#steel construction process

Explore tagged Tumblr posts

Text

You can rely on us to provide the best goods and services when it comes to Stainless Steel Construction. We are dedicated to offering our clients specialized solutions that are tailored to their demands as one of the top steel construction suppliers in the business.

#stainless steel construction#construction steel manufacturers#steel construction process#steel construction suppliers

1 note

·

View note

Text

Custom Metal Design and Manufacturing Services

Our platework steel fabrication methods utilize state-of-the-art machinery to ensure precision and consistency. Contact us now!

#custom steel tanks fabricator#chemical process tanks#fabricated tanks#settling tank wastewater treatment#custom industrial tanks#constructed steel process tanks#custom steel process tanks#platework steel fabrication#field erected storage tanks#stainless steel mixing tanks#stainless steel water tanks#stainless steel tank#stainless steel tanks

0 notes

Text

What Makes a Top Steel Pipe Company Stand Out in the Construction Industry?

Around the world, high-quality steel pipes are the foundation of contemporary infrastructure, industrial, and building projects. A difference between average and exceptional in a Steel Pipe Company is seen not only through their products but also through comprehensive manufacturing, quality control, and customer service approaches.

Manufacturing Excellence and Innovation

The leading manufacturers differ themselves by advanced production facilities and the latest technology. A leading Steel Pipe Company invests a lot in research and development to improve manufacturing processes to meet changing industry requirements. These innovations go beyond the basic pipe production to specialized products such as Super Rings and reinforcement solutions.

Quality Control Standards

High quality control is the differentiator of great manufacturers from others. Top-notch plants follow rigorous testing at each stage of production, thus ensuring that each pipe is manufactured to exceed the minimum requirements set by the industry. The same standards apply to TMT Steel and other structural products that ensure a product range for optimum performance.

Raw Material Choice

Premium steel pipes start with the best raw materials. Elite producers have very selective supplier relationships and procure high-grade steel and other materials that exactly meet their specifications. This care in raw material quality directly translates to the quality of finished products, from basic pipes to specialized Super Rings.

Diverse Product Range

Variety in product lines is another critical differentiator. Major producers offer a wide range of steel pipes, TMT Steel products, and specialized components to cater to the varied needs of projects. This extensive inventory enables contractors and developers to procure all the materials they need from a single trusted source.

Technical Know-how and Assistance

Industry leadership is not just about manufacturing capabilities. A renowned Steel Pipe Company has employed experienced engineers and technical experts who provide valuable consultation services. These professionals help clients select appropriate materials, offering insights into installation procedures and maintenance requirements.

Certification and Compliance

Industry certifications and adherence to international standards show commitment to excellence. Major producers retain several quality certifications, and their processes are updated constantly, always staying ahead of new requirements. This prevents questionable defects in their finished products, including the Super Rings and TMT Steel components, in accordance with international construction standards.

Supply Chain Management

Efficient logistics and distribution networks play a vital role in customer satisfaction. Leading manufacturers maintain robust supply chain systems, ensuring timely delivery and reducing project delays. This reliability proves particularly crucial for time-sensitive construction projects requiring precise material scheduling.

Customer Service Exceptionalism

Excellent customer care is what separates the best construction material manufacturers in the competitive industry. The leading companies offer a full cycle of support, starting from consultation during the project to guidance after installation. It helps to maintain long-term relationships and establish trust within the industry.

Market Flexibility

Because the construction business is always changing, producers must be able to quickly adjust to new demands. Leading businesses stay ahead of the competition by keeping an eye on market developments, creating creative solutions, and modifying their product lineups as necessary. This adaptability ensures clients access the latest advancements in construction materials and technology.

Quality Documentation and Traceability

Premium companies have all products with traceability information from raw material to finished product. This openness gives the client confidence in the quality of materials used and can help settle issues as they arise during construction.

Conclusion

The choice of a trustworthy Steel Pipe Company significantly affects the outcome of the project, making it very important for construction professionals to collaborate with manufacturers that can provide such unique characteristics. Projects, by choosing such suppliers, are then able to get superior products, expert support, and reliable service – the necessary elements for successful construction outcomes.

#hot rolled#coil processing#TMT bars#steel bars#construction steel#quality bars#metal rolling#steel rolling#heat treatment#coil to bar#steel manufacturing#durable bars#rolling mill#high strength#TMT process#bar production#steel quality#construction#metal shaping#industrial steel#steelwork

0 notes

Text

Hot Rolled Steel for Structures & Projects | DigECA - Tata Steel

Enhance your steel fabrication with premium hot rolled steel from DigECA - Tata Steel. Discover reliable solutions for all structural fabrication needs.

#hot rolled#steel fabrication#steel fabrication design#structural steel fabrication process#construction steel fabrication

0 notes

Text

A Revolution in Steel Shopping:Steeloncall

In the ever-evolving world of construction and manufacturing, the importance of high-quality steel cannot be overstated. From towering skyscrapers to intricate machinery, steel serves as the backbone of countless projects, providing strength, durability, and reliability. However, procuring the right steel products can often be a daunting and time-consuming task, fraught with challenges such as fluctuating prices, inconsistent quality, and unreliable suppliers.

#tmt bars#b2bmarketing#e-commerce#business#steelsupplier#construction#Steel Manufacturing#Steel Suppliers#Steel Fabrication#Steel Processing#Steel Distribution#Steel Prices#Steel M#Steel Delivery#Steel Customization#Steel Cutting#Steel Wel

0 notes

Text

Iron and Steel Market's Journey in Fueling the Engine of Progress

The global iron and steel market size is expected to reach USD 2,253.52 billion by 2030, according to a new report by Grand View Research, Inc. expanding at a CAGR of 3.8% from 2023 to 2030. Rising demand for heavy machinery and growth in the construction industry is expected to augment market growth over the forecast period.

Iron And Steel Market Report Highlights

Based on iron ore application, the steel segment is expected to register a growth rate of 2.0% in terms of revenue over the forecast period. The production of steel is expected to increase over the forecast period on account of rising investments in the construction of smart cities, led by increasing urbanization rates.

For example, Saudi Arabia’s NEOM project is anticipated to consume the largest amount of iron and steel. Further, at a capacity of 650 tons per day, the NEOM project will commence hydrogen production in 2026, which will be used by green steel and cement industries, for the city to run at 100% renewable energy.

Based on steel end-use, the building & construction segment captured the largest revenue share of the market, with over 45.0% in 2022. Rising investment by emerging economies to modernize their infrastructure is expected to propel the demand for the product.

Based on region, the Middle East & Africa is expected to achieve a revenue growth rate of 4.3%, over the forecast period. This growth is primarily driven by the emergence of infrastructure projects in the Middle East, which in turn is boosting the demand for products in the region.

For More Details or Sample Copy please visit link @: Iron And Steel Market Report

Over 98% of the total iron ore transforms into pig iron, which is a crucial component in the production of steel. Finished steel products are used in various industries, such as heavy industry, construction, automotive, and consumer goods. In heavy industry, steel is a strong material that can handle heavy weights and tough conditions. It provides stability and safety to heavy machinery, equipment, and infrastructure by maintaining their structural integrity. Thus, it is widely used in heavy industries such as shipbuilding, defense products manufacturing, and oil & gas.

Investment in the oil & gas industry is expected to drive the demand for steel over the forecast period. For instance, in April 2022, Cairn Oil & Gas, a Vedanta Group subsidiary, announced investing USD 700.0 million in oil & gas exploration projects in India. The company plans to invest in 100 exploratory wells, including the project in the Barmer region of Rajasthan, India.

Despite the rising penetration in various end-use industries, the product faces hindrances in the automotive industry. Electric vehicles prefer to use aluminum because of its lightweight and robust characteristics. This lightweight property helps reduce fuel consumption and lowers carbon emissions. As a result, aluminum is increasingly being used as a substitute for steel in electric vehicles, and this trend is expected to negatively affect the global market growth in the foreseeable future.

Region-wise, Asia Pacific is projected to undergo substantial revenue growth with a CAGR of 3.6% across the forecast period. This growth can be attributed to substantial investments in the region's construction and infrastructure sectors of developing economies. For instance, The Indonesian parliament approved the Capital City Bill in January 2022, paving the way for constructing a new capital city in the East Kalimantan province. The country has plans to invest USD 35 billion in the project, which is projected to be finalized by 2024.

IronAndSteel #SteelIndustry #Metallurgy #SteelProduction #SteelManufacturers #SteelMarketTrends #MetallurgicalProcesses #SteelDemand #SteelProducts #SteelTrade #ConstructionMaterials #EconomicProgress #MetalsMarket #MetalInnovation #GlobalInfrastructure #Manufacturing #IndustrialDevelopment #InfrastructureDevelopment #EconomicGrowth #GlobalCommerce

#Iron And Steel#Steel Industry#Metallurgy#Global Infrastructure#Steel Production#Construction Materials#Metals Market#Metal Innovation#Steel Manufacturers#Steel Market Trends#Metallurgical Processes#Steel Demand#Economic Growth#Global Commerce#Steel Products#Steel Trade

0 notes

Text

#savetime#savemoney#Stil Building kits#Real Estate#Construction#building#Residential Projects#commercial projects#Steel Building Kit Installation#cost effective#Simplify Process#low maintenance

0 notes

Text

Got sucked back into Warframe after a year and a half break. Here's some old stuff from a few years back when I was hardcore invested with headcannons and theories and a lot of salt about ESO.

The ink pieces were done for WF Inktober a few years back. I wound up being too busy to complete more than 8 or so days. The triptych at the end was going to be submitted for the art show for Tennocon one year, featuring my favourite frame and the favourite frames of my fellow ninjas, but I was beginning to get burned out on WF and mounting disappointments from the dev team before it could be finished.

Specific context for the """newd""" Limbo: the idea behind this and the Volt equivalent was related to Warframe construction and the possibility of errors resulting from genetic processing, re: reading errors from the component blueprints that could alter the structure of sword steel. Both of these were related to an "Anatomy of a Warframe" theoretical biology essay that would be hosted on my site, breaking down how a frame worked as an organism. I'm admittedly more concerned about addressing my backlog of farmables than worldbuilding at present, but once the checklist gets its due mind I might revisit the idea.

568 notes

·

View notes

Text

Conjugal Visit | Roman Reigns

Images/GIFs aren’t mine, credits to rightful owners.

Pairings: Roman Reigns x black! oc

Warnings: flashback of threatening assault, smut, oral (female receiving), slight (a little more than slight) daddy kink, fluff

Summary: Jada thinks she’s just going to visit her man while he’s doing his time in jail for assaulting this man who wouldn't leave her alone. Little does she know, he has a surprise when she gets there…

Word Count: 1.9k words

A/N: Hey my baes! This is my first story/one shot so please take it easy on me lmao. I’m sure as I keep writing, it’ll get better. I am so open to constructive criticism though. Yall PLEASE go easy on me abeg. okay enjoy!! please comment if you like it :))

As Jada drove down the road that seemed to never end, she could hardly contain the nerves and butterflies that were erupting in her stomach. Before leaving her apartment, she decided to put on her pink Skims Long Slip Dress, paired with a baby pink bolero, and a pair of platform UGGs.

Every day Jada wishes that it was the day Roman was coming home. She would always tell him that he needed to go to anger management counseling or something, but he constantly shrugged her off. Then one day at the grocery store, this creepy older white man kept hitting on Jada, so Roman stepped in.

“Aye man. Who are you?” Roman firmly asked the older man, and looking down at him as he was much shorter.

The man confidently looked up at Roman and even puffed his chest out a bit. Before he could even get a word out, Roman grabbed him by his shirt collar with both hands and roughed him up a little.

The older man’s eyes widened, now in fear of this huge Samoan man.

“She’s my woman. Now, I heard her tell you ‘bout three times that she wasn’t interested. Are you hard of hearing?” Roman was getting more irritated by the second, as Jada could tell by him scrunching his face.

“Sir, I- I didn’t know.” The man pleaded to Roman.

Roman pulled the man closer to his face and tightened his grip on his shirt. “Oh you didn’t know? You really wanna get yo’ ass beat huh?”

As Jada looked away, a bit embarrassed, she saw two police officers looking at them. This included Roman clearly threatening this old man. “Umm, Roman?” She gently tapped his shoulder.

“What baby?” He asked, still staring daggers into his victim.

Jada just pointed at the officers and her silence prompted Roman to follow her line of vision. A sudden realization hits Roman and he smacks his teeth and drops the creepy pervert.

Long story short, the man pressed charges and Roman was sentenced to 90 days in jail.

Thinking about the whole process that happened, Jada zoned out and arrived at the jail quicker than she realized. She quickly found a parking spot in the visitors lot and made sure to only grab her keychain that held her car/house keys and a little card holder, leaving her purse and phone under the passenger seat.

She stepped out of her car and made her way to the building to get searched and to check in for the visit.

Jada was actually nervous to see Roman. They usually talk on the phone more than physically seeing each other in person. In a lot of ways, hearing his voice made her miss him even more.

“Ms. Williams, you’re up next to visit inmate Reigns. Follow me.” A guard’s voice rang throughout the waiting room. Jada quickly got up and walked up to him, expecting to go the same route as usual.

The guard seemed to be going a different way than usual. She didn’t want to be rude, so she politely asked him if they were going the right way. It felt shady.

“Um, officer? Is this the way to visitation?” She asked from behind his moving figure. The officer led them to a part of the jail that seemed deserted.

“Oh yeah.” He said matter-of-factly. They finally came upon a silver steel door with no window and the officer knocked three times before opening the door for Jada. She was so confused that she didn’t even recognize the 6’3” man with tribal tattoos in a khaki uniform sitting with his back to her.

“Roman?” She softly said. The sound of her voice made him perk up and he stood up to physically take her in.

“Jada…” He breathed out her name in awe, walking up to her. He quickly dapped up the guard who helped him get the private, “conjugal” visit. “Thanks, man. I appreciate it.”

“No problem. You only got 1 hour though.” The guard said, then left and closed the door before locking it.

Roman focused his attention back on the beauty in front of him. He picked her up in a hug and spun her around before giving her a deep and slow kiss.

Roman slipped his tongue into Jada’s vulnerable mouth and walked them both over to the bunk bed in the corner of the room, laying her down on it.

When he pulled away from her soft lips, Jada slapped his arm. “Roman, how in the world did you set this up? Can’t you get in troub-”

“Shhh. Don’t worry about that, baby. I’m good with that officer.” He tucked some of her curly hair behind her ear. The gesture made her smile. She missed his touch so much.

Jada’s hand went to Roman’s face, caressing it, and he smiled, showing his dimples and beautiful smile. “Roman, I miss you so much.” He grabbed her hand and brought it to his mouth and laid a kiss there.

“I miss you too princess. I think about you every day. Listen…when I get out of here, I’mma go to that anger management class. And I want you to be there with me.” He gently says to her.

Hearing Roman finally say that he would try to get help made Jada’s heart swell. Even though he was never violent towards her, she wanted to help him with controlling his anger towards other things and people.

“Babe…of course I’ll be there with you…” Jada says lovingly. Roman leans in for another kiss, their lips moving in sync. The kiss soon turned heated and sloppy. Roman’s lips left Jada’s and trailed to her jaw, then to her neck.

As Roman kissed her neck, his large hand went to her waist, feeling the curves he missed so much. He sucked on her neck, knowing there would be hickeys later.

Jada’s hands came to rest on his shoulder blades and tugged on his khaki shirt. He took this silent signal to take it off, leaving his white wife beater on, which seemed to amplify his tribal tattoo that ran up his arm and covered half of his chest.

She noticed that he seemed…bigger. She squeezed his arms, even more turned on and bit her lip. “Babe. Oh my-you’re so sexy.”

This made Roman chuckle. “Yeah? You want more?” His deep voice dropped an octave as he took off his wife beater, now completely bare up top. Jada ran her fingers over his well-defined abs that seemed to glisten even under the fluorescent lights.

His hands went to her feet and slid off her UGGs, placing them on the floor. Then he pressed kisses on her feet and saw that she had perfectly manicured white toenails. His hands went under her dress, sliding against her thighs, and scrunched her dress up to rest on her waist.

Jada spread her legs for him, feeling herself get more wet. Roman kissed up her thighs after placing each one to rest over his broad shoulders. He didn’t even take her panties off, just moved them to the side before licking a slow stripe up her wet pussy.

He sloppily made out with her pussy, mixing his spit with her juices. Jada was moaning, but Roman could tell she was holding back. He moved his mouth away from her core. “No, baby let it out. Lemme hear how good it feels.”

He placed his tongue back directly on her clit, flicking it tender and slow, then in long circles.

“Mmm…fuck Ro,” Jada moans out, louder this time as usual. Hearing her moans made his dick harder than steel. As he kept eating her out, he tugged the neckline of her dress down to expose her tits and kneaded them in his hands, rolling her hard nipples between his fingers.

She was so wet, it was seeping down her crack and onto the bed. Roman felt her legs start shaking a little. “Fuck, baby. Nut on my tongue, come on.” He told her then went right back to stimulating her clit, faster this time.

Jada chased her orgasm, feeling that knot about to burst in her lower abdomen. Her back arched and she sucked on her own fingers as she came undone on Roman’s tongue. He let her come down from her high, her juices all in his thick beard.

He kissed her, letting her taste herself from his mouth. Roman pulled his pants down just enough to free his throbbing, thick cock. One of his large hands went to it, slowly stroking himself as he looked at the love of his life.

“You gonna cum like that again on this dick?” His husky voice asked her. She wanted it so bad that it hurt.

“Yes Daddy..” She slyly said then giggled. Roman laughed and then rubbed the head of his dick up and down her pussy, and then forced out a long trail of spit that landed just in the right spot.

He slowly pushed into her tight, wet pussy, feeling her walls squeeze the life out of him damn near.

After Jada adjusted to his size again, there was no stopping them now.

She was now on all fours, back arched and her ass in the air. “Ooh Daddy, you fuck me so good!” She said in between moans.

Roman’s grunts didn’t go unnoticed. “Yeah? Tell me how good that dick feels in you baby.” He said and slapped her ass.

“Yesss! Fuck, it feels so good. It’s in my stomach,” Jada tells him, not ever wanting it to end. He changed the angle he was hitting it and found her G spot, stroking against it over and over with powerful thrusts.

Roman looked down at her ass that moved with each of his thrusts and saw her creaming on his girthy dick, and dripping down her thighs. “Damn. Yeah, cream on me just like that.” He threw his head back in never ending pleasure, trying not to bust too quick.

Jada started fucking him back, meeting his hips with her own, making her ass clap and the sound resonate through the empty room. There was an even bigger knot forming in her abdomen and she chased it again.

“Cum on Daddy’s dick, princess. Show me you want that nut.” Roman coaxed her and not even 2 seconds later, Jada’s legs were shaking, and she pressed her face into the bed.

That’s what Roman loved about Jada coming on his dick. She didn’t need a break. After her orgasm she was right back to taking his slow, meaningful thrusts.

“Mmm, Daddy please cum in me.” She looked at Roman over her shoulder. She silently applauded herself for taking her birth control before she drove here.

His hands tightened on her waist and ass while he focused on his pleasure. “That pussy gripping me so tight baby...” His moans got louder, and his thrusts got sloppy.

“Oh fuck, I’m ‘bout to cum,” Jada feels his hot load inside of her and he moans in her ear. When he comes down, he slowly pulls out of her and flips Jada on her back. They were both glistening because of sweat. He gives her a tender kiss.

“I love you with all my heart, Jada.” He says, still trying to catch his breath.

“I love you, Roman.” She tells him and they cuddle, trying to enjoy what little time they have left before the guard comes knocking on the door to get them.

#roman reigns#roman reigns smut#roman reigns fanfiction#the bloodline#the tribal chief#wwe fanfiction#roman reigns x oc#wwe smut#wwe imagine#roman reigns imagine#the bloodline x oc

269 notes

·

View notes

Text

After emerging from its egg, the humble squire, but one of a clutch of as many as fifty, gorges itself on porridge oats before finding itself a safe space beneath a shield or within the buttresses of a castle where it can undergo its extraordinary transformation into a knight.

Once safe, the squire wraps itself in spun chainmail which develops into a sturdy, protective cuirass to guard it from natural predators such as clergymen, lords, and even fully mature knights.

After a sennight, the squire begins to emerge from the cuirass as a juvenile knight. This time and energy intensive process, aided by the squires specially developed dagger, can take a full day.

Once freed from the cuirass, it takes a further three days for the juvenile knight's plate armour to harden. This armour is formed of interlocking plates, which depending on the genus of the knight may be made from iron, steel, or in some cases even bronze or copper.

During this process, some sub-species of knights also develop their heraldic colours. These are typically displayed through shielding or upon the knight's cape, which will usually fully unfurl in the few hours after they emerge from the cuirass. These colours are often used to attract a mate, indicate allegiance, or as showy threat displays.

Once a knight has reached sexual maturity, it will develop a lance; a hard, long protuberance used to attack and ward off competitors. Territory challenges are regular and deadly, and mature knights can often be observed jousting in the field, during which they rush at each other with their lances. Often, this results in the shattering of a lance, which will lead to the knight's death.

During breeding season, knights will construct an intricate bower to attract a mate. The choosing of a mate is demonstrated through the giving and receiving of a favour, entering the two knights in a season-long bond. Favour-stealing is extremely common, especially amongst younger knights.

Despite their territorial nature, wild knights are very social, and thrive best in areas where they are able to feast and play fight with other knights. Solitary knights can become depressed and reclusive, and have been known to create vast, maze-like bowers, steal mates, and invade pack knight's feast days. Solitary knights are often easy to identify thanks to the vibrant green patina of their armour.

449 notes

·

View notes

Text

Water drips down in the corner, the steady dop drop drop— does wonders for the bat.

Batman has been taken, tied up, and undressed of his utility belt. It takes him a second to figure out who took him, by the large but empty and run down warehouse, the sound of the shore not far away.

The docks. He shuffles, bound and comm off.

Then, the steel enforced door slams open and Joker enters.

"Batsy!" He calls, overjoyed. The man walks to the bound vigilante and crouches to his height.

"It's been so long, hasn't it been?"

The vigilante grunts. "Joker."

"Today will be different." He goes on, "today, we have," the crime Prince drums his fingers on Batman's thigh. "A guest!"

He freezes at that, Joker has a civilian.

(Oracle sends out the message, her voice firm, and the coords are shared to the rest of the clan in seconds as she looks at her monitor. Batman's red dot at the harbour bright.)

"I'm a guest now?" The voice of a child asks, it brings slight confusion that the boy wasn't tied nor harmed in any way.

It's relief that he seems okay, but the danger of standing next to the Joker has Batman wiggling in his restrains.

"Is that a promotion or demotion for son?"

A brief look of annoyance enters Joker before being smoothed out, the boy is dealing with a delicate time bomb. Uncomfortably close to the madman.

(He hurries in the process of breaking free.)

"My son! My blood!" Sings the clown, throwing his hands around the boy's shoulders and prancing around.

Which brings another question.

Son?

Cool lighting hits the boy's head and the tuffs of pink, blue and green become more obvious, hidden beneath black hair previously.

Joker and Harley have a child. A son.

He will visit harley later. The boy comes first.

"Dante! Danyal! Daniel?" Joker croons, shaking the boy. "What was it again?" He stops, turning his son toward him with a grin.

(Robin drops down behind him, hiding, katana ready to be swung.)

"Danny, actually," the child— Danny– shrugs off the hands and steps back. Unflinching from the judging stare, simply waving off the hands creeping to his throat.

"Danny," the name is tested, and the Prince of Crime hums to himself. "We can always replace it as Joker Jr! It fits you better than Danny."

(Red Robin and Spoiler get on position above them, ready to pounce from the construction pillars.)

"Yeah, I don't know about that." He chuckles nervous, catching Batman's eyes and—

His eyes alone scream of fear, scared– scared—!!

"We will get you an acid flower, a new suit as well, the hoodie looks horrible on you." The man notes, humming.

"I prefer hammers." Danny replies with tense shoulders.

Joker clicks his tongue, "You always went after your mother." he hisses, outright glaring at his son now. His hand tightened around the crowbar he'd gathered not long ago.

"I mean," he hesitates, eye trailing off the Joker and over his shoulder. "I did come out of her."

The sound of a loaded gun shatters the silence, and Joker is pulling Danny, switching their positions and pushing him right in front of the gun in Red Hood's hand.

"Always a coward, hiding behind others, aren't you." Danny stops himself from squealing. That's the Red Hood!

(Escrima sticks light up with electricity as Red Hood speaks.)

Joker is ticked off, party ruined and surrounded now that he looks around.

Oh well, he can get his son on his villain path another day.

Cackling, he evades the escrimas, dodging the wonder boy and evading the twin attacks from above.

He pulls out a trigger and presses the bright red Button.

"Have fun bats and birds!"

The warehouse is completely flooded with fear gas, scarecrow wouldn't be mad he sacrificed one of his warehouses, will he?

It's all blurry. In one moment, his view is shrouded, and he's coughing. In another, he gets picked up and brought outside, the Joker gone.

An oxygen mask is placed on him by a paramedic, being handed off to an ambulance that had been called.

Peeking around, he sees Red Hood (!) still lingering around. Danny catches his eye and with a wave, the man is walking towards him.

He simply crosses his arms and tilts his head, waiting.

"Could I get a picture?" Danny blurts out, flushing after and coughing, holding the oxygen mask in his lap.

Red Hood makes a show of his shoulder sagging before crouching down and leaning toward him.

Later, Danny will look at the picture with a boyish grin, crooked and charming.

.・゜-: ✧ :-

A continuation

#dcxdp#dp x dc crossover#dpxdc#fic prompt#writing prompt#dc x dp prompt#idk how the chemicals in joker and harley would affect a child tbf#so danny gets nice tuffs of blue pink and green#danny is the kid of Joker and Harley Quinn#look man#if harley was aware he was back in gotham she would have killed the joker before he knew of his son#batman is so confused#who allowsd the joekr to reproduce#edited: im actually been thinking ahrd decided the original was better#child danny would be greay to traumatize#also#dannys fav robin was the sec one#he has a complicated relationship with his dad#or rayher no relationship at all#hes gonna bash this mans head in with a hammer#harley will be so proud#sorry rebloggers for changing it!!!

2K notes

·

View notes

Text

When it comes to architecture, steel is utilized for building work that not only has to fulfill its function and be durable, but also needs to create style, and stainless steel is perfect for both of these goals.

#stainless steel construction#steel construction company#construction steel manufacturers#steel construction materials#steel construction suppliers#modern steel construction#steel construction process

1 note

·

View note

Text

"Those who point to the lumpenproletariat as the revolutionary vanguard disregard the objective laws of historical development. In pre-capitalist societies, poverty and oppression were even greater than under capitalism. But oppression in itself, no matter how great, does not create the basis for the struggle to abolish oppression.

Because of the specific nature of exploitation under capitalism, the working class, which collectively operates the mass production process of the privately owned monopolies, is transformed into the gravedigger of the system. That is why Marx and Engels wrote in The Communist Manifesto: “Of all the classes that stand face to face with the bourgeoisie today, the proletariat alone is a really revolutionary class.”

No fundamental change—or even a challenge to the monopolists—can occur without the working class. And today the proportion of Black workers in basic industries such as steel, coal, auto, transport and others is transforming the prospects for the class struggle and Black liberation.

The degree of exploitation of Black workers is clearly much greater than that of white workers. Nevertheless, the collective form of exploitation in the decisive mass production industries is suffered by all workers. This creates the objective basis for solidarity, for their unity and leadership in the struggle against the monopolist ruling class.

At the same time, history has assigned a doubly significant role to Black workers—as the leaders and backbone of the Black liberation movement, and as a decisive component of the working class leadership of the anti-imperialist struggle as a whole.

It is the monopolists’ fear of Black, white, Brown, Yellow, Red and working class unity, which in turn can form the basis for still broader people’s unity, that is behind racism and anti-Communism, the main ideological weapons of the ruling class.

Leninism, the Marxism of the imperialist epoch, is the ideological weapon of the working class. It is the scientific guide that enables the working class to combine its struggle with national liberation movements against imperialism.

No other theory has served to free a single working class, a single people, from imperialism anywhere in the world. Beginning with the October revolution, only those guided by Marxism-Leninism have been able to free themselves from class and national oppression and take the road of socialist construction."

— "Objective Laws of Development" Henry Winston, The Crisis of the Black Panther Party (1971)

382 notes

·

View notes

Text

The Essential Role of TMT Bar Manufacturers in Producing Strong, Reliable Steel

Building something that the sands of time don't change requires very high-grade materials, especially in the case of steel reinforcement. In this regard, TMT bar manufacturers are a very important part of construction. Through advanced technology and strict quality control measures, innovative technologies develop the required backbone for modern buildings.

Understanding TMT Steel: The Foundation of Modern Construction

TMT steel, or Thermo-Mechanically Treated steel, is a product that marks the pinnacle of development in construction materials. Specialized bars are treated with a highly sophisticated cooling process, which helps create a hard outer layer and keeps the core ductile. Top TMT saria manufacturers use cutting-edge technology to achieve precise temperature control and optimum mechanical properties in every batch produced.

Raw material selection during the process primarily involves choosing high-grade raw materials and then controlling the chemical composition to achieve desired strength and durability. Every process, starting from heating to quenching, needs high expertise and better equipment for uniformity across batches.

Quality Control: The Strong Foundation of Credible TMT Saria Manufacture

Quality control within the production chain is carried out by all reliable saria manufacturers for TMT steel. This not only includes check-ups on properties like yield strength, ultimate tensile strength, and elongation. All these analyses ensure that whatever batch is available, it strictly meets or satisfies the international threshold for constructional steel.

Modern testing laboratories help in the achievement of premium steel. Assessments of TMT steel include tests such as:

Metallurgical analysis to compare chemical composition

Bend tests and rebend tests to guarantee ductility

Ultrasonic test for internal flaws

Load test to check strength parameters

Impact on Construction Safety and Durability

The quality of TMT bars directly influences the structural integrity of buildings and infrastructures. Quality TMT bar manufacturers realize this responsibility and invest heavily in research and development towards product improvement. Excellence in their operations means that construction projects benefit from steel capable of withstanding environmental stresses and maintaining structural stability for decades.

Modern TMT saria manufacturer facilities have incorporated automated production lines that minimize human error while maximizing efficiency. This technological integration helps maintain consistent quality while meeting the growing demand for construction materials in rapidly developing regions.

Environmental Considerations and Sustainable Manufacturing

Increasingly, progressive TMT steel producers focus on sustainable manufacturing practices. This includes using energy-efficient production methods, recycling water used in the cooling process, and utilizing scrap steel as raw material whenever possible. Such practices not only reduce environmental impact but also often result in cost savings that benefit end consumers.

Selecting the Right Manufacturing Partner

Construction companies and developers need to consider the following crucial factors when selecting a TMT bar manufacturer:

Manufacturing Capacity: The site should have newer equipment and regularly produce the ability to fulfill order requirements

Qualification Certificates: Reliable producers maintain up-to-date industry quality certificates and always undergo third party quality audits

Technical Support: Quality manufacturers develop extensive technical product documentation and experienced technical support regarding specific applications

Research and Innovation: Companies undertaking research and development often manufacture the best products compatible with changing requirements in construction works

Future View

The construction sector is always changing, and new problems require creative answers. Forward-thinking producers of TMT bars make investments in the creation of cutting-edge steel types with higher corrosion resistance and strength-to-weight ratios. This ensures that construction projects meet increasingly demanding architectural and engineering requirements. Building materials are the foundation of safe, robust infrastructure, and the quality of these materials lies entirely in the hands of their manufacturers. As such, with the choice of proper TMT bar manufacturers, the construction industry would receive materials bound to last for generations.

#TMT bars#steel strength#reliable steel#construction steel#TMT manufacturers#quality steel#strong steel#manufacturing#steel quality#raw materials#construction bars#durable steel#TMT production#steel process#building materials#TMT technology#steel durability#reliable bars#infrastructure steel#construction TMT#steel standards

0 notes

Text

"An upcoming community center in Tanzania will be defined by its cutting-edge 3D-printed design. However, rather than being built from layered concrete as you'd usually expect with 3D-printed projects, its walls will be created using locally sourced soil.

The community center is being headed by Hassell, in collaboration with Australian-based charity foundation One Heart, for the Hope Village in Tanzania. It forms part of a wider plan to provide housing, a school, childcare and skills training to vulnerable young girls in Kibaha, eastern Tanzania.

"The Hope Village community hall design seeks to create a beautiful, functional, safe and uplifting environment that provides both hope and education for vulnerable girls," says Mark Loughnan, Principal and Head of Design at Hassell. "The hall is a welcoming space that creates an innovative central activity hub that also connects with its surrounding environment. The design and building process for the hall aims to engage the community and provide ongoing opportunities for local participation and education throughout construction."

Structurally, the community center is quite complex. Its walls (which are not load-bearing) will be built using soil sourced within 25 km (15.5 miles) of the site and a WASP 3D printer. WASP has been researching this stuff for years now and a previous project used a mixture of mud, straw, rice husk and lime. A similar process will be happening here, with a clay based earthen mixture being extruded out of a nozzle in layers to build up the walls. A representative at Hassell told us that the walls will also be reinforced with a thin wire mesh between layers.

Inside, the design brief calls for a large, open floorplan that suits the local climate, with a limited number of columns to ensure its flexibility. To achieve this, Hassell has conceived a central steel beam that serves as the structural spine of the hall. This will support a roof made from locally sourced timber sections. The roof will feature cladding made of readily available corrugated metal sheet panels, helping to keep costs down.

The project also involves the Institute for Advanced Architecture of Catalonia, IAAC, and ClarkeHopkinsClarke. We've no word yet on when it's expected to be completed, though prototype walls have already been produced.

Pictured: A prototype of the community center's 3D printed walls has already been created.

-via NewAtlas, August 13, 2024

#architecture#sustainable architecture#tanzania#africa#3d printing#sustainability#ecofriendly#good news#hope

225 notes

·

View notes

Text

Cold Iron in folklore, fiction, and RPGs

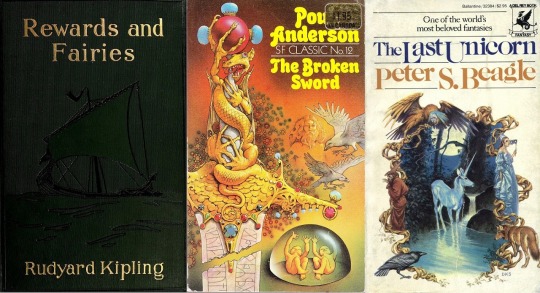

'Gold is for the mistress—silver for the maid! Copper for the craftsman cunning at his trade.' 'Good!' said the Baron, sitting in his hall, 'But Iron—Cold Iron—is master of them all!' — Rudyard Kipling, “Cold Iron”

Folklore

Drudenmesser, or "witch-knife", an apotropaic folding knife from Germany

The notion that iron (or steel) can ward against evil spirits, witches, fairies, etc is very widespread in folklore. You hang a horseshoe over your threshold to deny entry to evil spirits, you carry an iron tool with you to make sure devils won't assault you, you place a small knife under the baby's crib to ward it from witches, and so on. Iron is apotropaic in many many cultures.

In English, we often come across passages that refer to apotropaic cold iron (or cold steel). "All uncouth, unknown Wights are terrifyed by nothing earthly so much as by cold Iron", says Robert Kirk in 1691, which I believe is the earliest example. "Evil spirits cannot bear the touch of cold steel. Iron, or preferably steel, in any form is a protection", says John Gregorson Campbell in 1901.

Words

So what is cold iron? In this context, it’s just iron. The “cold” part is poetic, especially – but not only – if we’re talking about either blades (or swords, weapons, the force of arms) or manacles and the like. It just sounds more ominous. There are “cold yron chaines” in The Fairie Queene (1596), and a 1638 book of travels tells us that a Georgian general (in the Caucasus) vowed “to make the Turk to eat cold iron”.

Green’s Dictionary of Slang defines “cold iron” as a sword, and dates the term to 1698. From 1725 it appears in Cant dictionaries (could this sense be thieves’ cant, originally? why not, plenty of words and expressions started as underworld slang and then entered the mainstream), and from ~1750 its use becomes much more common.

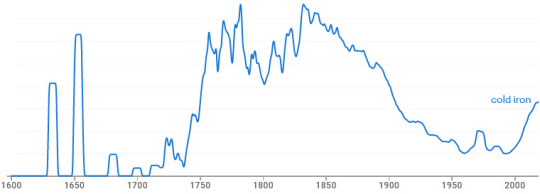

NGram Viewer diagram for 1600-2019.

In other contexts, cold iron is (surprise!) iron that’s not hot. So let’s talk a bit about metallurgy.

Metals

In nature, we can find only one kind of iron that’s pure enough to work with: meteoritic iron. It has to literally fall from the sky. Barring that very rare occurrence, people have to mine the earth for iron ore, which is not workable as is. To separate the iron from the ore we have to smelt it, and for that we need heat, in the form of hot charcoals. Throwing the ore on the coals won’t do much of anything, it’s not hot enough. But if we enclose the coals in a little tower built of clay, leaving holes for air flow, the temperature rises enough to smelt the ore. That’s called a bloomery.

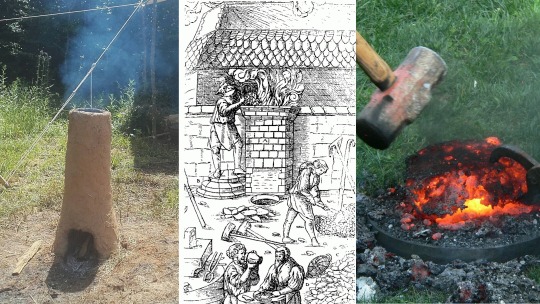

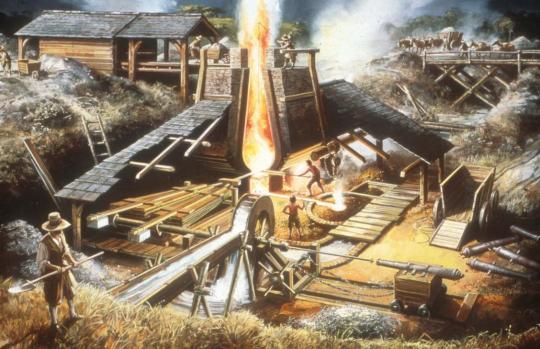

clay bloomery / medieval bloomery / beating the bloom to get rid of the slag

What comes out of the bloomery is a bloom: a porous, malleable mass of iron (that we need) and slag (byproducts that we don’t need). But now we can get rid of the slag and turn the porous mass to something solid, by hammering the hot bloom over and over. And once the slag is off, by the same process we can give it a desired shape in the forge, reheating it as needed. This is called “working” the iron, hence “wrought iron” objects, i.e. forged.

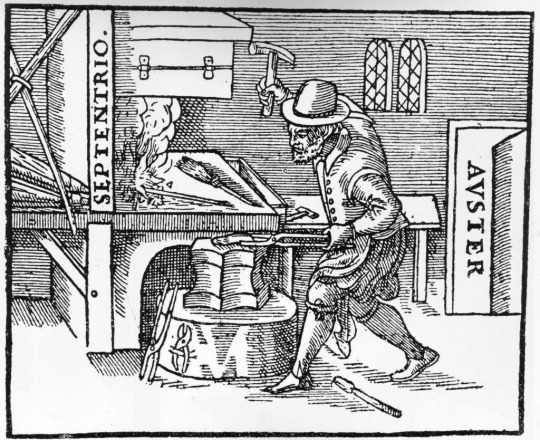

a blacksmith in his forge, with bellows, fire, and anvil (English woodcut, 1603)

This is the lowest-tech version, possibly going back to ~2000 BCE in Nigeria. If we add bellows, the improved air flow will raise the temperature. So smelting happens faster and more efficiently in the bloomery, and so does heating the iron in the forge, making it easier to work with. And that’s the standard process from the Iron Age all through the middle ages and beyond (although in China they may have skipped this stage and gone straight to the next one).

If we make the bloomery bigger and bigger, with stronger and stronger bellows, we end up with a blast furnace, a construction so efficient that the temperature outright melts the iron, and it’s liquified enough to be poured into a mould and acquire the desired shape when it cools off. This is “cast iron”.

a blast furnace

So in all of this, what’s cold iron? Well, it’s iron that went though the heat and cooled off. (No heat = no iron, all you got is ore.) If it came out of a bloomery, or if it wasn’t cast, it’s by definition worked, hammered, beaten, wrought, and that happened while it was still hot.

Is there such a thing as “cold-wrought” iron? No. In fact, “working cold iron” was a simile for something foolish or pointless. A smith who beats cold iron instead of putting it in the fire shows folly, says a 1694 book on religion, so you too should choose your best tools, piety and good decorum, to educate your children and servants, instead of beating them. When Don Quixote (1605) declares he’ll go knight-erranting again, Sancho Panza tries to dissuade him, but it’s like “preaching in the desert and hammering on cold iron” (a direct translation of martillar en hierro frío).

Minor work can be done on cold iron. A 1710 dictionary of technical terms tells us that a rivetting-hammer is “chiefly used for rivetting or setting straight cold iron, or for crooking of small work; but ’tis seldom used at the forge”. Fully fashioning an object out of cold iron is not a real process – though a 1659 History of the World would claim that in Arabia it’s so hot that “smiths work nails and horseshoes out of cold iron, softened only by the vigorous heat of the sun, and the hard hammering of hands on the anvil”. [I declare myself unqualified to judge the veracity of this statement, let's just say I have doubts.] And there is of course such a thing as “cold wrought-iron”, as in wrought iron after it’s cooled off.

Either way, in the context of pre-20th century English texts which refer to apotropaic “cold iron”, it’s definitely not “cold-wrought”, or meteoritic, or a special alloy of any kind. It’s just iron.

Fiction

The old superstition kept coming up in fantasy fiction. In 1910 Rudyard Kipling wrote the very influential short story “Cold Iron” (in the collection Rewards and Fairies), where he explains invents the details of the fairies’ aversion to iron. They can’t bewitch a child wearing boots, because the boots have nails in the soles. They can’t pass under a doorway guarded by a horseshoe, but they can slip through the backdoor that people neglected to guard. Mortals live “on the near side of Cold Iron”, because there’s iron in every house, while fairies live “on the far side of Cold Iron”, and want nothing to do with it. And changelings brought up by fairies will go back to the world of mortals as soon they touch cold iron for the first time.

In Poul Anderson’s The Broken Sword (1954), we read:

“Let me tell you, boy, that you humans, weak and short-lived and unwitting, are nonetheless more strong than elves and trolls, aye, than giants and gods. And that you can touch cold iron is only one reason.”

In Peter S. Beagle’s The Last Unicorn (1968) the unicorn is imprisoned in an iron cage:

“She turned and turned in her prison, her body shrinking from the touch of the iron bars all around her. No creature of man’s night loves cold iron, and while the unicorn could endure its presence, the murderous smell of it seemed to turn her bones to sand and her blood to rain.”

Poul Anderson would come back to that idea in Operation Chaos (1971), where the worldbuilding’s premise is that magic and magical creatures have been reintroduced into the modern world, because a scientist “discovered he could degauss the effects of cold iron and release the goetic forces”. And that until then, they had been steadily declining, ever since the Iron Age came along.

There are a million examples, I’m just focusing on those that would have had a more direct influence on roleplaying games. However, I should note that all these say “cold iron” but mean “iron”. Yes, the fey call it cold, but they are a poetic bunch. You can’t expect Robin Goodfellow’s words to be pedestrian, now can you?

RPGs

And from there, fantasy roleplaying systems got the idea that Cold Iron is a special material that fey are vulnerable to. The term had been floating around since the early D&D days, but inconsistently, scattered in random sourcebooks, and not necessarily meaning anything else than iron. In 1st Edition’s Monster Manual (1977) it’s ghasts and quasits who are vulnerable to it, not any fey creature. Devils and/or fiends might dislike iron, powdered cold iron is a component in Magic Circle Against Evil, and “cold-wrought iron” makes a couple of appearances. For example, in AD&D it can strike Fool’s Gold and turn it back to its natural state, revealing the illusion.

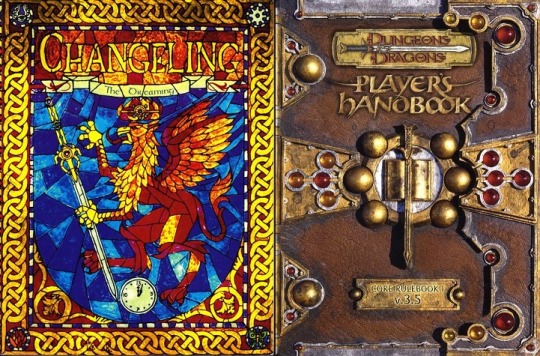

Then Changeling: The Dreaming came along and made it a big deal, a fundamental rule, and an anathema to all fae:

Cold iron is the ultimate sign of Banality to changelings. ... Its presence makes changelings ill at ease, and cold iron weapons cause horrible, smoking wounds that rob changelings of Glamour and threaten their very existence.... The best way to think about cold iron is not as a thing, but as a process, a very low-tech process. It must be produced from iron ore over a charcoal fire. The resulting lump of black-gray material can then be forged (hammered) into useful shapes. — Changeling: The Dreaming (2nd Edition, 1997)

So now that we know how iron works, does that description make sense? Well, if we assume that the iron ore is unceremoniously dumped on coals, it does not. You can’t smelt iron like that. If we assume that a bloomery is involved even though it’s not mentioned, then yes, this is broadly speaking how iron’s been made since the Iron Age, and until blast furnaces came into the picture. But the World of Darkness isn’t a pseudo-medieval setting, it’s modern urban fantasy. So the implication here is that “cold iron” is iron made the old way: you can’t buy it in the store, someone has to replicate ye olde process and do the whole thing by hand. Now, this is NOT how the term “cold iron” has been used in real life or fiction thus far, but hey, fantasy games are allowed to invent things.

Regardless, 3.5 borrowed the idea, and for the first time D&D made this a core rule. Now most fey creatures had damage reduction and took less damage from weapons and natural attacks, unless the weapon was made of Cold Iron:

“This iron, mined deep underground, known for its effectiveness against fey creatures, is forged at a lower temperature to preserve its delicate properties.” — Player’s Handbook (3.5 Edition, 2003)

Pathfinder kept the rule, though 5e did not. And unlike Changeling, this definition left it somewhat ambiguous if we’re talking about a material with special composition (i.e. not iron) or made with a special process (i.e. iron but). The community was divided, threads were locked over this!

So until someone points me to new evidence, I’ll assume that the invention of cold iron as a special material, distinct from plain iron, should be attributed to TTRPGs.

#long post#cold iron#d&d#Changeling: The Dreaming#World of Darkness#Peter S. Beagle#The Last Unicorn#Rudyard Kipling#Poul Anderson#The Broken Sword#how to rogue#pathfinder#rogues in fiction#Operation Chaos#rogue superstitions#words of the trade#thieves' cant#ad&d#d&d history#1st edition#fey#3.5#fluff#trs

405 notes

·

View notes