#steel wire industry in india

Explore tagged Tumblr posts

Text

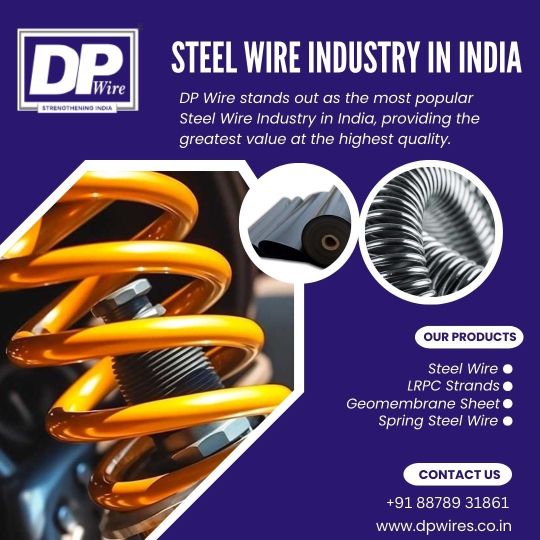

Top Steel Wire Manufacturers and Suppliers in India - Dp Wires

Dp Wires proudly stands as one of the top Steel Wire Manufacturers and suppliers in India, renowned for setting industry standards for reliability and quality. We not only lead the industry in the production of steel wires, but we also excel at providing a large selection of single-strand stainless steel wires.

Our products, which are carefully packaged in bundles or drums weighing 20 to 250 kg, are used in a wide range of industries, including the chemical, oil and gas, textile, machinery and pumping industries. Dp Wires guarantees excellent quality with finishes ranging from dull to bright drawn and shiny, making us the go-to option among those looking for dependable steel wire solutions in India.

For more information, Visit our site - Https://www.dpwires.co.in

#Steel Wire Manufacturers#Steel Wire Industry in India#Lrpc Strands#Geomembrane Sheet#Spring Steel Wire

2 notes

·

View notes

Text

Best MS Wire Mesh Manufacturer, Supplier, and Exporter in India - Mcneil Instrument

The best MS wire mesh manufacturer in India is Mcneil Instrument. A wide variety of MS Wire Mesh is available thanks in large part to us. These are highly praised by customers for their durable design, precise dimensional measurements, and great functional effectiveness. With excellent strength and corrosion resistance, MS wire mesh ensures long-lasting performance. Its affordability and easy maintenance further enhance its appeal for both industrial and residential projects. It provided a sturdy, long-lasting framework that could tolerate harsh external circumstances and was expertly welded from junction. McNeil Instrument ensures precision in every step of the production process. Our modern machinery and skilled workforce collaborate seamlessly to create mild steel wire mesh that meets the stringent requirements of diverse industries.

" https://www.mcneilinstrument.com/ms-wire-mesh.html "

0 notes

Text

#Steel wire ropes industry india#wire rope manufacturing company#Steel Wire Ropes manufacturer#Global wire rope manufacture#wire rope supplier in Germany#Netherlands#UK#Turkey#USA#Singapore#Dubai#Steel wire ropes manufacture#steel wire rope

0 notes

Photo

"Hatelloy Wires Manufacturer & Exporter."

Bhansali Enterprise sells a lot of products made of Hastelloy. One of them is Hastelloy C22 wire, which is made from the best raw materials. C22 alloy, a very versatile alloy, is used to make Hastelloy C22 wire. It is made up of chromium, nickel, tungsten, molybdenum, and other elements. Components made of material grade C22 have increased resistance to corrosion and a variety of industrial chemicals as a result of these elements. Bhansali Enterprise offers Hastelloy C276 Wire in various size shapes and details according to the prerequisite. These Hastelloy C276 Wires are made out of a super-compound that is appropriate in high-temperature applications. It is made up of chromium, nickel, and molybdenum alloy, which has excellent resistance to corrosion in an oxidizing environment. It is a corrosion-resistant alloy made of nickel, chromium, and molybdenum. Stress corrosion cracking, crevice corrosion, and pitting are all prevented by this alloy. These Hastelloy C276 Wires shows the capacity to limit the carbide precipitation while welding. Additionally, it exhibits excellent resistance to minimizing or preventing grain boundary precipitates during welding. HASTELLOY X WIRE is Bhansali Enterprise’ highest-grade wire and is widely used in a wide range of applications. Our wire is shaped in the ways that are needed in a variety of industries. These wires are held to specified standards, and dimensional changes define various specifications. With a higher Hastelloy grade, these wires are easier to form and more ductile. It has a higher tensile strength and is made specifically for use in applications at higher temperatures. HASTELLOY X, also known as a superalloy, is a high-performance alloy that keeps features like super strength, resistance to creep and cracking, and sustainability under high temperatures and corrosion.

#stainless steel wire#wire manufacturers#stainless steel wire manufacturers in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#hastelloy composition#hastelloy c276 chemical composition#polished stainless steel#stainless steel manufacturers in india

0 notes

Text

Cable Trays Manufacturers in India

Introduction

Cable trays are essential components in electrical and communication infrastructure, designed to support and organize cables in various settings. They provide a secure pathway for electrical wiring and data cables, ensuring they remain organized and protected. If you are searching for reliable Cable Trays Manufacturers in India, Santoshi Industries is your destination for high-quality products. Based in Bhilai, Chhattisgarh, we are recognized leaders in manufacturing and supplying perforated cable trays across the country. Our trays are expertly fabricated from M.S. sheets or pre-galvanized sheets, with perforations on top to ensure optimal ventilation and cable management.

Available in various widths and standard lengths, our cable trays provide versatile solutions for your needs. We source our raw materials from esteemed steel plants such as JSW, POSCO, TATA, and ESSAR steels, ensuring superior finishing and smoothness. Our pre-galvanized trays are ready for immediate use post-fabrication, while our M.S. trays receive treatments such as enamel paint, powder coating, or hot dip galvanizing. Trust Santoshi Industries for durable and reliable cable trays that prioritize safety and performance, making us a leading name among Cable Trays Manufacturers in India.

Durable and Reliable Cable Trays for All Applications from Leading Cable Trays Manufacturers in India

At Santoshi Industries, a leading name among Cable Trays Manufacturers in India, we understand the critical role that durable and reliable cable trays play in various applications. Based in Bhilai, Chhattisgarh, our commitment is to deliver cable trays that not only meet but exceed industry standards for strength and reliability.

Our cable trays are designed to withstand the toughest conditions and are ideal for a range of applications, including:

Industrial Factories

Warehouses & Manufacturing Plants

Office Buildings

Shopping Malls & Hotels

Data Centers

Electrical Installations

Utility Plants

Our cable trays are made from high-quality materials, including mild steel and pre-galvanized sheets, ensuring long-lasting durability. They feature perforated designs for ventilation and ease of cable tying, with options for finishing such as hot dip galvanizing, painting, and powder coating. Choose Santoshi Industries for your cable tray needs and benefit from our extensive expertise and dedication to quality. As one of the top choices among Cable Trays Manufacturers in India, we are committed to providing solutions that meet the diverse requirements of our clients across various industries.

Contact Us for Your Cable Trays Manufacturers in India Today

Looking for top-notch cable trays? Santoshi Industries, a prominent name among Cable Trays Manufacturers in India, is ready to assist with your requirements. From our base in Bhilai, Chhattisgarh, we offer a comprehensive range of high-quality cable trays across the country, including custom solutions tailored to your needs.

For inquiries or orders, reach out to us:Phone:+91-8109006000, 0788–4033833Email:[email protected] and [email protected]: 134/A, Light Industrial Area, Bhilai Nagar, Chhattisgarh 490026

Connect with us today for reliable cable trays and exceptional service!

2 notes

·

View notes

Text

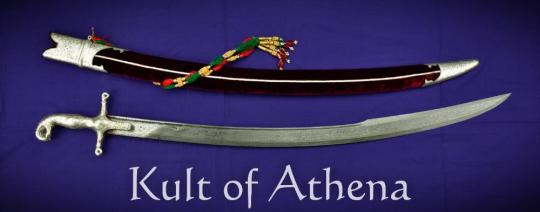

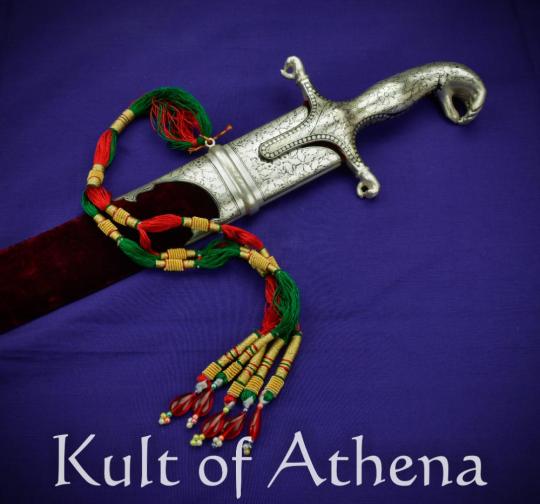

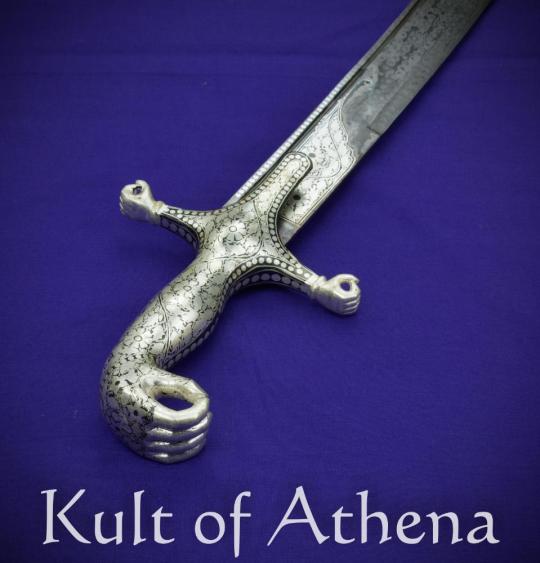

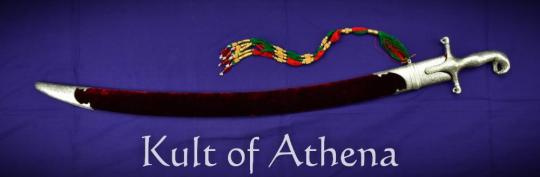

Damascus and Silver Koftgari Indian Saber with Hand design – Universal Swords

This ornate and entirely handcrafted saber from India with its damascus blade and koftgari-inlay embellishment is in itself a display of the traditional swordsmithing arts of India. The damascus steel blade features panels of silver inlay on both sides of the blade. The blade tang is secured by filling the hollow hilt and grip with a hardened resin to solidly anchor it into the hilt. This method of sword construction is a traditional technique in India.

The sword is paired with a wood-core scabbard overlaid in vibrant velvet. Its steel components were decorated with silver koftgari to match the sword. The Damascus steel blade is crafted from the melding of two different steels into a single billet from which the smith forges the blade; the mixed steel leaves a vibrantly visible rippled patterning on the blade surface. Traditionally this was a technique done to merge harder and softer steels into a single blade to impart it with both a hardness for durability and edge retention and a degree of flexibility to prevent the blade from becoming brittle.

This was done to get good results from the quality of iron available for smithing. Damascus is now technically inferior to pure steel made from modern industrial-scale methods, but it is still desired as the beauty of Damascus is instantly notable and is a testament to the skill of the smith who forged it with the traditional methods and the blade was further embellished with silver inlay at the base of the blade. The elegant and intricate design and patterning on the hilt was created with the laborious Koftgari technique; a traditional process exemplified by Indian smiths whereby a design is etched and chiseled and then strands of silver wire is carefully hammered into the etched design. The hilt is then heated in a kiln and the silver wire is then permanently annealed into a permanent design.

The patterning of the damascus blade varies with each blade in much the same manner as all fingerprints differ. Also the Koftgari designs are made to the individual design and artistry of the smith. Therefore every one of the swords of this type are uniquely crafted and are a testament to the traditional swordsmithing techniques of India.

Please Note: Unique Item – Only One Available!

#Kult of Athena#KultOfAthena#New Item Wednesday#Koftgari Indian Saber#Damascus and Silver Koftgari Indian Saber with Hand design#Universal Swords#Middle Eastern Indian & N. African Swords#sword#swords#weapon#weapons#blade#blades#sabers#Damascus Steel#Battle Ready#Indian Swords#Indian Weapons#Middle Eastern Swords#Middle Eastern Weapons

2 notes

·

View notes

Text

Supplier of Industrial Valve in Tamil Nadu

Meghmani Metal: Meghmani Metal is an ISO 9001:2015 certified supplier of industrial valves based in Tamil Nadu, India. The company offers a diverse range of stainless steel products, including steel flanges, SS fasteners, steel butt welding, steel pipe fittings, steel rods, wires, coils, and flats. Meghmani Metal crafts industrial valves from various material grades, including stainless steel and high nickel alloys. Their warehouse stocks a variety of valves such as ball valves, gate valves, control valves, needle valves, globe valves, butterfly valves, check valves, safety valves, and more. Specifications: Standard: ASTM A240, JIS4304-2005, ASTM A167, EN10088-2-2005, GB/T3280-2007, etc. Specifications: ASTM A240 / ASME SA240 Sizes: Ranging from 1000mm x 2000mm, 1220mm x 2440mm, 4′ x 8′, 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, and 2000mm x 4000mm to 6000mm. Length: Options include 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. Thickness: Varying from 0.3mm to 100mm. Range: Extending from 5mm to 150mm. Surface Finishes: Various surface finishes are available, including hot rolled plate (HR), cold rolled sheet (CR), 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hairline, sandblast, brush, etching, SATIN (met with plastic coated), and more. Service Coverage: Meghmani Metal serves as a prominent supplier of industrial valves in Tamil Nadu, covering areas such as Arcot, Chengalpattu, Chennai, Chidambaram, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kanchipuram, Kanniyakumari, Kodaikanal, Kumbakonam, Madurai, Mamallapuram, Nagappattinam, Nagercoil, Palayamkottai, Pudukkottai, Rajapalayam, Ramanathapuram, Salem, Thanjavur, Tiruchchirappalli, Tirunelveli, Tiruppur, Thoothukudi, Udhagamandalam, and Vellore. For further inquiries and information, interested parties are encouraged to contact Meghmani Metal. Read the full article

#Arcot#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#Exporter#India#IndustrialValve#Kanchipuram#Kanniyakumari#Kodaikanal#Kumbakonam#Madurai#Mamallapuram#Manufacturer#Nagappattinam#Nagercoil#Palayamkottai#Pudukkottai#Rajapalayam#Ramanathapuram#Salem#supplier#Thanjavur#Thoothukudi#Tiruchchirappalli

3 notes

·

View notes

Text

Complete Manual on Hanging Scaffold Systems or Suspended Rope Platforms for plastering

In the realm of construction and maintenance tasks, there’s a stalwart ally that stands tall, quite literally. The Suspended Rope Platform (SRP), often recognized as a gondola or working platform, has become an indispensable tool for a spectrum of vertical endeavors. Specifically, in India, these platforms have etched their place firmly in various industries, revolutionizing the way projects are undertaken.

Evolution of Rope Suspended Platforms

Initially embraced primarily by major facade contractors, the trajectory of SRPs has undergone a significant shift. Over the past three years, a seismic shift has been witnessed, with the paint industry, spanning from manufacturers to applicators, showing an avid interest. This surge in demand has propelled manufacturers of these platforms to the forefront, dominating the market for close to a decade.

The utilization of Suspended Rope Platform isn’t confined to a singular purpose. From external wall plastering, painting high-rise structures, installing glass facades to the maintenance of expansive external surfaces, the applications are diverse and extensive. Even in scenarios necessitating alterations or demolition of buildings, these platforms emerge as indispensable temporary structures.

The Rise of Rope Suspended Platforms

What sets SRPs apart is their ascendance as the preferred mode of access across construction sites. Traditionally, scaffolding held sway, but the inherent advantages of SRPs, including efficiency and versatility, have prompted their ubiquitous presence in the construction landscape.

Quality and Innovation

Platforms like the hanging rope platform hoists from Jaypee India epitomize excellence, constructed meticulously using premium materials such as stainless steel and aluminum. The emphasis on stringent quality control ensures adherence to specified durability and reliability standards, ensuring that only the finest products reach customers.

Moreover, manufacturers of SRPs have undertaken a trajectory of innovation. Varied versions of these platforms cater to diverse job site specifications. Engineers have meticulously designed these platforms, integrating multiple safety measures to mitigate the inherent risks associated with erecting and maintaining tall structures.

Safety Features and Engineering Excellence

Safety stands paramount in the realm of suspended platforms. Manufacturers have embedded an array of safety features into their products to ensure secure operations:

Rope Failure Prevention: Incorporating locks to prevent tilting due to rope failure.

Advanced Technology: Integration of sophisticated mechanical and control electronics.

Quality Wire Ropes: Utilization of high-grade steel wire ropes to guarantee robustness.

Optional Overload Sensing: Offering the option for sensing overload, further enhancing safety.

Cable Locking Angle: Ensuring a secure cable locking angle of 3–8 degrees.

Superior Suspension Systems: Technologically superior suspension systems enhancing stability.

Durability: A testament to longevity, these platforms are engineered to withstand prolonged usage without succumbing to wear and tear.

Sturdy Construction: With a solid construction, these platforms exude reliability and stability.

Energy Efficiency: Notably, the energy requirements for operating these platforms are considerably lower compared to alternative access systems.

Proficient Management and Operations

One defining aspect of the Suspended Rope Platform (SRP),landscape in India is the involvement of extensively trained professionals overseeing the operation and maintenance of these platforms. Amidst a competitive market, manufacturers differentiate themselves by providing top-tier suspended platform services. These adept specialists, well-versed in every facet of access equipment, ensure superior maintenance and repair services right on the job site. From initial setup to operationalizing the platform, these professionals handle it all with finesse and expertise.

In conclusion, the evolution of suspended rope platforms for plastering and other vertical endeavors has heralded a paradigm shift in the construction and maintenance landscape. With an emphasis on safety, innovation, and efficiency, these platforms have become the linchpin in accessing vertical spaces, promising durability, reliability, and optimal performance. As the industry continues to evolve, these platforms are poised to remain at the vanguard, catering to the ever-expanding demands of vertical construction and maintenance tasks.

#Suspended rope platform for plastering#Suspended rope platform#Rope Suspended platform for plastering#Buy Suspended Rope Platform#Rope Suspended Platform (RSP)#Construction Equipment Manufacturer and Supplier in India#Construction Equipment#Facade cleaning system manufacturers in india#Gondola Suspended Rope Platform Manufacturer

3 notes

·

View notes

Text

The Role of Wire Rope in Heavy Lifting Operations

When it comes to heavy lifting operations, wire ropes are indispensable. From construction sites to shipping yards, these robust cables serve as the backbone of lifting machinery, ensuring safety and efficiency. With their unparalleled strength and versatility, wire ropes enable industries to handle massive loads with ease. Understanding their role, construction, and application is essential for anyone involved in heavy lifting tasks.

What is a Wire Rope?

A wire rope is a complex assembly of wires twisted into strands and laid around a core. This design provides it with the flexibility, strength, and durability needed to handle heavy loads. Manufactured using high-grade steel, wire ropes are engineered to withstand extreme stress and harsh environmental conditions.

Why Are Wire Ropes Crucial in Heavy Lifting?

Wire ropes are essential in heavy lifting operations because of their ability to distribute loads evenly across multiple strands. This design minimizes wear and tear, ensuring a longer lifespan even under constant use. Industries such as construction, mining, and shipping rely heavily on wire ropes for their ability to handle loads safely and efficiently.

Applications of Wire Rope in Heavy Lifting

Construction: Wire ropes are used in cranes to lift and transport heavy materials.

Shipping and Ports: These ropes are essential for mooring, towing, and lifting cargo.

Mining: Wire ropes are crucial in hoisting equipment and extracting minerals.

Elevators and Lifts: Wire ropes ensure smooth and reliable operation in high-rise buildings.

How to Choose the Right Wire Rope

Selecting the right wire rope depends on various factors, including the load, environment, and type of operation. Consulting reputable wire rope suppliers in India is a good starting point to ensure you get a product tailored to your specific needs. A reliable wire rope manufacturer will provide guidance on materials, construction, and safety standards.

Maintenance and Safety Tips

To maximize the lifespan and ensure the safety of wire ropes:

Regular Inspection: Check for fraying, corrosion, or broken strands.

Proper Lubrication: Minimize friction and prevent rust.

Correct Usage: Avoid overloading and ensure proper alignment during operations.

The Importance of Trusted Suppliers

High-quality wire ropes are crucial for safety and efficiency in heavy lifting operations. Partnering with reputable wire rope suppliers in India ensures you receive products that meet industry standards. From construction projects to industrial applications, a trusted wire rope manufacturer provides not only durable products but also expert advice on maintenance and usage.

Future Trends in Wire Rope Technology

As industries evolve, so does the technology behind wire ropes. Modern advancements focus on enhancing strength, reducing weight, and improving corrosion resistance. Innovations like synthetic cores and advanced coatings are transforming the capabilities of wire ropes, making them even more reliable in demanding environments.

Conclusion

Wire ropes are the unsung heroes of heavy lifting operations, offering unmatched strength, durability, and versatility. Their role in industries like construction, shipping, and mining underscores their importance in modern infrastructure and logistics. By partnering with a reliable wire rope manufacturer or trusted wire rope suppliers in India, businesses can ensure operational efficiency and safety. As technology advances, the future of wire ropes looks promising, paving the way for even more efficient heavy-lifting solutions.

0 notes

Text

Discover the Best steel wire manufacturers - DP Wire

Discover unparalleled quality and reliability with DP Wire, one of the leading steel wire manufacturers in the industry. With a commitment to excellence and innovation, DP Wire stands out as a trusted name in providing high-quality steel wire products for a diverse range of applications. As one of the best steel wire manufacturers, DP Wire employs cutting-edge technology and stringent quality control measures to ensure that every product meets the highest standards of performance and durability. For more information, click on the given link - https://www.dpwires.co.in/understanding-lrpc-strands-a-comprehensive-overview-with-dp-wires/

#steel wire manufacturers#steel wires#spring steel wire#steel wire industry in india#spring wire#wire manufacturer#wire supplier#wire products#industrial wires#lrpc strands

0 notes

Text

What is Rolling Mill and Why is it Essential?

A rolling mill is a core component of the metalworking industry, playing an indispensable role in shaping, processing, and producing a wide range of metal products. By utilizing rotating rolls, a rolling mill transforms metal stock into sheets, bars, wires, or other shapes, depending on the specific application. This process not only improves the material’s mechanical properties but also ensures precision in thickness, dimensions, and surface quality.

The demand for rolling mills has surged globally, with industries such as construction, automotive, and aerospace relying heavily on these advanced machines. Manufacturers are continually innovating to enhance efficiency, automation, and production capacity.

Types of Rolling Mills

There are several types of rolling mills, each designed for specific applications:

Hot Rolling MillA hot rolling mill operates at high temperatures, typically above the metal’s recrystallization point. This allows the metal to be shaped easily, producing sheets or coils with superior mechanical properties. Leading hot rolling mill manufacturers in India provide state-of-the-art solutions tailored to meet industrial requirements.

Cold Rolling MillA cold rolling mill processes metal at room temperature, achieving a smooth surface finish and tighter dimensional tolerances. This type of mill is ideal for creating high-strength products.

Rolling Mill StandThe rolling mill stand is a crucial component that houses the rolls and provides the structural support required during the rolling process. The efficiency and durability of a rolling mill depend significantly on the quality of its stand.

Why Rolling Mills Are Essential

Rolling mills are essential for numerous reasons:

Versatility in ApplicationsRolling mills cater to various industries, from manufacturing construction beams and automotive parts to creating wires for electrical systems. Their ability to handle different types of metals, such as steel, aluminum, and copper, makes them indispensable.

Enhanced Material PropertiesThe rolling process improves the mechanical properties of metals, including tensile strength, ductility, and toughness. This ensures that products can withstand demanding applications.

Precision and EfficiencyModern rolling mill automation has revolutionized production. Automation ensures consistency, reduces human errors, and improves output, enabling manufacturers to meet market demands efficiently.

Turnkey SolutionsMany manufacturers offer turnkey solutions for rolling mills, covering everything from design and installation to maintenance. These comprehensive solutions reduce downtime and optimize operational efficiency, allowing industries to focus on core activities.

Choosing the Right Rolling Mill Manufacturer

Selecting a reliable rolling mill manufacturer is critical to achieving optimal performance. Key considerations include:

Experience and Expertise: Look for manufacturers with a proven track record of delivering innovative solutions.

Customization: Ensure the manufacturer can design mills tailored to your specific needs.

After-Sales Support: Comprehensive after-sales services, including maintenance and spare parts, are essential for long-term success.

India has emerged as a global leader in rolling mill manufacturing, with several companies specializing in hot rolling mills, automation, and turnkey solutions.

Conclusion

Rolling mills are at the heart of modern metalworking, enabling industries to produce high-quality products with precision and efficiency. From rolling mill stands to advanced automation systems, the industry is constantly evolving to meet global demands. By partnering with a reputable rolling mill manufacturer and leveraging turnkey solutions, businesses can achieve operational excellence and stay ahead in a competitive market.

Source URL: https://sites.google.com/view/akshi-engineers/blogs/what-is-rolling-mill

#rolling mill#rolling mill stand#rolling mill manufacturer#hot rolling mill#hot rolling mill manufacturer#turnkey solutions for rolling mill

0 notes

Text

#strands#Earth Wire Strand Manufacturer India#structural Wire Strands Manufacturer#stay wire strands#structural strands Manufacturer#Earth Wire Rope Strands#strands for electrical industry#Steel Wire Strands Online#galvanised steel wire strands#wireropestrands

0 notes

Photo

"Steel Manufacturers In India."

The quality assurance system is guided by principles that support our unique working culture which incorporates respect. We ensure that finest quality material is used for our products. Our team of experts maintain a vigil on the quality of the products. Every single piece is attached with test certificates and reports. We are continually improving our quality to serve our clients better. We help customers develop their energy resources; bringing world class capability and delivering it locally. Providing sources to customers for growing their business at their locality We are values your needs and help to grow in industry. We exercise stringent quality control measures for ensuring the accurate dimensions and mechanical properties of our products. we are believing to give the delivery of products within time assign by us and quick delivery as per the customers requirement.

#stainless steel round bar#stainless steel wire#manufacturer of stainless steel in india#duplex stainless steel#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel distributor#steel manufacturers in india#polished stainless steel#stainless steel manufacturers in india

0 notes

Text

The Versatile World of Wire Mesh: Types, Applications, and Benefits

Bhansali Wire Mesh is one of the leading Wire Mesh Manufacturers in India. Wire mesh, a grid-like structure composed of interwoven or welded wires, is a highly versatile material with countless applications across industries. Whether used for construction, filtration, or decoration, wire mesh is valued for its strength, durability, and adaptability. This blog delves into the different types of wire mesh, their uses, and the advantages they bring to various sectors.

What Is Wire Mesh?

Wire mesh, also known as wire cloth or wire fabric, is made by weaving or welding wires together to form a uniform grid. The wires can be composed of materials like stainless steel, aluminum, copper, or galvanized steel, depending on the intended use. Wire mesh comes in various forms, including fine mesh, coarse mesh, and welded mesh, offering a solution for virtually any application.

Types of Wire Mesh

Wire mesh suppliers in India can be categorized based on its manufacturing process and design:

Welded Wire Mesh: This type of mesh is created by welding wires at their intersections, forming a rigid and strong grid. It is commonly used for fencing, reinforcement, and partitions.

Rectangular Wire Mesh: Rectangular Wire Mesh Manufacturer in India is highly competitive and dynamic with quality and customer satisfaction.

Crimped Wire Mesh: Crimped wire mesh is produced by pre-crimping the wires before weaving them. This process enhances the mesh’s rigidity and ensures consistent openings, making it suitable for mining, quarrying, and security applications.

Hexagonal Wire Mesh: Also known as chicken wire, hexagonal wire mesh is commonly used in agriculture, gardening, and insulation support. Its flexibility and lightweight design make it easy to work with.

Benefits of Wire Mesh

Wire Mesh Manufacturer offers numerous advantages that make it a preferred choice across industries:

Durability and StrengthWire mesh supplier is resistant to wear, tear, and environmental factors, ensuring long-term reliability even under heavy loads.

Versatility With multiple types, sizes, and materials available, wire mesh can be customized to meet specific project requirements.

Cost-Effectiveness Wire mesh is relatively affordable, especially when considering its durability and low maintenance requirements.

Corrosion Resistance Certain materials, like stainless steel and galvanized wire, provide excellent resistance to corrosion, making them ideal for outdoor and industrial use.

Ease of Installation Wire mesh is lightweight and easy to handle, simplifying installation processes.

Eco-Friendly Wire mesh is often recyclable, making it an environmentally conscious choice for many applications.

Cities We Supply Wire Mesh

Wire Mesh Manufacturer in Ahmedabad

Wire Mesh Manufacturers in Kolkata

Wire Mesh Manufacturers in Raipur

Wire Mesh Manufacturers in Rajkot

Wire Mesh Manufacturer in Delhi

Choosing the Right Wire Mesh

When selecting wire mesh, consider the following factors:

Material: Choose a material that suits the environmental conditions and application requirements.

Mesh Size: The size of the openings and wire thickness should match the intended purpose.

Pattern and Design: Select a weave or weld type that offers the necessary strength and flexibility.

Coating: Protective coatings, such as galvanization, enhance durability and corrosion resistance.

0 notes

Text

HB Wire Manufacturers in India We Vishal Industries is the Leading Manufacturer and Supplier of premium quality MS Wire (HB & HHB), Since 1987. We are Providing a wide range of MS Wire such as HB Wire, HHB Wire, Annealed Wire, and Boron Steel Wire in India.

0 notes

Text

Biscuit Machine manufacturer - BBL Foods

The perfect breakfast for singles is soft, original and delicious bread from BBL Foods. Age doesn't matter when it comes to important roles. All over the world, delicious bread has a strong connection with people at all levels. Bread has overwhelming practicality, so it undergoes additional training at university level to enhance its appeal. Have you ever thought about the important points of running a bakery?

Biscuit Machine manufacturer mainly use butter and sugar to decorate the bread. In any case, the baking scene deals with various elements such as baking principles and consistency. Believe it or not, this is another world. You need to be prepared to spend money on various important tasks such as baking bread, applying glue, refilling crushed items, etc.

Various Biscuit Machine manufacturer around the world produce cookie machines. As a manufacturer, choose a standard size mobile unit. We recommend using a potential roll making device. This party has an easy way to actually target another machine party using manual construction and complex improvements. Some of the well-known manufacturers of biscuit machines have built up a very large customer base, so you should look more into family-run businesses.

Some of these machines have a large customer base. Really, how do the cookies stick to the bread? In conclusion, it is clearly a difficult process, taking into account everything from the initial cost, the right size and quality, the changing tastes of nearby and far-flung residents, the future and the simplicity of parts, machines, and life itself. Mix the many layers together and you get a great loaf of bread. High-quality ingredients are essential for bread to captivate and dominate the market. That's why visionaries came together to develop mixers, bowls, and mixing options that bring joy to professionals and many chefs in every industry.

Biscuit Machine manufacturer need to succeed in every field, but especially in the field that supports their business. We support manufacturers' business with a wide range of products. Whether you prefer a strategy plate for baking soft or hard bread, we have a safe and affordable mixer for gamers. It is also easy to manage inventory of products, which allows for smooth transactions.

Rotary model can be used to support decision-making of biscuit machine manufacturers. Biscuit Machine manufacturer companies. A Rotary moulding machine is used to divide the roll into the largest pieces and perspectives. In the steel baking chamber, the loaves are heated by imported burners and then transferred to a fixed area for grilling. To everyone's surprise, the roll was retrieved by an unknown car hauler. The wire-cut snack machine has been completely modernized to function as a crown, with multiple spouts and molded-in strainers for quick customer access.

For more details visit our website: Biscuit Machine manufacturer

BBL Foods Private Limited

Contact: 98480 50607

Address: Santosh Nagar 'X' Road,Hyderabad - 500 059,Telangana State, India.

Facebook: https://www.facebook.com/bblfoodsofficial/

Instagram: https://www.instagram.com/bblfoodsofficial/

#biscuit machine manufacturer#5 roll refiner machinery#food manufacturing consultants#chocolate machines manufacturer#chocolate moulding machines#pasta line supplier#potato chips line supplier#cookies plant#bblfoods

0 notes