#STAINLESS STEEL 321H WELDED TUBES

Explore tagged Tumblr posts

Text

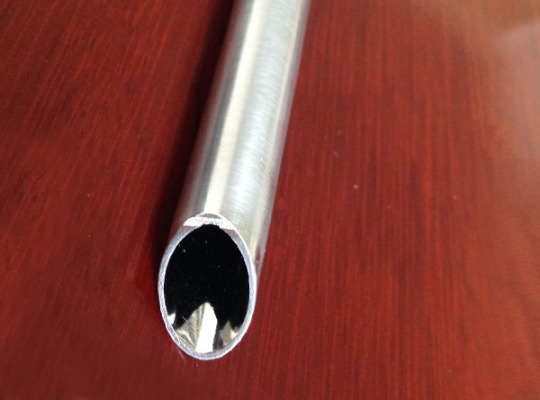

Stainless Steel 321 / 321H Tubes

Stainless Steel 321 / 321H Tubes

Stainless steel has revolutionized multiple industries with its superior properties such as corrosion resistance, durability, and ability to withstand high temperatures. Among the many grades of stainless steel, Stainless Steel 321 and 321H stand out for their unique characteristics and wide range of applications. Here, we explore these two variants and their benefits, presented by Metalloys International.

Understanding Stainless Steel 321

Stainless Steel 321 is a titanium-stabilized austenitic stainless steel known for its outstanding resistance to intergranular corrosion. This makes it an excellent choice for applications involving continuous and intermittent heating within the temperature range of 800 to 1500°F (427 to 816°C). The addition of titanium helps stabilize the material, preventing carbide precipitation and ensuring that it retains its mechanical properties even under high-temperature conditions.

Key Benefits of Stainless Steel 321 Tubes

Corrosion Resistance: Stainless Steel 321 exhibits excellent resistance to oxidation and corrosion, especially in high-temperature environments.

Thermal Stability: Its ability to maintain stability and strength at elevated temperatures makes it ideal for use in aerospace, chemical processing, and thermal processing applications.

Fabrication Ease: Despite its robustness, Stainless Steel 321 can be readily fabricated into tubes, making it highly versatile for various industrial applications.

Introducing Stainless Steel 321H

Stainless Steel 321H is a higher carbon version of 321, designed to offer enhanced high-temperature strength. The increased carbon content improves the material's creep resistance and strength, making it suitable for applications that require prolonged exposure to high temperatures.

Applications of Stainless Steel 321 / 321H Tubes

These tubes are utilized across various industries due to their unique properties:

Aerospace: Employed in jet engine parts, exhaust manifolds, and other high-temperature components due to their excellent thermal stability and corrosion resistance.

Chemical Processing: Ideal for handling corrosive substances and acids in the chemical industry, thanks to their superior corrosion resistance.

Petroleum Refining: Used in refining equipment and other components that require both high-temperature strength and resistance to corrosion.

Why Choose Metalloys International?

Metalloys International is a renowned supplier of Stainless Steel 321 / 321H Tubes, dedicated to delivering top-quality materials that meet the stringent demands of various industries. We prioritize customer satisfaction by ensuring our products adhere to international standards and are delivered promptly.

With a vast inventory and extensive industry expertise, Metalloys International is your trusted partner for all your stainless steel requirements. For more information and to explore our product range, visit our website at Metalloys International.

Conclusion :

Stainless Steel 321 / 321H Tubes are essential for industries that demand materials capable of withstanding high temperatures and corrosive environments. Their unique properties ensure durability and reliability in challenging applications. For premium quality Stainless Steel 321 / 321H Tubes, turn to Metalloys International, your reliable supplier for stainless steel solutions.

For inquiries and further details, submit your request on our website at Metalloys International.

#321H STAINLESS STEEL TUBES DEALER#SS 321H TUBES SUPPLIER#STAINLESS STEEL 321H TUBES MANUFACTURER#SS 321 ROUND TUBES#STAINLESS STEEL 321H WELDED TUBES#SS 321 TUBES SUPPLIER#STAINLESS STEEL 321H TUBES SUPPLIER#ASME SA213 TP 321H SS TUBE#ASTM A213 SS 321 SEAMLESS TUBES#SS 321 ERW TUBES#SS 321H CAPILLARY TUBES#SS 321 TUBES MANUFACTURER#STAINLESS STEEL 321 TUBES SUPPLIER#STAINLESS STEEL 321 HEAT EXCHANGER TUBES#SS 321H TUBES MANUFACTURER#STAINLESS STEEL 321H TUBING#SS 321 TUBES EXPORTER.

0 notes

Text

Stainless Steel 321/321H Welded U Tubes Exporters In India

Metinox Overseas stands as a distinguished manufacturer, exporter, stockist, stockholder, and supplier, offering a qualitative spectrum of Stainless Steel 321/321H Welded U Tubes. Crafted in adherence to both national and international standards, our Stainless Steel 321 ERW U-Tubes exemplify quality, reliability, and durability. These tubes undergo meticulous testing, adhering to globally recognized standards or our own stringent internal procedures, ensuring their resilience even in harsh field conditions.

#Stainless Steel 321/321H Welded U Tubes Stockists In India#Stainless Steel 321/321H Welded U Tubes Exporters In India

0 notes

Text

Supplier of Stainless Steel Hexagonal Bar in Andhra Pradesh

Arisa Impex is a leading Manufacturer, Exporter, and Supplier of Stainless Steel Hexagonal Bar in Andhra Pradesh. Our SS Angle, Black Round Bar, Coil, Flange, Flat Bar, Hexagonal Bar, Pipe and Tube, Round Bar, and more Manufacturing units are based in Ahmedabad, Gujarat. Our SS Hexagonal Bars offer superior quality, precision, and versatility, ideal for manufacturing, construction, automotive, aerospace, and more. Features of SS Hexagonal Bar: Durability and Strength: We design our stainless steel hexagonal bars for high strength and durability, ideal for demanding applications. Corrosion Resistance: Our high-quality stainless steel hexagonal bars are corrosion-resistant, ensuring long-lasting performance and integrity in harsh environments. Versatility: Industries like construction, automotive, machinery, aerospace, and more widely use these stainless steel hexagonal bars. Precision and Quality: Arisa Impex manufactures SS hexagonal bars with precise dimensions and high-quality standards, meeting national and international specifications. Easy Machining and Fabrication: Our stainless steel bars are easy to machine, fabricate, and weld, perfect for custom applications and processes. Specification: SS Hexagonal Bar Grades: 201, 202, 301, 302, 303, 304, 304H, 304L, 316, 316H, 316L, 309, 309S, 310, 310S, 316Ti, 317, 317L, 347, 321, 321H, 410, 416, 420, 430, 430F, 431, 440C, 630, 17-4PH, F51, ASTM A276, ASTM A484 Size: 16mm to 55mm Length: 4 to 6meters, or as customer’s requirements Tolerances: K11, K10, K12, H8, H10, K9, H9, H11, H13, H12 Packing: Standard packing Specifications: EN 10272, EN 10088-3 Grade 1.4301 (304), 1.4306 (304L), 1.4401 (316), 1.4404 (316L) Finish: Black, Peeled, Polished, Smooth Turned, Rough Turned, Centreless Ground, Grinding, Cold Drawn Turned, Bright Drawn, Bright, Annealed Applications of SS Hexagonal Bars: Manufacturing Automotive Aerospace Marine Electrical Arisa Impex is a Supplier of Stainless Steel Hexagonal Bar in Andhra Pradesh including locations like Visakhapatnam, Vijayawada, Guntur, Nellore, Kurnool, Kakinada, Rajamahendravaram, Kadapa, Mangalagiri-Tadepalli, Tirupati, Anantapuram, Ongole, Vizianagaram, Eluru, Proddatur, Nandyal, Adoni, Madanapalle, Machilipatnam, Tenali, Chittoor, Hindupur, Srikakulam, Bhimavaram, Tadepalligudem, Guntakal, Dharmavaram, Gudivada, Narasaraopet, Kadiri, Tadipatri, Chilakaluripet. For more information or to place an order, contact Arisa Impex today! Read the full article

0 notes

Text

Stainless Steel 321/321H Pipes & Tubes Stockists

INTRODUCTION:-

Alloy 321 is an austenitic SS that is titanium-balanced and has astounding general corrosion resistance. Moreover, it has an intergranular corrosion-safe breaking point straightforwardly following getting introduced to the temperature in the chromium carbide precipitation range of 427 to 816 °C. The alloy limits oxidation at 816 °C and holds high creep and stress-break properties. Additionally,

DESCRIPTION:-

Stainless Steel 321 and 321H are austenitic chromium-nickel stainless steels stabilized with titanium. The primary difference between the two grades lies in their carbon content: 321H has a higher carbon content, enhancing its strength at elevated temperatures. Both grades are known for their excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 800-1500°F (427-816°C). This makes them particularly suitable for high-temperature environments.

SPECIFICATION:-

Specification

Range : 6NB to 1200NB

Outer Diameter : 1/8″ NPS to 12″ NPS

Thickness : 0.6 mm to 12.7 mm

Schedules : SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS.

Length : Single Random, Double Random & Cut Length

Specifications : ASTM A312 / ASTM SA312

Types : Round, Square, Rectangle, Hydraulic, Honed Tubes

End : Plain End, Beveled End

PRODUCT OVERVIEW:-

At Manilaxmi Industrial, the inventory of Stainless Steel 321 and 321H pipes and tubes is extensive and meticulously maintained to ensure quality and availability. The products are manufactured using top-grade raw materials and cutting-edge technology. The range includes seamless, welded, ERW, and EFW pipes and tubes, meeting various industrial demands. Each product undergoes rigorous quality checks and complies with international standards, guaranteeing reliability and superior performance.

CONCLUSION:-

Stainless Steel 321 and 321H pipes and tubes from Manilaxmi Industrial are renowned for their high quality, exceptional durability, and superior performance in high-temperature and corrosive environments. These products are essential for industries ranging from aerospace to chemical processing, offering reliable solutions for demanding applications.

For more information or to place an order, contact Manilaxmi Industrial at [email protected] or call +91-7710800415. Trust Manilaxmi Industrial for all your stainless steel needs.

0 notes

Text

Nascent Pipe & Tubes is a basic suppliers and stockiest of the state of the art steel and SS 321/321H Pipes & Tubes. Our start and end is made with the remarkable of the crude substance and overall guidePipes & Tubes. We even hold the changed sort of the Pipes & Tubes and whole present day plans. Our start and end is in everyday around endeavored and analyzed before the vehicle to the clients and sellers.

Specification Of Stainless Steel 321/321H Seamless Welded Pipes & Tubes

Stainless Steel Pipe Specification :ASTM A312, A358 / ASME SA312, SA358

SS Tube Specification : ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

Pipe Size : 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Tube Size :1/2" OD to 8" OD.

Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type :Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length :Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish :2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports :Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :Sizes and Specifications other than above can be manufactured on request

0 notes

Text

What are stainless steel fittings used for?

Stainless steel fittings, where precision meets durability. Bullion Pipes & Tubes LLP is your premier destination for top-quality SS fittings. Our stainless steel buttweld fittings embody the perfect fusion of precision and durability. Renowned as a leading manufacturer, supplier, stockist, and exporter of SS fittings, we take pride in offering a diverse range that is meticulously tailored to meet the unique project requirements of our esteemed global clientele. Explore the excellence of Stainless Steel Buttweld Fittings with us – where precision meets durability in every weld.

Stainless Steel Fittings

Stainless steel fittings play a crucial role in ensuring the seamless flow of liquids and gases in diverse industries. These fittings are meticulously crafted from high-quality stainless steel, offering exceptional corrosion resistance, longevity, and low maintenance.

Specification of Stainless Steel Fittings

Standard

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size

1/2″ NB TO 48″ NB

Designation

A 182 / A 240, SA 182 / SA 240

Class

150#, 300#, 400#, 600#, 900#, 1500# & 2500#.

Grades

ASTM A182 F304, 304L, 304H, 316, 316Ti, 316H, 316L, 316LN, 309S, 309H, 310S, 310H,317, 317L, 321, 321H, 347, 347H, 201, 202, 904L ETC.

Type

Socket Weld Fittings, Screwed-Threaded Fittings, Stainless Steel Buttweld Fittings

Diverse Range of Stainless Steel Fittings:

Bullion Pipes & Tubes LLP provides an extensive array of Stainless Steel Fittings & Stainless Steel Buttweld Fittings ensuring that clients have a wide selection to meet their specific project needs. The range includes:

Elbows (90 degrees, 180 degrees, 45 degrees): These fittings facilitate changes in the direction of the pipeline, allowing for smooth flow transitions around corners.

Tee Fittings: Tees are used to create branch connections in a pipeline, providing a way to channel fluids or gases in different directions.

Cross Fittings: Cross fittings offer a four-way connection in pipelines, allowing for the seamless distribution of fluids or gases in multiple directions.

Reducers: Reducers are crucial for connecting pipes of different sizes, ensuring a smooth transition and efficient flow within the system.

Stub End Fittings: Stub ends are used for connecting flanges to pipes, offering versatility in various applications.

Pipe Bend Fittings: These fittings are designed to redirect the pipeline around obstacles or corners, maintaining the integrity of the system.

Bushing and Plug Fittings: Bushings and plugs play a role in sealing or closing off pipes, ensuring the integrity of the pipeline.

Uses of Stainless Steel Fittings

Stainless steel fittings are a critical component in various industries, offering a multitude of uses that guarantee exceptional performance and durability. With their unique chemical composition, these fittings possess outstanding corrosion resistance, making them highly reliable for applications exposed to high moisture or harsh environments. One prominent use of stainless steel fittings can be found in the construction industry. These fittings are extensively employed in plumbing and pipework systems, connecting different components and ensuring leak-proof connections. Their corrosion resistance ensures the longevity and integrity of the plumbing infrastructure, reducing the need for costly repairs and replacements in the long run. Here are some common applications of stainless steel fittings:

Plumbing and Water Systems

Chemical and Petrochemical Industries

Food and Beverage Industry

Pharmaceutical Industry

Oil and Gas Industry

Agricultural Equipment

Automotive Industry

Construction and Architecture

Marine Applications

Power Generation

Mining Industry

Other Applications

Final Words! Stainless Steel Fittings from Bullion Pipes & Tubes LLP stand as a testament to quality, durability, and versatility. With a comprehensive range of SS Fittings & Stainless Steel Buttweld Fittings that caters to various applications and a commitment to global standards, the company continues to be a trusted partner in providing top-notch stainless steel fittings for projects worldwide in various countries Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia and other region. Contact us today at [email protected] or [email protected] for fittings that go beyond expectations, ensuring the seamless flow and success of your industrial endeavors.

0 notes

Text

Stainless Steel Electropolished Tubes Exporters In India

Stainless Steel Electropolished Tubes Supplier In India, SS Electropolished Tubes Exporter Electropolished Stainless Steel Tubing, Electropolished Tubes, Electropolished Tube Fittings 304/304l Electropolished Pipes, 316/316l Electropolished Pipes, Seamless/Welded EP Pipes

Stainless Steel Electropolished Pipes Manufacturer, Electropolished Tubes Exporter, High Purity Stainless Steel Tubing, Electropolished Stainless Steel Tubes, EP Tubes Processor in Mumbai, SS Electropolished Tubes in India, SS 304L Electropolished Tubes, SS 316L Electropolished Pipes, SS 904L Electropolished Tubing Suppliers, Electropolished Tubes Suppliers in India, Dairy Tubes, Tubes for Pharma Industry, Electropolished Tubes for Food Processing Industry, Best Quality EP Tubes in India, Mumbai

Kobs India is a leading processor and supplier of high quality electropolished or mechanically polished stainless steel pipes, electropolished tubes in all major stainless steel grades including 304/304L and 316/316L. Electropolishing is also commonly known as electrochemical polishing or electrolytic polishing. EP stainless steel tubes are generally made by carrying out the electropolishing process on high quality seamless and welded stainless steel tubes.

Standards Specification:

Size : ½”Inch and 24”Inch

Specifications : ASTM A249, A269, A270

Grades: : 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Length: : Up to 6 meters, custom cut lengths

Thickness: 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

Finish:BA Finish inside and outside, Electropolished finish inside and outside

Specifications : ASTM A312 / ASTM SA312

Material & Grade :

Stainless Steel : Grade: 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Product Features:

Durability

High strength

Effective functionality

Sturdy construction

Corrosion resistance

Dimensional accuracy

Electropolished Tubes Manufacturer, Electropolished Tubes Manufacturers, Electropolished Tubes Suppliers, Electropolished Tubes Exporters, Electropolished Tubes Stockists.

Electropolished Tubes in Mumbai, Electropolished Tubes Manufacturers in Mumbai, Electropolished Tubes Suppliers in Mumbai, Electropolished Tubes Exporters in Mumbai, Electropolished Tubes Stockists in Mumbai.

Electropolished Tubes in India, Electropolished Tubes Manufacturers in India, Electropolished Tubes Suppliers in India, Electropolished Tubes Exporters in India, Electropolished Tubes Stockists in India.

Manufacturing Process :

The process commences with the formation of welded mother tube on the tube mill from imported and tested prime quality stainless steel strips. The latest TIG multi electrode welding technique is employed for superior weld quality and 100% Fusion, with argon purging, No filler metal added.

Product Usage & Application :

Useful in Paper & Pulp Companies

Useful in High Pressure Applications

Useful in Oil and Gas Industry

Useful in Chemical Refinery

Useful in Pipeline

Useful in High Temperature Application

Useful in Water Pipe Line

Useful in Nuclear Power Plants

Useful in Food Processing and Dairy Industries

Useful in Boiler & Heat Exchangers

Packing :

Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

Shrink-wrapped

Carton boxes

Wooden pallets

Wooden boxes

Wooden crates

Why Choose Us :

You can get the perfect material according to your requirement at the least possible price.

We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

e guarantee to give a response within 24hours(usually in the same hour)

You can get stock alternatives, mill deliveries with minimizing manufacturing time.

We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Tests we carry out (including both Destructive and Non-Destructive) :

Positive material recognition

Mechanical examining like tensile, Elongation and reduction of area.

Large-scale test

Chemical examination-Spectro analysis

Firmness test

Pitting protection test

Small tests

X-ray test

Impact analysis

Eddy current examining

Hydrostatic analysis

Prompt test

For more details: Website - http://kobsindia.in/ Phone No. - 9819523999 Email - [email protected]

#Electropolished Tubes in India#Electropolished Tubes Manufacturers in India#Electropolished Tubes Suppliers in India#Electropolished Tubes Exporters in India#Electropolished Tubes Stockists in India.

0 notes

Text

ASTM A249/ASME SA249 STAINLESS STEEL TUBE

ASTM A249/ASME SA249 stainless steel tube covers nominal wall thicknesses welded and heavily cold-worked welded pipes made of the following materials

Various grades of austenitic steel for boilers, superheaters, heat exchangers, or condenser pipes.

ASTM A249/ASME SA249 STAINLESS STEEL TUBE PROVIDED BY YUHONG

ASTM A249/ASME SA249 Stainless Steel Tube

YUHONG GROUP provides the best ASTM A249/ASME SA249 Stainless steel tubes including welded austenitic alloy steel boiler tube, superheater and heat exchanger tube, and U bending tube.

TP304/TP304L Stainless Steel Tube

TP316/TP316L Stainless Steel Tube

ASTM A249 TUBING FEATURES

ASTM A249/ASME SA249 stainless steel tube has good plasticity, low strength, and hardness. At the same time, ASTM A 249 also has a certain toughness, but it is not ferromagnetic.

ASTM A249/ASME SA249 stainless steel tube is not only resistant to oxidative acid medium corrosion, but also resistant to sulfuric acid, phosphoric acid, formic acid, acetic acid, urea, etc. if it contains Mo, Cu, and other elements. If the carbon content of ASME SA249/ASTM A249 tubing is less than 0.03% or contains Ti and Ni, the resistance of this SS steel tube to intergranular corrosion can be significantly improved.

ASME SA249/ ASTM A249 TP304 SPECIFICATIONS

ASTM A249 Standard

ASTM A249/ASME SA249

Tube Type

Welded Tube

Finishes

Annealing Pickling, Bright Annealing

Outside Diameter

6 Up To 304.8 Mm

Thickness

0.5 Up To 6 Mm

Application

Heat Exchanger System

GRADES OF SPECIFICATION ASTM A249/SA 249

Grade

Specification

Stainless 304/304L, 304/304H

ASTM A249/SA249

Stainless 309S

ASTM A249/SA249

Stainless 310S

ASTM A249/SA249

Stainless 316/316L, 316/316H

ASTM A249/SA249

Stainless 317/317L

ASTM A249/SA249

Stainless 321/321H

ASTM A249/SA249

Stainless 347/347H

ASTM A249/SA249

ASME SA249/ ASTM A 249 TUBING CHEMICAL COMPOSITION

Grade

UNS

Composition, %

Design

C

Mn

P

S

Si

Cr

Ni

Mb

Ti

Nb

N

Cu

Ce

B

Al

TP304

S30400

0.08

2

0.045

0.03

1

18.0–20

8.0–11

. . .

. . .

. . .

. . .

. . .

. . .

TP304L

S30403

0.035

2

0.045

0.03

1

18.0–20

8.0–13

. . .

. . .

. . .

. . .

. . .

. . .

TP304H

S30409

0.04 – 0.1

2

0.045

0.03

1

18.0–20

8.0–11

. . .

. . .

. . .

. . .

. . .

. . .

TP310S

S31008

0.08

2

0.045

0.03

1

24.0- 26

19.0- 22

0.8

. . .

. . .

. . .

. . .

. . .

TP310H

S31009

0.04 – 0.1

2

0.045

0.03

1

24.0–26

19.0–22

. . .

. . .

. . .

. . .

. . .

TP310H

S31035

0.04 – 0.1

0.6

0.025

0.015

0.4

21.5–23.5

23.5–26.5

. . .

. . .

0.40- 0.6

0.20- 0.3

2.5- 3.5

. . .

0.002- 0.008

TP316

S31600

0.08

2

0.045

0.03

1

16.0–18

10.0–14

2.00–3

. . .

. . .

. . .

. . .

. . .

TP316L

S31603

0.035

2

0.045

0.03

1

16.0–18

10.0–14

2.00–3

. . .

. . .

. . .

. . .

. . .

TP316H

S31609

0.04 – 0.1

2

0.045

0.03

1

16.0–18

10.0–14

2.00–3

. . .

. . .

. . .

. . .

. . .

TP317

S31700

0.08

2

0.045

0.03

1

18.0–20

11.0–15

3.0–4

. . .

. . .

. . .

. . .

. . .

TP317L

S31703

0.035

2

0.045

0.03

1

18.0–20

11.0–15

3.0–4

. . .

. . .

. . .

. . .

. . .

TP321

S32100

0.08

2

0.045

0.03

1

17.0–19

9.0–12

. . .

Ti 5 × (C+N) min, 0.70 max

. . .

0.1

. . .

. . .

TP321H

S32109

0.04 – 0.1

2

0.045

0.03

1

17.0–19

9.0–12

. . .

4(C+N) min; 0.70 max

. . .

0.1

. . .

. . .

TP321H

S32654

0.02

2.0-4

0.03

0.005

0.5

24.0–25

21.0–23

7.0-8

. . .

. . .

0.45- 0.55

0.30-0.6

. . .

TP321H

S33228

0.04 – 0.08

1

0.02

0.015

0.3

26.0–28

31.0–33

. . .

. . .

0.60- 1

. . .

. . .

0.05 – 0.1

0.025

TP321H

S34565

0.03

5.0-7

0.03

0.01

1

23.0–25

16.0–18

4.0-5

. . .

0.1

0.40- 0.6

. . .

. . .

TP347

S34700

0.08

2

0.045

0.03

1

17.0–19

9.0–13

. . .

. . .

See Spec

. . .

. . .

. . .

TP347H

S34709

0.04 – 0.1

2

0.045

0.03

1

17.0–19

9.0–13

. . .

. . .

See Spec

. . .

. . .

. . .

TP348

S34800

0.08

2

0.045

0.03

1

17.0–19

9.0–13

. . .

. . .

. . .

. . .

. . .

. . .

Co 0.20, Ta 0.10

TP348H

S34809

0.04-0.10

2

0.045

0.03

1

17.0–19.0

9.0–13

. . .

. . .

. . .

. . .

. . .

. . .

. . .

Co 0.20, Ta 0.10

ASME SA249/ ASTM A 249 TUBING SIZE TOLERANCE

OD

WTH

L

ASTM A249

<25.4mm

±0.10mm

±10.00%

OD<50.8mm +3.0mm -0mm

≥25.4mm-38.1mm

±0.15mm

≥38.1mm-50.8mm

±0.20mm

≥50.8mm-63.5mm

±0.25mm

≥63.5mm-76.2mm

±0.30mm

OD≥50.8mm +5.0 -0mm

≥76.2mm-101.6mm

±0.38mm

≥101.6mm-190.5mm

+0.38mm -0.64mm

≥190.5mm-228.6mm

+0.38mm -1.14mm

WHAT IS ASME ASTM SA 249 STAINLESS STEEL TUBE?

ASME ASTM SA 249 stainless steel tubes are used in a variety of applications, including boiler, superheater, heat exchanger, and condenser systems. These a249 stainless steel tubes are manufactured through a welding process and are typically made from austenitic stainless steel, although other stainless steel grades may also be used.

The astm a249 tp304 specification outlines the requirements for the manufacturing, dimensions, mechanical properties, and testing of these welded stainless steel tubes. It provides guidelines for various aspects, including tube dimensions, tolerances, chemical composition, mechanical properties, and nondestructive testing methods.

The stainless steel tubes produced under the ASME ASTM SA 249 standard are designed to withstand high temperatures, corrosion, and pressure in demanding industrial environments. ASME sa249 are known for their excellent corrosion resistance, strength, and durability, making them suitable for applications where reliability and longevity are essential.

Common stainless steel grades used in ASME ASTM SA 249 tubes include 304, 304L, 316, 316L, 317, and 321. These grades offer varying levels of corrosion resistance, mechanical properties, and heat resistance, allowing for the selection of the most appropriate grade based on the specific application requirements.

Overall, ASME ASTM SA 249 stainless steel tubes meet stringent industry standards, ensuring that they are manufactured to the specified dimensions, quality, and performance criteria. These ASTM a249 tubings play a critical role in various industrial sectors, providing efficient and reliable solutions for heat exchanger tube manufacturers and fluid transportation systems.

ASTM A249 VS A269 STAINLESS STEEL TUBE

Applications: ASTM A249 tubes are primarily intended for general corrosion-resisting and low- or high-temperature service, including heat exchangers, condenser tubes, and other applications. ASTM A269 tubes, on the other hand, are specifically designed for general service applications requiring high corrosion resistance and mechanical properties.

Manufacturing Process: ASTM A249 tubing is produced through the welding process, while a269 tubing can be either welded or seamless. Seamless stainless steel tubes are typically preferred for high-pressure or critical applications.

Dimensional Tolerances: ASTM a249 tubing has more lenient dimensional tolerances compared to ASTM A269. A269 tubes have tighter tolerances for outside diameter, wall thickness, and length, ensuring greater precision and consistency.

Surface Finish: ASTM A269 specifies stricter requirements for the surface finish of tubes, particularly for applications where cleanliness and smoothness are important, such as in the pharmaceutical and food processing industries.

0 notes

Text

Steel Pipes and Tubes Industries (SPTI)

An ISO 9001:2008 Certified Company, Steel Pipes & Tubes Industries is India’s most trusted manufacturer, exporter and supplier of stainless steel tubes (ASTM A 312 304/304L, 316/316L), carbon steel pipes (ASTM A A106, A53, API 5L), alloy steel seamless pipes (ASTM A335 P11, P22), mild steel pipes, industrial steel tubes, galvanized steel pipes and black steel pipes.

We can manufacture and supply steel pipes which can be fabricated to customers design and specification in a variety of length and thickness requirements. We can also offer cold drawn seamless steel tubes to meet the custom design and specifications of our customers. We specialise in the manufacture and supply of cold drawn seamless steel tubes, and large diameter stainless steel welded pipes (100% X-Ray Tested). ISO 9001:2008 Certification ensures consistency in our operations and testing procedures.

Steel Pipes and Steel Tubes supplied by Metline Pipes & Tubes are used across wide range of industries including food processing, power generation, oil and gas, petrochemicals, petroleum pipelines, medical equipment, biopharma, pharmaceuticals, electrical engineering, fertilizer industry, dairy processing, boiler manufacturing and nuclear energy among others.

METLINE has been proudly servicing the steel pipe industry for over 40 years, as a major supplier and manufacturer of custom size steel pipes and steel tubes. We are the exclusive suppliers of stainless steel welded pipes, stainless steel seamless tubes, stainless steel tubing, alloy steel seamless pipes, boiler steel tubes, heat exchanger tubes, capillary tubes, coiled tubing, and galvanized steel pipes. We are serving all major cities and countries in their needs for steel pipes and steel tubes.

Our products are supplied to all major Industrial areas and cities in India such as Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi.

Our high quality steel pipes, good customer service, and in house pipes and tubes processing capabilities have made us one of the emerging suppliers for steel pipes and tubes in Middle East countries including Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, Turkey, United Arab Emirates and Yemen.

India’s #1 Supplier of Stainless Steel Pipes/Tubes, Chrome Moly Pipes,Black Pipes, Galvanised Pipes, Carbon Steel Pipes

Stainless Steel Pipes, Carbon Steel Tubes, Alloy Steel Tubes, MS Pipes Production and Stock Range

Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range: 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type: Seamless / ERW / Welded / Fabricated / CDW

Key Steel Pipes & Tubes Products & Grades

1. Stainless Steel Seamless Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

2. Stainless Steel Welded Pipes & Tubes - 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

3. Square Stainless Steel Pipes, Round Stainless Steel Tubes,Rectangular Stainless Steel Pipes & Tubes

4. Carbon Steel Seamless Pipes as per ASTM A 106 Grade B/API 5L Grade B/ASTM A 53 Grade B

5. Carbon Steel Seamless Tubes as per BS 3059, ASTM A 179, ASTM A 192, ASTM A 210 GR.A1

6. Alloy Steel Seamless Pipes as per ASTM A335 Grade P1/ P5/ P9 / P11/ P12 / P22 / P91

7. LTCS Pipe - Low Temperature Carbon Steel Pipes as per ASTM A 333 Grade 6

8. Alloy Steel Seamless Tubes as per ASTM A213 Grade T5/T9/T11/T12/T22/T91

9. ERW Black Pipes as per IS:1239/I, IS: 3589 Grade 330 or Grade 410

10. Galvanised Pipes as per IS:1239/I

11. Square and Rectangular Steel Pipes as per IS: 4923

12. ERW Boiler Tubes: BS 3059, ASTM A 214

13. Air Pre Heater Tubes to BS: 6323 PART V

14. Hydraulic Tubes to DIN 2391 ST. 35, ST. 45 & ST. 52

15. Seamless Heat Exchanger Tubes ASTM A 179

16. CDW TUBES IS: 3074 or BS 980

17. CRCA ERW Tubes to IS 3601 OR IS 3074

18. Stainless Steel Electropolished Pipes Manufacturer/Supplier

19. Alloy Steel Fittings Manufacturer- ASTM A234 WP5, P11, P22, P91

1 note

·

View note

Text

C276 suppliers in India

C276 Round Suppliers in India

C276 Round Suppliers in India (by and large called Branch Connection Fittings or Outlet Fittings) which give an outlet from a more prominent funnel to a humbler one (or one of a near size).

C276 Round Suppliers in India are fanning fittings made by biggest producers of metal fittings like us. C276 Round Suppliers in India offer a substitute technique for interfacing into the essential run and don't require fortress or fortification. Krishna Steel & Alloys are pre-formed to the twist of the run pipe. Level based weldolets are open for interfacing with pipe tops and vessel heads.

The chief channel onto which the branch association is welded is generally called the Run or Header measure gauge. The funnel to which the branch alliance or affiliation gives a channel is known as the Branch or Outlet measure. Branch associations are in all sizes, sorts, types, bores, and classes, in an expansive arrangement of treated steel, chrome-molly, and particular amalgams mixes.

C276 Round Suppliers in India are for the most part used for stretching on high weight and high temperature applications. Most extreme acceptable weight of a fitting is same concerning associated straight steady or consistent run channel of proportionate material.

C276 Round Suppliers in India uses Materials and Grades (Weldolets, Threadolets, Sockolets)

1) Stainless Steel Olet Fittings - ASTM/ASME SA 182F GR. 304, 304L, 304H, 304N, 304LN, 316, 316L, 316H, 316N, 316LN, 309L, 310, 317, 317L, 321, 321H, 347, 347H AND UNS 31254 (254SMO)

2) Carbon Steel Olet Fittings - ASTM/ASME A105/A350 LF2, ASME SA105, A694 - F42, F46, F52, F60, F65, F70, A36, A516 GR. 70, 60

3) Alloy Steel Fittings - ASTM/ASME A182 GR. F1/F5/F9/F11/F22/F91

4) Duplex Steel Fittings - ASTM/ASME SA 182F GR. F44, F45, F51, F53, F55, F60, F61.WERKSTOFF NO. 1.4462

5) Nickel Alloy Steel FittFlangeings - ASTM/ASME SB 256 GR. NICKEL ALLOY 200, NICKEL ALLOY 20, MONEL ALLOY 400, INCONEL ALLOY 600, INCONEL ALLOY 625, INCOLOY ALLOY 800, INCOLOY ALLOY 800H, INCOLOY ALLOY 800HT, INCONEL ALLOY 825, ALLOY 20, HASTELLOY C-276, HASTELLOY C-4, HASTELLOY C-22, ALLOY 6XN

6) Low Temperature Pipe Fittings- A/SA 350 LF2, LF3

C276 Round Suppliers in India is Fittings are likewise accessible in other metal like titanium, aluminum, bronze, Lead, tantalum, zinc, metal and so on.

Application or Uses of Krishna steel & Alloys are are utilized in wide scope of businesses. Some of them are :

· Force Plants

· Water Pipelines

· Treatment facilities

· Nourishment and Beverages

· Pharmaceuticals

· Materials

· Railroads

· Petrochemicals

· Atomic Plants

· Sugar factories

Types of our Products:

1) Brazolet - Brazolet is utilized for the most part and for the most part to interface or partner the continued fittings. Brazolet is same like a weldolet, and is a marvelous fitting for metal channels, copper tubing and iron funnels pipes with metal.

2) Coupolet - Coupolet fittings are gotten ready for use in fire/fire assurance sprinkler structures and other low weight diverting applications.

3) Elbolet - Elbolet is utilized on 90° Long Radius Elbows (can be conveyed for Short Radius Elbows) for thermo well and instrumentation affiliations

4) Flexolet - Flexolets take after weldolets with a minor refinement for example flexolet has straight bore while weldolet has lessened bore.

5) Insert Weldolet - Insert Weldolet is the most extensively seen of all branch affiliations, and is welded onto the outlet pipe.

6) Latrolet - Latrolets are a variety of weldolets. You have to relate it in same manner, anyway these Latrolets make a 45-degree relationship with the standard channel as opposed to a 90 degree.

7) Nipolet - Nipolets is only a blend of olets with pipe areolas. These olets work like the weldolets or threadolets, yet are with areola.

8) Sockolet - Sockolets are in a general sense like weldolets and threadolets; close to the course that in Sockolets there is unique association fit welding.

9) Sweepolet - Sweepolet is a framed, essentially continued; butt-weld branch relationship with a low pressure elevating part for low loads and long consumption or depletion life.

10) Threadolet - Threadolets look like various olets; the essential contrast is that this olet is equipped with female strung affiliation.

11) Weldolet - Weldolets or welding olets or welding branch affiliation fittings are the most comprehended among all the olets. These are for the most used and organized as buttweld fittings, as these are welded into the branch pipe.

Assembling Standards

ASTM A182 - ASME SA182 - Standard Specification

ASME B16.11 - Forged Fittings Socket - Welding and Threaded

1 note

·

View note

Photo

"Stainless Steel Pipes & Tubes."

Bhansali enterprise is a Mumbai based manufacturer and trader of Stainless Steel 304 Pipes & Tubes. We are known for our extraordinary products and client engagements. We offer an extensive variety of goods in different sizes, grades, gauges, completions and materials that are conveyed to an extensive variety of businesses. Our SS 304 Pipes are astounding products with an exceptional finishing that we have on offer. We are suppliers, stocks and trades an extensive variety of goods to its clients around the world. Our group of experts monitor the changing market trends and demands to devise products as needs be. Our Stainless Steel 310s Pipes & Tubes are austenitic steel that are particularly devised for utilization in applications where high temperature corrosion resistance is required. These SS 310S Pipes & Tubes execute great imperviousness to aqueous corrosion and great strength at raised temperatures. Our SS 316/316Ti Pipes & Tubes are titanium stabilized variants of 316 Molybdenum bearing austenitic steel. 316/316Ti Stainless Steel Pipes & Tubes are more impervious to general corrosion, pitting and crevice corrosion when contrasted with other chromium-nickel austenitic steel. The expansion of titanium in 316/316Ti Pipes & Tubes make them insusceptible from Chromium Carbide precipitation. Our UNS S31635 Pipes & Tubes are widely utilized as a part of heavy gauge welding components. We are always producing the 321/321H stainless steel pipes and tubes by using premium quality of raw material that results in adding superiority, durability, flexibility in the product quality. The producers are also making effective use of the latest tool, technology so that it can easily withstand heavy loads, have the ability to work in the high-temperature surrounding. Stainless Steel 321H Condenser Tubes are supplied to various parts of the globe in wide comprehensive range at reasonable rates.

#stainless steel round bar#stainless steel wire#manufacturer of stainless steel in india#steel companies of india#steel industries in india#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india#pipe and fittings#pipe fittings

0 notes

Text

Stainless steel pipe- Petropipe oil and gas

Prominent supplier of stainless steel pipes in UAE

As a Stainless Steel Pipe supplier, Petropipe offers the most versatile Pipes packages for corrosive applications to Customers. Petropipe can provide the right product for customer’s needs which is beneficial in corrosive, high temperature or high-pressure applications. Our stainless steel pipe is available in seamless or welded in a wide range of sizes from 1/8” diameter through 120” diameter. Stainless Steel Pipes are widely used in the area of Heat Exchangers, Food and Dairy, Chemical and Petroleum industries. Our offered Pipes include various features like longer shelf life, smooth finish, compact design and resistance against corrosion. We are offered these Pipes in various sizes, grades, standards, and dimensions to meet the exact requirements of our valuable customers.

We provide the following features in Stainless Steel Pipes:

Desirable Hardness

High Electrical Conductivity

Resistance to corrosion.

We provide a complete range of Stainless Steel Pipe such a Seamless Stainless Steel Pipe

Specifications: ASTM A312 TP304/304L/304H/316/316L/316H/310S/317L/321/321H

Size ranges: 1/2” – 14”

Schedules: SCH 10, 20, STD, 40S, 80S, 120, 160

Manufacturers: Sumitomo,Productos Tubulares, Tubacex, Salzgitter Mannesmann,SchollereBlackmann, Sandvik, Jiangyin

Stainless Steel Welded Piping

Specification: ASTM A312, A358, A269 Size Range : 2” – 108”

Schedules: SCH 10, 20, STD, 40S, 80S, 120 and 160

Manufacturer: Froch Taiwan, BSL France, Butting Germany, Outokompu Germany, Pantech

Seamless Stainless Steel Tube

Specifications: ASTM A213/A269, TP316/316L, Cold Drawn Bright Annealed

Schedules: 0.035”—0.065”, 1.00 – 1.50MM

Size Range: ¼” to 1.1/2”, 6 MM – 16 MM

0 notes

Text

Stainless Steel 321 Pipes & Tubes Exporters In Mumbai

Stainless Steel 321 Pipes & Tubes: Unrivaled durability meets corrosion resistance. Precision-crafted from high-grade stainless steel, these tubes seamlessly balance strength with versatility. Engineered for diverse applications, they promise longevity and optimal performance, making them a resilient choice for demanding industrial and commercial projects.

Specification Of Stainless Steel 321/321H Seamless Welded Pipes & Tubes

Stainless Steel Pipe Specification :ASTM A312, A358 / ASME SA312, SA358

SS Tube Specification : ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

Pipe Size : 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Tube Size :1/2" OD to 8" OD.

Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type :Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length :Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish :2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports :Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :Sizes and Specifications other than above can be manufactured on request

Email: [email protected] Contact: 9930466755

0 notes

Text

What are Flanges and their types?

Flanges are an essential component of any piping system, as they provide a secure and leak-free connection between two pipes or valves. As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP understands the importance of choosing the right type of flange for your application.

In this blog post, we will cover everything you need to know about flanges, including their types, materials, and applications.

Before we dive into the details, let's start with the basics!

Introduction

Flanges are mechanical connectors used to join two pipes or valves. They are usually made of steel, and their main purpose is to provide a tight and leak-free seal between the two parts. Flanges come in various types and sizes, and choosing the right type of flange is essential for the safety and efficiency of your piping system.

Types of Flanges?

Flanges come in several types, including weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges. Each type has its unique characteristics and applications, and selecting the right one will depend on several factors, such as pressure ratings, temperature ratings, size, material compatibility, and cost.

● Weld Neck Flanges

Weld neck flanges are the most common type of flange, known for their high durability and strength. They are welded to the pipe or valve, making them ideal for high-pressure and high-temperature applications.

��� Slip-On Flanges

Slip-on flanges are easy to install and remove, making them ideal for applications that require frequent maintenance. They slide over the pipe or valve and are then welded or bolted in place.

● Socket Weld Flanges

Socket weld flanges are similar to slip-on flanges, but they are welded only on the outer side of the flange, leaving the inner side free of welding marks. They are ideal for smaller-sized pipes and low-pressure applications.

● Lap Joint Flanges

Lap joint flanges are used when a piping system requires dismantling frequently. They are also ideal for applications that require easy access to the pipe or valve.

● Threaded Flanges

Threaded flanges are designed to be screwed onto the pipe or valve, making them ideal for applications that require easy installation and removal. They are commonly used in low-pressure applications.

● Blind Flanges

Blind flanges are used to seal the end of a pipe or valve. They are commonly used for pressure testing and maintenance purposes.

Materials & Grades Available In Flanges with Bullion Pipes & Tubes LLP

Flanges can be made of various materials & Grades, such as,

● Stainless Steel - 904L Flanges, 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 446 Flanges

● Hastelloy Flanges - C22, B2 Flanges, C276 Flanges

● Carbon Steel Flanges - ASTM A350 15LF1, LF2 CL1/CL2, LF3 CL1/CL2 Carbon Steel Flanges

● Nickel Alloy - 200/201

● Duplex Steel Flanges - Duplex UNS S32205/31803 Flanges

● Alloy Steel Flanges - P5, P9, P11, P12, P22, P91 Flanges

● Super Duplex Steel - UNS S32750/S32760 Flanges

● Titanium Alloys - Gr 2 Flanges, Gr 5 Flanges, Gr 7 Flanges

● Aluminium Flanges - 5052 Reducing Flanges, 5082 Flanges, 5082 Flanges, 6063 SORF Flanges, 6082 Blind Flanges, 2024 Aluminum Weld Neck Flanges, and 5052 Threaded Flanges.

● Tantalum Flanges - ASTM B521 Tantalum Flanges, Spectacle Blind Flanges, Orifice Flange, Ta-10W Flanges, Tantalum UNS R05200 Flanges, ASTM B365 Ta2.5W Flanges

● Monel Flanges - Monel K500 Flanges, Monel 400 Flanges

● Alloy 20 Flanges - Alloy 20 RTJ Flange, Alloy 20 WNRF Flanges, Alloy UNS N08020 Pipe Flanges, Alloy 20 Weld Neck Flange, Alloy 20 Nipo Flanges, ASTM B462 Alloy Threaded Flanges, Alloy 20 Spectacle Blind Flanges, Alloy 20 Industrial Flanges, and UNS N08020 Alloy 20 Forged Flanges

● SMO 254 Flanges

● Inconel Flanges - Inconel 718, 600, 601 and 625 Flanges

● Incoloy Flanges - 825, 800/800H/800HT Flanges

Choosing the right material for your flange will depend on several factors, such as the application's temperature, pressure, and corrosion resistance requirements.

Factors to Consider When Selecting Flanges

Selecting the right flange for your application can be challenging, as there are several factors to consider, such as pressure ratings, temperature ratings, size, material compatibility, and cost. At Bullion Pipes & Tubes LLP, we can help you choose the right flange for your application, ensuring safety and efficiency.

Flange Standard Ratings

Flanges come in various standard ratings, such as ANSI, API, DIN, and JIS. These ratings determine the flange's pressure-temperature rating and its compatibility with other components in the piping system.

Flange Installation

Proper flange installation is essential for the safety and efficiency of your piping system. It involves several steps, such as preparation of the piping system, installation of the flanges, flange tightening process, flange alignment, and testing and inspection.

Maintenance and Repair of Flanges

Maintaining and repairing flanges is critical for the longevity and safety of your piping system. Regular inspections, leak checks, and maintenance can help detect any potential issues before they become a more significant problem.

Applications of Flanges

Flanges have a wide range of applications in various industries, including:

● Oil and Gas Industry

● Petrochemical Industry

● Chemical Industry

● Power Generation Industry

● Water Treatment Industry

They are used in various applications, including HVAC systems, plumbing, and firefighting systems.

Why Choose Bullion Pipes & Tubes LLP for Flanges?

As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP offers a wide range of flanges made from high-quality materials. We provide customized solutions to meet our customers' specific needs, and our flanges are available in various sizes, ratings, and materials.

We have been providing high-quality flanges to various countries, such as Ukraine, Australia, Syria, Iraq, Iran, Kazakhstan, Russia, Brazil, Armenia, Azerbaijan, Egypt, South Africa, Qatar, Turkey, Oman, Bahrain, and Germany, and our products are known for their durability, reliability, and safety.

Conclusion

Flanges are a critical component of any piping system, and selecting the right type of flange for your application is essential for safety and efficiency. Choosing a reliable and trustworthy supplier like Bullion Pipes & Tubes LLP can ensure that you get high-quality flanges that meet your specific requirements.

0 notes

Text

Neelam Forge is a leading Supplier of stainless steel 321h flanges in hyderabad, line and cylinder things including predictable and welded pipe, tube things, fittings, valves, and various fittings and valves. We are the top Supplier of STAINLESS STEEL, consolidating latest innovations with standard systems to present to you the very best quality things, strong. we are otherwise called NEELAM FORGE, we are the general driving Supplier of STAINLESS STEEL 321H FLANGES in Hyderabad. We have various models of Stainless Steel Flange as back figured out in the table. Our proactive methodology of supporting our clients has helped them with augmenting their ability to scale their associations by further developing their client help, bringing down practical costs, and improving the level of buyer devotion.

0 notes

Text

Titanium Gr. 11 (3.7225) Welded Pipe Manufacturers In India

Kobs India is one of the great Suppliers, manufacturers and Exporters of first rate Titanium Grade 1 Pipes and Tubes. Our Pipes and Tubes are tributes of our quality standards. Titanium Grade 1 Pipes and Tubes is the gentlest titanium having the blend of particular features like: most lifted malleability, awesome cool formability and an eminent resistance from smooth to high oxidization. This Titanium Grade 1 Pipes and Tubes is appeared as consistent seamless and welded funnels.

Titanium has some special characteristics like low density, strong, lustrous, corrosion resistant, high tensile strength and toughness. So, it has great features and offer good functionality and performance. These Titanium Grade 1 Pipes and Tubes are used as a piece of various application industry. Working towards the purpose of client satisfaction, we offer these things and no more sensible industry costs. These Titanium alloy Grade 1 seamless and welded pipes & tube are available in various grades (UNS R50250) and in various standard (ASTM B861, B338, B388, B862 / ASME SB861, SB338, SB388, SB862) and varied sizes (½”NB to 24”NB / SCH 10 – SCH XXS).

ASTM B338 Welded Pipes, High Temperature Welded Pipes, SCH20, SCH30 Welded Pipes, Titanium Alloy Welded Pipes, Electropolished Pipes, Titanium Alloy Gr.2 (3.7035) / Gr.3:(3.7055) Welded High Temperature Pipe Stockiest.

Material & Grade :

Stainless Steel :Grade: 304, 304L, 304H, 309, 309S, 310, 310S, 316, 316H, 316L , 317, 317L, 321, 321H, 347, 347H, 904L Duplex Steel:Grade: 2205 Super Duplex Steel:Grade: 2507 (UNS S32750) Inconel :Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718 Incoloy :Grade: Incoloy 800, Incoloy 800H, Incoloy 800HT Nickel :Grade: Nickel 200, Nickel 201 Monel :Grade: Monel 400, Monel K500, Monel R-405 Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information- Visit our website -http://www.kobsindia.in/titanium-welded-pipe.html Contact us - 9819523999 Email [email protected]

0 notes