#used ibc tank

Explore tagged Tumblr posts

Text

IBC Tanks: The Ultimate Solution for Safe Liquid Storage in the UAE

Introduction

As the UAE thrives as a hub for industrial, commercial, and agricultural activities, the need for efficient liquid storage and transportation solutions has grown significantly. Intermediate Bulk Containers (IBC Tanks) have emerged as a versatile and cost-effective option for storing and transporting liquids, chemicals, and other bulk materials. In this blog, we delve into the features, benefits, and applications of IBC tanks in UAE, highlighting why they are an indispensable asset for various industries.

What are IBC Tanks?

Intermediate Bulk Containers (IBC Tanks) are durable, reusable containers designed for the storage and transport of liquids, semi-solids, and granulated substances. Made from high-density polyethylene (HDPE) or metal, these tanks are engineered to withstand heavy loads and provide excellent chemical resistance.

Features of IBC Tank

Robust Construction: Made from high-quality materials for durability and longevity.

Large Capacity: Available in capacities ranging from 500 liters to 1,000 liters, catering to various needs.

Stackable Design: Optimizes storage space and simplifies transportation.

Leak-Proof: Equipped with secure seals and valves to prevent spillage.

Easy Handling: Compatible with forklifts and pallet jacks for efficient movement.

Importance of IBC Tanks

With the UAE’s diverse industries, including oil and gas, agriculture, and food processing, IBC tanks have become essential for efficient operations. Their versatility and safety features make them ideal for storing and transporting hazardous and non-hazardous materials across the region.

Key Benefits of IBC Tank

Cost-Effective: Reduces the need for multiple smaller containers, saving time and money.

Space Optimization: Stackable design ensures efficient use of warehouse space.

Environmental Sustainability: Reusable and recyclable, reducing environmental impact.

Chemical Compatibility: Resistant to corrosion, suitable for storing a variety of substances.

Ease of Transport: Designed for seamless handling with standard equipment.

Applications of IBC Tank

Chemical Industry: Safe storage and transport of hazardous chemicals and solvents.

Food and Beverage: Hygienic storage of edible liquids like oils, syrups, and beverages.

Agriculture: Transport of water, fertilizers, and pesticides.

Construction: Storage of construction chemicals and water.

Oil and Gas: Handling lubricants, fuels, and other petroleum-based products.

Why Choose IBC Tank for UAE Industries?

The UAE’s harsh climate and stringent safety standards require reliable storage solutions. IBC tanks provide:

UV Resistance: Withstands extreme sunlight exposure.

Spillage Prevention: Reduces environmental hazards in case of accidental leaks.

Compliance: Meets international and local safety regulations for hazardous material storage.

How to Select the Right IBC Tank

When choosing an IBC tank for your business, consider the following factors:

Material: HDPE for non-corrosive substances, stainless steel for high-strength requirements.

Capacity: Choose a size that matches your storage or transport needs.

Valve Type: Ensure compatibility with the type of liquid being stored.

Regulatory Compliance: Confirm adherence to UAE standards for hazardous materials.

Accessories: Options like liners, valves, and level indicators for added convenience.

Maintenance Tips for IBC Tanks

Regular Cleaning: Prevents contamination and maintains hygiene.

Inspect Seals and Valves: Ensure leak-proof operation.

Store in Proper Conditions: Protect from extreme heat or damage.

Use for Compatible Materials: Avoid storing substances that could degrade the tank material.

Conclusion

IBC tanks are a vital asset for industries in the UAE, offering an efficient, durable, and safe solution for liquid storage and transportation. Their adaptability to various applications and compliance with safety standards make them indispensable for businesses striving for operational excellence.

If you're looking for high-quality IBC tanks tailored to your needs in the UAE, explore our wide range of products designed for reliability and performance. Contact us today to learn more about how IBC tanks can revolutionize your storage and transport processes.

#ibc tank#ibc container#ibc tank 1000 liter#ibc tank price#used ibc tank#ibc tanks for sale#intermediate bulk container#uae#dubai#abudhabi#reconditioned ibc tanks#1000 litre ibc tank#ibc container for sale#ibc tank supplier#ibc tank distributor#ibc tank wholesalers#ibc dubai#new ibc tank

0 notes

Text

Why Choose Used IBC Tanks in UAE for Your Storage Needs

Looking for an affordable, reliable storage solution? Used IBC tanks in UAE offer a cost-effective option for storing liquids, chemicals, and food-grade materials. These refurbished tanks provide high durability and versatility at a fraction of the cost, making them the perfect choice for businesses across the UAE.

Why Choose Used IBC Tanks in UAE?

Cost-Effective Solution: Save money with affordable used IBC tanks without compromising on quality.

High-Quality Standards: Refurbished to meet high standards, ensuring functionality similar to new tanks.

Versatility: Ideal for storing a variety of materials, from chemicals to food-grade liquids.

Sustainability: Support recycling efforts and reduce waste by choosing used IBC tanks.

Why Trust an IBC Tank Supplier in UAE?

Wide Selection: Choose from various sizes and conditions from trusted suppliers.

Reliable Support: Timely delivery and maintenance services ensure smooth operation.

Durability: Well-maintained used tanks that provide long-term storage solutions.

For businesses in Dubai and across the UAE, used IBC tanks offer a cost-effective, versatile, and durable storage solution. Invest in high-quality reconditioned IBC tanks today for your storage needs.

#used IBC tank in UAE#IBC tank supplier UAE#IBC tanks Dubai#Crateco IBC tanks#refurbished IBC tanks UAE#second-hand IBC tanks UAE

0 notes

Text

OMAKHEATERS - PLATİN

Omak Heaters: Your Trusted Partner in Heating Solutions

When it comes to reliable and efficient heating solutions for various industrial applications, Omak Heaters stands out as a leading provider of top-quality products. Specializing in IBS tank heaters, barrel heaters, filter heaters, satellite dish heaters, and more, Omak Heaters offers innovative and dependable heating solutions to meet the diverse needs of its customers.

IBC Tank Heaters:

Omak Heaters offers a wide range of IBC tank heaters designed to provide consistent and uniform heating for industrial storage tanks. Whether you need to maintain the temperature of liquids or chemicals stored in tanks, our IBC tank heaters ensure optimal heating performance, enhancing operational efficiency and productivity.

Barrel Heaters:

For heating applications involving barrels and drums, Omak Heaters offers high-performance barrel heaters engineered to deliver efficient and uniform heat distribution. Our barrel heaters are designed to withstand harsh industrial environments and provide reliable heating solutions for various applications, including oil and chemical processing.

Filter Heaters:

Omak Heaters also specializes in filter heaters designed to prevent freezing and maintain optimal operating temperatures for filtration systems. Our filter heaters are built to deliver consistent and reliable heating performance, ensuring uninterrupted operation and prolonging the lifespan of filtration equipment.

Omak Heaters Quality Assurance:

At Omak Heaters, quality and reliability are our top priorities. All our heaters are manufactured using premium-quality materials and advanced manufacturing techniques to ensure superior performance and durability. Our team of experienced engineers and technicians conducts rigorous quality control tests at every stage of production to guarantee the highest standards of quality and reliability.

Customer-Centric Approach:

Omak Heaters is committed to providing exceptional customer service and support. We work closely with our customers to understand their unique heating requirements and offer customized solutions tailored to their specific needs. From product selection to installation and ongoing technical support, our dedicated team is here to assist you every step of the way.

Contact Omak Heaters Today:

Whether you're in need of IBS tank heaters, barrel heaters, filter heaters, or satellite dish heaters, Omak Heaters has the expertise and products to meet your heating needs. Contact us today to learn more about our comprehensive range of heating solutions and discover how we can help optimize your industrial heating processes.

625 notes

·

View notes

Text

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

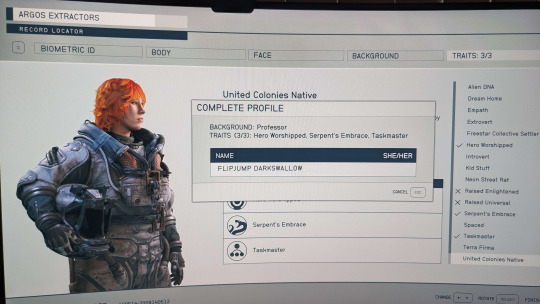

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

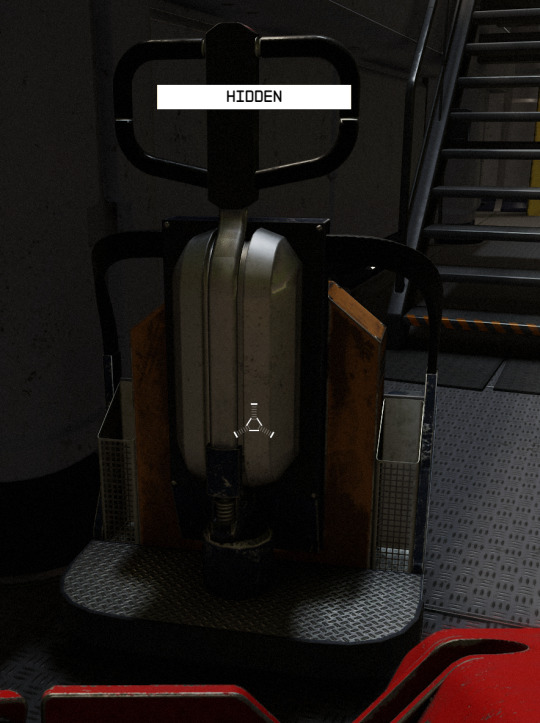

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

47 notes

·

View notes

Text

containers

as I sit on the rim of this bathtub, thawing (isn't it funny how thaw and dethaw mean the same thing?) my toes in foot-deep hot water (maybe, I don't know how tall a foot is anyway, and who's to say whether this water is sexy), I listen to the voice inside my head (which just happens, most of the time, to be my inner perception of my own voice). it tells me:

containers are fun, aren't they? no, not your common red-topped, tomato-sauce-stained Rubbermaids. I mean real containers, real big ones. cargo containers, grain silos, water tanks, that sort of thing. now, I don't care if they're cylindrical or rectilinear, ceramic or wooden or made of corrugated fiberboard, if they're IBCs or ULDs or FIBCs, nor whether they abide by the industry standard intermodal container size (which is, of course, the twenty-foot equivalent unit) or anything else of the sort. in fact, the only size standard I care about is big. come to think of it, maybe 'container' is too limiting a term for what I'm referring to, maybe what I'm really looking for is only properly contained within the well-defined borders of a stalwart pair of double quotes: "vessel that can hold large volumes of stuff." (the broadening of the definition of the ostensible topic of this post, as I've just done, does not work to subvert unconsciously built-up expectations because the bathtub context at the start prevents the building up of the unconscious expectations necessary for this to be considered a subversion.)

shut up, inner voice. (though, with the incorrect and incessant use of parentheses remaining largely constant between my apparent voice and my so-called inner voice, I begin to wonder who I'm really talking to.)

no no, but just think about it. do bathtubs not inspire within you the most pleasant form of joy?

given that that which is "within" me is you, and given your jolly tone, I suppose they do.

pools... are they not so rapturous to take in with your eyes? and the sea, the sea! is it not simply the largest container on earth? 71% of the planet's surface is a difficult number to beat. (since it is a majority, unless containers are in the business of sharing the earth's surface area with each other, it is actually an impossible number to beat. but then again, who knows? the containers may be commies.)

I'll concede that pools are in possession of a special something. (what, now you've gone mad too? -wait a minute, if you're you, then who was that? and who am I? this never would have happened if I'd just used the first-person singular pronoun in that first question (it even makes sense: first-person in the first question... you're grasping at straws, it is utterly nonsensical.), but, no! it's too late now and I've gone down a different branch of "me".) and as for the sea, what you meant was the ocean.

sea, ocean... what does it matter? it would take me but this bathtub to ruin your laptop. what- no- don't leave it, don't leave the bathtub, don't leave me!

fret not, dear me, I've concluded it makes no sense for the sphere of existence of my inner voice to be delimited by the immediate vicinity of the bathtub. since this is the conclusion I have drawn, you shall stay with me for the foreseeable future. rather tragically I must add.

your laptop is now out of reach of the water (which is itself disappearing down the drain), and yet you cry tragedy. the bright side is lost on you pessimists. you really cannot be helped. now please, focus, think of the sea. the... why are we thinking of the sea again?-

there it is!-

see what you've done to us, distracting us from our goals, rendering discursive (definitely the "rambling desultory digressive" definition of this word and not the "conscious reasoning" one. if you're looking on Collins dictionary, that is. why would I be? stop asking questions.) what was supposed to be a pleasant chat about containers. oh there it is, that's why we're thinking of the sea!

no, i meant there it is! the pronoun to resolve our issues of identity! first-person plural! "we"! that was a pretty long run of italics for me, I hope it doesn't confuse them on who's speaking. (hold on, where did they come from all of a sudden? can we keep these words that one may substitute for a noun or noun phrase to a strict minimum, please?) did you just quote fucking Wikipedia and in doing so introduce the indefinite pronoun into the mix? so much for wanting to keep things simple. and now you've ruined the little communist-flavoured celebration we were having at the top of this paragraph!

listen, can we go back to the sea? is it not, quite plainly, the most pretty?

I do love the sea, and I guess I do love containers. you were right all along, dear me.

#what the shit#i'm schizophrenic#just kidding i'm obviously not it's just funny to say that#what i am is sleep deprived#good night

3 notes

·

View notes

Text

Optimizing Bulk Chemical Transport with Flexitanks: A Cost-Effective and Safe Solution

Transporting bulk chemicals presents a unique set of challenges. Ensuring the safe and efficient transport of hazardous or sensitive chemicals requires a packaging solution that combines durability, reliability, and cost-effectiveness. One such solution that has become increasingly popular in recent years is the use of flexitanks.

What Are Flexitanks?

Flexitanks are large, flexible bags that are designed to fit inside standard shipping containers, offering a space-efficient, cost-effective, and environmentally friendly solution for transporting bulk liquids, including chemicals. Made from advanced, durable materials, flexitanks can hold large quantities of liquid cargo without compromising safety or quality during transportation.

Advantages of Flexitanks for Bulk Chemical Transport

Cost-Effective Solution:Flexitanks offer significant cost savings compared to traditional methods like drums and intermediate bulk containers (IBCs). Flexitanks allow businesses to maximize the space inside shipping containers, enabling them to transport more product per shipment. This results in fewer shipments, reduced transportation costs, and a more efficient supply chain.

Durability and Safety:Flexitanks are constructed from high-quality materials designed to withstand the rigorous demands of chemical transport. These tanks are equipped with advanced features to prevent leaks, contamination, and environmental hazards. With their reinforced structure, flexitanks ensure the safe and secure transport of chemicals, even in challenging conditions.

Space Efficiency:Flexitanks optimize available shipping container space, allowing for more efficient use of container capacity. This makes them an ideal solution for transporting bulk chemicals, especially when space is limited or when companies need to maximize storage. Unlike drums or IBCs, which are rigid and take up more space, flexitanks’ flexible design adapts to the shape of the container, minimizing unused space.

Environmental Benefits: Flexitanks are an eco-friendly alternative to traditional packaging methods. They reduce the need for single-use containers like drums or IBCs, which require more energy to manufacture and dispose of. Additionally, many flexitanks are recyclable, contributing to sustainability in the chemical transport industry. By reducing the number of shipments and optimizing space, flexitanks also lower carbon emissions, making them a greener option.

Preservation of Product Quality:When transporting chemicals, maintaining the integrity of the product is critical. Flexitanks are designed to protect the chemical contents from exposure to external factors such as light, moisture, and temperature fluctuations. Their airtight seals and customizable configurations ensure that the chemicals remain in optimal condition during transit, reducing the risk of contamination or degradation.

Why Choose Fluid Flexitanks for Chemical Transport?

Fluid Flexitanks is a trusted leader in the flexitank manufacturing industry, providing innovative and reliable solutions for bulk chemical transport. Our flexitanks are designed with industry-specific needs in mind, offering the flexibility, strength, and safety features required for chemical shipments. With years of experience and a commitment to quality, Fluid Flexitanks ensures that your chemical cargo is transported securely and efficiently, every time.

For more information on how our flexitanks can streamline your chemical transport, visit Fluid Flexitanks today.

Conclusion

Flexitanks have revolutionized the way chemicals are transported, providing businesses with a safer, more efficient, and cost-effective solution. With their space-saving design, durability, and environmental benefits, flexitanks are quickly becoming the go-to choice for companies in the chemical industry. For those looking to optimize their bulk chemical transport, flexitanks offer unmatched advantages that contribute to a more efficient and sustainable supply chain.

0 notes

Text

Why Every Center Requirements an IBC Tote Mixer: Enhancing Quality and Consistency

Introduction

In today's fast-paced industrial landscape, keeping quality and consistency in items is critical. Whether you remain in the food and drink sector, pharmaceuticals, or any manufacturing market, the importance of efficient blending can not be overemphasized. One buying a drum bung tool that has transformed Installing Drum Bung this process is the IBC lug mixer As we look into the important reasons why every facility requires an IBC carry mixer, we'll check out how it improves quality and consistency in operations.

Why Every Facility Requirements an IBC Tote Mixer: Enhancing Quality and Consistency

An IBC lug mixer is designed specifically to mix large quantities of liquids or slurries stored in Intermediate Bulk Containers (IBCs). The need for such a device occurs from numerous vital factors:

Uniformity of Mixtures: With time, parts can settle or separate within storage containers. An IBC lug mixer guarantees a homogenous mix, reducing item variability.

Efficiency: Mixing large volumes by hand can be labor-intensive and time-consuming. With an automated blending solution like a tote mixer, centers can streamline operations.

Quality Control: Constant item output causes much better quality control, decreasing waste and guaranteeing consumer satisfaction.

Versatility: IBC mixers are versatile to different markets, making them ideal for different applications-- from chemicals to food products.

Cost-Effective: By improving mixing efficiency, organizations can save on material costs and minimize the likelihood of rework due to inconsistencies.

Improved Safety: Automated mixing minimizes manual handling of materials, lessening risks associated with spills or accidents.

With these advantages in mind, let's more check out the benefits of having an IBC lug mixer in your facility.

Understanding the Parts of an IBC Lug Mixer What is an IBC?

Intermediate Bulk Containers (IBCs) are big containers typically used for storing bulk liquids or granulated compounds. They come in different sizes-- usually varying from 275 gallons to 330 gallons-- and are created for transport and storage efficiency.

youtube

Key Features of an IBC Carry Mixer

An effective IBC lug mixer will have several key functions:

Powerful Motor: Guarantees sufficient torque to mix even the most thick materials. Variable Speed Controls: Allows operators to adjust speeds based on material needs. Durable Construction: Made from materials resistant to deterioration and wear. Safety Features: Emergency shut-off switches and protective guards are necessary for safe operation. Types of Mixers Utilized with IBCs Drum Mixers Designed particularly for 55-gallon drums. Good for smaller sized batches but less effective than carry mixers for bigger volumes. Larger Tank Mixers Suitable for large quantities however not always useful for basic IBC sizes. Port

0 notes

Text

Industrial Safety and Supply: Your Trusted Safety Equipment Supplier

Industrial Safety and Supply is dedicated to providing high-quality safety equipment that supports safe and secure workplaces. This company offers spill contamination, spill response, and decon products to maintain safety and meet workplace standards. These tools are essential for controlling risks and protecting the environment from damage. Companies use this equipment to manage spills efficiently, ensuring the safety of workers and protecting the environment. This company provides reliable solutions that help businesses operate smoothly and comply with regulations. Industrial safety products provide reliable solutions to unexpected challenges, offering peace of mind.

Spill Containment Solutions Industrial Safety and Supply offers spill containment products that prevent spills from spreading and causing damage. The IBC pallet and Drum Containment are important for safely managing liquid leaks from storage tanks and barrels. Flexible Containment systems are designed to cover large areas, ensuring spills are contained quickly and efficiently. Hard wall containment provides strong and reliable protection against hazardous materials, which is perfect for long-term use. These containment options are designed to endure tough conditions, ensuring workplace safety and protecting employees and the environment from risks. Spill Response & Decon Equipment A quick and efficient response is essential to stop further damage when a spill happens. Spill Berms quickly control liquids, while Overpack drums and Containers ensure safe hazardous waste storage. Decontamination products are very essential for reducing contact with harmful chemicals and ensuring safety. These reliable and efficient spill response tools help businesses act quickly and reduce risks when spills occur. Using these products ensures hazardous materials are safely managed, reducing any harm to the environment. Industrial Safety and Supply offers these essential tools to help businesses handle spills safely and efficiently. With the right equipment, spills are managed quickly and effectively. Facility Protection Products Protecting the physical structure of a facility is as important as managing spills. Industrial Safety and Supply offers a variety of products designed to protect walls, equipment, and other parts of a facility. Wall protectors and drip diverters prevent spills and leaks from damaging walls and equipment. They effectively catch and contain liquids, keeping the area safe and clean. Post protectors and rack protectors are made to guard posts and storage racks from impact damage. I-Beam Protectors and Corner Protectors are built to safeguard beams and corners from damage. These products help reduce maintenance costs by preventing damage and enhancing safety in the workplace. To get more details, visit https://industrialandsafetysupply.com/ Original Source: https://bit.ly/4ffJipW

0 notes

Text

IBC 1000L Anti-Static Plastic Tank

💧 Featuring superior anti-static design ⚡, the IBC tank ensures safety in flammable environments, providing maximum protection for users and goods.

🛡️ With a large 1000L capacity, it is durable, easy to clean, and reusable

♻️. Choose the IBC 1000L anti-static tank to enhance efficiency and safety in production!

🚚 Contact us now for exclusive offers!

📞 +84 903186290

Bồn Nhựa IBC 1000L Chống Tĩnh Điện

#ibctank1000lit#tankibc1000lit#thungtankibc1000lit#bonnhuaibc1000l#tankibc#ibctank#thungnhuaibc1000l

1 note

·

View note

Text

0 notes

Text

Rotomolded Container Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Rotomolded Container Market – Industry Trends and Forecast to 2027

Global Rotomolded Container Market By Product Type (Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polyamide (PA), Others), Industry (Consumer Electronics, Material Handling, Chemicals & Fertilizers, Food & Beverages Processing, Petroleum & Lubricants), Distribution Channel (Direct Sales, Distributor), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2027

Access Full 350 Pages PDF Report @

**Segments**

- **Material:** The rotomolded container market can be segmented based on the material used in the manufacturing process. Common materials include polyethylene (PE), polypropylene (PP), and others. Polyethylene is widely preferred for its durability, resistance to chemicals, and flexibility, making it suitable for various industries.

- **Product Type:** Another key segment of the rotomolded container market is the product type. This includes drums, tanks, intermediate bulk containers (IBCs), and customized containers. Each type serves specific purposes such as storage, transportation, or processing of goods.

- **Application:** The application segment focuses on the diverse industries that utilize rotomolded containers. These industries include food and beverage, chemicals, pharmaceuticals, agriculture, and others. Rotomolded containers offer benefits like corrosion resistance, easy cleaning, and long-term durability, making them attractive to various sectors.

**Market Players**

- **Snyder Industries:** Snyder Industries is a prominent player in the rotomolded container market, offering a wide range of containers for industrial applications. The company is known for its innovative designs, quality manufacturing processes, and exceptional customer service.

- **Chem-Tainer Industries:** Chem-Tainer Industries specializes in rotomolded plastic tanks and containers for chemical storage, water treatment, and other industrial uses. With a focus on customization and quality control, Chem-Tainer is a trusted supplier in the market.

- **Mauser Packaging Solutions:** Mauser Packaging Solutions is a global leader in sustainable packaging solutions, including rotomolded containers. The company provides a comprehensive range of products for the food, beverage, and industrial sectors, backed by extensive R&D capabilities.

- **Granger Plastics Company:** Granger Plastics Company is known for its expertise in custom rotomolded solutions, catering to niche markets with unique requirements. The company's containers are used in automotive, defense, and other specialized industries, reflecting their versatility and quality.

TheThe rotomolded container market is a dynamic and growing industry with significant segmentation opportunities based on material, product type, and application. One key aspect of the market is the material used in manufacturing, with polyethylene (PE) being a popular choice due to its durability, chemical resistance, and flexibility. This makes it highly suitable for a wide range of industries that require robust and versatile containers. Polypropylene (PP) is also commonly used, offering its own set of benefits such as high heat resistance and stiffness. By segmenting the market based on material, manufacturers can tailor their offerings to meet the diverse needs of different sectors.

Product type is another crucial segment of the rotomolded container market, encompassing a variety of containers such as drums, tanks, intermediate bulk containers (IBCs), and customized solutions. Each product type serves specific purposes, ranging from storage and transportation to processing of goods. By understanding the unique requirements of each product type, manufacturers can develop specialized solutions that cater to the needs of different industries. Customized containers, in particular, offer a high level of flexibility and customization options, allowing businesses to tailor their containers to specific applications and environments.

The application segment of the rotomolded container market focuses on the diverse industries that utilize these containers, including food and beverage, chemicals, pharmaceuticals, agriculture, and others. Rotomolded containers provide numerous benefits to these industries, such as corrosion resistance, easy cleaning, and long-term durability. In the food and beverage industry, for example, rotomolded containers are used for storage and transportation of perishable goods, ensuring quality and freshness throughout the supply chain. In the chemicals sector, these containers offer protection against aggressive substances and hazardous materials, making them crucial for safe handling and storage.

Market players in the rotomolded container industry play a significant role in driving innovation, quality, and customer service. Companies such as Snyder Industries, known for their innovative designs and exceptional customer service, are shaping the market**Segments**

- **Material:** The rotomolded container market offers segmentation opportunities based on material, with polyethylene (PE) as a popular choice for its durability, chemical resistance, and flexibility. Polypropylene (PP) is also commonly used for its high heat resistance and stiffness, catering to industries with specific requirements. Manufacturers can tailor their offerings by material to meet diverse industry needs effectively.

- **Product Type:** Another key segment is product type, including drums, tanks, intermediate bulk containers (IBCs), and customized solutions. Each type serves distinct purposes such as storage, transportation, or processing of goods. Customized containers offer flexibility and customization options for businesses looking to address specific application requirements.

- **Application:** The application segment of the rotomolded container market spans across various industries like food and beverage, chemicals, pharmaceuticals, and agriculture. Rotomolded containers provide benefits such as corrosion resistance, easy cleaning, and long-term durability, making them attractive to different sectors for storage, transportation, and processing needs.

**Market Players**

Snyder Industries, Chem-Tainer Industries, Mauser Packaging Solutions, and Granger Plastics Company are key players driving innovation, quality, and customer service in the rotomolded container market. These companies offer a wide range of containers tailored to meet industry-specific demands, contributing to the market's growth and competitiveness.

The global rotomolded container market is poised for significant growth, influenced by factors like increasing demand for durable and versatile

The report provides insights on the following pointers:

Market Penetration: Comprehensive information on the product portfolios of the top players in the Rotomolded Container Market.

Product Development/Innovation: Detailed insights on the upcoming technologies, R&D activities, and product launches in the market.

Competitive Assessment: In-depth assessment of the market strategies, geographic and business segments of the leading players in the market.

Market Development: Comprehensive information about emerging markets. This report analyzes the market for various segments across geographies.

Market Diversification: Exhaustive information about new products, untapped geographies, recent developments, and investments in the Rotomolded Container Market.

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Objectives of the Report

To carefully analyze and forecast the size of the Rotomolded Container market by value and volume.

To estimate the market shares of major segments of the Rotomolded Container

To showcase the development of the Rotomolded Container market in different parts of the world.

To analyze and study micro-markets in terms of their contributions to the Rotomolded Container market, their prospects, and individual growth trends.

To offer precise and useful details about factors affecting the growth of the Rotomolded Container

To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Rotomolded Container market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Browse Trending Reports:

Ferrochrome Market Crop Development And Farming Market Wooden Furniture Market Rice Malt Syrup Market Ibc Cap Market Needle Free Blood Drawing Devices Market Regulatory Affairs Outsourcing Market Noise Source Mapping Market Cyclophilin Inhibitors Therapeutics Market Solid State Transformers Market Home Office Spending Market Dairy Ingredients Market University Management System Market Torticollis Treatment Market x Ray Detectors Market Access Control Market Milking Robots Market Cenospheres Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

LLDPE Rotomoulding Powder manufacturer and Supplier

Shree Umiya Group was started in 2002. We manufacture water storage tank however, after getting good to be true success in tank manufacture and due to high demand for good quality raw material, we started production of raw material on our own premises. LLDPE rotomoulding powder is a finely ground, processed plastic material specifically designed for a manufacturing Rotomolding, It is also known as rotational molding, is a forming process used to create hollow plastic parts.

LLDPE stands for Linear Low-Density Polyethylene. It’s a thermoplastic polymer known for its excellent flexibility, very good impact strength, and versatility.

Large tanks and containers: Chemical storage tanks, water tanks, IBC tanks, waste bins, and septic tanks.

Material handling products: Pallet boxes, totes, and crates.

Furniture and playground equipment: Tables, chairs, slides, and swings.

Marine applications: Kayaks, canoes, and buoys.

Specialty parts: Ducts, pipes, and automotive parts.

We are leading manufacturer and Supplier of LLDPE rotomoulding powder is available in a variety of colors, including black, white, natural, and even custom colors. It can also be formulated with additives to improve its properties for specific applications, such as UV resistance or fire retardancy.

Our Products

LLDPE FOAM MATERIAL

STONE EFFECT MARBLE COLOUR

LLDPE AGGLOMERATES

LLDPE POWDER

ROTOMOLDING POWDER

LLDPE PLASTIC RAW MATERIAL

For More Details Click here : https://www.lldpefoam.com/

0 notes

Text

Industrial Bulk Packaging Market Overview: Growth Factors and Future Trends (2023-2032)

The Global Industrial Bulk Packaging market is expected to witness a CAGR of 4.57% during the forecast period. The revenue generated by the global Industrial Bulk Packaging market in 2020 was over USD 20 billion and is expected to generate revenue worth USD 30.42 million in 2027.

The Industrial Bulk Packaging Market is witnessing significant growth driven by the increasing demand across various sectors such as chemicals and petrochemicals, food and beverages, pharmaceuticals, and building and construction. This market encompasses a wide range of packaging solutions including drums, IBCs (Intermediate Bulk Containers), bulk boxes, and sacks designed to transport and store large quantities of materials efficiently and safely. The rise in global industrial activities, coupled with the need for safe and effective packaging solutions, has bolstered the market's expansion.

The shift towards eco-friendly packaging solutions, driven by environmental concerns and regulatory pressures, is encouraging manufacturers to innovate and adopt sustainable practices. Regions such as North America and Europe are leading the market due to their established industrial base and stringent regulatory frameworks, while emerging economies in Asia-Pacific are rapidly catching up, fueled by industrialization and increasing foreign investments. The competitive landscape is characterized by mergers and acquisitions, strategic partnerships, and continuous R&D efforts aimed at product innovation and expansion of production capabilities. As industries continue to evolve and expand, the industrial bulk packaging market is poised for sustained growth, underpinned by the constant need for robust, efficient, and sustainable packaging solutions.

Industrial bulk packaging serves a critical role across various industries by providing efficient, safe, and cost-effective solutions for transporting and storing large quantities of materials.

Here are some key uses of industrial bulk packaging:

Chemical and Petrochemical Industry:

Transportation of Hazardous Materials: Industrial bulk packaging is essential for the safe transportation of hazardous chemicals, ensuring compliance with regulatory standards and preventing leaks or spills.

Storage Solutions: Drums, IBCs, and other bulk containers are used to store chemicals and petrochemicals, protecting them from contamination and maintaining their integrity.

Food and Beverage Industry:

Bulk Ingredients Handling: Large quantities of raw materials such as grains, sugars, and liquids are transported and stored using bulk packaging solutions, ensuring hygiene and quality.

Beverage Storage: IBCs and bulk tanks are used for storing and transporting beverages, including wine, juices, and syrups, in large volumes.

Pharmaceutical Industry:

Active Ingredients Transport: Bulk packaging is used to transport active pharmaceutical ingredients (APIs) and other raw materials required for drug manufacturing.

Finished Products Storage: Bulk containers are also employed for the storage of finished pharmaceutical products, ensuring they remain uncontaminated and secure.

Building and Construction:

Bulk Cement and Aggregates: Sacks, bulk bags, and other containers are used for transporting and storing cement, sand, gravel, and other construction materials in large quantities.

Chemical Additives: Packaging solutions for chemical additives used in construction processes help in maintaining product quality and ease of handling.

Agriculture:

Seed and Fertilizer Transport: Bulk packaging is utilized for the efficient transport and storage of seeds, fertilizers, and pesticides, ensuring they remain protected from moisture and pests.

Harvested Crops: Containers and bulk bags are used to store and transport harvested crops, maintaining their quality and freshness.

Manufacturing and Industrial Goods:

Raw Materials Handling: Industrial bulk packaging is employed for transporting and storing raw materials such as plastics, metals, and textiles used in manufacturing processes.

Finished Goods Packaging: Bulk packaging solutions are also used for the storage and transportation of finished industrial goods, providing protection and ease of handling.

Waste Management:

Hazardous Waste Disposal: Industrial bulk packaging is critical for the safe disposal and transport of hazardous waste materials, ensuring they do not pose a risk to the environment or public health.

Recyclable Materials: Bulk containers are used for the collection and transport of recyclable materials, facilitating efficient waste management and recycling processes.

The Industrial Bulk Packaging Market faces several challenges that impact its growth and development. One of the primary challenges is the fluctuation in raw material prices, particularly for plastics and metals, which are fundamental to bulk packaging products. These price variations can affect the overall cost structure and profitability for manufacturers. Additionally, stringent environmental regulations and increasing consumer demand for sustainable packaging solutions put pressure on companies to innovate and adopt eco-friendly materials, which can involve significant research and development investments. The need to comply with diverse regulatory standards across different regions also adds complexity to the market, requiring substantial efforts to ensure compliance and maintain product quality.

Another challenge is the high initial investment required for advanced packaging technologies and machinery, which can be a barrier for small and medium-sized enterprises. Furthermore, the market faces logistical challenges, including the need for efficient transportation and storage solutions to handle large volumes of bulk packaging products. The competitive landscape, marked by the presence of numerous players, drives the need for continuous innovation and cost optimization to maintain market share. Lastly, the market must address issues related to supply chain disruptions, which can affect the timely availability of raw materials and finished products, thereby impacting overall market operations. Addressing these challenges requires strategic planning, investment in sustainable practices, and technological advancements to ensure the market's sustained growth and resilience.

Major Key Players-

Cleveland Steel Container

Peninsula Drums

Hoover Ferguson Group, Inc.

International Paper

Myers Container

Grief

Time Technoplast Ltd.

BWAY Corporation

Composite Containers LLC

Eagle Manufacturing Company

More About Report- https://www.credenceresearch.com/report/industrial-bulk-packaging-market

The Industrial Bulk Packaging Market is driven by several key factors that contribute to its growth and expansion across various sectors:

Growing Industrialization: Rapid industrialization, especially in emerging economies, is a major driver. The expansion of manufacturing and production facilities increases the demand for bulk packaging solutions to transport and store raw materials and finished goods efficiently.

Increasing Demand in Chemical and Petrochemical Industries: The need for safe and reliable packaging for hazardous and non-hazardous chemicals and petrochemicals fuels the demand for industrial bulk packaging. Stringent regulations regarding the transportation and storage of these materials further boost market growth.

Rising Food and Beverage Industry: The food and beverage industry requires bulk packaging solutions for the transportation and storage of large quantities of raw materials and finished products. The growth of this industry, driven by increasing consumer demand, directly impacts the bulk packaging market.

Pharmaceutical Industry Growth: The pharmaceutical industry's expansion, driven by rising healthcare needs and increased drug production, boosts the demand for bulk packaging solutions for the safe and contamination-free transport and storage of pharmaceutical ingredients and products.

Sustainability and Environmental Concerns: The growing emphasis on sustainability and the need for eco-friendly packaging solutions drive innovation in the bulk packaging market. Companies are increasingly adopting sustainable practices and materials to meet regulatory requirements and consumer preferences.

Technological Advancements: Innovations in packaging materials and technologies enhance the durability, efficiency, and sustainability of bulk packaging solutions. These advancements meet the evolving needs of various industries, contributing to market growth.

Global Trade Expansion: The increase in global trade activities necessitates efficient bulk packaging solutions for the safe and secure transportation of goods across borders. The rise in exports and imports, particularly in chemicals, food and beverages, and pharmaceuticals, drives market demand.

Construction Industry Development: The growth of the construction industry, with its need for bulk materials such as cement, sand, and aggregates, drives the demand for bulk packaging solutions. The packaging ensures safe transportation and storage, supporting construction activities.

Economic Growth in Emerging Markets: Economic development in regions like Asia-Pacific and Latin America leads to increased industrial activities and investments, driving the demand for industrial bulk packaging solutions. The growing manufacturing sector in these regions further supports market growth.

Regulatory Compliance: Stringent regulations related to the safe transportation and storage of hazardous materials drive the adoption of high-quality bulk packaging solutions. Compliance with these regulations ensures safety and minimizes environmental impact, fostering market growth.

Browse the full report – https://www.credenceresearch.com/report/industrial-bulk-packaging-market

Browse Our Blog: https://www.linkedin.com/pulse/industrial-bulk-packaging-market-projections-mnuwc

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

The Ultimate Guide to Container Blending Suppliers

The Ultimate Guide to Container Blending Suppliers" serves as an indispensable resource for businesses seeking efficient and reliable solutions for blending and mixing various materials. This comprehensive guide covers everything from understanding the importance of container blending in manufacturing processes to evaluating different suppliers based on factors such as quality, reliability, and cost-effectiveness. Readers will gain insights into the latest innovations and technologies in container blending, as well as tips for selecting the right supplier to meet their specific needs. Whether you're in the pharmaceutical, food, chemical, or cosmetic industry, this guide equips you with the knowledge and tools necessary to make informed decisions and optimize your blending operations for maximum efficiency and productivity.

Introduction to Container Blending Suppliers

This section provides an overview of container blending suppliers and their role in the manufacturing industry. It introduces the concept of container blending and highlights its importance in achieving uniform mixing of materials for various applications.

Types of Containers Used in Blending

Here, we explore the different types of containers utilized by blending suppliers for mixing materials. This includes a discussion on the characteristics and advantages of containers such as drums, totes, tanks, and IBCs (Intermediate Bulk Containers), and how each type caters to specific blending requirements.

Blending Processes and Technologies

This section delves into the various blending processes and technologies employed by suppliers to achieve optimal mixing results. Topics covered may include batch blending, continuous blending, high-shear mixing, and inline blending, along with the benefits and limitations of each method.

Quality Assurance and Compliance Standards

Quality assurance is paramount in blending operations to ensure the consistency and integrity of the final product. Here, we examine the quality control measures implemented by container blending suppliers, including adherence to industry standards such as ISO 9001 and Good Manufacturing Practices (GMP).

Customization and Tailored Solutions

Container blending suppliers understand that each customer's blending requirements may differ. This section explores how suppliers offer customized blending solutions tailored to meet specific industry needs, including the customization of blending equipment, container sizes, and mixing parameters.

Supply Chain Management and Logistics

Effective supply chain management is essential for ensuring the timely delivery of blended products to customers. We discuss how container blending suppliers manage logistics, including inventory management, transportation, and distribution, to optimize supply chain efficiency and meet customer demands.

Industry Applications and Case Studies

Finally, we examine the diverse range of industries that benefit from container blending services, such as pharmaceuticals, food and beverage, chemicals, cosmetics, and more. Through real-world case studies and examples, we showcase how container blending suppliers have helped businesses achieve success and innovation in their respective industries.

Conclusion

In conclusion, container blending suppliers play a pivotal role in the manufacturing industry, providing essential services for achieving uniform mixing and blending of materials. Through a combination of advanced technologies, quality assurance standards, and customized solutions, these suppliers ensure the efficiency, consistency, and reliability of blending operations across various industries. As key partners in the supply chain, container blending suppliers contribute to the optimization of manufacturing processes, driving innovation and productivity. By offering tailored solutions, adhering to stringent quality control measures, and managing logistics effectively, they help businesses meet customer demands and stay competitive in the market. Overall, container blending suppliers serve as invaluable resources for businesses seeking efficient and reliable blending solutions to enhance their operations and deliver high-quality products to the market.

0 notes

Text

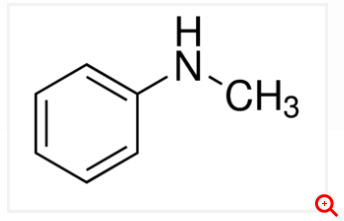

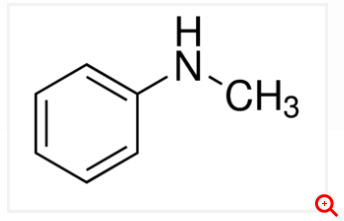

N-МЕТИЛАНИЛИН NMA МОНОМЕТИЛАНИЛИН 292142000 N-Methylaniline CAS 100-61-8 NMA sample is free have in stock

QUICK DETAILS Product name:N-Methylaniline CAS:100-61-8 Molecular formula:C7H9N Molecular weight:107.15 EINECS No.:202-870-9 Purity:≥99% Brand:MIT -IVY INDUSTRY CO.,LTD Other names:N-methyl-aniline;N-Methylaniline;N-methylphenylamine;N-methyl-N-phenylamine;N-Phenylmethylamine;Methylaniline;N-methyl-aminobenzene;Methylphenylamine;N-Monomethylaniline Appearance:light yellow liquid Port: any port in china Packing:according to the clients requirement Physicochemical Property It is inflammable and explosive when it comes in contact with fire,high temperature and oxidizers. It is a pale yellow or reddish brown liquid that is dissolved in alcohol, ether chloroform and semisoluble in water.The molecular weight is 107.15,boiling point is 194-197℃ and the melting point is -57℃. Application This product is mainly applicable to pesticide intermediate, dyestuff intermediate, medicinal intermediate and organic synthetic materials, as well as used as gasoline octane booster, acid absorbent, solvent and explosive stabilizer. Storage & Transport It should be stored in the cool ware-houses with good ventilation,keep from fire and heat source, packed in the sealed container and separated from oxidizer, acidoid and edible chemicals. Mixed storage and transportation are not allowed. It must be protected from insolation,rain and heat during transport. Specification N- methyl aniline content is not less than % 99.5 99.0 98.0 95.0 Aniline content is not higher than % 0.1 0.2 0.4 3.0 Content of N,N- dimethylaniline is not higher than % 0.3 0.7 1.6 2.5 Moisture content is not higher than % 0.1 0.1 0.1 0.5 CAS:100-61-8 N-MethylAniline NMA PACKING : 22.5 net TONS ISO TANK or IBC 1000KG we 1000monthly/ton payment : TT 50% IN advance ,the balance by delivery the goods MIT-IVY INDUSTRY is Product organic intermediates in China.which location in suzhou city ANHUI privince.Welcome to our factory. Your company is a very well-known company. I saw your company's customs procurement data that many products you purchased are from our factory, but you purchased from foreign trade companies. 1:One of our main products is N-MethylAniline, purity min 99%, CAS number 100-61-8, chemical formula C7H9N. 2:We have a total of 6 production lines, and now we are starting 2 equipment. The monthly output of NMA is 1000 tons. 3) If out of stock, We will immediately activate the other equipment to fulfill the order. 4: Recently, the market demand is very large, we are now going all out to produce, the use of technology is continuous production method, that is, gas chromatography 5: We have in stock for 500tons ,can deliver goods at any times.(But I've got a few clients in talks. They should be booked up soon.) 6: Can you come to inspect our the factory ? Storage: Store in dry, dark and ventilated place. Transportation: by sea or by air payment methods: L/C, T/T, D/A, D/P, O/A, paypal, western union etc.accept all payment. Application 1. Used as a dye intermediate 2. N-Methylaniline is not only the raw material for the insecticide buprofezin, but also used for the synthesis of its intermediate N-chloromethyl N-phenylcarbamoyl chloride and the intermediate for the herbicide fenthiazide. It is widely used in the dye industry. 3. The product is used as an intermediate of organic synthesis, acid absorbent and solvent, and used in the production of cationic brilliant red FG, cationic peach red B, active yellow brown KGR, etc. in the dye industry. Сведения О Продукте N-метиланилина NMA CAS 100-61-8 является анилин производной. Это органические соединения

с химической формулой C6H5NH(CH3) с кипения составляет 194-197C и точка плавления -57 C. . Вещество существует как бесцветная или слегка желтоватая вязкой жидкости и коричневого при контакте с воздуха . Химическое вещество нерастворимо в воде. это огнеопасных и взрывоопасных когда он приходит в контакт с огнем, высокой температуры и окислителей. он используется как латентных и растворителей муфты и также используется как промежуточного красители, агрохимикатов и других органических продуктов производства. NMA является токсичным и воздействие может вызвать повреждение центральной нервной системы и может также привести к пе��еночной и почечной недостаточности. спецификации элемента первый класс второй класс общий класс Assay % ≥99.00 ≥98.50 ≥95.00 анилина % ≤0.30 ≤0.50 ≤2.50 N, N-диметиланилин % ≤0.50 ≤0.80 ≤2.00 других и влаги % ≤0.20 ≤0.20 ≤0.50 применения применяются главным образом к пестицидов промежуточные, красители промежуточные, лекарственные промежуточные и органические синтетические материалы , как хорошо как используется как бензина октановым руля, кислоты абсорбента, растворителей и взрывных стабилизатора . упаковка 200 кг/Железный барабан, 80drums/20 ' FCL (16mt) Superiority 1. Best quality in your requirement 2. Competitive price in china market 3. Mature technical support 4. Professional logistic support 5 . Full experience of large numberscontainers loading in chinese sea port 6 .Fast shipment by reputed shipping line 7. Packing with pallet as buyer's special request 8. Best service after shipment. 9. Full experience in export 10. Raw materials from chinese origin Chi Tiết Sản Phẩm N Methylaniline NMA CAS 100-61-8 là một dẫn xuất anilin. Nó là một

hợp chất hữu cơ với công thức hóa học C6H5NH(CH3) với sôi là 194-197C và điểm nóng chảy là-57 C. . Các chất tồn tại như là một chất lỏng không màu hoặc màu vàng hơi nhớt và biến màu nâu khi tiếp xúc với không khí . Hóa chất được hòa tan trong nước. nó là dễ cháy nổ khi tiếp xúc với lửa, nhiệt độ cao và oxidizers. nó được sử dụng như là một tiềm ẩn và khớp nối dung môi và cũng sử dụng như trung gian cho thuốc nhuộm, agrochemicals và sản phẩm hữu cơ sản xuất. NMA là độc hại và tiếp xúc có thể gây ra thiệt hại cho hệ thần kinh trung ương và cũng có thể gây gan và suy thận. đặc điểm kỹ thuật hàng đầu tiên lớp thứ hai lớp chung lớp khảo nghiệm % ≥99.00 ≥98.50 ≥95.00 Anilin % ≤0.30 ≤0.50 ≤2.50 N, N-dimethylaniline % ≤0.50 ≤0.80 ≤2.00 khác & ẩm % ≤0.20 ≤0.20 ≤0.50 ứng dụng chủ yếu áp dụng đối với thuốc trừ sâu Trung cấp, thuốc màu trung gian, y học Trung cấp và hữu cơ tổng hợp vật liệu , như cũng được sử dụng như xăng tăng cường chỉ số octan, chất ổn định acid thấm nước, dung môi và chất nổ . đóng gói 200kg/sắt trống, 80drums/20 ' container (16mt) Company Information MIT-IVY INDUSTRY CO.,LTD is a manufacturer and exporter of fine chemical dyes & pharmaceutical intermediates in China. Mainly produce aniline series products and chlorine series products. We are a young company full of vitality and vitality. The company has a group of energetic, well-trained employees and strong technical research and development capabilities. We specialize in the production, development and sales of API intermediates, fine chemicals and plant extracts. Relying on advanced equipment and strict management, adhere to the business philosophy of "openness, tolerance, innovation, and sharing" to create a win-win cooperationplatform.Everything comes from innovation, it is our philosophy ! If you are interested in getting more quotations, please add WHATSAPP:0086-13805212761 or E-MAIL:[email protected] Main products MIT-IVYINDUSTRYCO.,LTDMit-Ivy is a well-known fine chemicals and pharmaceutical intermediates manufacturer with strong R&D support in China. Mainly involved Aniline, Chlorine products. Payment:DA 60 DAYS TEL:008619961957599 E-MAIL:[email protected] 产品 Product CAS N,N-二甲基-1,4-苯二胺 N,N-Dimethyl-1,4-phenylenediamine DMPD 99-98-9 N,N-二甲基苄胺 N,N-Dimethylbenzylamine BDMA 103-83-3 N,N-二甲基甲酰胺 N,N-Dimethylformamide DMF .68-12-2 N,N-二甲基甲酰胺二甲缩醛 DMF-DMA N,N-Dimethylformamidedimethyl acetal (DMF-DMA) 4637-24-5 N,N-二甲基乙酰胺 N,N-Dimethylacetamide DMAC 127-19-5 N,N-二乙基间甲苯甲酰胺 避蚊胺 N,N-diethyl-m-toluamide DEET 134-62-3 N,N-二乙基羟胺 N,N-Diethylhydroxylamine DEHA 3710-84-7 N-甲基-N-羟乙基苯胺 2-(N-甲基苯胺)乙醇 2-(N-methylanilino)ethanol 93-90-3 N-甲基吡咯烷酮 N-methylpyrrolidone 872-50-4 N,N-二甲基苯胺 N,N-Dimethylaniline DMA 121-69-7 N,N-二甲基对甲苯胺 N,N-Dimethyl-p-toluidine DMPT 99-97-8 N,N-二甲基邻甲苯胺 N,N-Dimethyl-o-toluidine DMOT 609-72-3 N,N-二乙基苯胺 N,N-Diethylaniline 91-66-7 N,N-二乙基间甲苯胺 N,N-Diethyl-m-toluidine 91-67-8 N,N-二羟乙基苯胺 N,N-Dihydroxyethylaniline PDEA 120-07-0 N-乙基间甲苯胺 N-乙基-3-甲基苯胺 N-Ethyl-m-toluidine/N-Ethyl-3-methylaniline 102-27-2 N-乙基-N-氰乙基苯胺 3-(N-ethylanilino)propiononitrile 148-87-8 N-乙基-N-羟乙基苯胺 N-Ethyl-N-hydroxyethylaniline 92-50-2 N-乙基-N-苄基苯胺 乙基苄基苯胺; N-苄基-N-乙基苯胺 N-ethyl-N-phenylbenzenemethanamine 92-59-1 N-乙基-N-氰乙基间甲���胺 N-2-cyanoethyl-N-ethyl-m-toluidine 148-69-6 N-乙基-N-苄基间甲苯胺 N-Benzyl-N-ethyl-m-toluidine 119-94-8 N-乙基邻甲苯胺 N-Ethyl-o-toluidine/2-Ethylaminotoluene 94-68-8 N-乙基苯胺 N-Ethylaniline 103-69-5 N-甲基苯胺 N-Methylaniline 100-61-8 N,N-二甲基-间甲基苯胺 N,N-DIMETHYL-M-TOLUIDINE 121-72-2 N-甲基二苯胺 N-Methyldiphenylamine 552-82-9 N-甲基-邻甲基苯胺 N-METHYL-O-TOLUIDINE 611-21-2 N-甲基-对甲基苯胺 N-METHYL-P-TOLUIDINE 623-08-5 4-甲基-N-苯基苯胺 N-PHENYL-P-TOLUIDINE 620-84-8 N-异丙基苯胺 N-ISOPROPYLANILINE 768-52-5 N,N-二氰乙基苯胺 N,N-Dicyanoethylaniline 1555-66-4 N,N-二羟乙基-对甲基苯胺 N,N-DIHYDROXYETHYL-P-TOLUIDINEDHEPT .3077-12-1 N-乙基-2-硝基苯胺 N-Ethyl-2-Nitro-Benzenamine 10112-15-9 2,4-二氯苯胺 2,4Dichloroaniline 554-00-7 N-(2-羟乙基)乙二胺 AEEA 111-41-1 1,3-二甲基-2-咪唑啉酮N,N-二甲基亚乙基脲1,3-二甲基-2-咪唑啉酮(DMI) 1,3-Dimethyl-2-imidazolidinone DMI N,N'-dimethylimidazolidinone 80-73-9 N,N-二苄基羟胺 N,N-Dibenzylhydroxylamine 621-07-8 对甲苯胺 P-Toluidine PT 106-49-0 邻甲苯胺 O-Toluidine OT 95-53-4 二乙基乙醇胺 DEEA;DEAE 100-37-8 甲萘胺 AlphaNaphthylamine 134-32-7 间二氯苯 1,3-Dichlorobenzene MDCB 541-73-1 间甲苯胺 M-Toluidine MT 108-44-1 间苯二胺 M-PHENYLENEDIAMINE MPDA 108-45-2 多乙烯多胺 PEPA 68131-73-7 二乙烯三胺(DETA) Diethylenetriamine DETA 111-40-0 三乙烯二胺 Triethylenediamine 280-57-9 三乙烯四胺 TriethylenetetramineTETA 112-24-3 四乙烯五胺 TEPA 112-57-2 Read the full article

#100-61-8#292142000#chemicalrawmaterials#Chemicals#Dyeintermediates#Finechemicals#inorganicchemicals#Insecticideintermediates#Methylaniline#methylphenylamine#Monomethylaniline#N-methyl-aminobenzene#N-methyl-aniline;N-Methylaniline;N-methylphenylamine;N-methyl-N-phenylamine;N-Phenylmethylamine#N-methyl-aniline,N-Methylaniline'N-methylphenylamine,N-methyl-N-phenylamine,N-Phenylmethylamine;Methylaniline,#N-Methylaniline#N-Monomethylaniline#N-МЕТИЛАНИЛИН#organicchemicalrawmaterials#Organicrawmaterials#pesticideintermediates#МОНОМЕТИЛАНИЛИН

0 notes

Text

Exploring the Benefits of Liquid Transport Tanks in Modern Logistics

Transporting bulk liquids across vast distances has always posed significant challenges, primarily due to the need for specialized containers that can handle large volumes while ensuring safety and efficiency. Traditionally, industries relied on standard methods like drums, ISO tanks, or IBCs (Intermediate Bulk Containers) for liquid transportation. However, a game-changing solution has emerged over the past few decades: Flexitanks, liquid transport tanks.

What are Flexitanks?

Flexitanks are large, liquid transport tanks (flexible containers) made from multiple layers of polyethylene and an outer covering of woven polypropylene. They are designed to fit inside standard 20-foot shipping containers, converting them into efficient bulk liquid transportation units. Capable of holding between 16,000 to 24,000 liters of liquid, flexitanks are quickly becoming the preferred choice for many industries, including food, chemicals, and pharmaceuticals.

Advantages of Using Liquid Transport Tanks

Cost-Effectiveness: Flexitanks significantly reduce transportation costs compared to traditional methods. They eliminate the need for returning empty containers, as they are single-use and disposable. This reduces shipping expenses by allowing companies to focus only on outbound logistics, avoiding the additional costs associated with the return of ISO tanks or other reusable containers.

Increased Payload: With flexitanks, businesses can maximize their cargo payload. The flexible design allows for more efficient use of container space, enabling the transportation of up to 30% more liquid than traditional containers of the same size. This increased capacity translates to fewer shipments and reduced freight costs.

Versatility: Flexitanks can transport a wide variety of non-hazardous liquids, including food-grade oils, wines, fruit juices, pharmaceuticals, and certain chemicals. Their adaptability makes them a valuable asset for industries with diverse liquid transportation needs.

Ease of Use: Installing a flexitank inside a shipping container is a straightforward process that requires minimal labor and time. Once the liquid is offloaded at the destination, the flexitank can be easily disposed of, simplifying the logistics chain and saving on labor costs associated with cleaning and returning traditional containers.

Environmental Benefits: While flexitanks are single-use, many manufacturers are committed to sustainability, offering recycling programs to minimize environmental impact. Additionally, the reduction in return freight trips contributes to lower carbon emissions, aligning with global efforts to reduce the transportation industry’s ecological footprint.

The Future of Liquid Bulk Transportation

The shift towards flexitanks, liquid transport tanks, signifies a broader trend in the logistics industry: the move towards more flexible, cost-effective, and sustainable solutions. As global trade continues to expand and the demand for efficient transportation grows, innovations like flexitanks will play a pivotal role in meeting these needs.

In conclusion, Fluid Flexitanks are revolutionizing the way bulk liquids are transported, offering numerous advantages over traditional methods. With their cost-effectiveness, increased payload, versatility, and ease of use, they provide a compelling alternative for industries looking to optimize their logistics operations. As technology continues to advance, we can expect flexitanks to become even more integral to the global supply chain, supporting businesses in their quest for efficiency and sustainability.

0 notes