#stainless steel welded tubes

Explore tagged Tumblr posts

Text

#automotive & non automotive#automotive heavy vehicle & farm equipment parts#cold drawn seamless tubes#srb / honed hydraulic cylinder tubes & sub#assemblies#transformer - radiator butterfly valves#stainless steel welded tubes#submersible pump parts#textile machinery tubes & parts

0 notes

Text

Welded Tubes SS430 - SPP Metal and Alloys Manufacturer and suppliers of Stainless Steel Products with quality assurance

SPP Metal & Alloys is one of the prominent Supplier of SS430 welded tubes. It is used in Dish washer linings, Refrigerator cabinet panels, Element supports and fasteners, Stove trim rings and chimney liners, Automotive trim and lashing wires. Stainless steel grade 430 has a low work hardening rate which enables easy bending and forming.

#Welded Tubes#SS 430 Tubes#Stainless Steel Welded tubes#SS430 Manufacturers and suppliers#Grade 430 SS

0 notes

Text

At Advance Tube Engineering, our material capabilities include bending aluminum, stainless steel, and mild steel, in addition to square tube bending services to customer specification. In addition to bending, we also offer beading, flaring, swaging, and other services.

We are capable of meeting your tube bending needs with a variety of applications including: beading, flaring and welding.

2 notes

·

View notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Understanding Stainless Steel Tubing Coil And Welded Pipe

Explore the uses, benefits, and manufacturing processes of stainless steel tubing coil and welded pipe in various industries. Learn how these products contribute to efficiency and durability in different applications. In the realm of industrial materials, stainless steel stands as a paragon of versatility, offering robust solutions across various applications. Among its numerous forms, stainless steel tubing coil and welded pipe are pivotal components known for their strength, resilience, and adaptability. These products play indispensable roles in industries ranging from construction and automotive to healthcare and food processing, embodying reliability and durability in diverse environments.

0 notes

Text

Both SS 347 and SS 347H, belonging to the austenitic stainless steel family, offer similar attributes with the primary distinction lying in their carbon content. SS 347H Welded Tubing, featuring a higher carbon content compared to Stainless Steel 347 Tubes, stands out for its enhanced toughness. These alloys, stabilized by the addition of columbium, exhibit remarkable resistance in strongly oxidizing environments and maintain their integrity even at elevated temperatures ranging from approximately 427 to 816 degrees Celsius.

#Stainless Steel 347/347H Welded Tubes Manufacturers#Stainless Steel 347/347H Welded Tubes Suppliers#Stainless Steel 347/347H Welded Tubes Stockists#Stainless Steel 347/347H Welded Tubes Exporters

0 notes

Text

Stainless steel tubing, manufactured by Raaj Tubes, exemplifies quality and durability, suitable for a wide range of industrial applications. Our tubing is known for its exceptional resistance to corrosion, high strength, and longevity, making it ideal for use in demanding environments such as chemical processing, oil and gas, and food and beverage industries. Raaj Tubes offers a variety of sizes and grades to meet the specific needs of our customers, ensuring precision and reliability in every product. Trust Raaj Tubes for superior stainless steel tubing solutions that deliver performance and dependability.

#stainless steel flat tubes#stainless steel profiles#stainless steel press brake tubes#stainless steel round tubing#stainless steel square tubing#welded stainless steel i-beams#raajtubes

0 notes

Text

Bright Annealed Tubes vs. Other Stainless Steel Tubes: Which Is Right for You?

When it comes to selecting stainless steel tubes, understanding the differences between bright annealed tubes and other options is crucial. Each type offers unique characteristics that cater to specific applications and requirements.

Bright Annealed Tubes: Shining Through Excellence

Definition and Characteristics: Bright annealed tubes undergo a specialized heat treatment process known as bright annealing. This process involves heating the tubes in a controlled atmosphere to prevent oxidation, resulting in a smooth, reflective surface finish. The bright annealing process enhances the tubes' corrosion resistance, improves their mechanical properties, and gives them an aesthetically pleasing appearance.

Key Advantages:

Superior Corrosion Resistance: Ideal for environments where resistance to corrosion is paramount, such as chemical processing plants and marine applications.

Enhanced Aesthetic Appeal: The bright, polished finish makes these tubes suitable for architectural and decorative uses.

Improved Mechanical Properties: Increased strength and durability compared to untreated stainless steel tubes.

Other Stainless Steel Tubes: A Comparative Analysis

Cold Drawn Tubes:

Definition and Characteristics: Cold drawn tubes are manufactured by pulling the stainless steel through a die to achieve the desired dimensions. This process results in a smooth surface finish and tight dimensional tolerances. However, cold drawn tubes may not offer the same level of corrosion resistance and aesthetic appeal as bright annealed tubes.

Key Considerations:

Mechanical Properties: Cold drawn tubes offer excellent dimensional accuracy and surface finish, making them suitable for precision applications.

Applications: Commonly used in industries where tight tolerances and high mechanical strength are required, such as automotive and hydraulic systems.

Welded Tubes:

Definition and Characteristics: Welded stainless steel tubes are formed by welding strips of steel together. While this method is cost-effective and suitable for large-scale production, welded tubes may have visible weld seams and reduced corrosion resistance compared to seamless bright annealed tubes.

Key Considerations:

Cost Efficiency: Welded tubes are often more economical than seamless options.

Appearance and Integrity: Welded tubes may have visible weld lines, which can affect their appearance and structural integrity.

Which Is Right for You?

Choosing the Right Tube for Your Application:

If Corrosion Resistance and Aesthetic Appeal Are Key: Bright annealed tubes are the clear choice, offering superior resistance to corrosion and a polished finish that enhances visual appeal.

For Precision and Mechanical Strength: Cold drawn tubes excel, providing tight tolerances and high mechanical properties suitable for demanding applications.

Cost-Effective Solutions: Welded tubes offer affordability and are suitable for applications where appearance is less critical.

Conclusion

In conclusion, the decision between bright annealed tubes and other stainless steel tube options depends on your specific application requirements. Whether you prioritize corrosion resistance, aesthetic appeal, mechanical strength, or cost efficiency, Krystal Global Engineering Limited can provide expert guidance and high-quality solutions tailored to meet your needs.

Contact Us Today: For more information on selecting the right stainless steel tubes for your project, contact Krystal Global Engineering Limited. With our expertise and commitment to quality, we ensure you get the optimal solution that meets your specifications and exceeds your expectations.

0 notes

Text

Stainless Steel 321 / 321H Tubes

Stainless Steel 321 / 321H Tubes

Stainless steel has revolutionized multiple industries with its superior properties such as corrosion resistance, durability, and ability to withstand high temperatures. Among the many grades of stainless steel, Stainless Steel 321 and 321H stand out for their unique characteristics and wide range of applications. Here, we explore these two variants and their benefits, presented by Metalloys International.

Understanding Stainless Steel 321

Stainless Steel 321 is a titanium-stabilized austenitic stainless steel known for its outstanding resistance to intergranular corrosion. This makes it an excellent choice for applications involving continuous and intermittent heating within the temperature range of 800 to 1500°F (427 to 816°C). The addition of titanium helps stabilize the material, preventing carbide precipitation and ensuring that it retains its mechanical properties even under high-temperature conditions.

Key Benefits of Stainless Steel 321 Tubes

Corrosion Resistance: Stainless Steel 321 exhibits excellent resistance to oxidation and corrosion, especially in high-temperature environments.

Thermal Stability: Its ability to maintain stability and strength at elevated temperatures makes it ideal for use in aerospace, chemical processing, and thermal processing applications.

Fabrication Ease: Despite its robustness, Stainless Steel 321 can be readily fabricated into tubes, making it highly versatile for various industrial applications.

Introducing Stainless Steel 321H

Stainless Steel 321H is a higher carbon version of 321, designed to offer enhanced high-temperature strength. The increased carbon content improves the material's creep resistance and strength, making it suitable for applications that require prolonged exposure to high temperatures.

Applications of Stainless Steel 321 / 321H Tubes

These tubes are utilized across various industries due to their unique properties:

Aerospace: Employed in jet engine parts, exhaust manifolds, and other high-temperature components due to their excellent thermal stability and corrosion resistance.

Chemical Processing: Ideal for handling corrosive substances and acids in the chemical industry, thanks to their superior corrosion resistance.

Petroleum Refining: Used in refining equipment and other components that require both high-temperature strength and resistance to corrosion.

Why Choose Metalloys International?

Metalloys International is a renowned supplier of Stainless Steel 321 / 321H Tubes, dedicated to delivering top-quality materials that meet the stringent demands of various industries. We prioritize customer satisfaction by ensuring our products adhere to international standards and are delivered promptly.

With a vast inventory and extensive industry expertise, Metalloys International is your trusted partner for all your stainless steel requirements. For more information and to explore our product range, visit our website at Metalloys International.

Conclusion :

Stainless Steel 321 / 321H Tubes are essential for industries that demand materials capable of withstanding high temperatures and corrosive environments. Their unique properties ensure durability and reliability in challenging applications. For premium quality Stainless Steel 321 / 321H Tubes, turn to Metalloys International, your reliable supplier for stainless steel solutions.

For inquiries and further details, submit your request on our website at Metalloys International.

#321H STAINLESS STEEL TUBES DEALER#SS 321H TUBES SUPPLIER#STAINLESS STEEL 321H TUBES MANUFACTURER#SS 321 ROUND TUBES#STAINLESS STEEL 321H WELDED TUBES#SS 321 TUBES SUPPLIER#STAINLESS STEEL 321H TUBES SUPPLIER#ASME SA213 TP 321H SS TUBE#ASTM A213 SS 321 SEAMLESS TUBES#SS 321 ERW TUBES#SS 321H CAPILLARY TUBES#SS 321 TUBES MANUFACTURER#STAINLESS STEEL 321 TUBES SUPPLIER#STAINLESS STEEL 321 HEAT EXCHANGER TUBES#SS 321H TUBES MANUFACTURER#STAINLESS STEEL 321H TUBING#SS 321 TUBES EXPORTER.

0 notes

Text

Dive into the world of stainless steel tubing welding with our comprehensive guide! Learn the ins and outs of this essential process and master the art of welding stainless steel tubing like a pro. From understanding different stainless steel alloys to selecting the right welding method, we’ve got you covered. Discover tips for success, troubleshooting techniques, and answers to common questions. Ready to elevate your welding skills? Check out our blog now!

0 notes

Text

Key Differences Between Seamless and Welded Stainless Steel Pipes

SPP Metals & Alloys, is your maximum suitable vacation spot for pinnacle-notch stainless steel pipes. As enterprise leaders in production, providing, stocking, and exporting stainless steel pipes, we recognize the significance of selecting the right form of pipe for your projects. In this complete guide, we can delve into the key disparities between Welded Stainless Steel Pipes and ss seamless pipes to help you make informed alternatives on your precise necessities. Whether you are trying to find stainless steel welded pipe or seeking out a reliable ss seamless pipe manufacturer in india, SPP Metals Alloys has you covered.

Seamless Stainless Steel Pipes:

The manufacturing manner entails the absence of any welding seam, resulting in a uniform form at a few level within the pipe duration. This seamless construction offers numerous advantages:

Strength and Durability: Seamless pipes display off high-quality energy and durability because of their homogeneous form, making them great for excessive-strain programs.

Enhanced Corrosion Resistance: The absence of weld seams reduces the risk of corrosion, ensuring sturdiness and reliability in corrosive environments.

Smooth Interior Surface: Seamless pipes boast a clean indoors ground, minimizing frictional resistance and facilitating inexperienced fluid float.

Welded Stainless Steel Pipes:

Welded pipes provide incredible benefits:

· Cost-Effectiveness: Welded pipes are usually extra rate-powerful than seamless pipes, making them a favored choice for price range-conscious tasks.

· Versatility: Welded pipes are available in various sizes and diameters, catering to a huge variety of packages across specific industries.

· Strength and Reliability: Although welded pipes may additionally moreover have a welded seam, cutting-edge welding strategies ensure excellent welds, keeping power and reliability.

· Customization Options: Welded pipes offer flexibility in customization, taking into account unique requirements together with non-popular lengths or diameters.

Key Differences Summarized:

· Construction: Seamless pipes are made from stable billets without any welding seam, at the same time as welded pipes are formed through welding steel plates or coils.

· Strength and Durability: Seamless pipes provide advanced electricity and sturdiness because of their homogeneous shape, whilst welded pipes show off robustness with the use of current welding techniques.

· Corrosion Resistance: Seamless pipes reduce the hazard of corrosion with their seamless creation, whilst welded pipes provide excellent sufficient corrosion resistance with proper floor treatment.

· Cost: Welded pipes are typically greater fee-powerful than seamless pipes, making them a preferred preference for budget-aware duties.

Final Words!

At SPP Metals & Alloys, as a primary ss seamless pipe manufacturer in India, we provide each welded stainless-steel pipes and ss seamless pipes, every providing remarkable blessings to satisfy numerous task necessities. Our entire range consists of diverse sizes, specs, standards, and grades of seamless and welded chrome steel pipes. Whether you prioritize energy, sturdiness, charge-effectiveness, or versatility, we've got the correct answer for your stainless-steel piping needs. Contact us these days to explore our big product variety and revel in high-quality best and provider in stainless-steel welded pipes and ss seamless pipes.

0 notes

Text

Starter motor components for non-automotive applications OR automotive applications

Automotive & Non Automotive

#assemblies#automotive & non automotive#srb / honed hydraulic cylinder tubes & sub#stainless steel welded tubes#cold drawn seamless tubes#submersible pump parts#textile machinery tubes & parts#automotive heavy vehicle & farm equipment parts#transformer - radiator butterfly valves

0 notes

Text

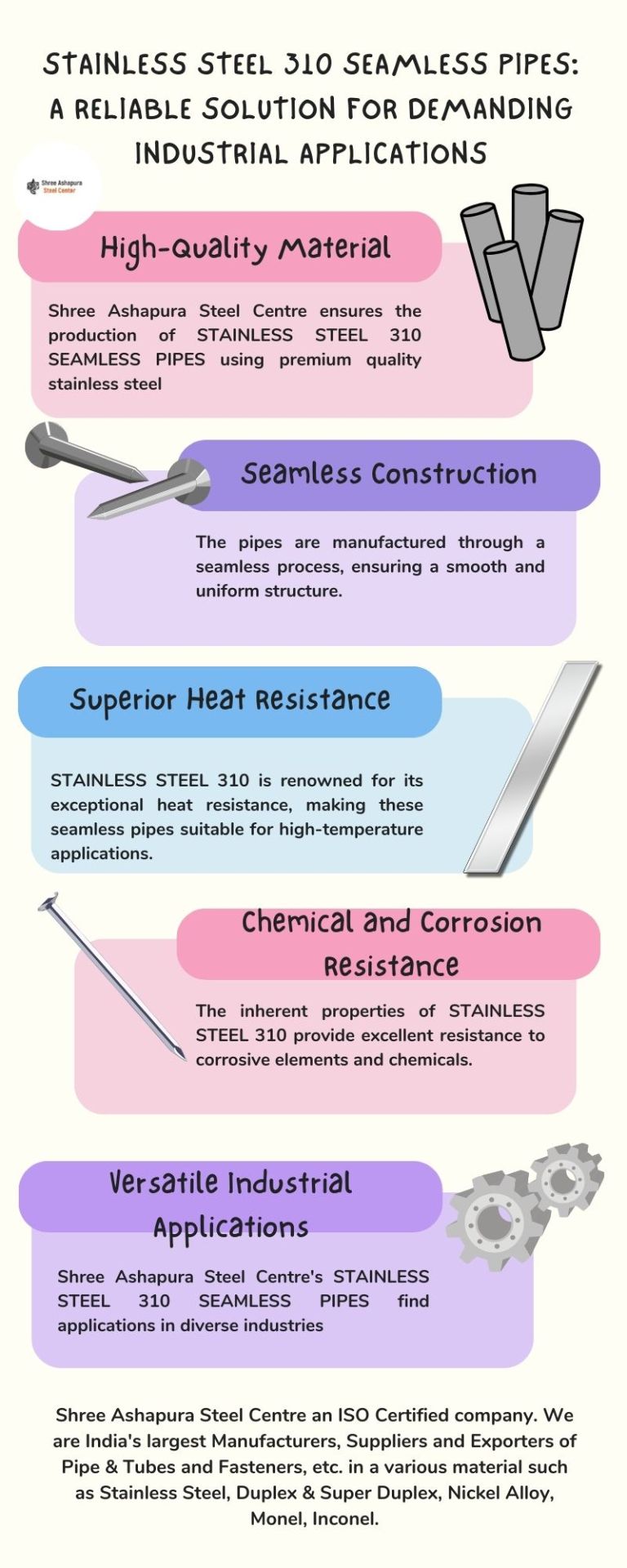

Shree Ashapura Steel Centre an ISO Certified company. We are India's largest Manufacturers, Suppliers and Exporters of Pipe & Tubes and Fasteners, etc. in a various material such as Stainless Steel, Duplex & Super Duplex, Nickel Alloy, Monel, Inconel.

#Stainless Steel 310 Seamless Pipe Manufacturer#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Pipe Supplier#ASTM A312 TP310 Pipe#Stainless Steel 310 ERW pipe Stockiest#ss 310 tube#310 stainless steel square tubing#DIN 1.4539 Seamless Tube#ASME SA673 SS 904L Polished Pipe Manufacturer#UNS N08904 Seamless Pipe Supplier#ASTM A312 tp 904L Welded Pipe#DIN 1.4539 Rectangular Pipe#Stainless Steel 904L Seamless Tube Stockiest

0 notes

Text

Austenitic stainless steel welded pipe/tube ASTMA 269 TP304/TP304L/TP316L/TP316Ti OD 38.1mm

Brands:HUZHOU DINGSHANG Certificate:TS,ISO9001-2015, PED, AD2000 SIZE:OD:6.0mm-114.3mm, W.T:0.4mm-6.0mm Standard:GB/T12771-19,GB/T24593-18,ASTMA249-16,ASTMA269-16,ASTMA312-16,EN10217-7-15,EN10312,etc. Welding type:GTAW(TIG) Finishing:Bright and Annealing, Pickling and annealing, Polishing, As welded,etc. Inspection method:The physical and chemical properties,Hydrostatic test,Air-underwater pressure test,ET. Packing:Plywood case, Seaworthy packing,According to customer requirements. Applications:Heat exchanger, Condenser,Pressure vesse,Chemical equipment,Food industry,Drinking water project,Desalination plants,etc.

Company Name:Huzhou Dingshang Stainless Steel Co., Ltd. Web:https://www.dsssco.com/product/austenitic-stainless-steel-welded-pipe-tube/astma-269-tp304-tp304l-tp316l-tp316ti-od-38-1mm.html ADD:"No. 19, Rongle Road, Economic Development Zone, Changxing County, Huzhou City, Zhejiang Province, China" Phone:572-6972982 Email:[email protected] Profile:Huzhou Dingshang stainless steel Co., Ltd. is located in Huzhou city Zhejiang province, about one hour to Jiangsu, Shanghai and Hangzhou. DINGSHANG is specializing in industrial stainless steel welded tube and special alloys tube, with annual production capacity up to 7,000 tons. The tubes are produced to conform to GB, ASTM/ASME, JIS, DIN, EN, GOST and ISO standards. Some special requirements from clients can al so be met.

0 notes

Text

Superior Quality Tubes Manufacturer in India

Zion Tubes & Alloys is a leading Stainless Steel Orbital Welding Tubes Manufacturer in India. Our Stainless Steel Instrument Tubing we supply and export an extensive range of products, including stainless steel 304, 304L, and 316 orbital welding tubes. For the availability and ranging of products we are always at your service.We are Also Leading Stainless Steel 317L Seamless Tubes Manufacturer in India.

We provide market-leading rates to all of our clients on Stainless Steel Instrumentation Tubing & Stainless Steel Electropolished Tubes hOur exclusive range of products includes electropolished tubes made of stainless steel 304 and 304L, as well as stainless steel 316.

Our Products Lists:Stainless Steel coil tube , Bright Annealed Stainless Steel Tubing & Nickel Alloy Tubes are used in a wide range of sectors and are manufactured with

Product Source:SS Orbital WeldingTubes

0 notes

Text

Unveiling Durability: Stainless Steel Tubing Coil and Welded Pipe Solutions

ZH Stainless Pipe's commitment to durability, precision, and versatility shines through in their stainless steel tubing coil and Stainless Steel Welded Pipe offerings. Whether you seek flexibility in tubing solutions or the structural integrity of welded pipes, ZH Stainless Pipe stands as a trusted provider of high-quality stainless steel solutions.

1 note

·

View note