#rolling mill manufacturer

Explore tagged Tumblr posts

Text

What is Rolling Mill and Why is it Essential?

A rolling mill is a core component of the metalworking industry, playing an indispensable role in shaping, processing, and producing a wide range of metal products. By utilizing rotating rolls, a rolling mill transforms metal stock into sheets, bars, wires, or other shapes, depending on the specific application. This process not only improves the material’s mechanical properties but also ensures precision in thickness, dimensions, and surface quality.

The demand for rolling mills has surged globally, with industries such as construction, automotive, and aerospace relying heavily on these advanced machines. Manufacturers are continually innovating to enhance efficiency, automation, and production capacity.

Types of Rolling Mills

There are several types of rolling mills, each designed for specific applications:

Hot Rolling MillA hot rolling mill operates at high temperatures, typically above the metal’s recrystallization point. This allows the metal to be shaped easily, producing sheets or coils with superior mechanical properties. Leading hot rolling mill manufacturers in India provide state-of-the-art solutions tailored to meet industrial requirements.

Cold Rolling MillA cold rolling mill processes metal at room temperature, achieving a smooth surface finish and tighter dimensional tolerances. This type of mill is ideal for creating high-strength products.

Rolling Mill StandThe rolling mill stand is a crucial component that houses the rolls and provides the structural support required during the rolling process. The efficiency and durability of a rolling mill depend significantly on the quality of its stand.

Why Rolling Mills Are Essential

Rolling mills are essential for numerous reasons:

Versatility in ApplicationsRolling mills cater to various industries, from manufacturing construction beams and automotive parts to creating wires for electrical systems. Their ability to handle different types of metals, such as steel, aluminum, and copper, makes them indispensable.

Enhanced Material PropertiesThe rolling process improves the mechanical properties of metals, including tensile strength, ductility, and toughness. This ensures that products can withstand demanding applications.

Precision and EfficiencyModern rolling mill automation has revolutionized production. Automation ensures consistency, reduces human errors, and improves output, enabling manufacturers to meet market demands efficiently.

Turnkey SolutionsMany manufacturers offer turnkey solutions for rolling mills, covering everything from design and installation to maintenance. These comprehensive solutions reduce downtime and optimize operational efficiency, allowing industries to focus on core activities.

Choosing the Right Rolling Mill Manufacturer

Selecting a reliable rolling mill manufacturer is critical to achieving optimal performance. Key considerations include:

Experience and Expertise: Look for manufacturers with a proven track record of delivering innovative solutions.

Customization: Ensure the manufacturer can design mills tailored to your specific needs.

After-Sales Support: Comprehensive after-sales services, including maintenance and spare parts, are essential for long-term success.

India has emerged as a global leader in rolling mill manufacturing, with several companies specializing in hot rolling mills, automation, and turnkey solutions.

Conclusion

Rolling mills are at the heart of modern metalworking, enabling industries to produce high-quality products with precision and efficiency. From rolling mill stands to advanced automation systems, the industry is constantly evolving to meet global demands. By partnering with a reputable rolling mill manufacturer and leveraging turnkey solutions, businesses can achieve operational excellence and stay ahead in a competitive market.

Source URL: https://sites.google.com/view/akshi-engineers/blogs/what-is-rolling-mill

#rolling mill#rolling mill stand#rolling mill manufacturer#hot rolling mill#hot rolling mill manufacturer#turnkey solutions for rolling mill

0 notes

Text

rolling mill

45 notes

·

View notes

Photo

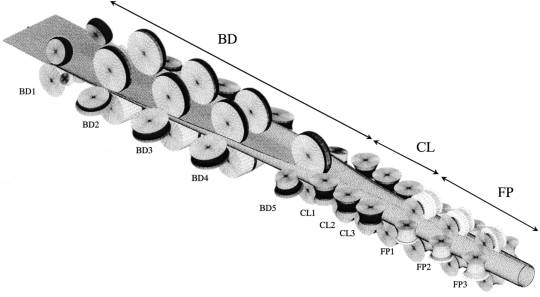

The new forming mill (FF mill) used for the study, Outline of New Forming Equipment for Hikari 24” ERW Mill, NIPPON STEEL TECHNICAL REPORT No. 90 July 2004

12 notes

·

View notes

Text

Elmira Rolling Mills By Rachel Dworkin, archivist

There’s something neat about shows like How It’s Made. If you, like me, have never worked in manufacturing, industrial processes can feel like something of a mystery. Over the years, Elmirans have made everything from aluminum cans to woolen cloth. From 1861 to 1883, the Elmira Rolling Mill Co. made iron. (READ MORE)

1 note

·

View note

Text

Leading Rebar and Steel Suppliers in UAE – Reinforcement, Manufacturing, and Cut & Bend Services

When it comes to reliable rebar exporters and steel suppliers in the UAE, we lead the industry with premium products and exceptional services. Our extensive portfolio includes reinforcement steel bars, plain bars, and epoxy-coated rebars, catering to diverse construction requirements across the region.

As one of the best steel manufacturers in the UAE, we focus on delivering superior-quality products that meet international standards. Whether you need steel bar suppliers in UAE for high-rise buildings, infrastructure projects, or residential developments, we ensure timely delivery and unmatched performance.

Reinforcement Steel Bar Specialists in Abu Dhabi

We are a leading reinforcement steel bar supplier in Abu Dhabi, trusted by contractors and developers for durable and reliable solutions. Our cutting-edge steel factory in Abu Dhabi employs advanced technologies to produce steel rebar with exceptional tensile strength, ensuring safety and durability for critical projects.

Comprehensive Steel Manufacturing Services

As a top steel manufacturing company in Abu Dhabi, we specialize in offering tailored solutions, including:

Rebar cut-and-bend services to enhance efficiency and precision at job sites.

Products from our state-of-the-art steel rolling mills in UAE that ensure consistent quality.

Epoxy-coated rebar in UAE to meet corrosion resistance requirements in demanding environments.

Trusted Partner for Reinforcement and Construction Steel

From reinforcement steel bar suppliers in Abu Dhabi to cut and bend steel manufacturers in UAE, our expertise spans the entire construction spectrum. Our best steel factory in Abu Dhabi delivers innovative solutions designed to optimize cost-efficiency and enhance project outcomes.

Why Choose Us?

Expertise in Rebar Manufacturing: As leading rebar manufacturers in UAE, we are equipped to handle projects of any scale with precision.

Wide Product Range: We offer everything from plain bars in UAE to advanced reinforcement solutions.

Commitment to Quality: Our steel manufacturing companies in UAE adhere to the highest industry standards, ensuring superior performance and durability.

With decades of experience, our steel suppliers in Abu Dhabi and across the UAE have earned the trust of countless contractors, architects, and engineers. Whether you need the best steel factory in UAE or specialized services like rebar cut-and-bend factories in UAE, we are your go-to partner for all steel and rebar requirements.

Let us help you build a stronger future with our reliable rebar UAE solutions. Contact us today for high-quality products and services tailored to your needs!

#Rebar Exporters#Plain Bars uae#reinforcement steel suppliers in uae#steel bar suppliers in uae#rebar suppliers in uae#reinforcement steel bar suppliers in abu dhabi#reinforcement steel bar supplier in abu dhabi#steel manufacturing company in Abu Dhabi#steel rebar manufacturers in uae#steel suppliers in abu dhabi#Rebar Supplier#rebar manufacturers in uae#Best steel manufacturers in uae#steel uae#rebar cut and bend factory in uae#Rebar UAE#best steel factory in abu dhabi#reinforcement steel bars#rebar manufacturers#cut and bend steel manufacturers in uae#steel companies in uae#steel manufacturers in abu dhabi#steel manufacturer in uae#steel manufacturing companies in uae#steel factory in uae#Steel Factory in Abu Dhabi#steel rolling mills in uae

0 notes

Text

What Makes a Top Steel Pipe Company Stand Out in the Construction Industry?

Around the world, high-quality steel pipes are the foundation of contemporary infrastructure, industrial, and building projects. A difference between average and exceptional in a Steel Pipe Company is seen not only through their products but also through comprehensive manufacturing, quality control, and customer service approaches.

Manufacturing Excellence and Innovation

The leading manufacturers differ themselves by advanced production facilities and the latest technology. A leading Steel Pipe Company invests a lot in research and development to improve manufacturing processes to meet changing industry requirements. These innovations go beyond the basic pipe production to specialized products such as Super Rings and reinforcement solutions.

Quality Control Standards

High quality control is the differentiator of great manufacturers from others. Top-notch plants follow rigorous testing at each stage of production, thus ensuring that each pipe is manufactured to exceed the minimum requirements set by the industry. The same standards apply to TMT Steel and other structural products that ensure a product range for optimum performance.

Raw Material Choice

Premium steel pipes start with the best raw materials. Elite producers have very selective supplier relationships and procure high-grade steel and other materials that exactly meet their specifications. This care in raw material quality directly translates to the quality of finished products, from basic pipes to specialized Super Rings.

Diverse Product Range

Variety in product lines is another critical differentiator. Major producers offer a wide range of steel pipes, TMT Steel products, and specialized components to cater to the varied needs of projects. This extensive inventory enables contractors and developers to procure all the materials they need from a single trusted source.

Technical Know-how and Assistance

Industry leadership is not just about manufacturing capabilities. A renowned Steel Pipe Company has employed experienced engineers and technical experts who provide valuable consultation services. These professionals help clients select appropriate materials, offering insights into installation procedures and maintenance requirements.

Certification and Compliance

Industry certifications and adherence to international standards show commitment to excellence. Major producers retain several quality certifications, and their processes are updated constantly, always staying ahead of new requirements. This prevents questionable defects in their finished products, including the Super Rings and TMT Steel components, in accordance with international construction standards.

Supply Chain Management

Efficient logistics and distribution networks play a vital role in customer satisfaction. Leading manufacturers maintain robust supply chain systems, ensuring timely delivery and reducing project delays. This reliability proves particularly crucial for time-sensitive construction projects requiring precise material scheduling.

Customer Service Exceptionalism

Excellent customer care is what separates the best construction material manufacturers in the competitive industry. The leading companies offer a full cycle of support, starting from consultation during the project to guidance after installation. It helps to maintain long-term relationships and establish trust within the industry.

Market Flexibility

Because the construction business is always changing, producers must be able to quickly adjust to new demands. Leading businesses stay ahead of the competition by keeping an eye on market developments, creating creative solutions, and modifying their product lineups as necessary. This adaptability ensures clients access the latest advancements in construction materials and technology.

Quality Documentation and Traceability

Premium companies have all products with traceability information from raw material to finished product. This openness gives the client confidence in the quality of materials used and can help settle issues as they arise during construction.

Conclusion

The choice of a trustworthy Steel Pipe Company significantly affects the outcome of the project, making it very important for construction professionals to collaborate with manufacturers that can provide such unique characteristics. Projects, by choosing such suppliers, are then able to get superior products, expert support, and reliable service – the necessary elements for successful construction outcomes.

#hot rolled#coil processing#TMT bars#steel bars#construction steel#quality bars#metal rolling#steel rolling#heat treatment#coil to bar#steel manufacturing#durable bars#rolling mill#high strength#TMT process#bar production#steel quality#construction#metal shaping#industrial steel#steelwork

0 notes

Text

Exporter in India: White Back Duplex Paperboard Roll

White Back Duplex Paperboard Roll

White Back Duplex Paperboard Roll is a type of paperboard that is commonly used in packaging, particularly in the production of boxes, cartons, and other forms of rigid packaging. It is a duplex board made from recycled or virgin paper fibers, with one side (the "white" side) being coated or bleached to give it a smooth, white surface, while the other side remains uncoated or is brown in color (the "grey" or "brown" back). The "white back" refers to the white-coated front side and the grey or uncoated back side, which is a distinguishing feature of this paperboard.

The quality of white back duplex paperboard can vary depending on the grade of pulp used, the manufacturing process, and the proportion of recycled vs. virgin materials. High-end versions might have more virgin pulp for superior surface quality, while more budget-friendly versions might incorporate more recycled content.

White Back Duplex Paperboard Roll is a versatile, high-quality paperboard used primarily in the packaging industry. Its white-coated front side allows for high-quality printing, making it suitable for branding and aesthetic packaging needs, while the uncoated back provides structural strength and durability. This combination makes it a popular choice for a wide range of products, from luxury goods to everyday consumer products, and its sustainability profile adds to its appeal in the growing market for eco-friendly packaging solutions.

#branding#marketing#startup#paper roll#manufacturer#duplex paper#sales#success#paper mill#paper#duplexroll

0 notes

Text

Reliable Rolling Mills Manufacturer

Rolling Mill Manufacturer is a trusted name in the steel and metal industry, specializing in the design and production of the best rolling mills. Our advanced solutions cater to many different applications, ensuring precision, durability, and efficiency. With the latest technology and a commitment to innovation, we deliver customized rolling mill systems that meet the unique requirements of our clients. Choose us for reliable products that drive performance and enhance productivity in your operations.

0 notes

Text

#Aluminium Production#Alloy Manufacturing#Metal Processing#Casting#Extrusion#Rolling Mill#Heat Treatment

0 notes

Text

How Many types of Tube mill Rolls?

Breakdown Rolls: These Tube Mill Rolls are the first set of rolls in the tube mill. They start the process of shaping the metal strip into a preliminary tube form. Breakdown rolls handle the initial heavy deformation of the material.

Fin Pass Rolls: After the initial shaping, the fin pass rolls refine the tube’s shape and weld seam. These rolls ensure that the tube’s edges are properly aligned and that the tube is of uniform thickness.

Sizing Rolls: The final stage involves sizing rolls that precisely control the tube’s outer diameter and wall thickness. These rolls ensure that the tube meets the specified tolerances and quality standards.

Forming Rolls: Used in various stages, forming rolls shape the metal into specific cross-sections, such as round, square, or rectangular tubes. They play a critical role in determining the final geometry of the tube.

What Are Tube Mill Rolls?

Tube mill rolls are specialized tools used in tube mills to form and shape metal tubes. They work by guiding and compressing metal strips or plates through a series of rolling processes. These rolls ensure the metal is consistently formed into the desired tube dimensions and characteristics. The process typically involves several stages, including breakdown, fin pass, and sizing.

Key Features of Tube Mill Rolls

Material Composition: Tube mill rolls are typically made from high-grade alloy steel to withstand the intense pressures and temperatures involved in the rolling process.

Surface Finish: The surface of tube mill rolls is precision-ground to ensure smooth and accurate tube formation. Any imperfections on the roll surface can affect the quality of the finished tubes.

Heat Treatment: Rolls undergo heat treatment processes to enhance their hardness and wear resistance. Proper heat treatment is crucial for the longevity and performance of the rolls.

Conclusion

Tube mill rolls are indispensable in the tube manufacturing process, directly influencing the quality and consistency of the final product. By understanding their types, features, and maintenance needs, manufacturers can ensure optimal performance and longevity of these critical components. Regular maintenance and proper handling of tube mill rolls not only enhance production efficiency but also contribute to the overall success of the manufacturing operation.

For more info, please contact us!

Website :- Tube Mill Rolls

Contact No. :- +91 7838467173

Email :- [email protected]

#Tube mill Rolls#tube mill rolls manufacturer#tube mill roll manufacturer#Tube mill Rolls supplier#kk engineering works

1 note

·

View note

Text

Essential Features of a Steel Rolling Mill

A steel rolling mill processes metal sheets into desired shapes and thicknesses through hot or cold rolling. It is essential in producing steel products like sheets, rods, and beams with uniform dimensions and surface finish. If you require any other details about the steel rolling mill then visit our website.

0 notes

Text

#rolling mill#rollingmillmanufacturers#hot rolling mill manufacturer#tmt rolling mill#turnkey solutions for tmt bar mill

0 notes

Text

hot rolled

20 notes

·

View notes

Photo

The former forming mill (cage roll forming mill) of NSC Hikari 24” ERW mill, Outline of New Forming Equipment for Hikari 24” ERW Mill, NIPPON STEEL TECHNICAL REPORT No. 90 July 2004

5 notes

·

View notes

Text

How Metal Buildings are Revolutionizing Storage Solutions

In today's fast-paced world, finding the right storage solutions is essential for both businesses and homeowners. Metal buildings are emerging as a revolutionary option, offering unparalleled benefits. From versatility to cost-effectiveness, metal buildings are transforming the way we think about storage. In this article, we'll explore how metal buildings are changing the storage landscape, with a particular focus on rent to own pole barns and metal garage rent to own options.

The Rise of Metal Buildings in Storage Solutions

Versatility and Customization

One of the most significant advantages of metal buildings is their versatility. Metal buildings can be customized to fit any storage need, whether it’s for residential, commercial, or agricultural purposes. The flexibility in design allows for:

Various Sizes and Shapes: Metal buildings can be constructed in a wide range of sizes and shapes to accommodate different storage needs.

Interior Layouts: Interiors can be designed with specific features, such as shelves, partitions, and open spaces, making them ideal for diverse storage requirements.

Aesthetic Options: Metal buildings can be finished with various coatings and colors to match the desired aesthetic appeal, ensuring they blend seamlessly with existing structures.

Durability and Longevity

Metal buildings are known for their durability and long lifespan. Unlike traditional wood or brick structures, metal buildings offer superior resistance to environmental factors. The benefits include:

Weather Resistance: Metal buildings can withstand extreme weather conditions, such as heavy snow, strong winds, and intense heat.

Pest Resistance: Unlike wood, metal is not susceptible to termite infestations or other pests that can damage the structure.

Fire Resistance: Metal buildings are less likely to catch fire, providing an added layer of safety and protection.

Cost-Effectiveness

Lower Initial Costs

Metal buildings generally have lower initial construction costs compared to traditional buildings. This cost-effectiveness makes them an attractive option for those looking to maximize their investment. Key cost-saving aspects include:

Material Costs: Metal is often cheaper than other building materials like wood or brick.

Labor Costs: The prefabricated nature of metal buildings reduces construction time and labor costs, leading to significant savings.

Long-Term Savings

In addition to lower initial costs, metal buildings offer substantial long-term savings. These savings come from:

Low Maintenance: Metal buildings require minimal maintenance compared to traditional structures, saving time and money on repairs and upkeep.

Energy Efficiency: Metal buildings can be designed with energy-efficient features, such as insulated panels and reflective roofing, which can lower energy bills.

Rent to Own Pole Barns: A Flexible Storage Solution

Rent to own pole barns are becoming an increasingly popular storage solution, offering flexibility and affordability. These structures are ideal for various storage needs, including:

Agricultural Storage: Rent to own pole barns provide ample space for storing farming equipment, livestock feed, and other agricultural supplies.

Residential Storage: Homeowners can use pole barns for storing vehicles, tools, and other household items.

Commercial Storage: Businesses can utilize pole barns for storing inventory, equipment, and other business-related materials.

Benefits of Rent to Own Pole Barns

Flexibility: The rent to own option allows individuals and businesses to acquire a storage solution without the need for a large upfront investment.

Affordability: Rent to own arrangements typically offer lower monthly payments, making it easier to budget for a new storage building.

Ownership: At the end of the rental term, the structure can be fully owned, providing long-term value and investment.

Sustainability

Eco-Friendly Construction

Metal buildings are an environmentally friendly choice, contributing to sustainability in several ways:

Recyclability: Metal is 100% recyclable, and many metal buildings are constructed using recycled materials.

Energy Efficiency: Metal buildings can be designed to be highly energy-efficient, reducing the overall carbon footprint.

Durability: The long lifespan of metal buildings means fewer resources are needed for repairs and replacements.

Reduced Waste

The prefabrication process of metal buildings results in less waste compared to traditional construction methods. This efficiency not only reduces environmental impact but also lowers overall construction costs.

Security and Safety

Enhanced Security Features

Metal buildings provide enhanced security features, making them an excellent choice for storage solutions:

Structural Integrity: Metal buildings are designed to be strong and sturdy, providing a secure environment for stored items.

Security Options: Metal buildings can be easily equipped with additional security features such as reinforced doors, windows, and surveillance systems.

Safety Benefits

Fire Resistance: As mentioned earlier, metal buildings are less likely to catch fire, offering superior protection for stored items.

Pest Resistance: The metal construction prevents damage from pests, ensuring the longevity and integrity of the stored goods.

Conclusion

Metal buildings are revolutionizing storage solutions with their versatility, durability, cost-effectiveness, and sustainability. From rent to own pole barns to customized commercial storage units, metal buildings offer a wide range of benefits that cater to various storage needs. At Bulldog Steel Structures, we provide top-quality metal buildings, including metal garage rent to own options, ensuring you get the best value for your investment. Choose metal buildings for your storage solutions and experience the unmatched advantages they offer.

#rent to own pole barns#metal garage rent to own#metal building#bulldog steel structure#steel structure#steel rolling mill#metal garage buildings#metal carport#steel ball run#usa news#manufacturer#metal gear solid

0 notes

Text

Rebar and Steel Solutions for UAE Construction Excellence

As a pioneer in the steel manufacturing industry in UAE, we cater to projects that demand superior-quality reinforcement steel bars and plain bars. Whether you need rebar suppliers in UAE for large-scale infrastructure or small residential builds, our team ensures that every product exceeds your expectations in terms of strength, durability, and cost-effectiveness.

Diverse Product Portfolio

Our wide array of steel products and services is designed to meet the varied needs of construction projects:

Reinforcement Steel Bars: Engineered for maximum strength and reliability in critical applications.

Epoxy-Coated Rebars in UAE: Ideal for projects requiring extra protection against corrosion, especially in marine and high-moisture environments.

Plain Bars in UAE: Perfect for general construction needs with high-quality finishes.

Steel Rolling Mills in UAE: Ensuring precise dimensions and consistent quality across all products.

With a focus on sustainability and innovation, our steel manufacturing companies in UAE are committed to creating products that align with modern construction demands.

Comprehensive Services to Streamline Your Projects

Our steel manufacturers in Abu Dhabi offer a variety of value-added services that enhance efficiency and accuracy:

Rebar Cut and Bend Services in UAE: Save time and reduce waste at construction sites with pre-fabricated, project-specific rebar solutions.

Customized Steel Manufacturing: Our steel factory in UAE works closely with clients to deliver tailor-made solutions that fit their unique requirements.

Steel Supply Chain Management: From raw materials to finished products, we ensure a seamless and timely supply process.

Leaders in Steel and Rebar Manufacturing in UAE

Our reputation as one of the best steel manufacturers in UAE stems from our commitment to excellence. Our advanced steel factories in Abu Dhabi utilize cutting-edge technologies to produce steel products that meet the highest standards. This ensures that our clients receive the best materials for their projects, whether they are sourcing from reinforcement steel bar suppliers in Abu Dhabi or partnering with steel bar suppliers in UAE.

Unmatched Expertise and Reliability

As a trusted name among rebar manufacturers in UAE, we understand the critical role steel plays in construction. Our products are designed to provide unmatched performance, ensuring that your projects stand the test of time.

Why Contractors and Developers Choose Us:

Top Steel Manufacturers in UAE: Our track record for quality makes us the go-to choice for steel suppliers in Abu Dhabi and beyond.

Comprehensive Offerings: From rebar exporters to cut-and-bend services, we cover all your steel needs.

Innovation-Driven Solutions: Our steel manufacturing companies in UAE are constantly evolving to bring the latest innovations to the market.

Customer-Centric Approach: We work closely with our clients, ensuring timely deliveries and tailored solutions.

Building the Future, One Bar at a Time

Whether you need rebar UAE solutions, reinforcement steel bar suppliers in Abu Dhabi, or the best steel factory in Abu Dhabi, we are here to help you achieve your construction goals. With a focus on quality, precision, and efficiency, we continue to be the preferred choice for developers and contractors across the region.

Contact us today for the finest steel and rebar solutions, and let’s build the future together!

#Rebar Exporters#Plain Bars uae#reinforcement steel suppliers in uae#steel bar suppliers in uae#rebar manufacturers in uae#rebar suppliers in uae#reinforcement steel bar suppliers in abu dhabi#reinforcement steel bar supplier in abu dhabi#steel rebar manufacturers in uae#steel suppliers in abu dhabi#Rebar Supplier#Best steel manufacturers in uae#steel uae#steel companies in uae#best steel factory in abu dhabi#reinforcement steel bars#rebar manufacturers#cut and bend steel manufacturers in uae#Rebar UAE#steel manufacturers in abu dhabi#steel manufacturer in uae#steel manufacturing company in Abu Dhabi#rebar cut and bend factory in uae#Steel Factory in Abu Dhabi#steel factory in uae#steel manufacturing companies in uae#steel rolling mills in uae

0 notes