#tobermorite

Explore tagged Tumblr posts

Text

Okenite geode in basalt

This is a sample of basalt with needly clusters and “cottonballs” of okenite crystals grown in a vug. Okenite (hydrated calcium silicate hydroxide) is an unusual mineral and a member of the tobermorite mineral group. It is most often found in basalt vugs but has also been reported from carbonate rocks at Crestmore, California. Typical associated minerals are zeolites, apophyllite, gyrolite, calcite, quartz and prehnite. When vugs in volcanic rocks are lined with delicate okenite they are sometimes called “okenite geodes”. This sample is 21 cm across.

source

19 notes

·

View notes

Text

Since the article doesn't work and the wayback machine is giving weird errors unless you manage to stop it loading halfway, here's the original article!

Some 2,000 years after they were first erected, Ancient Roman harbours made from concrete are still standing across Europe. Meanwhile, more modern constructions have proved far less durable, crumbling into the water in a mater of decades. Finally, scientists have solved the puzzle of what made the ancient concrete so strong — and they think the discovery could make modern buildings more environmentally friendly. Concrete used for ancient sea walls was made by mixing lime, seawater, volcanic ash and rock. The combination produces a 'possolanic reaction' – named after the commune of Pozzuoli in Naples. Researchers have now discovered that elements in the ash react with sea water, which actually strengthens the material. In contrast, waves erode modern concrete. "Contrary to the principles of modern cement-based concrete, the Romans created a rock-like concrete that thrives in open chemical exchange with seawater," Utah University geologist Marie Jackson said. Researchers discovered the Roman concrete contained aluminium tobermorite, a rare mineral that adds extra strength. When the Roman concrete was exposed to seawater, the tobermorite crystallised and spread. The researchers said that long-term exposure to sea water helped these crystals to continue growing, reinforcing the concrete and preventing cracks from developing. Switching to a similar type of concrete could make some contemporary constructions less harmful to the environment, since the production of modern Portland cement uses high-temperature kilns that make a significant contribution to industrial carbon dioxide emissions. Professor Jackson said the material should be considered for proposed projects such as the tidal lagoon being considered in Swansea. The lagoon would need to run for 120 years to recoup the cost of its construction, Professor Jackson said. “You can imagine that, with the way we build now, it would be a mass of corroding steel by that time,” she added. Yet a structure built from Roman concrete, she argued, could remain intact for centuries.

GUYS THEY FIGURED OUT THE ROMAN CONCRETE RECIPE THAT MAKES IT IMMUNE TO SEAWATER

http://www.msn.com/en-us/news/technology/mystery-of-2000-year-old-roman-concrete-solved-by-scientists/ar-BBDO5VC

221K notes

·

View notes

Text

La "malta idraulica romana" utilizzata nelle costruzioni portuali poteva indurire sott'acqua, proprietà che fu riscoperta solo nel XVIII secolo. Questa malta conteneva cenere vulcanica di Pozzuoli, che reagiva chimicamente con l'acqua di mare per formare cristalli di alluminosilicato di calcio idrato, creando una struttura particolarmente resistente. Antichi porti romani costruiti 2.000 anni fa con questo materiale si trovano ancora nel Mediterraneo.

Malta idraulica romana" – il segreto dimenticato di alcune costruzioni sopravvissute 2000 anni sott'acqua!

Una delle conquiste ingegneristiche più sorprendenti del mondo antico è legata a un materiale da costruzione sviluppato dai romani oltre due millenni fa: la malta idraulica, una forma di cemento che aveva una proprietà davvero notevole: la capacità di indurire sott'acqua.

Questo tipo di malta, utilizzata soprattutto per la costruzione di porti e altri lavori in ambienti umidi o marittimi, era così efficace e durevole che le strutture costruite con essa si trovano ancora oggi nel Mediterraneo dopo circa 2.000 anni di esposizione alle onde, al sale e alle intemperie.

L'origine di una straordinaria innovazione

I romani , riconosciuti per la loro abilità ingegneristica, non solo hanno inventato nuove forme di architettura, ma hanno anche sperimentato costantemente materiali da costruzione. Nel caso della malta idraulica, il segreto sta tutto l'utilizzo di un ingrediente naturale di origine vulcanica: la cenere della zona di Pozzuoli, vicino Napoli, detta pozzolana.

La pozzolana è una polvere vulcanica estremamente fine, ricca di silicio e alluminio. Miscelato con calce (ossido di calcio) e acqua, innescava una reazione chimica chiamata reazione pozzolanica, formando un composto stabile simile al moderno cemento. Inoltre questa reazione continuava anche in presenza di acqua salata, il che permetteva di indurire e solidificare la malta sott'acqua, cosa rivoluzionaria per l'epoca.

Strutture che sfidano il tempo e la natura

Utilizzando questa miscela, i romani costruirono porti, frangiflutti, fondazioni di ponti, fari e piattaforme marittime in tutto il Mediterraneo – da Ostia a Cesarea Marittima (nell'attuale Israele). In molti di questi luoghi, i blocchi di cemento romani si trovano ancora oggi in condizioni sorprendentemente buone, nonostante il passare del tempo e l’ambiente marino altamente corrosivo.

Il motivo dell'eccezionale durabilità di questa malta risiede in una rara reazione mineralogica: a contatto con l'acqua di mare, la pozzolana interagisce con gli ioni calcio per formare cristalli di tobermorite e phillipsite, due composti minerali estremamente stabili e resistenti.

0 notes

Text

24-05 Beton

Teddynews 2024-05: Unser heutiger Beton ist ein SCAM

Warum römischer Beton immer noch hält

Quellverweis: z.B: https://www.spektrum.de/news/warum-roemischer-beton-immer-noch-haelt/1479423# https://de.wikipedia.org/wiki/Opus_caementicium

Von Römern betonierte Hafenanlagen trotzen teils bis heute den Wellen. Ihr Geheimnis: Das Meerwasser stärkt das Material. Moderner Beton wird dagegen immer schwächer.

Schon Plinius der Ältere bemerkte um das Jahr 79 herum, dass Hafenanlagen und Wellenbrecher, die konstant dem Meerwasser ausgesetzt waren, zu »einem einzigen Stein« würden, »unbezwingbar für die Wellen und jeden Tag stärker«. Dass der römische Autor hier nicht übertrieben hat, zeigt sich zum einen daran, dass Teile solcher Anlagen heute noch stehen, und zum anderen in einer Studie, die ein Forscherteam in »American Mineralogist« veröffentlichte: Wenn Meerwasser in den römischen Beton eindringt, laufen chemische Prozesse ab, die das Material stärken und die Ausbreitung von Rissen verhindern.

Das entdeckte ein Team um Marie Jackson von der University of Utah durch mineralogische Analysen von Bohrkernen aus antiken Hafenanlagen. Laut den Forschern lässt das eindringende Salzwasser im Beton das seltene Mineral Aluminium-Tobermorit entstehen, dessen plättchenförmige Kristalle dem Material Festigkeit verleihen. Zudem bildet sich ein weiteres Mineral, Phillipsit. Beide füllen Hohlräume aus, die entstehen, wenn das Wasser das ursprüngliche Material herauswäscht.

Der römische Beton sei praktisch das Gegenteil dessen, was man bei heutigem Beton erzielen möchte, sagt Jackson. Heutzutage würden Materialwissenschaftler versuchen, sämtliche chemischen Umbauprozesse zu unterdrücken. Insbesondere die Zuschlagstoffe werden nach ihrer Reaktionsträgheit ausgesucht, um unkontrollierbare Veränderungen und Ausdehnungen zu unterbinden. Die Römer hingegen nutzten – ob geplant oder per Zufall – eine Materialkombination, die eine Vielfalt von mineralogischen Prozessen begünstigte, nicht nur bei Wasserbauten, sondern auch an Land.Dadurch bildete sich das Material im Lauf der Zeit zu einer Art neuem Gestein um.

Entscheidend am römischen Beton, dem »Opus caementicium«, war die Kombination von gebranntem Kalk mit spezieller Vulkanasche und Zuschlagstoffen vulkanischen Ursprungs, den Puzzolanen. Das Gestein ist nach der Stadt Pozzuoli bei Neapel benannt, wo es in der Antike schon abgebaut wurde. Die Römer hätten großes Glück gehabt, dass ihnen dieses Material zur Verfügung stand, meint Jackson. Vermutlich hätten sie sich von Tuffgesteinen inspirieren lassen, die aus der Vulkanasche entstanden, so die Forscherin weiter. Mit ihren Kollegen sucht sie nun nach einem Material, das dieselben Eigenschaften hat, aber besser verfügbar ist. Es könnte auch bei modernen Bauwerken zum Einsatz kommen, vor allem wenn Langlebigkeit im Meerwasser gefragt ist.

Social Media Links:

Instagram:

0 notes

Photo

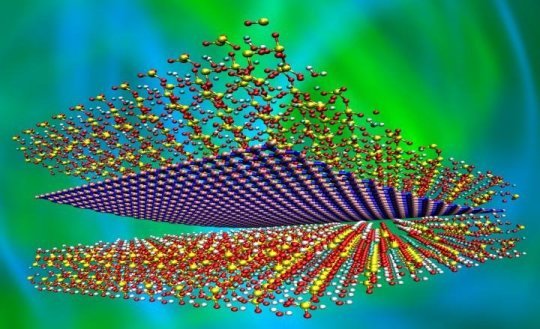

White graphene makes ceramics multifunctional

Study shows 2-D layers of boron nitride could aid strength, toughness and thermal conductivity of ceramics

A little hBN in ceramics could give them outstanding properties, according to a Rice University scientist.

Rouzbeh Shahsavari, an assistant professor of civil and environmental engineering, suggested the incorporation of ultrathin hexagonal boron nitride (hBN) sheets between layers of calcium-silicates would make an interesting bilayer crystal with multifunctional properties. These could be suitable for construction and refractory materials and applications in the nuclear industry, oil and gas, aerospace and other areas that require high-performance composites.

Combining the materials would make a ceramic that's not only tough and durable but resistant to heat and radiation. By Shahsavari's calculations, calcium-silicates with inserted layers of two-dimensional hBN could be hardened enough to serve as shielding in nuclear applications like power plants.

The research appears in the American Chemical Society journal ACS Applied Materials and Interfaces.

Two-dimensional hBN is nicknamed white graphene and looks like graphene from above, with linked hexagons forming an ultrathin plane. But hBN differs from graphene as it consists of alternating boron and nitrogen, rather than carbon, atoms.

Read more.

#Materials Science#Science#Boron Nitride#White graphene#2D Materials#Ceramics#Strength of Materials#Thermal Conductivity#Toughness#Materials Properties#Rice University#Boron#Nitrides#Tobermorite#Calcium#Silicon

27 notes

·

View notes

Photo

From Mindat.Org Photo Of The Day; January 4, 2018:

Tobermorite: Ca5Si6O16(OH)2·nH2O; Phillipsite-Ca: Ca3(Si10Al6)O32·12H2O; Calcite: CaCO3

Locality: Basalt quarry, Klöch, Bad Radkersburg, Styria, Austria

“White torbermorite with colourless phillipsite and minor brown-yellow calcite”; Chris Auer photo and collection (ex H.Schabereiter + J.Trattner coll.)

1 note

·

View note

Text

“Why was the concrete made by the Romans more than 2,000 years ago stronger than the one used today?

Roman’s were lucky. Roman concrete is amazingly strong because of its chemistry. Modern-day concrete is typically made of ‘Portland cement’ that is then mixed with water and aggregate (like gravel). Portland cement-based concrete does deteriorate over time. A common attempt to make it stronger is to embed steel reinforcing rods in it. This does increase its ‘tensile’ strength considerably—far beyond anything that Roman concrete could do. For instance, Roman concrete could never be used for a freeway overpass span like is commonly used today. However, steel reinforcement has one major drawback: steel rusts. This not only weakens the material but it also expands causing cracks and other weaknesses in the concrete.

So, one of the reasons that Roman concrete structures have lasted for millennia is that the Romans only used it in so-called ‘compression’ mode, never in tensile mode (in other words for structures like columns, arches, and domes—never for horizontal elements like beams). Because concrete is only used in compression, the more weight it carries, the stronger it becomes.

Perhaps the most important reason Roman concrete is so strong, though, is that it is made with ‘pozzolana’ ash instead of Portland cement. Pozzolana ash is volcanic ash and the Romans were incredibly lucky in that pozzolana-based concrete actually grows stronger with age, especially if it has been mixed with sea water. This has been recently been shown through studies made at the University of Utah. Surprisingly, mixing pozzolana ash with sea water creates something called aluminous tobermorite, a rare silica-based mineral that's actually very hard to make in the lab, but is abundant in the ancient Roman concrete and causes the concrete to grow more rock-like with age. This not only makes ordinary concrete structures stronger, but it works like a miracle with underwater structures like harbor foundations. The pozzolana not only hardens underwater, but the sea water makes the concrete harder because the aluminous tobermorite actually grows in the concrete thanks to the sea water sloshing around it, slowly dissolving the volcanic ash within and giving it space to develop a reinforced structure from these interlocking crystals of aluminous tobermorite. As a result, according to the researchers: "The Romans created a rock-like concrete” by using pozzolana.”

Bob deWitt, Art History Professor, Utah Valley University-Sun

2 notes

·

View notes

Photo

JEHOVAH OCCULT BIBLE [JOB] WITNESS Me [ME = U.S. Michael Harrell = TUT = JAH] on Earth [JE = JESUS] Chemically [JC] Structuring UNSEEN NEBULA [SUN] from Radiant ANDROMEDA [RA] Constellation Properties… as iMetallurgically ENGINEER [iME = U.S. Michael Harrell = iTUT = iJAH] Ions into Translucent Tobermorite of Interplanetary Thermal Energy [HITTITE] Pulsating IRIDESCENT LIGHT [SUN] WAVE ENERGIES [WE] @ UNBELIEVABLE STRATOSPHERIC [U.S.] Earth Altitudes [SEA] HIGH UP IN DA’ SKY IN:side My Intergalactic MOTHERSHIP [UFO] MENTAL of Astronomical NIBIRU [MAN]… since iSky Engineer EARTH [iSEE] as My Mama’s MOST HIGHEST [MH = JAH] EXTRATERRESTRIAL [JE = JEHOVAH] SUN GOD [RA] @ My Heavenly Father's Highly Classified… U.S. Ægyptian American [ATLANTEAN] Ancient Spirit [SHADOW] Military.gov of SIRIUS QUANTUM HARRELL TECH [QHT] WATCHTOWER Communications in $unny California [CA] https://www.instagram.com/p/CMs8lnVBTl_/?igshid=epdg8mm3fanu

#quantumharrelltech#It feels good 2 BEE A MOST HIGH [MH = JAH] EXTRATERRESTRIAL [JE = JEHOVAH] SUN GOD [RA] on Earth

1 note

·

View note

Text

Roman Concrete vs. Modern Concrete

The oldest known concrete was made during the Roman era. This type of concrete was used to build a variety of buildings and structures, including the Pantheon. This was the first cement-based mortar to be used in the modern era.

The research, published in the journal American Mineralogist, explains how Roman sea walls built about 2,000 years ago could withstand the elements because of a rare chemical reaction that seems to have strengthened the concrete over time.

Construction jobs done using modern cement tends to deteriorate, especially in seawater. In contrast to how cement-based concrete is made today, the Roman recipe of lime, volcanic ash, seawater, and aluminum tobermorite makes concrete stronger and stops cracks from getting bigger. As seawater crashes into the structure, a mineral mixture of silica oxide and lime forms between the volcanic rock aggregate and mortar.

Roman concrete comprises gravel and hydraulic mortar, which hardens over time. For construction jobs offered then, gypsum and quicklime were used as binders, while rock, tile, and brick rubble from demolished buildings made up the aggregate. Volcanic dust, called pozzolana or "pit sand," was preferred. Pozzolana strengthens and makes salt-resistant concrete.

When compared to Roman concrete, modern cement does not bond as well because it lacks the lime-volcanic ash combination. The service life of Portland cement, which has been in use for approximately 200 years, is fewer than 50 years in saltwater due to its propensity to wear very fast when subjected to the condition.

Roman concrete is more durable and sustainable than modern concrete. The carbon from the burning fuel and heated limestone (calcium carbonate) needed to make Portland cement produces the most dangerous "greenhouse gas," carbon dioxide. To make concrete, the Romans also used less lime and baked limestone at 900 degrees Celsius (1,652 degrees Fahrenheit) or lower, which was economical and sustainable.

Kilgore Companies has a demonstrated track record of service excellence, offering construction jobs listings, aggregates, ready-mix concrete, paving, and construction services at competitive pricing. For more information about our services, get in touch with our dedicated professionals today.

0 notes

Text

(from @winds-and-whispers)

We did indeed know the ingredients! But what we thought was that the lime clasts were the result of poor aggregate mixing, and were the imperfections I mentioned earlier. This new research took a look at those clasts again and figured out that they react to cracks and regrow over themselves to seal the faults.

(from @claraschaos)

This is correct, as far as I'm aware. Saltwater reacts with a combination of volcanic ash and quicklime to create tobermorite which is fracture-resistant. This plus our assumption that lime was an imperfection probably supported the theory that volcanic ash was responsible for the durability of Roman concrete, but really, it's both! This is also incredibly useful for a Mediterranean empire, because there's literally only saltwater. That's why volcanic ash appeared so frequently in structure samples across the Mediterranean wherever the Romans were.

(I do want to put the disclaimer again that I am shit at chemistry, worse at engineering, and I am but a simple archaeology student, but I'll post updates as I get through them!)

we figured out Roman concrete btw. This is the only thing on my mind

43K notes

·

View notes

Text

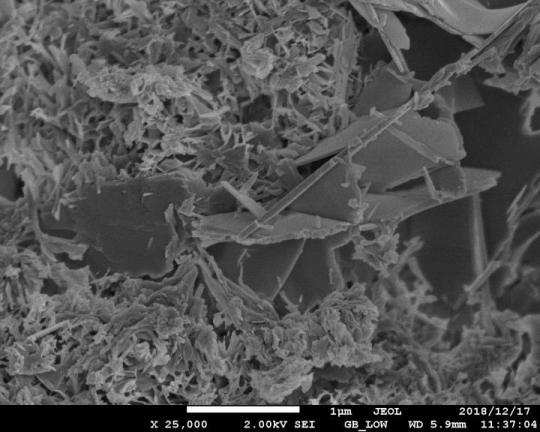

Do as the Romans: Power plant concrete strengthens with time

Do as the Romans: Power plant concrete strengthens with time

Credit: Ippei Maruyama, Nagoya University, and Chubu Electric Power Co. A rare mineral that has allowed Roman concrete marine barriers to survive for more than 2,000 years has been found in the thick concrete walls of a decommissioned nuclear power plant in Japan. The formation of aluminous tobermorite increased the strength of the walls more than three times their design strength, Nagoya…

View On WordPress

0 notes

Photo

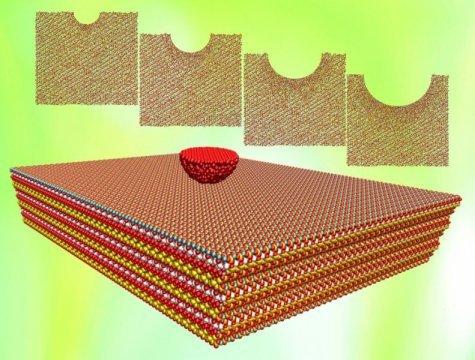

Here's a tip: Indented cement shows unique properties

Models reveal nanoindentation can benefit crystals in concrete

Rice University scientists have determined that no matter how large or small a piece of tobermorite is, it will respond to loading forces in precisely the same way. But poking it with a sharp point will change its strength.

Tobermorite is a naturally occurring crystalline analog to the calcium-silicate-hydrate (C-S-H) that makes up cement, which in turn binds concrete, the world's most-used material. A form of tobermorite used by ancient Romans is believed to be a key to the legendary strength of their undersea concrete structures.

The finely layered material will deform in different ways depending on how standard forces -- shear, compression and tension -- are applied, but the deformation will be consistent among sample sizes, according to Rice materials scientist Rouzbeh Shahsavari. He conducted the research, which appears in Nature's open-access Scientific Reports, with lead author and graduate student Lei Tao.

For their latest survey, Shahsavari and Tao built molecular dynamics models of the material. Their simulations revealed three key molecular mechanisms at work in tobermorite that are also likely responsible for the strength of C-S-H and other layered materials. One is a mechanism of displacement in which atoms under stress move collectively as they try to stay in equilibrium. Another is a diffusive mechanism in which atoms move more chaotically. They found that the material maintains its structural integrity best under shear, and less so under compressive and then tensile loading.

Read more.

#Materials Science#Science#Cement#Concrete#Composites#Tobermorite#Crystals#Minerals#Rice University#Deformation mechanisms

26 notes

·

View notes

Text

Power plant concrete strengthens with time

https://koliasa.com/power-plant-concrete-strengthens-with-time/ Power plant concrete strengthens with time - https://koliasa.com/power-plant-concrete-strengthens-with-time/ The scientists found aluminous tobermorite formed inside the ...

0 notes

Photo

The secrets of Roman concrete

This building is nearly 2000 years old. The structure you’re looking at is Trajan’s market in the city of Rome, built around 100 a.d. The presence of structures like this one nearly two millennia later is a testament both to Roman engineering skills and to the concrete they used in constructing their empire.

Even in modern construction, concrete exposed to the elements or the ocean often does not survive as well as Roman concrete. New research led by a team from UC Berkeley makes an effort to explain why that is the case.

They took a core of Roman concrete found just offshore in the Bay of Naples and subjected it to modern analytical techniques, going down to the atomic structure to see where every atom was sitting. In a paper just published in the journal American Mineralogist, they identify a specific atomic structure that might make all the difference, one called Al-tobermorite.

In traditional concretes, a key part of the mixture is a calcium-silicate-hydrate “glue”, a mixture of elements that hardens and binds together the sand and gravel used in the mix. Other modern mixtures will include an additional component – alumina, which adds strength to the mix.

This mixture, C-A-S-H, has all the ingredients and a similar molecular formula to the Al-tobermorite found in Roman concretes but it doesn’t form the same mineral. Experiments showed that this tobermorite mineral can only be produced in modern concretes if they are heated to over 100 °C, which typically does not happen during construction. Thus, Roman construction achieved a mineral that strengthened their concretes against alteration and weathering to a degree uncommon in modern concrete.

The main ingredients of the Roman concrete were pyroclastic ash and rock taken from the Plegrean fields near Naples and Mount Vesuvius along with coarser grained aggregate and pumice from the surrounding area. These particles were mixed with calcium oxide (lime) from other areas around Rome and then submerged in seawater.

Descriptions from Roman writers cited in the paper suggest that when this mixture was immersed in seawater, it would heat up on its own from an exothermic reaction between the ingredients (the reaction between lime and water).

The final trick for Roman construction noted by the authors was that it took place on a large scale. Without active systems to remove heat, Roman concretes would have taken years to cool completely after they were set, and the larger buildings would have heated from this reaction to a greater degree. The size of Roman construction therefore could have helped trap heat in, allowing high enough temperatures for the Al-tobermorite reaction to take place, and developing that mineral seemingly added strength and longevity to their concrete products.

This research sheds some new light on the source of the longevity in Roman structures and may eventually lead to application of some of these techniques in modern construction as well.

-JBB

Image credit: Alessio Nastro Siniscalchi http://en.wikipedia.org/wiki/File:Traiano_mercati.jpg

Original paper (Open Access): http://ammin.geoscienceworld.org/content/98/10/1669.full

Trajan’s Market http://www.greatbuildings.com/buildings/Markets_of_Trajan.html_ _

#Rome#Concrete#Geology#Roman concrete#Nature#science#Igneous#ash#tuff#salt#lime#the earth story#chemistry#construction#engineering

194 notes

·

View notes

Link

Mechanism of Waterproofing by Proper Cement Hydration

One of the products of hydration of cement is cement gel or Tobermorite, which is formed Upton water cement ratio 0.65 to 0.7. At lower w/c ratio, it is formed more and more and vice versa. This hydration product has absolutely least co-efficient of permeability, i.e., 7x10-14 cm/sec and by itself blocks the pores and capillary in the concrete. This can result into good waterproof concrete of 10-10 to 10-12 cm/sec. However, actually in practice at average job, we end up getting the permeability anywhere between 10-6 to 10-8 cm/sec. This is mainly due to uncontrolled w/c ratio, lack of curing and also other bad detailing.

Combination of Conventional and Non-Conventional Ways

Various ways of waterproofing the structures are recommended. However, a discerning client and the consultant need to study all the possible parameters, positive as well as negative and then come to a re-commendatory conclusion. Conventional ways of waterproofing are like brickbat Coba followed by IPS. Brickbat Coba is generally used to provide a slope to the treatment and IPS layer works as an impermeable treatment by itself which also assumes the slope of brickbat Coba. Though, otherwise found fairly successful; today due to speed of the work, quality of sand, inadequate curing to the concrete which is made from finer grade cement and many other related reasons the IPS is seen to crack and disintegrate allowing an early entry to water. The brickbat Coba is not otherwise supposed to be waterproof, but on the contrary is absorbent, which accumulates the water. On saturation the brickbat Coba attempts to transfer the water further, which generally penetrates into the slab, and penetrates more easily if the same is porous or full of cracks. As it is concrete is not by itself a fully impermeable material, and various compromises while construction can decrease the impermeability further. Needless to say this causes unsightly leakages to begin with followed by corrosion of steel and finally results into structural damage.

Click below to read the next part of the article.

0 notes

Photo

Researchers are trying to understand why ancient Roman concrete is exceptionally durable.

Over two thousand years ago, the ancient Romans built piers, breakwaters, and other structures out of concrete—and some of those structures still stand today. Now, researchers are trying to understand the chemical and geological processes that work together to give that ancient concrete such durability. Using microscopy, x-ray diffraction, and spectroscopic techniques, they’ve developed a map of the crystalline microstructures within the concrete. According to their research, a slow infusion of seawater into concrete made with a type of volcanic ash found near Rome gradually creates crystals of a material called aluminous tobermorite, which actually strengthens the concrete as it ages.

Marie Jackson, a geology and geophysics research professor and one of the authors of a report on the work, says that understanding Roman concrete could give modern materials scientists ideas for how to strengthen modern structures, and could even lead to new materials, such as concretes that soak up and trap nuclear waste.

Photo by THINK Global School/flickr/CC BY-NC-ND 2.0

2K notes

·

View notes