#Stainless Steel Pallet Lifts

Explore tagged Tumblr posts

Text

If the operation needs constant cleanliness and it is being commenced in a hostile environment then, it would be best to invest in stainless steel pallet lifts. These self-adjusted lifts are capable to be operated in a hostile environment. Superlift Material Handling offers quality pallet lifts that are best in quality. Visit the website or call on 1.800.884.1891 to know more about these lifts.

0 notes

Text

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

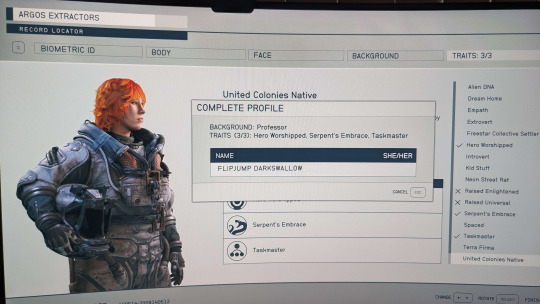

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

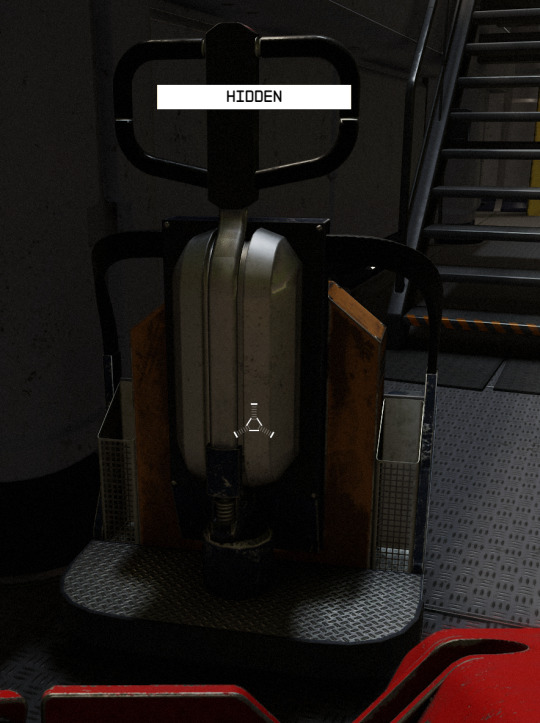

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

47 notes

·

View notes

Text

Cargo Lifting Net: Essential Equipment for Safe and Efficient Load Handling

Introduction

In industries that involve heavy lifting and material handling, safety and efficiency are paramount. One of the most crucial tools in this domain is the Cargo Lifting Net, a durable and flexible solution designed to secure and transport various types of loads. Whether in construction, shipping, or warehousing, Cargo Lifting Nets provide a reliable method for moving goods without compromising safety.

This article explores the importance, types, applications, and benefits of Cargo Lifting Nets, along with key considerations for selecting the right one for your needs.

What Is a Cargo Lifting Net?

A Cargo Lifting Net is a heavy-duty netting system made from high-strength materials such as nylon, polyester, or steel wire. These nets are engineered to securely hold and lift different types of cargo, including construction materials, industrial equipment, and bulk goods.

Unlike rigid lifting devices, Cargo Lifting Nets offer flexibility, allowing them to conform to the shape of the load, ensuring better weight distribution and minimizing the risk of damage.

Types of Cargo Lifting Nets

There are several types of Cargo Lifting Nets, each designed for specific applications:

1. Nylon and Polyester Cargo Nets

Ideal for lightweight to medium-weight loads.

Resistant to moisture, chemicals, and UV rays.

Commonly used in shipping and logistics.

2. Steel Wire Cargo Nets

Designed for extremely heavy or sharp-edged loads.

Highly durable and resistant to abrasion.

Often used in construction and heavy machinery transport.

3. Knotted vs. Knotless Nets

Knotted nets provide extra grip and are suitable for irregularly shaped cargo.

Knotless nets offer smoother handling and reduce the risk of load damage.

4. Custom-Designed Lifting Nets

Tailored to specific load dimensions and weight requirements.

Used in specialized industries like aerospace and automotive manufacturing.

Key Applications of Cargo Lifting Nets

Cargo Lifting Nets are versatile and used across multiple industries:

1. Shipping and Maritime Industry

Securing containers and loose cargo on ships.

Preventing shifting loads during transit.

2. Construction and Heavy Lifting

Transporting construction materials like bricks, pipes, and steel beams.

Assisting in crane operations for safe load handling.

3. Warehousing and Logistics

Moving bulk goods and palletized items.

Enhancing workplace safety by reducing manual lifting risks.

4. Military and Defense

Transporting equipment and supplies in challenging environments.

Used in airlifting operations for rapid deployment.

Benefits of Using Cargo Lifting Nets

The advantages of incorporating Cargo Lifting Nets into material handling processes include:

1. Enhanced Safety

Prevents load slippage and accidental drops.

Reduces the risk of workplace injuries.

2. Improved Load Stability

Evenly distributes weight, minimizing stress on lifting equipment.

Adapts to irregularly shaped items for better grip.

3. Durability and Longevity

Made from high-tensile materials that withstand harsh conditions.

Resistant to wear, tear, and environmental factors.

4. Cost-Effectiveness

Reduces the need for multiple lifting devices.

Low maintenance compared to rigid lifting solutions.

5. Versatility

Suitable for a wide range of industries and load types.

Can be customized for specialized applications.

How to Choose the Right Cargo Lifting Net

Selecting the appropriate Cargo Lifting Net depends on several factors:

1. Load Weight and Size

Ensure the net’s working load limit (WLL) matches your cargo requirements.

Consider the dimensions of the load for proper coverage.

2. Material Compatibility

Choose nylon or polyester for general-purpose lifting.

Opt for steel wire nets for heavy or sharp-edged materials.

3. Environmental Conditions

For outdoor use, select UV-resistant and waterproof nets.

In corrosive environments, stainless steel or coated nets are ideal.

4. Compliance with Safety Standards

Verify that the net meets industry regulations (e.g., OSHA, ISO).

Look for certification marks to ensure quality and reliability.

5. Customization Needs

If standard nets do not fit your requirements, consider custom-designed solutions.

Maintenance and Care for Cargo Lifting Nets

To maximize the lifespan of your Cargo Lifting Net, follow these maintenance tips:

Regular Inspections: Check for fraying, cuts, or weakened strands before each use.

Proper Storage: Keep nets in a dry, shaded area to prevent UV degradation.

Cleaning: Remove dirt and debris to avoid material degradation.

Avoid Overloading: Always adhere to the manufacturer’s weight limits.

Conclusion

The Cargo Lifting Net is an indispensable tool in modern material handling, offering safety, efficiency, and versatility across various industries. By understanding the different types, applications, and selection criteria, businesses can optimize their lifting operations while ensuring worker safety and load integrity.

Investing in high-quality Cargo Lifting Nets not only enhances operational efficiency but also contributes to long-term cost savings by reducing equipment wear and workplace hazards. Whether in construction, shipping, or logistics, the right lifting net can make a significant difference in productivity and safety.

By prioritizing durability, compliance, and proper maintenance, companies can rely on Cargo Lifting Nets for secure and effective load management in any environment.

1 note

·

View note

Text

The Ultimate Guide to Choosing the Right Pallet Truck for Your Business

Introduction

Pallet trucks, also known as pallet jacks, are essential tools for businesses that require efficient material handling. Whether you operate a warehouse, retail store, or manufacturing unit, choosing the right pallet truck can increase productivity, reduce manual labor, and enhance workplace safety. However, with various types and features available, selecting the right pallet truck can be challenging.

This ultimate guide will walk you through the types, key features, and factors to consider before purchasing a pallet truck for your business.

1. Understanding Different Types of Pallet Trucks

Before selecting a pallet truck, it’s important to understand the different types available in the market.

A. Manual Pallet Trucks

Operated by hand-pumping the hydraulic system to lift loads.

Ideal for small warehouses and short-distance transport.

Cost-effective and easy to maintain.

Best for businesses handling light to medium loads (up to 2500 kg).

B. Electric Pallet Trucks

Powered by a battery-operated motor.

Reduces manual effort and speeds up operations.

Suitable for medium to large warehouses handling frequent material movement.

Can handle heavier loads, typically up to 3000 kg.

C. Semi-Electric Pallet Trucks

Combines manual lifting with an electric drive system.

More affordable than fully electric models.

Great for businesses transitioning from manual to powered equipment.

D. High-Lift Pallet Trucks

Designed to lift pallets to a higher height.

Useful for loading/unloading trucks and stacking.

Prevents strain on workers by reducing excessive bending.

E. Weighing Scale Pallet Trucks

Equipped with a built-in scale to weigh loads instantly.

Useful in warehouses, shipping, and production units.

F. Rough Terrain Pallet Trucks

Designed for outdoor and uneven surfaces.

Features large, durable wheels for stability.

Ideal for construction sites and agricultural businesses.

2. Key Factors to Consider Before Choosing a Pallet Truck

Once you understand the types, consider the following factors to select the best pallet truck for your business needs:

A. Load Capacity

Choose a pallet truck with a capacity that matches or exceeds your typical load weight.

Standard pallet trucks support 1500–3000 kg.

Overloading can cause wear and tear and reduce the truck’s lifespan.

B. Fork Length & Width

Standard fork length: 1150mm (suitable for standard pallets).

Short forks: Ideal for small pallets and confined spaces.

Wide forks: Better for handling large or custom-sized pallets.

C. Lift Height

Standard pallet trucks lift up to 200mm.

High-lift pallet trucks can reach 800mm or more.

Consider lift height based on your racking and storage requirements.

D. Material & Build Quality

Opt for high-quality steel construction for durability.

Galvanized or stainless-steel models are ideal for corrosive environments (e.g., food & chemical industries).

E. Wheels & Manoeuvrability

Polyurethane wheels: Quiet, smooth rolling, and floor-friendly.

Nylon wheels: Ideal for rough surfaces and wet environments.

Rubber wheels: Provide better grip and shock absorption.

Consider 360-degree swivel wheels for enhanced maneuverability in tight spaces.

F. Ease of Use & Ergonomics

Look for ergonomic handles to reduce strain on workers.

Electric models with easy-to-use control panels improve efficiency.

Low-resistance pumps and smooth-rolling wheels make manual handling easier.

G. Battery Life (For Electric Pallet Trucks)

Ensure long-lasting battery performance for uninterrupted operations.

Lithium-ion batteries offer faster charging and longer life.

Check for easy battery replacement and charging options.

3. Benefits of Choosing the Right Pallet Truck

Investing in the correct pallet truck can benefit your business in several ways:

✅ Increases efficiency – Faster material handling reduces downtime. ✅ Enhances worker safety – Reduces the risk of injuries from manual lifting. ✅ Saves operational costs – Reduces labor costs and increases productivity. ✅ Improves space utilization – Enables better storage management. ✅ Extends equipment lifespan – Choosing the right model reduces wear and maintenance costs.

4. Best Practices for Maintaining Your Pallet Truck

To maximize your pallet truck’s lifespan, follow these maintenance tips:

🔹 Regularly inspect wheels for wear and tear. 🔹 Check hydraulic fluid levels and top up when necessary.

🔹 Lubricate moving parts to ensure smooth operation.

🔹 Keep the forks clean and free from debris.

🔹 Store electric pallet trucks properly and charge batteries as required.

5. Where to Buy the Best Pallet Trucks Online?

If you are looking to buy a pallet truck online, consider the following tips:

🔸 Choose a trusted supplier with positive customer reviews. 🔸 Compare features, warranties, and after-sales support. 🔸 Check if the seller offers fast shipping and easy returns. 🔸 Look for discounts and bulk purchase deals.

Conclusion

Selecting the right pallet truck for your business involves understanding your operational needs, load capacity, terrain, and budget. Whether you need a high-lift, electric, or manual hand pallet truck, choosing the correct model will boost efficiency, enhance safety, and save costs in the long run.

Take your time to assess your requirements and invest in a high-quality pallet truck to improve material handling operations.

Looking to buy the best pallet truck online? Explore top-rated models from leading suppliers and make an informed decision today!

0 notes

Text

Fence Building in the USA: Tools, Grit, and the Mindset of Master Craftsmen

The fence business in the USA is built on a foundation of hard work, precision, and pride in craftsmanship. It’s not just about enclosing spaces; it’s about creating structures that serve as protectors, dividers, and works of art. Professionals in this field rely on a blend of experience, the right tools, and high-quality materials to make every project a success. This blog dives into the world of fence building, highlighting the tools and techniques that define the trade and drawing comparisons with other industries like flooring, industrial manufacturing, and outdoor structures. Along the way, we’ll explore what it takes to succeed in business and what 2025 might hold for the USA economy.

Tools of the Trade: What Keeps the Fence Business Standing Tall?

Every craft has its tools, and fencing is no exception. At the heart of this trade is the humble yet indispensable fence coil nail. Whether you’re constructing a sturdy privacy fence or an elegant picket design, these nails are what keep the structure together. The quality of the nails determines not just the durability of the fence but also its ability to withstand harsh weather and time.

For projects demanding exceptional strength, stainless steel fence nails are a popular choice. These nails resist rust and maintain their integrity even in the most challenging environments. Similarly, stainless coil nails are preferred by professionals looking for longevity and reliability in their work. On the other hand, aluminum coil nails bring a lightweight and corrosion-resistant option, especially suited for decorative fencing or areas where moisture is a concern.

Lessons from Other Trades: Tools Across Industries

The importance of using the right tools and materials isn’t unique to fencing. Let’s take a look at some other industries and draw parallels:

Flooring Installations: Precision is key in flooring, where nailers and fasteners ensure planks are laid seamlessly. Just as a poorly fastened floorboard can disrupt a room’s harmony, a fence with subpar nails can fail to deliver both function and form.

Industrial Manufacturing: Heavy machinery demands high-strength fasteners to hold components together under immense pressure. Similarly, fences require durable coil nails for fencing to remain intact against strong winds and external forces.

Pallets and Crating: In shipping, pallets need to endure weight and rough handling. The nails used here must be as robust as those in fencing to maintain structural integrity.

Sheds and Gazebos: These outdoor structures, much like fences, are exposed to the elements. Builders of sheds and gazebos rely on weather-resistant materials, drawing a clear parallel to the use of stainless steel coil nails in fencing.

Quality Over Cost: Why Compromising is Never an Option

One of the biggest mistakes a fencing company can make is opting for low-quality materials to save costs. Cheap nails may seem like a good idea initially, but they often lead to rust, weakening, and eventual failure. Imagine the frustration of a customer calling you back just months after installation to fix a collapsed fence.

The same holds true across other trades. Flooring professionals avoid low-grade adhesives to prevent lifting planks, and industrial manufacturers steer clear of weak metals that can cause machinery breakdowns. In the fence business, the mantra is simple: invest in quality, and the results will speak for themselves. Using trusted products like stainless steel coil nails ensures durability and customer satisfaction.

Supply Chain and Material Shortages: A Challenge Across Industries

One of the most significant challenges in the fence business—and many others—is the non-availability of high-quality materials. Delays in getting the right fence coil nails or other essential supplies can disrupt schedules and strain customer relationships. To combat this, successful businesses prioritize finding reliable manufacturers and suppliers from the very beginning.

This strategy is not unique to fencing. In the pallet and crating industry, companies often source materials from multiple suppliers to avoid shortages. Flooring businesses establish partnerships with timber providers for consistent quality and availability. Similarly, fencing companies should focus on building strong supply chains, ensuring that even during global disruptions, essentials like aluminum fence nails are always on hand.

Mindset for Success: Lessons from the Fencing Business

Running a successful fence company—or any business—requires more than technical skills. It takes a mindset of resilience, adaptability, and forward-thinking. Fence professionals know that every project comes with its challenges, from uneven terrains to tight deadlines. Their ability to problem-solve and innovate is what sets them apart.

The same principles apply to entrepreneurs in other fields. Whether it’s a flooring specialist finding ways to perfect installations in old houses or an industrial manufacturer adapting to new technology, success comes to those who embrace challenges. A forward-thinking mindset also includes planning for the future, like investing in high-quality coil nails for fencing to reduce long-term costs and ensuring your business remains competitive.

The USA Economy in 2025: Opportunities and Challenges

As we look toward 2025, the USA economy is expected to see growth in construction and infrastructure sectors, which bodes well for the fence industry. However, challenges like inflation and potential supply chain disruptions remain on the horizon. Fence businesses must stay informed and agile, adapting their strategies to navigate these changes.

For instance, businesses might consider diversifying their product offerings or exploring innovative materials like eco-friendly fences. Keeping a close eye on the market for tools like stainless steel nails and establishing strong partnerships with manufacturers can also help mitigate risks. The companies that plan strategically and prioritize quality will be best positioned to thrive.

Philosophy of Craftsmanship: The Human Element

At its core, the fence business is about more than just tools and materials. It’s about the people—the hardworking experts who put their sweat and skill into every project. Craftsmanship isn’t just about precision; it’s about pride in your work and a commitment to doing the job right.

This philosophy is evident in every trade. Flooring installers measure each plank with meticulous care, industrial workers ensure every component meets rigorous standards, and gazebo builders pay attention to every detail to create structures that inspire. In fencing, this dedication shines through in the choice of materials like stainless coil nails, the precision of every cut, and the satisfaction of a job well done.

Practical Tips for Aspiring Fence Professionals

If you’re considering entering the fence business or looking to improve your craft, here are some practical tips:

1. Invest in Quality Materials: Using products like stainless steel coil nails ensures durability and reduces maintenance costs.

2. Build Strong Supplier Relationships: Reliable manufacturers are your backbone; find ones that deliver consistently.

3. Embrace Technology: Modern tools like advanced nailers can significantly improve efficiency and precision.

4. Learn from Other Trades: Observe best practices in industries like flooring and industrial manufacturing to refine your methods.

5. Stay Adaptable: Be prepared to face challenges, from material shortages to changing customer preferences.

The Future of the Fence Business: Building Legacies

The fence business in the USA is more than just a trade; it’s a reflection of resilience, innovation, and the enduring spirit of craftsmanship. From choosing the right tools and materials to navigating economic challenges, this industry exemplifies what it means to build with purpose and pride.

As we approach 2025 and beyond, let’s celebrate the professionals who make this industry remarkable. With their dedication, the support of high-quality materials like fence coil nails, and a mindset of continuous improvement, they’re not just building fences—they’re building legacies.

0 notes

Text

Pallet Truck Rental: A Comprehensive Guide to Choosing the Right Equipment

Pallet trucks, also known as pallet jacks, are essential for efficiently moving and lifting pallets within warehouses, distribution centers, and other industrial settings. If you need a pallet truck for a short-term project or seasonal peak, renting can be a cost-effective and flexible solution. In this guide, we’ll explore the benefits of pallet truck rent, the types available, and key considerations to help you make an informed decision.

Benefits of Renting a Pallet Truck

Renting a pallet truck offers several advantages compared to purchasing, especially if you need the equipment for a limited time. Here are some key benefits of pallet truck rental:

1. Cost-Effectiveness

Renting can be more affordable than buying, particularly if you need the pallet truck for a short period. Rental agreements often include maintenance and repair services, reducing your overall costs and financial risk.

2. Flexibility

Rental options offer flexibility, allowing you to choose the right pallet truck for your specific needs and rental duration. You can easily adjust the rental agreement based on changing requirements, whether you need the truck for a few weeks, months, or longer.

3. Access to New Equipment

Renting provides access to the latest models and technology without the upfront investment required for purchasing. This allows you to benefit from advanced features and improved efficiency without worrying about equipment obsolescence.

4. Maintenance and Support

Most rental agreements include maintenance and support services, ensuring that the pallet truck remains in good working condition. This minimizes downtime and alleviates the hassle of managing repairs and upkeep.

Types of Pallet Trucks Available for Rent

When considering pallet truck rent, it’s important to understand the different types of pallet trucks and their specific uses. Here are the main types you may encounter:

1. Manual Pallet Trucks

Manual pallet trucks are operated by hand and use a hydraulic pump to lift and lower loads. They are ideal for lighter loads and smaller facilities where the handling frequency is moderate. Manual pallet trucks are cost-effective and simple to use, making them a good choice for occasional material handling needs.

2. Electric Pallet Trucks

Electric pallet trucks are powered by batteries and designed for heavier loads and continuous use. They offer greater lifting power and efficiency compared to manual pallet trucks and are suitable for larger warehouses and distribution centers. Electric pallet trucks reduce physical effort and improve productivity, making them ideal for indoor environments where low emissions and noise are important.

3. High-Lift Pallet Trucks

High-lift pallet trucks can elevate loads to a higher height, facilitating easier loading and unloading at different levels. They are useful for tasks that involve working with pallets at various heights, improving ergonomics and efficiency.

4. Rough Terrain Pallet Trucks

Rough terrain pallet trucks are built to handle uneven surfaces and outdoor environments. They feature rugged wheels and durable construction, making them suitable for use on construction sites, outdoor storage areas, and other challenging conditions.

5. Stainless Steel Pallet Trucks

Stainless steel pallet trucks are designed for environments where hygiene and corrosion resistance are crucial, such as food processing or pharmaceutical industries. They are durable, easy to clean, and resistant to harsh conditions.

Key Considerations When Renting a Pallet Truck

To ensure you select the right pallet truck for your needs, consider the following factors:

1. Load Capacity

Determine the maximum load capacity required for your operations. Pallet trucks come in various capacities, typically ranging from 1 ton to 5 tons or more. Choose a pallet truck that can safely handle the weight of your pallets and any additional loads.

2. Lift Height

Consider the lift height needed for your tasks. High-lift pallet trucks offer the ability to raise loads to various heights, which can improve ergonomics and efficiency. Ensure the pallet truck’s lift height matches your requirements for loading and unloading.

3. Warehouse Layout

Evaluate the layout of your warehouse or facility, including aisle widths and surface conditions. Choose a pallet truck that is suitable for your workspace and can navigate through aisles and around obstacles effectively.

4. Rental Duration

Assess how long you will need the pallet truck and choose a rental agreement that aligns with your timeline. Rental terms can vary, so select an option that provides the flexibility you need for your project duration.

5. Power Source

For electric pallet trucks, consider the power source and battery type. Electric pallet trucks are available with different battery options, including lead-acid and lithium-ion. Choose a battery type that fits your operational needs and maintenance preferences.

Tips for Finding the Best Pallet Truck Rental Deals

To make the most of your rental and find the best deals on pallet truck rental, follow these tips:

1. Work with Reputable Rental Providers

Choose a reputable rental provider with a track record of offering high-quality equipment and excellent customer service. A reliable provider will help you select the right pallet truck and provide support throughout the rental period.

2. Compare Rental Rates

Compare rental rates from different providers to find the best deal. Consider factors such as rental duration, included services, and any additional fees or charges. Ensure you understand the total cost of the rental and any terms and conditions.

3. Inspect the Equipment

Before finalizing the rental, inspect the pallet truck to ensure it is in good working condition. Check for any signs of wear and tear, such as hydraulic leaks, worn tires, or damaged components. Request a maintenance report if available.

4. Review the Rental Agreement

Thoroughly review the rental agreement, including terms and conditions, insurance coverage, and maintenance responsibilities. Ensure you understand your obligations and the provider’s responsibilities to avoid any surprises.

5. Consider Training and Support

Check if the rental provider offers training and support for operating the pallet truck. Proper training ensures safe and efficient use of the equipment, reducing the risk of accidents and improving productivity.

Conclusion

Renting a pallet truck can provide a flexible and cost-effective solution for your material handling needs, especially for short-term projects or seasonal peaks. By understanding the different types of pallet trucks, key considerations, and tips for finding the best rental options, you can make an informed decision and select the right equipment for your operations.

Working with reputable rental providers, comparing options, and ensuring proper inspection and training will help you get the most out of your pallet truck rental and enhance your material handling efficiency.

0 notes

Text

Material Handling Equipment Manufacturer & Exporter in India

Material Handling Equipment Manufacturer - Future Industries Pvt. Ltd. is Leading Exporter of Pallet Truck, Pallet Truck Exporter in India, Pallet Truck Manufacturer in Ahmedabad, Electric Pallet Truck Manufacturer, Stainless Steel High Lift Truck Manufacturer, High Lift Pallet Truck Manufacturer, High Lift Pallet Truck Manufacturer in India

0 notes

Text

Clean room applications need several types of equipment that are perfectly made and shouldn’t react to the water or any other harassing chemicals. Superlift Material Handling offers 316 stainless steel cleanroom drum lifts that work well within any environment without compromising cleanliness. Visit the website or dial 1.800.884.1891 for more information!

0 notes

Text

How Do I Maintain a Round Bar for Longevity?

Shashwat Stainless Inc. is the largest Round Bars Manufacturers in India. One of our popular products in the Metal Market is Round Bars. Round bars, also known as rods or solid bars, are cylindrical metal rods usually composed of stainless steel, aluminum, or brass. When it comes to extending the life of round bars, proper care is essential. Round bars, which are often used in many sectors for structural support, machining, and fabrication, require special care to retain their quality and durability over time. In this detailed article, we'll look at the most important strategies for keeping round bars looking good for a long time.

Understanding Round Bars

Round bars are cylindrical metal bars having a circular cross-section. They are often referred to as round steel bars or rods. They are used in many different sectors, including aerospace, automotive, manufacturing, and construction. They are often composed of carbon steel, stainless steel, or alloy steel.

Proper Handling and Storage

Proper handling and storage of round bars is one of the most important aspects impacting their lifetime. To avoid damage and corrosion, round bars must be handled carefully during shipping and storage. Here are some important considerations:

Handling:

Make sure round bars are securely fastened when being transported to avoid rolling or moving.

To properly handle big bars, use the proper lifting equipment, such as cranes or forklifts.

Steer clear of falling or hitting the bars as this may result in surface deformation or damage.

Storage:

To reduce the danger of corrosion, store round bars in a clean, dry environment.

To avoid moisture absorption, keep the bars elevated using pallets or racks.

Protect the bars against harsh factors including high temperatures, humidity, and corrosive chemicals.

Regular Inspection and Maintenance

Routine inspection and maintenance are essential for identifying any signs of damage or deterioration early on and addressing them promptly. Here's what you should include in your maintenance routine:

Visual Inspection:

Regularly inspect round bars for signs of surface damage, such as scratches, dents, or rust.

Check for any cracks, fractures, or other structural issues that may compromise the integrity of the bars.

Pay attention to any changes in appearance or dimensions that could indicate wear or corrosion.

Cleaning and Lubrication:

Clean round bars regularly using a mild detergent and water to remove dirt, debris, and surface contaminants.

Dry the bars thoroughly after cleaning to prevent moisture buildup.

Apply a thin layer of lubricant, such as oil or grease, to protect the surface and reduce friction during machining or fabrication processes.

Corrosion Protection:

Implement corrosion protection measures, such as applying rust inhibitors or coatings, to safeguard round bars from environmental corrosion.

Monitor the effectiveness of corrosion protection methods and reapply as necessary to maintain optimal protection.

Proper Machining and Fabrication Practices

It's critical to adhere to standard practices while machining or fabrication round bars in order to reduce stress and avoid damage. Here are some pointers to think about:

Cutting and Drilling:

Use proper cutting tools and procedures to reduce heat generation and prevent the material from overheating.

Use suitable coolant systems to disperse heat and lubricate cutting surfaces during drilling or milling operations.

Choose modest and steady cutting rates to avoid excessive friction and vibration, which can cause surface damage.

Welding and Joining:

Adhere to the specified welding processes and guidelines to guarantee correct fusion and reduce the possibility of weld imperfections.

To lessen thermal loads and avoid cracking during welding, preheat the round bars as needed.

Without sacrificing the integrity of the bars, create strong and long-lasting weld connections by using suitable filler metals and welding procedures.

Conclusion

Maintaining round bars for longevity requires a proactive approach that includes proper handling, storage, inspection, and maintenance practices. By following the tips outlined in this guide, you can ensure that your round bars remain in optimal condition, providing reliable performance for your applications.

Follow For More Detail

Website: shashwatstainless.com

Product Source: Round Bar Supplier in India

Other Product Source: Nickel Alloy Seamless Pipe Manufacturer in India.

0 notes

Text

HUIZE SS304 SEMI ELECTRIC PALLET JACK IS EASY OPTION TO IMPTOVE EFFICIENCY

This semi electric pallet stacker is made of high quality stainless steel with excellent anti-corrosion and anti-rust ability, whether in wet or heavily polluted environments, it can maintain its everlasting bright appearance and its durability is beyond imagination.

#jack #lift #ss304 #forklift #lift #lifting #equipment #LiftTruck #pallets #logistics #stacker #ReachTruck

0 notes

Text

Compelling Reasons to Buy Stainless Steel Low Profile Table

Stainless steel low-profile tables are mostly used in different fields due to their unique characteristics like reduced height and sleek design. Loaded with outstanding industry-friendly features like versatility, durability, and aesthetic appeal, they make the working environment smooth and free from clutter. Due to these outstanding features, one can buy stainless steel low profile table to make the industrial application even more efficient.

Application of Stainless Steel Low Profile Table

Here is the major application of the stainless steel low-profile table.

Manufacturing and Industrial Application

These low-profile tables are used extensively in various industrial applications to smooth out processes while carrying out different manufacturing applications. Their robust construction allows them to withstand heavy machinery and equipment, and their low profile makes them easy for industrial operators to access. These tables work well, particularly at workstations where workers have to move large or heavy items.

Food Processing Industry

When it comes to the food processing industry, they ought to be safe from all odds, and in such conditions, low-profile stainless steel tables become essential. This is because the material is completely non-porous, resistant to corrosion, and easy to clean, so there will not be much effort required to ready the table for the next process. These tables offer ample workspace for food preparation and can withstand the constant cleaning and sanitizing required in these environments.

Medical and Laboratory

Stainless steel is perfect for use in medical and laboratory environments because it is resistant to germs and other diseases. Low profile tables minimize the danger of strain and injury for laboratory workers and other medical professionals by providing a sturdy surface for tools and equipment and by having a lower height that may be modified to meet individual ergonomic needs.

Retail Industry

These tables are used for product displays in retail environments. Their sleek, contemporary look improves the merchandise's aesthetic appeal. The low profile makes it simple for customers to interact with the products, which could improve engagement and lead to a rise in sales.

Residential Application

Low-profile stainless steel tables provide fashionable and useful furniture for homes. They are especially well-liked in industrial and contemporary home design styles. Kitchens, dining rooms, and workplaces can all benefit from their robustness and resilience to stains and damage.

Why Use Stainless Steel Low Profile Table?

The best advantages of these stainless steel low-profile tables are mentioned here.

Durable and Hygienic

Stainless steel is well known for being strong and resilient to deterioration. This material is suitable for low profile tables that must withstand severe usage and weather without losing structural integrity. They are therefore an affordable investment for both home and business use. Because stainless steel is non-porous and does not retain bacteria, maintaining a sterile atmosphere is simple. In environments where cleanliness is crucial, such as hospitals, labs, and food preparation areas, this is especially crucial.

Corrosion Resistance and Aesthetically Rich

Stainless steel's clean and contemporary appearance improves any space's aesthetics. Because of its sophisticated reflecting surface, it's a popular option for high-end kitchens, cutting-edge labs, and chic retail spaces. These tables will always look good and work well because stainless steel is resistant to rust and corrosion, even in the presence of chemicals and moisture. This is especially helpful in contexts like the industrial and culinary industries where exposure to these components occurs often.

When you buy a stainless steel low-profile table, you have plenty of reasons to rejoice. From durability, aesthetic appeal, and versatility to making them for a wide range of applications, these tables can make the work environments safe and sound. Whether you install these tables in any industrial setting, culinary environment, or medical facility, they can deliver the best results as per your requirement by optimizing the space and making the work environment even more productive.

Resource: https://superliftcanada.wordpress.com/2024/06/18/compelling-reasons-to-buy-stainless-steel-low-profile-table/

#Buy stainless steel lift trucks online#Stainless steel lift table#Stainless steel double lift table#Stainless steel triple lift table#Stainless steel ground level lifts#Stainless steel mezzanine lifts#Stainless steel column lifts#Electric stainless steel lifts#Cleanroom electric lifts#Cleanroom lift tables#Cleanroom stainless lifts#Cleanroom stainless mezzanine lifts#Mezzanine stainless lifters#Buy stainless steel lift tables online#buy stainless steel pallet lift table online#Order stainless steel scissor lifts online#Buy stainless steel platform lift online#hydraulic scissor lift#high lift table#heavy duty scissor lifts#stainless steel lift trucks#stainless manlifts#Buy Stainless Steel Portable Lift Table online#Stainless Steel Triple Scissors Lift Tables#Stainless Steel Low Profile Lift Table#Stainless Steel Ergonomic Lift Table#Buy Stainless Steel Low Profile Table#Stainless Steel Pallet Lifts#Stainless Steel Lift Table#Stainless Steel Uplift Pallet Trucks

0 notes

Text

Stainless steel material handling equipment is mainly used in cleanroom operations. Pallet stainless steel is designed to have no sandwiched material and no cracks or crevices. We at Superlift Material Handling Inc use the highest grade stainless steel to make these equipment that deliver the best result. Visit our website or dial 1.800.884.1891 for more information!

0 notes

Text

Best weighing scales to buy for industrial businesses

Industrial floor scale at Kampala scale suppliers

An industrial floor scale which weighs incorrectly can lead to challenges such as customers dissatisfaction, invoicing inaccuracies, failure to comply with business regulations, safety problems, overloaded vehicles and many other, which can slow down organizational supply chain process while substantially putting productivity at risk

Why are Commercial Floor Scales are Essential For Warehouses

When it comes to distribution and manufacturing industries, commercial floor scales play a pivotal role in daily business activities. From pallet weighs for logistics to quality control checks for huge batches of produced product floor scales offer several useful weighing options.

1. Easy loading options with warehouse floor scales:

Warehouse scales are portable in nature and offer a low-profile structure to promote easy loading either by forklift or by hand. Some scale accessories also contain ramps that permit the materials to be wheeled onto the scale.

2.Waterproof platform scale features:

A stainless-steel platform scale can even perform efficiently in harsh environments due to the scale’s IP rating. This implies the scale provides a specific degree of water resistance, which is convenient for commercial use.

Types of Platform Scales from Accurate Weighing Scales Ltd

Weighing Platforms: Made of extremely sturdy, rugged and durable stainless steel or plastic powder coated steel, the platforms with wide spaces come in models namely, BSB, AGU, BHB, BSR, BSW, BXT, MPH, and BHA respectively. The scales can have optional ISB/ISC indicator stands as well.

Weighing Scales: These come with fixed indicator stands with models named as TCS, A12, ADAM, KOBASTOR, HIWEIGH, METTLER TOLEDI, AGU, AKX, ATK, BBK, BBQ, BBX, BSA, BSD, BSE, BSX, K9T, KPC, LOG, MP, PBS, and TZ respectively.

Notable Features

1. Load cells with IP65/IP66 protection. In other words, the load cells are fully protected from the ingress of dust and low-pressure jets of water

2. Bright FSTN backlit LCD display for easy reading, even under the sun

3. IP67 rated indicators that are fully dust protected and can withstand immersion in water between 15cm to 1m of depth

4. RS232 interface for easy connectivity to a printer and computer

5. Optional WIFI and Bluetooth

Use of Washable Scales in Weighing Food

Washdown scales are widely used in the food industry for various applications like weighing fruits and vegetables, etc. For instance, a sack of potatoes not only weigh heavy but also makes the scale pan dirtier. And over time a large scale of dirt accumulates on the scale pan. To overcome this issue, a washable scale remains as the best choice. The scale is not only robust but easy to clean and use.

The heavy weight of a potato sack makes lifting a challenge. The washable scale has a low weighing pan that helps in placing a heavy sack of potatoes on the pan without requiring any extended lifting. Moreover, sacks of vegetables are sure to carry dirt and bacteria, and can easily contaminate objects that they come in contact with.

The presence of a protected load cell chamber in the scale makes it cleaning easy without any possibility of damaging the internal parts while maintaining the hygiene of the food.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance.

For inquiries on deliveries contact us

Office +256 705 577 823, +256 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

0 notes

Text

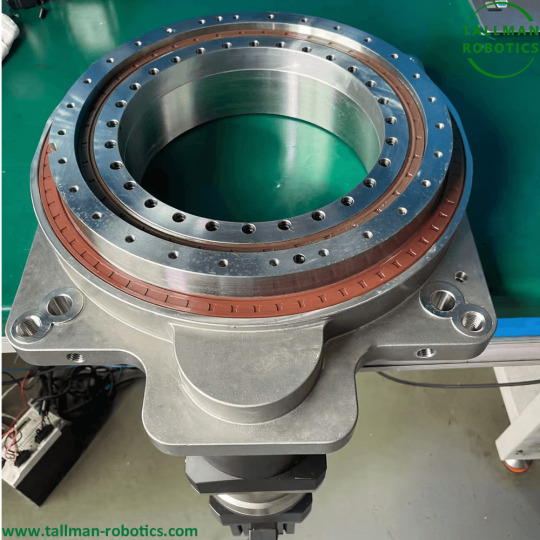

Large Aperture Hollow Indexers

Large Aperture Hollow Indexers from Tallman Robotics Limited

450 stainless steel series: load weight 1.0 ton Suitable for (working conditions with high overturning force during side mounted lifting) Rotating diameter 400mm, middle hole 270mm Repetitive positioning accuracy of 60 arcseconds Adapted to 2kw-5kw or 130-150 stepper motors Large aperture hollow indexers are devices used in various industries, including manufacturing, automation, and robotics, for precise positioning and rotation of heavy loads. These indexers are designed with a large central hole or aperture, which allows for easy integration with other equipment or for routing cables, hoses, or other utilities through the center. Key features and benefits of large aperture hollow indexers include: 1. High precision: These indexers are known for their accuracy and repeatability in positioning, ensuring that the workpieces are always aligned correctly during the production process. This results in higher quality products and reduced waste. 2. Load capacity: The large aperture hollow indexers are designed to handle heavy loads without compromising on accuracy and precision. This makes them ideal for industries that require the handling of large and heavy components. 3. Versatility: The large central hole in these indexers allows them to be easily integrated with other equipment, such as robotic arms, cameras, or sensors. This means they can be adapted for various applications, making them a versatile choice production lines. 4. Flexibility: The large hollow center also provides flexibility for routing cables, hoses, or other utilities through the indexer. This can help reduce clutter and improve organization in the production environment. 5. Reduced maintenance: Large aperture hollow indexers are often designed with low-maintenance components, such as wear-resistant materials and sealed bearings. This can help reduce downtime and maintenance costs over time. 6. Customization: Many manufacturers offer custom designs and configurations for large aperture hollow indexers, which means they can tailored meet specific application requirements. Applications of large aperture hollow indexers may include: 1. Automotive industry: These indexers can be used for processes such as assembling and welding large automotive components like chassis and body panels. 2. Aerospace industry: Indexers may be used for precise positioning of large aerospace components during assembly or inspection processes. 3. Machining centers: Hollow indexers can be integrated with CNC machines for accurate positioning and rotation of workpieces during milling, drilling, or grinding operations. 4. Packaging and material handling: Large aperture indexers can be used in automated packaging lines for precise positioning of products, as well as for handling and positioning large containers or pallets in warehouses. 5. Medical and pharmaceutical industries: These indexers can be used for applications such as assembling and inspecting medical devices or for precise positioning of pharmaceutical products during packaging processes. Overall, large aperture hollow indexers offer a high level of precision and flexibility for various industries, making them an essential component in many production and automation processes. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#ChinaHighQualityProgremmableRotaryIndexingTable#ChinaLargeApertureRotaryTableManufacturers#HighworkloadCNCIndexingTable#HollowApertureRotaryTableHighPrecisionmotorizedrotarytable#MotorizedRotaryTable#ProgrammableHollowRotaryTableServoIndexingTable#Rotarytablelargehollowbore#ServoRotaryTable

0 notes

Text

Fence Building in the USA: Tools, Grit, and the Mindset of Master Craftsmen

The fence business in the USA is built on a foundation of hard work, precision, and pride in craftsmanship. It’s not just about enclosing spaces; it’s about creating structures that serve as protectors, dividers, and works of art. Professionals in this field rely on a blend of experience, the right tools, and high-quality materials to make every project a success. This blog dives into the world of fence building, highlighting the tools and techniques that define the trade and drawing comparisons with other industries like flooring, industrial manufacturing, and outdoor structures. Along the way, we’ll explore what it takes to succeed in business and what 2025 might hold for the USA economy.

Tools of the Trade: What Keeps the Fence Business Standing Tall?

Every craft has its tools, and fencing is no exception. At the heart of this trade is the humble yet indispensable fence coil nail. Whether you’re constructing a sturdy privacy fence or an elegant picket design, these nails are what keep the structure together. The quality of the nails determines not just the durability of the fence but also its ability to withstand harsh weather and time.

For projects demanding exceptional strength, stainless steel fence nails are a popular choice. These nails resist rust and maintain their integrity even in the most challenging environments. Similarly, stainless coil nails are preferred by professionals looking for longevity and reliability in their work. On the other hand, aluminum coil nails bring a lightweight and corrosion-resistant option, especially suited for decorative fencing or areas where moisture is a concern.

Lessons from Other Trades: Tools Across Industries

The importance of using the right tools and materials isn’t unique to fencing. Let’s take a look at some other industries and draw parallels:

Flooring Installations: Precision is key in flooring, where nailers and fasteners ensure planks are laid seamlessly. Just as a poorly fastened floorboard can disrupt a room’s harmony, a fence with subpar nails can fail to deliver both function and form.

Industrial Manufacturing: Heavy machinery demands high-strength fasteners to hold components together under immense pressure. Similarly, fences require durable coil nails for fencing to remain intact against strong winds and external forces.

Pallets and Crating: In shipping, pallets need to endure weight and rough handling. The nails used here must be as robust as those in fencing to maintain structural integrity.

Sheds and Gazebos: These outdoor structures, much like fences, are exposed to the elements. Builders of sheds and gazebos rely on weather-resistant materials, drawing a clear parallel to the use of stainless steel coil nails in fencing.

Quality Over Cost: Why Compromising is Never an Option

One of the biggest mistakes a fencing company can make is opting for low-quality materials to save costs. Cheap nails may seem like a good idea initially, but they often lead to rust, weakening, and eventual failure. Imagine the frustration of a customer calling you back just months after installation to fix a collapsed fence.

The same holds true across other trades. Flooring professionals avoid low-grade adhesives to prevent lifting planks, and industrial manufacturers steer clear of weak metals that can cause machinery breakdowns. In the fence business, the mantra is simple: invest in quality, and the results will speak for themselves. Using trusted products like stainless steel coil nails ensures durability and customer satisfaction.

Supply Chain and Material Shortages: A Challenge Across Industries

One of the most significant challenges in the fence business—and many others—is the non-availability of high-quality materials. Delays in getting the right fence coil nails or other essential supplies can disrupt schedules and strain customer relationships. To combat this, successful businesses prioritize finding reliable manufacturers and suppliers from the very beginning.

This strategy is not unique to fencing. In the pallet and crating industry, companies often source materials from multiple suppliers to avoid shortages. Flooring businesses establish partnerships with timber providers for consistent quality and availability. Similarly, fencing companies should focus on building strong supply chains, ensuring that even during global disruptions, essentials like aluminum fence nails are always on hand.

Mindset for Success: Lessons from the Fencing Business

Running a successful fence company—or any business—requires more than technical skills. It takes a mindset of resilience, adaptability, and forward-thinking. Fence professionals know that every project comes with its challenges, from uneven terrains to tight deadlines. Their ability to problem-solve and innovate is what sets them apart.

The same principles apply to entrepreneurs in other fields. Whether it’s a flooring specialist finding ways to perfect installations in old houses or an industrial manufacturer adapting to new technology, success comes to those who embrace challenges. A forward-thinking mindset also includes planning for the future, like investing in high-quality coil nails for fencing to reduce long-term costs and ensuring your business remains competitive.

The USA Economy in 2025: Opportunities and Challenges

As we look toward 2025, the USA economy is expected to see growth in construction and infrastructure sectors, which bodes well for the fence industry. However, challenges like inflation and potential supply chain disruptions remain on the horizon. Fence businesses must stay informed and agile, adapting their strategies to navigate these changes.

For instance, businesses might consider diversifying their product offerings or exploring innovative materials like eco-friendly fences. Keeping a close eye on the market for tools like stainless steel nails and establishing strong partnerships with manufacturers can also help mitigate risks. The companies that plan strategically and prioritize quality will be best positioned to thrive.

Philosophy of Craftsmanship: The Human Element

At its core, the fence business is about more than just tools and materials. It’s about the people—the hardworking experts who put their sweat and skill into every project. Craftsmanship isn’t just about precision; it’s about pride in your work and a commitment to doing the job right.

This philosophy is evident in every trade. Flooring installers measure each plank with meticulous care, industrial workers ensure every component meets rigorous standards, and gazebo builders pay attention to every detail to create structures that inspire. In fencing, this dedication shines through in the choice of materials like stainless coil nails, the precision of every cut, and the satisfaction of a job well done.

Practical Tips for Aspiring Fence Professionals

If you’re considering entering the fence business or looking to improve your craft, here are some practical tips:

1. Invest in Quality Materials: Using products like stainless steel coil nails ensures durability and reduces maintenance costs.

2. Build Strong Supplier Relationships: Reliable manufacturers are your backbone; find ones that deliver consistently.

3. Embrace Technology: Modern tools like advanced nailers can significantly improve efficiency and precision.

4. Learn from Other Trades: Observe best practices in industries like flooring and industrial manufacturing to refine your methods.

5. Stay Adaptable: Be prepared to face challenges, from material shortages to changing customer preferences.

The Future of the Fence Business: Building Legacies

The fence business in the USA is more than just a trade; it’s a reflection of resilience, innovation, and the enduring spirit of craftsmanship. From choosing the right tools and materials to navigating economic challenges, this industry exemplifies what it means to build with purpose and pride.

As we approach 2025 and beyond, let’s celebrate the professionals who make this industry remarkable. With their dedication, the support of high-quality materials like fence coil nails, and a mindset of continuous improvement, they’re not just building fences—they’re building legacies.

0 notes

Text

Pallet Trucks for Sale: A Comprehensive Guide to Making the Right Purchase

Pallet trucks, also known as pallet jacks, are crucial tools for moving and lifting pallets in warehouses, distribution centers, and manufacturing facilities. They streamline the handling of goods and materials, making them an indispensable part of many industrial operations. If you’re in the market for pallet trucks, understanding the types available, key features, and essential factors to consider will help you make an informed decision.

In this blog, we’ll explore the different types of pallet trucks, important considerations when buying, and tips for finding the best deals on pallet trucks sale.

Types of Pallet Trucks

When searching for pallet trucks for sale, it’s important to understand the different types available and their specific applications. Here are the primary types of pallet trucks:

1. Manual Pallet Trucks

Manual pallet trucks are operated by hand and use hydraulic pumps to lift and lower the load. They are ideal for lighter loads and smaller facilities where the handling frequency is moderate. Manual pallet trucks are cost-effective, easy to use, and suitable for businesses with occasional material handling needs.

2. Electric Pallet Trucks

Electric pallet trucks are powered by batteries and are designed for heavier loads and continuous use. They offer greater lifting power and efficiency compared to manual pallet trucks, making them suitable for larger warehouses and distribution centers. Electric pallet trucks reduce physical effort, improve productivity, and are ideal for indoor environments where low emissions and noise are important.

3. High-Lift Pallet Trucks

High-lift pallet trucks are designed to elevate the load to a higher height, allowing for easier loading and unloading at different heights. They are useful for tasks that involve working with pallets at various heights and can improve ergonomics and efficiency in material handling.

4. Rough Terrain Pallet Trucks

Rough terrain pallet trucks are built to handle uneven surfaces and outdoor environments. They have rugged wheels and durable construction, making them suitable for use in construction sites, outdoor storage areas, and other challenging conditions.

5. Stainless Steel Pallet Trucks

Stainless steel pallet trucks are designed for use in environments where hygiene and resistance to corrosion are critical, such as food processing, pharmaceuticals, and chemical industries. They are durable, easy to clean, and resistant to harsh conditions.

Key Considerations When Buying a Pallet Truck

To ensure you select the right pallet truck for your needs, consider the following factors:

1. Load Capacity

Determine the maximum load capacity required for your operations. Pallet trucks come in various capacities, typically ranging from 1 ton to 5 tons or more. Choose a pallet truck that can safely handle the weight of your pallets and any additional loads.

2. Lift Height

Consider the lift height needed for your tasks. High-lift pallet trucks offer the ability to raise the load to various heights, which can improve ergonomics and efficiency. Ensure the pallet truck’s lift height matches your requirements for loading and unloading.

3. Warehouse Layout

Evaluate the layout of your warehouse or facility, including aisle widths and surface conditions. Choose a pallet truck that is suitable for your workspace and can navigate through the aisles and around obstacles effectively.

4. Power Source

For electric pallet trucks, consider the power source and battery type. Electric pallet trucks are available with different battery options, including lead-acid and lithium-ion. Choose a battery type that aligns with your operational needs and maintenance preferences.

5. Ergonomics and Comfort

Look for features that enhance operator comfort and ergonomics, such as adjustable handles, ergonomic controls, and easy maneuverability. Operator comfort can impact productivity and safety, so choose a pallet truck that provides a comfortable working environment.

Tips for Finding the Best Deals on Pallet Trucks for Sale

To make the most of your purchase and find the best deals on pallet trucks sale, follow these tips:

1. Work with Reputable Dealers

Choose a reputable dealer with a track record of offering high-quality pallet trucks and excellent customer service. A reliable dealer will provide detailed information about the pallet trucks, including their specifications, condition, and pricing. They can also offer expert advice and support throughout the buying process.

2. Compare Different Models

Don’t settle for the first pallet truck you find. Compare different models from various manufacturers and dealers to evaluate features, pricing, and performance. Consider both new and used pallet trucks to find the best value for your budget.

3. Inspect Used Equipment Carefully

If you’re considering a used pallet truck, inspect it thoroughly to ensure it’s in good working condition. Check for signs of wear and tear, such as hydraulic leaks, worn tires, or damaged components. Request maintenance records and a service history from the dealer to verify the truck’s condition.

4. Consider Financing Options

Many dealers offer financing options to make purchasing a pallet truck more affordable. Explore leasing or payment plans that allow you to spread the cost over time, making it easier to fit the purchase into your budget. Financing options can help you acquire the equipment you need without a large upfront expense.

5. Evaluate Total Cost of Ownership

Consider the total cost of ownership, which includes not only the purchase price but also maintenance, operating costs, and any additional features or accessories. A lower purchase price may result in higher long-term costs, so factor in these additional expenses when making your decision.

Conclusion

Purchasing a pallet truck is an important investment that can greatly impact the efficiency and productivity of your material handling operations. Whether you’re looking for a manual, electric, high-lift, rough terrain, or stainless-steel pallet truck, understanding the different types and key considerations will help you make an informed decision.

By working with reputable dealers, comparing options, and considering financing and total cost of ownership, you can find the perfect pallet truck to meet your needs and enhance your material handling capabilities. Investing in the right pallet truck will contribute to the success and efficiency of your operations.

0 notes