#textile inkjet printing

Explore tagged Tumblr posts

Text

Xaar’s drupa presentation on textile inkjet printing

Xaar, an inkjet innovator, providing printheads and technologies for OEM and UDI customers worldwide, is inviting visitors at drupa to hear how the latest inkjet technologies are rewriting the rulebook for textile printing in a presentation to be made as part of the show’s touchpoint textile forum.

Speaking on June 3 in hall 4, Karl Forbes, the Xaar group’s R&D director, will show how its Aquinox printhead, utilizing Xaar’s Ultra High Viscosity printing and patented High Laydown Technology, is transforming productivity in digital textile printing.

Chemists at Nazdar were able to produce a new fluid technology that can deliver clarity and high pigment loading while simultaneously reducing the use of raw materials and energy costs. Vibrant, color-rich textiles can now be achieved by using half the traditional amount of ink and printhead passes, delivering significant machine productivity savings.

Notably, Nazdar’s new HighV Aqua Series includes a high viscosity white ink, which when coupled with the TF Technology embedded within Xaar’s Aquinox printhead, provides customers with quality textile printing at an efficiency that was previously unmatched.

Drupa will also see Xaar technology across the show – including its recent collaboration with Koenig & Bauer Kammann (Kammann) to create personalized embossed effects on glass bottles, plastic and metal containers at a build height of up to 3mm. Utilizing Xaar’s Nitrox printheads with new high viscosity fluids developed by global ink manufacturer Marabu, Kammann’s machines can jet at greater viscosity and carry a significantly increased pigment load, delivering more color vibrancy and capturing fine details with up to 50 per cent less ink.

Colors no longer need pinning, delivering significant savings in the time required for printing, as well as reductions in energy and material use. Overall, the speed of production can be more than doubled, making inkjet printing a greater reality for a much wider variety of decorative applications.

Commenting on the exhibition, Karl Forbes said, “drupa is the perfect show for visitors to hear how Xaar’s inkjet technology is enabling the development of new fluids and providing access to the many potential benefits of digital printing.

“From UV inks requiring less curing energy to aqueous inks containing high pigment loading and a lower ratio of water, inkjet is now able to deliver the performance, sustainability and innovation demanded, rewriting the rulebook for textile printing and many other applications.”

0 notes

Text

Sustainable e-textiles: Biodegradable wearables can monitor health and reduce waste

A research team led by the University of Southampton and UWE Bristol has shown wearable electronic textiles (e-textiles) can be both sustainable and biodegradable. The study, which also involved the universities of Exeter, Cambridge, Leeds and Bath, describes and tests a new sustainable approach for fully inkjet-printed, eco-friendly e-textiles named "Smart, Wearable, and Eco-friendly Electronic Textiles," or "SWEET." Their findings are published in the journal Energy and Environmental Materials. E-textiles are those with embedded electrical components, such as sensors, batteries or lights. They might be used in fashion, for performance sportswear, or for medical purposes as garments that monitor people's vital signs.

Read more.

#Materials Science#Science#Textiles#Electronics#Wearable technology#Medical technology#University of Southampton

6 notes

·

View notes

Text

DTF Transfer Printing for Beginners: A Comprehensive Guide to Printing DTF Transfers at Home

As custom apparel and personalized items continue to gain popularity, creative enthusiasts are looking for efficient and affordable ways to produce high-quality prints from the comfort of their homes. Direct-to-Film (DTF) transfer printing has emerged as an accessible and versatile method for producing vibrant designs on various surfaces, especially textiles. DTF printing offers the advantage of application on a range of materials while maintaining exceptional color fidelity and detail. This article will introduce beginners to the DTF printers printing process, the equipment and materials needed, step-by-step instructions for printing transfers at home, tips for successful application, and the benefits of incorporating DTF printing into your crafting repertoire.

Understanding DTF Transfer Printing

DTF transfer printing is a relatively new technology that combines elements from both Direct-to-Garment (DTG) and traditional heat transfer methods. DTF printing involves printing designs onto a special film using specific inks that offer excellent adhesion and durability. The printed film is then coated with a layer of adhesive powder, which, when heated, bonds securely to the fabric. This process differentiates DTF from other transfer methods, providing vibrant prints, the ability to work with a wide variety of fabrics, and ease of application. For beginners, understanding the mechanics of DTF printing is essential for achieving high-quality results and exploring the potential of this versatile printing method.

Equipment and Materials Needed

To embark on your DTF printing journey, you'll need a collection of essential equipment and materials. The primary equipment required is a DTF printer, specifically an inkjet printer that can accommodate DTF transfer films. You’ll also need DTF inks, which are specifically formulated for this printing process, along with adhesive powder that helps form a strong bond between the transfer and fabric. Other necessary items include DTF transfer film, heat press, a weeding tool for removing excess film, and protective sheets to place between the fabric and heat press for safe application. While it may seem like a considerable investment upfront, many of these items can be purchased gradually as you become more comfortable with the process.

Step-by-Step Process for Printing DTF Transfers

Once you have gathered the necessary equipment and materials, the process of printing DTF transfers can begin.

1. Design Creation: Start by creating your design using graphic design software (like Adobe Illustrator or CorelDRAW) or purchasing premade designs. Ensure your design is in a compatible format and sized appropriately for your project.

2. Printing: Load the DTF transfer film into your printer. Print your design, ensuring to set it for "mirror" mode so that the image transfers correctly when applied to the fabric.

3. Adhesive Application: Once printed, sprinkle the adhesive powder evenly onto the wet ink immediately after printing. Gently shake off any excess powder.

4. Curing: Use a heat source, such as a heat press, to cure the transfer. This generally involves setting the heat press to a specific temperature (around 160-180°C) and applying even pressure for roughly 20-30 seconds. This step helps melt the adhesive powder into the print.

5. Weeding: Allow the transfer to cool, then weed out the unwanted areas of the film using a weeding tool, leaving you with your desired design.

6. Pressing on Fabric: Place your fabric on the heat press, position the transfer film (ink side down), apply the heat press again for another 10-15 seconds, and then let it cool before peeling off the film backing.

Tips for Successful DTF Transfers

To achieve the best results with DTF transfer printing, several tips can help ensure success. Begin by investing time in acclimating yourself to the equipment and practicing with various designs and fabrics. Experiment with different print settings, as printing at the right resolution and using suitable profiles for DTF printing can significantly influence the final output. It's also important to use high-quality DTF films and inks, as these will directly affect the vibrancy and durability of your prints. Lastly, always remember to conduct washing tests on fabric after the initial applications; this will provide insight into the longevity and durability of your DTF transfers and help you adjust your processes accordingly.

Benefits of DTF Printing for DIY Enthusiasts

For those interested in custom apparel, DTF transfer printing offers multiple benefits. One significant advantage is its versatility; DTF printing can be applied to a wide range of fabrics, including cotton, polyester, and blends. This flexibility enables crafters to experiment with different materials and styles without being restricted to specific substrates. Additionally, DTF transfers deliver vibrant colors and intricate details, making them ideal for creating striking designs on clothing. The process is also relatively straightforward compared to other printing methods, often requiring less upfront investment and offering rapid turnaround times for small batch production. Overall, DTF printing not only encourages creativity but also offers an efficient way to produce high-quality custom items.

Final Thought

In summary, DTF transfer printing provides an exciting opportunity for beginners and craft enthusiasts to produce professional-quality prints from home. By understanding the mechanics behind the process, gathering the right equipment, and following the steps outlined, you can start your venture into the world of custom printing today. Embrace the versatility and ease of DTF printing to create personalized apparel and accessories that reflect your unique style. As you gain experience and confidence, your creative possibilities will expand, allowing you to explore the full potential of DTF transfer printing. So grab your supplies, start experimenting, and watch your designs come to life through this innovative medium!

6 notes

·

View notes

Text

"Eco-solvent inks in 2024: sustainability and high quality change the printing industry"

In an era where environmental concerns are at the forefront, the emergence of eco-solvent ink represents a significant milestone in the printing industry.

Unlike its counterparts, UV and water-based inks, eco-solvent ink is a composition of non-toxic solvents and natural pigments.

Please take note: a remarkable 50% of its components derive from renewable resources. With a minimal volatile organic compound (VOC) content, this ink is virtually odorless.

The Birth of Eco-Solvent Ink:

Since the advent of inkjet printers in the 1990s, the ink industry has grappled with toxicity, irritation, and high pollution.

However, through three generations of technological evolution and the relentless efforts of scientists, the printing world has been introduced to a game-changer – the non-toxic, non-irritating, and odorless eco-solvent ink. It signifies the industry's definitive break from the stigma of high pollution associated with traditional printing practices.

Cost Control and Print Quality of Eco-Solvent Ink:

The high cost of traditional inks has long been a bone of contention in the printing industry. Eco-solvent ink has opened a window of opportunity, epitomized by the phrase “a long slope with thick snow.” The substantial investment required yields a steady and stable return. Boasting excellent adhesion and vibrant color, eco-solvent ink has solidified its position in an era where print quality is a critical differentiator.

Applications of Eco-Solvent Ink:

A chasm exists between traditional inks and eco-solvent inks in the industry. The market for eco-solvent inks spans a wide range, from outdoor billboards to textile banners and car stickers, showcasing its boundless adaptability. It also defines the contours of modern printing practices:

Indoor and outdoor advertising and signage printing Automobile body stickers and wraps Industrial labeling and packaging printing Textile and eco-friendly fabric printing

Amidst the daunting challenges, from increasingly stringent regulations to technological iterations, our company, Panjet(https://www.pan-jet.com/), remains committed to the path of green and sustainable development. We stand as your provider of high-quality printing ink solutions.

3 notes

·

View notes

Text

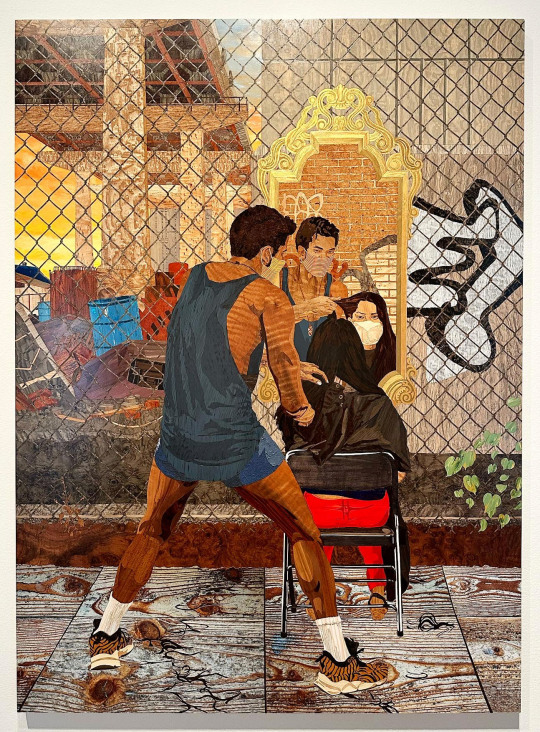

(Alison Elizabeth Taylor, “Anthony Cuts under the Williamsburg Bridge, Morning”, 2020 Marquetry hybrid (wood veneers, oil paint, acrylic paint, inkjet prints, shellac, and sawdust on wood)

Currently at Orlando Museum of Art is The Outwin: American Portraiture Today, an impressive collection of work in a variety of mediums.

From the museum’s website-

Launched in 2006 to support the next wave of contemporary portraiture in the United States, the National Portrait Gallery’s celebrated triennial Outwin Boochever Portrait Competition is a major survey of the best American portraiture selected by internationally prominent jurors and curators. Now in its sixth edition, The Outwin: American Portraiture Today presents 42 works selected from over 2,700 entries, that foreground the vibrancy and relevance of portraiture today. In addition to paintings, photographs, drawings, and sculptures, The Outwin includes video, performance art, and textiles, highlighting the limitless possibilities of contemporary portraiture.

Open to both emerging and established artists, this year’s entrants were encouraged to submit work that moves beyond traditional definitions of portraiture, and to explore a portrait’s ability to engage with the social and political landscape of our time. The variety of media and subjects featured in the exhibition invite audiences of all backgrounds to find relation in the human experience.

Since its inception, finalists for the exhibition have been determined by a panel of jurors including three Portrait Gallery staff members and four external professionals (critics, art historians, artists). The competition is endowed by and named for Virginia Outwin Boochever (1920 – 2005) who, for 19 years, volunteered as a docent at the Portrait Gallery. Her commitment to advancing the art of portraiture is continued through the support of her children.

Below are a selection of works from the show and information about them from the museum.

Alison Elizabeth Taylor– Anthony Cuts under the Williamsburg Bridge, Morning, 2020 (pictured above)

On walks around her Brooklyn neighborhood during the COVID-19 lockdowns, Alison Elizabeth Taylor encountered the hair groomer Anthony Payne, who,with his workplace shuttered, had taken his scissors, mirror, and chair to the streets. Payne sought to financially support the Black Lives Matter movement, especially in the aftermath of George Floyd’s murder, and turned over proceeds from his donation-based haircuts to organizations advocating for social justice.

Taylor’s process, one she developed and named “marquetry hybrid,” incorporates vivid paints, inkjet prints, and the natural grains of over one hundred veneers. Marquetry, with its inlaid combination of woods, can “memorialize,” Taylor notes. She acknowledges the history of the craft, which was favored by Louis XIV (1654-1715) when he was acquiring furniture for Versailles. By giving Payne this “royal treatment,” Taylor aims to pay tribute to him. ”I want him to see how much his example meant to me,” she explained.

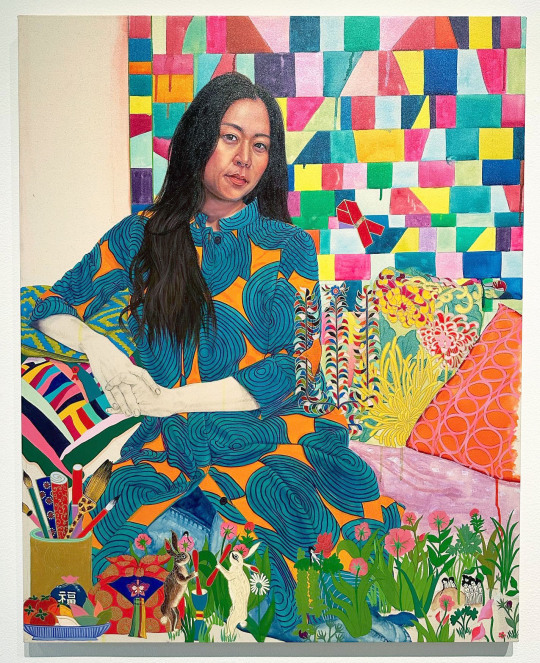

Kira Nam Greene– Kyung’s Gift in Pojagi (From the series “Women in Possession of Good Fortune”), 2019, Oil, gouache, colored pencil, and acrylic ink on canvas

In this mixed-media work, by Kira Nam Greene, the artist Kyung Jeon faces us with relaxed self-assurance. She is carefully positioned on her couch as her long black hair falls over her orange and turquoise tunic. In the foreground, a wooden cylinder containing paint brushes reveals her medium of choice. A plate with persimmons, consumed during the harvest festival Chuseok to celebrate good fortune, brims with potential while the rest of the painting pulsates with action.

Greene situates her friend in a fantasy world that echoes Jeon’s artwork and their mutual interest in the traditional Korean fabric quilting technique of pojagi. Two rabbits, representing Jeon’s Chinese zodiac, appear to be concocting a potion. Flowers sprout as kaleidoscopic patterns envelop her. The reference to pojagi, the visible paint drips in the background painting, and the hands of the sitter- left unfinished- invoke the role of tradition, process, and exploration in artmaking.

Stuart Robertson– Self Portrait of the Artist from the Out and Bad series, 2020, Aluminum, earth, acrylic paint, enamel, paper,metallic bubble wrap, sequins, and gold foil on wood

“In my world, skin is high-tech, amorphous, and armored,” the artist Stuart Robertson observes. “Blackness is percussive, lustrous, flexible, and indestructible.” Self-Portrait of the Artist depicts a fragment of a man- half of his face and his upper torso-shiny and monumental. A black beard delineates his jaw, and a small gold hoop adorns his ear. Although the figure is cropped beyond recognition, the work’s title provides a clue.

Through the alternation of flat and repoussé aluminum sheets, Robertson achieves a hypnotic effect, a poignant tension playing on what he reveals or hides from us viewers. His refusal to depict his entire face or figure challenges the notion of what a portrait should be and blocks the objectification of the Black male body, so often sexualized in visual culture. Simultaneously, Robertson delivers an irrepressible, resplendent image of that body, one inspired by the aesthetics of Jamaica’s dancehall culture.

Vincent Valdez– People of the Sun (Grandma and Grandpa Santana), 2019, Oil on canvas

An elderly couple faces us with the gentle authority that old age provides. People of the Sun (Grandma and Grandpa Santana) is a portrait of Vincent Valdez’s maternal grandparents. “My grandparents spent most of their time outside,” the artist recalled. “Grandpa spent his entire life working under the blazing Texas sun as a carpenter and yard worker, cutting lawns in the wealthy communities of San Antonio right up until he passed away. Grandma was constantly working with her hands–raising kids, washing, sewing clothes, and tending the plants in her yard.”

The Santanas are depicted in a space defined by details the artist remembers: their vintage AM radio, their plants, their homemade clothes. The bedsheet, like the Virgen de Guadalupe’s aura, signals their spiritual role in the family. This portrait connects the pair to the Indigenous and mestizo cultures of the American Southwest, including the Aztec and Maya, who honored the sun.

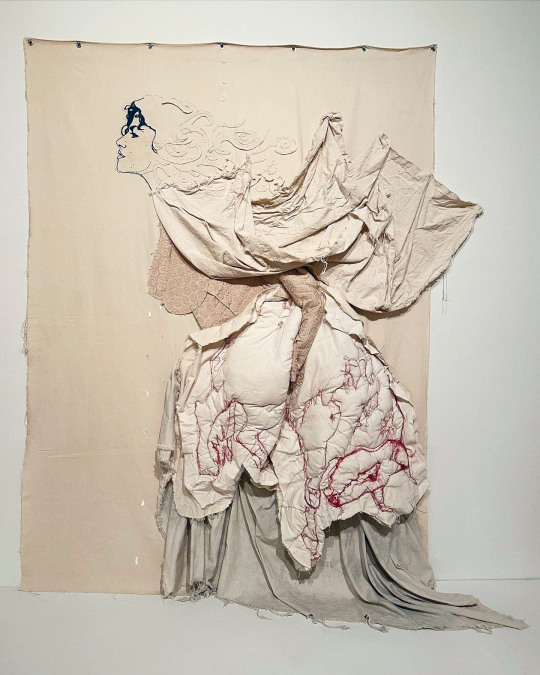

Elsa María Meléndez– Milk, 2020, Canvas with silkscreen, embroidery, ink, and other textiles

Elsa María Meléndez routinely crosses the boundaries between artistic mediums in large-scale artworks that command space and attention. Combining silkscreen, drawing, and various needlework techniques, Milk portrays the artist charging forward, determined. She carries a limp bull and advances while her breasts drip glistening drops of milk.

Created six months into the COVID-19 lockdown, this artwork encapsulates Meléndez’s reflection on the fight for gender equality in Puerto Rico. As people went into quarantine, gender violence escalated around the world. In Puerto Rico, where femicides increased substantially, feminist organizations took to the streets, demanding that the government declare a state of emergency. They received the scorn of substantial sectors of society, across gender lines. In response, Meléndez created Milk, an icon of indomitability that recognizes the strength of women and their life-sustaining force while acknowledging their willingness to nurse the beast that sustains patriarchy.

Timothy Lee– A portrait of the comet boy as a bearer of memories, 2019, Silk, heat-transfer ink, gold leaf, and oil on canvas

In his practice, Timothy Lee investigates his struggles with anxiety, which he feels stem from his Asian American, queer, immigrant, and diasporic identities. Yet, while drawing from his personal narratives more broadly, Lee also attends to the disquieting complexities that are intrinsic to growing up as part of two cultures.

The ironic figure of the “comet boy,” visualized here as if emerging from a halo, is both an embrace of and a departure from the artist’s past. The dynamic interplay of light, shadow, and texture evince the layered nature of Lee’s inquiry. A keen attention to materials and precision, as evidenced by the incised cuts throughout much of the work’s surface, allude to the artist’s earlier scientific training. Snapshots of the artist’s childhood in South Korea emblazon the comet boy’s body. Memories, and with them the past, become part of the flesh, like tattoos.

Clarissa Bonet– Glimpse, 2019 from the City Space series, Inkjet print

The discovery of a figure amongst a grid of windows and vertical blinds conjures the disorienting situation of coming upon an unknown face peeking through a window. With that chance encounter comes the recognition that one is being watched, possibly even surveilled. Glimpse is part of a series that explores urban life, specifically the relationship between private and public spaces and the daily experiences of those traversing these areas, including those of the artist.

Though made before the COVID-19 pandemic lockdowns, for Clarissa Bonet, this photograph brings to mind the recent state of being “isolated from the public spaces we all used to enjoy freely.” The unidentified woman may be looking onto an unknown subject left out of the composition, or onto nothing at all.

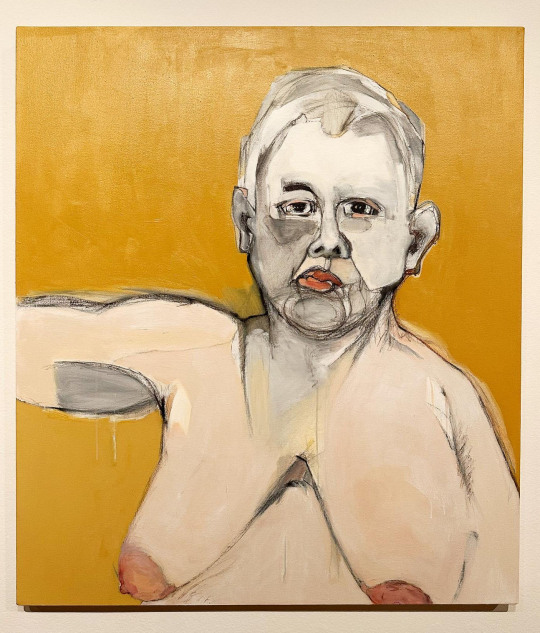

Ilene Spiewak– Deeper into the Isolation of Self Information and Gender, 2020, Acrylic paint and charcoal on canvas

For over fifty years, Ilene Spiewak has focused on the relations between color and visual space, painting at the edge of representation and abstraction. The introspection and solitude brought by the pandemic made her compositions more sparse and her palette more restrained. “I realized what I had in my studio was myself always. . .. I began to insert myself in my paintings more than I was conscious of in the past.”

In this self-portrait, Spiewak outlines her silhouette in charcoal. Her face and nude torso are rendered in soft shades of white, pink, and gray that push against the yellow background. With frankness, she paints her aging body, countering centuries of idealized, youthful, slender female nudes in art. By placing her figure off-center on the picture plane, with her right arm extended but truncated, Spiewak subtly allows us into the intimate act of observing and painting herself.

Inga Guzyte– Cutting Edge, 2020, from the Kindred Spirits series, wood and used skateboards

Inga Guzyte recycles old skateboards, sawing and reassembling them into new sculptural configurations. Cutting Edge, a portrait of Alison Saar, is from Guzyte’s series “Kindred Spirits.” which honors women who have made their mark in the art world. The ethos of bravery and independence that is part of skateboard culture conveys the tenacity and perseverance of Guzyte’s role models.

Aptly made from reclaimed wood, a recurrent material in Saar’s sculptures and installations, this portrait stands between painting and sculpture. Saar’s expression evokes her fierceness and commitment to her practice. Her headdress points to her Afro-diasporic background, while its dynamic red and orange twists suggest her fiery creative energy. Like a flame, the headwrap attracts a multitude of moths, which recur in Saar’s work to signify a go- between for the real world and the spiritual world.

This exhibition is on view until 10/8/23.

#Orlando Museum of Art#The Outwin#Florida Art Shows#Art Shows#Outwin Boochever Portrait Competition#Alison Elizabeth Taylor#Art#National Portrait Gallery#Timothy Lee#Stuart Robertson#Art Installation#Clarissa Bonet#Elsa María Meléndez#Vincent Valdez#Fiber Art#Fiber Arts#Ilene Spiewak#Inga Guzyte#Kira Nam Greene#MIxed Media Art#Mixed Media Photography#Orlando Art Shows#Outwin 2022#Painting#Photography#Portrait#Portraits#Portraiture#Sculpture#Triennial

4 notes

·

View notes

Photo

FILM POSITIVES 👉 http://ow.ly/UK1v308KbeU 👈👀❤️😍😉 #Inkjet & #LaserJet A4 & A3 100per box & 30m Rolls 432 & 610mm wide #Screenprinting #Tshirts #Posters Micro-porous aqueous coated translucent #Inkjet film, specially developed for producing high quality positives, negatives and colour separations. Instant dry with good water resistance. Our film offers excellent dimensional stability and high HV density. ALSO Double matt translucent polyester #Laserjet film. Antistatic treated, excellent for reproduction. High contrast visuals can be easily produced and further work added using drafting pens or pencils. Available in 0.100mm Both in A4 and A3 100 sheets per box And Micro-porous aqueous coated translucent inkjet film, specially developed for producing high quality positives, negatives and colour separations. Instant dry with good water resistance. Our film offers excellent dimensional stability and high HV density. Roll: 432 mm wide x 30mtr Roll: 610 mm wide x 30mtr Price Online http://www.screenstretch.co.uk/inkjet-laserjet-films/ Ideal for all types of #Silkscreen #Textiles #Handmade #Illustration #Graphics #Merchandise #Merch #BandMerch #Apparel #FineArt #Printmaking #Signs #HandPulled #TShirtPrinting Screen Print Industry #ScreenprintingUK (at Screenstretch Ltd) https://www.instagram.com/p/Cr1hssmo773/?igshid=NGJjMDIxMWI=

#inkjet#laserjet#screenprinting#tshirts#posters#silkscreen#textiles#handmade#illustration#graphics#merchandise#merch#bandmerch#apparel#fineart#printmaking#signs#handpulled#tshirtprinting#screenprintinguk

2 notes

·

View notes

Link

0 notes

Text

Scientists Develop Biodegradable Smart Textile–A Big Leap Forward for Eco-Friendly Wearable Technology

Great potential here... 🌞

1 note

·

View note

Text

Sublimation Printing vs. Digital Textile Printing: Which is Right for You?

When it comes to textile printing, businesses and creatives are often faced with the choice between two popular methods: sublimation printing and digital textile printing. Each of these techniques offers unique advantages, and understanding which one suits your needs can make a significant difference in your production process. At True Colors Group, we specialize in helping you navigate the world of textile printing, ensuring that your products meet the highest standards of quality.

In this article, we’ll explore the key differences between sublimation printing and digital textile printing to help you decide which method is best for your next project.

What is Sublimation Printing?

Sublimation printing is a process where heat is used to transfer dye onto materials such as polyester fabric, ceramics, or metal. The dye changes from a solid to a gas and bonds with the fibers of the fabric, resulting in vibrant, long-lasting colors. This method works best on synthetic fabrics like polyester, which allows the dye to infuse deeply into the material.

Advantages of Sublimation Printing:

Vivid Colors: Sublimation creates vibrant, full-color prints that are hard to match with other methods.

Durability: Because the dye is embedded into the fibers, the prints are resistant to fading, cracking, or peeling, even after extensive washing.

No Feel: The print becomes part of the fabric, so there's no thick layer on top, giving the garment a smooth, soft feel.

At True Colors Group, we use state-of-the-art printing machines to deliver high-quality sublimation prints that provide excellent color accuracy and exceptional durability.

What is Digital Textile Printing?

Digital textile printing, on the other hand, uses inkjet technology to apply water-based inks directly onto fabric. This method works on both natural and synthetic fabrics, giving it a broader range of applications than sublimation. With digital textile printing, the fabric is printed with the ink directly onto its surface, allowing for intricate designs and smaller production runs.

Advantages of Digital Textile Printing:

Versatility: Digital textile printing can be used on a wider variety of fabrics, including cotton, linen, and silk, in addition to polyester.

High Detail: This technique allows for printing complex, detailed images with fine lines and vibrant colors.

Eco-Friendly: Water-based inks used in digital textile printing are generally more environmentally friendly, reducing harmful emissions and chemical waste.

Digital textile printing has become a go-to choice for custom fabrics, making it a perfect solution for everything from fashion design to home décor. At True Colors Group, we offer cutting-edge digital textile printing that ensures precise, high-quality results.

Key Differences Between Sublimation and Digital Textile Printing

Fabric Type: Sublimation works best on synthetic fabrics like polyester, whereas digital textile printing can be used on a broader range of natural and synthetic materials.

Color Quality: Sublimation typically produces brighter and more vibrant colors, while digital textile printing excels at reproducing intricate designs and fine details.

Durability: Sublimation prints are more durable and resistant to fading, while digital prints may require more careful handling to ensure longevity.

Cost-Effectiveness: Sublimation printing tends to be more cost-effective for larger production runs, while digital textile printing can be more economical for smaller, custom batches.

Which Printing Method is Right for You?

The choice between sublimation printing and digital textile printing depends largely on your specific needs and the type of product you're creating. If you're looking for vibrant prints on polyester fabrics and need a durable, long-lasting result, sublimation is the way to go. However, if you need to print on a variety of fabrics or require fine details and intricate designs, digital textile printing may be the better option.

At True Colors Group, we pride ourselves on offering both sublimation printing and digital textile printing solutions. Whether you're producing custom apparel, home textiles, or promotional products, we have the expertise and the printing machines to bring your vision to life.

Conclusion

Both sublimation printing and digital textile printing have their unique strengths, and the choice between the two will depend on your project’s requirements. With True Colors Group, you can be confident that we’ll help you select the right method to achieve the best results, no matter what type of textile you're working with.

0 notes

Text

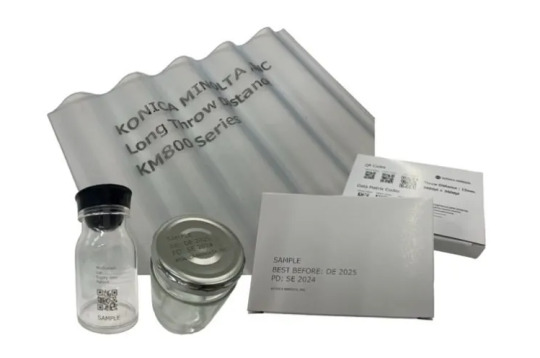

Konica Minolta launches KM800H-MR industrial inkjet printhead

Konica Minolta has launched the KM800H-MR, which supports various inks with an internal heater, as a new product of the industrial inkjet printhead KM800 series featuring a long throw distance.

In the logistics industry, there is growing need for higher productivity due to an increase in cargo volumes. Compared to the method of attaching printed labels, direct printing using inkjet technology on industrial products, such as metals and wood, and other target objects, such as pharmaceuticals, food packaging, and corrugated cardboard, can increase the efficiency by reducing the downtime due to replacement of label rolls, and contributes to a lower environmental impact by reducing waste.

Inkjet printing is also characterized by ease of design changes and production adjustments because the information to be printed can be changed flexibly. It is applicable to small lots, helping reduce inventory losses. Notably, piezo inkjet is suitable for high-resolution printing in small areas and printing of complex designs, such as 2D barcodes, because of its printing capabilities and high image quality.

Konica Minolta has been working on 'Improving fulfillment in work and corporate dynamism,' 'Addressing climate change,' and 'Using limited resources effectively' as its material issues through expansion of the inkjet printhead business, which contributes to higher efficiency of work processes and a lower environmental impact. Because this business can help reduce processes and handle small lots through direct printing on target objects in the logistics industry, Konica Minolta will further strengthen its capabilities to make proposals that contribute to higher productivity.

Values provided by the KM800H-MR

The KM800 series is characterized by long throw distance performance, which enables printing with high image quality on target objects 20 mm away from the printhead, and the ink jetting stability. The long throw distance enables printing even on base materials where the distance from the nozzles to the printing surface varies, such as curved and rough surfaces. The distance between printhead and material should be enough to reduce the chance of head strike or material collision with the printhead.

Equipped with an internal heater, the KM800H-MR achieves a long throw distance even for UV inks, which are more viscous than water-based inks at normal temperature. The ability to support UV inks enables printing on non-absorbing base materials, such as plastics, films, and paper containers, expanding the coding and marking applications to bottles, packages, pharmaceutical packaging, and medical supplies.

Inkjet jetting technology of KM800 Series

High-resolution printing on curved and rough surfaces realized by superb long throw distance performance

In general, the throw distance is about 1 mm to 3 mm. The greater the distance, the lower the likelihood of inks being placed accurately on positions, resulting in low image quality. Konica Minolta’s long throw distance technology realizes excellent high-resolution printing of 2D barcodes and other designs even when the nozzles and target object are 20 mm apart. It is also suitable for textile printing because the distance between the printhead and the printing surface can be maintained to avoid interference by fuzz. It is also expected to be applied to DTS for direct printing on three-dimensional objects because the narrow width between nozzle rows enhances the printing performance on curved and rough surfaces.

Usability in various usage environments by vertical placement and color printing

In general, an inkjet printhead is placed horizontally to print in the direction perpendicular to the target object. When printing on the side of a target object in the transfer process, it is desirable to place an inkjet printhead vertically in some cases. However, vertical placement causes the jetting characteristics to vary between nozzles in the upper positions and those in the lower positions, resulting in lower image quality. The KM800 series can perform printing while maintaining the image quality through stable ink jetting even in the vertical placement by applying Konica Minolta’s nano-fabrication and driving technologies. The inkjet printhead also supports color printing and can be used for various applications, including embellishment. The series also features a compact product design to facilitate installation in printing equipment.

0 notes

Link

0 notes

Text

Digital Printing Market

Digital Printing Market Size, Share, Trends: HP Inc. Leads

Sustainable Printing Solutions Gain Traction as Eco-Conscious Consumers Drive Demand for Greener Alternatives

Market Overview:

The global digital printing market is rapidly expanding, projected to grow at a CAGR of 6.2% from 2024 to 2031, reaching USD 35.7 billion by 2031. Asia-Pacific dominates the market due to increasing adoption in textile and packaging industries, rising demand for personalized products, and a growing e-commerce sector. The industry is shifting from traditional printing technologies to digital alternatives, driven by technological advancements, demand for eco-friendly solutions, and the rise of on-demand printing. Key drivers include the need for reduced contamination risk, lower capital investment, and faster setup times.

DOWNLOAD FREE SAMPLE

Market Trends:

Sustainable printing solutions are gaining traction as eco-conscious consumers drive demand for greener alternatives. Companies are investing in environmentally friendly inks, energy-efficient printers, and recyclable substrates to lower their carbon footprints. For instance, HP Inc.'s Latex R Series printers use water-based inks to produce odorless prints with reduced environmental impact. This trend is further supported by the rising demand for sustainable packaging solutions in the e-commerce sector.

Market Segmentation:

Inkjet technology dominates the digital printing market, accounting for over a significant share of the global market. Its versatility, cost-effectiveness, and ability to print on various substrates have made it the preferred choice in multiple industries. Inkjet technology has seen significant advancements in print quality, speed, and color accuracy, expanding its applications to textiles, ceramics, and even 3-D printing. The commercial printing industry benefits from inkjet's capability to handle print-on-demand services, reducing inventory costs while offering a wide range of titles. Its growing popularity in the packaging industry, particularly for producing high-quality, personalized labels and packaging, further strengthens its market dominance.

Market Key Players:

The digital printing market is fiercely competitive, with several key players driving innovation and growth. Leading companies include:

HP Inc.

Canon Inc.

Xerox Corporation

Konica Minolta, Inc.

Ricoh Company, Ltd.

EFI, Inc.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Inkjet Printer Market Revenue Trends and Growth Drivers Global Forecast To 2030

The inkjet printer market is a significant segment of the global printing industry, known for its versatility, cost efficiency, and ability to produce high-quality outputs.

Inkjet printers use fine nozzles to spray ink droplets directly onto substrates, enabling detailed and vibrant prints. These printers cater to various applications, from office and home use to industrial printing, packaging, textiles, and electronics. The market’s growth is driven by increasing demand for customized and on-demand printing solutions across diverse industries, coupled with ongoing innovations in printhead technology and ink formulation.

0 notes

Text

Printed Electronics: Revolutionizing Modern Technology

The world of electronics is undergoing a paradigm shift with the advent of printed electronics. Unlike traditional methods of manufacturing electronic circuits, this innovative technology relies on printing techniques to fabricate devices on a variety of surfaces. The result? A cost-effective, versatile, and sustainable way to produce electronic components. As industries continue to explore its potential, printed electronics is proving to be a game-changer, unlocking possibilities that were once deemed impossible.

What Are Printed Electronics?

Printed electronics refer to a set of processes where conductive, dielectric, and semiconducting inks are printed onto substrates such as plastic, glass, paper, or even textiles. Using techniques like screen printing, inkjet printing, gravure, and flexographic printing, electronic circuits are created with precision and efficiency. This process eliminates the need for complex and expensive manufacturing setups traditionally associated with electronics production.

The versatility of printed electronics lies in its ability to accommodate flexible substrates. This has given rise to a new class of electronics that are lightweight, bendable, and even wearable. From smart packaging to flexible displays, the applications of this technology are growing exponentially.

Advantages of Printed Electronics

The shift towards printed electronics is driven by several key advantages:

Cost-Efficiency: Traditional circuit manufacturing involves high costs due to expensive raw materials and labor-intensive processes. Printed electronics, however, utilize less material and faster production methods, leading to significant cost savings.

Design Flexibility: With printed electronics, manufacturers can design circuits on unconventional surfaces, opening new avenues for product innovation.

Scalability: Printing processes are inherently scalable, making it easier to transition from prototyping to mass production without substantial changes in infrastructure.

Sustainability: The use of eco-friendly inks and minimal material wastage aligns printed electronics with sustainable manufacturing practices.

Printed Electronics Applications

The real potential of printed electronics lies in its diverse applications across various industries. Below are some of the most transformative examples:

Healthcare: Printed electronics have made a significant impact on the healthcare sector. Flexible sensors, wearable medical devices, and disposable diagnostic tools are just a few examples where this technology is driving advancements.

Automotive: Modern vehicles integrate printed electronics in the form of sensors, touch controls, and even in-mold electronics to enhance functionality and aesthetics.

Consumer Electronics: Flexible screens, foldable smartphones, and smart clothing are increasingly leveraging printed electronics for their unique properties.

Energy Solutions: Solar cells, printed batteries, and energy-harvesting devices are gaining traction as sustainable energy solutions enabled by printed electronics.

Smart Packaging: Interactive packaging solutions equipped with NFC or RFID tags are transforming the retail and logistics industries.

These applications highlight the versatility of printed electronics, making it a preferred choice for industries looking to innovate and stay competitive.

The Role of Printed Electronics Manufacturers

As the demand for printed electronics continues to surge, the role of a printed electronics manufacturer becomes more pivotal than ever. These manufacturers are at the forefront of innovation, combining expertise in material science, engineering, and design to develop reliable and high-performing printed electronics.

Manufacturers must also stay abreast of the latest developments in conductive inks, substrate materials, and printing techniques. This enables them to create products that meet the growing demand for customization and performance. Additionally, partnerships with research institutions and technology firms help manufacturers push the boundaries of what is possible with printed electronics.

Challenges in Printed Electronics

Despite its promise, the journey of printed electronics is not without challenges. Ensuring the durability and reliability of printed circuits, especially in harsh environments, remains a key concern. Furthermore, the development of advanced inks with higher conductivity and compatibility with various substrates is an area of ongoing research.

Another challenge is the integration of printed electronics into existing manufacturing ecosystems. While the technology is inherently flexible, aligning it with traditional processes requires significant adjustments and investments.

Future of Printed Electronics

The future of printed electronics is incredibly bright. With advancements in nanomaterials, conductive inks, and high-resolution printing techniques, the scope for innovation is immense. Experts predict that printed electronics will play a vital role in the proliferation of the Internet of Things (IoT), smart cities, and next-generation consumer electronics.

Moreover, as industries adopt sustainable practices, the eco-friendly nature of printed electronics will make it a cornerstone of green manufacturing. Its ability to reduce material wastage and enable energy-efficient production processes positions it as a technology for the future.

Cutek Circuits: A Pioneer in Innovation

As industries evolve, embracing innovative technologies like printed electronics becomes imperative. Companies like Cutek Circuits have recognized the immense potential of this technology and are leading the way in delivering cutting-edge solutions. By leveraging expertise in design, manufacturing, and material science, Cutek Circuits is committed to providing high-quality products tailored to meet the unique needs of its clients. Whether it’s exploring printed electronics applications or advancing manufacturing techniques, Cutek Circuits is shaping the future of technology with unwavering dedication. In conclusion, printed electronics represents a groundbreaking shift in how electronic devices are designed and manufactured. Its vast potential across industries ensures that it will remain a critical area of innovation and investment in the years to come.

0 notes

Text

Mastering DTG Printing: A Step-by-Step Guide to Modern Apparel Design

Direct-to-Garment (DTG) printing has become a game-changer in the world of custom clothing, enabling designers and businesses to create vibrant, high-quality apparel with ease. By directly applying ink to textiles using advanced inkjet technology, DTG eliminates the limitations of traditional methods like screen printing. Whether you’re a small business owner, a hobbyist, or a designer exploring modern printing techniques, this guide will provide a step-by-step approach to mastering DTG printing.

What is DTG Printing?

DTG printing involves using a specialized inkjet printer to apply water-based inks directly onto fabric. This method supports detailed, full-color designs, making it ideal for custom apparel. Unlike screen printing, which requires separate screens for each color, DTG printing simplifies the process by digitally transferring designs to garments. It’s especially suited for small batches or on-demand orders, providing unparalleled flexibility and efficiency.

Benefits of DTG Printing

High-Quality Prints

DTG printing delivers detailed, vibrant prints that capture intricate designs and photo-realistic images. It allows for unlimited colors and gradients, ensuring artistic freedom.

Cost-Effective for Small Orders

Since DTG has minimal setup requirements, it’s a cost-effective solution for small runs or even single-item production. This makes it perfect for businesses offering personalized or on-demand apparel.

Eco-Friendly Solution

DTG uses water-based inks that are free of harmful chemicals, making it a more sustainable alternative to plastisol inks commonly used in screen printing.

Versatility

DTG works on a variety of textiles, including cotton and blended fabrics. It’s suitable for t-shirts, hoodies, tote bags, and other apparel types, offering creative flexibility.

Essential Tools and Materials

DTG Printer

Choose a reliable DTG printer like the Epson SureColor F2100 or the Brother GTX. These machines are designed for high-quality output and user-friendly operation.

Pretreatment Solution

Pretreatment is essential for vibrant and durable prints, especially on dark fabrics. You’ll need a pretreatment solution and a sprayer or pretreatment machine to apply it evenly.

Heat Press

A heat press is necessary for curing the ink and pretreatment, ensuring the print adheres properly to the fabric.

Garments

Select high-quality garments with a high cotton content, as DTG inks bond better with natural fibers.

Step-by-Step Guide to DTG Printing

Step 1: Design Creation

Prepare your design using graphic design software such as Adobe Illustrator or Photoshop. Ensure the resolution is at least 300 DPI for crisp and detailed prints. Export the design in a compatible format, like PNG, with a transparent background.

Step 2: Pretreatment Application

Apply a pretreatment solution to the garment if it’s a dark fabric. Use a pretreatment machine or a handheld sprayer for even application. The pretreatment helps the ink adhere better and enhances color vibrancy. After applying the solution, use a heat press to dry and flatten the fabric.

Step 3: Setting Up the DTG Printer

Load the garment onto the printer’s platen, ensuring it is flat and secure. Use the printer’s software to position your design on the garment and adjust settings like resolution and color profiles.

Step 4: Printing the Design

Start the printing process. The printer will apply ink directly onto the garment, layer by layer. Monitor the process to ensure everything runs smoothly.

Step 5: Curing the Print

Once printing is complete, use a heat press to cure the ink. This step is crucial for ensuring durability and washability. Follow the ink manufacturer’s recommended temperature and time settings for the best results.

Step 6: Quality Check

Inspect the final product for any imperfections or inconsistencies. Check the print’s durability by gently stretching the fabric or performing a quick wash test if necessary.

Tips for Success

Maintain Your Equipment

Regularly clean your DTG printer to prevent clogs and maintain print quality. Follow the manufacturer’s maintenance guidelines.

Experiment with Fabrics

While cotton is ideal for DTG, experimenting with blends or specialty fabrics can help you expand your product offerings.

Offer Customization

One of the biggest advantages of DTG printing is its ability to produce personalized apparel. Encourage customers to submit their designs or add custom text to boost engagement.

Conclusion

Mastering DTG printing opens a world of possibilities for modern apparel design. Its combination of precision, flexibility, and eco-friendliness makes it an invaluable tool for anyone in the custom clothing industry. By following the steps and tips outlined in this guide, you can create high-quality garments that meet the growing demand for unique and personalized fashion. Embrace the power of DTG printing and take your apparel business or creative projects to the next level.

0 notes

Text

FILM POSITIVES

➡️ http://ow.ly/UK1v308KbeU ⬅️😉

#Inkjet & #LaserJet A4 & A3 100per box & 30m Rolls 432 & 610mm wide #Screenprinting #Tshirts #Posters

Micro-porous aqueous coated translucent #Inkjet film, specially developed for producing high quality positives, negatives and colour separations.

Instant dry with good water resistance.

Our film offers excellent dimensional stability and high HV density.

ALSO

Double matt translucent polyester #Laserjet film. Antistatic treated, excellent for reproduction.

High contrast visuals can be easily produced and further work added using drafting pens or pencils.

Available in 0.100mm

Both in A4 and A3 100 sheets per box

And

Micro-porous aqueous coated translucent inkjet film, specially developed for producing high quality positives, negatives and colour separations.

Instant dry with good water resistance.

Our film offers excellent dimensional stability and high HV density.

Roll: 432 mm wide x 30mtr

Roll: 610 mm wide x 30mtr

Price Online

http://www.screenstretch.co.uk/inkjet-laserjet-films/

Ideal for all types of #Silkscreen #Textiles #Handmade #Illustration #Graphics #Merchandise #Merch #BandMerch #Apparel #FineArt #Printmaking #Signs #HandPulled #TShirtPrinting Screen Print Industry #ScreenprintingUK

#screenprinting#silkscreen#screenprintinguk#screenprint#merch#merchandise#apparel#tshirts#tshirtprinting#bandmerch

0 notes