#tensile strength

Explore tagged Tumblr posts

Text

Sun in Sagittarius II (12/2-12/2023)

Sagittarius II covers 2-12 December 2023 — the season of Kore, the girl-goddess sent to be Hades' bride in the underworld. When she returns in the spring, she's Persephone, powerful and frightening. What part of yourself is still afraid of the dark?

The Sun enters Sagittarius II on December 2, 2023 at 6:16 am EST. Austin Coppock called this decan The Bridle, while T. Susan Chang named it Tensile Strength for its associations with the Tarot card the 9 of Wands (a card that the Golden Dawn and its associated orders called The Lord of Strength. The Sun will be here until December 12. I wrote about Sagittarius II in 2019, 2020, 2021, and…

View On WordPress

#astrology#Lord of Strength#Sagittarius#sagittarius II#Sagittarius II 2023#Tensile Strength#The Bridle

3 notes

·

View notes

Text

Best Tensile Strength Tester in Delhi NCR – Buy Now

Why Choose LabZenix for the Best Tensile Strength Tester in Delhi NCR?

LabZenix has established itself as a leading manufacturer and supplier of tensile strength testers in Delhi NCR. Our machines are equipped with cutting-edge technology, ensuring precise and reliable results. Whether you are in the packaging, automotive, construction, or textile industry, our best tensile strength tester in Delhi NCR – buy now is the ideal choice for your testing needs.

#my writing#marketing#100 days of productivity#machine learning#commercial#tensile tester#tensile strength tester#tensile test#tensile strength#tensile structure manufacturer#tensile car parking#strength#wire test

0 notes

Text

#tensile strength#Tensile Strength Formula#Measuring Tensile Strength#Material Strength Test#Strength Testing Machine#Tensile Testing Equipment

0 notes

Text

How Tensile Strength Testing Affects Textile Production and Design Decisions?

In the world of textile manufacturing, one of the most critical factors influencing the durability and functionality of fabrics is tensile strength. Tensile strength is a measure of a fabric’s ability to resist breaking or stretching when subjected to tension. For textile manufacturers, understanding and testing tensile strength is vital for ensuring the quality and performance of their products, and it plays a significant role in various design and production decisions.

Tensile strength testing offers valuable insights into the fabric’s resistance to stress, which ultimately influences its application, aesthetics, and cost. In this blog, we will explore the importance of tensile strength testing in the textile industry and how it impacts key production and design decisions.

What is Tensile Strength in Textile?

Tensile strength in textiles refers to the maximum amount of force a fabric can withstand while being stretched before it breaks or deforms. This property is a crucial measure for evaluating the durability and performance of textiles under mechanical stress. The higher the tensile strength, the more resistant the fabric is to tears, rips, and stretching, making it ideal for applications where the material will undergo significant stress, such as in upholstery, industrial fabrics, and sportswear.

Tensile strength is typically expressed in units of force, such as pounds per inch (lb/in) or newtons per millimeter (N/mm). During testing, a sample of fabric is subjected to a controlled force to measure how much it can endure before it breaks, providing manufacturers with the data they need to make informed decisions during production and design.

Why is Tensile Strength Testing Important in Textile Production?

Tensile strength testing serves several key purposes in textile manufacturing. Here are some of the most significant reasons why it’s essential:

Ensures Durability and Longevity: Testing tensile strength helps manufacturers ensure that fabrics will last under normal wear and tear. Fabrics with higher tensile strength are less likely to rip, stretch, or lose their shape over time, which makes them ideal for durable products like outdoor gear and heavy-duty workwear.

Validates Quality Control: Tensile strength testing is an essential part of quality control in textile production. By subjecting fabrics to these tests, manufacturers can verify that their products meet the required standards for strength and performance, ensuring consistency across batches.

Determines Fabric Suitability: Not all fabrics are designed to withstand the same level of stress. By testing tensile strength, manufacturers can identify the appropriate applications for each textile. For example, lightweight fabrics may not have the tensile strength required for heavy-duty applications, while industrial textiles may require high tensile strength to resist wear and tear.

Supports Compliance with Standards: Tensile strength testing is often required to meet industry regulations and standards. Whether it's for garments, automotive textiles, or medical fabrics, manufacturers must ensure their products comply with safety and durability regulations.

How Tensile Strength Testing Impacts Design Decisions

Tensile strength testing provides designers with invaluable insights that help shape the direction of their creative processes. Here's how tensile strength testing affects key design decisions:

1. Fabric Selection and Material Innovation

One of the first decisions that designers make is choosing the right material for a particular project. Tensile strength testing allows designers to assess how various materials perform under stress and determine which fabric is best suited for a specific design.

For example, a designer working on a collection of outdoor sportswear will need fabrics with high tensile strength to withstand the rigors of physical activity. In contrast, a designer creating soft, luxurious fabrics for evening wear may prioritize other attributes, such as softness and drape, over tensile strength. By testing tensile strength, designers can choose the most appropriate material based on the fabric's durability and suitability for the intended use.

Innovations in materials also rely heavily on tensile strength testing. Textile engineers may develop new fibers, yarns, or blends with enhanced tensile strength properties to meet the growing demand for durable and long-lasting textiles.

2. Weave and Knit Structures

The way fibers are arranged and interwoven in textiles has a significant impact on tensile strength. In woven fabrics, the tightness of the weave and the type of weave structure used influence the tensile strength of the fabric. Similarly, knitted fabrics, made by interlocking loops of yarn, have different tensile strengths depending on the knit pattern.

Tensile strength testing allows designers to understand how various weaving and knitting techniques affect the fabric's ability to resist tension. For example, a dense twill weave provides greater tensile strength compared to a loose plain weave, which may be more flexible but less durable. A designer may use this knowledge to decide which weave or knit pattern will best serve the intended purpose of the fabric.

3. Fiber Blending and Composition

In many cases, manufacturers use a blend of fibers to achieve the desired properties in a textile. The composition of these blends plays a critical role in tensile strength. For example, combining natural fibers like cotton with synthetic fibers such as polyester can result in a fabric that offers the softness of cotton with the durability and tensile strength of polyester.

By testing the tensile strength of various fiber combinations, designers can fine-tune fabric compositions to optimize their performance. This is especially important when creating textiles for specific applications, such as sportswear, work uniforms, or technical fabrics.

4. Performance Testing for Specialized Applications

Certain applications require fabrics with specific tensile strength characteristics to ensure performance. For example, fabrics used in automotive interiors, safety gear, or military uniforms need to be highly durable and resistant to stress and wear. In these cases, tensile strength testing helps ensure that the fabric will perform under the demanding conditions associated with the intended use.

In industries like aerospace, construction, or firefighting, fabrics must meet rigorous tensile strength standards to ensure they will not fail under stress. Designers can use tensile strength testing to develop specialized fabrics that meet the exact requirements for these high-performance applications.

5. Cost-Effective Design Choices

Tensile strength testing also has a significant impact on the cost-effectiveness of textile production. Fabrics that are more durable and require less maintenance can ultimately reduce costs over time. Designers and manufacturers who test the tensile strength of their materials are better equipped to choose fabrics that meet the desired performance standards without unnecessarily increasing production costs.

For example, using high tensile strength fabrics in garments designed for heavy-duty use can reduce the frequency of replacements, making them more cost-effective in the long run. On the other hand, using overly durable fabrics in fashion collections where soft and flexible materials are needed can lead to increased material costs without providing added value to the final product.

How Tensile Strength Testing Influences Production Decisions

In addition to design decisions, tensile strength testing significantly impacts production processes in the textile industry. Here’s how:

1. Optimizing Manufacturing Techniques

Tensile strength testing can reveal weaknesses in manufacturing processes that may affect fabric durability. For example, if a batch of fabric is found to have low tensile strength, manufacturers may need to adjust the weaving or knitting process, increase the twist in the yarn, or improve the quality of raw materials used in production. Regular tensile strength testing helps identify issues early in the production process, ensuring that corrective actions are taken before a large batch is produced.

2. Standardizing Quality Control

For manufacturers, tensile strength testing is a critical component of quality control. By conducting these tests regularly, manufacturers can ensure that their products consistently meet the required strength standards. This process helps reduce defects, returns, and customer dissatisfaction, leading to better brand reputation and customer loyalty.

Conclusion

Tensile strength testing is an indispensable part of the textile production and design process. It affects nearly every aspect of textile manufacturing, from the selection of materials and fibers to the choice of weaving or knitting techniques, and even the cost-effectiveness of the final product. By providing valuable insights into the durability and strength of fabrics, tensile strength testing enables manufacturers and designers to create high-performance textiles that meet the demands of consumers, regulatory standards, and specialized applications. Ultimately, tensile strength testing ensures that textile products are both functional and durable, delivering long-lasting value to customers.

#tensile strength in textile#tensile strength testing#tensile strength#testing lab near me#testing lab delhi

0 notes

Note

I was trying to explain this to my sister after I heard about the carbon fiber hull but it's been a long time since my physics classes so I had trouble finding the words. This is great.

Is spider silk being as strong as steel another lie from childhood? Bc you're able to break it pretty easily on accident. Genuinely asking.

spider silk IS actually significantly stronger pound-for-pound than the same amount of steel, but only in one direction! and coincidentally, it's the same exact direction that got a bunch of people killed in a submersible last month.

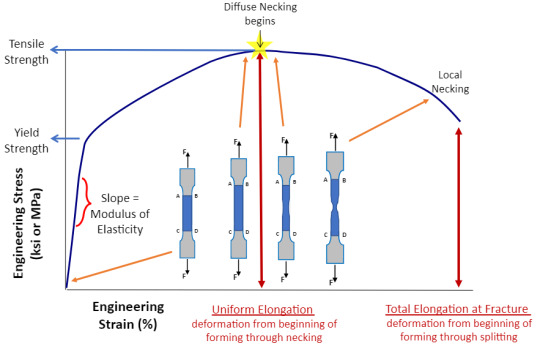

see, when people talk about the "strength" of spider silk versus steel, they're specifically talking about tensile strength:

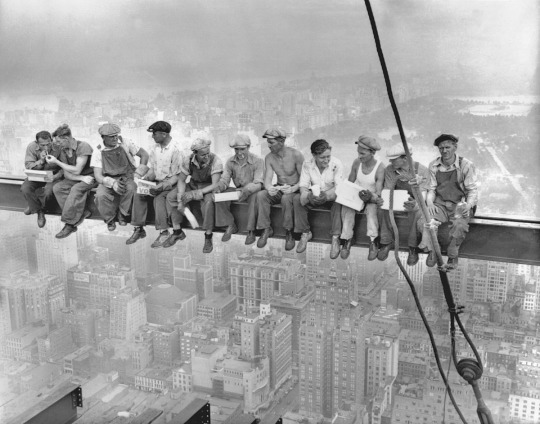

which is specifically the measure of the strength of a material when two forces are pulling at it from the ends, like when a steel cable is holding up a bridge support, or crane cargo:

or like when a strand of silk is supporting the entire spider.

that's tensile strength, baby!

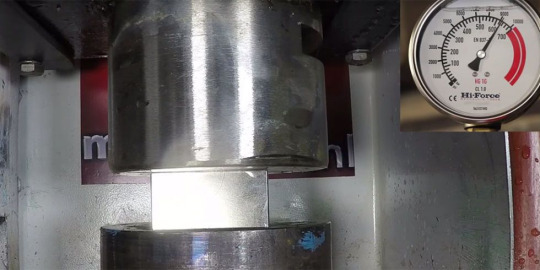

but there's another type of strength that's very important to take into consideration when you're actually building things like bridges and submersibles, and spider silk and similar materials like carbon fiber are absolutely garbage at it! and that's compressive strength.

this is basically the inverse of tensile strength, where instead of being yanked at from both ends, the forces are crushing inwards at the material from both directions instead.

you can expect to see these kinds of forces involved in road surfaces, vehicle engines, and again, submersibles.

now steel and its more competent cousin titanium are fucking GREAT at compressive strength! the harder the outside forces are compressing them, the stronger the metals get.

NOT TODAY, FUCKERS

but strand-based materials like spider silk and, again, carbon fiber, are fucking garbage at this. they can take a certain amount of pressure, but each round with compressive forces snaps some of the strands that makes up the material! and those don't grow back, so basically you're just gradually reducing your poor overstressed carbon-fiber hull into a completely useless shell of shattered thread fragments over time as the strands of fiber that actually give it strength die off one by one.

and eventually, something's gotta give! and then people die about it.

this is why, even though spider silk IS stronger than steel in one specific way, we're never going to stop using steel in industrial applications and switch over to spider silk or carbon fiber full time. these materials all have their areas of use, and steel just covers a wider base of applications.

and don't even get me started on shear strength. we'll be here all damn day.

5K notes

·

View notes

Link

Get ready to be amazed! This article explores the fascinating world of rubber science, revealing the secrets behind its strength and the innovative ways scientists are pushing its limits.

0 notes

Text

Discover top-notch tensile structure manufacturer services. Explore innovative designs and durable solutions for your architectural needs. Contact us today!

1 note

·

View note

Video

youtube

👍 Check the FIXDEX wedge anchor tensile strength and reach the standard ...

#youtube#Trubolt Wedge Anchor#wedge anchor tensile strength#Technical Specifications for Wedge Anchors#wedge anchor strength#wedge anchor bolt weight#FIXDEX wedge anchor#tensile strength#through bolt#through bolt tensile strength#data sheet

0 notes

Text

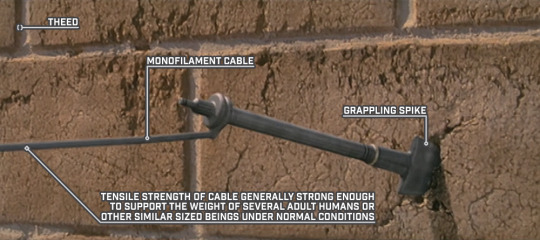

Grappling Spike Starts to Shake

STAR WARS EPISODE I: The Phantom Menace - Deleted Scene: The Waterfall Sequence 00:50

#Star Wars#Episode I#The Phantom Menace#deleted scene#The Waterfall Sequence#Naboo#Theed#monofilament cable#grappling spike#tensile strength

0 notes

Text

another thing fantasy writers should keep track of is how much of their worldbuilding is aesthetic-based. it's not unlike the sci-fi hardness scale, which measures how closely a story holds to known, real principles of science. The Martian is extremely hard sci-fi, with nearly every detail being grounded in realistic fact as we know it; Star Trek is extremely soft sci-fi, with a vaguely plausible "space travel and no resource scarcity" premise used as a foundation for the wildest ideas the writers' room could come up with. and much as Star Trek fuckin rules, there's nothing wrong with aesthetic-based fantasy worldbuilding!

(sidenote we're not calling this 'soft fantasy' bc there's already a hard/soft divide in fantasy: hard magic follows consistent rules, like "earthbenders can always and only bend earth", and soft magic follows vague rules that often just ~feel right~, like the Force. this frankly kinda maps, but I'm not talking about just the magic, I'm talking about the worldbuilding as a whole.

actually for the purposes of this post we're calling it grounded vs airy fantasy, bc that's succinct and sounds cool.)

a great example of grounded fantasy is Dungeon Meshi: the dungeon ecosystem is meticulously thought out, the plot is driven by the very realistic need to eat well while adventuring, the story touches on both social and psychological effects of the whole 'no one dies forever down here' situation, the list goes on. the worldbuilding wants to be engaged with on a mechanical level and it rewards that engagement.

deliberately airy fantasy is less common, because in a funny way it's much harder to do. people tend to like explanations. it takes skill to pull off "the world is this way because I said so." Narnia manages: these kids fall into a magic world through the back of a wardrobe, befriend talking beavers who drink tea, get weapons from Santa Claus, dance with Bacchus and his maenads, and sail to the edge of the world, without ever breaking suspension of disbelief. it works because every new thing that happens fits the vibes. it's all just vibes! engaging with the worldbuilding on a mechanical level wouldn't just be futile, it'd be missing the point entirely.

the reason I started off calling this aesthetic-based is that an airy story will usually lean hard on an existing aesthetic, ideally one that's widely known by the target audience. Lewis was drawing on fables, fairy tales, myths, children's stories, and the vague idea of ~medieval europe~ that is to this day our most generic fantasy setting. when a prince falls in love with a fallen star, when there are giants who welcome lost children warmly and fatten them up for the feast, it all fits because these are things we'd expect to find in this story. none of this jars against what we've already seen.

and the point of it is to be wondrous and whimsical, to set the tone for the story Lewis wants to tell. and it does a great job! the airy worldbuilding serves the purposes of the story, and it's no less elegant than Ryōko Kui's elaborately grounded dungeon. neither kind of worldbuilding is better than the other.

however.

you do have to know which one you're doing.

the whole reason I'm writing this is that I saw yet another long, entertaining post dragging GRRM for absolute filth. asoiaf is a fun one because on some axes it's pretty grounded (political fuck-around-and-find-out, rumors spread farther than fact, fastest way to lose a war is to let your people starve, etc), but on others it's entirely airy (some people have magic Just Cause, the various peoples are each based on an aesthetic/stereotype/cliché with no real thought to how they influence each other as neighbors, the super-long seasons have no effect on ecology, etc).

and again! none of this is actually bad! (well ok some of those stereotypes are quite bigoted. but other than that this isn't bad.) there's nothing wrong with the season thing being there to highlight how the nobles are focused on short-sighted wars for power instead of storing up resources for the extremely dangerous and inevitable winter, that's a nice allegory, and the looming threat of many harsh years set the narrative tone. and you can always mix and match airy and grounded worldbuilding – everyone does it, frankly it's a necessity, because sooner or later the answer to every worldbuilding question is "because the author wanted it to be that way." the only completely grounded writing is nonfiction.

the problem is when you pretend that your entirely airy worldbuilding is actually super duper grounded. like, for instance, claiming that your vibes-based depiction of Medieval Europe (Gritty Edition) is completely historical, and then never even showing anyone spinning. or sniffing dismissively at Tolkien for not detailing Aragorn's tax policy, and then never addressing how a pre-industrial grain-based agricultural society is going years without harvesting any crops. (stored grain goes bad! you can't even mouse-proof your silos, how are you going to deal with mold?) and the list goes on.

the man went up on national television and invited us to engage with his worldbuilding mechanically, and then if you actually do that, it shatters like spun sugar under the pressure. doesn't he realize that's not the part of the story that's load-bearing! he should've directed our focus to the political machinations and extensive trope deconstruction, not the handwavey bit.

point is, as a fantasy writer there will always be some amount of your worldbuilding that boils down to 'because I said so,' and there's nothing wrong with that. nor is there anything wrong with making that your whole thing – airy worldbuilding can be beautiful and inspiring. but you have to be aware of what you're doing, because if you ask your readers to engage with the worldbuilding in gritty mechanical detail, you had better have some actual mechanics to show them.

#finx rambles#worldbuilding#for writers#honestly I quite liked the asoiaf books I read#it's a well-constructed story! it's a well-constructed world too on its own merits#none of this stuff about grain and spinning is actually important to the story#the problem is that grrm himself seems to just. not realize this#and goes about blithely insisting he's created an extraordinarily realistic fantasy world where all the tax policies make sense#he has not!#he has invited people to tear his creation apart if they can and! it turns out! they absolutely can!#this shit's got no tensile strength! it's made of glue and popsicle sticks!#you're not supposed to put weight on it

5K notes

·

View notes

Text

The i10™ Tensile Strength Tester from Paramount is an advanced piece of equipment, embodying the most up-to-date technology by employing the Constant Rate of Elongation (CRE) principle. It seamlessly integrates with sophisticated software provided with the equipment via the included laptop.

#paramountinstruments#qualitycontrol#textile#textileindustry#qualitycontrolassessment#tensile strength#tensile strength tester#elongation#seam- slipage#tear

0 notes

Text

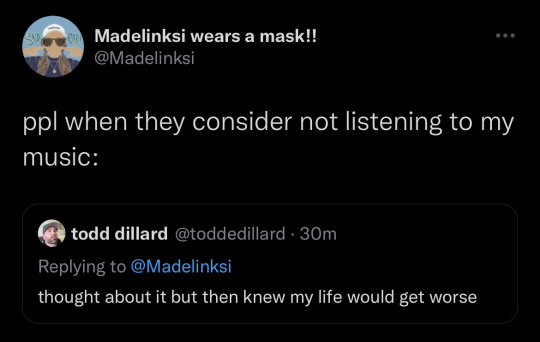

#stream tensile strength#by#madelinksi#madelinksi music#love songs#yeehaw#tensile strength#new music#fuck it we fall like crowley#crowley is bae

1 note

·

View note

Text

didn't want him to lose his seat on the bus

#sami rambles#8x13 invisible eddie diaz testing the tensile strength of my lesbianism#911 spoilers#911 show#eddie diaz

60 notes

·

View notes

Text

tensile strength 1

15 notes

·

View notes

Text

How Tensile Strength Testing Contributes to Sustainable Textile Manufacturing?

Sustainability is a key consideration in today’s textile industry, and with rising concerns over environmental impact and consumer demand for eco-friendly products, manufacturers are increasingly focusing on creating sustainable fabrics. One of the most effective ways to ensure the durability and long-lasting performance of textiles is through tensile strength testing. This process plays a crucial role in sustainable textile manufacturing, allowing manufacturers to enhance product quality, reduce waste, and ultimately create more environmentally responsible fabrics.

In this blog, we’ll explore how tensile strength testing contributes to sustainable textile manufacturing, its role in reducing waste, improving product longevity, and helping manufacturers meet sustainability goals.

What is Tensile Strength in Textiles?

Tensile strength refers to the maximum force that a textile can withstand while being stretched or pulled before it breaks. It is a key physical property that determines the strength and durability of a fabric, which directly affects how the material will perform in real-world conditions. When a fabric is subjected to tensile strength testing, the force required to stretch or tear it is measured, providing valuable data that manufacturers use to assess its quality.

For textile manufacturers, ensuring that their products have the right tensile strength is essential, not just for performance but also for creating sustainable, long-lasting textiles that reduce environmental impact over time.

The Importance of Tensile Strength Testing in Textile Manufacturing

Tensile strength in textile is an essential process in textile manufacturing. It provides key insights into the fabric’s ability to withstand stress and wear, and helps manufacturers ensure that the fabrics they produce meet quality and performance standards. However, its importance goes beyond just performance—tensile strength testing plays a critical role in driving sustainability in the following ways:

1. Enhancing Fabric Durability and Longevity

A fabric’s tensile strength is directly linked to its ability to endure wear and tear over time. Stronger, more durable fabrics can withstand repeated use and washing without breaking down or losing their structural integrity. By testing tensile strength, manufacturers can ensure that their fabrics meet the necessary durability standards, which results in longer-lasting products.

When a fabric is designed to withstand stress without deteriorating, the need for frequent replacements is minimized. This leads to a decrease in overall consumption, reducing the demand for new raw materials and minimizing textile waste. Consumers also benefit from the longevity of these textiles, which means fewer discarded products and a reduction in landfill contributions.

2. Reducing Textile Waste

One of the major environmental challenges faced by the textile industry is the issue of waste. According to the Ellen MacArthur Foundation, the fashion industry alone generates millions of tons of textile waste each year. Much of this waste stems from poorly constructed fabrics that tear or degrade quickly, forcing consumers to dispose of them prematurely.

By conducting tensile strength testing during the production process, manufacturers can identify fabrics that may be prone to premature breakage and address weaknesses before they become a problem. This ensures that the fabrics being produced are durable, reducing the likelihood of fabric failures that contribute to textile waste. It also helps manufacturers avoid overproduction of subpar materials, which could otherwise end up in landfills.

3. Promoting Resource Efficiency

Tensile strength testing allows textile manufacturers to use materials more efficiently by ensuring that the fabric’s strength is optimized for its intended application. By selecting the right fibers, weaving techniques, and finishing processes that enhance tensile strength, manufacturers can create textiles that perform well with less material usage. This is particularly relevant in the production of lightweight yet durable fabrics, which can be used in a variety of applications without excessive material waste.

In many cases, stronger fabrics allow for thinner or lighter textiles that still meet the necessary strength requirements. This not only reduces material waste but also minimizes the energy consumption associated with the production of thicker, bulkier fabrics. As a result, tensile strength testing directly contributes to more sustainable manufacturing practices that reduce both material and energy consumption.

4. Supporting Recycling and Circularity

Sustainable textile manufacturing aims to move towards a circular economy, where materials are reused and recycled rather than disposed of. Tensile strength testing plays a role in this by ensuring that textiles retain their strength even after recycling. When textiles are recycled, they often undergo processes like shredding or reprocessing, which can degrade their integrity. By ensuring that the original fabric has high tensile strength, manufacturers can produce textiles that are better suited to the recycling process and can be reprocessed without losing quality.

This contributes to the development of fabrics that are easier to recycle and maintain their structural integrity even after multiple life cycles. A fabric that retains its tensile strength is more likely to be reused and repurposed in a circular supply chain, further reducing environmental impact.

5. Facilitating Certification and Compliance with Eco-Standards

Sustainability certifications and standards play a significant role in promoting environmentally responsible practices within the textile industry. Various eco-labels, such as OEKO-TEX, GOTS (Global Organic Textile Standard), and Fair Trade, require manufacturers to meet specific criteria related to environmental impact and product quality.

Tensile strength testing ensures that fabrics meet the performance requirements of these certifications by validating their durability and resistance to wear. This enables manufacturers to showcase their commitment to quality and sustainability through certified products. Moreover, compliance with such eco-standards is an important selling point in the growing consumer market that prioritizes sustainability.

6. Reducing Carbon Footprint in the Textile Industry

The production of textiles requires significant resources, including water, energy, and raw materials. Weak or low-quality fabrics that fail prematurely often require more energy to produce, and their disposal contributes to environmental harm. By focusing on fabrics with optimal tensile strength, manufacturers can reduce the frequency of production cycles, leading to energy savings, fewer raw material inputs, and less waste generation.

Stronger fabrics also result in a reduced need for washing and repairing textiles, further lowering the carbon footprint associated with textile maintenance. Additionally, the overall demand for new products is minimized when fabrics are designed to be more durable, leading to further reductions in environmental impact.

Conclusion

Tensile strength testing is a critical process that not only ensures the durability and performance of textiles but also supports sustainable manufacturing practices. By enhancing fabric strength, reducing waste, promoting resource efficiency, and supporting the circular economy, tensile strength testing contributes significantly to a more sustainable textile industry. Manufacturers who prioritize tensile strength testing can create longer-lasting, higher-quality textiles that meet the growing demand for eco-friendly products.

As sustainability becomes increasingly important in textile production, tensile strength testing offers a powerful tool for improving the environmental footprint of the industry. By ensuring that textiles are strong, durable, and long-lasting, manufacturers can reduce their reliance on raw materials, decrease textile waste, and contribute to a more circular and environmentally responsible textile supply chain. In this way, tensile strength testing plays a pivotal role in the ongoing push towards sustainable textile manufacturing.

#tensile strength in textile#tensile strength testing#tensile strength#textile testing#textile testing lab

0 notes

Text

episode 39 I love you

24 notes

·

View notes