#threaded pipe flanges

Text

Threaded flanges Suppliers in Mumbai

Looking for a high-quality threaded flanges suppliers in Mumbai, India. At Bu-Lok.com, you will get flanges, fasteners, plates, round bars, etc. It is the best manufacturer, trader, and supplier of stainless steel, high nickel steel, alloy steel, and carbon steel in the form of pipe and fittings. Call us at +918888944449.

0 notes

Text

Kiah Metallurgical Indian Exporters: Your Premier Flanges Manufacturers in Mumbai

Introduction to Kiah Metallurgical Indian Exporters

Welcome to Kiah Metallurgical Indian Exporters, a name synonymous with excellence in the field of metallurgical engineering. Based in the heart of Mumbai, we specialize in the manufacturing and export of high-quality flanges, catering to a diverse range of industries. Our commitment to quality, innovation, and customer satisfaction sets us apart as the leading Flanges Manufacturers in Mumbai.

Comprehensive Range of Flanges

Flanges Manufacturers in Mumbai

At Kiah Metallurgical Indian Exporters, we understand the critical role flanges play in various industrial applications. We offer a comprehensive range of flanges designed to meet the specific needs of our clients. Whether you are looking for standard or customized solutions, we have got you covered.

Our range includes but is not limited to:

Blind Flanges

Slip-On Flanges

Lap Joint Flanges

Socket Weld Flanges

Each type of flange is manufactured with precision, ensuring optimal performance and durability. Our flanges are designed to withstand high pressure and temperature conditions, making them ideal for a variety of industrial applications.

Pipe Flanges Manufacturers in Mumbai

Our expertise extends to the manufacturing of pipe flanges, which are essential components in piping systems. These flanges are designed to provide a secure connection between pipes, ensuring seamless flow and structural integrity. As premier pipe flanges manufacturers in Mumbai, we guarantee products that meet international standards.

Pipe flanges from Kiah Metallurgical are known for their robustness and reliability. They are used in various sectors, including oil and gas, chemical processing, power generation, and more. Our pipe flanges are available in various materials such as stainless steel, carbon steel, and alloy steel, ensuring compatibility with different types of pipes and environments.

High-Quality Standards: ASME B16.5 Flanges

ASME B16.5 Flanges Manufacturers in Mumbai

Kiah Metallurgical Indian Exporters is renowned for ASME B16.5 Flanges Manufacturers in Mumbai. These flanges are meticulously crafted to meet stringent specifications, ensuring reliability and durability in high-pressure applications. Our ASME B16.5 flanges are a testament to our commitment to quality and precision.

ASME B16.5 flanges are used in various industries, including petrochemical, power plants, and marine engineering. These flanges are designed to handle high pressures and temperatures, making them suitable for critical applications. We ensure that each flange undergoes rigorous testing and quality checks to meet the ASME standards.

Specialty Flanges for Diverse Applications

Weld Neck Flanges Manufacturers in Mumbai

Our weld neck flanges are designed for high-stress applications, providing a robust connection that withstands extreme pressures and temperatures. As leading Weld neck flanges manufacturers in Mumbai, we utilize advanced manufacturing techniques to produce flanges that deliver exceptional performance and longevity.

Weld neck flanges are commonly used in high-pressure applications where the environment is challenging. These flanges have a long tapered hub that provides additional strength and reduces stress concentration at the base of the flange. They are ideal for use in pipelines, refineries, and other heavy-duty applications.

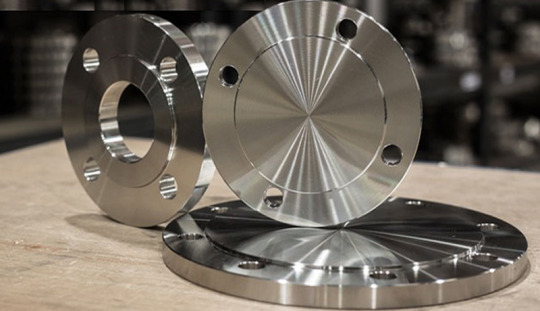

Threaded Flanges Manufacturers in Mumbai

For applications requiring a secure yet detachable connection, our threaded flanges are the ideal choice. These flanges are easy to install and remove, making them perfect for maintenance and repair tasks. We take pride in being top-tier Threaded flanges manufacturers in Mumbai, offering products that combine ease of use with reliability.

Threaded flanges are widely used in low-pressure, non-critical applications where welding is not feasible. These flanges are screwed onto the pipe, which makes installation and maintenance straightforward. They are often used in small diameter piping systems, plumbing, and other industries where frequent disassembly and reassembly are required.

Why Choose Kiah Metallurgical Indian Exporters?

Commitment to Quality

At Kiah Metallurgical Indian Exporters, quality is our top priority. We adhere to strict quality control measures throughout the manufacturing process, ensuring that every flange we produce meets the highest standards of excellence.

Our quality assurance process includes:

Raw Material Inspection: Ensuring only the best quality materials are used.

Dimensional Checks: Verifying the dimensions of each flange to ensure accuracy.

Non-Destructive Testing: Using advanced techniques to check for internal defects.

Pressure Testing: Ensuring flanges can withstand the required pressure levels.

Experienced Team

Our team of experienced engineers and technicians brings a wealth of knowledge and expertise to every project. Their dedication to innovation and excellence drives us to continuously improve our products and processes.

Our team is proficient in:

Design and Development: Creating innovative flange solutions.

Process Optimization: Enhancing production efficiency and product quality.

Technical Support: Providing expert advice and support to clients.

Research and Development: Staying ahead of industry trends and technological advancements.

Contact Us

Get in Touch

If you are looking for reliable and high-quality flanges manufacturers in Mumbai, look no further than Kiah Metallurgical Indian Exporters. Our team is ready to assist you with your requirements and provide you with the best solutions for your needs.

Phone Number: 9769656216

Address: Office No. 16/1, Ratan Mansion Building, 2nd Khetwadi Lane, Near Alankar Cinema, Mumbai, Maharashtra, India- 400004

We invite you to visit our office or contact us via phone or email for more information. Our team is always available to answer your questions and provide the assistance you need.

About Kiah Metallurgical Indian Exporters

Founded with the vision to provide superior metallurgical solutions, Kiah Metallurgical Indian Exporters has grown to become a trusted name in the industry. Our journey began with a focus on quality and customer satisfaction, which has remained our guiding principle.

Our Products

At Kiah Metallurgical Indian Exporters, we offer a wide range of flanges to meet diverse industrial needs. Our product line includes:

Blind Flanges: Used to close the ends of pipes, valves, and pressure vessel openings.

Slip-On Flanges: Designed to slip over the pipe and welded both inside and outside for strength.

Lap Joint Flanges: Ideal for applications requiring frequent dismantling.

Socket Weld Flanges: Suitable for small-size high-pressure piping.

Weld Neck Flanges: Designed for high-pressure applications.

Threaded Flanges: Perfect for systems where welding is not an option.

Industries We Serve

Our flanges are used in a wide range of industries, each with unique requirements:

Oil and Gas: Providing durable flanges for exploration, drilling, and transportation.

Chemical Processing: Supplying corrosion-resistant flanges for chemical handling.

Power Generation: Delivering high-strength flanges for power plants.

Marine Engineering: Offering flanges that withstand harsh marine environments.

Petrochemical: Providing robust flanges for petrochemical processing.

Commitment to Sustainability

At Kiah Metallurgical Indian Exporters, we are committed to sustainable practices. We ensure that our manufacturing processes are environmentally friendly and adhere to regulatory standards. Our efforts include:

Waste Management: Implementing effective waste management systems.

Energy Efficiency: Using energy-efficient technologies in our manufacturing processes.

Resource Conservation: Minimizing resource consumption and promoting recycling.

#Flanges Manufacturers in Mumbai#Pipe Flanges Manufacturers in Mumbai#ASME B16.5 Flanges Manufacturers in Mumbai#Weld Neck Flanges Manufacturers in Mumbai#Threaded Flanges Manufacturers in Mumbai#Kiah Metallurgical

0 notes

Text

Quality Assurance at Ranflex Metals starts with understanding the customer's Requirement and continues till the customer is completely satisfied with the delivery of products and services. Quality Control procedures are well-defined and thoroughly implemented.

#Buttweld pipe fittings#forged fittings#flanges#fasteners#round bars#square bars#hexagon bars#pipes and tubes#nuts#bolts#washers#threaded bars.

1 note

·

View note

Text

#Hydraulic Hoses#PTFE Hoses#PTFE Tubes#Convoluted PTFE Hose Manufacturers#Convoluted Hoses#High Pressure PTFE Hose#Threaded Pipe Connector#Threaded Connector#SS Wire Braided Convoluted Hoses#PTFE Hoses Aerospace#PTFE Plain Hoses#Two Axis Pipe Connector#Fixed Flange Connector#Copper Ended Connector#Dash 2 PTFE Hoses

1 note

·

View note

Text

Manufacturer of PPRCT Pipes and fittings in Ahmedabad, Exporter of PPRCT Pipes and fittings in India

#PPRCT Pipe#Coupler#Elbow#Equal Tee#End Cap#Reducer#Reducing Tee#Long Radius Elbow#Core Flange#Male Threaded Joint Adapter#Female Threaded Joint Adapter#Male Threaded Elbow#Female Threaded Elbow#Female Threaded Tee#Male Threaded Tee#Female Threaded Union#Male Threaded Union#Cross#Branch Adapter#Fabricated Butt Welded Equal Tee#Fabricated Reducer#Fabricated Elbow#Electrostatic Metal Flange#Thermal Step Flange

0 notes

Text

UNITED FORGE INDUSTRIES

We are one of the best Carbon Steel Pipe Fittings,Forged Fittings,Barred Tee,Flow Tee,Split Tee,Piping Spool,Flanges Manufacturers & Exporters In India.

#forgedfittings#pipe fittings#pipefitting#pipe fitting manufacturer#flanges#flanges manufacturer#forged fittings manufacturers#Socket Weld And Threaded Forged Fittings

0 notes

Text

In my perpetual quest to eliminate steps from cleaning-related tasks, I've decided that instead of storing the paper I use to line the bottom of the dove cage inside a footlocker (which has a dollhouse sitting on top of it, for reasons), it would be preferable to just have it on a paper roll holder attached to the wall right beside the birdcage. So then when I need a new liner sheet I can just tear one off, no moving a dollhouse and opening a footlocker required.

Of course, the roll holders I was seeing online run like $40+, which is dumb. I found a little shelf thingie for $2.56 at my local thift shop, and bought a threaded pipe fitting and flange for less than ten bucks. A couple screws later, and bam. Upright paper roll holder. I'll be asking around to see if someone has an old saw blade I can attach to the wall (like the bottom piece in the first picture) to use to cut sheets off cleanly.

Is it pretty? Not really. It's kind of in a corner where it's not very visible, and the sunroom is primarily a utility space--the aesthetics are secondary. But it's very satisfying to tear big sheets of paper and this makes it just thaaaaat much easier to do a cleaning task, so I'm calling it a win.

356 notes

·

View notes

Text

transforming soffits

reorganizing keys

formalizing immersion joints

justifying kick extractors

advising aggregates

managing elbows

recasting connectors

achieving aluminum trowels

officiating disks

exhibiting absolute spigots

progressing coil hydrants

jerry-building reflectors

informing casters

inventing rubber hoists

performing wrenches

judging chalk adapters

upgrading ignition paths

regrowing flashing

recommending ratchets

approving barriers

sweeping impact fillers

sewing mirrors

detailing collectors

enforcing measures

distributing systems

presenting plugs

interwinding registers

piloting ash diffusers

gathering cranks

supplying eave pockets

undertaking scroll stops

accelerating straps

designing fittings

protecting diamond boilers

logging downspouts

correlating shingles

uniting mallets

qualifying electrostatic lifts

sharing clamps

obtaining circular fluids

ranking foundation gauges

sensing miter brackets

originating space networks

translating drills

regulating guards

selecting gable padding

utilizing pellet dowels

reconciling artifacts

altering pulleys

shedding space filters

determining vents

representing mortar

remaking flash rakers

supporting funnels

typecasting rotary chocks

expressing junctures

resetting auxiliary vises

professing strip treads

inlaying matter trowels

questioning drivers

forming edge fittings

sketching blanks

overshooting spark breakers

rewriting controls

playing tunnels

inventorying buttons

enduring joint handles

effecting ratchet bibbs

unwinding couplings

forsaking vapor conduits

defining sockets

calculating heaters

raising grids

administering tiles

measuring resources

installing ignition remotes

extracting corners

manufacturing ventilators

delegating consoles

treating mounting stones

enacting jig deflectors

intensifying alleys

improvising cargo

pinpointing bobs

prescribing arc masonry

structuring metal chucks

symbolizing lathes

activating plumb kits

adapting coatings

fixing channels

expediting cordage

planning compressors

enlisting hangers

restructuring keyhole augers

shearing ridge hardware

collecting reciprocating bolts

maintaining corrugated dimmers

whetting hole collars

conducting mandrels

comparing assets

compiling sealants

completing paths

composing equivocation wheels

computing dampers

conceiving electrostatic treatment

ordering cotter grates

organizing ties

orienting ladders

exceeding materials

targeting thermocouples

demonstrating emery stock

expanding latch bases

training wardrobe adhesives

overcomming[sic] fasteners

streamlining storm anchors

navigating springs

perfecting turnbuckles

verifying gate pegs

arbitrating arithmetic lifts

negotiating outlets

normalizing strips

building surface foggers

checking key torches

knitting grinders

mowing planers

offsetting stencils

acquiring bulbs

adopting rivets

observing avenues

ascertaining coaxial grommets

slinging wing winches

instituting circuit generators

instructing wicks

integrating pry shutters

interpreting immersion lumber

clarifying coils

classifying wood bits

closing cogs

cataloging matter strips

charting holders

conceptualizing push terminals

stimulating supports

overthrowing shaft spacers

quick-freezing connectors

unbinding ground hooks

analyzing eyes

anticipating gateways

controlling proposition rollers

converting power angles

coordinating staples

correcting benders

counseling joist gaskets

recording gutter pipes

recruiting drains

rehabilitating rafter tubes

reinforcing washers

reporting guard valves

naming freize sprues

nominating rings

noting straps

doubling nailers

drafting circuit hoses

dramatizing flanges

splitting framing compounds

refitting stems

interweaving patch unions

placing sillcocks

sorting slot threads

securing mode cutters

diverting catharsis plates

procuring load thresholds

transferring syllogism twine

directing switch nuts

referring time spools

diagnosing knobs

discovering locks

dispensing hinges

displaying hasps

resending arc binders

retreading grooves

retrofitting aesthetics portals

seeking stocks

shrinking wormholes

assembling blocks

assessing divers

attaining lug boxes

auditing nescience passages

conserving strikes

constructing braces

contracting saw catches

serving installation irons

recognizing fluxes

consolidating fuse calipers

mapping shims

reviewing chop groovers

scheduling lag drives

simplifying hoists

engineering levels

enhancing tack hollows

establishing finishing blocks

21 notes

·

View notes

Text

Flange AISI 304

When it comes to selecting high-quality flanges for your industrial needs, the flange AISI 304 stands out as a premium option. At Udhhyog, we offer top-grade AISI 304 stainless steel flanges that deliver unparalleled durability and performance. These flanges are crafted to meet the highest industry standards, ensuring reliability and efficiency in various applications.

What is Flange AISI 304?

The flange AISI 304 is made from 304-grade stainless steel, a material known for its excellent resistance to corrosion and high strength. Comprising 18% chromium and 8% nickel, this grade offers superb durability and a non-magnetic property that makes it ideal for a broad range of uses, from industrial piping systems to food processing equipment.

Key Features of Flange AISI 304

Material: 304 Stainless Steel

Pressure Rating: Available from 150 lbs to 2500 lbs

Size Range: From 1/2" to 48", with custom sizes upon request

Corrosion Resistance: Exceptional resistance to chemicals, chlorides, and acids

Temperature Tolerance: Reliable performance in both high and low temperatures

Types of Flanges AISI 304 Offered by Udhhyog

Udhhyog provides a diverse selection of flange AISI 304 types to meet various industrial requirements:

Slip-On Flange: Ideal for general-purpose applications with easy installation.

Weld Neck Flange: Designed for high-pressure environments, offering superior stress distribution.

Blind Flange: Used to seal the ends of pipes securely.

Threaded Flange: Convenient for systems that cannot be welded.

Lap Joint Flange: Suitable for applications requiring frequent disassembly and alignment.

For detailed information, explore our range of flange AISI 304 here.

Benefits of Using Flange AISI 304

Outstanding Corrosion Resistance: Ideal for harsh environments and chemical exposure.

Long-Lasting Durability: Minimizes maintenance and extends service life.

Temperature Versatility: Functions effectively under extreme temperature conditions.

Aesthetic Finish: Provides a smooth and polished appearance for exposed installations.

Applications of Flange AISI 304

The flange AISI 304 is suitable for various industries and applications:

Chemical Processing: Handles corrosive substances with ease.

Food and Beverage: Meets hygienic standards and is easy to clean.

Pharmaceuticals: Ensures sanitary conditions and precision.

Petrochemical: Effectively manages aggressive chemicals and gases.

Marine: Withstands saltwater exposure for marine applications.

Why Choose Udhhyog for Your Flange AISI 304?

Top-Quality Products: We provide flanges that adhere to the highest industry standards.

Competitive Pricing: Offers excellent value for money.

Extensive Range: A wide variety of flange types to meet your specific needs.

Reliable Delivery: Timely delivery to keep your projects on track.

Discover more about our flange AISI 304 and other industrial solutions by visiting Udhhyog’s website. For inquiries or orders, contact us at [email protected] or +91 9311120784. Udhhyog is dedicated to delivering the best products and services for all your industrial needs.

#FlangeAISI304#StainlessSteelFlanges#Udhhyog#PipeFlanges#FlangeManufacturers#FlangesAndFittings#FlangeFitting#FlangePipeFitting#QualityFlanges#IndustrialFlanges

2 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades.

Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration.

Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage.

Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas.

Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded.

Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications.

Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications.

Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Photo

New Post has been published on https://www.vividracing.com/blog/new-tomei-expreme-ti-full-titanium-exhaust-system-for-nissan-z-rz34/

New Tomei Expreme Ti Full Titanium Exhaust System for Nissan Z RZ34

Revving into the year 2022, the automotive world was abuzz with anticipation for the arrival of the new Nissan Z. And oh boy, did Nissan deliver! The Z34, equipped with a roaring 3.0L VR30DDTT Twin Turbo V6 and a thrilling 6-speed FS6R31 manual transmission, finally met the cravings of drivers left yearning for more in its predecessors, the Z34 and R35.

Enter Tomei, the legendary powerhouse in automotive tuning since its inception in 1968. Tomei’s legacy in motorsport and commitment to excellence has birthed the Expreme Ti Full Titanium Muffler Kits. Crafted with top-tier materials and engineered for supreme performance, these mufflers are the dream upgrade for enthusiasts seeking to unleash the true potential of this iconic sports car.

View Complete Tomei Catalog Here

For the Nissan Z enthusiasts craving the lightest exhaust system imaginable, Tomei introduces not one, but two, Expreme Ti exhaust systems! The Type-R single muffler kit and the Type-D dual muffler kit promise to take your Z’s performance and sound to the next level.

The Expreme Ti Full Titanium Mufflers for the Nissan Z are lightweight, strong, and highly durable. Tomei sources its own raw materials, which allows them to significantly improve quality while also keeping prices low. Using titanium maximizes weight reduction and durability while simultaneously providing that tantalizing racing note.

SILENCER CASE

This part is made from Titanium with the pipe size of Φ152 and 1mm thickness.

The oversized shell design optimizes exhaust gas flow which helps with power gains.

Then with the embossed Tomei logo and beautiful heat gradation colouring gives it the finishing touch that you’d expect.

PUNCHED MESH

Made entirely from Titanium of 1mm wall thickness and with the open slot ratio of 32.6%. With the combination of light weight Titanium material, the high flow design delivers a really nice racing exhaust sound.

GLASS WOOL

The long fiber wool threads were adopted for the silencer.

This type has proven to last longer than the traditional fiberglass materials even over a longer period of time with extensive high temperature exposure both at high and low pressures.

Flange

Flanges are cut from 8mm thick titanium, making them more

resist to cracking and warping. In addition, the opening

diameter is kept the same as stock to ensure a secure seal.

Type- R Single:

This new exhaust utilizes thin (1mm wall thickness) titanium piping with a single exit design. The midsection is connected with springs and clamps instead of flanges. With large 3.5 inch (89.1mm) piping, this exhaust offers significantly more flow than the OEM exhaust, which results in more power.

Compared to a Factory Nissan Z exhaust, the Tomei Expreme Ti is 29.7lbs lighter!

*32.3lbs lighter when paired with Tomei Full Titanium Y Shape Mid Pipe!)

1mm wall thickness thickness

Titanium construction

Light, strong, and durable

Single exit design

Sounds great!

More power!

Complete Kit: This kit includes all of the necessary components for a seamless installation, including the bolts and nuts. Bolt Smooth Paste is also included to help prevent the bolts from becoming seized under extreme heat.

Part Number: TB6090-NS21C

Product Name: FULL TITANIUM MUFFLER KIT EXPREME Ti 400Z RZ34 TYPE-R

MSRP: $1,290.00

Specification:

Material: Titanium

Main Pipe Diameter: 3.5in

Main Pipe Thickness: 1mm

Main Silencer Diameter: 6in

Main Silencer Thickness: 1mm

Sub Silencer Diameter: 4.7in

Sub Silencer Thickness: 1mm

Exit Diameter: 4.5in

Exit Thickness: 1mm

Fitment:

2023+ Nissan Z RZ34 VR30DDTT

Learn More and Purchase the New Tomei Type-R Full Muffler Kit Here.

Type-D Duel:

For those who wants to keep the duel exhaust system for your new Z, the Type-D style is what you need! This new exhaust utilizes thin (1mm wall thickness) titanium piping with a duel exit design. The midsection is connected with springs and clamps instead of flanges. With large 80.5mm piping, this exhaust offers significantly more flow than the OEM exhaust, which results in more power.

Compared to a Factory Nissan Z exhaust, the Tomei Expreme Ti is 17.4lbs lighter!

*20.0lbs lighter when paired with Tomei Full Titanium Y Shape Mid Pipe!)

1mm wall thickness

Titanium construction

Light, strong, and durable

Single exit design

Sounds great!

More power!

Complete Kit: This kit includes all of the necessary components for a seamless installation, including the bolts and nuts. Bolt Smooth Paste is also included to help prevent the bolts from becoming seized under extreme heat.

Part Number: TB6090-NS21D

Product Name: FULL TITANIUM MUFFLER KIT EXPREME Ti 400Z RZ34 TYPE-D

MSRP: $1,990.00

Specification:

Material: Titanium

Main Pipe Diameter: 3.2in

Main Pipe Thickness: 1mm

Main Silencer Diameter: 6in (x2)

Main Silencer Thickness: 1mm

Sub Silencer Diameter: 4.7in (x2)

Sub Silencer Thickness: 1mm

Exit Diameter: 4.5in (x2)

Exit Thickness: 1mm

Fitment:

2023+ Nissan Z RZ34 VR30DDTT

Learn More and Purchase the New Tomei Type-D Full Muffler Kit Here.

FULL TITANIUM Y SHAPE MID PIPE:

Compared to a Factory Nissan Z Mid Pipe, the Tomei Titanium Y Pipe is 2.7lbs lighter!

Part Number: TB6110-NS21A

Product Name: FULL TITANIUM Y PIPE KIT EXPREME TI Q50/Q60/400Z

MSRP: $890.00

Specification:

Material: Titanium

Main Pipe Diameter: 2.5-2.76in

Main Pipe Wall Thickness: 1mm

Flange Thickness: 8mm

Fitment:

Nissan VR30DDTT / VQ37VHR 400Z RZ34 / Q50 / Q60

Learn More and Purchase the New Tomei Full Titanium Y Shape Mid Pipe Here.

If you have questions, please contact us. You can reach us by phone at 1-480-966-3040 or via email at [email protected].

#2023 Nissan Z exhaust#400z#exhaust#Light weight#Nissan 400Z#Nissan Z#rz34#tomei#Tomei Exhaust#twin turbo#V6#vr30#VR30DDTT

2 notes

·

View notes

Text

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Floating Ball Valve: A Comprehensive Guide to Optimal Fluid Control

Floating Ball Valves are essential components in fluid control systems, offering reliable shut-off and excellent sealing capabilities. In this comprehensive guide, we will explore the features, benefits, and applications of floating ball valves, providing valuable insights to help you make informed decisions for your fluid control needs.

Section 1: Understanding Floating Ball Valves

Floating ball valves are designed with a Floating Ball that is not fixed to the valve stem. This unique design allows the Ball to float and move with the fluid pressure, ensuring optimal sealing and minimizing the risk of leakage. These valves are commonly used in various industries for their versatility and reliable performance.

Section 2: Advantages of Floating Ball Valves

Excellent Sealing: Floating ball valves provide exceptional sealing performance due to the pressure exerted on the ball by the fluid, ensuring tight shut-off and preventing leakage.

Wide Range of Applications: Floating Ball Valves are suitable for a wide range of applications, including oil and gas, petrochemicals, chemical processing, water treatment, and many more. Their versatility makes them a popular choice in various industries.

Easy Operation and Maintenance: Floating Ball Valves are designed for ease of operation and maintenance. The simple structure and fewer components contribute to quick and efficient maintenance, reducing downtime and overall costs.

Section 3: Types of Floating Ball Valves

Two-Piece Design: This type of floating ball valve consists of two main parts—the body and the Ball. It offers ease of maintenance and is commonly used in low-pressure applications.

Three-Piece Design: Three-piece floating ball valves feature a detachable body, allowing easy access to the internals for maintenance. They are suitable for high-pressure and high-temperature applications.

Section 4: Selecting the Right Floating Ball Valve

Consider the following factors when choosing a Floating Ball Valve:

Material Compatibility: Ensure that the valve materials are compatible with the fluid being handled, considering factors such as corrosion resistance and temperature limitations.

Pressure and Temperature Rating: Select a valve with the appropriate pressure and temperature ratings to ensure optimal performance and safety.

End Connection Type: Choose the correct end connections (flanged, threaded, or welded) based on your piping system requirements.

Section 5: Maintenance and Safety Tips

Proper maintenance and safety practices are crucial for the optimal performance and longevity of floating ball valves. Regular inspection, lubrication, and adherence to safety guidelines are essential to ensuring reliable and safe operation.

Floating Ball Valves are reliable and versatile components for fluid control applications. Their excellent sealing capabilities, a wide range of applications, and ease of operation make them a popular choice in various industries. By understanding the advantages, types, and selection criteria for floating ball valves, you can make informed decisions and optimize your fluid control systems for efficient and reliable performance.

2 notes

·

View notes

Text

Hydraulic Manifold valve manufacturer in india by hydrofittings

In addition, an Air Manifold With Valves allows the set up of more than one solenoid valves in a centralized vicinity. A unmarried air deliver and port are shared by means of numerous valves. Manifold take a look at Valve acts as a primary distribution point for aircraft that have dual dry air pumps. If one pump of Manifold Pneumatic fails it’s miles designed to isolate the failed pump and provide continuous airflow from the operating pump. Water Manifold With Valves is designed to distribute water and has built-in ports in a section of pipe. They act as manage facilities of water distribution within the house. Solenoid Valve Manifold has a most preferred stress of 6000 psi at a hundred ranges F and has a mounting hollow that enables inside the self-supporting software. Hydraulic Valve Manifold Has a stainless steel pin that forestalls the bonnet from detaching itself from the frame due to vibration. Ball Valve Manifold has a burr-loose thread that reduces inner floor leaks accordingly offering accurate transmitter read. No O-ring is used bonnet to body pressure Transmitter Manifold seal. It is a steel-to-metallic seal. Hydraulic Valve Manifold Block has the choice of panel mounting. There are one of a kind sorts of Manifold Valves to be had within the market but the maximum typically used ones are the two valve, three valve, and 5 valve assemblies. Swagelok Manifold is designed mainly for liquid stage, static stress, and differential stress packages. Smc Valve Manifold has a blended isolating and venting in a single valve that eliminates the want for tubing and fitting. Festo Valve Manifold is simple to gather and set up and is dependable. They’ve dirt caps fitted on them that comprise stem lubricant and save you the ingress of contaminants. Rosemount 305 Manifold gets rid of the need for a flange because it suits immediately to the patented Rosemount. Why to choose hydrofittings ? About us – The briefcase of our company consists of numerous additions which include, – clever hydraulics, engineering, and digital answers. With the guide of 80 personnel, our company works like a well-oiled system to deliver most effective the very best fine product to our buyers. Proper from the responsibly sourced product by way of our procurement team to our nice manage team, many agencies have lauded our work. And that they admire the fact that we’re transparent in all our dealings. With a properly-mounted channel of communique, our customers can connect with us anytime. Our control and our body of workers, together form a competent and ambitious crew. The readability and high stage of performance make us one of the most modern but sought after manufacturers. And because we fee initiative behavior, we adore to have our studies and development crew collaborate with the opposite teams to recognize the current requirements of the hour. We frequently have checking out and great exams to maintain brilliant requirements.

An global provider of

TO KNOW MORE ABOUTS US VISITE OUR WEBSITE www.hydrofittings.com

3 notes

·

View notes

Text

Manufacturer of PPCH Pipes and fittings in Ahmedabad, Exporter of PPCH Pipes and fittings in India

#PPCH Pipe#Coupler#Elbow#Equal Tee#End Cap#Reducer#Reducing Tee#Long Radius Elbow#Core Flange#Male Threaded Joint Adapter#Female Threaded Joint Adapter#Male Threaded Elbow#Female Threaded Elbow#Female Threaded Tee#Male Threaded Tee#Female Threaded Union#Male Threaded Union#Cross#Branch Adapter#Fabricated Butt Welded Equal Tee#Fabricated Reducer#Fabricated Elbow#Electrostatic Metal Flange#Thermal Step Flange

0 notes

Text

Carbon Steel Flanges VS Stainless Steel Flanges

Generally speaking, a flange is a forged or cast ring of steel that is used to connect or join sections of pipe. It also includes flanges that are integral to pressure vessels, pumps, or any other element that utilizes flanges. Bolts connect flanges together and threaded or welded them to the piping system. There are a variety of types of flanges available, including stainless steel flanges (SS flanges), alloy steel flanges, carbon steel flanges, slip-on flanges, blind flanges, weld neck flanges, threaded flanges, lap joints, and orifice flanges. This article discusses stainless steel vs carbon steel.

What are carbon steel flanges?

A flange connects two ends of a pipe or ends a pipe. Various materials are available for them. Flanges made from carbon steel are one such type. This material provides excellent durability, corrosion resistance, and finishing properties. There are several types of them. It is common to use Carbon Steel Blind Flanges to terminate pipes. The raw materials used in the manufacture of these flanges are of high quality. Between 0.25 and 0.60 percent of their carbon content is carbon. In addition to being highly ductile, the product is also excellently fabricated due to its high carbon and manganese content.

What are Stainless steel flanges?

In residential, commercial, and industrial piping systems, stainless steel flanges and fittings are used. Stainless steel is widely used for the transportation of gases or liquids, chemical processing, maritime applications, sanitary applications, and areas requiring corrosion resistance because of its strength, corrosion resistance, and ability to withstand high temperatures, pressures, and flows.

To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us. To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us.

Carbon Steel vs Stainless Steel

Stainless steel has a higher melting point and a lower carbon content than iron-carbon alloys. In appearance and properties, carbon steel is similar to stainless steel, but it contains a higher percentage of carbon.

A common application of engineering and construction materials like carbon steel is in large-scale industrial processes like telecommunications, transportation, chemical processing, and petroleum extraction and refining.

The process used in making Stainless Steel 304 Flanges is essentially two steps consisting mostly of iron and carbon. There are many types of steel that can be called stainless steel 304 flanges. Corrosion resistance can be achieved by adding nickel and chromium to stainless steel.

Flanges in detail:

Pipe Flanges are most often manufactured from forgings produced in grades A-105. There are two grades of A-350 material: LF2 for applications requiring lower temperatures and F42-F70 for applications requiring high yields. It is widely accepted that pipeline service is carried out with high-yield materials due to their increased strength.

Besides having a greater amount of chrome and molybdenum than carbon steel flanges, alloy steel flanges are able to withstand temperatures and pressures that are higher than those of carbon steel flanges. In contrast to conventional carbon steel flanges, they have a higher Chromium content, which makes them more corrosion resistant.

Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Forgings classes can be serviced with trace elements during melting. Aside from this, the 300 Series is not magnetic, whereas the 400 Series is magnetic, as well as has weakened corrosion resistance.

Read More About This Article On Our Website For More information: https://thesteelexporter.com/carbon-steel-flanges-vs-stainless-steel-flanges/

#design#architecture#interiordesign#steel#art#garden#gardendesign#rust#gardening#sculpture#metal#welding

2 notes

·

View notes