#PLCAutomation

Explore tagged Tumblr posts

Text

Enhancing Industrial Efficiency with PLC Automation Panels

Today’s industrial world revolves around one term: automation. Gently changing the face of the industrial world, automation has become the backbone of manufacturing excellence. As a company that began as a pioneer in turnkey electrical solutions in 2002, Accord Automation has witnessed at first hand how PLC Automation Panels have changed the industrial processes of most sectors.

1. What are PLC Automation Panels?

PLC automation panels are advanced control systems, which have been considered the brain of industrial automation in the modern age. These panels integrate PLCs with a number of control components for the management and monitoring of manufacturing processes. Our strength in developing rugged, user-friendly solutions has made us a partner of reliance for the implementation of automation systems across various industries-from food and beverages automation to complex manufacturing operations.

2. Key Components of a PLC Automation Panel

The industrial automation degree depends on the quality and integration of these key components:

a. Programmable Logic Controller (PLC)

b. Human Machine Interface (HMI)

c. Input/Output Modules

d. Power Supply Units

e. Circuit Protection Devices

f. Communication Interfaces

Our research team is optimising these components so that they can handle hostile operating environments with simplicity in operation.

3. Benefits of Using PLC Panels in Industrial Automation

Through MCC Panels Automation Services with PLC systems, the following benefits are integrated:

a. Improvement in Operations Efficiency

b. Less Human Error

c. Real-time Monitoring Abilities

d. Higher Safety Standards

e. Predictive Maintenance

f. Energy Efficiency

g. Improved Machine Intelligence

Our focus on machine intelligence has allowed us to create systems that transcend simple automation, integrating predictive maintenance and sophisticated safety solutions.

4. Applications of PLC Automation Panels Across Industries

Our systems fit industrial applications in the following sectors:

a. Food and Beverage

The Food Beverages Automation division enjoys our control systems’ accuracy, which means consistent outcomes in the products while adhering to food safety standards.

b. Weighting and Treatment

Our Weighing and Batching Automation incorporates accuracy measurement and control, always a critical need for those industrial sectors involved with accurate material handling.

c. Fortification Systems

The Rice Fortification System designed by our engineers proves our capability to design customised solutions for particular industrial needs hence supporting public health initiatives through automated nutrient addition.

d. Manufacturing and Process Control

Our MCC Panels Automation Services are indispensable in manufacturing processes as they offer trustworthy power distribution and motor control.

5. How to Choose the Right PLC Automation Panel for Your Needs

Selecting the appropriate automation system is a significant decision that involves considering a number of criteria:

a. Process Requirements

b. Production volume

c. Automation level

d. Required synch

e. Environmental Conditions

f. Operating temperature

g. Moisture range

h. Dust exposure and vibration

i. Operator Skill Level

j. Training required

k. Ease of maintenance

l. Technical support required

m. Scalability

n. Future expansion

o. Compatibility with existing systems

We believe at Accord Automation that every industry has something unique about their requirements. We work closely with our clients to put together specifically customised solutions to the unique and specific needs of our clients. Whether it is implementing Weighing and Batching Automation or designing comprehensive Rice Fortification System solutions, our team ensures that the final implementation meets the requirements of today and the scalability needs of tomorrow.

We learned that successful automation installation goes beyond just installing the equipment with 18 years of industry experience. It is an understanding of the client’s process, the different challenges he might face, and his goals as well. Hence the simplicity we make it as simple, so operators with minimal technical expertise can effectively manage the systems.

Intelligent systems that predict and prevent problems from happening form the future of industrial automation. We work on our innovations; continuous feedback from our customers has enabled us to make them more efficient and reliable. Whether it is simple PLC Automation Panels or sophisticated machine intelligence applications, we’re about breaking the limits of what can be done in industrial automation.

You choose Accord Automation not only for a system but for an entire solution that is reinforced by years of experience, continuous research, and comprehensive support. Through respect, professionalism, and perseverance, our core values ensure solutions that don’t just meet expectations but exceed clients’ expectations.

Do not hesitate to contact us today to learn how our automation solutions can transform your industrial operations in order to be moved forward for better efficiency and effectiveness.

#PLCAutomation#IndustrialAutomation#AutomationSolutions#ManufacturingExcellence#SmartFactories#ProcessOptimization#MachineIntelligence#EfficiencyBoost#AccordAutomation

0 notes

Text

PLC Automation Panels Compared: OEM vs. Custom Solutions

In the realm of industrial automation, Programmable Logic Controllers (PLCs) serve as the backbone, orchestrating the intricate dance of machinery, processes, and data. However, when it comes to implementing PLC systems, businesses are often faced with a crucial decision: should they opt for Original Equipment Manufacturer (OEM) panels or invest in custom solutions tailored to their specific needs? Let’s delve into the nuances of each option to uncover which best suits your industrial automation requirements.

OEM Panels:

Pros:

1. Standardization: OEM panels are pre-designed and manufactured to industry standards, ensuring compatibility with a wide range of applications. 2. Cost-Effectiveness: Mass production of OEM panels often translates to lower costs per unit, making them a more budget-friendly option for businesses with standardized automation needs. 3. Ease of Installation: With standardized designs and components, OEM panels typically offer straightforward installation processes, minimizing downtime during setup.

Cons:

1. Limited Customization: While OEM panels offer a plug-and-play solution, they lack the flexibility to accommodate unique requirements or specialized functionalities specific to your operations. 2. Scalability Challenges: As your automation needs evolve, OEM panels may struggle to scale alongside your business, potentially requiring costly upgrades or replacements in the future.

Custom Solutions:

Pros:

1. Tailored to Your Needs: Custom solutions are designed from the ground up to align precisely with your operational requirements, offering bespoke functionalities and features tailored to optimize efficiency and productivity. 2. Enhanced Compatibility: By integrating seamlessly with existing systems and processes, custom solutions mitigate compatibility issues and streamline data exchange across your automation ecosystem. 3. Scalability and Future-Proofing: Designed with scalability in mind, custom solutions can adapt and grow alongside your business, accommodating evolving needs and technological advancements without necessitating complete overhauls.

Cons:

1. Higher Initial Investment: Custom solutions often require a higher initial investment compared to off-the-shelf OEM panels due to the design and development processes involved. 2. Extended Lead Times: The bespoke nature of custom solutions means longer lead times for design, development, and manufacturing, potentially delaying implementation timelines.

Conclusion:

In the realm of PLC automation panels, the choice between OEM and custom solutions hinges on the unique requirements, priorities, and long-term objectives of your business. While OEM panels offer standardized functionality at a lower cost, they may fall short in accommodating specialized needs or future scalability. On the other hand, custom solutions provide unparalleled flexibility, scalability, and optimization tailored to your specific operational landscape, albeit at a higher initial investment. Ultimately, businesses must weigh the trade-offs between cost, customization, and long-term scalability to make an informed decision that aligns with their automation strategy and objectives. If you want more information on these type of topics so,

visit here👉https://www.pujacontrols.com/

#PLCautomation#AutomationPanels#OEMvsCustom#IndustrialAutomation#ManufacturingTech#CustomSolutions#PLCcomparison#FactoryAutomation#EngineeringSolutions#ProcessControl

0 notes

Video

tumblr

IPCS as a Company, always known as expertise in Industrial Automation Training as well as Services. The Training Programs that we provide are the latest in technological advancements trends to challenge in the immensely competitive areas of PLC, SCADA, DCS, HMI, VFD, Panel Design & Electrical Controls. Our Training programs are built to be Practically Oriented aimed at Training Freshers & Professionals equally so that they could meet up with the Industry expectations. Provided below are the list of Programs which are custom built for Freshers, Professionals or Industry Experts.

0 notes

Photo

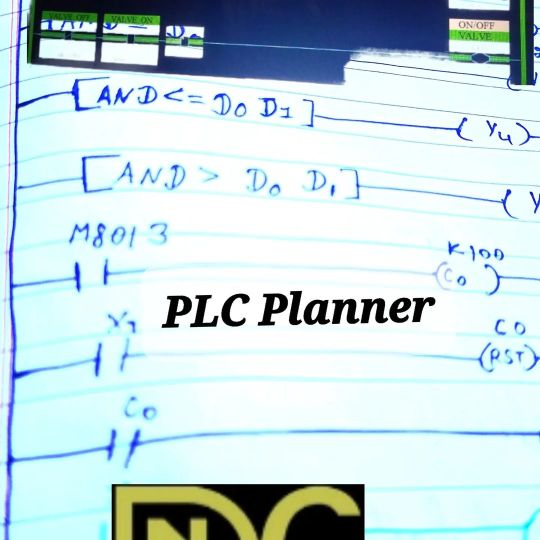

Logics for Control Process 🌐🔮 . . . . . . . . . . . #plc_delta #plcautomation #plcgroup #plcplanner #plcladderlogic #plcscada #plctraining #plcnext #plcsiemens #plcproject #plcs #plcindonesia #plc_challenge #plccourse #plcprogrammingclasss #plcbandung #automation #automationtesting #automationanywhere #automationengineering #automationsystems #automationcontrol #industrialautomation #industrialdesign #designer #industrialplcmonitoring #industrialautomation #industrialevent #industrialdesigner (at Alwar City, Rajasthan, India) https://www.instagram.com/p/Ca5G6hwPhI_/?utm_medium=tumblr

#plc_delta#plcautomation#plcgroup#plcplanner#plcladderlogic#plcscada#plctraining#plcnext#plcsiemens#plcproject#plcs#plcindonesia#plc_challenge#plccourse#plcprogrammingclasss#plcbandung#automation#automationtesting#automationanywhere#automationengineering#automationsystems#automationcontrol#industrialautomation#industrialdesign#designer#industrialplcmonitoring#industrialevent#industrialdesigner

0 notes

Text

PLC SCADA Training at SAGE India

PROGRAMMABLE LOGIC CONTROLLER (PLC)

What is a PLC?

A Programmable Logic Controller, or PLC, is a ruggedized PC utilized for industrial automation. These controllers can automate a particular cycle, machine work, or even a whole creation line. A PLC is a Computer specially intended to operate reliably under harsh industrial conditions – like outrageous temperatures, wet, dry, and/or dusty conditions. PLCs are utilized to automate industrial cycles, for example, a manufacturing plant assembly line, a metal handling plant, or a wastewater treatment plant. A PLC shares some of its features with a PC that we use at home although it uses a different operating software.

How does a PLC Work?

● A PLC Scan Process incorporates the accompanying advances

● The operating framework starts cycling and checking of time.

● The CPU starts reading the data from the information module and checks the status of all the data sources.

● The CPU starts executing the client or application program written in relay-ladder logic or any other PLC-programming language.

● Then, the CPU plays out all the internal diagnosis and communication tasks.

● According to the program results, it composes the data into the yield module so that all yields are updated.

● This cycle proceeds as long as the PLC is in run mode

A PLC program is normally composed on a computer and afterward is downloaded to the controller

Most PLC programming offers programming in Ladder Logic, or "C". Ladder Logic is the conventional programming language. It mirrors circuit graphs with "rungs" of logic read passed on to the right. Each rung addresses a particular activity constrained by the PLC, beginning with information or series of data sources (contacts) that outcome in a yield (curl). On account of its visual nature, Ladder Logic can be simpler to execute than numerous other programming dialects.

"C" writing computer programs is a later development.

Some PLC producers supply control programming.

PHYSICAL STRUCTURE OF A PLC

Programmable Logic Controllers consistently monitor the input esteems from different input detecting gadgets (for example accelerometer, weight scale, designed signs, and so forth) and produce corresponding output contingent upon the idea of creation and industry. A commonplace square outline of PLC comprises of five sections to be specific: ● Rack or chassis

● Power Supply Module

● Central Processing Unit (CPU)

● Input and Output Module

● Communication Interface Module

CERTIFIED PLC PROGRAMMER COURSE AT SAGE AUTOMATIONS

SAGE Automations India offers the best and an all-round certification course in PLC that can help all kinds of engineers, working professionals and freshers to level up their skill in the field of automation.

COURSE HIGHLIGHTS:

➔Complete understanding of all the aspects of the Programmable Logic Control (PLC) ➔ PLC Learning with a 90% practical and 10 % theory ➔ Award winning TTIM training platform Ideal for :Working professionals with prior work knowledge & experience, who currently require a skill upgrade in PLC technology

WHY SAGE AUTOMATIONS?

For most Universities in India, the prospectus doesn't cover the Automation subjects in detail. Engineering students need some extra exposure and skills as far as ideas and application to become industry-prepared. The courses at Sage India are intended to make your work prepared and are application-oriented along these lines to how any Automation organization would do their task. Consequently, this will assist you with beginning working straightforwardly on projects when you go into the Automation Industry. Check out our automation courses now to gain an edge in the working industry!

0 notes

Link

#industrial#industrialautomation#industrialautomationtraining#industrialautomationtraininginchennai#plcautomation#plc#scada#wiztech#wiztechteam#wiztechautomation#wiztechautomationsolutions#automationtraining.info#www.automationtraining.info

0 notes

Link

IPCS as a Company, always known as expertise in Industrial Automation Training as well as Services. The Training Programs that we provide are the latest in technological advancements trends to challenge in the immensely competitive areas of PLC, SCADA, DCS, HMI, VFD, Panel Design & Electrical Controls. Our Training programs are built to be Practically Oriented aimed at Training Freshers & Professionals equally so that they could meet up with the Industry expectations. Provided below are the list of Programs which are custom built for Freshers, Professionals or Industry Experts.

1 note

·

View note

Photo

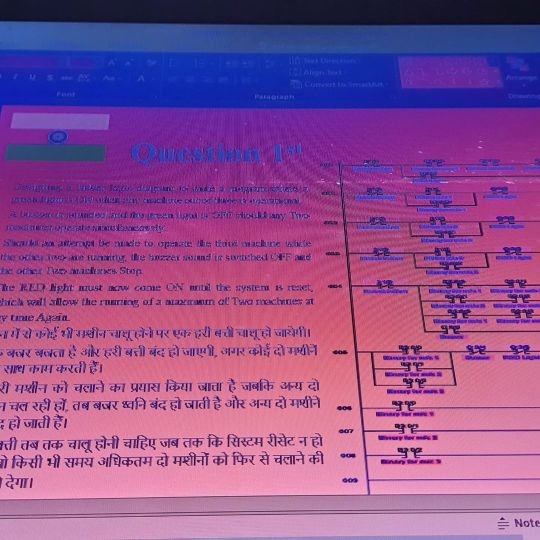

Process Control Question = logical Stepping Solution #plc #plcautomation #plctraining #plcproject #plcindonesia #plccourse #plc_challenge #plcprogrammer #plcprogramming #plcprogrammingclasss #plcsiemens #plc_delta #plcscada #plcgroup @plcscada_automation_electrical #plcs #plcfamily #plcplanner (at Alwar City, Rajasthan, India) https://www.instagram.com/p/CXokxidvmy_/?utm_medium=tumblr

#plc#plcautomation#plctraining#plcproject#plcindonesia#plccourse#plc_challenge#plcprogrammer#plcprogramming#plcprogrammingclasss#plcsiemens#plc_delta#plcscada#plcgroup#plcs#plcfamily#plcplanner

0 notes

Photo

Sink Input Connection #plctraining #programmingmemes #plcproject #plc #plcautomation @out.of.controls #plcprogramming #plcprogrammer #automazioneindustriale #industrialdesign #industrial #industrialtraining (at Jaipur, Rajasthan) https://www.instagram.com/p/CVQnw-vBIsX/?utm_medium=tumblr

#plctraining#programmingmemes#plcproject#plc#plcautomation#plcprogramming#plcprogrammer#automazioneindustriale#industrialdesign#industrial#industrialtraining

0 notes

Photo

LogixPro Control Process #plctraining #plc #plcproject #plcautomation #plccourse #plcprogrammingclasss (at Jaipur, Rajasthan) https://www.instagram.com/p/CTzyht0IBrM/?utm_medium=tumblr

0 notes

Text

One Choice To Choose Your Career in PLC Automation Institute

Sage Automation has a well-prepared hardware lab for PLC training in Thane. Our trainers organize job oriented PLC training. Sage Automation is one of the well-equipped PLC SCADA training center in Thane. we offer training on a real-time industrial project which helps the student during a better understanding. Sage Automation & our trainers also help the student to urge placement in top MNCs by preparation at different strategies. we've designed PLC SCADA course syllabus as per industrial requirements to realize their professional goals.

In addition to the present, we've updated the syllabus as per industry requirements and well-structured lab through which aspirants learn the talents for Introduction to PLC SCADA, PLC SCADA Architecture, Programming, .dat and .dml files, Database components, Translate components, PLC training on real-time projects alongside placement. PLC Training Thane is provided by us as per the newest industry trends. we offer PLC SCADA Course in Thane ensuring the optimum level of data and efficiency to beat any critical technical issue. Since the day of our commencement, it's been our aim to assist the scholars to urge placement in reputed companies.

Facilitated with high tech infrastructure and modern lab facilities and therefore the options of choosing multiple courses at Thane location, Sage Automation campus is that the best PLC-SCADA Training Institute in Thane. we've trained thousands of aspirants automation at an affordable fee also provides course content notes to every candidate. PLC-SCADA Course in Thane is provided by us using ultra-modern infrastructure for performing well-practiced and real-time activities. Moreover, our well-trained and highly experienced counselors will assist you until placement. We warmly welcome our student’s feedback that helps us to form our training as better as possible.

Continue to read more

0 notes