#Pallet stainless steel

Explore tagged Tumblr posts

Text

Stainless steel material handling equipment is mainly used in cleanroom operations. Pallet stainless steel is designed to have no sandwiched material and no cracks or crevices. We at Superlift Material Handling Inc use the highest grade stainless steel to make these equipment that deliver the best result. Visit our website or dial 1.800.884.1891 for more information!

0 notes

Text

When it comes to washing any part of the industry using reliable equipment that can hold your load along with the washing agent, then you should choose stainless steel lift tables for this task. These are designed for your heaviest wash down requirements. Superlift Material Handling offers quality lift tables that can rightly meet your needs. Call on 1.800.884.1891 for the information.

#material handling tugger#superlift canada#stainless steel lift table#superlift material handling#super lift#paper roll lifter and rotator#superlift#tuggers material handling#stainless steel pallets#stainless steel lift tables

0 notes

Text

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

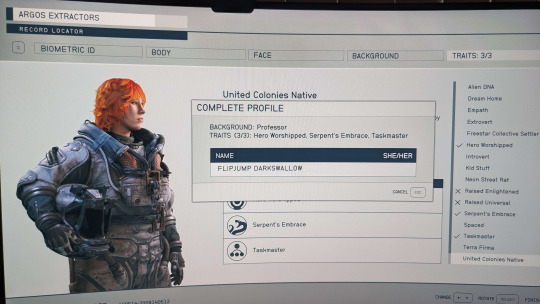

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

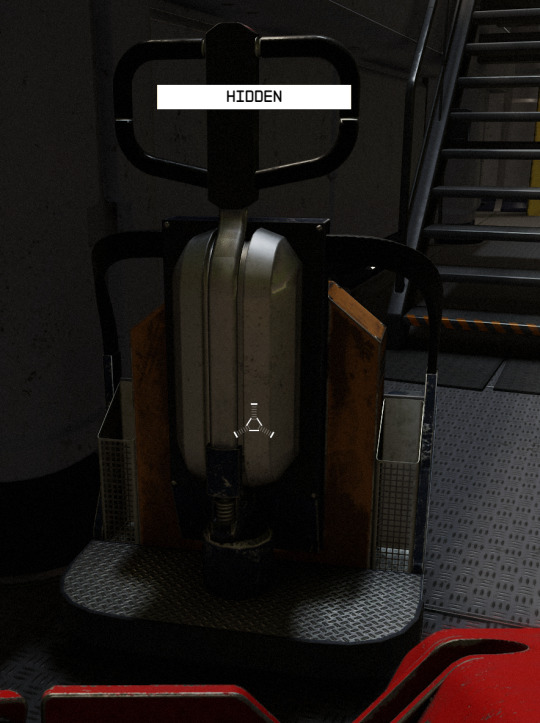

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

47 notes

·

View notes

Text

Chapter Five: Small and Needy

Azul needs an even more simple favour from Floyd. Surely there is no possible way he can mess this up.

Chapter contains no warnings, but Riddle IS a tragic, deprived bby who needs cuddles and would probably accept them from literally anyone at this point.

Previous | Next Chapter | Fic Index

A03 Link: https://archiveofourown.org/works/46007587?view_full_work=true

Floyd tosses a stack of cardboard boxes into the walk-in freezer, then grumpily leans against the wall to let the chill soak into his skin. Azul wants him to move a pallet of perishable ingredients from the loading dock into the freezer before they get icky, but he seriously isn’t into it. Sooooooo BORED. Azul is acting like a stupid clam, burying himself in the sand and texting him instructions without even showing his face. He HATES it when he does that.

Floyd places both hands in the small of his back and arches, looking at the profile of his reflection in the stainless steel freezer wall. He doesn’t have a bump or anything, but he swears he can feel the extra weight from his new hitchhikers.

‘Doesn’t matter. They’ll get absorbed anyway. Gotta go before Azul yells at me... uuuugh... this sucks.' Floyd kicks the freezer door closed and walks down the hall, rubbing his eyes. The loading dock is just past the VIP room. He has half a mind to sneak inside and see if he can persuade Azul to have sex on the desk~

“…and I thought we agreed that you would tone down your predatory contracts.”

An evil smile spreads across Floyd’s face. Goldfishie! Lil Goldfishie came to visit Azul! Heh heh heh, yesssss. This is EXACTLY what he needs. Dropping all the dumb, perishable boxes, Floyd lurks in a doorway just outside the room, listening in on the conversation.

“…hearing that one of my freshmen is about to drop out five days before finals because he is convinced that your henchmen are going to EAT him?!”

Floyd winces. Oopsie, sounds like Riddle’s mad he licked that freshman. Sheesh, he hadn’t even taken a bite, it wasn’t that bad…

“A misunderstanding,” Azul soothes. “I negated the rest of his contract. There’s no need for hostility, Riddle…”

“Good. Because I assumed we had a mutually agreed upon set of rules regarding this matter. If I hear one more time that your consultations are doing more harm than good, then I will HAPPILY forbid my dorm from seeking them at all.”

“Your dormmate will pass his finals with flying colours,” Azul replies softly. “As I said before, it was a misunderstanding. And frankly, it’s one that I believe he got the better deal out of.”

“Good. I’m happy to hear it.”

The imperious tap of Riddle’s high-heeled boots walking across the floor approaches the door of the VIP room, and he steps outside with a grumpy sigh. Floyd freezes, hit with a wave of... smells. He can smell Azul's sweat, and while that is both delicious and tempting... it’s barely half of what he’s picking up on. Sweet tarts, strawberry, old books… His insides churn for a moment, and now he feels... bashful? His tummy is doing flippy flips. Why is it doing flips?? THAT IS SO INTERESTING~!

He curls both hands in front of his eye as though holding an invisible spyglass, smiling down at the Riddle’s approaching form. "Hiiiiii Goldfishie~"

An expression rolls over Riddle’s face. It could mean many things, but in this situation, the best translation is most likely ‘why me.’

“Floyd.” He stares straight ahead and walks past him.

“Hmm~” Floyd follows after Riddle. His long legs have no trouble keeping pace as he follows that intriguing smell. “You came all this way to visit, and you're not gonna say hi? Ruuuuuude.”

Riddle’s face is beginning to simmer from peeled-potato pale, to carnation pink. He takes larger steps to try and get away, but it’s a hopeless attempt when Floyd towers head and shoulders over him. His efforts just make him start to limp slightly, which makes Floyd frown. Are his feet in pain?

“Hi,” Riddle finally grumbles.

“Hiiiiii~” Floyd smiles, feeling those butterflies again. He wants Riddle to stay! He wants to keep him here, and get a little closer, and let him find out why his feet are hurting! “Where are you going in such a hurry?”

“Back to Heartslabul. It’s finals week and I need to study. Why are you following me?” Riddle glances back suspiciously. “I don’t have time to entertain your nonsense, if that’s what you’re after.”

“I just spy, with my little eye, that somebody’s limping.” Floyd hums, slipping in front of Riddle to cut him off. “Goldfishie’s feet are hurting.”

“I…” Riddle’s eyes widen in surprise. He limps to a stop, grumpily crossing his arms and looking up at Floyd. “It’s just a blister. Don’t you get those?”

“Ehhhh. Only when I first started walking. Since then, I make sure I wear custom made shoes that fit me just right.” Floyd frowns as the smell becomes laced with something coppery. Blood? That’s one heck of a blister if he can smell blood…

“YOU wear custom shoes?” Riddle sounds incredulous.

“I sure do! These shoes are made for more than walking.” Floyd proudly lifts up his foot to show off his comfy shoes. “They gave us these suuuuper cheap sneakers to wear when we were first going through land boot camp. They were all too small for me, but I didn’t know any better at the time so I wore ‘em anyway. Blisters are the WORST.”

“I suppose that makes sense. It must have been difficult, to transition from swimming to walking,” Riddle muses.

“Yeah it does! So that’s why you should sit down! Give your feet a break,” Floyd grins. Riddle sighs and looks up at him with a tired expression.

“There’s no point in sitting down if I don’t have bandages with me. My feet can have a break while I’m studying. Aren’t YOU worried about your finals?”

“Finals…” Floyd muses. “Goldfishie is such a hard worker… you're very admirable. That is what I think right now. But Goldfishie is also silly to keep walking on feet that need a break. You know I could give you stuff for blisters, right? Mostro Lounge has a first aid kit.”

Riddle hesitates, biting his lip. His heel REALLY hurts. He doesn’t want to walk on this all the way back to the mirror room…

“I guess… If it isn’t any trouble,” he finally sighs. “I will bring you new supplies tomorrow, if you can accommodate me.”

“Ok! Come to my room!” Floyd takes Riddle by the arm, and leads him to his dorm room. Jade is out, so they’ll be all alone. He’s so excited, his heart is jumping up into his throat. “I’ll clear a space for you!”

A little reluctantly, Riddle limps after him. He pauses at the threshold of his room, looking around with raised eyebrows.

“How on earth do you find anything when your room is such a mess?” He sounds a little disdainful, but also legitimately curious, as though the idea of NOT keeping his space in strict order at all times had simply never occurred to him before.

“Whenever I want something I guess.” Floyd shrugs as he shoves a pile of books off his bed and onto the floor. He smooths out the sheets and comforter before kicking his pajamas to the side. “My room has its own order. Clothes on the bottom. Snacks on the top.” He pats the newly cleared space, offering it for Riddle to sit on. “It’s not hard for me to grab something on the fly. Your room must be like Jade’s, all straight and tidy.”

“Probably more like that, yes.” He sits gingerly on the edge of the bed and pulls his boot off with a wince. “I was always told that an orderly space made for an orderly mind. Ugh, this got worse than I thought…”

There’s a raw blister the size of Floyd’s thumb in the back of his heel. It’s broken open, scabbed, and looks extremely painful.

“Does an orderly mind also mean, ‘ignore my pain ’? Cause OUCH Goldfishie.” Floyd hisses in empathy. He grabs onto Riddle’s foot to examine it more closely.

“AGHHH?!” Riddle falls backward onto the mattress at the unexpected grab, face turning bright red and arms flailing to push himself back upright.

“Your feet are so small!!!” Floys lightly squeezes the teeny toes out of adoration, even though they’re trying to hop out of his hands. “For such small feet you sure got big blisters! Maybe Goldfishie shouldn’t wear heels anymore.”

“They’re not small! And high heels are TRADITIONAL DRESS FOR MY DORM. Let me go this instant!”

Floyd tsks at Riddle, kneading his arch and heel to calm him down. As he does, he picks up Riddle’s boot and holds it up for a size comparison. Yeesh! Goldfishie has teeny feet, but this shoe is even teenier!

“Does Goldfishie like getting into tight spaces? I do too! But these shoes are waaaaaay too small. Betcha I’d find another blister on your other foot if I look.” Floyd sets the boot back down, then rolls his thumbs over the ball of Riddle’s foot to spread out his toes. He smiles down at him, thoroughly enjoying his reddened face. “Is Goldfishie embarrassed?”

“NO. I want my foot back,” Riddle grumbles, even though he isn’t trying to pull away anymore. “And the store clerk told me that high heels must be tight! Otherwise they are harder to walk in.”

“Whoever told ya that scammed ya HARD… heels don’t need to be tight to walk in.” Floyd winces as he rolls his palm over the tops of Riddle’s toes and the ligaments pop audibly. Riddle shivers. A guilty, but relieved expression flickers over his face, even though his cheeks are still blazing a five-alarm red. Floyd recognizes it as the same one Azul gets when he’s been running himself ragged for weeks, and then someone finally tricks him into taking a moment to relax. Sheesh, no wonder Goldfishie isn’t kicking up a fuss anymore. This massage probably feels REALLY good after all that self-inflicted torture.

“Your poor feet… you’ve been treating yourself bad when you're supposed to be treated like a queen.” Floyd sets his foot down, and slides himself between Riddle’s legs. He looms over the blushing beauty and looks him dead in the eye with a promising grin.

“I can massage more than just your feet, you know. ‘Cause now that I look at ya… everything looks wound up WAY too tight. So? Want the royal treatment?”

Riddle blinks up at him, looking mostly confused. “More than…? You mean you can show me the right size shoe to order?”

It’s suddenly adorably clear that UNLIKE Azul, Riddle has completely missed the sexual overtone of Floyd’s offer.

“Oooh… ahahaha… Goldfishie is cute.” Floyd snickers, cracking a wider smile. “Yeah I can help ya with that. And more.”

Floyd gets off him and casually takes off his other boot. There is a layer of medical tape over his other heel, showing he must have treated an identical blister on that foot as well.

“Ha! Called it!” Floyd tosses the ill-fitting shoe next to its buddy.

“Hey-! Hn-mmmm…”A surprised little squeak escapes Riddle’s mouth. It dissolves into a stifled moan when Floyd starts to massage his arch.

“You're so tight… Isn’t there anything else I can help loosen up? Think bigger, Goldfishie.” Floyd asks huskily. He rolls his thumbs over Riddle’s ankle and calf.

“T-think bigger?” Riddle seems to be having trouble thinking at all. “Vil told me about putting cushions in the heel to pad them, but that just made it worse.”

“Cushions in shoes that are ALREADY too small? Nahhh… that’s not what you need. Hmmmm… let me help ya. Just tell me if you want to go lower, or higher…” Floyd picks up Riddle’s other foot and rolls his knuckles along his calf, trying to convince his muscles to stop being one giant knot. He does feel a little sorry for him, but mostly he’s curious… How far will Riddle let him go? Poor, sweet virgin that he most likely is…

“Well? Higher? Or lower?” Floyd prompts.

“W-which way is higher…?” Riddle is literally melting under Floyd’s hands. It’s blatantly obvious that he’s touch starved, on top of his leg muscles being all balled up and tight. Too bad he can’t make a rule for his legs to follow to force ‘em to relax.

“Here…” Floyd whispers. “This is higher.” He smoothly rolls both thumbs along the top of Riddle’s thigh, growing more and more excited. He wants to spread Riddle out, and split him in half - He wants to see this uptight, virgin queen lose it all and turn into a fucked-out, silly, needy little thing~

“O-oh…” Riddle stifles another moan, and Floyd can see that goosebumps are running up his arms. “That’s…mmmm…I…”

Riddle’s body very much wants to go limp against Floyd’s mattress, even as a strange tightness flutters through the pit of his stomach. Higher…higher feels good…

“W-wait, what do…ohhhhhh” Riddle moans aloud, weakly trying to focus past the large, strong fingers squeezing upward along his thigh muscles. “You always want something…in exchange…?”

Floyd giggles as he works up higher. Much further and he’ll practically have both hands in Riddle’s crotch~

“Hmm…I want… you! Just you. Deal?”

Riddle pants lightly. “What? ME? I don’t…I’m not…” He knows FULLY…haaahhh…f-fully well to be wary of contracts and schemes from Azul and Jade. But Floyd is a wild card. He only seems to follow their rules when it suits him, but what does that mean in this situation…? All of Riddle’s awareness has been narrowed down to the kneading touches squeezing their way up his trembling legs, evoking longing memories of watching other people be hugged…

Even more faintly, of someone hugging HIM…

Floyd tilts his head with a crooked grin. "Yes you! Doesn't have to be now but...in the future sometime? Mmkay?" Floyd giggles as Riddle leans into his touches, as though silently pleading for more. His Goldfishie is so needy! Small and needy. He lets go of Riddle's thigh, and crawls on top of him, straddling his legs with his own. He lightly brushes away Riddle's bangs, tempted for more. More skin contact. More blushing Riddle. More... everything.

Riddle stiffens underneath him for just for a second, eyes widening in uncertainty. But then the fingers brush back his hair, and the touching…the closeness…

Something inside Riddle wants to break down and cry, it feels so nice. Tingles roll down the side of his face and he simply stares back up at Floyd with a faintly terrified expression. He’s sweating, and shaking ever-so-slightly. He’s also holding his breath, though judging from his expression he’s probably just forgotten to breathe instead of doing it on purpose.

‘So cute.’ Floyd brushes his thumb across Riddle’s check before lightly tracing his lips. “Do you like this?” He asks quietly. This is fun, but he doesn’t want to continue unless Riddle says yes. He wanted his Goldfishie to come to him in the end, and beg him to turn him into mush…

The inside of Riddle’s brain best resembles a highway intersection with sixty cars all piled up in a massive, panicked trainwreck. On one side of the pileup is a voice screaming that this has to be breaking half a dozen rules, though unhelpfully, it isn’t coming up with a specific example. On the other is a growing sense of existential panic at something he refuses to even let himself think about-

And then a fingertip brushes over his lower lip and he gasps, chest burning and heart pounding as the most important rule of all simply asks that he answer honestly…

And he nods.

Floyd smiles, “Do you want more?” He grinds ever-so-lightly against Riddle’s crotch with his own. He wants Riddle to feel him. Feel his size…

Riddle does feel Floyd’s size, and it’s comforting in spite of everything he knows about him. There’s something about being curled beneath him that feels instinctively like he’s been given permission to be small, and for once, not responsible for every tiny thing around him. He nods again, half thinking Floyd is going to keep massaging his legs…even as a very quiet part of him is finally starting to catch onto what Floyd ACTUALLY wants to do…

Floyd trills happily at the confirmation. “I’ll keep you safe, like I do Azul and Jade. We’ll have fun!”

"Haahhh..." Riddle pants, tilting his head back and closing his eyes as Floyd nuzzles into his neck. Ha ha...fun...he remembers someone else once coming up to his window and stealing him away for a few, blissful hours for fun…

Floyd smothers Riddle in his sweet, musky, ocean scent, marking him all over so that everyone will know who he belongs to~ “My Goldfishie.” He whispers in Riddle’s ear as he rubs his little pet up and down. “Say it out loud… that you want this?” Floyd asks as he squeezes Riddle to him, lifting him off the mattress to grind longingly into his hips.

"Hnnnnn…I want this," Riddle whispers, feeling small and protected again as Floyd's hands wrap completely around his hips, nearly meeting around the back.

“Me too… ” Floyd whispers back. Perfect. This is perfect. Floyd kisses Riddle’s forehead, protectively curling over him like a giant, living blanket. Riddle sighs and melts into the hug, tentatively reaching up to return it after just a moment's hesitation. Encouraged, Floyd covers Riddle’s neck in kisses and tiny love bites. He needs to make it known that Riddle is spoken for, that he is claimed-

Riddle gasps, feeling little flashes of heat and tingles wherever the kisses touche him. The heady feeling of being cared for and wanted is so powerful that he wants to soak into it like a flower opening into a sunbeam. He closes his eyes, letting Floyd explore where he wants. Is this...how it's supposed to feel...? He’s so warm…

“Floyd? Are you here? I need… Riddle?” Jade trails off, incredulously staring down at the mop of red hair underneath Floyd’s arms. Floyd growls at his brother, caging Riddle underneath him. DAMMIT-

“NNGH?!” Riddle panics, squirming out from under Floyd and falling gracelessly to the floor. Floyd lets him escape, grabbing a pillow and throwing it irritably at Jade. “Healing in progress?! Goldfishie has blisters.”

“On his face?”

“JADE!”

Panting and chest tight with far too many emotions, Riddle snatches up his boots, viciously kicking himself for letting his guard down. So furious that his eyes are burning with unspilled tears, he jams them back onto his feet and pulls the laces tight, ignoring the flash of pain from his blistered heel.

“I apologize. I knocked, but no one answered. I thought Floyd was alone, and sleeping.“ Jade says softly. Riddle hurries out of the room without a word, feeling too ashamed to make eye contact as he ducks past him. Jade WILL use this as blackmail against him later, and so be it. Riddle deserves it for being so. Blatantly. STUPID.

“Riddle stop!” Floyd calls out, “You're still hurt!”

“…did you just use his real name?” Jade raises his eyebrows as Riddle walks around a corner and out of sight.

“What? No, I said Goldfishie…” Floyd watches him disappear with a disappointed sigh. “Jaaaaade…”

“My my, I wouldn’t have thought he had it in him,” Jade smiles. “Or you, come to think of it. Floyd, have you been feeling unusually flirtatious today?”

“Oh, you too?” Floyd grumbles, glaring up at Jade. “Yee. Why, who did you try to jump on? Sea Lion?”

“Oh Seven, perish the thought…”

“Mmmmm~ What about Sea Slug? Let’s go find him. If we’re lucky he’s packing one for each of us-” Jade throws the pillow into his face, and Floyd giggles as he’s tackled onto the bed.

#eels in spawn#fanfic#twisted wonderland#Jade Leech#Floyd Leech#azul ashengrotto#comedy#romance#pregnancy#eggs#twst#riddle rosehearts

4 notes

·

View notes

Text

Leelee Chan, Oculus (Budding Amethyst), 2022, found plastic pallet, chevron amethyst, stainless steel mirror and hardware, steel, epoxy, urethane resin, UV-resistant pigment, 72 x 72 x 17 cm, 28 1/2 x 28 1/2 x 6 1/2 in, Copyright the Artist. Courtesy of the Artist and Capsule Venice

4 notes

·

View notes

Note

POINTS!! ANOTHER TOMMY! HELLO!! AND HELLO TO MODS TUBBO AND WILBUR!!

I’m a Tommy fictive (if you can’t tell LOL) and I stumbled across this blog and I was like WOAH !! I’m doing a Big Important Dinner tonight for the system and I was wondering if I could maybe get a care kit? If you guys are cool with that!!

For like, specific themes, I really like stuff reminiscent of my brothers Techno and Wilbur, and I LOVE fidget toys like pick pallets and the little wiggly animals! I also love plushies especially raccoons and foxes :D!! Thank you for lookin at my request, I hope your day goes great!!

-📀🧭anon

HI KING HELLO!! I CANT FORMAT IT WELL RIGHT NOW BECAUSE I AM IN THE MIDDLE OF A PUBLIC SPACE EHKP BUT IM GONNA FUCKIN DO THIS ANYWAY WE BALL

BUTT heres links to cool shit! (+ GOOD LUCKN WITH DINNER)

RACOCON

CUSTOMCOMPASSES

MINECRAFT FOX MUFG (BECAUSE WHY NOT SPICE IT UP FROM PLUSHIES)

SILLY RACCOON FIDGET TOY

A CHEAP CROWN THAT REMINDS ME OF THE BLADE

A BLUE CLOAK JACKET!! THAT REMINDS ME OF WHEN WE WERE HIdING FROM GREEN BOY WITH TH BLADE

FUC K MGIE STARTING BY E BYE BE SHANAN D

3 notes

·

View notes

Text

Signals

A (Kagaku Ninja Tai) Gatchaman fic written for the Secret Santa gift exchange in 2017. The prompt I was given tasked me with giving Joe and Jun a moment alone, lost on an island with time to reflect on their hopes and fears, and a possibility of romance between them.

I hope there is an audience for this fic here. I loved writing this, and the challenge of shipping these two (who I'd never really considered would end up together) pushed me to write something I was quite proud of.

It is fairly long at just over 14000 words, so this is just the first part. Rated G Minor injury Minor character death budding romance (I've tagged with Battle of the Planets as some fans may recognise enough familiar content to follow the story.)

Signals (link to AO3)

Four birdlike shadows flashed across the stainless steel wall of the compound. Two streaked left and disappeared behind pallets piled high with boxes, while the other two headed right and vanished into the darkness between the dimly lit doorways.

“This doesn’t look like the stolen electronics components,” Ken whispered.

“No,” Jun agreed, “it seems more like catering supplies.”

“I guess even Galactor have to eat.”

“Hey, kid, what’d you see?” Joe prompted Jinpei after a brief reconnoitre.

“First door leads to bathrooms, second one looks like kitchens,” the youngster responded. “You?”

“Last door looks like it leads to living quarters. Door three’s the winner – stairs leading down.” He grinned a mirthless grin, then spoke into his bracelet. “G2 to G1. I think we’ve found the way in.” There was no response.

“Aniki?” Jinpei tried whispering into his own communicator. “Should we go in?”

“Comms are down. They must be jamming us,” Joe surmised. “Go see if you can find them. I’ll stay here.”

“What’s taking Joe and Jinpei so long?” wondered Jun. “We should have heard something by now.”

“G1 to G2. Found anything? . . . Joe?” Ken waited but received no answer. “No response. Do you think they could be jamming us?”

“Yep!” Jinpei popped his head around the corner of the stack of boxes, then continued as he joined his teammates. “That’s what Joe thinks too. There’s a way down over there. Come on!”

“Hold on,” Ken grabbed the young swallow’s cowl and held him back. “We need to try contacting Ryu before we get any deeper into the base.”

“Are you kidding?” Jinpei turned to Jun. “Does he really expect to be able contact to Ryu out there in the God Phoenix when we can’t even get a signal in here?”

“G5, this is G1. Do you copy?” Ken spoke into his bracelet. “G5, do you read?”

“He’s not expecting an answer, but you know we have to try,” Jun reminded him. “It’s procedure. And the God Phoenix has signal boosters.”

Just then Joe dropped down from the top of one of the taller stacks to join the others.

“I guess we can’t call in the cavalry?” Joe’s question was answered by a shake of Ken’s head. “The jamming device must be somewhere in the base. Last time we contacted Ryu we were less than a hundred meters away from where we are now.”

“Maybe I can find a way to detect the device,” Jun suggested as she opened her bracelet’s faceplate.

“Good idea,” Ken agreed. “We get in, Jinpei and I will find the stolen equipment, you and Joe find and neutralise the jamming device. Twenty minute time limit – if communications haven’t been restored by then we get out and blow the base.”

“We won’t have that long if we go now,” Joe said, ominously. “There’s a lot of activity over there now. Change of shift, meal time or something.”

A five minute wait allowed the foot traffic around the stairs to die down while Jun found a signal that could be the jamming device, and a way to track its location.

The four ninjas made it down the long flight of stairs without needing to deal with more than a half dozen Galactor infantry. The staircase opened out to a wide intersection of corridors. They’d seen similar layouts before and could make educated guesses as to which direction to head in to find what they were looking for.

“Signal seems strongest this way.” Jun indicated the corridor leading straight ahead of the stairs.

“Twenty minutes,” Ken reminded them, then took off down the corridor on the left with Jinpei close behind.

The corridor Jun and Joe needed to take appeared to be a main artery through the base. It was wide with a high ceiling and doors leading off either side at regular intervals. A suspended catwalk allowing access to the corridor lights and air ducts ran above the centre of the corridor. Joe suggested they’d encounter less goons if he and Jun traversed the catwalk. Progress was slightly cautious to prevent the suspended lights from swinging as they walked. All the while the signal Jun was following became stronger. The end of the corridor brought them to a large set of interlocking, sliding steel doors.

“Whatever we’re looking for is through there,” Jun whispered.

“Looks like it has a keypad lock, that’ll mean we need a code.” Joe groaned at the prospect. “That door will be too thick to drill through or torch – it’ll take too long.”

“Maybe we’ll get lucky,” Jun smiled and nodded towards a pair of Galactor soldiers approaching the doors.

Sure enough, they stopped at the doors and the taller of the two punched a series of numbers into the keypad. As the huge doors slid apart the two men started to walk through, and Jun and Joe swooped. Quick as a flash, a streak of pink and another of blue descended from the catwalk and flew through the doors. The two Galactor goons never knew what hit them – both were out of action before the double doors had closed again.

Jun and Joe found themselves inside a large hangar. Technicians and mechanics in Galactor uniforms, and small service vehicles moved about the vast space. An enormous, somewhat bird-shaped aircraft occupied the centre of the domed area. A kind of mezzanine level jutted three meters out of the side walls about ten meters above floor level, extending three quarters of the way around the room, leaving a semi-circular hangar door at the far end.

After dragging the hapless goons out of sight, Joe and Jun crouched beside equipment racks against the side wall and took stock of their surroundings.

“What is that?” Joe asked, indicating the massive, blue-ish metal aircraft with a nasty looking long, thin, slightly curved beak. “Some kind of wading bird?”

“I don’t know,” Jun replied distractedly, “but the jamming device is probably somewhere on board.”

At that moment an alarm started blaring.

“Jinpei and Ken!” Jun gasped.

“. . . can take care of themselves,” Joe reassured her. “But if I’m not mistaken, we’re gonna have to hurry this up.”

The amount of activity in the hangar (and by the sound of it, on the mezzanine level above them) began to increase as uniformed soldiers began responding to the alarm. Orders were being barked, weapons collected and readied for action, and likely locations for the intruders suggested; “The Command Centre!” . . . “the plant room” . . . “The power generator!”

“Do you think they found the stolen components?” Jun whispered.

“I think they found trouble.”

“Then maybe we should go and help them.”

“The best way for us to help would be to get inside that . . . thing and find the jamming device.” Joe studied her expression for a moment. He hoped his own concern for Ken and Jinpei was not as obvious, but he could also see determination behind that golden visor. She nodded, doing her best to put aside her unease.

There were now less technicians and mechanics in the hangar, but there was still some activity audible above them. Guards could be seen posted at entrances on the mezzanine, but they were focussing their attention away from the hangar floor.

“Looks like now’s our best chance,” Joe suggested before heading off in a blue streak across the hangar and concealing himself behind one of the long, folded metal legs of the giant bird. Jun quickly followed.

The main hatch and ramp was closed, but a small opening in the bird’s hull, designed to allow maintenance access, had been left open in the rush to respond to the alarm. The ladder had been removed, but a five meter, near-vertical leap was no challenge for the two ninjas.

Just as Joe made his landing inside the iron bird, and Jun was preparing to jump, the vibrations and muffled sounds of an explosion somewhere within the base shook them. Jun fought the urge to look for the source of the detonation and instead focussed her energy into her leap, and soon joined Joe in a narrow space running uphill towards the bird’s left wing. They couldn’t fit side by side, and Joe had to stoop to keep from hitting his head. The tunnel was designed to give maintenance crews access to control cables, electrical circuits and crawl spaces between mechanical sections.

Another, slightly louder explosion and the sound of distant gunfire reached their ears.

“We need to hurry,” Joe grumbled and began making his way up the access tunnel.

“I wish I knew what was going on,” Jun complained.

“Then we’d better find this thing and disable it so we can get hold of Ken and ask him!” Joe shot back as he continued up the tunnel, leaving Jun little choice but to follow.

They had made about ten meters of steady progress when another alarm began to sound. A different tone from the earlier one. The maintenance hatch Jun and Joe had entered through clanged shut below and behind them. Sounds of running feet and voices made their way nearer and the loud, mechanical cacophony of the main belly hatch mechanism clunked to life, culminating in the gritty clang and grind of the ramp hitting the hangar floor.

Jun took a breath to steady her pounding heart, and consulted her bracelet to try and get a fix on the location of the jamming device. They had to be pretty close.

“We need to make our way up and to the right,” she stated in a far less panicky tone than she felt.

“Then we’ll need to check out these side shafts,” Joe suggested.

Footsteps and voices were now evident both inside and outside the mecha. A distinctly metallic screeching sound indicated the opening of the main hangar doors. Servos began clicking as the mecha’s systems started to come online, engines whined into their warm-up sequence. Preparations for take-off had begun.

“Okay,” Joe backed out of one of the side shafts. “Not that way! By the sound of it, that leads to an engine.”

“This one!” Jun exclaimed from another shaft a little further up.

The side tunnel she had found led a short distance into a small room lined with shelves and racks stocked with tools and spare parts. Joe crawled through into the room and stood at his full height for the first time since they’d entered the mecha, then strode straight over to the door at the other end of the room and listened.

“. . . base is compromised, Lord Katse has set the self-destruct. As soon as he is aboard we’ll take off . . .”

As he turned to face Jun he saw her expression change to one of alarm and Joe realised his own expression was a mix of surprise and concern. He relayed the overheard information to her.

“Then we need to get out of here,” she responded. “We have to warn Ken and Jinpei!”

“They will have figured it out by now,” Joe reassured her. “They’ll find a way out of the base. Right now our best chance of escape is to stay aboard this mecha. If Katse is using it as a lifeboat then it’s a guaranteed safe ride out.”

“Then what? Our comms are still down. The others won’t know where we are.”

“We stick to the plan – find the jamming device and disable it. Then we can contact the others and . . .” he trailed off in thought. “Maybe we can track Katse back to Galactor’s headquarters.”

“And what if we can’t disable it? Or if we can’t find it? Or if we’re discovered and . . .”

“Then we blow this thing to pieces and hope for a soft landing.”

Just then the engine noise increased and the mecha lurched as it moved into take-off position. The belly hatch ramp could be heard retracting and closing. There was a large explosion somewhere close by, perhaps even within the hangar. Another change in engine note and a sudden jolt accompanied the take off. The bird mecha barely cleared the hangar entrance as a massive fiery explosion blasted out of the base. The shockwave and turbulence sent the aircraft lurching and rocking, causing badly restrained equipment to fly in all directions about the storeroom. A large tool chest began to topple.

“Jun!” Joe warned as he staggered and struggled to stay upright amid the aircraft’s erratic movements.

Jun tried to leap clear of the heavy chest as it fell, but she was off balance and struggling to find her footing. As she jumped the mecha pitched sideways violently and her right ankle buckled beneath her. The tool chest crashed to the floor, narrowly missing her feet on its way down and her way up. She landed heavily in a half-kneeling position next to Joe with a grunt and a grimace of pain.

They rode out the rest of the turbulence in silence, concentrating on staying balanced and clear of further falling objects. Then as the mecha’s flight began to level out into clear air, Joe reached out to help Jun to her feet.

“You okay?”

Jun kept hold of Joe’s arm as she tested her weight on her right foot.

“Aaaaah!” She hopped a little on her left foot. “No! I don’t think anything’s broken, but I can’t put much weight on it.”

“Okay,” he said, slowly, “so, you stay here. Show me how to track this jamming device and I’ll go find it. Then I’ll come back here and we’ll get out the way we came in. Moving through these tunnels is too slow for my liking, but it’s a more discreet option than using the main corridors.”

She considered his plan for a moment. She didn’t much like the idea of sitting around helplessly, wondering if Joe was having any luck. The chances of him finding it without drawing unwanted attention were too slim.

“No,” she asserted, a look of steely determination in her emerald eyes as she fixed them on his. “Let’s go with Plan B – blow this thing to pieces!”

He held her gaze a while, discerning how much of this was pain talking and how much was about wanting to know if Jinpei and Ken were okay. He could see that she wanted this over quickly, but she was looking at the options. If they destroyed the mecha it might destroy the jamming device as well.

“Alright,” Joe sighed and gave a nod. “What kind of charges have you got?”

He and Jun took stock of their combined stash of explosives and timing devices, discussed what little they knew so far of the mecha’s structure, propulsion system and dimensions, and came up with a plan of action. Joe would need to leave Jun on her own for a while, but there was little chance of either of them being detected while he was gone. Jun handed over the two small, but powerful devices she’d assembled. All Joe would need to do was place them and set the timers.

Joe returned to the maintenance tunnel and followed it upward, looking for a lateral corridor that would cross over to the other side. Just as Jun had predicted a cramped tunnel, presumably somewhere close to the bird’s shoulders provided access to a central power cell which supplied most of the ship’s critical systems. It was likely the path he had just travelled would be mirrored on the other side of the ship.

It took only a few minutes for Joe to secure the explosive device directly to the power cell, set the timer and make his way back to Jun. Together they made their way back through the maintenance tunnel toward the small hatch in the hull where they had come in. On the way Joe ducked into the side shaft he’d found earlier and set the second explosive device close to the engine, this one on a shorter timer.

They were delayed slightly by the seal on the exit hatch. Jun used a small charge to blow the electronic lock and they were able to drop through and freefall clear of the giant metal bird, just as the timer on the first explosive reached zero.

As two sets of Birdstyle wings unfurled the dull crump and thud of the first explosion caused the steel bird to buckle outwards between the metal wings. Joe began to ride the air currents, searching for a place to land on one of the small islands dotting the Pacific Ocean below them. He spotted a likely candidate and looked back to check that Jun was following as he directed his glide towards it. The second explosive detonated, causing a fireball and black smoke to belch from the engine behind the mecha’s left wing. The ugly steel bird was losing altitude, breaking apart and beginning to tumble as further explosions flashed across its body. The spindly legs were among the first large pieces to break away, along with large sheets of the outer casing and smaller pieces of flaming debris.

The long, narrow curved beak detached and plunged into the ocean as the spherical head launched away from the elongated neck and steered up and away. It had to be Katse’s escape vessel.

Checking over his shoulder at regular intervals to watch for debris, and to ensure Jun was still close by, Joe glided above the wooded area of the island and started descending toward a long stretch of beach. Dodging various jagged pieces of hot metal jutting out of the sand, he touched down gently in the soft, white sand close to the trees. Knowing Jun would find landing difficult with an injured ankle, he immediately turned to check her position. Following her trajectory, he ran along the beach to meet her at her landing point.

Jun glided in to land, seeing Joe waiting to assist. She touched her left foot down and allowed her momentum to take her forward towards Joe’s waiting arms so that she didn’t have to put weight on her right foot as she put the toe of her boot onto the sand. She held Joe’s right forearm and left shoulder as she steadied herself, and looked up to meet his concerned gaze.

“Thanks, Joe”

At that moment the largest remaining section of the bird mecha, which had only remained in the air this long through the sheer determination of a small Galactor flight crew who were desperately hoping against all hope that they may somehow survive this catastrophe, finally succumbed to its fate and crashed into the ocean in a dramatic and bright ball of flame. Joe closed his eyes and turned his head against the irritation of the flash of light. Jun turned to study the colour and shape of the flames and smoke on the horizon, analysing the probable cause of the aircraft exploding on impact the way it did.

The bright flash faded to an orange glow and began to disappear as the smoke billowed, rose and dissipated. Joe, no longer irritated by the light, turned back towards the crash site.

“I guess that’s it. Now we’ll never figure out what it was meant to be.”

“I think it was an ibis,” Jun informed him, “although I’m not sure why they decided to paint it blue.” She shifted her position slightly with an awkward pivot and a limping half step.

“Here, let me take a look at that ankle.” Joe indicated a nearby fallen tree trunk and gently guided Jun over to it, lending a hand to help her sit. Kneeling at her feet, he took her right foot in his hands. “This isn’t going to be easy, but we need to get this boot off.”

“It’ll be easier if I transform out of Birdstyle,” Jun offered.

“Check your communicator,” Joe suggested. “Can you contact the others?”

“What? Why?” Jun responded with appropriate confusion, raising her bracelet to follow Joe’s instruction.

“Just try it.” Joe had that look that said he was thinking two steps ahead and waiting for her to catch up.

“G3 to G1. Do you read me, Commander? . . . Jinpei? Ryu? Do you copy?” There was no response.

“Comms are still jammed. That means the device is still active and somewhere nearby.” Joe watched Jun as she concentrated on where this train of thought was going. “There is a chance that there are survivors from the crash who could also be monitoring our transformation frequency. It’s a slim chance, but do you want to risk it?”

Since Galactor had gained the knowledge of the team’s transformation frequency some months back Dr Nambu had cautioned them all to be even more careful of when and where they transformed.

“No,” Jun conceded. “But how did you know our communications were still down?”

“I know Ken,” Joe grinned. “As soon as that jamming device is out of action we’ll hear him chirp.” The grin faded as Joe began to concentrate on the job at hand. “Okay, you ready?”

Jun gave a nod and manoeuvred her foot as best she could while Joe gently eased the long, white boot off, revealing her reddened, swollen ankle. She found herself marvelling at the gentle touch of his hands, the tender care he took as he had her test the range of movement, and that mixture of calm, controlled confidence, and pure concern in his eyes each time he looked up at her to ask a question. It didn’t take long to determine the injury was most likely to be a sprain, albeit a nasty one. Joe reached into a pouch on his belt and brought out a compression bandage. She watched in silence as those hands that she knew could be deadly when necessary expertly wound the bandage around her ankle with such gentleness.

“You’re good at that,” she remarked as he finished pinning the bandage in place. He gave her a bemused look. “The first-aid thing. You have excellent field dressing skills.”

He found himself unsure of how to react, so he smirked, shrugged and adopted his best doctor-ish voice. “Well, without ice to bring the swelling down you will have to make sure you rest and elevate that ankle.”

“I’ll rest it when we get back to the God Phoenix.” Jun’s expression changed to one of resolve as she reached for her boot. “Right now we need to find that jamming device.”

(Read the rest on AO3)

#science ninja team gatchaman#gatchaman#joe asakura#jun (gatchaman)#fanfiction#joe/jun#battle of the planets

9 notes

·

View notes

Text

Leading Warehouse Rack Manufacturers in Manesar

Welcome To Beeco Storage Systems

Do you need reliable and reputable companies that offer a wide range of storage solutions, including heavy-duty storage units, slotted angle storage units, supermarket contents, hand pallet trucks, cable trays, and plastic pallets? Look no further than Beeco Storage Systems – the exclusive warehouse rack manufacturers in Manesar. With a proven track record and commitment to quality, Beeco Storage Systems stands out as one of the best storage solution providers in the industry. Trust us to meet your needs and exceed your expectations.Our wide range of storage solutions meets the needs of different businesses. We pride ourselves on high-quality products including industrial storage, storage, pallet storage, storage, mezzanine floors, FIFO products, slotted corner racks, heavy-duty racks, cantilever racks, shelving racks, light-duty racks, medium-duty racks, pallets Racks, Warehouse Racks, Modern Warehouse Storage Racks, Mobile Compressors, Long Term Racking Systems, Skeletal Industrial Racks, File Storage Compressors, Utility Racks, Bulk Storage Racks, Anti Dust Certification Arm Storage Racks, Multi-Level Racks, Beam Racks, Loading Racks, Pigeon Holes, Upright Pallet Racks, Stainless Steel Racks, and mezzanine floor plan. With our unique qualities and durable construction, you can optimize the quality of your warehousing and ensure optimal performance in your warehouse or plant.

warehouse rack manufacturers suppliers in Manesar: Your Ultimate Solution

Looking for Warehouse Racks Manufacturers in Manesar? Look no further! Whether you need slotted angle racks, shelving racks, light duty storage racks, or medium duty storage racks, our company stands as one of the leading industrial slot angle rack manufacturers in various locations like Hapur, Vadodara, Rewari, Kashmir , Rajokari, Sahibabad , including Udaipur, Ahmedabad, . Samlakha, Rampur, Bahadurgarh, Bawana, Manesar, Rajpura, Rupnagar, Ambala, Mumbai, Palwal, Behror, Vijayawada, Gurgaon, Sonipat, Medchal, Kapshera, Barabanki, Udhampur, Dadri, Muradnagar, Kundli, Neemrana, Jaisalmer, Naraingarh, Himachal Pradesh , Bareilly, Cotton Hera, Ajmer, Dhankot; We are your trusted platform that offers nothing less than the best.We always keep our promise to deliver unsurpassed quality. With us, you get a wide variety of the best products under one roof. Say goodbye to the hassle of searching for manufacturers, as we offer complete solutions to meet all your warehouse and rack needs. Trust us to deliver the best you deserve. Browse Our Industrial Rack Gallery

We are Manufacturers and Suppliers

Heavy Duty Rack manufacturers & suppliers in Manesar

When it comes to organizing and optimizing storage space, Beeco Heavy Duty Rack Manufacturers in Manesar stand out as a trusted name in the industry. With a strong reputation for delivering high-quality and reliable heavy-duty rack solutions, Beeco has been assisting businesses across various sectors in maximizing their storage efficiency. This article explores the key features and benefits of Beeco’s heavy-duty rack systems. When it comes to heavy-duty rack solutions, Beeco Manufacturers stands as a reliable and trusted provider. With their durable construction, customizable design, versatile applications, optimized space utilization, easy installation and maintenance, and commitment to quality, Beeco helps businesses of all sizes enhance their storage capabilities. If you are looking for robust and efficient heavy-duty racks, Beeco Manufacturers should be your go-to partner, offering reliable solutions tailored to your unique requirements.

Slotted Angle Rack manufacturers & suppliers in Manesar

When it comes to efficient and versatile storage solutions, Slotted Angle Rack Manufacturers in Manesar have become a popular choice for businesses across various industries. These racks offer flexibility, durability, and easy customization, making them ideal for organizing and optimizing storage spaces. If you are looking for reliable slotted angle rack manufacturers to meet your storage needs, look no further. Our company stands as a leading provider of high-quality slotted angle racks, designed to enhance productivity and streamline your storage operations. When it comes to slotted angle racks, Beeco Storage Systems is your trusted partner for top-quality products, customized solutions, and exceptional customer service. With our expertise in manufacturing, we strive to provide you with storage solutions that optimize space, improve efficiency, and enhance overall productivity. Contact us today to discuss your storage requirements and discover how our slotted angle racks can transform your storage space.

Supermarket Rack manufacturers & suppliers in Manesar

Supermarket Rack Manufacturers in Manesar and retail stores rely heavily on efficient storage solutions to showcase their products effectively and create a pleasant shopping experience for their customers. Supermarket rack manufacturers play a vital role in providing high-quality and customizable racking systems that maximize space utilization and enhance visual appeal. In this article, we will explore the benefits of working with supermarket rack manufacturers and highlight the key factors to consider when choosing the right supplier for your store. Supermarket rack manufacturers are essential partners for retailers looking to optimize their store space and enhance product presentation. By collaborating with reputable manufacturers, retailers can benefit from efficient space utilization, increased product visibility, and custom-made solutions. When choosing a supermarket rack manufacturer, consider their expertise, quality standards, customization options, and customer support to ensure a successful collaboration that meets your store’s specific needs.

Hand Pallet Truck Suppliers in Manesar

The Beeco Storage Systems Supplier Hand Pallet Truck Suppliers in Manesar is a versatile and reliable material handling solution designed to efficiently transport and maneuver heavy loads within warehouses, distribution centers, and various industrial settings. This hand pallet truck is built to high-quality standards, ensuring durability, ease of use, and enhanced productivity in your daily operations. The Beeco hand pallet truck stands out for its versatility, allowing it to handle a wide range of applications and adapt to various industries. Its ease of use and intuitive controls make operation effortless, saving time and increasing productivity. Moreover, the emphasis on safety features ensures the well-being of operators and reduces the risk of workplace accidents.

Cable Tray manufacturers & suppliers in Manesar Beeco Storage Systems, the leading manufacturer of high-quality Cable Tray Manufacturers in Manesar for all your industrial and commercial needs. With our extensive expertise and state-of-the-art manufacturing facilities, we are dedicated to providing efficient and reliable storage solutions for cable management.At Beeco Storage Systems, we understand the importance of safe and organized cable management in various industries, such as construction, telecommunications, power generation, and more. Our cable trays are designed to offer superior support, protection, and accessibility for all types of cables, ensuring seamless operations and minimizing the risk of damage or downtime.When it comes to cable management, Beeco Storage Systems is the name you can trust. With our expertise, quality products, and commitment to customer satisfaction, we have established ourselves as a leader in the industry. Choose Beeco Storage Systems for reliable, efficient, and customizable cable trays that meet your unique requirements. Contact us today to discuss your project needs and let us provide you with the perfect cable management solution.

Plastic Pallet Suppliers in Manesar

Beeco Storage Systems – your premier supplier of high-quality Plastic Pallet Suppliers in Manesar. With our extensive range of storage solutions, we cater to businesses across various industries, helping them optimize their supply chain management and streamline their operations. At Beeco, we understand the importance of reliable and durable storage systems that can withstand the demands of modern-day logistics. Our plastic pallets offer a superior alternative to traditional wooden pallets, providing numerous benefits for your business. At Beeco Storage Systems, we take pride in delivering top-notch storage solutions and exceptional customer service. We are committed to ensuring that your business experiences seamless operations and optimized logistics with our high-quality plastic pallets. Contact us today to discuss your storage needs, and let us provide you with the best plastic pallet solutions to enhance your supply chain management. Together, we can take your business to new heights of efficiency and success. We are one of the leading manufacturers of Heavy Duty Storage Racks in Manesar

Source Link: www.beecostorage.in

2 notes

·

View notes

Text

Art Exhibition review: Ajyal Exhibition

This is a review of the art exhibition Ajyal that was opened on the 30th of April at the Bahraini women’s monument Athar. This gallery is supposed to represent the diversity of art and artists through generations in Bahrain. It is run by the Bahrain Art Society. How ever the gallery wasn’t limited to Bahraini Artists only, it included other nationalities.

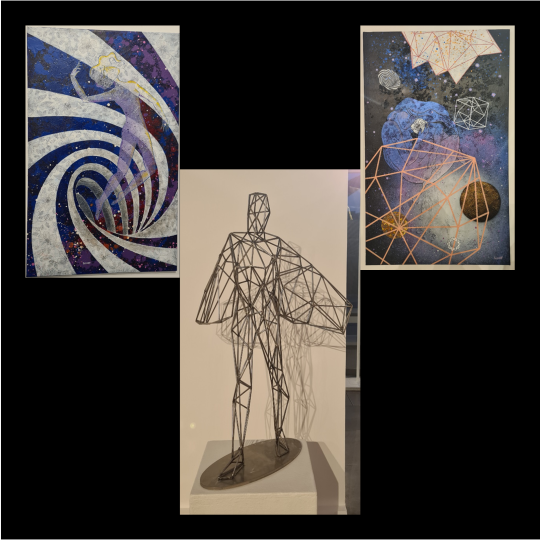

There are many well known names amongst the artists participating here, naturally because the Bahrain Art Society is The Sponsor. One of which, Adnan AL Ahmed, who presented his infamous style with a bit of a masculine twist this time. His style I’d describe to be his own twist on cubism. The same firm clean look you’d come to expect from a typical cubist but with some streamlined shapes where the mostly female figures would be. His work in this exhibition is called (I and the storm, oil on canvas) which features a male figure but also a dynamic balanced composition that portraits an emotional scene, which the artist is no stranger to.

Another well known name is Abbas Almosawi, who presented (deers in the wild, acrylic on canvas) and (horses in the desert, acrylic on canvas) which are his typical landscape impressionism that needs no introduction. Brilliant understanding of color with the vibrant and lively shades and tones that provide high contrast and visual interest. The delicate well calculated brushstrokes that bring texture, like the texture of the sand hills that feels so real. Both works have a focal point on the animals but upon drifting away from that point you will have a pleasant journey through the lines of the painting guiding you back where you were, such strong composition.

Nabeela Alkhayyer is another landscape artist but far more abstractionist. She presents gorgeous bodies of water with a lot of creative ways. She creates the waves of the water with gesso on the canvas and lets the cracks and rips happen as the primer dries, and the results are unique and eye catching. She also manages to pull us in further with the saturated pallets of blues and greens for the vast spaces of water, and the casual oranges and reds to break the pattern every once in a while. In total we get an image of the body of water but through a unique lens that adds the emotion to the scene.

Mariam Bukhamsin had 2 paintings on display. Both acrylic on canvas and tackle the subject of a female figure in space. Such a simple idea but with addition of other elements like a spiral or other floating objects gives movement and dynamics and the effect of floating. The usage of the light sources balances the composition and provides a strong focal point as well.

The work of Jamal Alyousif Is truly captivating. I am not an expert on sculptures but (emergence II, stainless steel) pulled my eyes with its duality. The idea of movement and freedom something so dynamic and stream lined is being represented buy a stiff material that looks like prison bars. Despite that the human figure has a great deal of dynamics that peak through those angular shapes and forms.

Over all, I personally think that there is a great deal of diversity in art styles in this gallery. How ever it leans more towards the more modern and contemporary art styles. While there are artist that chose to portrait more traditional subject matter it was done through a current style like the artist Abdullah Almuharraqi and Herz Albanki.

2 notes

·

View notes

Text

Steel-Metal Pallet: The Ultimate Solution for Heavy-Duty Storage

A steel-metal pallet is a robust and durable solution for industries that require high-strength storage and transportation options. Unlike wooden or plastic pallets, steel-metal pallets offer superior load-bearing capacity, resistance to environmental damage, and longevity. Designed to withstand extreme conditions, these pallets are an essential component in logistics, warehousing, and industrial manufacturing.

Advantages of Using Steel-Metal Pallet

1. Exceptional Durability

A steel-metal pallet is built to last, making it the ideal choice for industries dealing with heavy loads. Unlike wooden pallets that may break under pressure or plastic pallets that degrade over time, steel-metal pallets can handle excessive weight without losing structural integrity.

2. Resistance to Environmental Factors

Steel is resistant to moisture, chemicals, and temperature variations. This makes a steel-metal pallet suitable for harsh environments such as cold storage, chemical processing plants, and outdoor logistics operations. Unlike wooden pallets, they do not absorb moisture, eliminating risks of rot, mold, and insect infestations.

3. High Load-Bearing Capacity

Industries that require the transportation of heavy goods benefit significantly from the exceptional strength of a steel-metal pallet. With the ability to support thousands of kilograms, steel pallets outperform traditional alternatives in weight distribution and durability.

4. Fire Resistance and Safety

Unlike wood, steel is non-combustible, reducing fire hazards in warehouses and factories. A steel-metal pallet is a safer option for industries that store flammable materials, as it does not contribute to the spread of fire.

5. Cost-Effectiveness in the Long Run

Although the initial investment for a steel-metal pallet may be higher than wooden or plastic pallets, its long lifespan results in lower replacement costs over time. Companies benefit from a significant reduction in pallet-related expenses, leading to better cost efficiency in the long run.

Applications of Steel-Metal Pallet in Various Industries

1. Warehousing and Logistics

A steel-metal pallet is extensively used in warehouses and distribution centers where heavy goods need to be transported efficiently. The strength and durability of steel pallets ensure that products remain intact during storage and transit.

2. Automotive and Manufacturing

Manufacturing facilities and the automotive sector rely on steel-metal pallet solutions to transport large machinery parts, engines, and industrial components. The high load-bearing capacity ensures safe handling of goods during production and assembly.

3. Pharmaceutical and Chemical Industries

The chemical and pharmaceutical sectors require storage solutions that resist chemical spills and corrosion. A steel-metal pallet provides a hygienic and contamination-free surface, making it an ideal choice for transporting sensitive materials.

4. Food and Beverage Storage

Unlike wooden pallets that absorb moisture and bacteria, a steel-metal pallet offers a hygienic surface for storing and transporting food products. Stainless steel versions are widely used in food production and beverage industries to meet safety standards.

Choosing the Right Steel-Metal Pallet

1. Load Capacity Considerations

When selecting a steel-metal pallet, it is crucial to assess the weight capacity requirements. Standard steel pallets support loads ranging from 1,000 kg to 5,000 kg, with reinforced designs capable of handling even greater weights.

2. Design and Customization Options

Steel-metal pallets come in various designs, including open or closed deck configurations, collapsible versions, and stackable models. Customization options allow businesses to tailor the pallet design based on their specific storage and transport needs.

3. Surface Coating for Corrosion Protection

To enhance the longevity of a steel-metal pallet, manufacturers apply protective coatings such as galvanized or powder-coated finishes. This ensures resistance to rust and prolongs the pallet’s usability in extreme environments.

Sustainability and Environmental Impact

One of the key benefits of a steel-metal pallet is its recyclability. Unlike wooden pallets that contribute to deforestation or plastic pallets that generate waste, steel pallets can be recycled and repurposed, reducing the overall environmental footprint. Additionally, the durability of steel pallets reduces the need for frequent replacements, further supporting sustainability initiatives.

Conclusion

A steel-metal pallet is an indispensable asset for industries requiring high-strength, long-lasting, and reliable storage solutions. With unmatched durability, superior load capacity, and environmental benefits, steel pallets outperform traditional wooden and plastic alternatives. Whether for logistics, manufacturing, or food storage, investing in high-quality steel-metal pallets ensures efficiency, cost-effectiveness, and long-term reliability.

0 notes

Text

Best Practices to Store and Handle Ground Granulated Blast Furnace Slag

Ground granulated blast furnace slag price is one of the many considerations when using the GGBS in your construction material. It is usually considered for the cementitious properties along with the material’s durability and sustainability benefits.

You must ensure that the quality of GGBS is preserved over time and is always at the peak of its performance. For this purpose, you must consider using the right storage and handling practices. Here are some of the best practices that can help maintain the quality of GGBS, especially during storage and transportation.

• It is important to understand the properties of GGBS before you set out to understand the ways to maintain the quality of the product. GGBS is a fine and powdery material that is produced when you grind the granulated blast furnace slag.

This slag is a byproduct of iron and steel manufacturing. As they are available in fine particle size, they are easily vulnerable to external factors like contamination and moisture. When you are storing or handling the GGBS, you must consider a few factors. The hygroscopic nature of the product allows it to absorb the moisture from the air. As a result, it leads to clumping. Moreover, the density and flowability of the fine particles is limited, making it important to make way for these aspects during transportation. Lastly, you must consider the reactivity of GGBS with water, which makes you look for solutions that are airtight and moisture-proof. The granulated blast furnace slag suppliers should be aware of these factors to create the best solution for storage and transportation.

• There are a few best practices to consider when planning the storage of these materials. You should ensure that the product stays free of contamination, moisture and degradation. Using these practices, you can design a storage facility that maximizes the quality of the GGBS.

o The first thing you must do is design the storage facility in silos or as a closed storage area. This way you can shield the products from the extreme weather conditions, such as rain, wind and temperature fluctuations. This will also prevent external contamination of the products. You must consider the ground granulated blast furnace slag price for this purpose.

o The next step in designing the facility would be to create airtight silos to contain the moisture. You can avoid storing them in semi-open containers. Make sure to have consistent temperatures in the storage facility to prevent condensation.

o You can also consider bulk storage in silo corrosion-resistant materials like stainless steel. You can also use aeration equipment to avoid the compaction and free flow of materials. Lastly, you must use dehumidifiers and desiccants to control humidity.

o It is also a great idea to use bagged storage if you want to handle smaller quantities of the slag. You can use moisture-proof bags made of polyethylene materials to protect the product against humidity. You can also use store bags on pallets, which can eliminate the water seepage. You can also reduce overstacking to prevent tearing or crushing of bags.

• You should also consider the handling practices to minimize the material loss and contamination. o Use sealed conveyors to transfer the GGBS while avoiding the material spillage and exposure o Make sure to use dust extraction systems at the different transfer points to eliminate the airborne particles and ensure material conservation.

Make sure to choose right granulated blast furnace slag suppliers for the right conservation and transfer of your products.

0 notes

Text

Stainless steel material handling equipment is mainly used in cleanroom operations. Pallet stainless steel is designed to have no sandwiched material and no cracks or crevices. We at Superlift Material Handling Inc use the highest grade stainless steel to make these equipment that deliver the best result. Visit our website or dial 1.800.884.1891 for more information!

0 notes

Text

Heavy coils are hard to handle unless there is adequate equipment to handle them. Coil upenders are meant to meet this requirement because these are designed to handle heavy rolls and can tilt up to 90 degrees. Contact Superlift at 1.800.884.1891 or visit the website to know more!

#superlift#superlift material handling#material handling tugger#superlift canada#super lift#paper roll lifter and rotator#stainless steel lift table#tuggers material handling#stainless steel pallets#stainless steel lift tables

0 notes

Text

Choosing the Right Racking and Shelving Suppliers for Your Business

When it comes to increasing organisation, efficiency, and storage capacity, choosing the right racking and shelving suppliers is critical. Whether you run a retail store, a warehouse, or a healthcare facility, the right supplier can help you turn storage challenges into streamlined solutions. With so many options available, knowing what to prioritise can make a significant difference.

Why Racking and Shelving Matter

The value of proper racking and shelving cannot be overstated. Businesses rely on these systems to maximise space, improve workflow, and protect their inventory. The applications are limitless, ranging from durable racking for heavy-duty storage to sleek shelving for retail displays. Partnering with expert racking and shelving suppliers guarantees that your specific requirements are met with high-quality, long-lasting solutions.

Key Qualities to Look for in Racking and Shelving Suppliers

Customisation Options: Not all businesses have the same storage requirements. A reputable supplier will provide customisable options that address the specific dimensions and challenges of your space. Flexibility is essential, whether it's for modular shelving in a boutique store or sturdy racking in a warehouse.

Product Quality: The materials used to build your racking and shelving systems determine their durability. Reliable suppliers offer systems made of high-quality materials like stainless steel, mild steel, or powder-coated finishes, ensuring durability even in harsh environments. High-quality solutions reduce the likelihood of structural failure and the costs associated with repairs or replacement.