish, including sanitary and pharmaceutical requirements, and requires a very small space.

Non-Clogging Design:

Shaftless Construction: The impeller is designed without a central shaft, which reduces the number of components and potential points of failure. This design also minimizes the risk of material accumulation around the shaft, which can lead to clogging.

Open Structure: The impeller blades are typically open, allowing larger particles to pass through without getting stuck. This open structure ensures that the impeller can handle a wide range of particle sizes and viscosities without clogging.

Robust Blades: The blades are often made from durable materials and designed to withstand heavy loads and abrasive materials.

If you have any need of process equipment please contact me without hesitation, thanks.

Helena Xiao / Sales Manager

Email: [email protected]

Phone: +86 510 8758 8707

Mobile: +8618261586225

0 notes

Text

CoolVac Electric Insulation Removal Vacuums and Their Benefits

Electric insulation vacuums for insulation service professionals

Today when you desire to make and create a well-insulated home during summer season then you can make use of a cool insulation removal vacuum. Now these machines are being sold in the form of coolvac electric insulation removal vacuums.

These are those machines and equipment with which you can remove the old insulation coatings of your walls easily. You might also see that coolvac electric insulation removal vacuums run with power supply and yet many of them are very portable and light in body weight. So if you are an insulation service professional then these machines can help you well in this kind of profession.

The main features of a cool insulation removal vacuum

The features of cool insulation removal vacuums are immense that all of you will appreciate well.

These vacuum machines can help you well during winter months when outside cold enters your home and makes you feel weary.

In this way you can have a very option instead of using room heaters.

These equipment of insulation removal will help you well in the task of replacing old insulation layers with new ones.

If and when you feel the urge of removing the old cool insulation layers from the walls of your living place then you can choose and use cool insulation removal vacuums.

These machines are being sold of various brands in the consumer market.

How to removal old insulation layers easily?

The importance of insulation removal vacuum bags has increased too much during the present time. With these kinds of bags you will see that the task of insulation layers removal can be done easily. You can do this task by yourself. However if you do not know how to operate these bags then you can take help and support from insulation service professionals.

These people will take a very fair cost fee for their services given to you. In most conditions you can choose cellulose insulation material while you make the use of these insulation removal vacuum bags. With this option you can save much money in your wallet.

How to buy insulation removal vacuums at a low cost?

In case if you feel that any insulation removal vacuum for sale is very much expensive in a brand new condition then you can buy used pieces that are in a fine working condition.

About us:- Here in this matter the local hardware vendors of your city will help you. Even you can get smart price discounts in this concern from internet based online vendors. This can be the best way to save money while buying insulation removal vacuum for sale.

0 notes

Text

CO2 Metal and Non-Metal Laser Machine in Madhya Pradesh

Success Technologies is a trusted Manufacturer, Exporter, and Supplier of CO2 Metal and Non-Metal Laser Machines in Madhya Pradesh. Our manufacturing unit is located in Ahmedabad, Gujarat, India. Success Technologies is dedicated to empowering businesses with state-of-the-art equipment, providing the tools necessary for success in today's competitive market. Over time, Success Technologies has earned a reputation for its unwavering commitment to quality, precision, and innovation. We offer an extensive selection of industrial machines, from mini tabletop CNC routers to advanced vacuum forming machines, designed to meet the specific needs of various industries. Our products are engineered to deliver the highest levels of precision, efficiency, and reliability across a range of industries. Features of Our CO2 Metal and Non-Metal Laser Machines: High-Speed Engraving and Cutting: Achieve fast and precise results, even with complex designs. Long-Lasting Performance: Built with high-quality components for durability and a longer machine life. Automatic Focus: The machine automatically adjusts to different materials for optimal cutting or engraving. Versatile Materials: Cut or engrave a wide range of materials, including metal, acrylic, wood, leather, fabric, and more. Advanced Control System: Offers precise control over speed, power, and direction for a variety of applications. Low Maintenance: The design requires minimal maintenance and ensures easy servicing to minimize downtime. Applications of CO2 Metal and Non-Metal Laser Machines: Metal Engraving and Cutting Wood and Acrylic Cutting Leather and Fabric Engraving Plastic and Rubber Marking Advertising and Signage CNC Router Machine What materials can CO2 Laser Machines cut and engrave? CO2 laser machines are highly versatile and can cut and engrave both metal and non-metal materials, including stainless steel, aluminum, acrylic, wood, leather, plastic, and fabric. Are Success Technologies' laser machines easy to operate? Yes, our CO2 laser machines feature an easy-to-use interface with intuitive software, making them simple to operate for both beginners and experienced users. What industries benefit from CO2 Metal and Non-Metal Laser Machines? Various industries, including manufacturing, advertising, automotive, textiles, jewelry, architecture, and sign-making, widely use these laser machines. Do you offer after-sales service for your laser machines? Yes, Success Technologies offers full after-sales support, including installation, training, and ongoing maintenance to ensure that your CO2 laser machine operates efficiently. Success Technologies is a Supplier of CO2 Metal and Non-Metal Laser Machines in Madhya Pradesh, including locations: Indore, Bhopal, Jabalpur, Gwalior, Ujjain, Sagar, Dewas, Satna, Ratlam, Rewa, Katni, Singrauli, Burhanpur, Khandwa, Bhind, Chhindwara, Guna, Shivpuri, Vidisha, Chhatarpur, Damoh, Mandsaur, Khargone, Neemuch, Pithampur, Narmadapuram, Itarsi, Sehore, Morena, Betul, Seoni, Datia, Nagda, Dindori. Contact us today for more information, pricing, and availability. View Product: Click Here Read the full article

0 notes

Text

Maintain Sparkling Clean Pools: Your Guide to Swimming Pool Cleaning Chemicals

Keeping a swimming pool clean and safe requires the right combination of chemicals and equipment. Whether you're a pool owner or a professional pool cleaner, understanding the importance of swimming pool cleaning chemicals is crucial. In this blog, we’ll explore the essentials of maintaining a pristine swimming pool, focusing on the role of cleaning chemicals, equipment, and tools. We'll also discuss the benefits of purchasing swimming pool chemicals online and where to find the best deals on pool chemicals in Dubai.

Understanding Swimming Pool Cleaning Chemicals

Swimming pool cleaning chemicals are the backbone of maintaining a clean and healthy pool. These chemicals not only keep the water clear and sparkling but also ensure that it is safe for swimmers by eliminating harmful bacteria, algae, and other contaminants. Here are some of the most essential swimming pool cleaning chemicals you need to know about:

Chlorine: A widely used pool chemical, chlorine sanitizes water by eliminating harmful bacteria and algae. Available in various forms such as tablets, granules, and liquid, chlorine is a must-have for every pool owner.

pH Balancers: Maintaining the correct pH level in your pool is vital for both the effectiveness of chlorine and the comfort of swimmers. pH balancers, including pH increasers and decreasers, help maintain the water’s pH level between 7.2 and 7.6, which is ideal for most pools.

Algaecides: Algae growth can turn your pool water green and make the surfaces slippery. Algaecides are used to prevent and control algae blooms, ensuring that your pool remains clear and safe.

The Role of Swimming Pool Cleaning Equipment

In addition to chemicals, having the right swimming pool cleaning equipment is essential for maintaining a clean and inviting pool. The combination of effective chemicals and quality equipment ensures that your pool stays in top condition. Here are some of the key pieces of swimming pool cleaning equipment:

Swimming Pool Cleaning Brush: A swimming pool cleaning brush is essential for scrubbing the walls and floor of the pool to remove algae, dirt, and debris. Brushes come in various shapes and sizes, including those designed specifically for corners and steps.

Pool Vacuum: A pool vacuum is used to remove debris from the pool floor. There are manual and automatic pool vacuums available, with automatic vacuums providing a more convenient cleaning solution.

Skimmer Net: Skimmer nets are used to remove leaves, insects, and other debris floating on the surface of the water. Regular skimming helps prevent debris from sinking to the bottom, where it becomes harder to remove.

Buying Swimming Pool Chemicals Online

In today’s digital age, purchasing swimming pool chemicals online has become increasingly popular. There are several advantages to buying pool chemicals online:

Convenience: Shopping for swimming pool chemicals online allows you to browse a wide range of products from the comfort of your home. You can easily compare prices, read reviews, and place an order with just a few clicks.

Wider Selection: Online stores often offer a broader selection of swimming pool chemicals and equipment than local stores. This means you’re more likely to find the exact product you need.

Competitive Pricing: The online marketplace is highly competitive, which often results in better prices for consumers. Many online stores offer discounts, promotions, and bulk deals on pool chemicals.

Pool Chemicals on Sale: Finding the Best Deals in Dubai

If you’re based in Dubai or the surrounding areas, you’re in luck when it comes to finding great deals on swimming pool chemicals. Dubai is home to a variety of suppliers offering high-quality pool chemicals at competitive prices. Here’s how to find the best deals on pool chemicals in Dubai:

Search for Promotions: Many suppliers in Dubai offer seasonal promotions and discounts on pool chemicals. Keep an eye out for these deals, especially during the off-season, when prices may be lower.

Buy in Bulk: Purchasing swimming pool chemicals in bulk can save you money in the long run. Many suppliers offer discounts on bulk purchases, making it a cost-effective option for those who need large quantities of chemicals.

Compare Options: Explore multiple deals before making a decision. Take the time to compare prices across different suppliers, both online and offline, to ensure you’re getting the best value for your money.

Essential Swimming Pool Cleaning Tools

Having the right swimming pool cleaning tools is just as important as using the right chemicals. These tools help ensure that the cleaning process is thorough and efficient. Some essential swimming pool cleaning tools include:

Pool Brush: A sturdy pool brush is necessary for scrubbing the pool walls, floor, and steps to remove algae and grime. For best results, choose a brush with stainless steel bristles for concrete pools or nylon bristles for vinyl-lined pools.

Pool Skimmer: A pool skimmer is used to remove floating debris from the water’s surface. Regular skimming prevents debris from sinking and reduces the load on the pool filter.

Vacuum Hose and Head: A vacuum hose and head are used to remove dirt and debris from the pool floor. Automatic pool cleaners can make this task easier, but manual vacuuming is sometimes necessary for a deeper clean.

Leaf Rake: A leaf rake is designed to scoop up larger debris, such as leaves and twigs, from the pool. It’s particularly useful for cleaning up after a storm or during the fall season when trees shed their leaves.

Aquasplash: Your Go-To for Pool Cleaning Needs

At Aquasplash, we prioritize keeping your swimming pool clean and safe. That's why we offer a comprehensive range of swimming pool cleaning chemicals, equipment, and tools to meet all your needs. Whether you’re looking for high-quality pool chemicals, reliable cleaning equipment, or expert advice, Aquasplash is your go-to destination. Trust us to help you keep your pool sparkling clean and ready for endless enjoyment.

0 notes

Text

Find High-Quality Thermoforming Machines for Sale at Gobelovac

Looking for top-notch thermoforming machines for sale? Visit Gobelovac for premium quality machines that meet all your thermoforming needs. Browse our selection now!

0 notes

Text

Effects of Manufacturing Defects on Thermoformed Packaging Quality

With the improvement of consumers' own consumption and health awareness, the concreteness and transparency of product information have become the focus of consumers' attention when purchasing products.

Thermoformed packaging has a good sales display effect because the packaged contents are visible. Generally, irregular objects are sealed and protected by using PVC or PET transparent thermoforming, and then the blister and the paper card (paper) coated with thermoforming oil are bonded together by hot pressing to form a complete, regular and transparent object package style. The function of the blister card is to seal and fix the object, and the paper card supports the object.

At the same time, graphic information must be printed on the paper card. The thermoforming oil will firmly bond the blister card and paper card together under heated conditions to ensure the integrity of the packaging during storage and transportation.

At present, the processes, materials and equipment of thermoforming packaging are relatively mature, and related process technologies have been industrialized, such as: batteries, stationery, hardware, toys, personal care, cosmetics, small household appliances, other daily necessities and other product fields. In carton packaging has been widely used.

The quality evaluation indicators of thermoformed products generally include plastic absorption, anti-adhesion, gloss, wear resistance, environmental resistance, high-speed line processability, etc. In the production process, the most prominent problem is that the heat sealing effect of the carton product after molding is not up to standard, that is, the quality problem of poor thermoforming.

The quality requirements are generally: after the product is packaged, the blister card can be torn open under the premise of a drop test at least Open 80% of the paper fiber layer.

In practice, there are many factors that affect the poor thermoformability of products, including: thermoforming quality and stability of paper cards (paper), ink materials, blister card quality, thermoforming oil materials, heat sealing process conditions, etc. Among these conditions The interaction between them directly affects the vacuum forming effect.

Ⅰ. Advantages of Thermoformed Packaging

Thermoformed packaging blister cards are made of transparent materials, with PVC and PET being the most commonly used. At the product terminal, the paper cards are generally hung and placed on the shelf.

The shape of the product is clear at a glance, which is in line with the current consumer consumption patterns. Therefore, this kind of packaged products Usually hung in a prominent position on shopping mall shelves to facilitate sales.

By wrapping irregular products with blister cards, the appearance of special-shaped products can be relatively neat and beautiful, making storage and transportation more convenient, and no additional buffering materials are needed for packaging.

Thermoforming packaging can ensure that the products in the thermoformed blister card are not contaminated by external dust and have a certain barrier effect on water vapor, which not only ensures that the quality of the product is not affected, but also meets the requirements of environmentally friendly green packaging.

It has a certain function of preventing opening and being used at any time, allowing consumers to purchase with more confidence.

Ⅱ. Principle of Thermoforming and Heat Sealing Packaging Process

The blister card and the paper card coated with thermoforming oil are heated through a customized mold using electric heating or high frequency. The softened blister card and the melted pressure forming oil are heated under pressure.

After solid fusion and cooling, the blister card, thermoforming oil, and paper card form one body to complete the thermoforming packaging process.

During thermoforming heat sealing and encapsulation, the thermoforming oil is heated until it softens and becomes viscous (at room temperature, thermoforming oil, as a special varnish coating, has the characteristics of a general varnish coating, that is, it has a certain gloss and wear resistance. properties), if any material is below its softening point, fusion cannot occur effectively and the seal becomes very poor.

Ⅲ. Factors Affecting Thermoforming Effect

There are many factors that affect the thermoforming effect. Usually, during the product sampling process, companies will use the empirical elimination method to find the factors that cause the poor thermoforming effect of the product.

The main factors that affect the thermoforming effect include: influence of materials (paper, ink, thermoforming oil), improper process parameters and methods (temperature, pressure, thermoforming time), and different equipment heating methods.

The Influence of Paper

The different properties of paper (paper card) materials directly affect the thermoforming effect. Factors including: paper tightness, paper fiber, surface strength, surface flatness, smoothness, sizing degree, etc., will all affect the thermoforming effect. Combined with the actual production, the proofing process was tested and analyzed, and the following empirical conclusions were drawn:

Paper absorbency effects. The penetration ability of ink or thermoforming oil into the paper is very important. The thermoforming effect of mechanical wood pulp with low tightness and fluffy fiber inside the paper is better.

The thermoforming oil can easily penetrate into the inside of the paper. When the thermoforming oil is completely When dry, the thermoforming effect is very good; otherwise, the thermoforming oil accumulates on the surface of the paper, which is not easy to dry and will easily fall off after thermoforming.

The lower the surface strength and internal bonding strength of the paper, the better the thermoforming effect. It is best to have no internal and surface sizing. However, if the amount of sizing on the paper is too small, the surface strength of the paper will easily decrease, surface peeling will easily occur during the printing process (commonly known as lint and powder loss), and the paper hardness will be poor.

Effect of paper moisture content on thermoformability. If the moisture content of the paper is too high, the surface strength will be reduced and the drying speed will be slow. When the molding oil is overheated, the surface will bubble, resulting in poor thermoforming and poor results. Generally, it is required that the paper should be processed to balance the moisture content, and it is better to dry it.

At the same time, the product generally needs to be left for 8-12 hours after thermoforming before use. On the contrary, it is not good if the paper is too dry and brittle, which may easily cause the thermoforming part to be unstable.

The Influence of Printing Ink

Factors such as different components of printing ink materials, film thickness, compatibility of ink and thermoforming oil, ink drying speed, etc., directly affect the thermoforming effect. General requirements:

1. The ink used should be free of silicone wax and oil as much as possible. It has good gloss and smoothness, but the thermoforming oil is not easy to penetrate, and the thermoforming effect will be lower.

2. If the printing ink layer is thin and the viscosity is low, the inside of the ink dries quickly, the thermoforming oil can easily penetrate, and the thermoforming effect is better; the toner particles in the ink component are small and the ink color concentration is high, which is beneficial to the thermoforming effect. .

3. It is difficult to thermoform metal ink, but it can be achieved when the ink layer is thin.

4. The properties of the ink and the thermoforming oil must match, have strong adhesion to each other, and will not produce other chemical reactions.

5. Some resin materials in the ink components will have high hardness after curing (such as UV ink), resulting in unstable thermoforming effects. Generally, printing inks with resin components that do not have high hardness after curing are selected.

The Influence of Thermoforming Oil

Thermoforming oil is a polymer material with many types, which can be classified according to applicable materials, such as PET thermoforming oil, PVC thermoforming oil, gold and silver card thermoforming oil, cardboard thermoforming oil, etc. Its main components are resins (such as polyurethane, acrylic), additives (such as anti-aging agents, diluents, etc.).

According to different properties, it is divided into water-based thermoforming oil, oil-based thermoforming oil, polishing thermoforming oil, wear-resistant thermoforming oil, powerful thermoforming oil, etc.

General requirements: During the coating process, the coating amount should be controlled to ensure the leveling, gloss, penetration, and dryness of the film surface. The thermoforming process mainly controls temperature, pressure, and time to ensure that the thermoforming is firm.

The Influence of Blister Card

Blister card is a transparent material used for thermoforming packaging (generally PET polyester, PVC polyvinyl chloride, PS polystyrene and other materials), which is heated by paper that has been coated with thermoforming oil. Press, shrink and bond together to form a complete, regular and transparent packaging product.

The most commonly used A-PET (Amorphous Polyethylene Terephthalate) thermoforming material is a kind of PET material. It is a thermoplastic environmentally friendly plastic product. It is stable at room temperature. It shrinks when heated (above the glass transition temperature of the material) and in one direction.

A thermal shrinkage of more than 50% is ideal. Compared with PVC materials, APET materials have obvious advantages: light specific gravity (low density), high strength, good folding resistance, high transparency, strong impact resistance, no crystal points, easy to decompose and environmentally friendly.

General requirements in actual production:

1. If APET is heated beyond the crystallization temperature and the heating time is too long, PET may be converted into a crystalline state and become white, which will lead to a significant reduction in sealing quality in the crystalline state and poor thermoformability.

2. The heat sealing temperature must be controlled enough to soften the thermoforming oil layer and PET vacuum forming, but not to convert PET into a crystalline state.

3. In actual production, if the material type of the thermoformed cover is changed, such as changing the PET model or changing PVC to PET, a comprehensive test and evaluation must be conducted first.

4. Combined with the actual production requirements, the design parameter requirements for the thermoformed cover:

The thickness must be greater than 0.15mm. The film thickness will be reduced during thermoforming. Pay attention to incoming material inspection. •Effective thermoforming area width >5mm.

The deformation of the thermoforming cover will affect the thermoforming effect.

If the release oil used in manufacturing the thermoformed cover remains on the surface of the thermoformed cover, it will affect the surface tension of the thermoformed cover, reduce the dyne value, and affect the thermoforming effect.

The Influence of Thermoforming Process Production

The thermoforming process includes: printing and coating thermoforming oil process and thermoforming heat sealing process. Currently, there are three ways to realize the coating process: offline oiling machine, full page oiling, silk screen partial oiling, and offset printing in-line oiling.

Offline coating and thermoforming processes generally require that the product be left for at least 72 hours after printing. After the large dark ink area is completely dry, hot molding oil can be applied to the surface and left for at least 24 hours before the thermoforming process can be carried out.

The current method of oiling the line (usually using water-based thermoforming oil) can shorten the time, but the thermoforming effect is not good. The main control objectives of the oiling process are: appropriate amount of oil (generally about 3-5g/m2, depending on the surface properties of the material and the concentration of the thermoforming oil), and full penetration of the thermoforming oil.

The coating amount must be controlled during the coating process to ensure the leveling, gloss, penetration, dryness, etc. of the film surface. The pressure forming process mainly controls temperature, pressure, time and other conditions to ensure the thermoforming effect.

The Influence of Thermoforming Equipment

There are three types of heating methods for thermoforming packaging equipment: traditional back heating, heating plate surface heating, and high-frequency internal heating. Different heating methods, different temperature control methods, and different heat transfer effects result in different thermoforming oil softening and thermoforming cooling forming effects.

The traditional thermoforming process uses back heating. The heated plate is heated, and heat is transferred to the surface of the thermoforming oil and the thermoforming cover through the back of the paper card to complete the thermoforming process.

The thermoforming temperature is relatively constant and cannot be adjusted quickly; the heat transfer is affected by the thickness of the paper has a great influence. The thicker the paper, the harder it is for the heat to be quickly transferred to the thermoforming cover.

Therefore, sufficient thermoforming pressing time must be given to allow the heat to be fully transferred to the thermoforming cover to ensure the thermoforming effect.

The heating plate thermoforming machine heats the surface of the thermoforming cover and transfers heat to the surface of the thermoforming oil to complete the vacuum forming process. The thermoforming temperature can be quickly adjusted; because the heating plate is in direct contact with the thermoforming cover, when the temperature is too high, the thermoforming cover is extremely susceptible to thermal deformation and it is difficult to transfer heat to the surface of the thermoforming oil (the thinner the thermoforming cover, the easier it is to transfer heat, but the easier it is to deform).

To ensure a good thermoforming effect, you must choose a thermoforming material with an appropriate thickness. Cover and adjust the thermoforming temperature and fusion time.

High-frequency internal heating uses a high-frequency electric field to oscillate the internal molecules of the thermoforming cover and thermoforming oil to generate heat energy to complete the thermoforming process. The temperature can be quickly adjusted.

This heating method has the most stable heat transfer and can adjust the corresponding temperature at will according to the properties of the material. However, because a large current is generated at the moment of fusion and sparks are easily generated, it is not suitable for transferring silver card products to thermoforming.

In practice, since the thermoforming temperature has a greater impact on the thermoforming effect, it is generally recommended to use thermoforming packaging equipment that can quickly adjust the temperature.

Conclusion

This article focuses on analyzing the quality problems of poor thermoformability during the thermoforming process of color box packaging products, and qualitatively analyzes the possible influencing factors from three aspects: materials, process methods, and equipment, which has obvious guiding significance for actual production. In actual work, we must first understand the customer's product requirements, master good problem analysis and solution methods, and be as familiar as possible with the thermoforming process principles, materials, equipment, and production processes in business.

When encountering quality problems, we must analyze them in principle, test and verify raw materials, process technology, and equipment control, find the causes and solutions in a timely manner, and ensure that each link is continuously carried out in strict accordance with the production operation process in daily work. monitor.

0 notes

Text

Made in China sensor PR9628/011-100 for thermal power plant

Made in China sensor PR9628/011-100 for thermal power plant Is YOYIK for the use of units of the power plant supporting professional models of products. YOYIK main generator accessories, generator sets of accessories. For decades, the company relies on advanced technology, technology, materials and scientific management to improve the stability and reliability of the pump, for hundreds of thermal power plants, hydropower stations, cement plants, coal gangue power plants, metallurgical companies, steel and other overhaul , Technical transformation to provide a reasonable and excellent equipment selection, construction planning, installation commissioning, after-sales service, such as perfect complete service, won the power industry industry wide acclaim. Yoyik can offer many spare parts for power plants as below: #DF-sensor PR9628/011-100-DF k type thermocouple 1200 degree WRNK2-391 lvdt displacement transducer TD1000 sensor lvdt HL-6-700-15 thermocouple voltage WRNK2-332 transmission speed sensor D-065-05-01 lvdt transducer TD4000 lvdt displacement transducer TDZ-1B-05 vacuum pressure gauge Z1223938 steam turbine bolt heater ZJ-20-39 lvdt 0-300 DET-200A input speed sensor CS-1-G-075-05-01 displacement transducer ZDET1000B Platinum-Iridium Wire TC03A2-KY-2B/S17 tachometer rpm DF9011-B Resistance Temperature Detector WZPM2-001 Φ5 Shaft Rotation Speed Sensors G-065-02-01 LVDT Displacement Transducer Sensors 2000TDGN-15-01 speed meter sensor CS_1 G-110-03-00 Resistance thermometer WZPK-24 φ6 rpm sensor indicator CS_1 D-088-02-01 sensor lvdt TDZ-1E-33 non-contact displacement sensor 12000TDGN Gear rpm sensor D075-05-01 LVDT Displacement Transducer Sensors TDZ-1E-011 wire pt100 WZPK-24 φ6 LVDT Measurement TDZ-1E-31 Magnetic Sensors ZS-04-150-5000 platinum rhodium thermocouple wire TE-204 lvdt linear position sensor TD-1 100S Tachometric Sensor QBJ-CS-2 non-contact displacement sensor K156.36.06.003 electronic pressure switch 3051TG3A2B21AB4M5 lvdt 0-300 A181.36.06G03 thermal resistance unit WZPK-24 φ6 Rotation Speed Sensor ZS-03 inductive displacement sensor 1000TDZ-A sensor PR9628/011-100 Rotary Torque Sensor 70C85-1010-423 industrial displacement sensor C9231117 full form of lvdt TDZ-1E-05 LVDT Measurement B151.36.06(1)G03 temperature thermometer WSS-581W thermocouple TC03A2-KY-2B/S5 linear displacement sensor 191.36.09.03(1) displacement sensor sany 5000TDGN-80-01-01 rotation sensor 143.35.191 LVDT 191.36.09.19 lvdt sensor B151.36.09.14G18 thermocouple thermometer TE-205 Gear speed sensor CS-3F-M10-L55-1 sensor lvdt HL-3-100-15 lvdt transducer displacement TDZ-1D-05 linear displacement transducer 191.36.09(1).09 Magnetic Proximity Sensors ZS-03 L=65 thermocouple temperature meter TE-108 electric heat elements ZJ-22-49 displacement sensor sany TD2-1 Platinum RTD Sensor WZPM2-08 displacement transducer B151.36.09G18 thermowell WREK2-191 Indicator light XB4BVM5 LVDT Displacement Sensors 4000TDG-15-01 LVDT 191.36.09.05 rpm speed meter 240IBTESTO linear displacement sensor 5000TDZ-B pt100 rtd500 3Q13661 linear displacement transducer HTD-200-6 linear variable displacement transducer 6000TDGN-30-01-01 Tiny oil ignition gun EHE-20-B-1-16H-S temp gauge WSS-481 φ8 non contact rpm sensor ZS-04 L=80 angular displacement sensor 191.36.09.01 rtd thermocouple WREKD2-04 sensor PR9628/011-100 DFYLSYC-2024-6-17-A

0 notes

Text

Rubber Gym Mats

Rubber Gym Mats are rugged flooring solutions that offer an effective level of traction and support for high impact workouts. They also provide a layer of cushioning that protects the floor beneath from damage or injury. Rubber matting is often a popular choice for weight rooms, but it also works well in a wide variety of other residential and commercial fitness spaces. It is available in a number of different forms and designed for various applications, including roll mats, interlocking tiles, and even some pre-cut workout pads.

There are many reasons why rubber gym mats are a popular choice for both commercial and home fitness spaces. For one, they are highly durable and easy to maintain. The material resists dirt and dust, which reduces the need for frequent vacuuming or sweeping, and most rubber mats are water resistant and can be wiped clean in case of spills. In addition, the material provides an extra layer of comfort and stability under workout equipment like treadmills or ellipticals.

Another key benefit of using a rubber gym mat is its ability to absorb shock and vibration during strenuous exercises. This feature helps prevent impact injuries such as ankle sprains and back or leg strains. It also reduces noise from rattling weights and the pounding of free weights, which can disturb others in a home gym environment.

Some types of rubber matting are designed to be reversible, which increases their longevity and makes them an affordable long-term investment. This feature is especially useful for areas that will see a lot of traffic and heavy use. Many are also odorless, which eliminates the need for costly cleaning products or professional odor removal services.

Many of the rubber mats we carry are also available in a range of color options. This allows customers to match the mats to their existing color scheme and create a cohesive look throughout the fitness space. These color choices also help limit the amount of time and money that would be needed to redo the entire room when it is time for a new color palette.

For those who are concerned about a lack of installation options, there are some rubber gym mats that can be secured simply by using strips of double-sided tape. This method creates a strong connection between the mat and the hard floor, but it does leave small lines of tape at the seams.

0 notes

Text

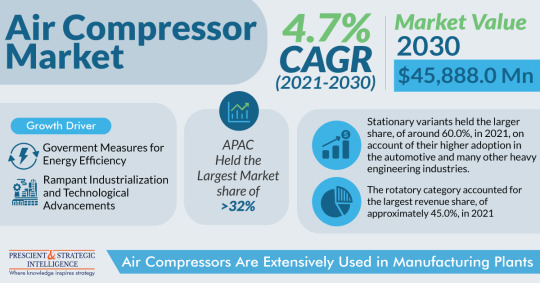

Air Compressor Market Analysis by Trends, Size, Share, Growth Opportunities, and Emerging Technologies

A diesel engine or electric motor powers an air compressor, a mechanical device that converts energy from one form to another and stores it in the pressured air. Powered machine tools, ventilation systems, HVAC control systems, and other industrial and non-industrial uses for powered air employ pressurized air.

Air compressors use the kinetic energy stored in the compressed air to deliver the required power to various machinery, tools, and equipment in different industrial verticals. Additionally, the continuous compression supports the transportation of gases and liquids, the production of goods connected to petrochemistry, and cooling applications.

It has various uses, including cleaning, vacuum packing, spray painting, and other things. Additionally, a wide range of end customers employs air compressors for dehydration, air blowing, cleaning, powering tools, and medical equipment.

Rapid industrialization in developing nations is a crucial element driving the demand for air compressors. The market is expanding because industries worldwide are increasing their need for energy-efficient air compressors.

Browse detailed report - Air Compressor Market Analysis and Demand Forecast Report

Which Category Lead Industry?

Historically, the rotatory category holds the most significant share of about 45.0% because of these types' excellent efficiency and durable construction. Additionally, the category's expansion is aided by the numerous standards issued by government organizations throughout the globe to improve the output energy and efficiency optimization of the rotatory type.

The sales potential is also increased by the rotatory compressor's numerous advantages, including its longer lifespan and significant battery energy savings. Additionally, it is anticipated that the equipment's costly installation and maintenance costs will slow expansion in the upcoming years.

But as technology has advanced, air compressors' compression capacities have increased, which is expected to increase the demand for air compressors. Developing portable and energy-efficient air compressor designs have been widely embraced by businesses worldwide.

0 notes

Text

Crafting Excellence: Guide to Choosing the Best Vacuum Forming Tray Manufacturer

Welcome to the world of vacuum forming tray manufacturing, where precision meets artistry to craft versatile and durable solutions for various industries. As you embark on the journey of selecting the right vacuum forming tray manufacturer, this guide aims to provide insights into the importance of these trays, the intricate manufacturing process, and the key factors to consider when choosing a vacuum forming tray manufacturer.

The Significance of Vacuum Forming Trays

Vacuum-formed trays are the unsung heroes behind organized displays, secure packaging, and efficient organizational solutions. Their significance lies in their ability to offer a cost-effective and customized approach to creating trays of various shapes and sizes without compromising on durability. From protecting delicate products to enhancing retail displays, vacuum-formed trays play a crucial role in numerous industries.

The Vacuum Forming Process Demystified

At the heart of vacuum forming is a meticulous process that combines heat, suction, and precision. The journey begins with a thermoplastic sheet, such as ABS, PETG, or polystyrene, which is heated until pliable. Through the application of vacuum pressure, the sheet conforms to the shape of a mould, resulting in a precisely moulded tray. This process ensures that each tray meets the exact specifications of its intended purpose, whether it's for medical applications or product packaging.

The Artistry of Design

Design is a crucial aspect of vacuum-formed trays, where form and function harmonize. Skilled manufacturers understand the importance of creating trays that not only serve their purpose efficiently but also captivate visually. Whether designing trays for product packaging or point-of-sale displays, the artistry of design is essential in translating ideas into functional and aesthetically pleasing solutions.

Material Matters

Choosing the right material is a critical decision in the vacuum forming process. Different thermoplastics offer varying properties, such as impact resistance, transparency, and ease of processing. A reputable manufacturer guides clients through the material selection process, considering the specific requirements of the end product. The right material ensures that the vacuum-formed tray not only meets aesthetic expectations but also withstands the demands of its intended use.

Precision and Consistency

Precision and consistency are non-negotiable in vacuum forming tray manufacturing. Manufacturers employ advanced techniques and stringent quality control measures to ensure that each tray meets the highest standards. Consistency throughout the manufacturing process guarantees that every tray leaving the production line is a testament to craftsmanship and attention to detail.

Why Manufacturer Choice Matters

Amidst the plethora of manufacturing options, choosing the right vacuum forming tray manufacturer is paramount for project success. Opt for a manufacturer with a proven track record, a commitment to quality, and flexibility in adapting to unique needs. Experience across diverse industries equips a manufacturer to tackle challenges and provide innovative solutions, making them an invaluable partner in bringing projects to fruition.

In conclusion, as we celebrate the art of crafting excellence in vacuum forming tray manufacturing, remember to choose your manufacturer wisely. Let the precision and artistry of vacuum forming elevate your projects to new heights. Cheers to crafting excellence with the best vacuum forming tray manufacturer!

reference url: https://blogsubmissionsite.com/blog/details/crafting-excellence-guide-to-choosing-the-best-vacuum-forming-tray-manufacturer

#vacuum forming tray manufacturer#esd tray manufacturers#packaging tray manufacturer#blister packaging tray manufacturer

0 notes

Text

Top 5 Forms of Commercial Cleaning You Need to Know About

When it comes to maintaining a clean and healthy workplace, commercial cleaning Melbourne CBD services play a vital role. Whether it's an office, retail store, or any other commercial space, regular cleaning is essential to create a hygienic environment for employees and customers. In this blog post, we will explore the top five forms of commercial cleaning that every business should know about.

1. Office Cleaning

Offices are one of the most common spaces that require commercial cleaning Melbourne CBD services. From cubicles and conference rooms to kitchen areas and restrooms, office cleaning covers a wide range of tasks. Commercial cleaners ensure that all surfaces are thoroughly cleaned and disinfected, floors are vacuumed or mopped, and trash is properly disposed of. A clean office not only promotes a healthier work environment but also improves the overall productivity and morale of employees.

2. Retail Cleaning

In the fast-paced world of retail, it's crucial to maintain a clean and presentable store environment. Retail cleaning services focus on keeping the sales floor, shelves, and display areas spotless. Commercial cleaners pay attention to high-traffic areas, such as entranceways and checkout counters, to ensure they create a positive first impression on customers. Regular retail cleaning helps maintain the store's reputation, enhances the shopping experience, and ultimately boosts sales.

3. Healthcare Facility Cleaning

Cleaning in healthcare facilities goes beyond just aesthetics. Thorough cleaning and disinfection are necessary to prevent the spread of germs and infections in these environments. Commercial cleaners in healthcare facilities are trained to follow strict protocols and use specialised equipment and cleaning agents. They focus on areas such as waiting rooms, patient rooms, operating rooms, and common areas to maintain a safe and sterile environment for patients, staff, and visitors.

4. Industrial Cleaning

Industrial spaces, such as warehouses, factories, and manufacturing plants, have unique cleaning requirements due to the presence of heavy machinery and potentially hazardous materials. Industrial cleaning services involve deep cleaning, dusting, and equipment maintenance. Commercial cleaners in industrial settings are trained to handle specialised equipment and follow safety protocols to ensure a clean and safe working environment for employees.

5. Education Facility Cleaning

Schools and educational institutions are hubs of activity, which means they require regular and thorough cleaning. Education facility cleaning covers classrooms, offices, libraries, cafeterias, and restrooms. Commercial cleaners pay attention to high-touch surfaces, such as desks, doorknobs, and light switches, to prevent the spread of germs. They also ensure that floors are properly cleaned and sanitised. A clean educational facility promotes a healthy learning environment for students and staff alike.

Conclusion

These are just a few of the forms of commercial cleaning that businesses should know about. By investing in professional commercial cleaning services, businesses can ensure that their spaces are clean, hygienic, and presentable. Whether it's an office, retail store, healthcare facility, industrial space, or educational institution, commercial cleaning plays a crucial role in creating a safe and welcoming environment.

So, if you're a business owner looking to maintain a clean and healthy workplace, consider partnering with a reputable commercial cleaning Melbourne CBD company that can cater to your specific needs.

0 notes

Text

High-Quality Curing Oven for Sale | Gobelovac

Upgrade your industrial process with our top-of-the-line curing oven for sale at Gobelovac. Increase efficiency and quality today!

0 notes