#stainless steel forklifts

Explore tagged Tumblr posts

Text

Advantages to Get When You Buy Stainless Steel Ground Level Scissors Online

Material handling industries are one of the most crucial aspects that no one can ignore. There are different types of material handling equipment available with dissimilar functionality and features. Due to this, they offer versatile and reliable solutions for material handling, maintenance, and construction tasks. Their significance solely depends on their design combined with robustness, adaptability, and robustness. When you buy stainless steel ground-level scissors online, there are a lot of advantages to grab from. Here is all about this outstanding material handling equipment and how it helps to streamline the material handling job in various industrial setups.

Durable and Free from Corrosion

Stainless steel is preferred for its outstanding durability and corrosion resistance. This is one of the most reliable and popular features that is being used in various industrial environments where they have to deal with harassing environments. The stainless steel ground-level scissors normally operate in various harsh environments where they have to deal with moisture, chemicals, and other corrosive elements. With stainless steel construction, these scissors can easily withstand such conditions, which ensures longevity and minimal maintenance requirements. This durability helps reduce costs because it requires fewer replacements and repairs compared to any type of alternatives that are made from conventional materials.

Unmatchable Safety and Stability

The main objective of the ground-level scissors is to offer a stable platform for lifting and positioning heavy loads close to the ground level. Stainless steel construction enhances stability and safety to many extend, and needless to say, safety is a crucial factor in industries where mishaps can lead to significant injuries or damage to equipment and material. The robust design, along with the materials, helps to reduce the risk of structural failures, ensuring a safe and secure working environment for industrial operators.

Versatility to Meet Specific Requirements

Versatility is one of the biggest advantages of the stainless steel ground-level scissors. They can be easily customized to meet any specific requirements like load capacity, platform size, and lifting height. Due to this outstanding adaptability, this material handling equipment is being used in various applications across various industrial landscapes like manufacturing, warehousing, logistics, and construction. Whether it's moving heavy machinery in a factory setting or facilitating maintenance tasks in a warehouse, these scissors mainly offer different types of flexible solutions that can be tailored to meet different types of operational requirements.

Precision Control

When it comes to thorough control over the material, ground-level scissors meet this parameter in the industrial landscape. They offer unmatchable lifting and lowering operations, allowing the operators to position loads with utmost accuracy and efficiency. The stainless steel construction contributes to this precision by ensuring smooth and constant performance even under heavy loads. This kind of control is crucial in various tasks, specifically where the precise positioning is critical, like assembly lines where the components are required to be aligned thoroughly or at the construction sites where the materials need to be placed in the perfect position. In this way, it becomes the most important player in these industrial landscapes that helps to avoid any kind of delays or errors.

Environmental Sustainability

Stainless steel, with its extended lifespan and capacity for recycling, is a very sustainable material. Stainless steel ground-level scissors save waste and require fewer replacements, which helps to promote environmental sustainability. Stainless steel's eco-friendliness is further enhanced by the fact that its production procedures have less of an impact on the environment than those of many other materials.

These are the best features that you can get when you buy stainless steel ground-level scissors online. So, relying on this material handling equipment can greatly contribute to your industrial operation.

Resource: https://superliftcanada.wordpress.com/2024/04/23/advantages-to-get-when-you-buy-stainless-steel-ground-level-scissors-online/

#stainless manlifts#Buy Stainless Steel Portable Lift Table online#Stainless Steel Triple Scissors Lift Tables#Stainless Steel Low Profile Lift Table#Stainless Steel Ergonomic Lift Table#Buy Stainless Steel Low Profile Table#Stainless Steel Pallet Lifts#Stainless Steel Lift Table#Stainless Steel Uplift Pallet Trucks#Stainless Steel Self Adjusting Pallet Positioners#Clean Room Compliant Lift Tables#Buy Stainless Steel Ground Level Scissor online#Stainless Steel Electric High Lifts#Buy Stainless Steel Powered Pallet Truck online#Buy Stainless Steel Straddle Stacker online#Stainless Steel Counterbalance Stacker#Stainless Steel Pallet Jack#Stainless Steel Hybrid Pallet Jack#Stainless Steel Reach Truck#Stainless Steel Push Stacker#Stainless Steel Walkie Stacker#Buy Stainless Steel Walkie Fork Over Stacker online#Stainless Steel Forklifts#Stainless Steel Portable Tote Tilter#Stainless Steel Straddle Tote Tilter#Stainless Steel Portable Dumpers#Stainless Steel Portable Tipper#Stainless Steel Pneumatic Tilter#Stainless Steel IBC Lift#Stainless Steel High Point Tilter

0 notes

Text

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

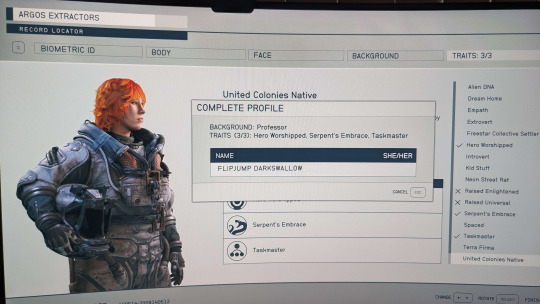

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

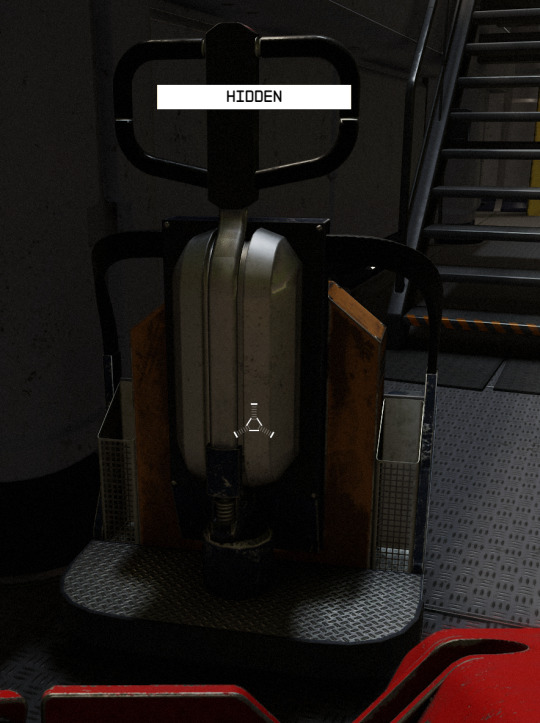

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

47 notes

·

View notes

Text

All-Steel Stress, Blast and Coating

All-Steel Stress, Blast & Coating is a subsidiary steel heating treating company under the All-Steel Brand. All-Steel Stress, Blast and Coating provides heat treatment of steel, thermal stress relieving, industrial sandblasting/steel shotblasting and steel coating of: Fabricated weldments Machined parts Machine components Dry Outs

Their Massachusetts Facility offers a 40 Ton lifting capacity, 20 Ton forklift capacity and a dedicated, professional staff with over 50 years of combined experience in thermal stress relieving, sandblasting and priming/painting.

Thermal Stress Relieving, also referred to as Stress Relieving, Heat Treating, Post Weld Heat Treating (PWHT) and can also be referred to as annealing.

In our new, state of the art industrial size stress relieving oven we can stress relieve: Fabricated Weldments for post-weld heat treatment Machined Parts Metal Components In addition, we provide dry-out services for paint and refractory process curing. Our furnace will operate between 250 degrees F and 1600 degrees F. We perform quality inspections during the stress relieving process and we can provide our customers with Certificates of Compliance and detailed Heat Charts when required.

Our Stress Oven can accommodate customer jobs that are 12’H x 11’ W x 31’L and our rail-car capacity is 54,000lbs.

We meet the following standards: ASME Section I: (900 – 1300F) Stress relieve /post -weld heat treat in accordance with ASME Sect. I, PW-39 for carbon steel weldments. ASME Section VIII: (900 – 1300F) Stress relieve/post-weld heat treat in accordance with ASME Sect. VIII, USC-56 for carbon steel weldments. AWS D1.1 (900-1200F): Stress relieve/post-weld heat treat in accordance with AWS D1.1, 5.8 for carbon steel weldments. Westinghouse 83030QA: (1175F +/- 25F) Westinghouse-approved stress relieve procedure for carbon steel welded structures. General Electric P8A-AG1, P10G-AL-0003 & 0004: (1125 – 1275F, 1125-1200F and 125-1300F) General Electric-approved stress relieve procedures for carbon steel. Standard Stress Relieve: (1100-1200F) Applied to ferrous materials to reduce residual stresses for improved dimensional stability or reduced risk of premature failure in service. Low Temperature Stress Relieve: (325-775F) Typically applied to stainless steel and aluminum welded fabrications to reduce residual stresses with little or no effect of the corrosion resistance and/or mechanical properties. Industrial Sandblasting Services, also referred to as shot blasting can be done in our state-of-the-art facility in Central Massaschusetts. Our new, industrial-size facility provides our customers with sandblasting for: Fabricated Weldments Machined Parts Metal Frames and Components

In our modern, clean blast room, our experienced blasters can accommodate the most specific blast media required for the job. We can blast customer jobs that are 16’H x 13’W x 30’L; and we have 40,000lbs rail-car capacity for our blasting facility.

Steel Coating Services: Industrial Priming, Painting and Coating for Steel and other Metals. Our new coating facility will be capable of providing priming/painting/coating services up to 16’H x 20’W x 50’L and weigh up to 80,000lbs. Our painters have extensive experience coating: Fabricated Weldments Industrial Machine Bases Industrial Frames Construction Equipment Holding Tanks & Silos

Address: 84 Creeper Hill Road,North Grafton MA 01536 Phone: (508) 839-4471

Our Social Pages:

facebook

twitter

linkedin

youtube

pinterest

3 notes

·

View notes

Text

Slot Drain Systems Highlights The 6000 Series Slot Drain: A Game-Changer In Industrial Water Management

Slot Drain Systems Highlights The 6000 Series Slot Drain: A Game-Changer In Industrial Water Management https://ift.tt/iIvwBm1 Innovative drainage solution combines superior performance and durability, catering to the needs of modern commercial and industrial facilities. WINNIPEG, MB – Slot Drain Systems, a leader in the manufacturing of high-quality drainage systems, highlights its innovative 6000 Series Slot Drain, a state-of-the-art drainage system designed to meet the demanding needs of industrial and commercial environments, offering unparalleled performance, durability, and versatility. The 6000 Series Slot Drain features a sleek, efficient design with a narrow 1/2″ slot opening, maximizing water flow while minimizing visual impact. Its robust stainless steel construction ensures longevity and reliability in high-traffic areas and harsh conditions. The system boasts an impressive flow rate of up to 27 gallons per minute per linear foot, making it ideal for handling large volumes of water quickly and efficiently. One of the key advantages of the 6000 Series Slot Drain is its modular design, allowing for easy customization to fit specific project requirements. The system is available in various lengths and can be configured with multiple outlet options, providing flexibility for diverse installation needs. Its ADA-compliant design ensures accessibility and safety in public spaces. The 6000 Series Slot Drain excels in corrosion resistance, making it suitable for environments exposed to chemicals and other corrosive substances. This feature, combined with its durability, significantly reduces maintenance costs and extends the system’s lifespan. The drain’s pre-sloped design ensures efficient water drainage by directing water flow towards the outlet, while also facilitating easy cleaning and debris removal, further minimizing operational expenses. This versatile drainage solution is ideal for numerous applications, including manufacturing facilities, warehouses, food processing plants, commercial kitchens, car washes, and airport hangars. Its ability to withstand heavy loads is evidenced by its Load Class C rating, allowing it to endure up to 56,200 lbs per foot of pressure. This makes it particularly well-suited for areas with heavy pedestrian traffic or industrial equipment such as forklifts. For more information on the 6000 Series Slot Drain, visit https://www.slotdrainsystems.com/products/6000-series/. The post Slot Drain Systems Highlights The 6000 Series Slot Drain: A Game-Changer In Industrial Water Management appeared first on Slot Drain Systems. via Slot Drain Systems https://ift.tt/Y3tNIjs January 16, 2025 at 03:18PM

0 notes

Text

Type and functions of Forklift Safety Lights

Transporting heavy loads can be conducted securely and efficiently through the assistance of forklifts, which serve as vital instruments of efficiency across various industries. Nevertheless, their usage in congested warehouses or industrial structures can pose hazards.

Among the array of safety features integrated into forklifts, safety lights are particularly crucial. This post will delve into seven specific types of forklift safety lights, elucidating their role in enhancing worker safety.

7 Types of forklift safety lights and their uses

Presented below are seven categories of forklift safety lights, each with its distinct functions. Understanding the purposes of these lights empowers operators and pedestrians to steer clear of accidents and injuries, promoting secure navigation around forklifts.

1. Forklift Arc Light

The forklift arc light is one of the prevalent safety lights incorporated into forklifts. Typically affixed to the front or rear of the forklift, this light emits a vibrant spot onto the ground, aligning with the forklift's travel direction.

The primary role of the forklift arc light is to notify pedestrians and fellow workers about the presence of an approaching forklift. The projector spot on the ground functions as a visual alert, signaling the proximity of a forklift and urging caution. This proactive measure helps avert unintended collisions and ensures that workers remain cognizant of their surroundings.

Product Features:

Tempered Glass Cover.

High power LED with High quality.

The high performance of 100% waterproof, dustproof & quakeproof.

Beam: Projector spot on the ground.

Ingress protection: IP-67

Warranty: 1 year

Double insulated silicon rubberized wire, which can bear very low & high temperatures.

Casting Aluminum Alloy Housing, the suitable design for heating elimination.

2. Forklift Red Danger Light

Forklifts come equipped with a vital safety feature known as the red danger light. Typically positioned on the front, back, or sides of the forklift, it comprises one or more conspicuous red lights. Designed for enhanced visibility, especially in low-light conditions.

The red hazard light serves as a clear warning signal, alerting individuals to the presence of the forklift. This is particularly crucial when the forklift is moving in reverse or operating in poorly lit areas. By notifying bystanders and other workers to steer clear of the forklift's path, this light significantly reduces the risk of accidents and mishaps.

Product Features:

Light source: High-power Osram LED 6pcs*3w

Operating Voltage:10-80V DC

LED power:18W

Double insulated silicon rubberized wire, Which can bear very low & high temperatures.

Material: Aluminium Die-Cast Housing, PC

Cover, Stainless Steel Bracket

Optional beam: line beam

Warranty: 1 year

3. Forklift Laser Light

Forklift laser lights represent a cutting-edge safety feature found in certain forklift models. These lights project a visible laser line or pattern onto the floor, aiding in delineating a secure path for the forklift's movement.

The forklift laser safety lights provide a precise visual reference for operators by indicating the exact path the machine's wheels will traverse. This feature facilitates precise forklift positioning, assists in avoiding obstacles, and enhances navigation in confined spaces. Additionally, it reduces the likelihood of accidents by signaling bystanders and other workers about the forklift's intended route.

Every year, forklift accidents lead to the tragic loss of approximately 75 to 100 workers, with an average of around 87 fatalities annually.

Product Features:

Suitable for Class 1,2,3 and 4

Type: Red laser alignment system

Remote control switch

Laser Light/Battery

Power Source rechargeable battery

Full Recharge time 8 Hours

Use time per recharge 50-70 hours

Laser Wavelength 650mm (red)

Laser power 100mw

Laser safety class IIB

Warranty: 1year

Boost your forklift's visibility and reduce collision risks by 60%. Tap into our 7 unique safety light solutions now!

Reach out to Us

4. Forklift Blue Spot Light

Similar to the forklift arc light, the forklift blue spotlight serves the purpose of creating a visible warning zone around the forklift. It emits blue light, outlining the forklift's perimeter and signalling its presence to others.

The incorporation of forklift blue safety lights contributes to overall safety by clearly delineating the area surrounding the forklift. This innovative feature significantly diminishes the risk of accidents and injuries by alerting workers and pedestrians who might unintentionally enter the forklift's operational zone. These safety lights become especially advantageous in environments with simultaneous operation of multiple forklifts, such as densely packed warehouses or bustling loading docks.

The forklift's spotlight casts a bright beam to alert pedestrians when the forklift manoeuvres through blind intersections or crosses busy aisles. It serves as a proactive warning, enhancing safety and awareness in dynamic work environments.

Product Features:

Casting Aluminum Alloy Housing, the suitable

Design for heating elimination.

Tempered Glass Cover.

High power LED with High quality.

The high performance of 100% waterproof, dustproof & quakeproof.

Double insulated silicon rubberized wire, which can bear very low & high temperatures.

Beam: Projector spot on the ground.

Ingress protection: IP-67

Warranty: 1 Year.

5. Forklift Blue Arrow Light

Forklift blue arrow lights are similar to the forklift blue spotlight but come with an additional feature – they function as LED forklift lights, projecting directional arrows onto the ground to signify the forklift's planned path or direction of movement.

The blue arrow light not only serves as a warning to pedestrians about the forklift's presence but also communicates its intended route. This feature facilitates pedestrians in anticipating the forklift's movements, enabling them to choose optimal spots for walking or standing. This is particularly beneficial in scenarios where forklifts frequently change directions or execute turns.

Product Features:

Casting Aluminum Alloy Housing, the suitable

Design for heating elimination.

Tempered Glass Cover.

High power LED with High quality.

The high performance of 100% waterproof, dustproof & quakeproof.

Double insulated silicon rubberized wire, which can bear very low & high temperatures.

Beam: Projector spot on the ground.

Ingress protection: IP-67

Warranty: 1 Year.

6. Forklift Warning Light

The forklift beacon light, also known as a strobe light or warning beacon, is a highly visible flashing light affixed to the forklift's roof or other conspicuous locations.

Functioning as a strobe light, the forklift warning light emits a bright, flashing signal from the forklift's roof or another prominent location.

Product Features:

Casting Aluminum Alloy Housing, the suitable design for heating elimination.

Tempered Glass Cover.

High power LED with High quality.

The high performance of 100% waterproof, dustproof & quakeproof.

Ingress protection: IP - 65

Warranty: 2 years.

Light source: High - power Osram LED 5pcs*1w

Operating Voltage: 10 - 110V DC

Colour: Amber, Red, Green, Blue & Purple

Pattern: Rotating, Flashing (Once, Twice), Solid (No Pattern)

Material: aluminium die - cast housing, Hard glass cover, stainless steel bracket

Working environment: - 40° - 80°

Elevate your forklift operations with lights that cut down hazard rates by half. Unveil the power of our safety lights today!

Talk to our Expert

7. Overhead Crane Light

While not limited to forklifts, facilities utilising both forklifts and overhead cranes employ overhead crane lights. These lights project a distinct, visible signal onto the ground, indicating the position of the overhead crane's load.

In facilities housing both types of machinery, overhead crane lights play a vital role in ensuring security. These lights aid forklift operators and other workers in accurately determining the position of the overhead crane's load, contributing to the safety and avoidance of potential hazards. This preventive measure helps mitigate accidents and collisions between forklifts and overhead crane loads.

Product Features:

Power: 72 Watts

Current: 2.3A @24V Blue, 1.4A @24V RED

Voltage: 9-48 Volts DC

Lumens: 12,000 lumens(each light creates one line)

LEDs: 24

LED colour: Blue Or Red

Beam Type: Line Beam or Spot Light

Working life: Up to 50,000 hours

Size: 9” X 3.9” X 8.6” (228 X 98 X 220mm)

Waterproof: IP67

Working temperature: -40~85°C

Material: Aluminum die-cast housing.

Adjustable mounting bracket: 150 degree up/down.

Cable Length: 0.6 metres.

One year warranty

Importance of Forklift Safety Lights

The key motive of Forklift safety lights is to alert pedestrians and other forklift operators about the presence of the forklift in their vicinity and enlarge the warning area. The lights prevent rear-end collisions and foot injuries by making a noticeable boundary around the forklift. The sturdy design of these safety lights can also withstand vibrations and shocks as forklifts are devoid of any conventional suspension setup.

Besides, as the forklifts fetch and transport heavy loads, carrying such an enormous weight, especially on the slopes, can be challenging without any safety accessories. Forklift lights, when combined with speed limiter and forklift camera systems, can further enhance safety and allow easy negotiations on the slopes, preventing a potential collision. With efficient illumination, these lights create trails for the docking forklift trucks by projecting outlines, and safety signage in and out.

The importance of forklift safety lights goes well beyond this paragraph, and for more info — check this guide!

Choose SharpEagle and turn your forklift into a mobile warning system

Forklift lights serve as a critical enhancement in warehouses, significantly boosting safety levels and minimising the risk of injuries and fatalities. These lights form an essential part of the pedestrian warning system for forklifts, alerting workers who may be engrossed in paperwork, conversations on mobile phones, or moving from aisle to aisle, thereby ensuring they are aware of and can steer clear of an approaching forklift.

The pedestrian warning system for forklifts, with its array of specialised lights, plays a pivotal role in ensuring utmost safety during forklift operations. In addition to standard headlights, taillights, and brake lights, other crucial lights such as red, blue, arc, laser, and various warning lights significantly enhance the forklift's safety features. SharpEagle, a leader in safety product innovation, offers a diverse range of safety lights. Contact our expert team today for competitive pricing quotes, and benefit from our comprehensive services including the installation and maintenance of forklift safety lights.

The Final Thought

Both forklift operators and employees must comprehend the purposes of these forklift safety lights. To make the workplace safer and lower the risk of accidents and injuries, proper training and awareness campaigns can be implemented. As technology advances, We can expect to see even more comprehensive safety features added to forklift technology in order to further improve workplace safety in industries that depend on these necessary vehicles.

Let our team help you with the right choice for your workplace safety. We are just a click away!

Get Free Expert Consultation

You can also call us at +971-45549547 or mail us at [email protected]

#Forklift Arc Light#forklift blue light#forklift blue safety lights#forklift light#forklift red zone light#forklift safety laser light#forklift safety light#overhead crane warning lights#Forklift safety lights#blue spot light for forklifts#forklift safety lights red#blue forklift safety light

0 notes

Text

Why are pallet racking anchors critical to the entire structure?

Pallet racking anchors are mechanical fasteners used to attach a racking system to a building. Their purpose is to hold the pallet racking in place and resist continuous counter forces such as: earthquakes, wind and tipping forces caused by narrow/high racking, accidental impact forces at the bottom of the columns (i.e. from forklifts) and shear forces (horizontal reaction forces) ) reducing the restraining capacity of the racking.

If the anchors are unable to withstand these attack forces, the consequences can lead to significant bending forces on the columns, affecting the overall stability of the system and, in the worst case scenario, leading to collapse. To avoid this, it is critical to select the correct type of anchor for the different conditions and types of racks in the facility.

What common types of pallet rack anchors can be found in warehouses?

Wedge anchors are a popular type of anchor made of carbon steel, hot-dip galvanized, stainless steel or galvanized steel. These fasteners are primarily used for solid concrete and cannot be removed if you decide to rearrange your pallet racking, as doing so would damage your floor. Concrete impact anchors are anchors in the form of impact expansion and are also used in solid concrete; given their mechanical properties, they should not be installed in any other type of masonry material.

Screw anchors are a less common type of fastener found in warehouses. They are used for temporary or permanent anchoring, since they can be removed and can be installed in concrete and masonry.

Finally, we have sleeve anchors that are perfect for light to medium anchoring in concrete and masonry. Whichever type of anchor you choose, you will find a variety of diameters, lengths and thread lengths.

What size pallet rack anchor is appropriate?

A rule of thumb is that the wider the diameter and the deeper the embedment, the stronger the anchor will be. Therefore, it is important to check local building codes or have an engineer determine the bolt size given that several factors need to be considered: the size of the hole in the base plate of the column, seismic activity, and the area where the anchor is to be used. In addition, the thickness of the floor material, the mechanical properties of the floor material and the flatness of the floor should also be considered in case shims are needed.

How many anchors should a post base carry?

The ANSI/RMI standard states that all rack columns should be anchored using at least one anchor per column. Depending on the type of anchor, two anchors may be installed to prevent the column from rotating upon impact. In the event that the user is unable to properly secure the rack, it is recommended to work with the rack manufacturer’s engineers to verify alternative methods of securing the system while ensuring the structure is safe for use.

Should I tighten a loose anchor?

Bolts and anchors must be properly tightened to the minimum recommended torque specified by the manufacturer. 3/8'’ anchors are typically 40 foot pounds. Under-tightening will cause the anchors to fail.

Why are pallet racking anchors critical to the entire structure?

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Description: This chain adjuster can change multi-speed bikes into single speed bike.The flywheel made of highly resistant stainless steel, hardness of 18 degrees. The screws made of stainless steel, anti corrosion and anti rust. The compression piece and gasket are made of 6061 aluminum alloy, CNC cutting, smooth surface and hollow design.Ensures perfect tension for your chain to make you pedal with less efforts, suitable for long time outdoor riding.This flywheel is compatible with 7-10 speed cassette flywheel, please choose 7-10 chain to install.Lightweight and mini, easy to install and use. Installation skills: the angle between the chain presser and the lower forklift frame ≤ 45 degrees to maximize the pulling force. Specification: Material: Aluminum AlloyFlywheel: 13T/14T/15T/16T/17T Size Chart: Chain Tensioner Length: 98.3mm/3.87inch Package Includes: 5 Pieces Tower Base Gaskets1 Piece Flywheel Cover1 Piece Flywheel1 Piece Bike Chain Tensioner2 Pieces Wrenches Note: 1. Please allow slightly error due to manual measurement.2. Due to the difference between different monitors, the picture may not reflect the actual color of the item.3. Wish you a wonderful on-line shopping! This chain adjuster can change multi-speed bikes into single speed bike. The flywheel made of highly resistant stainless steel, hardness of 18 degrees. The screws made of stainless steel, anti corrosion and anti rust. The compression piece and gasket are made of 6061 aluminum alloy, CNC cutting, smooth surface and hollow design. Ensures perfect tension for your chain to make you pedal with less efforts, suitable for long time outdoor riding. Package Includes:5 Pieces Tower Base Gaskets1 Piece Flywheel Cover1 Piece Flywheel1 Piece Bike Chain Tensioner2 Pieces Wrenches [ad_2]

0 notes

Text

IBC Tanks: The Ultimate Solution for Safe Liquid Storage in the UAE

Introduction

As the UAE thrives as a hub for industrial, commercial, and agricultural activities, the need for efficient liquid storage and transportation solutions has grown significantly. Intermediate Bulk Containers (IBC Tanks) have emerged as a versatile and cost-effective option for storing and transporting liquids, chemicals, and other bulk materials. In this blog, we delve into the features, benefits, and applications of IBC tanks in UAE, highlighting why they are an indispensable asset for various industries.

What are IBC Tanks?

Intermediate Bulk Containers (IBC Tanks) are durable, reusable containers designed for the storage and transport of liquids, semi-solids, and granulated substances. Made from high-density polyethylene (HDPE) or metal, these tanks are engineered to withstand heavy loads and provide excellent chemical resistance.

Features of IBC Tank

Robust Construction: Made from high-quality materials for durability and longevity.

Large Capacity: Available in capacities ranging from 500 liters to 1,000 liters, catering to various needs.

Stackable Design: Optimizes storage space and simplifies transportation.

Leak-Proof: Equipped with secure seals and valves to prevent spillage.

Easy Handling: Compatible with forklifts and pallet jacks for efficient movement.

Importance of IBC Tanks

With the UAE’s diverse industries, including oil and gas, agriculture, and food processing, IBC tanks have become essential for efficient operations. Their versatility and safety features make them ideal for storing and transporting hazardous and non-hazardous materials across the region.

Key Benefits of IBC Tank

Cost-Effective: Reduces the need for multiple smaller containers, saving time and money.

Space Optimization: Stackable design ensures efficient use of warehouse space.

Environmental Sustainability: Reusable and recyclable, reducing environmental impact.

Chemical Compatibility: Resistant to corrosion, suitable for storing a variety of substances.

Ease of Transport: Designed for seamless handling with standard equipment.

Applications of IBC Tank

Chemical Industry: Safe storage and transport of hazardous chemicals and solvents.

Food and Beverage: Hygienic storage of edible liquids like oils, syrups, and beverages.

Agriculture: Transport of water, fertilizers, and pesticides.

Construction: Storage of construction chemicals and water.

Oil and Gas: Handling lubricants, fuels, and other petroleum-based products.

Why Choose IBC Tank for UAE Industries?

The UAE’s harsh climate and stringent safety standards require reliable storage solutions. IBC tanks provide:

UV Resistance: Withstands extreme sunlight exposure.

Spillage Prevention: Reduces environmental hazards in case of accidental leaks.

Compliance: Meets international and local safety regulations for hazardous material storage.

How to Select the Right IBC Tank

When choosing an IBC tank for your business, consider the following factors:

Material: HDPE for non-corrosive substances, stainless steel for high-strength requirements.

Capacity: Choose a size that matches your storage or transport needs.

Valve Type: Ensure compatibility with the type of liquid being stored.

Regulatory Compliance: Confirm adherence to UAE standards for hazardous materials.

Accessories: Options like liners, valves, and level indicators for added convenience.

Maintenance Tips for IBC Tanks

Regular Cleaning: Prevents contamination and maintains hygiene.

Inspect Seals and Valves: Ensure leak-proof operation.

Store in Proper Conditions: Protect from extreme heat or damage.

Use for Compatible Materials: Avoid storing substances that could degrade the tank material.

Conclusion

IBC tanks are a vital asset for industries in the UAE, offering an efficient, durable, and safe solution for liquid storage and transportation. Their adaptability to various applications and compliance with safety standards make them indispensable for businesses striving for operational excellence.

If you're looking for high-quality IBC tanks tailored to your needs in the UAE, explore our wide range of products designed for reliability and performance. Contact us today to learn more about how IBC tanks can revolutionize your storage and transport processes.

#ibc tank#ibc container#ibc tank 1000 liter#ibc tank price#used ibc tank#ibc tanks for sale#intermediate bulk container#uae#dubai#abudhabi#reconditioned ibc tanks#1000 litre ibc tank#ibc container for sale#ibc tank supplier#ibc tank distributor#ibc tank wholesalers#ibc dubai#new ibc tank

0 notes

Text

Portable Drum Tipper: Enhancing Mobility in Industrial Settings

A portable drum tipper is a game-changer in industrial material handling, offering unparalleled mobility and efficiency. Designed to lift, tilt, and pour drums with ease, these versatile tools streamline operations in warehouses, factories, and processing plants. Their compact and lightweight design ensures easy maneuverability, even in tight spaces, while robust construction handles heavy loads with precision. By reducing manual labor, portable drum tippers minimize the risk of workplace injuries and enhance overall productivity. Whether dealing with hazardous materials, bulk liquids, or powders, these tippers provide a safe and ergonomic solution. Ideal for industries ranging from chemical and food processing to pharmaceuticals, portable drum tippers are essential for businesses seeking to optimize operations and improve workflow efficiency.

What Is a Portable Drum Tipper?

A portable drum tipper is a specialized material-handling tool designed to lift, tilt, and pour drums of various sizes and weights. Its mobility and ergonomic design make it an essential piece of equipment in industries where liquid, powder, or granular materials are handled. Unlike stationary models, portable drum tippers are easy to move across workspaces, enhancing operational flexibility and efficiency.

Key Features of Portable Drum Tippers

Mobility: Durable wheels and compact designs enable easy transportation.

Safety Mechanisms: Locking clamps and secure grips reduce the risk of spills or accidents.

Adjustable Controls: Operators can customize tilt angles for precise pouring.

Capacity and Durability: Designed to handle heavy-duty loads, some models can lift drums weighing over 1,000 pounds.

These features not only simplify the handling of bulky drums but also minimize the risks associated with manual lifting.

Industries Benefiting from Portable Drum Tippers

Food and Beverage: For safely transferring liquids or powders like oils, syrups, and flour.

Chemical Manufacturing: Handling hazardous or corrosive materials with care.

Pharmaceuticals: Ensuring clean and precise material transfer in production environments.

Automotive and Lubrication: Managing heavy drums of oils and lubricants effectively. These industries rely on portable drum tippers to enhance safety, efficiency, and compliance with workplace regulations.

Benefits of Using Portable Drum Tippers

Increased Productivity: They allow workers to handle materials quickly and with minimal effort.

Improved Workplace Safety: Ergonomic designs reduce the risk of injuries associated with manual drum handling.

Space-Saving Design: Compact and portable, they can be easily stored when not in use.

Cost-Effectiveness: By reducing downtime and injuries, businesses see significant operational cost savings over time.

Portable Drum Tipper vs. Traditional Drum Handling Methods

Mobility Advantage: Portable drum tippers can navigate narrow spaces, unlike bulky forklifts.

Ease of Use: They require minimal training and effort, making them accessible for workers of all skill levels.

Lower Cost: Portable options are often more affordable and require less maintenance than larger machinery.

Choosing the Right Portable Drum Tipper for Your Needs

Drum Size and Weight Capacity: Ensure compatibility with the types of drums used in your operations.

Material Handling Requirements: For hazardous materials, look for safety-certified models.

Mobility Needs: Opt for lightweight designs with durable wheels for ease of transportation.

Durability: Choose a model made from high-quality materials like stainless steel for longevity.

Automation Options: Some advanced tippers offer powered lifting or tilting for added convenience.

Maintenance Tips for Long-Lasting Performance

Regular Inspections: Check for wear and tear on wheels, clamps, and hydraulic systems.

Lubrication: Keep moving parts well-lubricated to ensure smooth operation.

Cleaning: Clean the equipment after handling corrosive or hazardous materials to prevent damage.

Manufacturer Guidelines: Follow user manuals for servicing schedules and parts replacement.

Conclusion

Portable drum tippers are essential tools for industries looking to enhance material-handling efficiency, improve safety, and reduce operational costs. Their ergonomic designs, mobility, and versatility make them a smart investment for businesses handling heavy or hazardous materials. By choosing the right model and maintaining it properly, organizations can streamline workflows and ensure long-term productivity. Embracing portable drum tippers is not just about meeting immediate operational needs—it’s about future-proofing your business with reliable and efficient solutions.

0 notes

Text

Silos Loading System | Silo Storage | Silo Discharge System - Lorandi Silos

Silo loading system are ideal for transporting your products from the truck or big-bag location onto the Silos. Lorandi Silos, Silo loading system is used to charge the material from the big bags or sacks onto the Silos OR to another location with the help of compressor. Our loading systems deliver from 4 tons/ hour to 12 tons/ hour, to a height of 15 meters in height.

Lorandi’s Silo loading system can be moved over by forklift for easy usage of loading at multiple locations with single equipment.

It’s possible to complete them with unloading big-bag frame, sound-proof cabin and Silos connection flexible pipe. Available in stainless steel AISI 316* version.

Other Products

Recycling Silos

Buffer Silos

Textile Silos

0 notes

Text

Elegant Rose Gold Elevator Cabin Decoration

Optional:

Ceiling: Mirror stainless steel, acrylic transparent plate, LED light Car wall: Rose gold mirror etching, rose gold mirror, rose blonde grain Floor: PVC floor (Optional marble mosaic)

1) High-quality production process design and program control, make each batch of custom Elegant Rose Gold Elevator Cabin Decoration more stable and traceable, and obtain high-efficiency production control; strictly follow the supplier's indicators to inspect and monitor the quality of each batch of custom Elegant Rose Gold Elevator Cabin Decoration. 2) The company's superior geographical location and capable management team reduce transportation and labor costs; the professional R&D team and technical service team can continue to provide new products with higher cost performance.

Company Name:Zhejiang Hongmin Elevator Technology Co., Ltd. Web:https://www.hmvillaelevator.com/product/elevator-car-decoration-series/elegant-rose-gold-elevator-cabin-decoration.html ADD:No.10 Guying Road, Nanxun Economic Development Zone, Huzhou City, Zhejiang Province Phone:86 13867284775 Email:[email protected] Profile:Cooperative customers with many clients of trains, cars, forklifts and engineering machinery, including over 10 of the world's top 500 companies, have become an important supplier of their precision castings in China.

0 notes

Text

Why Commercial Hollow Metal Doors Are a Smart Choice for Your Business

Introduction

When it comes to ensuring safety, durability, and style in commercial spaces, commercial hollow metal doors stand out as an excellent choice. These doors are widely used in offices, warehouses, hospitals, and schools because of their unmatched strength and versatility. Whether you're looking for security, fire resistance, or long-term performance, hollow metal doors deliver exceptional value.

In this blog, we’ll explore why these doors are so popular, their benefits, and why they’re a smart investment for any commercial property.

What Are Commercial Hollow Metal Doors?

Commercial hollow metal doors are typically made from sheets of galvanized steel, stainless steel, or other metals. The core of these doors is filled with materials like steel reinforcements, honeycomb patterns, or fire-resistant mineral cores. This construction gives them durability and insulation while keeping them lightweight compared to solid metal doors.

These doors come in various styles, including flush designs, paneled options, and even ones with glass inserts. They are highly customizable, making them suitable for a variety of commercial applications.

Benefits of Commercial Hollow Metal Doors

1. Durability and Strength

Commercial hollow metal doors are built to withstand heavy use and harsh conditions. They resist impacts, corrosion, and wear and tear, ensuring long-term reliability. This makes them an ideal choice for high-traffic areas like factories, retail stores, and educational institutions.

2. Enhanced Security

Security is a top priority for businesses, and hollow metal doors are among the most secure options available. Their sturdy construction makes them difficult to break through, helping protect your property, employees, and valuable assets.

3. Fire Resistance

Many hollow metal doors come with fire-rated cores, which can resist fire for up to three hours, depending on the rating. This feature provides added safety and compliance with building codes, especially in sensitive environments like hospitals and laboratories.

4. Energy Efficiency

The insulated core in these doors helps regulate indoor temperatures, reducing energy costs. Whether it’s keeping the heat in during winter or maintaining cool air during summer, hollow metal doors contribute to energy savings.

5. Noise Reduction

For businesses that value a quiet environment, such as offices or recording studios, hollow metal doors offer excellent soundproofing capabilities. Their solid construction blocks external noise effectively, creating a more focused workspace.

6. Low Maintenance

Hollow metal doors require minimal maintenance. They are resistant to rust, scratches, and dents, and a simple cleaning routine is enough to keep them looking and functioning like new.

Applications of Commercial Hollow Metal Doors

Offices and Corporate Buildings Hollow metal doors provide a professional appearance while ensuring security. They are often used for entryways, conference rooms, and storage areas.

Healthcare Facilities Hospitals and clinics benefit from fire-rated hollow metal doors, which offer safety, easy maintenance, and a hygienic surface.

Educational Institutions In schools and universities, these doors are used for classrooms, libraries, and emergency exits due to their durability and soundproofing.

Industrial and Warehouse Spaces Hollow metal doors are ideal for industrial settings, as they can withstand heavy machinery, forklifts, and other equipment without damage.

Retail Stores Retail spaces use these doors for storage rooms, delivery areas, and secure entrances to protect merchandise and staff.

Customization Options

One of the biggest advantages of commercial hollow metal doors is their flexibility in design. Businesses can customize these doors with various finishes, colors, hardware, and accessories to suit their aesthetic and functional needs. Options include:

Glazed Panels: For added visibility or natural light.

Painted Finishes: Available in different colors to match your brand.

Hardware Integration: Including locks, handles, and access control systems.

Installation and Maintenance

Proper installation is crucial to ensure that your hollow metal doors function effectively. Hiring professional installers guarantees a secure fit and compliance with local building codes. Once installed, these doors require little upkeep. Regular checks on hinges, locks, and seals can further extend their lifespan.

Why Choose Hollow Metal Doors Over Other Materials?

Metal vs. Wood Doors

While wood doors may offer a classic look, they can’t match the strength or fire resistance of metal doors. Wood is also prone to warping and damage from moisture, unlike hollow metal doors.

Metal vs. Aluminum Doors

Aluminum doors are lightweight and stylish, but they lack the durability and security features of hollow metal doors. Hollow metal doors strike the perfect balance between strength and aesthetics.

Choosing the Right Supplier

Selecting a reliable supplier is essential to ensure you get high-quality hollow metal doors. Look for a provider with experience, positive reviews, and a variety of customization options. A trusted supplier will also offer expert guidance on choosing the best doors for your specific needs.

Conclusion

Investing in commercial hollow metal doors is a smart decision for businesses seeking security, durability, and versatility. Their long-lasting performance, low maintenance, and customizable designs make them an excellent choice for various industries. Whether you’re upgrading your existing doors or planning a new installation, hollow metal doors provide unmatched value and peace of mind.

0 notes

Text

Shaping the Future of Lithium-ion Batteries: Cylindrical, Prismatic, or Pouch?

In the relentless pursuit of advancing battery technology, the shape and structure of lithium-ion batteries play a pivotal role. These batteries come in three primary forms, each with unique characteristics, advantages, and drawbacks.

Here we will discuss Lithium-ion Batteries: Cylindrical, Prismatic, or Pouch. Notably, in recent years, the market has witnessed a significant surge in the popularity of pouch batteries, hinting at a potential market takeover, with experts predicting that the market share of pouch batteries will soon surpass 50%.

The Triad of Lithium-ion Batteries

Cylindrical Batteries: Proven and Prolific

Cylindrical lithium-ion batteries come in various models, such as 14650, 17490, 18650, 2170, and 26500. These batteries have a well-established production process, offering low PACK costs and high yield, ensuring consistency across battery packs.

With its ample heat dissipation area, the cylindrical form outperforms prismatic and pouch batteries in terms of thermal management. The mature production of these batteries is seen in countries like China, Japan, South Korea, and the United States.

While cylindrical batteries have gained acclaim for their reliability, they tend to be heavier, less space-efficient and offer relatively low energy density at the pack level.

With the growing demands of the electric vehicle market, there's a push to increase the size of cylindrical batteries, aiming to extract more battery capacity.

Prismatic Batteries: Bigger and Bolder

Prismatic batteries are encased in materials like aluminum alloy, and stainless steel, and are assembled through winding or lamination.

They excel in safety and flexibility, and their design allows for easy assembly of high-capacity batteries.

Prismatic batteries boast higher pack density but require improved heat dissipation due to the smaller gap between cells.

The transition from steel shells to aluminum shells has gained momentum, given their lightweight, safety, and performance advantages. These batteries find extensive application in electric vehicles and are renowned for their robustness.

Pouch Batteries: Market Dominance on the Rise

Pouch batteries maintain traditional cathode and anode materials but differ in their flexible packaging material, typically an aluminium-plastic composite film.

This unique packaging material accounts for their lighter weight, making them 40% lighter than steel-shell batteries and 20% lighter than aluminium-shell batteries of the same capacity.

The flexible design of pouch batteries allows for variable shapes and thinness, facilitating the development of new battery models tailored to customer needs.

However, pouch batteries grapple with issues of poor consistency, higher production costs, and susceptibility to leakage, challenges that can be mitigated through scale and quality improvement.

Pouch batteries find extensive use in consumer electronics like smartphones, tablets, and wearable devices.

Comparing the Three Batteries

Conclusion

Each of these battery types serves as a pioneer in its respective field, driving fierce competition in the battery market. Cylindrical batteries have found their niche in power tools, toys, lamps, automobiles, electric bicycles, and portable mobile energy systems. Pouch batteries are well-suited for smartphones, drones, laptops, and wearable devices due to their lightness and customizable shape. Prismatic batteries stand tall in the realm of electric vehicles, including industrial trucks, forklifts, power grid energy storage, and medical equipment.

With a multitude of shapes and sizes, the future of lithium-ion batteries is as diverse as the technology they power. Each variant brings its strengths and innovations to the table, ensuring that the world of battery technology continues to evolve and adapt to our ever-changing needs.

#Cylindrical Batteries#cylindrical lithium-ion batteries#lithium-ion batteries#pouch cell batteries#pouch cell lithium-ion batteries#Prismatic Batteries#prismatic lithium-ion batteries

0 notes

Text

Top 6 Benefits of Forklift LED Warning Lights

The invention of forklifts has shed the industrial workload of carrying and transporting heavy goods right to a great extent. Today, transporting goods for a shorter distance no longer remains an issue. However, at places where heavy machinery is used, proper safety precautions have to be taken, to ensure everything goes well, without compromising on work efficiency. Typically, the warehouses are activity-filled with lots of movement of forklifts and pedestrians.

According to Occupational Safety and Health Administration (OSHA), pedestrians in warehouses account for about 40 percent of overall accidents. Though all this movement occurs for the common goal of achieving productivity and efficiency, accidents in these high-paced environments can happen in a blink of an eye. So, for ensuring proper safety, Forklift LED warning lights can be used to force pedestrians to keep a safe distance during work activities. Here we will learn about the top benefits of forklift warning lights.

Read More : 5 salient features of fork view camera system

➢ Top reasons to have forklift LED warning lights

It's of utmost importance to warn pedestrians of the oncoming forklift to avoid collisions and fatalities. Warning lights ensure excellent levels of effectiveness in the warehouses. Let’s know how these forklift safety lights can ensure the safety of the employees.

1. Rugged design that guarantees durability

Given the conditions in various industries, the safety lights have to be robust enough to sustain the working environments. The encasing of such forklift safety lights is prepared using a durable tempered glass cover, with a stainless-steel bracket, and aluminum alloy casting for dissipating heat. The body is 100 percent water, dust and quakeproof with an IP 65 protection level. These warning lights can also be customized in different colors, and various rotating and flashing patterns. And with high-powered LEDs inside, the long-term service and low energy consumption can eventually save you money on maintenance costs.

2. Helps boost productivity and efficiency

It is a no-brainer that whenever events of collision or accidents occur in the working premises, the colleagues will rush to check the incident or merely watch as a spectator. These incidents hamper overall productivity and decrease work efficiency. If warning lights are there in the first place, accidents won’t happen and the focus of workers will be entirely on their tasks. The warning lights help keep the pedestrians away by alerting them well in advance of the presence of the forklift in their vicinity.

3. Helps avoid possible lawsuits and adverse effects on the brand

When forklift-related accidents happen in the warehouse, you won’t be delighted to see your worker in agony. And even if you take care of their hospital bills, some workers might not be able to work after serious injuries. They might file a lawsuit against you, which can be a distasteful experience. You would need to hire a lawyer to represent your case in court, and still, it cannot be guaranteed, that you will not lose the case and end up recompensing a hefty amount to the worker. Contrary to this, having forklift warning lights in place can let you avoid a lawsuit, a time-consuming inspection process, as well as, spoiling the brand image.

Longevity You Can Trust! With 90% energy efficiency, our Forklift LED warning lights are your sustainable choice.

Reach out to Us

4. Increases Visibility and forms a safe surrounding

The safety warning lights feature high-powered LEDs, making it easier even for the distant workers to spot the oncoming forklift and keep a safe distance. These lights help form a safe and visible border around it as forklifts are large and heavy machinery carrying loads of goods. It is especially beneficial in and around construction sites where there are a lot of workers around. The warning lights hold the attention of the people around it instantly.

5. Prevents damage of goods

The cost of human life is invaluable, but at the same time, the damage to properties will also set you back right to some extent, especially when it comes to net-worth investments. Moreover, a collision between the forklifts would also cost you extra bucks on repairing. So, warning lights can prevent the loss of goods and costly repairs.

6. Helps you comply with the law

There are rules and regulations set by the governing or regulatory bodies to help keep a safe working atmosphere, not to punish anybody. We must always see things from a positive perspective as to how they can benefit us. Installing forklift safety lights would ensure zero chances of quarrels with the governing authorities. Such incidences can save you from high penalties and improve your brand image. Hence, warning lights can help you comply with the existing laws.

➢ Conclusion

In summary, a typical working day in a warehouse involves plenty of activities, and busy workers can get lost in this hustle and bustle. Forklift safety light is an ideal and most practical solution to avoid potential accidents. SharpEagle, with its range of forklift safety lights, helps you override all these problems and create a safe working atmosphere. Get in touch with SharpEagle, and our experienced team of experts will look after your needs.

You can also call us at +971-45549547 or mail us at [email protected]

#beacon light#forklift safety warning lights#Forklift warning lights#fork truck warning lights#warning light for forklift#overhead crane warning light#forklift beacon light#osha overhead crane warning lights#side-mounted Forklift warning light

0 notes

Text

Comprehensive Guide to Truck and Pallet Scale Sales in Oregon

In Oregon, where the transportation and logistics industries are vital to the economy, truck scales play a crucial role. Truck scales, also known as weighbridges, are large weighing platforms that allow for the precise measurement of truck loads, helping companies avoid overloading, reduce wear on vehicles, and improve safety on the roads. With increased regulations on freight weight, truck scales have become essential in ensuring compliance with state and federal laws.

For businesses in Oregon, finding the right truck scale is critical, as it can significantly impact operational efficiency and cost savings. High-quality truck scales ensure that goods are accurately weighed before transportation, which helps avoid fines associated with overloading, decreases the risk of accidents, and contributes to fuel efficiency. For companies with heavy goods transportation needs, investing in a reliable truck scale is a long-term asset that can enhance their overall productivity and safety.

Key Considerations When Purchasing Truck Scales in Oregon

When exploring truck scale sales Oregon, it’s essential to assess several factors. First, consider the type of truck scale that best suits your business needs. Truck scales come in various designs, including above-ground, pit-mounted, and portable scales, each offering unique benefits. Above-ground truck scales, for example, are commonly used and relatively easy to install, while pit-mounted scales are ideal for sites with limited space. Portable truck scales, on the other hand, offer flexibility for companies with changing weighing needs.

Another essential factor to consider is scale capacity. Make sure to choose a truck scale that can handle the weight range of your typical loads to ensure accurate measurements. Calibration and maintenance requirements should also be assessed. Regular calibration is necessary to maintain accuracy, especially in high-usage environments, and purchasing from a provider that offers these services can be beneficial.

Pallet Scales: The Backbone of Warehouse Operations in Oregon

While truck scales are crucial for transportation, pallet scale sales in Oregon are equally significant for warehouse and manufacturing operations. Pallet scales are smaller, mobile scales designed to weigh pallets quickly and accurately, making them ideal for warehouses, shipping docks, and industrial facilities. They provide essential weight data for inventory management, shipping calculations, and production control, making them invaluable for various industries across Oregon.

Pallet scales help businesses ensure that inventory records are precise and shipments meet weight specifications. These scales are typically placed directly beneath pallets or on forklifts for easy weighing without interrupting workflows. Some advanced pallet scales come with digital displays, making it easy for operators to read measurements on the go. Pallet scales also come in a variety of capacities and designs to meet the specific needs of each business, from heavy-duty models for industrial operations to lighter, more portable scales for smaller warehouses.

Choosing the Right Pallet Scale for Your Oregon Business

When considering pallet scale sales Oregon, focus on durability, accuracy, and compatibility with your existing equipment. Pallet scales often need to withstand rough handling, so it’s wise to select models built with robust materials like stainless steel or heavy-duty aluminum. Accuracy is another critical factor, especially in industries where precise weights are essential, such as food processing and pharmaceuticals. Some scales offer advanced calibration options to ensure accuracy over time, and many come with built-in protections against dust and moisture, enhancing their durability in challenging environments.

Additionally, check if the pallet scale integrates with your company’s existing systems, such as inventory management software or forklifts. This compatibility can streamline operations by automating data transfer, reducing the time spent manually logging weights, and improving overall workflow efficiency.

The Benefits of Investing in High-Quality Truck and Pallet Scales

Investing in quality truck and pallet scales is more than just a regulatory requirement; it’s a smart business decision. Reliable scales not only prevent overloading fines but also extend vehicle life by reducing strain on trucks. Accurate weight measurements also mean more precise shipping costs, avoiding profit loss due to miscalculations. For warehouses and manufacturing facilities, pallet scales improve inventory accuracy, streamline workflows, and increase productivity.

With Oregon's growing emphasis on sustainable and efficient logistics, having the right scales can support green initiatives by optimizing load distribution, reducing fuel consumption, and contributing to environmentally conscious business practices. Choosing trusted providers for truck scale sales in Oregon and pallet scale sales in Oregon ensures that you’re getting equipment built to last, calibrated for accuracy, and compliant with regulatory standards.

Compliance and Support: Essential for Long-Term Scale Performance

Keeping scales in optimal working condition is crucial for maintaining accuracy and regulatory compliance. Regular maintenance and calibration are key, and most reputable vendors of truck scale sales in Oregon offer these services as part of their packages. For businesses that rely heavily on accurate weight measurements, finding a partner that offers on-site calibration, maintenance support, and customer service is invaluable. This level of support ensures that your truck and pallet scales remain functional and compliant with any regulatory requirements in Oregon, minimizing downtime and protecting your investment.

Finding Reliable Scale Providers in Oregon

Selecting a trusted vendor is essential for ensuring high-quality, dependable scales. Oregon businesses should look for providers with a strong reputation, expertise in various types of industrial scales, and a commitment to customer service. It’s beneficial to choose a vendor that understands the unique challenges of the Oregon market, including regional logistics, environmental factors, and compliance requirements. Many providers offer on-site consultation to help businesses determine the best type of truck or pallet scale for their specific needs, ensuring a seamless purchasing and installation process.

0 notes

Text

AgriEyes 9016B Forklift Safety Light

Greetings, comrades of the warehouse! In terms of maintaining safety at work, attention to every small detail is important. This is why we're thrilled to present to you the AgriEyes 9016B forklift safety light. This light serves a dual purpose: enhancing appearance and ensuring safety for you and your coworkers while working. Let's explore the specifics and find out why this safety light is truly authentic.

Superior Quality: Built to Last

To start off, let's discuss the construction quality. The AgriEyes 9016B forklift safety light is built with a durable aluminum alloy casing, a stainless steel bracket that can be adjusted 360°, and a PC lens that is shatterproof. This design guarantees quick dispersal of heat and minimal heat production, ensuring durability and reliability. Having an IP65 waterproof certification allows it to withstand the demands of a bustling warehouse setting.

Enhanced Safety: Keeping Everyone Alert

The AgriEyes 9016B emits a vivid red line on the floor close to the forklift, instructing pedestrians to maintain a secure distance and prevent accidents. This greatly enhances safety in the workplace by decreasing the likelihood of accidents and injuries. It's similar to having a virtual protective area surrounding your forklift!

Wide Applications: Versatility at Its Best

Lighter and more compact than other models, the AgriEyes 9016B forklift safety light is suitable for various settings such as warehouses, stacking yards, loading docks, and enclosed spaces. It's ideal for forklifts in warehouses, farms, trucks, trailers, pickups, excavators, and more. It's like having a Swiss Army Knife of forklift safety lights!

Outstanding Illumination: Clear and Bright

Equipped with customized spot lenses and high-brightness LEDs, the AgriEyes 9016B LED forklift safety light delivers high brightness, clear and bright light beams, and soft, non-glaring light. It provides a more concentrated beam and wider illumination range compared to other forklift lights. It's like having a spotlight that keeps everything in focus!

Wide Voltage: Compatibility Made Easy

The warning light is suitable with the majority of forklifts since it functions within a broad input voltage range of 10 to 80 V. Because it may be used directly without requiring a separate power adaptor, this feature provides convenience. It is similar to having a forklift safety light with a global charger!

Conclusion

So, that's everything for now, everyone! For your job site, the AgriEyes 9016B forklift safety light is the ideal safety accessory. For those who operate forklifts, this safety light is revolutionary due to its superior quality, enhanced safety features, ease of use, outstanding visibility, and compatibility with several voltage levels. The 9016B will suit your demands whether you are operating a forklift on a farm or managing a busy warehouse.

0 notes