#Metal Processing

Explore tagged Tumblr posts

Text

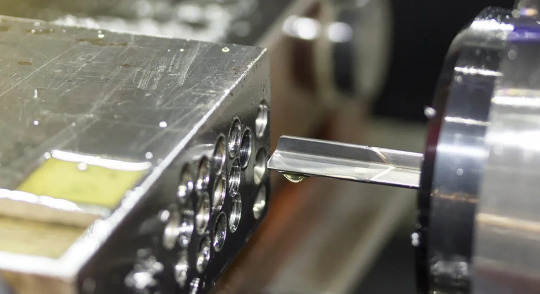

Non-standard CNC machining parts

#design#business#autos#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc precision machining#cnc precision#cnc machining service#cnc services#cnc metal machining#metal machining#cnc metal processing#metal processing#high precision

2 notes

·

View notes

Text

#Aluminium Production#Alloy Manufacturing#Metal Processing#Casting#Extrusion#Rolling Mill#Heat Treatment

0 notes

Text

Oh, my God, this effect is too good.

Oh, my God, this effect is too good. Have you ever used the filter aid for rolling oil and Zhijing, the bosses who do metal processing? Look at this filtering effect. This dark rolling oil has been filtered twice by Zhijing, and this oil is actually clear! Great to use! Come and try it!

#aluminium foil#cold rolling#rolling mill#Rolling oil#metal processing#Aluminum plate processing#filter

1 note

·

View note

Text

Pyramid Steve's favourite treat is pre-1982 pennies

(Ford slooooowly starting to realize his muse of infinite knowledge might, in fact, be a dumbass.)

#non euclidean geometry au#billford#pyramid steve#bill cipher#ford pines#lore dump#gravity falls#pre1982 pennies are 95% or more copper#post1982 pennies are 97% zinc 3% copper#which is not bad but it's just not the same is it#spec bio below#I think Euclideans benefit from the occasional transitional metal nom-nom#it's good for strengthening their exoskeletons through a kind of biomineralization process#Bill eats the odd gold bar#he's not entirely sure why#Humans also need copper to function#it helps maintain the nervous system-immune system- brain development-#and make connective tissue and red blood cells#too much copper is still bad for you#it's a sometimes food for little baby hybrid creatures#my art#they should not be parents#parent au

707 notes

·

View notes

Text

An Efficient Processing Method For Complex Deep Holes, It Will Not Be Difficult For You After Reading The Hole Processing!

In fact, complex deep hole machining is becoming more and more challenging. Parts often require additional features such as very small hole finishes, internal chambers, hole diameter variations, contours, grooves, threads, and varying hole orientations. Efficiently obtaining such tight-tolerance holes requires not only extensive experience and R&D resources, but also engineering capability, application facilities, and substantial customer involvement.

Deep Hole Machining (DHM) is a machining field dominated by tools designed for existing applications. Many different industries are involved in deep hole machining, but the most widely used are the energy and aerospace industries. Certain deep-hole part features often seem impossible to form at first, but the non-standard cutting tool solutions designed by experts not only solve process problems, but also ensure that they are executed with high efficiency and error-free features to some extent. The ever-increasing demand for complex holes and the urgent need to shorten machining times have promoted the development of modern deep hole machining technology. Deep hole drilling has been an efficient machining method using carbide tools for decades, but bottom boring is starting to emerge as a bottleneck.

Today, success in this machining area is often based on the use of a mix of standard and specialty tooling components that have been designed with experience as specialized deep hole machining tools. Equipped with extended high-precision shanks with support features and integrated reamers, these tools, combined with the latest cutting edge geometries and insert grades, and efficient coolant and chip control, allow for the highest penetration and Get the high-quality results you need with process security. In deep hole drilling, small diameter holes below 1mm are processed by carbide gun drills, but for holes of 15mm and above, welding edge drills are generally used, and for holes of 25mm and above, indexable drills are used. Insert drills are required for very efficient drilling. Modern indexable insert technology and drill tube systems are also opening up new possibilities for special tools for deep hole machining.

When the hole depth exceeds 10 times the hole diameter, the processed hole is generally considered to be very deep. Holes as deep as 300 diameters require specialized techniques and can only be drilled with single or dual pipe systems. The long run down to the bottom of these holes requires specialized kinematics, tool configurations and the correct cutting edge to complete the chambers, grooves, threads and cavities. Backer plate technology is another important area, also crucial in deep hole drilling, which is now also progressing considerably as part of deep hole machining technology. These include qualified drills for this field that offer higher performance.

1 note

·

View note

Text

Get Best Quality Metal Pre-Treatments from PGV Sun Chemicals

Don’t let corrosions🤩 hold you back from achieving superior-quality🙋 metal finish😀! Get rid of corrosions⚒🛠 with the best quality metal pre-treatments⚙️ from PGV Sun Chemicals. Contact us to know more!

0 notes

Text

🎀

#revolver ocelot#mgsv ocelot#metal gear soild 5#work in progress#digital art#metal gear solid#fanart#mgs ocelot#mgsv#mgs art#metal gear solid phantom pain#mgs#metal gear solid fanart#video games#game fanart#big boss#game art#color art#ocelot metal gear#phantom pain#metal gear solid art#art#digital fanart#ocelot mgs#hideo kojima#mgsv fanart#work in process

229 notes

·

View notes

Text

Mouvement - World Deafening Eclipse 💽

#song by the angelic process!!#my art#digital art#fanart#james bucky barnes#marvel mcu#mcu#the winter soldier#bucky barnes#oughhh hes also so drone metal coded guys trust me

156 notes

·

View notes

Text

MGSV sketch dump. The brainrot is thriving

#mgs#metal gear solid#mgsv#mgs5#mgsvtpp#I’ve let the brainrot simmer for a couple of days and dare I say I think I love this game#I mean there are things I hated but overall an absolute banger#I’ll definitely be replaying it#one thing I think the game would’ve benefitted from is taking more time for the ending#it was too abrupt#the additional higher difficulty missions could’ve been a mode#and those episodes could’ve been used to pace the ending#I also hesitate to recommend the game cuz it really benefits from the context of previous games#and that’s a lot of game#mgs5 also covers some very heavy topics#that hit very close to reality#I might have gotten more squeamish with time but some of those things were very difficult to process#one thing I think mgs does very well is it never settles for one side or one person being the absolute hero#in this plot they may be a relatively good person#but in the next they’re the villain#but it’s never static#and it u can’t get cozy with tropes#it’s not even grey morality it’s just human nature

325 notes

·

View notes

Text

coming in hot with another Tretij Rebenok piece

#mgs#metal gear solid#psycho mantis#tretij rebenok#mgsv#tessart#digital art#and you will never guess where I uploaded the process video of this ...#still trying to branch out to other social medias but it's haaaarrrrdddd#anyways throwing my shit at the tiktok void now ahahah

712 notes

·

View notes

Text

CNC precision machining parts

#design#autos#business#prototyping#prototype#prototype machining#cnc machining#rapid prototyping#precision machining#machining parts#metal machining#cnc metal processing#cnc metal fabrication#cnc metal process#cnc metal machining#metal processing#cnc precision machining#cnc precision

2 notes

·

View notes

Text

#Aluminium Production#Alloy Manufacturing#Metal Processing#Casting#Extrusion#Rolling Mill#Heat Treatment

0 notes

Text

hehe, what happens to him after Eggman dies???

#metal sonic#sonic the hedgehog#hiiii#fanart#art#digital art#hi im gonna go hide now fgfgdg#but im so happy with this#i wasnt going to post it but i just like it so much dfgfgg#i wish i recorded the process oughh#Spotify

2K notes

·

View notes

Text

They're Tired

Lineart available for download on my patreon if any of yall wanna colour them

KoFi || Patreon

#sad•leonart#rottmnt#rise of the tmnt#rise leo#rise leonardo#rise future leo#rise ruture leonardo#rottmnt leo#rottmnt leonardo#rottmnt future leo#rottmnt future leonardo#damn. tumblr really killed the quality on this one#had lyrics and dialogue ideas but none of them stuck#also i fucking hate it#the second metal knee thing shouldnt be visilbe according to the foot position#but i only noticed after i completely finished#i do really love how the mask tails came out tho#if i get any weird comments on this i will fight#because that was a consistent thought throughout the whole fucking 6 hour process#i should stop venting in the tags slfjsldjfsd#vent art#technically#probably shoulda put a shadow under them#oh well

646 notes

·

View notes

Note

I've always thought a Liliana compleation would be a compelling alternate way for her immortality quest to culminate, and I wonder how you'd design her? 👀

I feel like I got possessed for this 💀

#really just found a whole new process for metal to do this#she’s just too powerful#honestly I prefer the second design but I think they both work#liliana vess#compleated planeswalker#asks#my art

347 notes

·

View notes