#smartfactories

Explore tagged Tumblr posts

Text

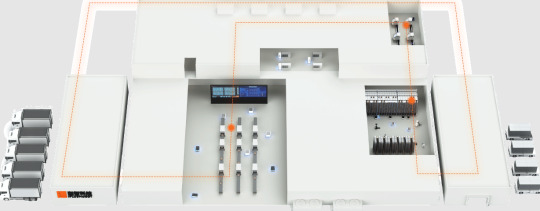

The Rise of Smart Factories: IPLUSMOBOT’s Cutting-Edge Manufacturing Solutions

As technology continues to evolve and disrupt traditional industries, manufacturing has been one of the most impacted. In recent years, smart factories have emerged as the future of manufacturing, enabling businesses to leverage the latest technological advancements to improve production efficiency, quality, and reduce costs. IPLUSMOBOT is at the forefront of this revolution, offering cutting-edge manufacturing solutions that help businesses stay ahead of the curve.

Smart factories are essentially manufacturing plants that rely on advanced technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and robotics to streamline production processes, enhance worker safety, and boost productivity. IPLUSMOBOT’s Futuristic Manufacturing Technologies have been developed with these technologies in mind, helping businesses overcome the challenges of traditional manufacturing.

One of the key benefits of IPLUSMOBOT’s smart manufacturing solutions is improved efficiency. The company’s state-of-the-art technology enables businesses to automate repetitive and mundane tasks, freeing up workers to focus on more strategic and creative work. This can significantly reduce production time and increase output, leading to a more efficient and profitable manufacturing process.

In addition to increased efficiency, IPLUSMOBOT’s solutions also enhance quality control. Smart factories rely on sensors and real-time monitoring to identify potential defects or issues in the production process, allowing businesses to take corrective action before products leave the factory floor. This leads to fewer defects, reduced waste, and improved customer satisfaction.

Another benefit of IPLUSMOBOT’s smart manufacturing solutions is increased safety for workers. By automating dangerous or hazardous tasks, businesses can minimize the risk of workplace accidents and injuries, protecting both their workers and their bottom line.

Finally, IPLUSMOBOT’s smart factories are highly flexible, enabling businesses to adapt quickly to changing customer demands and market trends. The company’s solutions can be easily reconfigured to accommodate new product lines or changes in production processes, allowing businesses to stay agile and responsive to market demands.

In conclusion, smart factories represent the future of manufacturing, and IPLUSMOBOT is leading the charge with its cutting-edge solutions. By leveraging advanced technologies such as IoT, AI, and robotics, the company’s smart factories offer businesses significant benefits in terms of efficiency, quality control, worker safety, and flexibility. With IPLUSMOBOT’s solutions, businesses can stay ahead of the curve and maintain a competitive edge in today’s fast-paced manufacturing environment.

2 notes

·

View notes

Text

Enhancing Industrial Efficiency with PLC Automation Panels

Today’s industrial world revolves around one term: automation. Gently changing the face of the industrial world, automation has become the backbone of manufacturing excellence. As a company that began as a pioneer in turnkey electrical solutions in 2002, Accord Automation has witnessed at first hand how PLC Automation Panels have changed the industrial processes of most sectors.

1. What are PLC Automation Panels?

PLC automation panels are advanced control systems, which have been considered the brain of industrial automation in the modern age. These panels integrate PLCs with a number of control components for the management and monitoring of manufacturing processes. Our strength in developing rugged, user-friendly solutions has made us a partner of reliance for the implementation of automation systems across various industries-from food and beverages automation to complex manufacturing operations.

2. Key Components of a PLC Automation Panel

The industrial automation degree depends on the quality and integration of these key components:

a. Programmable Logic Controller (PLC)

b. Human Machine Interface (HMI)

c. Input/Output Modules

d. Power Supply Units

e. Circuit Protection Devices

f. Communication Interfaces

Our research team is optimising these components so that they can handle hostile operating environments with simplicity in operation.

3. Benefits of Using PLC Panels in Industrial Automation

Through MCC Panels Automation Services with PLC systems, the following benefits are integrated:

a. Improvement in Operations Efficiency

b. Less Human Error

c. Real-time Monitoring Abilities

d. Higher Safety Standards

e. Predictive Maintenance

f. Energy Efficiency

g. Improved Machine Intelligence

Our focus on machine intelligence has allowed us to create systems that transcend simple automation, integrating predictive maintenance and sophisticated safety solutions.

4. Applications of PLC Automation Panels Across Industries

Our systems fit industrial applications in the following sectors:

a. Food and Beverage

The Food Beverages Automation division enjoys our control systems’ accuracy, which means consistent outcomes in the products while adhering to food safety standards.

b. Weighting and Treatment

Our Weighing and Batching Automation incorporates accuracy measurement and control, always a critical need for those industrial sectors involved with accurate material handling.

c. Fortification Systems

The Rice Fortification System designed by our engineers proves our capability to design customised solutions for particular industrial needs hence supporting public health initiatives through automated nutrient addition.

d. Manufacturing and Process Control

Our MCC Panels Automation Services are indispensable in manufacturing processes as they offer trustworthy power distribution and motor control.

5. How to Choose the Right PLC Automation Panel for Your Needs

Selecting the appropriate automation system is a significant decision that involves considering a number of criteria:

a. Process Requirements

b. Production volume

c. Automation level

d. Required synch

e. Environmental Conditions

f. Operating temperature

g. Moisture range

h. Dust exposure and vibration

i. Operator Skill Level

j. Training required

k. Ease of maintenance

l. Technical support required

m. Scalability

n. Future expansion

o. Compatibility with existing systems

We believe at Accord Automation that every industry has something unique about their requirements. We work closely with our clients to put together specifically customised solutions to the unique and specific needs of our clients. Whether it is implementing Weighing and Batching Automation or designing comprehensive Rice Fortification System solutions, our team ensures that the final implementation meets the requirements of today and the scalability needs of tomorrow.

We learned that successful automation installation goes beyond just installing the equipment with 18 years of industry experience. It is an understanding of the client’s process, the different challenges he might face, and his goals as well. Hence the simplicity we make it as simple, so operators with minimal technical expertise can effectively manage the systems.

Intelligent systems that predict and prevent problems from happening form the future of industrial automation. We work on our innovations; continuous feedback from our customers has enabled us to make them more efficient and reliable. Whether it is simple PLC Automation Panels or sophisticated machine intelligence applications, we’re about breaking the limits of what can be done in industrial automation.

You choose Accord Automation not only for a system but for an entire solution that is reinforced by years of experience, continuous research, and comprehensive support. Through respect, professionalism, and perseverance, our core values ensure solutions that don’t just meet expectations but exceed clients’ expectations.

Do not hesitate to contact us today to learn how our automation solutions can transform your industrial operations in order to be moved forward for better efficiency and effectiveness.

#PLCAutomation#IndustrialAutomation#AutomationSolutions#ManufacturingExcellence#SmartFactories#ProcessOptimization#MachineIntelligence#EfficiencyBoost#AccordAutomation

0 notes

Text

Predictive Maintenance in Smart Factories: Combining AI, IoT, and Blockchain for Transparent Operations ⚙️🤖

In the era of Industry 4.0, smart factories are rapidly transforming the manufacturing landscape. By integrating advanced technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and Blockchain, predictive maintenance is taking operational efficiency to new heights. Here’s how these technologies work together to optimize manufacturing processes and ensure transparency:

1. AI-Driven Predictive Analytics 🧠🔍

AI algorithms analyze vast amounts of sensor data from machines to predict potential equipment failures before they occur. By detecting patterns and anomalies, AI enables maintenance teams to address issues proactively, reducing downtime and minimizing disruptions.

2. IoT-Connected Devices for Real-Time Monitoring 📡⚙️

IoT sensors are embedded into machinery to continuously monitor equipment health. These devices collect real-time data on temperature, vibration, pressure, and more, providing actionable insights. This constant monitoring allows for timely interventions, ensuring that maintenance is performed exactly when needed.

3. Blockchain for Transparency and Trust 🔗🔐

Blockchain technology adds a layer of security and transparency to maintenance records. Every action taken on a machine, from repairs to software updates, is recorded in an immutable ledger. This ensures that all stakeholders have access to a trusted, tamper-proof history of equipment performance, maintenance activities, and warranties.

4. Cost Efficiency and Extended Equipment Lifespan 💡💸

Predictive maintenance reduces unnecessary repairs and extends the life of expensive machinery by ensuring that it’s serviced based on actual conditions rather than fixed schedules. This minimizes costs related to breakdowns and parts replacement, making factory operations more cost-efficient.

5. Enhanced Productivity and Reduced Downtime ⏳🔧

By predicting potential equipment failures, factories can schedule maintenance during off-peak times, avoiding costly shutdowns. This proactive approach keeps production lines running smoothly, boosting productivity and optimizing operational efficiency.

#PredictiveMaintenance#SmartFactories#AI#IoT#Blockchain#Industry40#ManufacturingInnovation#SMT#FactoryEfficiency#IndustrialIoT#TechInManufacturing

0 notes

Text

How Automation is Transforming Plastic Processing Machinery

In today’s fast-paced world of plastic processing machinery, the introduction of automation is transforming how manufacturers operate. The demand for precision, speed, and efficiency has pushed companies to adopt advanced automation technologies that not only improve productivity but also reduce waste, lower energy consumption, and increase overall production quality. Automation in plastic processing has moved beyond simple mechanization—it's now the driving force for industry leaders looking to stay competitive.

The Role of Automation in Plastic Processing

Automation plays a critical role in streamlining plastic processing operations. Traditionally, many tasks in plastic processing—such as material handling, part inspection, and quality control—were labor-intensive and prone to human error. By integrating automated systems, companies can now achieve greater accuracy, enhanced repeatability, and shorter production cycles. This ultimately leads to higher production outputs without compromising product quality.

Material Handling Efficiency

One of the key areas where automation is revolutionizing plastic processing is material handling. Automated systems, such as robotic arms, are now widely used to manage raw materials, move components between different stages of production, and organize the final product. These systems are highly efficient in reducing human intervention, thus minimizing the risks of contamination and material loss. Additionally, the speed and precision of automated material handling systems greatly surpass what human workers can achieve, resulting in faster throughput times.

Precision and Accuracy in Molding Processes

Injection molding is a critical process in plastic manufacturing that benefits tremendously from automation. In traditional setups, manually operated machines could introduce significant variations in product quality. Automated injection molding machines use advanced control systems to regulate temperature, pressure, and timing with a level of precision unattainable by human operators. This leads to consistent quality across large production runs and significantly reduces the rejection rate due to defects. Automation ensures that every part is produced to exact specifications, meeting the increasingly stringent standards of various industries such as automotive, aerospace, and medical devices.

Increased Speed and Reduced Cycle Times

One of the most prominent advantages of automation is the drastic reduction in cycle times. In plastic processing, every second saved in production is crucial to maintaining profitability. Automated machinery can operate continuously without the fatigue or errors associated with human labor. As a result, manufacturers can achieve faster turnaround times on large orders while maintaining a high level of consistency and quality. Additionally, automation allows for quicker changeovers between different production lines, which is particularly valuable in industries that require customized plastic products.

Robotics in Assembly and Post-Processing

Automated robotics are also playing a transformative role in assembly and post-processing tasks. For instance, robots can be programmed to perform complex assembly tasks that would be difficult or time-consuming for human workers. They can handle intricate procedures such as welding, cutting, trimming, and polishing plastic components with unmatched precision and speed. By automating these processes, manufacturers can significantly cut down on labor costs while ensuring the highest standards of quality.

Automation in Quality Control and Inspection

In plastic processing, ensuring product quality is of paramount importance. Automation is increasingly being applied to quality control and inspection processes to detect defects or inconsistencies that might not be easily noticeable by the human eye. Automated vision systems equipped with high-resolution cameras and AI-driven algorithms can inspect every part in real-time, identifying defects at an early stage. This proactive approach helps to minimize waste, as faulty components can be immediately removed from the production line, preventing costly downstream issues.

Data Collection and Analysis

Another benefit of integrating automation into plastic processing machinery is the ability to collect and analyze large amounts of operational data. Automated systems are equipped with sensors that monitor various parameters—such as temperature, pressure, and cycle times—throughout the production process. This data can be used for predictive maintenance, which reduces downtime by identifying potential equipment failures before they occur. Additionally, data analytics helps manufacturers optimize their processes by pinpointing inefficiencies and making real-time adjustments.

Sustainability and Energy Efficiency

The integration of automation in plastic processing machinery is also driving significant improvements in sustainability and energy efficiency. Automated systems can be programmed to minimize energy consumption, ensuring that machinery only operates at full capacity when necessary. This leads to reduced power usage, which in turn lowers production costs and minimizes the environmental footprint of manufacturing operations. Moreover, automation helps to reduce material waste by improving the accuracy of production processes and limiting the need for rework or material scrapping.

Reducing Human Labor and Increasing Safety

While automation increases production efficiency, it also improves workplace safety by reducing the need for human labor in hazardous environments. Many tasks in plastic processing involve exposure to high temperatures, heavy machinery, and harmful chemicals. By replacing human workers with automated machinery, manufacturers can drastically lower the risk of workplace accidents. Automated systems are also equipped with safety features that shut down the machinery in the event of malfunctions, further enhancing operational safety.

The Future of Plastic Processing Machinery

As technology continues to advance, we can expect even more sophisticated automation solutions to emerge in the plastic processing industry. Artificial Intelligence (AI) and machine learning are poised to play a significant role in the next phase of innovation. These technologies will enable plastic processing machinery to self-optimize, learning from past data to improve performance over time. Collaborative robots, or cobots, will also become more prevalent, working alongside human operators to handle more complex tasks and further boosting productivity.Smart factories equipped with fully automated systems and interconnected machinery will redefine the landscape of plastic manufacturing. These factories will leverage the power of IoT (Internet of Things) to communicate real-time data across the production floor, ensuring seamless operation and instant troubleshooting. Ultimately, the future of plastic processing will be marked by increased automation, reduced environmental impact, and greater efficiency in every aspect of production.

#Automation#PlasticProcessing#ManufacturingTech#IndustrialAutomation#SmartFactories#RoboticsInManufacturing#InjectionMolding#Sustainability#AIinManufacturing#MachineLearning#FactoryAutomation#EnergyEfficiency#Industry40#AdvancedManufacturing#PrecisionEngineering

0 notes

Text

Unlocking the Future of Manufacturing with Generative AI! 🌟

Generative AI is revolutionizing the manufacturing industry by optimizing designs, reducing costs, and speeding up production. With its ability to analyze vast data sets, it empowers companies to create innovative products tailored to customer needs. Imagine smart factories that adapt in real time, ensuring efficiency and sustainability!

Explore how generative AI is shaping the future of manufacturing and driving competitive advantages for companies worldwide.

👉 Read more to see how this technology is transforming industries!

0 notes

Text

0 notes

Text

What are the latest trends and innovations in the manufacturing industry?

The manufacturing industry is experiencing several trends and innovations that are transforming operations and improving efficiency. Here are some of the latest trends:

1.Industry 4.0: The creation of smart factories through the integration of cutting-edge technologies like big data analytics, artificial intelligence (AI), and the Internet of Things (IoT). Predictive maintenance, real-time monitoring, and more productive manufacturing procedures are made possible by these technologies.

2. Automation and Robotics: These technologies are being used more often in manufacturing to increase productivity, lower labor costs, and improve precision. Because of their capacity to securely assist human workers, collaborative robots, or cobots, are likewise becoming more and more popular.

3. Additive Manufacturing (3D Printing): 3D printing is becoming more and more popular for producing complicated parts, bespoke products, and quick prototypes. With this technique, production may be done on demand and waste can be decreased.

4. Digital Twins: Virtual representations of real assets or processes made possible by the application of digital twin technology. This makes it possible to simulate, analyze, and optimize manufacturing processes in a virtual setting prior to deployment.

5. Smart Supply Chains: Implementation of AI and blockchain to enhance transparency, traceability, and efficiency in supply chains. Smart supply chains enable better inventory management and demand forecasting.

6. Sustainability: A greater emphasis on energy-efficient procedures, eco-friendly material selection, waste minimization programs, and other sustainable manufacturing techniques. Reuse and recycling are encouraged through the integration of circular economy ideas.

7. Advanced Materials: The creation of novel materials with improved characteristics, such as alloys with high strengths, lightweight composites, and materials with intelligence that adapts to changes in the environment.

8. Augmented Reality (AR) and Virtual Reality (VR): Utilization of AR and VR for training, maintenance, and design processes. Workers can enjoy immersive experiences thanks to these technologies, which also aid in envisioning intricate industrial scenarios.

9. Cybersecurity: There is a growing focus on defending data and manufacturing systems against online attacks. The increasing digitization of production makes network and data security against hackers essential.

10. Predictive Analytics: Use of predictive analytics to forecast equipment failures, optimize production schedules, and improve overall operational efficiency. Minimizing downtime and making well-informed decisions are facilitated by data-driven insights.

These trends and innovations are shaping the future of manufacturing, driving efficiency, reducing costs, and improving product quality.

#Industry4.0#IoT#ArtificialIntelligence#3DPrinting#AdditiveManufacturing#Automation#Robotics#GreenManufacturing#SmartFactories#DigitalTwins#AdvancedMaterials#Blockchain

0 notes

Text

#IndustrialWLAN#IIoT#EdgeComputing#SmartFactories#WirelessNetworking#IndustrialAutomation#NetworkSecurity#WirelessConnectivity#C#CyberSecurity

0 notes

Text

Unlock the future of manufacturing with AI agents

Unlock the future of manufacturing with AI agents! Transform your production lines into highly efficient, smart systems that predict maintenance needs, optimize workflows, and enhance quality control. AI agents provide real-time insights and adapt to changes, ensuring seamless operations and minimizing downtime. Imagine a factory where machines communicate, learn, and improve autonomously. This isn't the future—it's now! Embrace innovation and stay ahead of the curve by integrating AI into your manufacturing process.

Ready to revolutionize your manufacturing?

Read More:

#Manufacturing#Industry4#AI#SmartFactories#Innovation#TechRevolution#Automation#EfficientProduction#SmartManufacturing

0 notes

Video

youtube

Industrial Data Acquisition Solution Based on FET6254-C SoM featuring TI’s AM6254 CPU

#IndustryTechTalk EP 06: Transform your smart factory operations with the Forlinx FET6254-C SoM!

The FET6254-C SoM, using TI’s AM62x series processor, supports multiple communication interfaces and peripherals, ensuring efficient and reliable industrial data management and control. Benefit from robust connectivity with dual Gigabit Ethernet and a plethora of interfaces.

Designed with ARM Cortex-A53 and Cortex-M4F cores, this SoM excels in real-time industrial data acquisition and processing. FET6254-C SoM:

https://www.forlinx.net/product/am625x-system-on-module-127.html

The Blog:

https://www.forlinx.net/article_view_550.html

#youtube#forlinxembedded#FET6254CSoM#TexasInstruments#AM6254#TI SitaraAM62x#IndustrialIoT#SmartFactories#DataAcquisitionControl#automation

0 notes

Text

The Evolution of Industrial Manufacturing Companies: Adapting to the Digital EraIndustrial

Industrial manufacturing companies have long stood as pillars of economic growth and technological advancement. These entities are integral to the production of goods, infrastructure development, and the creation of employment opportunities worldwide. Over time, these companies have navigated through various eras of the Industrial Revolution, adapting to changing technologies, market demands, and global trends. Today, the digital era presents a new set of challenges and opportunities for industrial manufacturing companies, urging them to embrace innovation and transformation to stay competitive in a rapidly evolving market.

Evolution through Industrial Revolutions:

1. First Industrial Revolution – Mechanization and Steam Power

During the 18th and 19th centuries, the First Industrial Revolution marked the shift from hand production methods to machinery, powered primarily by steam engines. Industries such as textiles, iron, and coal mining saw substantial transformations, setting the foundation for modern manufacturing practices.

2. Second Industrial Revolution – Mass Production and Electricity

Advancements in the late 19th and early 20th centuries brought forth the Second Industrial Revolution. Electricity, assembly lines, and mass production techniques revolutionized manufacturing, leading to increased productivity and the rise of large-scale factories.

3. Third Industrial Revolution – Automation and Computers

The latter half of the 20th century witnessed the Third Industrial Revolution, characterized by the integration of electronics, IT, and automation into manufacturing processes. Computers, robotics, and programmable logic controllers (PLCs) redefined production methods, streamlining operations and enhancing precision.

4. Fourth Industrial Revolution – Industry 4.0 and Digitalization

The ongoing Fourth Industrial Revolution, often termed Industry 4.0, emphasizes the convergence of physical and digital technologies. This era is marked by interconnected systems, IoT (Internet of Things), AI (Artificial Intelligence), machine learning, big data analytics, and cyber-physical systems, transforming traditional manufacturing into smart, data-driven processes.

Challenges Faced by Industrial Manufacturing Companies in the Digital Era:

1. Technological Integration:

Adopting and integrating advanced technologies into existing infrastructures pose challenges regarding compatibility, cybersecurity, and workforce upskilling. Industrial manufacturing Companies must invest in R&D and training to leverage these innovations effectively.

2. Data Management and Security:

With increased connectivity and data collection, the challenge lies in managing vast amounts of data securely. Cybersecurity threats are a growing concern, requiring robust systems to safeguard sensitive information.

3. Changing Consumer Expectations:

Consumer demands for customization, faster delivery, and sustainable products are reshaping manufacturing processes. Flexibility and agility are essential to meet these evolving preferences.

4. Global Competition and Supply Chain Disruptions:

Globalization has intensified competition while exposing vulnerabilities in supply chains, as seen during recent disruptions like the COVID-19 pandemic. Companies need resilient, adaptable supply chains to mitigate risks.

Embracing Opportunities and Innovations:

1. Implementing Smart Manufacturing Practices:

Leveraging IoT sensors, AI-driven predictive maintenance, and real-time analytics, industrial manufacturing companies can optimize production processes, minimize downtime, and enhance quality.

2. Adoption of Additive Manufacturing (3D Printing):

3D printing technology offers the flexibility to produce complex components on demand, reducing waste and inventory while enabling rapid prototyping and customization.

3. Focus on Sustainability and Green Manufacturing:

Embracing eco-friendly practices and renewable energy sources not only reduces environmental impact but also resonates with a growing segment of environmentally conscious consumers.

4. Investing in Talent and Skill Development:

Addressing the skills gap through training programs and partnerships with educational institutions is crucial for a workforce capable of operating and optimizing digitalized manufacturing systems.

Enhancing Connectivity and Interoperability:

1. Embracing Interconnectivity:

Industrial IoT and interconnected devices facilitate seamless communication between machinery, systems, and stakeholders. This interconnectedness optimizes operations, enhances collaboration, and enables real-time decision-making.

2. Standardization and Interoperability:

Adopting common standards for communication protocols and interoperability frameworks is crucial for ensuring compatibility across diverse technologies and equipment, fostering a more cohesive and efficient manufacturing ecosystem.

Advanced Robotics and Automation:

1. Collaborative Robotics (Cobots):

Integration of collaborative robots alongside human workers streamlines tasks, improves safety, and boosts efficiency. These robots are designed to work in close proximity to humans, aiding in intricate or repetitive tasks.

2. Autonomous Systems:

The deployment of autonomous systems, including self-driving vehicles for material movement and drones for inventory tracking and inspection, optimizes logistics and enhances operational efficiency.

Digital Twin Technology:

1. Simulation and Modeling:

Digital twin technology creates virtual replicas of physical assets, enabling predictive analysis, scenario testing, and optimizing manufacturing processes without disrupting actual operations.

2. Lifecycle Optimization:

By monitoring and analyzing real-time data from the digital twin, companies can improve product development, optimize performance, and predict maintenance needs, leading to cost savings and improved product quality.

Reshaping Business Models:

1. Servitization and Product-as-a-Service (PaaS):

Shifting from a traditional product-centric model to offering services or outcomes allows companies to forge closer relationships with customers, providing solutions rather than just products.

2. Circular Economy Initiatives:

Adopting circular economy principles by reusing, refurbishing, or recycling products and materials contributes to sustainability goals while opening new revenue streams through reverse logistics and remanufacturing.

Regulatory and Ethical Considerations:

1. Compliance and Ethical Use of Data:

Navigating regulatory frameworks regarding data privacy, intellectual property rights, and ethical AI usage is essential. Companies need to uphold ethical standards while harnessing the power of data-driven technologies.

2. Sustainability Regulations:

Adhering to evolving environmental regulations and sustainability standards becomes paramount. Companies must align their practices with these regulations to meet market expectations and ensure long-term viability.

Conclusion:

The evolution of industrial manufacturing companies in the digital era transcends technological advancements; it encompasses a holistic transformation in business strategies, operational paradigms, and societal responsibilities. Embracing connectivity, advanced robotics, digital twin technology, innovative business models, and ethical considerations defines a new era of manufacturing excellence. As these entities navigate the complexities of the digital age, their ability to harness these opportunities while addressing challenges will determine their resilience and success in shaping a sustainable and technologically advanced future.

Also Read: The Evolving Landscape of Manufacturing Jobs: Opportunities and Challenges

#IndustryEvolution#digitaltransformation#sustainability#smartfactories#DataDrivenManufacturing#greentechnology#digitaltwin

0 notes

Text

How to make a Kamishibai board?

Read More: https://tcard.leantransitionsolutions.com/kamishibai-kanban-boards

#industry4.0#industry4now#lean#leanprinciple#leantransformation#digitaltransformation#tcards#innovation#manufacturing#digitisation#manufacturers#smartfactories#kamishibailean#resourcemanagement#tcardsonline#digitaltcards#kamishibai#processconfirmation#kamishibaitcard#digitalkamishibaiboard#kamishibaikanbanboard#kanbanboards

0 notes

Text

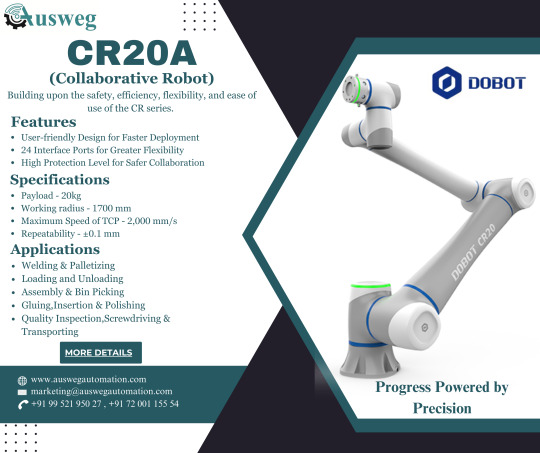

DOBOT CR20A Performance Unleashed With High Payload and Wide Radius

www.auswegautomation.com [email protected] +91 99 521 950 27, +91 72 001 155 54

#cobots#collabrativerobots#automation#industry40#robotics#manufacturing#ai#roboticstechno#digitaltransformation#innovation#techtrends#futureofwork#smartfactory#industrialautomation#productivity#workplacesafety#efficiency#humanrobotcollabration#roboticsindustry#advancedmanufacturing

2 notes

·

View notes

Text

Explore how Blockchain and IoT together are game-changers for Industry 4.0 and how businesses can leverage this powerful combination to create a smarter, more connected future.

0 notes

Text

#5G#smartfactories#next_gen#data#seamlesscommunication#machines#automation#electronicsnews#technologynews

0 notes

Text

Smart Factory ( ThirdEye AI)

Contact for more- https://third-eye.ai

0 notes