#thermal insulation packaging

Explore tagged Tumblr posts

Text

Thermal Insulation Packaging Market: An In-Depth Analysis

The thermal insulation packaging market is experiencing significant growth, driven by increasing demand for temperature-sensitive goods and advancements in packaging technologies. According to a report by Report Prime, the market is projected to expand from USD 26.50 billion in 2023 to USD 45.12 billion by 2030, at a compound annual growth rate (CAGR) of 7.90% during the forecast period.

Market Overview

Thermal insulation packaging involves materials and solutions designed to maintain the temperature of products during storage and transportation. This is particularly crucial for industries such as pharmaceuticals, food and beverages, and chemicals, where temperature control is essential to preserve product integrity.

Get Sample PDF

Key Drivers

Growing Demand for Temperature-Sensitive Products: The pharmaceutical and biotechnology sectors require stringent temperature control for products like vaccines and biologics. Similarly, the food industry demands thermal packaging to maintain the freshness of perishable items.

Expansion of E-commerce: The rise in online retailing of perishable goods has necessitated efficient thermal insulation solutions to ensure products reach consumers in optimal condition.

Regulatory Compliance: Stringent regulations regarding the transportation of temperature-sensitive goods compel industries to adopt reliable thermal insulation packaging to meet compliance standards.

Market Segmentation

The thermal insulation packaging market can be segmented based on product type, material, application, and region.

By Product Type:

Boxes: Widely used for shipping temperature-sensitive products.

Bags: Employed for smaller quantities requiring thermal protection.

Carton Liners: Used to line cartons, providing an additional layer of insulation.

Bubble Cushioning: Offers both insulation and protection against physical damage.

By Material:

Polystyrene: Includes expanded (EPS) and extruded (XPS) forms, known for excellent insulation properties.

Polyurethane (PUR): Offers superior thermal resistance, suitable for extreme temperature conditions.

Polyethylene: Commonly used due to its flexibility and durability.

Vacuum Insulated Panels (VIPs): Provide high thermal resistance in a thin profile, ideal for space-constrained applications.

Corrugated Fiber Board: An eco-friendly option with moderate insulation properties.

By Application:

Pharmaceuticals: Ensuring the efficacy of temperature-sensitive drugs and vaccines.

Food & Beverages: Maintaining the freshness and safety of perishable goods.

Chemicals: Preventing temperature-induced reactions during transport.

Horticulture Products: Protecting plants and flowers from temperature extremes.

Electronics: Safeguarding temperature-sensitive electronic components.

Regional Analysis

North America: Dominates the market due to advanced pharmaceutical and food industries, along with stringent regulatory standards.

Europe: Significant growth attributed to increasing demand for sustainable packaging solutions and a robust pharmaceutical sector.

Asia-Pacific: Expected to witness substantial growth owing to rapid industrialization, urbanization, and expanding e-commerce activities.

Middle East & Africa: Growth driven by the development of cold chain logistics and increasing pharmaceutical imports.

Latin America: Steady growth anticipated due to improving economic conditions and rising demand for temperature-sensitive goods.

Challenges

High Costs: Advanced thermal insulation materials like VIPs and PUR can be expensive, impacting adoption among cost-sensitive end-users.

Environmental Concerns: Disposal of non-biodegradable materials such as polystyrene poses environmental challenges, prompting a shift towards sustainable alternatives.

Supply Chain Complexity: Maintaining the integrity of thermal insulation packaging throughout complex supply chains requires meticulous planning and execution.

Opportunities

Sustainable Materials: Development of eco-friendly insulation materials presents opportunities for market growth, aligning with global sustainability trends.

Technological Advancements: Integration of smart technologies, such as temperature monitoring sensors, can enhance the functionality of thermal insulation packaging.

Emerging Markets: Expansion into developing regions with growing pharmaceutical and food industries offers potential for market penetration.

Recent Developments

Innovations in Sustainable Packaging: Companies are investing in research to develop biodegradable and recyclable thermal insulation materials to address environmental concerns.

Strategic Partnerships: Collaborations between packaging manufacturers and pharmaceutical companies are on the rise to develop customized solutions for specific temperature-sensitive products.

Regulatory Compliance Initiatives: Businesses are enhancing their packaging solutions to comply with evolving regulations, ensuring product safety and quality during transportation.

Conclusion

The thermal insulation packaging market is poised for robust growth, driven by increasing demand for temperature-sensitive products, advancements in packaging technologies, and a global emphasis on sustainability. However, challenges such as high costs and environmental concerns need to be addressed. Companies that invest in sustainable materials, technological innovations, and strategic partnerships are well-positioned to capitalize on emerging opportunities in this dynamic market.

0 notes

Text

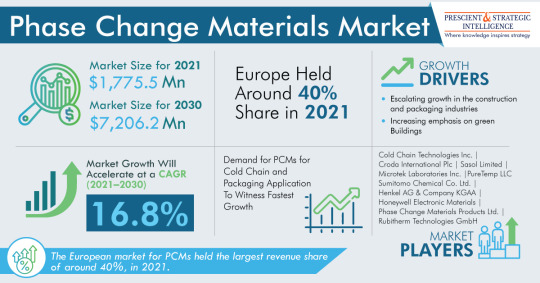

Transforming Industries: Phase Change Materials Market Insights

As stated by P&S Intelligence, the total revenue generated by the phase change materials market was USD 1,775.5 million in 2021, which will power at a rate of 16.8% by the end of this decade, to reach USD 7,206.2 million by 2030.

This has a lot to do with the increasing growth in the construction and packaging sectors and increasing importance on green buildings.

Cold chain and packaging category will grow at the highest rate, of above 17%, in the years to come. This can be mostly because of the surge in PCM requirement to sustain precise temperatures through the supply chain while lowering the emissions of carbon dioxide. Using ACs and electric fans to stay cool contributes to approximately 20% of the total electricity employed in buildings globally. The increasing requirement for space cooling is straining quite a few countries' power infrastructure, along with bringing about increased emissions.

With the enormous increase in the requirement for energy-efficient ACs, the requirement for PCMs will soar, as the electrical consumption of modified ACs with PCMs could be brought down by 3.09 kWh every day.

Europe dominated the industry with a share, of about 40%, in the recent past. The predisposition toward the acceptance of eco-friendly materials will power the PCM industry in the region. European regulatory associations, such as the SCANVAC, took more than a few initiatives for developing and promoting and effective building mechanical solutions and increase awareness pertaining to PCM applications.

The convenience of paraffin at a wide range of temperatures is a major reason for its appropriateness as an energy storage medium. Likewise, paraffin-based PCM is called a waxy solid paraffin, safe, dependable, noncorrosive, and economical material.

HVAC systems had the second-largest share, of about 30%, in phase change materials market in the recent past. This has a lot to do with the fact that PCM installation decreases fluctuations of temperature. HVAC with PCM supports in maintaining a steadier temperature and eliminating thermal uneasiness caused by alterations in temperature. It is because of the emphasis on green buildings, the demand for phase change materials will continue to rise considerably in the years to come.

#Phase Change Material Market#Phase Change Material Market Size#Phase Change Material Market Share#Phase Change Material Market Growth#Phase change materials (PCMs)#Thermal energy storage#Energy efficiency solutions#Heat management technology#Sustainable materials#Building insulation#HVAC systems#Thermal regulation#Cold chain logistics#Renewable energy storage#Temperature-sensitive packaging

0 notes

Text

https://www.databridgemarketresearch.com/reports/north-america-thermal-insulation-packaging-market

0 notes

Text

"SILTS camera infrared image of the flight surfaces of Columbia during STS-28 reentry."

"The Shuttle Infrared Lee-side Temperature Sensing (SILTS) camera package made its second flight aboard Columbia on this mission. The cylindrical pod and surrounding black tiles on the orbiter's vertical stabilizer housed an imaging system, designed to map thermodynamic conditions during reentry, on the surfaces visible from the top of the tail fin. Ironically, the camera faced the port wing of Columbia, which was breached by superheated plasma on its disastrous final flight, destroying the wing and, later, the orbiter. The SILTS system was used for only six missions before being deactivated, but the pod remained for the duration of Columbia's career. Columbia's thermal protection system was also upgraded to a similar configuration as Discovery and Atlantis in between the loss of Challenger and STS-28, with many of the white LRSI tiles replaced with felt insulation blankets in order to reduce weight and turnaround time. One other minor modification that debuted on STS-28 was the move of Columbia's name from its payload bay doors to the fuselage, allowing the orbiter to be easily recognized while in orbit."

Information from Wikipedia: link

Date: August 13, 1989

source, source, source

#STS-28#Space Shuttle#Space Shuttle Columbia#Columbia#OV-102#Orbiter#NASA#Space Shuttle Program#August#1989#Shuttle Lee-side Temperature Sensing#SILTS#re-entry#my post

26 notes

·

View notes

Text

Modern log home designs are a marvel of energy efficiency and environmental friendliness. With advancements in design and materials, these homes blend the timeless appeal of wood with cutting-edge energy-saving technologies. The thermal mass of logs allows them to act as natural insulators, absorbing heat during the day and releasing it at night. The floor to ceiling windows and multi-slide patio doors allow for an abundance of natural light, all of which lead to significant energy savings.

This combination of natural beauty and modern efficiency makes log homes an attractive option for those looking to reduce their carbon footprint without sacrificing comfort or style.

Contact Cascade Handcrafted for a Free Quote on a beautiful handcrafted log package 1-604-703-3452

#modernloghome#contemporaryloghome#modernlogcabin#cabinliving#architecture#loghouse#loghomes#offgridliving#cabinstyle#loghomeliving#logcabins#customhomes#carbonneutral#energyefficient#naturallypassiveloghomes

2 notes

·

View notes

Text

Melamine Market is Expected to Grow at a CAGR of 3.87% during the forecast period until 2032

The melamine market has witnessed remarkable growth and diversification in recent years, propelled by a myriad of factors shaping the global landscape. Melamine, a nitrogen-rich organic compound, finds extensive applications across various industries, including construction, automotive, textiles, packaging, and food service. Its unique properties, such as high flame resistance, thermal stability, durability, and chemical inertness, have made melamine a versatile and indispensable material in numerous manufacturing processes and end-use applications.

One of the primary drivers of the melamine market is the increasing demand from the construction industry. Melamine-based products, such as melamine formaldehyde resins and melamine foam insulation, are widely used in construction applications such as laminates, decorative panels, flooring, countertops, and insulation materials. With rapid urbanization, infrastructure development, and construction activities on the rise globally, the demand for melamine-based construction materials is expected to surge.

Read Full Report: https://www.chemanalyst.com/industry-report/melamine-market-812

Moreover, the automotive sector represents another significant market for melamine, driven by the increasing demand for lightweight, durable, and aesthetically appealing materials. Melamine-based components, such as automotive interior trim, dashboard panels, door panels, and decorative parts, offer excellent properties such as scratch resistance, color stability, and surface finish, thereby enhancing the overall aesthetics and functionality of vehicles. As automotive manufacturers focus on improving fuel efficiency, reducing emissions, and enhancing passenger comfort and safety, the demand for melamine-based automotive materials is projected to grow substantially.

Furthermore, the textiles industry presents lucrative opportunities for the melamine market, particularly in the manufacturing of melamine-formaldehyde resins for textile finishing and coating applications. Melamine resins impart crease resistance, wrinkle resistance, and color fastness to textiles, thereby enhancing their durability, appearance, and performance. With the growing demand for high-quality textiles, home furnishings, and apparel, the demand for melamine-based textile additives is expected to increase.

Additionally, the packaging industry represents a significant market for melamine, driven by the rising demand for lightweight, durable, and eco-friendly packaging materials. Melamine-based products, such as melamine-formaldehyde resins and melamine foam packaging, offer excellent properties such as thermal insulation, moisture resistance, and shock absorption, making them ideal for packaging applications such as food packaging, electronics packaging, and industrial packaging. As consumers increasingly prioritize sustainability, recyclability, and environmental friendliness, the demand for melamine-based packaging solutions is expected to grow.

Despite the promising outlook, the melamine market faces challenges and constraints, including fluctuating raw material prices, regulatory compliance issues, and environmental concerns related to formaldehyde emissions. However, industry stakeholders are actively addressing these challenges through initiatives focused on product innovation, sustainability, and regulatory compliance. Moreover, strategic partnerships, mergers, and acquisitions are driving consolidation and market expansion in the melamine industry.

In conclusion, the melamine market is poised for continued growth and innovation, driven by its versatile applications, inherent properties, and compatibility with evolving market trends. By leveraging its strengths in construction, automotive, textiles, packaging, and other sectors, the melamine market can navigate towards a more sustainable and prosperous future, ensuring its relevance and competitiveness in the global marketplace.

About us:

ChemAnalyst is an online platform offering a comprehensive range of market analysis and pricing services, as well as up-to-date news and deals from the chemical and petrochemical industry, globally.

Being awarded ‘The Product Innovator of the Year, 2023’, ChemAnalyst is an indispensable tool for navigating the risks of today's ever-changing chemicals market.

The platform helps companies strategize and formulate their chemical procurement by tracking real time prices of more than 400 chemicals in more than 25 countries.

ChemAnalyst also provides market analysis for more than 1000 chemical commodities covering multifaceted parameters including Production, Demand, Supply, Plant Operating Rate, Imports, Exports, and much more. The users will not only be able to analyse historical data but will also get to inspect detailed forecasts for upto 10 years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

Contact us:

420 Lexington Avenue, Suite 300

New York, NY

United States, 10170

Email-id: [email protected]

Mobile no: +1-3322586602

#Melamine#Melaminemarket#Melaminemarketsize#Melaminemarkettrends#Melaminemarketgrowth#Melaminemarketshare#Melaminedemand

2 notes

·

View notes

Text

Thought I'd throw up some pics of the cold frame I slapped together on my south-facing front porch.

It's mostly made from windows I scavenged this year. There's a bank of them snugged up against the front railing, there are ones on each side held in place with cinder blocks, and the one in back is resting on what I'm using for thermal mass.

It's a row of those Tidy Cats litter tubs filled 3/4 up with water and stuffed into black plastic contractor bags. The plastic bags not only help with the absorption of solar heat, but also fill in the spaces between the tubs. They're only filled 3/4 full because they're inevitably going to freeze at some point--some will crack at the bottom seam but most will make it. I do have plans to go out this weekend on a Styrofoam panel scavenging mission--you know, after people blow all their money on new tvs and stuff on black friday and throw the packaging away. Then I'll insulate the back of the thermal shelf to direct the heat all inward.

The top is just a shower door plus a small window. I can shift/lift them for harvesting and watering.

I've got two regular sized Earthboxes and two smaller in there. The smaller ones are on the ledge and the larger are on the concrete. I've got several lettuces, several spinaches, Swiss chard, and some teeny kale seedlings going. The kale is teeny because the @#@^=$_!! midnight wildlife tore apart the initial transplants when I first planted them in the boxes back in September and I had to restart from seed.

It took me a solid month to work up the energy to put this all together, but only an hour or two to construct. Thankfully, autumn seems to be on a one month delay this year except for one or two short dips below freezing. Looking forward to at least a weekly salad for as long as we don't have another "arctic blast" like we did last year.

#cold frames#they can be as simple and janky as this one and still work to extend your growing season#i'm going to try to get my hands on some more lumber this next year so i can build panels i can just snap together#but this year all the lumber went to the new chicken coop/run and rebuilding the rotting back stairs that i kept slipping and falling on#gardening#extending the growing season#lettuce#spinach#kale#swiss chard#i ran out of room or the green onions would also be out there#instead they're in a basement window

4 notes

·

View notes

Text

Aluminum Market: Products, Applications & Beyond

Aluminum is a versatile element with several beneficial properties, such as a high strength-to-weight ratio, corrosion resistance, recyclability, electrical & thermal conductivity, longer lifecycle, and non-toxic nature. As a result, it witnesses high demand from industries like automotive & transportation, electronics, building & construction, foil & packaging, and others. The high applicability of the metal is expected to drive the global aluminum market at a CAGR of 5.24% in the forecast period from 2023 to 2030.

Aluminum – Mining Into Key Products:

Triton Market Research’s report covers bauxite, alumina, primary aluminum, and other products as part of its segment analysis.

Bauxite is anticipated to grow with a CAGR of 5.67% in the product segment over the forecast years.

Bauxite is the primary ore of aluminum. It is a sedimentary rock composed of aluminum-bearing minerals, and is usually mined by surface mining techniques. It is found in several locations across the world, including India, Brazil, Australia, Russia, and China, among others. Australia is the world’s largest bauxite-producing nation, with a production value of over 100 million metric tons in 2022.

Moreover, leading market players Rio Tinto and Alcoa Corporation operate their bauxite mines in the country. These factors are expected to propel Australia’s growth in the Asia-Pacific aluminum market, with an anticipated CAGR of 4.38% over the projected period.

Alumina is expected to grow with a CAGR of 5.42% in the product segment during 2023-2030.

Alumina or aluminum oxide is obtained by chemically processing the bauxite ore using the Bayer process. It possesses excellent dielectric properties, high stiffness & strength, thermal conductivity, wear resistance, and other such favorable characteristics, making it a preferable material for a range of applications.

Hydrolysis of aluminum oxide results in the production of high-purity alumina, a uniform fine powder characterized by a minimum purity level of 99.99%. Its chemical stability, low-temperature sensitivity, and high electrical insulation make HPA an ideal choice for manufacturing LED lights and electric vehicles. The growth of these industries is expected to contribute to the progress of the global HPA market.

EVs Spike Sustainability Trend

As per the estimates from the International Energy Agency, nearly 2 million electric vehicles were sold globally in the first quarter of 2022, with a whopping 75% increase from the preceding year. Aluminum has emerged as the preferred choice for auto manufacturers in this new era of electromobility. Automotive & transportation leads the industry vertical segment in the studied market, garnering $40792.89 million in 2022.

In May 2021, RusAl collaborated with leading rolled aluminum products manufacturer Gränges AB to develop alloys for automotive applications. Automakers are increasingly substituting stainless steel with aluminum in their products owing to the latter’s low weight, higher impact absorption capacity, and better driving range.

Also, electric vehicles have a considerably lower carbon footprint compared to their traditional counterparts. With the growing need for lowering emissions and raising awareness of energy conservation, governments worldwide are encouraging the use of EVs, which is expected to propel the demand for aluminum over the forecast period.

The Netherlands is one of the leading countries in Europe in terms of EV adoption. The Dutch government has set an ambitious goal that only zero-emission passenger cars (such as battery-operated EVs, hydrogen FCEVs, and plug-in hybrid EVs) will be sold in the nation by 2030. Further, according to the Canadian government, the country’s aluminum producers have some of the lowest CO2 footprints in the world.

Alcoa Corporation and Rio Tinto partnered to form ELYSIS, headquartered in Montréal, Canada. In 2021, it successfully produced carbon-free aluminum at its Industrial Research and Development Center in Saguenay. The company is heralding the beginning of a new era for the global aluminum market with its ELYSIS™ technology, which eliminates all direct GHG emissions from the smelting process, and is the first technology ever to emit oxygen as a byproduct.

Wrapping Up

Aluminum is among the most widely used metals in the world today, and is anticipated to underpin the global transition to a low-carbon economy. Moreover, it is 100% recyclable and can retain its properties & quality post the recycling process.

Reprocessing the metal is a more energy-efficient option compared to extracting the element from an ore, causing less environmental damage. As a result, the demand for aluminum in the sustainable energy sector has thus increased. The efforts to combat climate change are thus expected to bolster the aluminum market’s growth over the forecast period.

#Aluminum Market#aluminum#chemicals and materials#specialty chemicals#market research#market research reports#triton market research

4 notes

·

View notes

Text

AlN ceramic PCB (aluminum nitride ceramic) is a new type of high thermal conductivity ceramic packaging material. It has been extensively studied in the 1990s and gradually developed. It is currently generally considered to be a promising electronic ceramic packaging PCB.

AlN material has high thermal conductivity, excellent dielectric properties, high electrical insulation strength, stable chemical properties, strong corrosion resistance, and good mechanical properties. In particular, its thermal expansion coefficient matches with silicon, which makes it an ideal semiconductor packaging substrate materials and have been widely used in integrated circuits, microwave power devices, millimeter-wave packaging, high-temperature electronic packaging and other fields.

If you want to know more about ceramic PCB, please enter our website: https://hitechcircuits.com/pcb-products/ceramic-pcb/

0 notes

Text

Silicone Foam: The Ultimate Material For Insulation Needs

Silicon Foam sheets are bindandy, durable substances that are used for insulation, sealing and cushioning. They provide great resistance to heat, moisture and chemicals, making them ideal for cars, electronics and commercial packages. These sheets provide vibrations, thermal stability and electrical insulation, ensuring reliable performance in harsh environments and serious conditions.

0 notes

Text

What Are the Disadvantages of a Sunroom?

Adding a sunroom to your home sounds like a dream—extra space, natural light flooding in, a cozy spot to sip coffee on chilly mornings. But, before you start sketching out plans and picking out patio furniture, there are a few things you should know. Sunrooms aren’t all sunshine and rainbows. They come with drawbacks that can affect your budget, comfort, and even long-term home maintenance.

If you're in South Bend and thinking about installing a sunroom, here’s what you need to consider.

They Can Get Uncomfortably Hot (or Freezing Cold)

Sunrooms might be designed for year-round enjoyment, but in reality, they often struggle with temperature control.

Summer Heat: Without proper ventilation or shading, a sunroom can turn into a greenhouse. The glass walls trap heat, making it feel like an oven in the peak of summer.

Winter Chill: On the flip side, a sunroom can be unbearably cold in the winter, especially if it's not well-insulated. Even with a space heater, keeping the room warm can be a challenge.

Inconsistent Use: Because of these extreme temperatures, many homeowners find themselves avoiding their sunroom for large chunks of the year.

Investing in thermal glass, insulated flooring, or a mini-split HVAC system can help, but these upgrades can drive up the cost significantly.

They Can Be Expensive to Build and Maintain

Sunrooms might seem like a budget-friendly way to expand your living space, but the costs can add up quickly.

High Upfront Costs: A basic sunroom can cost anywhere from $10,000 to $50,000—or more if you want it fully insulated with HVAC.

Ongoing Maintenance: Cleaning the glass, sealing leaks, and dealing with condensation buildup are all part of the package. If you neglect maintenance, moisture issues can lead to mold or rot.

Unexpected Repairs: Over time, sunrooms are prone to wear and tear, especially in areas with harsh winters or heavy storms (like South Bend). Wind, hail, and extreme temperatures can weaken the structure.

So, while a sunroom might be a more affordable alternative to a full home addition, it still requires a significant financial commitment.

They Might Not Add as Much Value as You Think

A sunroom might feel like an attractive selling point, but does it actually increase your home’s value?

Not Always Considered "Livable" Space: Unlike a traditional home addition, many sunrooms don’t count toward a home's total square footage unless they’re fully insulated and heated.

Buyers' Preferences Vary: Some people love the idea of a sunroom, while others see it as wasted space or a heating and cooling nightmare.

ROI Can Be Lower Than Expected: Home improvements like kitchen remodels or bathroom upgrades tend to yield a higher return on investment compared to sunrooms.

If you’re adding a sunroom purely for resale value, it might not be the best investment. However, if you’re planning to stay in your home long-term and love the idea of a bright, open space, it might still be worth it.

They Can Be Prone to Leaks and Drafts

One of the biggest complaints homeowners have about sunrooms? They don’t always hold up well against the elements.

Leaks: With so much glass and framing, even small cracks in the seals can lead to leaks when it rains.

Drafts: Poor insulation or improperly installed windows can create noticeable drafts, making the room uncomfortable in colder months.

Condensation Issues: Moisture buildup on the windows can lead to mold and mildew problems if not properly managed.

To avoid these headaches, high-quality materials and expert installation are a must. Cutting corners to save money on the initial build can lead to costly repairs down the line.

Privacy Can Be an Issue

Love the idea of basking in the sun with your morning coffee? So might your neighbors.

Too Much Visibility: Because sunrooms often feature floor-to-ceiling windows, privacy can become an issue—especially if you live in a suburban area with homes close together.

Limited Window Covering Options: You can install curtains or blinds, but that kind of defeats the purpose of having a sunroom in the first place.

Feeling Exposed: Some homeowners end up avoiding their sunrooms because they don’t like feeling like they’re on display.

If privacy is a concern, consider tinted or frosted glass, strategic landscaping, or retractable shades to help create a more secluded feel.

Bugs and Pests Can Be a Problem

South Bend’s warm months bring out all kinds of bugs, and unfortunately, sunrooms can be a magnet for them.

Mosquitoes and Flies: If your sunroom has screens instead of glass windows, expect to deal with insects finding their way inside.

Spiders and Other Critters: Small gaps in the structure can invite spiders, ants, or even rodents to take up residence.

Cleaning Woes: Keeping the space bug-free requires regular cleaning and sometimes sealing up small cracks or holes.

A well-sealed, fully enclosed sunroom with proper screens and weather stripping can help keep pests at bay, but it’s something to keep in mind.

They Can Limit Your Outdoor Space

This one depends on the size of your yard, but adding a sunroom might mean sacrificing valuable outdoor space.

Less Room for a Patio or Deck: If you love grilling, gardening, or just relaxing outside, a sunroom could take up space that might have been better used for a patio or deck.

Reduced Backyard Functionality: If you have kids or pets that need room to run, shrinking your backyard might not be ideal.

A Permanent Structure: Once a sunroom is built, it’s not easy (or cheap) to remove if you change your mind later.

Before committing, consider how much outdoor space you’re willing to give up and whether a sunroom is truly the best use of that area.

Final Thoughts: Is a Sunroom Right for You?

Sunrooms can be a fantastic addition to a home—when done right. But they’re not perfect for everyone.

If you live in South Bend and are considering adding a sunroom, ask yourself:

Do I have the budget for high-quality materials and professional installation?

Am I comfortable dealing with temperature fluctuations, maintenance, and possible repairs?

Will I actually use this space year-round, or is it more of a luxury add-on?

Does it fit my long-term home goals?

If you answered “yes” to most of these, a sunroom might be worth it. But if the downsides are making you second-guess, you might want to explore other options—like a covered patio or screened-in porch.

No matter what you decide, make sure your new space truly enhances your home and lifestyle. After all, a home upgrade should be something you enjoy—not something you regret later.

2 notes

·

View notes

Text

0 notes

Text

Bio-based Foam Market Plans Research and Development for Product Performance

The increasing demand for sustainable materials has prompted bio-based foam manufacturers to develop strategic growth plans. Companies are focusing on expanding their production capacities, reducing reliance on fossil fuels, and integrating bio-based alternatives. With governments pushing for sustainability, bio-based foam is set to play a crucial role in the green economy.

Bio-based Foam Market Plans: Enhancing Eco-Friendly Production Processes

Manufacturers are investing in cleaner and more efficient production techniques to reduce carbon footprints. The adoption of energy-efficient processes, closed-loop manufacturing, and waste reduction strategies are gaining traction. Companies are also exploring the use of renewable energy sources in production to align with global sustainability goals.

Bio-based Foam Market Plans: Innovations in Raw Materials and Biopolymers

Research into alternative raw materials is driving innovation in the bio-based foam industry. Companies are experimenting with plant-based feedstocks, algae-derived foams, and biodegradable polymers to enhance performance. These advancements are aimed at improving durability, flexibility, and thermal insulation while ensuring complete recyclability and environmental safety.

Bio-based Foam Market Plans: Supply Chain Optimization for Market Expansion

To meet the rising demand, companies are optimizing their supply chains by securing reliable bio-based raw material sources. Diversifying suppliers, implementing digital tracking systems, and reducing transportation emissions are key strategies. Improved logistics and localized production facilities are also being considered to enhance market reach.

Bio-based Foam Market Plans: Addressing Regulatory Challenges and Compliance

Stringent environmental regulations are influencing the bio-based foam market. Companies must comply with industry standards such as ASTM and ISO certifications while meeting evolving governmental guidelines on biodegradability and carbon emissions. Strategic plans include continuous monitoring of global policies and proactive adaptation to new regulatory frameworks.

Bio-based Foam Market Plans: Competitive Positioning in the Green Economy

With an increasing number of companies entering the bio-based foam sector, competitive positioning has become essential. Brands are differentiating themselves by highlighting superior environmental credentials, offering customizable solutions, and engaging in transparent sustainability reporting. Collaborations with eco-conscious brands are also driving visibility and market penetration.

Bio-based Foam Market Plans: Research and Development for Product Performance

Investments in R&D are crucial for improving bio-based foam performance. Companies are working on enhancing mechanical strength, moisture resistance, and longevity to match or surpass synthetic foams. R&D initiatives also focus on developing recyclable and compostable formulations, making bio-based foam a viable alternative across industries.

Bio-based Foam Market Plans: Consumer Preferences and Market Demands

Shifting consumer preferences towards sustainable products are shaping the bio-based foam market. Brands are aligning their strategies with consumer demands for non-toxic, biodegradable, and recyclable materials. Increased awareness about environmental impact has led to rising adoption in packaging, construction, automotive, and furniture applications.

Bio-based Foam Market Plans: Future Growth Opportunities in Key Industries

The market for bio-based foam is expanding across various industries. The automotive sector is integrating lightweight, sustainable foams for vehicle interiors, while the packaging industry is replacing polystyrene with biodegradable alternatives. Construction and furniture industries are also leveraging bio-based foams for insulation and cushioning applications.

Bio-based Foam Market Plans: Investment Strategies for Long-Term Sustainability

To ensure long-term growth, companies are adopting strategic investment plans. Venture capital and government incentives are fueling innovation in the sector. Partnerships with research institutions, acquisitions of sustainable startups, and large-scale funding for bio-based material development are key investment strategies driving market expansion.

Conclusion

The bio-based foam market is rapidly evolving as companies implement strategic plans to drive sustainability, innovation, and efficiency. By optimizing supply chains, investing in R&D, and complying with regulations, manufacturers are positioning themselves for long-term success. As industries continue to adopt eco-friendly solutions, bio-based foam will play an integral role in the future of sustainable materials.

0 notes

Link

0 notes

Text

Europe Aluminium Magnesium Spinel Market Industry Trends, Competition Strategies, Revenue Analysis and Forecast to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Europe Aluminium Magnesium Spinel Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the Europe Aluminium Magnesium Spinel Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Europe Aluminium Magnesium Spinel Market?

Europe aluminium magnesium spinel market was valued at US$ 166.4 Million in 2023 and is expected to register a CAGR of 4.1% over the forecast period and reach US$ 238.3 Mn in 2032.

What are Europe Aluminium Magnesium Spinel?

Aluminium Magnesium Spinel in Europe is a high-performance ceramic known for its outstanding thermal and mechanical properties. Made from aluminum oxide (Al₂O₃) and magnesium oxide (MgO), it offers excellent resistance to thermal shock, corrosion, and mechanical wear. This material is widely used in industrial applications including refractory linings in furnaces and reactors, as well as in aerospace components and advanced ceramic products. Its exceptional combination of high melting point, hardness, and chemical stability makes it ideal for demanding environments where durability and reliability are essential.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2351

What are the growth prospects and trends in the Europe Aluminium Magnesium Spinel industry?

The Europe aluminium magnesium spinel market growth is driven by various factors and trends. The Aluminium Magnesium Spinel market in Europe is experiencing growth, fueled by its widespread adoption in multiple industries due to its strong thermal and mechanical properties. This high-performance ceramic, comprised of aluminum oxide (Al₂O₃) and magnesium oxide (MgO), is prized for its resilience against thermal shock, corrosion, and mechanical wear. It is utilized extensively in industrial refractories, aerospace components, and advanced ceramics, leveraging its high melting point, hardness, and chemical stability. Market expansion is driven by rising demand for durable materials in industrial applications and continuous advancements in technology to enhance its effectiveness across various uses. Hence, all these factors contribute to Europe aluminium magnesium spinel market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Fused Spinel

Reaction Bonded Spinel

Sintered Spinel

Others

By Composition

Al2O3 (76/78%)

MgO (24/22%)

By Form

Powder

Granules

Bricks

Others

By Production Method

Sol-Gel Process

Conventional Solid-State-Reaction

Spray Drying (Atomization)

Chemical Vapor Deposition (CVD)

Electrical Fusion Process

Wet Synthesis Techniques

Mechano-Chemical Alloying

Molten Salt Synthesis

Others

By Purity

99%

Above 99%

By Packaging

Steel Drum

Container

By Application

Refractory Materials

Metal Casting

Electrical Insulators

Iron And Steel Smelting

Glass Furnace

Calcined Lime Furnace Lining

Cement Rotary Kiln

Steel Ladles

Alumina-Magnesia Brick

Sliding Nozzle

Ceramics Manufacturing

HumiditySensors

Others

By End-Use Industry

Automotive

Electronics

Refractories

Cement

Iron and Steel

Glass

Water Treatment

Others

Europe

Germany

Austria

Switzerland

Italy

Spain

Portugal

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Ukraine

Moldova

Balkan Countries

Rest of Europe

Who are the key players operating in the industry?

The report covers the major market players including:

Almatis

Refratechnik Group

Keralit LLC

Surmet Corporation

CeraNova Corporation

Washington Mills

Baikowski

MFE Magnesium

View Full Report: https://www.reportsandinsights.com/report/Europe Aluminium Magnesium Spinel-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Europe Aluminium Magnesium Spinel Market share#Europe Aluminium Magnesium Spinel Market size#Europe Aluminium Magnesium Spinel Market trends

0 notes

Text

AAC Block Manufacturing: Step-by-Step Process from Factory to Construction

AAC blocks, also known as Autoclaved Aerated Concrete blocks, are the future of construction due to their lightweight, eco-friendly, and high-strength properties. Evergreen Enterprises is a leading manufacturer of AAC blocks, providing top-quality products for sustainable construction. In this blog, we will walk you through the step-by-step AAC block manufacturing process, from raw materials to final construction.

Step 1: Raw Material Selection

The manufacturing of AAC blocks starts with carefully selected raw materials, including:

1.Cement – Acts as a binding material

2.Fly ash – A key ingredient providing strength and sustainability

3.Lime – Enhances the aeration process

4.Gypsum – Improves durability

5.Aluminum Powder – Reacts with lime and fly ash to form air pockets

These materials are proportionally mixed to ensure the best quality AAC blocks.

Step 2: Mixing and Slurry Preparation

The raw materials are mixed with water in a large slurry tank to form a uniform mixture. The addition of aluminum powder causes a chemical reaction, generating hydrogen gas, which creates tiny air bubbles. This aeration process makes AAC blocks lightweight and porous.

Step 3: Molding and Rising

The prepared slurry is poured into large molds, where it begins to expand. The controlled rising process gives AAC blocks their signature aerated structure. The mixture is left to set for a few hours before it is ready for cutting.

Step 4: Cutting into Desired Shapes

Once the block has gained sufficient strength, it is cut into standard sizes using precision wire cutting machines. The automated cutting process ensures that each AAC block is uniform in shape and size, making it easier to use in construction.

Step 5: Autoclaving for Strength

The cut blocks are then transferred to an autoclave, where they are cured under high-pressure steam at around 180°C for 10-12 hours. This autoclaving process enhances the strength and durability of AAC blocks, making them ideal for long-lasting structures.

Step 6: Quality Control and Testing

Evergreen Enterprises ensures that every AAC block undergoes rigorous quality checks, including:

1.Compressive strength testing

2.Density and weight analysis

3.Thermal insulation performance

4.Soundproofing efficiency

Only blocks that meet the highest industry standards are sent for distribution.

Step 7: Packaging and Dispatch

The finished AAC blocks are packed and transported to construction sites. Evergreen Enterprises ensures timely delivery, maintaining product quality during transit.

Step 8: Construction with AAC Blocks

Builders and architects prefer AAC blocks due to their easy handling, energy efficiency, and fire resistance. These blocks are used in various applications, including:

1.Residential and commercial buildings

2.Industrial structures

3.Hospitals and schools

Conclusion

Evergreen Enterprises is a trusted name in the AAC block manufacturing industry, offering:

1.High-quality, eco-friendly AAC blocks

2.Cost-effective and energy-efficient solutions

3.Reliable and timely delivery

Whether you’re planning a small home or a large commercial project, AAC blocks from Evergreen Enterprises are the perfect choice for sustainable and durable construction.

For more details, contact Evergreen Enterprises today and get premium-quality AAC blocks for your next construction project!

0 notes