#HighworkloadCNCIndexingTable

Explore tagged Tumblr posts

Text

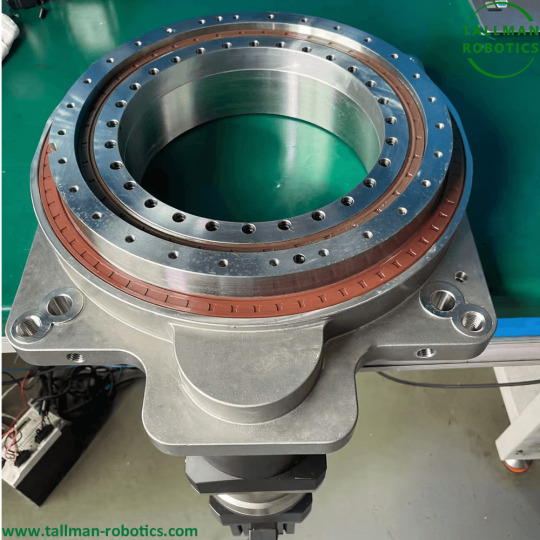

Large Aperture Hollow Indexers

Large Aperture Hollow Indexers from Tallman Robotics Limited

450 stainless steel series: load weight 1.0 ton Suitable for (working conditions with high overturning force during side mounted lifting) Rotating diameter 400mm, middle hole 270mm Repetitive positioning accuracy of 60 arcseconds Adapted to 2kw-5kw or 130-150 stepper motors Large aperture hollow indexers are devices used in various industries, including manufacturing, automation, and robotics, for precise positioning and rotation of heavy loads. These indexers are designed with a large central hole or aperture, which allows for easy integration with other equipment or for routing cables, hoses, or other utilities through the center. Key features and benefits of large aperture hollow indexers include: 1. High precision: These indexers are known for their accuracy and repeatability in positioning, ensuring that the workpieces are always aligned correctly during the production process. This results in higher quality products and reduced waste. 2. Load capacity: The large aperture hollow indexers are designed to handle heavy loads without compromising on accuracy and precision. This makes them ideal for industries that require the handling of large and heavy components. 3. Versatility: The large central hole in these indexers allows them to be easily integrated with other equipment, such as robotic arms, cameras, or sensors. This means they can be adapted for various applications, making them a versatile choice production lines. 4. Flexibility: The large hollow center also provides flexibility for routing cables, hoses, or other utilities through the indexer. This can help reduce clutter and improve organization in the production environment. 5. Reduced maintenance: Large aperture hollow indexers are often designed with low-maintenance components, such as wear-resistant materials and sealed bearings. This can help reduce downtime and maintenance costs over time. 6. Customization: Many manufacturers offer custom designs and configurations for large aperture hollow indexers, which means they can tailored meet specific application requirements. Applications of large aperture hollow indexers may include: 1. Automotive industry: These indexers can be used for processes such as assembling and welding large automotive components like chassis and body panels. 2. Aerospace industry: Indexers may be used for precise positioning of large aerospace components during assembly or inspection processes. 3. Machining centers: Hollow indexers can be integrated with CNC machines for accurate positioning and rotation of workpieces during milling, drilling, or grinding operations. 4. Packaging and material handling: Large aperture indexers can be used in automated packaging lines for precise positioning of products, as well as for handling and positioning large containers or pallets in warehouses. 5. Medical and pharmaceutical industries: These indexers can be used for applications such as assembling and inspecting medical devices or for precise positioning of pharmaceutical products during packaging processes. Overall, large aperture hollow indexers offer a high level of precision and flexibility for various industries, making them an essential component in many production and automation processes. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#ChinaHighQualityProgremmableRotaryIndexingTable#ChinaLargeApertureRotaryTableManufacturers#HighworkloadCNCIndexingTable#HollowApertureRotaryTableHighPrecisionmotorizedrotarytable#MotorizedRotaryTable#ProgrammableHollowRotaryTableServoIndexingTable#Rotarytablelargehollowbore#ServoRotaryTable

0 notes