#Best PLM Software

Explore tagged Tumblr posts

Text

A2000 Software: Transform Product Lifecycles with Apparel PLM Software

Apparel PLM Software by A2000 Software empowers brands to efficiently oversee the entire product lifecycle, from design to distribution. This robust PLM tool enhances collaboration, reduces time-to-market, and ensures quality across the board. A2000’s PLM software offers the insights and control needed to innovate confidently in the fashion industry.

0 notes

Text

Unveiling the Dynamics of Siemens' Product Lifecycle Management Software in Canada: Redefining Innovation and Cost Management

In today's intricate industrial landscape, where innovation, efficiency, and cost-effectiveness converge, Product Lifecycle Management (PLM) software stands as the linchpin of success. Siemens, a global leader in cutting-edge technology, introduces its groundbreaking PLM software suite, Teamcenter®, revolutionizing the Canadian industry landscape and redefining the benchmarks of innovation and cost management.

What is PLM Software

At its core, PLM software encompasses a comprehensive approach to manage a product's lifecycle, spanning its inception, design, production, and service. It acts as a cohesive platform, streamlining processes, facilitating collaboration, and optimizing operations, thereby enhancing productivity and reducing time-to-market.

Siemens Product Lifecycle Management Software

Siemens' PLM software, notably Teamcenter, epitomizes excellence in managing the entire lifecycle of products. With a suite of tools and modules designed to address diverse industry needs, Teamcenter stands tall as a comprehensive solution for businesses seeking to streamline their operations, enhance collaboration, and drive innovation.

PLM Software in Canada: Siemens' Impact

The adoption of Siemens' PLM software in Canada has been transformative. Industries ranging from automotive to aerospace, and beyond, have embraced Teamcenter for its ability to unify data, streamline processes, and drive efficiency. The integration of Teamcenter's Cost Management module has enabled businesses to meticulously analyze and optimize product costs, thereby maximizing profitability without compromising quality.

The Power of Free PLM Software Trial

The accessibility of free PLM software has democratized innovation, empowering startups, educational institutions, and emerging businesses to explore the realms of product lifecycle management without financial constraints. This availability fosters a culture of innovation, allowing for the incubation of groundbreaking ideas and fostering a new wave of entrepreneurs in Canada's industrial landscape.

Teamcenter: Defining Excellence in PLM

Siemens' Teamcenter software remains at the forefront of the best PLM software available, not just in Canada but globally. Its seamless integration, robust features, and intuitive interface make it a preferred choice for businesses seeking to optimize operations, reduce costs, and drive innovation.

Siemens Teamcenter Price and Cost Management

Siemens' commitment to delivering value extends to its pricing strategy for Teamcenter, offering scalable solutions tailored to diverse business needs. The integration of cost management tools within Teamcenter further solidifies its position as an indispensable asset, enabling businesses to analyze, forecast, and optimize product costs throughout the lifecycle.

Empowering Industries with Teamcenter PLM

The amalgamation of Siemens Teamcenter software and its cost management capabilities has positioned Canadian industries on a trajectory of sustained growth and innovation. By leveraging the power of PLM, businesses across the country are achieving new heights of efficiency, collaboration, and profitability.

Conclusion

Siemens Product Lifecycle Management software, exemplified by Teamcenter, continues to redefine industry standards in Canada. Its prowess in driving innovation, streamlining operations, and optimizing costs underscores its significance in the modern industrial landscape. As Canadian businesses embrace PLM solutions, Siemens remains a guiding force, empowering industries to innovate, collaborate, and thrive in an ever-evolving market.

#free plm software#plm software#costmanagementsoftware#best plm software#cost reduction software#plmsolutions#PLM Software in Canada

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the manufacturer TeamGroup T-Force Cardea Z44L NVMe M.2 2280 PCIe Gen 4 SSD Not only faster but also more stable and durable Supporting SLC Cache technology and smart algorithm management mechanism can help ensure operational efficiency and maximize the performance of SSD. It is a reliable and trustworthy choice for data storage. Enjoy the read/write performance of PCIe Gen4 x4 It supports the latest PCIe Gen4 x4 with up to 3500/3000 MB/s*, offering superior performance which is 7 times faster than typical SATA SSD, while also downward compatible with PCIe 3.0 specification. Supports the latest NVMe standard By supporting the latest NVMe spec and optimizing the work division of NVM Sets and PLM (Predictable Latency Mode), it effectively reduces latency time, write loss, and improves the system's QoS. Usage of the latest RRL (Read Recovery Level) technology also improves the lifespan of the SSD. SSD smart monitoring software TEAMGROUP provides an exclusive SSD smart monitoring software. It can keep track of the status of the products at any time, monitor their quality and performance, and then perform quick and easy related setup and testing. Patented ultra-thin graphene heat spreader The use of patented ultra-thin graphene heat spreader provides the best thermal conductivity material and assembly flexibility, allowing gamers to easily DIY on their own, and any motherboard heat spreader can be supported without interference. Responsive: This PCIe Gen 4 SSD Comes With Read & Write Speed Upto 3500/3000 MB/s, Supports Smart SLC Caching Algorithm Making It 25X Faster Than Traditional HDDs. Reliability: Supports S.M.A.R.T Technology For Monitoring & Windows TRIM For Optimized Performance. Built-in ECC & Wear Level Technology Ensure Reliable Storage. Cooling: Ultra Thin Graphene Heat Spreader Provides The Best Cooling Performance Which Ennahces Gaming Performance & Longevity. Fast : This Nvme M.2 2280 PCIe Gen 4 Solid State Drive Uses Latest Nvme Standard For Excellent Performance. Latest Tech: Equipped With New 3D NAND TLC Flash Memory Chips For Fast And Seamless Gaming Experience. Durability: With Upto 600TBW (Terra Bytes Written) Rating, Your SSD Will Handle More Write Operations And last Long. Warranty: Backed By Limited 5 Year Warranty Providing Peace Of Mind With Long Term Protection Against Defects. [ad_2]

0 notes

Text

Apparel Product Lifecycle Management Software: Why A2000 Software Can Help Maximize Your Fashion Business

Being ahead and having things processed in a systematized way is what helps its survival in this era of fast fashion. Apparel Product Lifecycle Management (PLM) Software is turning out to be the best way to remain in touch with fashion houses who are willing to maintain their processes at their optimal level from designing to the customer. A2000 Software offers a complete Apparel Product Lifecycle Management Software in which all and each product development process is simplified, and your business operates smoothly and competitively.

Visit Us - https://medium.com/@sanjanabrainfoster/apparel-product-lifecycle-management-software-why-a2000-software-can-help-maximize-your-fashion-d4c8335a77e3

0 notes

Text

Best Software Development Company for Manufacturing Industry

The manufacturing industry is undergoing a significant transformation with the integration of advanced technologies such as IoT, AI, and cloud computing. To stay competitive, manufacturers need robust software solutions that can streamline operations, improve productivity, and reduce costs. Choosing the right software development company for manufacturing industry can be the key to transforming your operations and enabling long-term success.

This article explores what makes a company the best software development partner for the manufacturing sector, and what specific manufacturing software development services they offer to help companies optimize their processes.

Why Manufacturing Industry Needs Specialized Software Development

Manufacturing is a complex industry with numerous processes, from procurement and production to inventory management and distribution. Standard off-the-shelf software may not address the intricacies of these workflows. Custom-built software solutions for manufacturing provide an integrated approach to handle the following:

Production Planning & Scheduling: Streamline the manufacturing process to optimize resources and ensure timely delivery.

Supply Chain Management: Maintain full control over suppliers, vendors, and distribution channels.

Inventory Control: Ensure real-time tracking of raw materials, in-progress items, and finished products.

Quality Assurance: Implement automation and monitoring tools to guarantee that products meet required standards.

Equipment Maintenance: Predictive maintenance tools can help reduce downtime and extend equipment life.

A trusted software development company with expertise in the manufacturing industry can offer tailored solutions that address all these needs.

Key Features of Software Development Company for Manufacturing Business

To determine the best software development company for manufacturing, it’s important to evaluate key factors that indicate reliability, technical expertise, and an understanding of the industry’s unique challenges. Here’s what to look for:

1. Industry-Specific Expertise

The manufacturing sector has its own set of challenges, from fluctuating supply chains to complex production schedules. The best software development company will have experience in working with manufacturing clients and possess a deep understanding of the industry’s specific requirements. They should be able to offer custom solutions that directly address issues like production efficiency, process automation, and supply chain optimization.

2. Proven Track Record

Look for companies with a proven track record of delivering successful manufacturing software projects. A portfolio of satisfied clients and case studies detailing previous work in the manufacturing domain can provide reassurance that the company can handle your unique software requirements.

3. Comprehensive Manufacturing Software Development Services

The best software development companies provide a range of services designed to meet the evolving needs of manufacturers. These include:

Enterprise Resource Planning (ERP) Systems: Fully integrated systems that help manufacturers manage everything from inventory to accounting in one place.

Manufacturing Execution Systems (MES): Software solutions that control and monitor production processes in real-time, ensuring maximum efficiency.

Supply Chain Management (SCM) Solutions: Platforms that allow manufacturers to track and manage every aspect of their supply chain, from raw materials to delivery.

Product Lifecycle Management (PLM) Software: Tools that help manufacturers manage the entire lifecycle of a product, from conception to disposal.

IoT Integration: Internet of Things (IoT) technologies that allow for real-time data collection and monitoring of manufacturing equipment.

4. Scalability and Flexibility

Manufacturing operations often change as businesses grow or enter new markets. The software development company you choose should provide scalable solutions that can adapt to your evolving needs. This means the software should be flexible enough to accommodate new processes, technologies, or increased production demands without major disruption.

5. Focus on Innovation

Technology is constantly evolving, and the manufacturing industry is no exception. The best software development companies stay up to date with the latest trends, such as Industry 4.0, AI-driven automation, and cloud-based solutions. They should be able to leverage these innovations to create cutting-edge software that gives manufacturers a competitive advantage.

Top Manufacturing Software Development Services

Leading software development companies offer a variety of services aimed at optimizing manufacturing processes and improving operational efficiency. Here are some core manufacturing software development services that are critical for modern manufacturers:

1. Custom ERP Solutions for Manufacturing

ERP systems are essential for coordinating different parts of the manufacturing process, including production, finance, human resources, and inventory. Custom ERP solutions can be tailored to meet the specific demands of each manufacturer, providing full integration across departments and improving overall efficiency.

2. Manufacturing Execution Systems (MES)

An MES tracks and documents the transformation of raw materials to finished products. These systems monitor real-time production, gather data, and analyze process performance. With an effective MES, manufacturers can reduce waste, increase production efficiency, and improve product quality.

3. Supply Chain Management Software

Supply chain visibility is crucial for manufacturers, especially in the face of global disruptions. Custom SCM solutions enable companies to optimize logistics, track inventory, predict demand, and manage suppliers in real time. With these tools, manufacturers can create more resilient supply chains and prevent bottlenecks.

4. Quality Management Systems (QMS)

Ensuring product quality is one of the most important aspects of manufacturing. A QMS helps track defects, monitor compliance, and implement corrective actions. Custom-built quality management systems ensure that products consistently meet customer and regulatory standards.

5. IoT Solutions for Smart Manufacturing

With the rise of the Internet of Things (IoT), manufacturers can now connect machines, equipment, and devices to the internet for real-time monitoring and control. IoT solutions enable predictive maintenance, remote monitoring, and data-driven insights that reduce downtime and increase productivity.

Conclusion

The best software development company for the manufacturing industry will understand the complexity of your business and offer customized solutions to meet your needs. By partnering with an experienced provider of manufacturing software development services, you can optimize your operations, reduce costs, and boost productivity. Be sure to choose a partner with a proven track record, industry expertise, and a commitment to innovation that will help take your manufacturing business to the next level.

👉 Contact Us Today for a Consultation and Turn Your Vision into Reality!

🌐 www.ebslon.com

#Manufacturing Software Development Company#Manufacturing Software Development#Software Development Company for Manufacturing Industry#Software Development for Manufacturing#Manufacturing Software Developer#Manufacturing Software Development services#Software#Software Development#Manufacture#Manufacturing

1 note

·

View note

Text

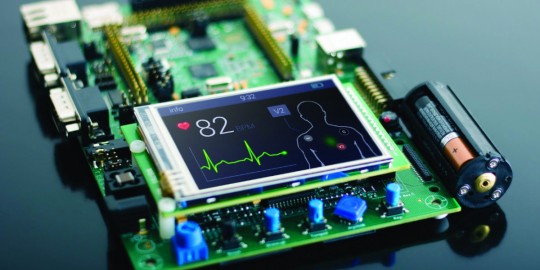

Bangalore's Best Embedded Systems Courses for Product Life Cycle Management Skills

Embedded systems are at the heart of modern technology, seamlessly integrating hardware and software to create intelligent devices. These systems, from smartphones to smart appliances, power our daily lives in ways we often overlook. As industries continue to evolve, Product Life Cycle Management (PLM) has emerged as a critical skill set that enhances the development and management of products throughout their life span. (Information Credit - https://semicontechs.com/embedded-systems-training.php)

In Bangalore, a city renowned for its vibrant tech scene and educational institutions, aspiring engineers can find numerous opportunities to master embedded systems. Whether you're looking to upskill or start fresh in this dynamic field, understanding PLM within embedded systems is essential for staying competitive. Let's explore some of the best courses available in Bangalore that focus on embedding this vital knowledge into your career toolkit.

Importance of Embedded Systems in the Current Technological Landscape

Embedded systems are at the heart of modern technology. The power everything from smart home devices to medical equipment and automotive systems. As we move towards an increasingly connected world, their role becomes even more critical.

These systems enhance functionality while ensuring efficiency. They enable real-time processing and automation across industries, improving overall application performance.

They contribute to life-saving technologies that monitor patient health seamlessly. In transportation, embedded systems facilitate advanced driver-assistance features that improve safety.

With the rise of IoT (Internet of Things), the demand for skilled professionals specializing in embedded systems continues to grow. Companies seek experts who can design and implement these complex solutions effectively. This increasing need highlights just how vital embedded system knowledge is today.

Top Embedded Systems Courses in Bangalore

Bangalore is a hub for technology and innovation, making it an ideal place to explore embedded systems courses. Numerous institutions offer specialized programs catering to various skill levels.

Semicon TechnoLabs Pvt. Ltd stands out as a premier embedded training institute in Bangalore. Their curriculum covers essential topics like microcontrollers, real-time operating systems, and hardware-software integration.

Another notable option is the best VLSI training institute in Bangalore with placement support. This course delves into VLSI design and integrates embedded system concepts crucial for product life cycle management.

For those looking for flexibility, there are online VLSI courses in Bangalore with placement assistance available too. These courses ensure you can learn at your pace while gaining industry-relevant skills.

The diverse offerings allow students to choose what aligns best with their career goals and interests within the dynamic field of embedded systems.

Course Features and Curriculum

Embedded systems courses in Bangalore are designed to provide comprehensive knowledge and hands-on experience. These programs often cover various topics, including microcontrollers, real-time operating systems, and hardware-software integration.

Students typically engage in practical labs that simulate real-world scenarios. This approach enhances learning by allowing them to apply theoretical concepts immediately.

The curriculum also emphasizes product life cycle management skills. Participants learn to develop products from the design phase through testing and deployment.

Many institutes include projects that reflect industry needs. This not only boosts confidence but also prepares students for immediate employment opportunities.

Interactive workshops led by industry experts are another critical feature. They offer insights into current trends and technologies, giving students a competitive edge in the job market.

Real-Life Applications and Case Studies

Embedded systems are the backbone of countless devices we rely on daily—their vast and varied applications, from smart home gadgets to advanced medical equipment.

Take automotive engineering, for instance. Modern vehicles utilize embedded systems for real-time data processing and safety features like anti-lock braking systems (ABS) and adaptive cruise control. These innovations enhance both performance and safety on the roads.

Embedded systems play a crucial role in patient monitoring devices in the healthcare sector. They ensure continuous tracking of vital signs, allowing for timely interventions when necessary.

Industries such as telecommunications depend heavily on these technologies. Communication networks leverage embedded solutions to manage data flow efficiently, ensuring seamless platform connectivity efficiently.

Each case study illustrates how mastering product life cycle management within embedded systems can lead to ground-breaking advancements across multiple sectors.

Benefits of Pursuing an Embedded Systems Course in Bangalore

Pursuing an embedded systems course in Bangalore opens doors to numerous opportunities. The city is a tech hub, attracting leading companies that seek skilled professionals. This demand translates into ample job openings for graduates.

Students benefit from hands-on training with state-of-the-art tools and technologies. They gain practical skills for tackling real-world challenges in product life cycle management.

Networking plays a vital role as well. Connecting with industry experts during the course can lead to mentorship and job referrals, enhancing career prospects significantly.

Courses often include project-based learning that mimics workplace scenarios. This approach prepares students effectively for future roles in various sectors like automotive, healthcare, and consumer electronics.

Choosing the right embedded training institute in Bangalore also ensures quality education aligned with current market trends while providing placement assistance.

Conclusion

Bangalore is a hub for technology and innovation. As the demand for embedded systems continues to rise, so does the need for skilled professionals. Mastering product life cycle management (PLM) skills through dedicated courses can significantly enhance career prospects.

Semicon TechnoLabs Pvt. Ltd ensures you receive quality education tailored to industry needs. Their curriculum encompasses essential concepts of PLM, providing you with practical insights into real-world applications.

With various VLSI courses in Bangalore and placement options, students have ample opportunities to kickstart their careers post-training. The best VLSI training institute in Bangalore focuses on theoretical knowledge and emphasizes hands-on experience and case studies, preparing graduates for immediate employment.

As industries evolve rapidly, staying ahead means investing time and resources into learning new skills. Engaging with the top 10 VLSI training institutes in Bangalore opens doors to networking opportunities and collaboration within tech communities.

Pursuing these specialised courses could be a game-changer for anyone looking to excel in embedded systems and product life cycle management. Embrace this opportunity today; it might just redefine your professional journey.

#top 10 VLSI training institutes in Bangalore#embedded training institute in Bangalore#best VLSI training institute in Bangalore#online VLSI courses in Bangalore

0 notes

Text

Best Practices for Eco-Friendly Computer Recycling

The rapid pace of technological upgrades means that computers and other electronic devices quickly become obsolete. However, simply discarding these outdated machines is not only wasteful but also harmful to the environment. With electronic waste being a growing concern, it’s more important than ever to recycle computers in an eco-friendly manner.

Today, responsible computer recycling isn’t just about getting rid of old equipment—it’s about making a conscious choice to protect our planet. Here’s how you can do it effectively while ensuring your actions contribute positively to environmental sustainability.

The Importance of Eco-Friendly Computer Recycling

Recycling computers in an eco-friendly manner is crucial because electronic waste (e-waste) is one of the fastest-growing waste streams in the world. Improper disposal of computers can lead to harmful chemicals like lead, mercury, and cadmium seeping into the environment. This not only pollutes the soil and water but also poses serious health risks to humans and wildlife.

Eco-friendly computer recycling ensures that valuable materials like metals, plastics, and glass are recovered and reused, reducing the need for raw material extraction. Additionally, it minimizes the amount of waste that ends up in landfills, supporting a more sustainable approach to product lifecycle management.

Here are the best practices for eco-friendly computer recycling

Selecting A Certified Computer Recycling Service That Meets Your Environmental Goals

Selecting the right computer recycling service is crucial to ensure that your old devices are disposed of responsibly. Look for a service provider that is certified by recognized environmental standards, such as R2 (Responsible Recycling) or e-Stewards. These certifications ensure that the recycling process meets strict environmental and data security standards.

It's also important to choose a recycling service that aligns with your company’s environmental goals. Ask about their methods for data destruction, as well as their processes for recycling different components of computers. A certified provider will also offer documentation and reports that confirm your devices have been recycled according to regulatory guidelines.

Ensuring Data Security Before Recycling

One of the main concerns when recycling computers is ensuring that all data is securely wiped from the devices. Simply deleting files is not enough, as data can still be recovered. To protect your business or personal information, it's essential to use certified data destruction methods before recycling your computer.

Certified computer recycling services offer data destruction processes that ensure all data is permanently removed. This includes options like physical destruction of the hard drive or using software to overwrite data multiple times. Ensuring data security not only protects sensitive information but also aligns with product lifecycle management by responsibly handling the end-of-life stage of your computer.

Incorporating Computer Recycling into Your Product Lifecycle Management Strategy

Effective product lifecycle management (PLM) involves planning for the entire lifespan of a product, from design and manufacturing to end-of-life disposal. Incorporating computer recycling into your PLM strategy ensures that your business handles outdated technology in a way that supports sustainability and compliance.

Start by creating a recycling policy that outlines how computers and other electronic devices will be disposed of when they reach the end of their useful life. This policy should include steps for secure data destruction, selection of a certified recycling service, and documentation of the recycling process. By making computer recycling a part of your PLM strategy, you demonstrate a commitment to environmental responsibility and resource conservation.

Overcoming Common Challenges in Computer Recycling for Businesses & Individuals

Recycling computers can come with challenges, especially when it comes to ensuring that the process is both environmentally friendly and secure. One common issue is the lack of awareness about how and where to recycle computers. Many businesses and individuals are unsure of the options available to them or may assume that simply dropping off devices at a local recycling center is sufficient.

To overcome this, research and identify certified computer recycling services in your area. These services often provide pick-up options for businesses, making it easier to recycle large volumes of equipment. Additionally, consider partnering with organizations that specialize in product lifecycle management to ensure that your recycling efforts are efficient and effective.

Another challenge is ensuring compliance with data protection regulations during the recycling process. By partnering with a certified recycling provider that offers secure data destruction, you can address this concern and confidently recycle your old computers.

Ready to Recycle? Contact Us for Certified & Secure Computer Recycling Services

Recycling your old computers in an eco-friendly manner is an essential step toward reducing e-waste and protecting the environment. By following these best practices and incorporating computer recycling into your product lifecycle management strategy, you can ensure that your technology is disposed of responsibly.

If you’re ready to take the next step, contact 3R Technology today to learn more about our certified and secure computer recycling services. Let us help you meet your environmental goals while ensuring that your data is protected and your old devices are recycled the right way.

3R Technology

8002 S 208th St E105, Kent, WA 98032

+12065827100

0 notes

Text

Upraise your Manufacturing business with Transines Solutions

Step Up Your Manufacturing Game and Embrace the Future-Ready Manufacturing Landscape

For business management, companies prefer a single software that can manage all the departments, like the accounting section, CRM management, sales and purchase section, and manufacturing field. Odoo simplifies all the different business stages and sections and integrating Odoo ERP for manufacturing will empower the business with increasing efficiency.

ERP software is the most important for a company since progress depends highly on the ERP System a company uses. the RRP System can make a business shine. So, a business should follow before choosing the Odoo Partner in UAE.

One Software for the Manufacturing processes Odoo ERP for the manufacturing business revolutionizing in the UAE market as the best manufacturing software.

Odoo Manufacturing Software Features

Odoo manufacturing ERP software is an ideal platform for production managers working in the manufacturing field. with Odoo ERP manufacturing businesses can get the Maximum retail price, execution systems (MES), Product lifecycle management (PLM), ERP Maintenance, and everything you need. the manufacturing ERP Simulates business operations in real-time, Manufacturing orders, capacity planning, components availability, and cost control. Odoo has barcode scanning for lots or serial numbers.

SCHEDULE YOUR ODOO CONSULTATION WITH TRANSINES SOLUTIONS

Business Scheduling with Odoo

Businesses must have experienced the pressure of hitting a deadline. Odoo ERP allows you to plan schedules with MRP Scheduler, multiple levels billing, a Kit for salespersons to sell products, and more

Manufacturing ERP lets you transform into a complete paper-free company, feedback scheduling, so the employe ain't want waste time in the manufacturing process.

Manufacturing business management software is a transformative power in the manufacturing industry. Odoo ERP helps with the processing of quality products and product maintenance, Odoo holds an automatic feature in the IoT box to trigger a quality check of all products before sending them to the manufactory. and Odoo provides a full maintenance report calculated from statistics.

The control panel has several convenient options like production recording, worksheets, alerts, work order steps, etc. Also directly from the work center more processes can created such as scraping products, perform checking and quality alerts creation.

Simplify cost counting with ease

Odoo Simplifies the manufacturing cost counting as it firstly calculates the cost of the components and the cost of operations, for sample, labor or material, and then tracks the cost of manufacturing consequently. All the traceability reports of the components used in the manufacturing business are accessible. Odoo Allows users to identify trends, uncover opportunities for improvement, and continuously optimize.

Transines Solutions Provides Odoo ERP Solutions to UAE businesses to raise the quality of your manufacturing business to another level with our Odoo Manufacturing Software. To learn more contact us

Also Read: How Odoo ERP can benefit the manufacturing industry

0 notes

Text

Revolutionizing Product Lifecycle Management: Unveiling the Power of SaaS PLM Solutions with Siemens Teamcenter

Title: Revolutionizing Product Lifecycle Management: Unveiling the Power of SaaS PLM Solutions with Siemens Teamcenter

With the evolving business landscape, digital transformation stands strong for companies striving to stay competitive. Particularly in the realm of Product Lifecycle Management (PLM), the choice between on-premises and Software-as-a-Service (SaaS) models significantly impacts efficiency, scalability, and innovation. Siemens Teamcenter emerges as a transformative hero, showcasing the unparalleled advantages of SaaS PLM solutions over traditional on-premises setups.

The SaaS PLM Software Advantage

1. Cost Efficiency

SaaS PLM solutions offer a cost-effective approach, eliminating the need for substantial upfront investments in hardware, infrastructure, and dedicated IT resources. With Siemens Teamcenter's SaaS model, companies can subscribe to tailored packages, paying only for the services they use. This drastically reduces capital expenditure while providing access to state-of-the-art PLM capabilities.

2. Scalability and Flexibility

Scalability remains a paramount factor in a dynamic market. SaaS PLM solutions offer seamless scalability, allowing businesses to adapt to evolving demands without over-provisioning resources. Siemens Teamcenter Software, as a SaaS PLM solution, enables easy scaling up or down based on project needs, ensuring flexibility in operations and resource utilization.

3. Accessibility and Collaboration

Cloud-based SaaS PLM solutions redefine accessibility and collaboration. Siemens Teamcenter facilitates real-time data access and collaboration from anywhere, fostering streamlined communication among teams, suppliers, and partners across the globe. This accessibility enhances decision-making, accelerates product development cycles, and strengthens inter-departmental synergy.

4. Rapid Deployment and Updates

Unlike on-premises models that often require lengthy deployment periods, SaaS PLM solutions like Siemens Teamcenter offer rapid implementation. Furthermore, updates and enhancements are seamlessly integrated into the system without disrupting ongoing operations, ensuring that companies consistently leverage the latest features and functionalities.

The Siemens Teamcenter Difference

Siemens Teamcenter emerges as a transformative force in the SaaS PLM landscape, embodying innovation, reliability, and comprehensive functionality:

1. Holistic PLM Capabilities

Siemens Teamcenter offers a comprehensive suite of PLM functionalities encompassing product data management, collaboration tools, manufacturing process planning, simulation, and more. This holistic approach streamlines workflows, enhances data integrity, and optimizes the entire product lifecycle.

2. Enhanced Security Measures

Data security is a critical concern in today's digital environment. Siemens Teamcenter prioritizes robust security measures, ensuring data encryption, role-based access controls, and compliance with industry standards, assuring companies of the highest level of protection for their sensitive information.

3. Future-Ready Innovation

With a commitment to innovation, Siemens Teamcenter constantly evolves to meet the ever-changing industry demands. Its SaaS model ensures that companies always have access to the latest technologies, such as AI-driven analytics, IoT integrations, and advanced visualization tools, empowering them to stay ahead in a competitive market.

4. Customer-Centric Approach

Siemens Teamcenter's customer-centric approach involves continuous support, training, and customization options tailored to individual business needs. This ensures a seamless onboarding experience and ongoing assistance to maximize the benefits of the PLM solution.

The Verdict

In the digital age, embracing SaaS PLM solutions like Siemens Teamcenter stands as a strategic imperative for businesses aiming to thrive in a rapidly evolving landscape. The unparalleled advantages of scalability, accessibility, cost-efficiency, and comprehensive functionalities position Siemens Teamcenter as the hero of digital transformation, enabling companies to innovate, collaborate, and drive success across the entire product lifecycle. As technology continues to advance, the SaaS model coupled with Siemens Teamcenter promises to redefine the future of Product Lifecycle Management Software, empowering businesses to achieve unparalleled efficiency and competitive edge.

#plm software#free plm software#plmsolutions#siemens plm solution#saas plm solution#saas plm software#product lifecyycle management software#siemens plm software#best plm software#plm experts

0 notes

Text

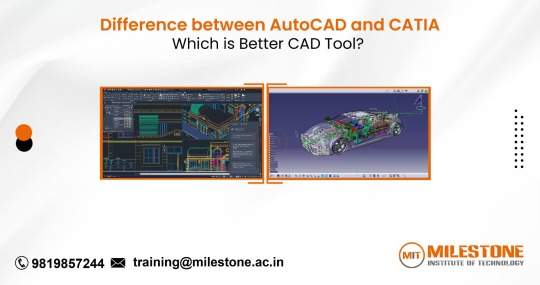

Difference Between AutoCAD and CATIA: Which is Better CAD Tool?

When it comes to Computer-Aided Design (CAD) tools, AutoCAD and CATIA stand out as two of the most prominent software options in the industry. Both tools are renowned for their robust capabilities, but they serve distinct purposes and excel in different areas. If you're trying to determine which CAD tool is best suited for your needs, understanding Catia vs AutoCAD key differences can guide your decision. In this blog, we'll explore the features, strengths, and typical applications of AutoCAD and CATIA to help you make an informed choice.

AutoCAD: The Versatile Workhorse

AutoCAD, developed by Autodesk, has been a staple in the CAD industry since its inception in 1982. It is renowned for its versatility and broad applicability across various industries, including architecture, engineering, and construction (AEC). Here are some of its standout features:

1. 2D Drafting and 3D Modeling: AutoCAD excels in 2D drafting, offering a range of tools for creating detailed floor plans, technical drawings, and schematics. While its 3D modeling capabilities are not as advanced as CATIA’s, AutoCAD still provides essential tools for creating and manipulating 3D models. This makes it suitable for projects that require a combination of 2D and basic 3D designs.

2. User-Friendly Interface: One of AutoCAD's significant advantages is its user-friendly interface. Its tools and features are relatively easy to learn and use, making it accessible for both beginners and experienced designers. Autodesk also offers extensive online resources, tutorials, and a large community that can assist with troubleshooting and tips.

3. Compatibility and Integration: AutoCAD supports various file formats and integrates well with other Autodesk products, such as Revit and Civil 3D. This compatibility is particularly beneficial for collaborative projects involving different software tools. Additionally, AutoCAD's widespread adoption means that file sharing and communication with other professionals are generally smooth.

4. Customization and Automation: AutoCAD allows for a high degree of customization through AutoLISP, VBA, and .NET programming. Users can create custom scripts and automation to streamline repetitive tasks, which can significantly enhance productivity.

CATIA: The Advanced Design Powerhouse

CATIA, developed by Dassault Systèmes, is renowned for its advanced capabilities in 3D design and is widely used in industries such as aerospace, automotive, and industrial design. It offers a suite of powerful tools tailored to complex design and manufacturing processes. Here’s what sets CATIA apart:

1. Advanced 3D Modeling and Simulation: CATIA excels in advanced 3D modeling and simulation. Its robust surface modeling, parametric design, and generative shape design tools make it ideal for creating intricate and highly detailed models. CATIA is particularly strong in handling complex geometries and assemblies, which is crucial for industries with demanding design requirements.

2. Integrated Product Lifecycle Management (PLM): CATIA is integrated with Dassault Systèmes' PLM solutions, offering comprehensive management of the entire product lifecycle. This integration provides tools for product design, simulation, and manufacturing, all within a unified platform. It’s particularly useful for managing complex projects and coordinating between different teams.

3. Industry-Specific Solutions: CATIA offers specialized tools and modules tailored to specific industries. For example, the automotive and aerospace industries benefit from CATIA’s advanced capabilities in creating and managing complex parts and assemblies. This industry-specific focus allows for optimized workflows and better alignment with sector-specific standards.

4. High-Precision Design: CATIA’s tools are designed for high precision and accuracy, making it ideal for projects that require detailed and exact design specifications. This precision is essential for industries where design errors can lead to significant costs or safety issues.

Choosing the Right Tool

Deciding between AutoCAD and CATIA depends largely on your specific needs and the nature of your projects:

For General Drafting and Basic 3D Modeling: If your work primarily involves 2D drafting with occasional 3D modeling, AutoCAD’s versatility and ease of use make it an excellent choice. It’s also a good fit if you need a tool that integrates well with other Autodesk products and provides robust support and community resources.

For Complex 3D Design and Industry-Specific Applications: If your work involves intricate 3D modeling, simulation, or product lifecycle management, CATIA is likely the better option. Its advanced features and industry-specific tools cater to complex design needs, especially in sectors like aerospace and automotive.

Ultimately, both AutoCAD and CATIA are powerful CAD tools with their own strengths and specializations. By evaluating the specific requirements of your projects and considering the features offered by each software, you can choose the CAD tool that aligns best with your needs and enhances your design capabilities.

0 notes

Text

Solidworks Software Reseller in Noida | Solidworks In India

Tech Savvy Engineers Pvt Ltd is an authorized SOLIDWORKS Software reseller in Delhi NCR, Gurgaon, Rajasthan, Haryana and Uttrakhand since 2002 . With our long-standing association with SOLIDWORKS in India, we are delivering the world class 3D CAD/CAM/CAE/PLM solutions. Being one of the reputed and renowned SOLIDWORKS Software distributors in India, we provide innovative, practical and cost-effective CAD/CAM/CAE/PLM solutions to product design and manufacturing companies in India. Our experienced and certified SOLIDWORKS Industry Consultants will help you to buy SolidWorks Software licenses at best prices and take ownership for effective implementation.

#BuySolidworksinHaryana#BuySolidworksSoftwareLicense#BuySolidworksSoftwareinIndia#SolidworksSoftwarePrice#SolidworksSoftwarePriceinIndia#solidworkspriceFaridabad#solidworksreseller#solidworkspriceGurgaon

0 notes

Text

CATIA vs SolidWorks: Making the Right Choice with Dynamic CAD CAM CAE in Chennai

Choosing the right CAD (Computer-Aided Design) software is crucial for engineering professionals and organizations that aim to excel in design, simulation, and manufacturing processes. Two of the most popular and powerful CAD software options available today are CATIA and SolidWorks. Both are developed by Dassault Systèmes and offer extensive features tailored to various industries and applications. However, each software has its unique strengths and caters to different user needs. In this blog, we will explore the key differences, advantages, and applications of CATIA and SolidWorks to help you make an informed decision. Additionally, we will highlight the best training institutes for both software in Chennai, such as Dynamic CAD CAM CAE, to support your learning journey.

Introduction to CATIA

CATIA (Computer-Aided Three-dimensional Interactive Application) is a comprehensive multi-platform suite developed by Dassault Systèmes. It is widely recognized for its robust capabilities in 3D design, engineering, and product lifecycle management. CATIA is extensively used in industries like aerospace, automotive, shipbuilding, and industrial equipment, where complex and high-precision designs are essential.

Key Features of CATIA

Advanced 3D Modeling: CATIA excels in creating highly detailed and complex 3D models. It supports a wide range of design processes, from conceptualization to detailed engineering.

Multidisciplinary Approach: CATIA integrates multiple disciplines within a single platform, including mechanical engineering, systems engineering, and electrical design. This holistic approach enables seamless collaboration among various engineering teams.

Product Lifecycle Management (PLM): CATIA is known for its strong PLM capabilities, allowing organizations to manage the entire lifecycle of a product from inception through engineering design and manufacturing.

Simulation and Analysis: The software provides advanced simulation tools for stress analysis, kinematics, and fluid dynamics, helping engineers validate designs and optimize performance.

Surface Modeling: CATIA offers powerful surface modeling tools, making it ideal for industries that require complex surface designs, such as automotive and aerospace.

Introduction to SolidWorks

SolidWorks is another powerful CAD software developed by Dassault Systèmes, designed primarily for mechanical engineering and product design. It is widely used in industries such as consumer products, machinery, and electronics due to its user-friendly interface and robust design capabilities.

Key Features of SolidWorks

User-Friendly Interface: SolidWorks is known for its intuitive and easy-to-use interface, which significantly reduces the learning curve for new users.

Parametric Design: The software uses parametric design principles, allowing designers to easily make changes and updates to their models. This feature is particularly beneficial for iterative design processes.

Extensive Library of Components: SolidWorks offers a vast library of pre-built components and parts, saving time and effort in the design process.

Simulation and Analysis: Similar to CATIA, SolidWorks provides powerful simulation tools for stress analysis, motion analysis, and thermal analysis, enabling engineers to test and validate their designs.

Integration with CAM: SolidWorks integrates seamlessly with Computer-Aided Manufacturing (CAM) tools, facilitating the transition from design to manufacturing.

Comparing CATIA and SolidWorks

While both CATIA and SolidWorks are highly capable CAD software, their distinct features and functionalities make them suitable for different types of projects and industries. Let’s compare some key aspects to help you determine which software is the right fit for your needs.

Complexity and Scope

CATIA: Designed for large-scale and complex projects, CATIA is ideal for industries that require high precision and intricate designs. Its advanced surface modeling and PLM capabilities make it the preferred choice for aerospace, automotive, and industrial equipment sectors.

SolidWorks: Best suited for small to medium-sized projects, SolidWorks is widely used in industries like consumer products, machinery, and electronics. Its user-friendly interface and parametric design capabilities make it an excellent choice for mechanical engineering and product design.

Learning Curve

CATIA: Due to its extensive features and advanced functionalities, CATIA has a steeper learning curve. It requires more time and effort to master, making it essential for users to undergo comprehensive training.

SolidWorks: Known for its intuitive interface, SolidWorks has a shorter learning curve. Users can quickly become proficient with the software, making it a popular choice for beginners and those who need to start designing without extensive training.

Cost

CATIA: As a more complex and feature-rich software, CATIA tends to be more expensive than SolidWorks. The cost includes not only the software license but also potential training and implementation expenses.

SolidWorks: Generally more affordable than CATIA, SolidWorks offers a cost-effective solution for small to medium-sized businesses. The lower cost makes it accessible to a wider range of users and organizations.

Industry Applications

CATIA: Primarily used in aerospace, automotive, shipbuilding, and industrial equipment industries, CATIA’s advanced features and capabilities make it the go-to choice for companies involved in complex and large-scale projects.

SolidWorks: Widely used in consumer products, machinery, and electronics industries, SolidWorks is ideal for mechanical engineering, product design, and manufacturing processes that require a straightforward and efficient design tool.

Training and Certification

Proper training is essential to maximize the potential of any CAD software. In Chennai, Dynamic CAD CAM CAE is a renowned training institute offering comprehensive courses for both CATIA and SolidWorks. Let’s explore the training programs offered by this institute.

CATIA Training at Dynamic CAD CAM CAE

Dynamic CAD CAM CAE provides in-depth CATIA training programs designed to equip students with the knowledge and skills required to excel in the industry. The training covers:

Introduction to CATIA: Basics of the software, interface navigation, and essential tools.

3D Modeling: Techniques for creating detailed 3D models, including part design and assembly design.

Surface Modeling: Advanced surface design tools and techniques for creating complex shapes.

Simulation and Analysis: Utilizing CATIA’s simulation tools for stress analysis, kinematics, and more.

PLM Integration: Understanding CATIA’s PLM capabilities and how to manage product lifecycles effectively.

SolidWorks Training at Dynamic CAD CAM CAE

Dynamic CAD CAM CAE also offers specialized SolidWorks training programs tailored to meet industry standards. The training includes:

Introduction to SolidWorks: Basics of the software, interface, and core functionalities.

Part and Assembly Design: Techniques for creating parametric models, assemblies, and detailed drawings.

Simulation and Analysis: Using SolidWorks simulation tools for stress analysis, motion analysis, and thermal analysis.

CAM Integration: Understanding the integration between SolidWorks and CAM tools for seamless manufacturing processes.

Advanced Features: Exploring advanced design features, such as sheet metal design, weldments, and surfacing.

Choosing between CATIA and SolidWorks depends on your specific needs, industry requirements, and project complexity. CATIA is the preferred choice for industries that require advanced 3D modeling, surface design, and PLM capabilities, such as aerospace and automotive. On the other hand, SolidWorks is ideal for mechanical engineering, product design, and manufacturing processes in industries like consumer products, machinery, and electronics.

For those looking to gain expertise in either software, Dynamic CAD CAM CAE in Chennai offers top-notch training programs to help you master CATIA and SolidWorks. Whether you are an individual seeking to enhance your skills or an organization looking to train your team, Dynamic CAD CAM CAE provides comprehensive training solutions to meet your needs.

By understanding the key differences and advantages of CATIA and SolidWorks, and with proper training from a reputable institute like Dynamic CAD CAM CAE, you can make an informed decision and excel in your CAD projects. Embrace the right CAD software and unlock your potential in the world of design and engineering.

Choosing Between CATIA and SolidWorks: FAQs to Guide Your Decision with Dynamic CAD CAM CAE in Chennai

1. What are the primary differences between CATIA and SolidWorks?

CATIA and SolidWorks are both powerful CAD software developed by Dassault Systèmes, but they cater to different needs and industries. CATIA is designed for large-scale and complex projects, particularly in aerospace, automotive, shipbuilding, and industrial equipment industries. It excels in advanced 3D modeling, surface modeling, and product lifecycle management (PLM). SolidWorks, on the other hand, is best suited for small to medium-sized projects in consumer products, machinery, and electronics industries. It is known for its user-friendly interface, parametric design capabilities, and cost-effective solutions.

2. How do the learning curves of CATIA and SolidWorks compare?

CATIA has a steeper learning curve due to its extensive features and advanced functionalities. It requires more time and comprehensive training to master, making it essential for users to undergo in-depth courses. SolidWorks is known for its intuitive and easy-to-use interface, which significantly reduces the learning curve. Users can quickly become proficient with the software, making it a popular choice for beginners and those who need to start designing without extensive training.

3. What industries are CATIA and SolidWorks most suitable for?

CATIA is primarily used in industries that require high precision and intricate designs, such as aerospace, automotive, shipbuilding, and industrial equipment. Its advanced features and PLM capabilities make it the preferred choice for companies involved in complex and large-scale projects. SolidWorks is widely used in consumer products, machinery, and electronics industries. It is ideal for mechanical engineering, product design, and manufacturing processes that require a straightforward and efficient design tool.

4. How much does it cost to get trained in CATIA and SolidWorks in Chennai?

The cost of training in CATIA and SolidWorks can vary based on the training institute and the depth of the course. At Dynamic CAD CAM CAE in Chennai, comprehensive training programs are offered for both software. While the exact costs can vary, investing in quality training ensures that you gain the necessary skills to excel in your career. It is advisable to contact Dynamic CAD CAM CAE directly for detailed pricing and course information.

5. Why should I choose Dynamic CAD CAM CAE for CATIA and SolidWorks training in Chennai?

Dynamic CAD CAM CAE is a renowned training institute in Chennai, offering in-depth courses for both CATIA and SolidWorks. The institute provides specialized training programs designed to meet industry standards and equip students with the knowledge and skills required to excel in their careers. With comprehensive courses covering everything from basic to advanced features, simulation and analysis, and integration with other tools, Dynamic CAD CAM CAE ensures that you receive top-notch training and are well-prepared for the demands of the industry.

0 notes

Text

Top 9 Reasons why AWS jobs pay $100,000+ a year

What are the benefits of learning AWS technology? Cloud enthusiasts curiously ask this question.

There are tens of benefits of learning AWS skills but the most obvious one is that it pays you way more than your investment in its learning. Today, AWS professionals earn a handsome basic salary of approximately US$100,000/year with jobs guaranteeing security along side offering a wide range of career options. The pay trend has been common worldwide because top global companies have shifted to the new, remote work model.

Talking on facts, AWS skills are higher in demand compared to Azure and Google Cloud Platform. This article uses the most credible research sources to discern why over 1 million end-users, early stage startups and cloud learners prefer AWS to process their workloads and acquire free hands-on experience.

1. Enterprises increasingly find value on AWS Cloud

Enterprises around the globe have migrated their workloads on the AWS Cloud. According to official figures from AWS, there are over 1 million active customers of AWS that carry business workloads over the cloud. A market research from Enlyft reveals that there are 1,046,008 companies on AWS with most of the users belonging to the United States and from the Retail Industry.

Along with the above, a large span of 100,000 global partners, as well as the largest suite of 200 services (compared to Azure and GCP), companies preferably find value on the AWS platform.

AWS also offers small and medium businesses (SMBs) three types of absolutely free access to its cloud services unlocking for them incredible value through the most innovative cloud brand.

To understand how companies drive value from the AWS cloud, consider the following real-world problem scenarios that have been successfully tackled by Amazon Web Services.

LU-VE is an Irish global air heat exchanger manufacturer who saw an increase in business units using its core applications: ERP and Siemens PLM. With 30% more users on the softwares now, LU-VE’s existing IT infrastructure needed to be scaled. With SAP HANA on AWS, LU-VE not only leveraged the cost benefits but acquired greater computation speed, and improved availability for the users.

Amgen, a pharmaceutical company in the United States has recently built a data lake on Amazon Redshift (one of the AWS services). Producing new products, the leading manufacturer met an increased number of consumers resulting in greater data volume and variety. Having to move to big data, Amgen’s existing data warehouse became paltry with new hardware installations becoming expensive and time consuming. With AWS, Amgen saved hardware costs and enhanced patient experience from an end-to-end automation making data driven decision making faster and reliable.

ISM Conseil is a drafting and design consultancy based in Canada. Innovating in floor panel designs, ISM required uninterrupted computation in simulating a floor panel design to protect workers from harmful components during smelting. Using the OnScale Solve service on AWS, ISM reached a 400% gain in processing its simulation thereby saving time and prohibitive hardware costs.

With such profound value provided to organizations, no wonder why companies see AWS skills as highly valuable and are willing to pay the highest salaries.

Jump to read the salary information against each cloud computing job role.

2. AWS shows Sustainable Potential for future growth

As a final prospect, another Gartner forecast says that the ‘end-user spending on cloud services’ are to increase a wholesome of 46%, reaching $600 billion by 2023, from $410.9 billion in 2021.

In the light of above stats: when more end-users will spend on the cloud, and AWS leads in the cloud services, job security of cloud professionals is guaranteed. If you’re thinking of adopting a cloud career, then this is the best time to invest in learning cloud computing skills.

3. AWS offers Free Tier Access to its largest, geographically available services

Anyone can sign-up for a free tier access on AWS and get valuable hands-on experience on over 100 services, for the next 12 months for free. Some winning AWS services, including AWS Lambda and DynamoDB, are labeled under ‘always-free’ and don’t expire even after the 12 month period.

Moreover, for early stage startups, the AWS Activate Founders program lets enthusiasts build business on the cloud, for free. The program includes: access to AWS services under its vast 21 product categories including: ‘compute’, ‘storage’, ‘database’, ‘mobile and web’ and ���machine learning’, as well as founder learning through free training on ‘AWS cloud practitioner Essentials’.

In comparison to the immediate competitors: Azure and Google Cloud Platform, AWS free tier offers more extensive services; over 100. For example, Azure offers over 47 services under its free tier feature whereas GCP allows for a smaller 20+ services.

As another point of comparison, the compute engine and cloud storage by GCP are restricted to just a few regions whereas end-users get free access to AWS compute and storage from any corner of the world.

The vast free services and tools available over a wider geographical reach makes AWS top priority for end-users. This creates a greater chance of conversion to the AWS paid services compared to what Azure and GCP offers. With this in mind, it’s not an over statement to day that when more companies are adopting AWS, the hands-on experience in Azure and GCP are pretty much less required compared to AWS thereof.

In conclusion, learning AWS skills is a way to promising cloud computing careers where organizations are increasingly seeking AWS experts across the platform’s largest 21 product categories housing over 200 total services.

4. AWS Skill Builder offers Free Learning Resources

At the AWS Trainings and Certification program, the AWS Skill Builder offers free digital learning content on 500+ courses, 10 AWS practice question sets for clearing the certification exam, and using its playful AWS Cloud Quest game as a virtual AWS practitioner.

This free digital learning, created by AWS experts, not only builds an everlasting foundation for freshers but also helps them decide a cloud computing job role that suits their interests.

The AWS community is another platform that treasures vast learning resources from AWS content creators who share solutions to the hard-to-solve problems. Apart from reading insightful blog posts, AWS enthusiasts can join the vibrant network of AWS developers to connect, ask questions, exchange ideas, seek technical support and career mentorship, and learn about best practices in the AWS landscape.

Additionally, there are volunteer-led AWS communities run by local AWS developers and industry leaders. Such platforms offer a unique support to AWS developers taking on problems in the local market. For example: the AWS Community Pakistan works to bridge the gap in academia and industry, taking students and freshers over a concrete path of AWS career.

In short, starting and sustaining a career in cloud computing is made super easy with the vastly available, free learning resources created and shared by the global and local AWS experts themselves.

5. AWS Certified experts can earn $100,000+/year

AWS certification brings credibility to the profile of a cloud engineer. This way, aspiring AWS experts can target high paying job roles, such as that of a cloud engineer manager, at corporate level organizations. The certification is also compulsory for a cloud architect (the most senior level job role) that pays a minimum $100,000/year in salary.

Organizations with a coherent vision on cloud initiatives seek experts with AWS official certification. According to the official AWS research, 90% of partner companies whose employees were AWS trained, are in a competitive position for the next three to five years. Over 70% of companies achieved many business benefits such as improved operational efficiency in cloud engineering workflows.

Note, the only way for a recognized AWS certification is through passing the official exam by AWS. Starting your AWS knowledge with its free digital training is a good idea. But to pass the exam, the majority of individuals prefer an in-person and interactive learning environment that provides an in-depth theoretical and hands-on experience by an industry expert. This way, aspiring individuals can quickly and easily grasp the crux of AWS infrastructure, tools and services.

One such opportunity is to prepare for the AWS certification exam through Dice Analytics. An in-person, interactive yet affordable learning is provided to freshers and working professionals in the AWS cloud workspace. Visit our upcoming AWS training details at Dicecamp.

6. AWS Skills are highly compensated

According to Glassdoor, AWS cloud experts earn a basic pay that is one of the highest in IT disciplines. Following are the salary data on six AWS cloud computing job roles in the US market. Please note that, in 2022 global companies have hired cloud computing talent based on remote work model, across different regions including Pakistan. The salary is therefore competitive across the globe.

An average basic pay:

AWS Cloud Engineer: $101,259 / yr

AWS Cloud Architect: $117,630 / yr

AWS Cloud Developer: $96,316 / yr

AWS Cloud Administrator: $82,874 / yr

Cloud Network Engineer: $101,570 / yr

Security Engineer: $97,171 / yr

7. AWS leads in Innovation

AWS was an early adopter of cloud technology back in 2006 when no other competitor existed. In collaboration with its largest partner network of 100,000 global partners, a host of AWS services are truly innovative in nature and are novel to the AWS platform. These services include, for example, AWS Lambda and Amazon SageMaker.

As of AWS Lambda, it’s a highly value-adding feature for cloud developers that automates tasks in server management. This means, a developer just uploads the code (containing essential information on when a Lambda event is triggered and its response), and the rest of what to do with the workflow is taken care of by Lambda.

Even today, as break through technologies such as AI are increasingly used within business applications, AWS leads with its Amazon SageMaker, a cloud AI tool that lets developers deploy and run an AI trained model in a single click.

Due to its ability to innovate new tools that address challenging business problems, professionals make AWS a top priority in seeking top-notch and customized cloud services.

8. Foolproof Security services on the AWS Cloud

AWS protects workloads and applications running on its global cloud with a comprehensive set of 28 security services. AWS’s protection of the cloud is centered around three dimensions: security, identity and compliance.

AWS encryption, access management and threat detection services allow end-users to protect their data on the cloud from unauthorized and fraudulent access.

Identity management at scale, allows companies to seamlessly manage access control for employees and customers-facing applications. Users can protect their cloud network through AWS network security policies.

AWS also offers compliance monitoring through its automated compliance check service using which a company can get security compliance reports based on AWS best practices and industry standards the organization follows.

9. Regions and Availability

AWS cloud infrastructure is dotted around the largest, 28 geo locations that carry 90 availability zones in total. In the realm of cloud computing, an availability zone is a geographically dependent region that is assigned from to an end-user closer to its premises. Using Availability zones, AWS offers its services with a single digit millisecond latency.

Furthermore, AWS divides its availability zones into local zones and wavelength zones to provide ultra low latency to its users.

There’s more coming.

As of Q4, 2022, AWS announced 21 new availability zones and 7 new geo locations in Australia, Canada, India, Israel, New Zealand, Spain, and Thailand. Find latest information at the AWS Global Infrastructure.

An affordable, quick path to AWS official certification!

Dice Analytics brings an affordable and quick path for cloud learners to securing an AWS official certification through its interactive live 2-month training on Cloud Computing with AWS.

In this course learners will gain working knowledge of how to effectively design, deploy and manage scalable cloud infrastructure for any business scenario. The course contents focus on core AWS concepts (essential for passing official AWS certification exam) and include an in depth hands-on practice on:

Linux CLI

Amazon Elastic Compute Cloud (EC2)

Elastic load balancer

Virtual private cloud (VPC)

Simple Storage Services (S3)

Cloud monitoring

Database management

View course details of our live training on Cloud Computing with AWS.

What’s the value?

Cloud computing with AWS training offers an in-person, virtual classroom environment through Dice Analytics’ digital learning portal. This empowers learners to gain an in-depth theoretical and technical understanding of AWS concepts in an interactive live session.

Through our digital portal, learners have the opportunity to study at their own schedule via recorded lectures, thereby offering the advantage of managing the course and exam preparation at self-pace with a free re-enrollment in the subsequent batch.

Mentorship, career counseling and AWS official exam preparation guide is offered to learners alongside an industry recognized certificate of completion, on successful passing of the exam.

0 notes