#teamcenter

Explore tagged Tumblr posts

Text

Improve Efficiency in Component Manufacturing with Teamcenter PLM!

Are fragmented processes slowing down your manufacturing operations? Discover how a streamlined PLM solution can revolutionize your workflow!

The PLM for Component Manufacturers by Siemens Teamcenter X helps standardize processes, accelerate time-to-market, and optimize collaboration.

Try the 30-day free trial and experience the future of component manufacturing! Start today - https://www.plmnordic.com/teamcenter-x/

0 notes

Text

Unlock the full potential of Opcenter and Mendix with Athena’s complementary solutions! We provide: 🔹 End-to-end Opcenter Execution support for Semiconductors, Electronics, Medical Devices & Discrete industries 🔹 Seamless Teamcenter, Opcenter & Mendix integration for smoother operations 🔹 Athena’s Chatbot Co-pilot for task assistance & management efficiency 🔹 Shopfloor automation with Master Data Loader & Automated Testing Script Processor 🔹 Touchscreen UIs for a frictionless shopfloor experience Maximize efficiency, simplify processes, and empower your team with Athena, which is designed to complement and enhance your Opcenter & Mendix journey!

0 notes

Text

youtube

Special Offer: Buy One, Get One 50% OFF on Select PROLIM Software Products! Place Order: https://www.prolim.com/plm/

Bring the spirit of July with a bang through our exciting Christmas in July sale at PROLIM! For a limited time, when you purchase one of our cutting-edge products, you'll receive the second one at a remarkable 50% discount.

Don't miss out on this amazing offer! Visit our website today to learn more and to place your order.

#ThinkPROLIM#DigitalTransformation#TodayMeetsTomorrow#PLMSolutions#Teamcenter#NXCAD#NXCAM#SolidEdge#sale2024#softwaresale#christmas#christmassale#offer#Youtube

0 notes

Text

The Power of Online Learning: Teamcenter PLM Training Made Convenient

In today's fast-paced and ever-evolving world, the demand for continuous learning and skill development has become more crucial than ever. With the rise of technology and the internet, online learning has emerged as a powerful tool for individuals and organizations alike. In the field of product lifecycle management (PLM), the need for comprehensive training and upskilling is imperative for businesses to stay competitive. This is where Teamcenter PLM training comes into play, providing a comprehensive set of skills and knowledge to manage the entire product lifecycle efficiently. However, traditional classroom training can be time-consuming and expensive, making it challenging for individuals and organizations to keep up with the constantly changing PLM landscape. Fortunately, online learning has revolutionized the way we acquire knowledge and skills, offering a convenient and cost-effective solution. In this article, we will explore the power of online learning and how it has made Teamcenter PLM training more accessible and convenient for individuals and organizations.

Flexible scheduling options for training

With the Teamcenter PLM Training Course, individuals have the opportunity to experience the benefits of flexible scheduling options for their training needs. This online training platform allows participants to access the course materials and modules at their convenience, eliminating the limitations imposed by rigid training schedules. Whether professionals have busy work schedules or personal commitments, they can easily fit in their training sessions at a time that works best for them. This flexibility empowers learners to take control of their learning journey, ensuring that they can fully absorb and apply the knowledge gained from the Teamcenter PLM Online Training. By offering flexible scheduling options, the training program accommodates the diverse needs of individuals and promotes a more efficient and effective learning experience.

Interactive courses with expert instructors

The success of online learning lies not only in its flexibility but also in the quality of instruction provided. That's why our Teamcenter PLM Training Course offers interactive courses with expert instructors who bring a wealth of industry knowledge and experience to the virtual classroom. These instructors are highly skilled in delivering engaging and informative sessions, ensuring that participants receive the highest level of education and support throughout their training journey. With their expertise, learners gain valuable insights and practical skills that can be directly applied to real-world scenarios. The interactive nature of these courses fosters active engagement, encouraging meaningful discussions and collaborative learning among participants. By combining the convenience of online learning with the expertise of our instructors, individuals can receive a comprehensive and enriching educational experience that propels their career growth in the field of Teamcenter PLM.

Conveniently learn from any location.

The Power of Online Learning: Teamcenter PLM Training Made Convenient

In today's fast-paced world, the ability to conveniently learn from any location has become a game-changer for professionals seeking to enhance their skills and knowledge. With our Teamcenter PLM Online Training, individuals can now access high-quality training courses from the comfort of their surroundings, eliminating the need for travel and hours spent in a physical classroom. Whether you're located in a different city or halfway across the globe, our online platform ensures that you have the same opportunity as anyone else to receive top-notch instruction and gain expertise in Teamcenter PLM. This flexibility allows you to fit your learning around your schedule, making it ideal for busy professionals juggling multiple commitments. By taking advantage of the convenience provided by online learning, you can stay ahead of the curve and acquire the skills necessary to excel in today's competitive market.

Customized training for specific needs

When it comes to mastering the intricacies of Teamcenter PLM, we understand that every individual has different learning needs and objectives. That's why our Teamcenter PLM Training Course offers customized training options to cater to specific requirements. Whether you are a beginner looking to build a solid foundation or an experienced user aiming to enhance your expertise in a particular area, our tailored courses ensure that you receive the necessary knowledge and skills to meet your objectives. Our team of experienced instructors works closely with you to assess your current proficiency level and identify areas of improvement. From there, we develop a personalized training plan that focuses on addressing your specific needs, allowing you to maximize your learning potential and achieve tangible results. With our customized approach to training, you can acquire the precise skills and knowledge you need to excel in your Teamcenter PLM endeavors.

Access to resources and support.

Our Teamcenter PLM Online Training not only provides comprehensive course content but also offers participants access to a wide range of valuable resources and support. Through our online learning platform, learners can access a wealth of supplementary materials such as tutorial videos, reference guides, and interactive exercises. These resources serve as invaluable tools to reinforce learning, allowing learners to revisit and review concepts at their own pace. Additionally, our training program provides a dedicated support system, including forums and live chat sessions, where participants can connect with instructors and fellow learners to ask questions, seek guidance, and share experiences. This collaborative environment fosters a sense of community and encourages continuous learning and growth. The accessibility of resources and the availability of ongoing support ensure that learners have the necessary tools and assistance to succeed in their Teamcenter PLM training journey.

In today's fast-paced and ever-changing world, the power of online learning cannot be underestimated. Teamcenter PLM training has become even more convenient with the availability of virtual classes and self-paced courses. With the flexibility and accessibility that online learning provides, individuals and organizations can stay ahead of the curve and continuously improve their skills and knowledge. Embracing online learning not only enhances personal and professional growth but also allows businesses to stay competitive in the ever-evolving landscape of technology. So why wait? Take advantage of the power of online learning and elevate your Teamcenter PLM skills today.

Are you interested in Teamcenter PLM Training?

Contact us at: [email protected]

0 notes

Text

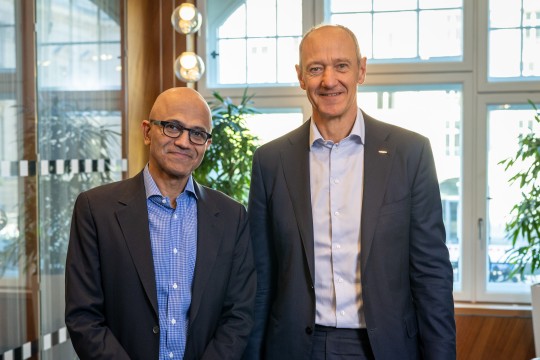

Siemens and Microsoft partner to drive cross-industry AI adoption

Exciting times ahead as #Siemens and #Microsoft join forces to propel cross-industry #AI adoption! Introducing Siemens Industrial Copilot, your AI-powered assistant for enhanced human-machine collaboration. #SPS2023 #SIEX

Companies introduce Siemens Industrial Copilot, a generative AI-powered assistant, designed to enhance human-machine collaboration and boost productivity. Companies will work together to build additional copilots for manufacturing, infrastructure, transportation, and healthcare industries. Leading automotive supplier, Schaeffler AG, is an early adopter of Siemens Industrial Copilot. In…

View On WordPress

#Cross-industry AI adoption#Generative AI#Healthcare AI#Human-machine Collaboration#Industrial Metaverse#Infrastructure AI#Manufacturing Innovation#microsoft#Microsoft Teams Integration#Product Lifecycle Management#Productivity Enhancement#Schaeffler AG#Siemens#Siemens Industrial Copilot#SPS Expo Nuremberg#Teamcenter#Transportation AI#Virtual Collaboration

0 notes

Text

Teamcenter PLM Costing

#Siemens teamcenter price#cost reduction software#plm software#costmanagementsoftware#free plm software#plmsolutions#Siemens product lifecycle management#siemens teamcenter cost#teamcenter software#cost management software#Best PLM Software#teamcenter plm

0 notes

Text

Join a student engineering team they said. It will be fun they said. You definitely won’t spend 30 min waiting for a program to stop not responding in order to open a file they said.

#hey at least at this point I’ve procrastinated on my onboarding so much that my subteam lead has let me work on actual projects#and is going to count designing a mount for one of our motors as finishing my onboarding#also the process for if I want to work on the cad from scratch (which I usually don’t have to do) would be#1. open teamcenter and load in the model (15 min)#2. select assemblies and export from team center (45+ min)#3. open in NX (30 min)#4. open motor files (3 min each)#5. open the assembly I’m working on (10 min)#6. ACTUALLY START WORKING

1 note

·

View note

Text

Siemens PLM software in pune | spiritplm

The Teamcenter gateway for SAP Business Suite (T4S) software solution is a general purpose integration software that provides data and process integration between Teamcenter by Siemens PLM and SAP. Spiritplm Solutions provides Teamcenter Implementation in Pune, we bring the right combination of domain and product knowledge for efficient implementation. Solution Architect Program SAP gives you in detail information about actual implementation of Teamcenter on live environment. This program give you in detail information like program solutions, deployment, project planning, requirement gathering, customization, and support of highly available architecture. Siemens PLM Training in Pune Program is a cutting edge solution for controlling production processes, from product concept to product manufacturing. This course will teach you how to work effectively in team, from design to manufacture. PLM plays an important role in assisting manufacturers in developing a new generation of products at a reduced cost with a time to market. you have complete control over the integration technology used and the optimized business processes.

read more:https://spiritplm.com/teamcenter-integration-for-t4s/

2 notes

·

View notes

Text

Industry X Teamcenter Business Consultant

Search for the latest Canada jobs on Careerjet, the employment search engine. Covers all industry sectors. Missing: cache: ca465d73a4f82b969ef3f247d483922a4c Apply Now

0 notes

Text

Streamline your design process and boost productivity with NX X Essentials lightweight, web-based platform.

Introducing SiemensNX X Essentials - a powerful, yet intuitive solution that combines CAD, CAM, and CAE in a single, web-based platform. Designed to simplify your workflow, NXX Essentials empowers you to create, simulate, and manufacture your designs with ease.

Key Features:

- Predictive design intent for seamless model modifications

- Symmetric design for efficient part updates

- Concentric and aligned hole relationships for precise adjustments

- Coplanar relationship for quick surface edits

- Offset relationship for effortless feature resizing

Contact us today to request a demo, pricing, and explore licensing and trial opportunities at: https://www.plmnordic.com/siemens-nx-x-essentials/

0 notes

Text

Remote Cloud Teamcenter Infrastructure Architect

Siemens. United States – Virginia, Arlington Industry: Internships As a Siemens Government Technologies (SGT) Professional Services Infrastructure Architect, you will be responsible to install, administer and maintain Teamcenter and other Xcelerator products. This position requires prior experience installing… Date posted: 11/22/2024 01:17 PM

0 notes

Text

Foxconn Builds Robotic Factories With Omniverse & NVIDIA AI

Foxconn Adds New Factories in the US, Mexico, and Taiwan to Increase Blackwell Testing and Production.

Foxconn Introduction

To get facilities online as quickly as possible, the biggest electronics manufacturer in the world leverages digital twins and industrial AI developed on top of NVIDIA Omniverse.

NVIDIA Omniverse is being used by Foxconn, the largest electronics manufacturer in the world, to satisfy demand for Blackwell, which is currently in full production. Facilities in the United States, Mexico, and Taiwan are going online more quickly than ever with to the platform for creating industrial AI simulation applications.

The employs NVIDIA Metropolis for vision AI, NVIDIA Isaac Sim for autonomous robot testing and simulation, and NVIDIA Omniverse to realistically integrate their facility and equipment layouts.

Through testing and optimization in a digital twin prior to implementing expensive change orders in the real world, Omniverse allows industrial developers to optimize efficiency. Foxconn anticipates that its Mexico site alone will provide in considerable cost savings and a yearly decrease in kilowatt-hour use of over 30%.

World’s Largest Electronics Maker Plans With Omniverse and AI

Factory planners are using Omniverse and NVIDIA AI to create actual AI-powered robotic factories in order to satisfy Foxconn’s expectat

In order to enable their teams to realistically combine facility and equipment information from top industry apps, like Siemens Teamcenter X and Autodesk Revit, the organization has created digital twins using Omniverse. First, floor plan layouts are optimized in the digital twin. With Metropolis visual AI agents, planners may find the best camera placements to measure and find methods to improve operations.

The Omniverse digital doppelganger serves as the Foxconn teams’ source of truth during construction, allowing them to communicate and verify the precise equipment location and layout.

By lowering expensive change orders in actual operations, virtual integration on Omniverse has the potential to save factory planners millions of dollars.

Delivering Robotics for Manufacturing With Omniverse Digital Twin

After the factory’s digital duplicate is constructed, Foxconn‘s fleets of autonomous robots including industrial manipulators and autonomous mobile robots use it as a virtual gym. Before deploying their AI robot models to their real-world robots, Foxconn’s robot developers may use NVIDIA Isaac Sim to test, simulate, and evaluate their models.

Foxconn may model robot AIs using Omniverse before using NVIDIA Jetson-powered mobile robots.

They may model automated visual inspection, item recognition, defect detection, and trajectory planning on assembly lines using AI models and Isaac Manipulator libraries.

In order to promote worker safety and serve as the basis for visual AI agent frameworks, Omniverse also gives their facility planners the ability to test and improve the placement of intelligent cameras before putting them in the real world. This ensures that the whole factory floor is covered.

Creating Efficiencies While Building Resilient Supply Chains

Foxconn intends to duplicate its precision production lines globally using AI and NVIDIA Omniverse. This will boost the company’s competitive advantage and market flexibility by allowing it to swiftly implement top-notch production facilities that adhere to common standards.

Because it can swiftly modify production plans and reallocate personnel to provide continuity and stability to meet shifting needs, Foxconn’s capacity to duplicate quickly will speed up its worldwide deployments and improve its resilience in the supply chain in the event of interruptions.

Production at Foxconn’s facilities in Mexico and Taiwan will start in December and early, respectively, of next year.

In Summary

NVIDIA Omniverse is being used by Foxconn, the biggest electronics manufacturer in the world, to construct and run new plants in Taiwan, Mexico, and the United States. Foxconn uses Omniverse, a platform for creating industrial AI simulation applications, to test autonomous robots, improve camera positioning, and visually integrate facility and equipment layouts.

Foxconn may save millions of dollars by minimizing expensive modifications to physical plants through the use of digital twins. In order to swiftly establish top-notch production facilities and strengthen its supply chain resilience, Foxconn also intends to employ Omniverse to duplicate its precision production lines all over the world.

Read more on govindhtech.com

#Foxconn#BuildsRoboticFactories#NVIDIAAI#Blackwell#IsaacSim#digitaltwin#AImodels#ai#NVIDIAOmniverse#OmniverseDigitalTwin#LargestElectronics#technology#technews#news#govindhtech

0 notes

Text

Black Friday Extravaganza! Buy 1 Software License, Get 1 FREE!Seize the ultimate Black Friday tech upgrade.Embrace efficiency, unleash innovation, and elevate your workflow.This exclusive deal is your ticket to unlocking the full potential of your digital toolkit without breaking the bank. Don't miss the chance to redefine your digital experience this Black Friday

See Exclusive Offer - https://www.prolim.com/plm/

#ThinkPROLIM#DigitalTransformation#TodayMeetsTomorrow#PLMSolutions#50%off#PROLIMsoftwares#Solidedge#NX#Teamcenter#Mendix#LimitedTimeOffer#DigitalToolkit#SoftwareSpecial

0 notes

Text

CISA: Sicherheitshinweise für 21 industrielle Steuerungssysteme

Die CISA hat 21 Sicherheitshinweise zum Thema Industrial Control Systems (ICS) veröffentlicht. Dabei führt die oberste US-IT-Sicherheitsbehörde alle ICS Komponenten und die dabei erkannten Schwachstellen und ihre CVSS-Werte auf. Es sind auch kritische Lücken mit dabei. Die aktuellen Hinweise der CISA - Cybersecurity and Infrastructure Security Agency, die oberste US-IT-Sicherheitsbehörde, haben es in sich. Gleich 21 Warnungen zu angreifbaren industriellen Steuersysteme sind in der Liste zu finden. Es sind alles IIoT-Systeme der Hersteller Siemens, Schneider Electric, Rockwell Automation und Delta Elektronik. Jedes Produkt wird auf einer gesonderten Seite vorgestellt. Dabei nennt die CISA den Risikowert nach CVSS 4. Viele Werte liegen bei hochgefährlich - einige bei kritisch. So findet sich etwa bei Siemens SENTRON PAC3200 Devices der CVSS-Wert 4 mit 9.3 von 10. 21 Schwachstellen in ICS-Systemen Die Hinweise bieten aktuelle Informationen zu aktuellen Sicherheitsproblemen, Schwachstellen und Exploits im Zusammenhang mit ICS. Die genannten Produktgruppen umfassen natürlich weitere Modelle die von der jeweiligen Sicherheitslücke betroffen sind. - ICSA-24-284-01 Siemens SIMATIC S7-1500 und S7-1200 CPUs - ICSA-24-284-02 Siemens Simcenter Nastran - ICSA-24-284-03 Siemens Teamcenter Visualisierung und JT2Go - ICSA-24-284-04 Siemens SENTRON PAC3200 Geräte - ICSA-24-284-05 Siemens Questa und ModelSim - ICSA-24-284-06 Siemens SINEC Sicherheitsmonitor - ICSA-24-284-07 Siemens JT2Go - ICSA-24-284-08 Siemens HiMed Cockpit - ICSA-24-284-09 Siemens PSS SINCAL - ICSA-24-284-10 Siemens SIMATIC S7-1500 CPUs - ICSA-24-284-11 Siemens RUGGEDCOM APE1808 - ICSA-24-284-12 Siemens Sentron Powercenter 1000 - ICSA-24-284-13 Siemens Tecnomatix Anlagensimulation - ICSA-24-284-14 Schneider Electric Zelio Soft 2 - ICSA-24-284-15 Rockwell Automation DataMosaix Private Cloud - ICSA-24-284-16 Rockwell Automation DataMosaix Private Cloud - ICSA-24-284-17 Rockwell Automation Verve Asset Manager - ICSA-24-284-18 Rockwell Automation Logix-Steuerungen - ICSA-24-284-19 Rockwell Automation PowerFlex 6000T - ICSA-24-284-20 Rockwell Automation ControlLogix - ICSA-24-284-21 Delta Electronics CNCSoft-G2 Über die CISA CISA ist die operative Leitung für die Cybersicherheit des US Bundes und der nationale Koordinator für die Sicherheit und Belastbarkeit kritischer Infrastrukturen. Wir sind auf Zusammenarbeit und Partnerschaft ausgelegt. Erfahren Sie mehr über unsere vielschichtige Mission zur Risikominderung für die Cyber- und physische Infrastruktur des Landes. Passende Artikel zum Thema Lesen Sie den ganzen Artikel

0 notes

Text

SAP PLM Training in pune | spiritplm

Solution Architect Program SAP gives you in detail information about actual implementation of Teamcenter on live environment. This program give you in detail information like program solutions, deployment, project planning, requirement gathering, customization, and support of highly available architecture. SAP PLM Training in Pune Program is a cutting edge solution for controlling production processes, from product concept to product manufacturing. This course will teach you how to work effectively in team, from design to manufacture.PLM plays an important role in assisting manufacturers in developing a new generation of products at a reduced cost with a time to market.you have complete control over the integration technology used and the optimized business processes.

read more-https://spiritplm.com/teamcenter-sap-plm-integration-pune/

0 notes