#side sealing machine manufacturers

Explore tagged Tumblr posts

Photo

Heinkel He 111

The Heinkel He 111 was a medium two-engined bomber plane used by the German Air Force (Luftwaffe) during the Second World War (1939-45). Heinkel He 111s contributed significantly to such campaigns as the Battle of France, the Battle of Britain, and the London Blitz, but were increasingly replaced from 1941 by the more modern and faster Junkers Ju 88.

Early Designs

The He 111 was first imagined as a civil airliner for Lufthansa, but when the Nazis came to power in Germany in 1933, production turned more openly towards machines of war. The Treaty of Versailles after the First World War (1914-18) had strictly forbidden Germany from possessing a military air force, but the German leader Adolf Hitler (1889-1945) went ahead and formed several secret squadrons anyway. Another way around the restriction was to build civilian craft that could easily be converted into bombers; the He 111 fell into this latter category.

Designed by Siegfried and Walter Günter and based on their earlier He 70 model, the He 111 bomber was manufactured by Heinkel, an aviation company founded and run by Ernest Heinkel (1888-1958). Heinkel had extensive experience with military aircraft, having built planes for the German Navy and the Austro-Hungarian army in the First World War. After much debate between the German high command and Hitler, the Luftwaffe bomber command (Kampfwaffe) was obliged to adopt the position that bombers should primarily be used strategically to assist ground troops. This meant that unlike, say, the British Royal Air Force, the Luftwaffe concentrated not on heavy bombers but building squadrons of more versatile medium bombers. The He 111 was the result of this thinking, that is, an aircraft with multiple tactical uses, but one not capable of carrying very heavy bomb loads that could deliver a significant blow to ground targets. The He 111 was hampered, too, by its short range as the theatre of war expanded and Germany sought to bomb Britain.

The first He 111 prototype model was flown in February 1935 at the Heinkel works at Rostock-Marienehe (now Rostock). Design tweaks included shortening the wings and improving stability. At this stage, the aircraft were powered by BMW engines. By 1936, Lufthansa was flying a number of He 111s as airliners and transport planes. The aircraft achieved the title of 'the world's fastest passenger plane' when a top speed of 250 mph (402 km/h) was recorded.

Meanwhile, military versions were being built, which had a slightly longer nose and machine-gun armaments. The bomber version was not powerful enough for requirements, though, and the BMW engines were replaced with Daimler-Benz engines (later models replaced these again, this time with Junkers Jumos). By 1937, and thanks to a large ministerial order, Heinkel built a dedicated factory for He 111s at Oranienburg close to Berlin. Further developments followed such as increasing the fuel capacity and making the tanks self-sealing, increasing the armour protection, making a straighter wing so that factory production was more efficient, moving the forward gunner a little to the side to give the pilot better visibility, and giving more transparency to the cockpit area and nose section, a distinctive feature of the He 111.

Heinkel He 111s were first used in action by German forces participating in the Spanish Civil War (1936-9) in the Legion Condor units and then throughout the Second World War by the Luftwaffe. Other air forces which used He 111s included the Chinese, Hungarian, Romanian, Slovakian, Spanish, and Turkish.

Continue reading...

24 notes

·

View notes

Text

Curtiss SB2C-5 Helldiver

The Helldiver was developed to replace the Douglas SBD Dauntless. It was a much larger aircraft, able to operate from the latest aircraft carriers and carry a considerable array of armament. It featured an internal bomb bay that reduced drag when carrying heavy ordnance. Saddled with demanding requirements set forth by both the U.S. Marines and United States Army Air Forces, the manufacturer incorporated features of a "multi-role" aircraft into the design.

The Model XSB2C-1 prototype initially suffered development issues connected to its Wright R-2600 Twin Cyclone engine and three-bladed propeller; further concerns included structural weaknesses, poor handling, directional instability, and bad stall characteristics. In 1939, a student took a model of the new Curtiss XSB2C-1 to the MIT wind tunnel. Professor of Aeronautical Engineering Otto C. Koppen was quoted as saying, "if they build more than one of these, they are crazy". He was referring to controllability issues with the small vertical tail.

The first prototype made its maiden flight on 18 December 1940. It crashed on 8 February 1941 when its engine failed on approach, but Curtiss was asked to rebuild it. The fuselage was lengthened and a larger tail was fitted, while an autopilot was fitted to help the poor stability. The revised prototype flew again on 20 October 1941, but was destroyed when its wing failed during diving tests on 21 December 1941.

Large-scale production had already been ordered on 29 November 1940, but a large number of modifications were specified for the production model. Fin and rudder area were increased, fuel capacity was increased, self-sealing fuel tanks were added, and the fixed armament was doubled to four 0.50 in (12.7 mm) machine guns in the wings, compared with the prototype's two cowling guns. The SB2C-1 was built with larger fuel tanks, improving its range considerably.

The program suffered so many delays that the Grumman TBF Avenger entered service before the Helldiver, even though the Avenger had begun its development two years later. Nevertheless, production tempo accelerated with production at Columbus, Ohio and two Canadian factories: Fairchild Aircraft Ltd. (Canada), which produced 300 (under the designations XSBF-l, SBF-l, SBF-3, and SBF-4E), and Canadian Car and Foundry, which built 894 (designated SBW-l, SBW-3, SBW-4, SBW-4E, and SBW-5), these models being respectively equivalent to their Curtiss-built counterparts. A total of 7,140 SB2Cs and equivalent models were produced in World War II.

Initially poor handling characteristics and late modifications caused lengthy delays to production and deployment, to the extent that it was investigated by the Truman Committee, which turned in a scathing report. This contributed to the decline of Curtiss as a company. Neither pilots nor aircraft carrier skippers seemed to like it. Nevertheless, the type was faster than the Dauntless, and by the end of the Pacific War, the Helldiver had become the main dive bomber and attack aircraft on USN carriers.

By the time a land-based variant, known as the A-25 Shrike, became available in late 1943, the Western Allied air forces had abandoned dedicated dive-bombers. A majority of A-25s delivered to the US Army Air Forces were transferred to the US Marine Corps, which used the type only in one side campaign and non-combat roles. The British Royal Navy and the Royal Australian Air Force also cancelled substantial orders, retaining only a few aircraft for research purposes.

Nicknames for the aircraft included "Big-Tailed Beast" or just "Beast", "Two-Cee", and "Son-of-a-Bitch 2nd Class"; the latter nickname was derived from the name SB2C and the aircraft's reputation for having difficult handling characteristics.

Photo-Description:

Aircraft

Commemorative Air Force

Curtiss SB2C-5 Helldiver

Reg.: N92879

Code: 32

Location & Date

Wichita - McConnell AFB (IAB / KIAB)

Kansas, USA - September 25, 2010

Caption:

Photographer:

J Snyder (Oklahoma, USA)

18 notes

·

View notes

Text

What are the Uses of Custom Plastic Manufacturing ?

In this day and age, custom plastic manufacturing has turned into a foundation of current industry, giving custom-made solutions across a wide cluster of areas. From medical services to auto, the versatility of plastics and the accuracy of custom manufacturing methods have made it conceivable to address explicit issues with unmatched productivity. We should probably dig into the main purposes of custom plastic manufacturing and grasp its effect on different businesses.

1. Medical and Healthcare Applications

Custom plastic manufacturing is reforming the medical services industry. Medical gadgets, prosthetics, and parts of symptomatic machines are progressively being produced using custom-planned plastics. A plastic manufacturing company offers a few benefits, including solidness, lightweight properties, and the capacity to be cleaned. Custom plastic parts are utilized in creating needles, IV cylinders, catheters, and, surprisingly, perplexing parts of medical imaging machines. The accuracy presented by custom manufacturing guarantees that these parts fulfill severe medical guidelines, adding to better understanding consideration and results.

2. Automotive Industry

In the automotive sector, custom plastic parts are fundamental for both execution and style. From dashboard parts to many-sided motor parts, custom plastics give arrangements that assist with lessening the general load of vehicles, further developing fuel efficiency. They also offer resistance to corrosion and wear, enhancing the longevity of parts. Custom plastics are used in manufacturing bumpers, interior trims, and even under-the-hood components. Their versatility, akin to the innovations seen with plastic bottle manufacturers, allows for innovative designs and improved safety features, making modern vehicles more reliable and efficient.

3. Consumer Electronics

The consumer electronics industry depends intensely on custom plastic assembling for making solid and smooth items. Cell phones, workstations, and domestic devices frequently consolidate custom plastic parts that are intended to fit definitively and capability perfectly. These parts need to withstand day to day wear and tear while keeping an engaging look. Custom plastics are utilized in housings, buttons, connectors, and different inward parts, offering both underlying respectability and plan adaptability.

4. Packaging Solutions

Custom plastic manufacturing assumes an urgent part in the packaging business. It empowers the formation of packaging arrangements that are custom fitted to secure and protect items during transportation and capacity. Custom plastic packaging can be intended to meet explicit necessities, for example, being lightweight, strong, and impervious to dampness and synthetics. This is especially significant in the food and refreshment industry, where keeping up with the newness and security of items is principal. Custom packaging likewise takes into consideration creative shapes and plans that upgrade brand character and purchaser advance.

5. Industrial and Mechanical Parts

Businesses that require hearty and high-performance components frequently go to custom plastic manufacturing. Plastics can be designed to display properties like high rigidity, protection from outrageous temperatures, and compound strength. This makes them ideal for making parts utilized in apparatus, gear, and different modern applications. Custom plastic pinion wheels, orientation, seals, and lodgings are normally utilized in manufacturing settings, adding to the productivity and dependability of modern tasks.

6. Aerospace and Defense

In aerospace and defense, the demand for lightweight yet solid materials is basic. Custom plastic manufacturing meets this need by providing components that can withstand harsh environments while reducing the overall weight of aircraft and defense equipment. From interior cabin parts to specialized components in satellites and military gear, custom plastics offer the necessary performance characteristics and design flexibility required in these high-stakes applications.

Ely Global Pte. Ltd - Leaders in Custom Plastic Manufacturing

Ely Global Pte. Ltd spends significant time in custom plastic manufacturing, giving fitted solutions to different businesses. With state of the art innovation and a pledge to quality, they convey accurately designed plastic parts that meet explicit client needs, upgrading item execution and productivity across multiple sectors.

#plastic manufacturing company#wholesale plastic bottle suppliers#plastic water bottle caps recyclable

2 notes

·

View notes

Text

Did you know that some of America’s most popular candies (Tootsie Rolls! Peeps! Peanut Chews!) were invented by Jews?

How and why this came to pass is a remarkable tale that needs no sugarcoating.

In the 18th and 19th centuries, Jewish beet farmers throughout the Russian empire produced the bulk of the sugar necessary to satisfy the high demand of the European market. When many of these impoverished farmers fled their shetls at the turn of the 20th century and immigrated to the United States, they leveraged their sugar-processing skills to find employment in candy factories.

Many went on to open their shops; such is the case with Morris “Moishe” Cohen, founder of New York’s famous Economy Candy. Cohen, whose primary trade was shoe and hat repair, ran a sweets cart originally as a side hustle, but found that during the Depression, candy rather than cobbling was bringing in more cash. In 1937, Cohen converted his shop into a full-time confectionary selling sweetmeats, dried fruit, nuts, and gift baskets. More than 80 years later, Economy Candy is still run by Cohen’s descendants and has become a landmark for its incredibly vast (2,000 items and counting) selection of current, vintage and hard-to-find candies.

instagram

Having come from an esteemed line of candymakers in his native Austria, Leo Hirshfield simply thought he was carrying on his familial legacy when he opened his corner candy store in New York in 1896. But in 1908, he unknowingly permanently made the world a little sweeter upon rolling out his own personal invention: a chocolate-flavored chewy cylindrical roll he dubbed “Tootsie,” after his pet name for his daughter Clara.

instagram

A similar sweet success story is that of Romanian immigrant David Seltzer. After setting foot in his new home of Philadelphia, Seltzer made two fortuitous decisions. First, he changed his name to Goldenberg (a variation of Goldberg, which he heard was a “good” name to have in the United States), thereby relieving himself of a moniker that might have condemned him to a career involving bubbly water. Second (and to seal the deal), he went to work making carnival treats, then eventually transitioned into running his own candy business. One of Goldenberg’s most popular creations was a chewy walnut and molasses candy. Later, he swapped walnuts for more cost-effective peanuts, and Goldenberg’s Peanut Chews were born. During the First and Second World Wars, Goldenberg won numerous government contracts to produce Peanut Chews as a “nutritious” non-ration bar for American soldiers.

The flourishing family business was passed on to Goldenberg’s children, Sylvia and Harry, the latter of which passed it onto his sons, Ed and Carl, the latter of which passed it on to his son (also named) David. This great grandson of the original founder eventually sold the Peanut Chew empire in 2003 to Just Born candy company, which still produces the candy to this day under the Goldenberg name.

instagram

Jewish owned and operated Just Born company was also the catalyst for pioneering another classic confection. In 1953, the candy conglomerate acquired the Rodda company, which at the time devoted the majority of its production capacity to churning out jelly beans, only occasionally dabbling at the (significantly more labor-intensive) marshmallow treats known as Peeps. After owner Sam Born’s son Robert invented a machine that reduced production time from 27 hours to six minutes, the company rapidly became the world’s leading manufacturer (irony noted) of arguably America’s most iconic Easter candy.

instagram

What is perhaps most compelling about these bonbon backstories is that Hirshfield, Goldenberg, and others took what many might relegate as culinary juvenilia, candymaking, and demonstrated its potential as a form of high art by designing confections that made a lasting impact on the gastronomic landscape. In summarizing the American candy tradition, one might riff on the famous Marvin Gaye lyric, How sweet it is — and it’s made by Jews.

8 notes

·

View notes

Note

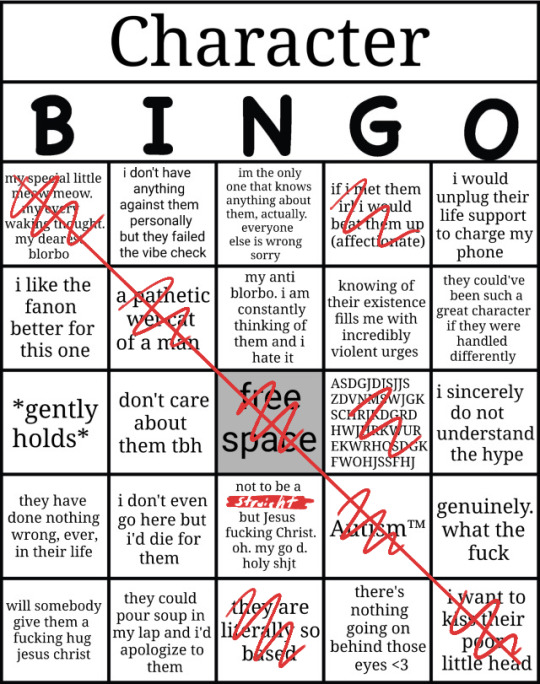

red and/or blue (this is how you lose the time war) for the character bingo !! :D

Hi

This is How You Lose the Time War is a story between Red and Blue. The two women are agents of warring entities; Red is a cybernetically enhanced super soldier operating under the Agency, a society manufactured from the heart of the great computer known only as “Commandant.” On the flip side, Garden is a growing collective consciousness in the form of a fungus tree, and Blue is its changeling scion turned paladin. Red and Blue travel through and bend timelines, or “strands”, to create a reality where their respective realms are dominant. The novel begins with an ill-intended letter from Blue and an unexpected response from Red, beginning a taunting, curious, and later intimate correspondence between the women as things fall apart.

Time War is epistolary science fiction. The novella complements its strict structure with fleshy, melodic language. Such as when the text says, “But when I think of you, I want to be alone together. I want to strive against and for. I want to live in contact. I want to be a context for you, and you for me.” Red and Blue’s letters to each other read like beating hearts- viscerally raw, their pulsating rhythm guides the reader through a cat-and-mouse game across strands of time. Messages are left in the rings of a tree destined to be cut down by the Mongols, in the innards of a whacked seal (a horrifying play on waxed seal), in the flowing lava of one of many sinking Atlantises. What one girl cultures, the other destroys; and by the time one future is eradicated another has already been seeded. Time War’s sci-fi setting is filled out by narrative sections seamlessly blending fact and the absurd. The Londons are just as much a physical place as the aforementioned Atlantises. Pilgrims to a labyrinth of bones created by the first snake are as tangible a group as the aforementioned Mongols. Wars and great men are footnotes to the designs prophesized for seemingly insignificant people. After Red hijacks a war in her Agency’s favor the text reads:

One spared life might be worth more to the other side than all the blood that stained Red’s hands today. A fugitive becomes a queen or a scientist, or, worse, a poet. Or her child does, or a smuggler she trades jackets within some distance spaceport. And all this blood for nothing.

The novel’s science fiction reflects the structure of its narrative. Just as the strands of time are non-linear and dependent on the person, Time War fully abandons genre fiction’s bias towards grand plot-driven epics in favor of an intimate love ballad- a window into two people’s struggle to accept the self and the other. Blue and Red are the best at their jobs and they are completely alone. Initially, the women believe each other to be a dreaded alien. A being incapable of existing in the same room as them, incapable of knowing them. But her curiosity gets the better of her; Blue asks Red if and how she eats. And then she asks Red if she knows hunger.

Turning and turning in the widening gyre / The falcon cannot hear the falconer.

Hunger is the omnipresent catalyst of this apocalypse. Red is a soldier, a remote mechanism in the clutches of a much larger machine. Her body, deisgned to endure, has no need for food; yet still her voracity knows no bounds. Red remarks that Commandent is suspicious of those who eat. At it’s core, her interest in food is her interest in the other. Her interest in Blue. Both are a betrayal to the Agency. Blue asks her, “Have you ever had a hunger that whetted itself on what you fed it, sharpened so keen and bright that is might spilt you open, break a new thing out?”

Things fall apart; the centre cannot hold; / Mere anarchy is loosed upon the world.

The women reflect on the few moments they have been truly alone. When Blue is sent by Garden to grow the plant that will kill the young, for-once alone Red, she takes the form of a six-legged wolf, butching the plant so that Red may live to tell her the tale. Later, when Blue consumes the poison Red, under the grasp of Commandment, set out for her, Red goes downthread to find young Blue and inject her a bit of anti-venom- enough for her to develop resistance to the posion. Blue was compromised by enemy action and will be sent away from Garden- she will be alone and she will be saved.

This is How You Lose the Time War is a brilliant deconstruction of science fiction- using the broad trope of time travel to express a complex, character-driven narrative. The story between Red and Blue is the story of self and the other- and the relaization that they were never separate in the first place. The book is cyclical in nature. At the end of every narrative section there is a mention of a “seeker” who is later revealed to be Red. The events of the novel are in the past, the present, and the future. Eternal. This is the nature of the Red and Blue.

#I’m so proud of myself for coming up with changeling scion#hmm I want to reorganize this . and talk about more stuff. meow.#wife is life tag

3 notes

·

View notes

Text

There is someone saying this about pretty much every brand of computer in the notes.

Failure rates across the big three brands (Dell, HP, and Lenovo) have consistently been at around 5% during the warranty period (typically one year for laptops and three years for desktops) since I started buying a few thousand computers a year in 2011.

If you are considering buying a laptop and you aren't certain if it's crap or not, check for reviews/product comparisons on PCWorld, PCMag, and Tom's Hardware.

There are people in the notes saying "how could you recommend dell when they have proprietary hardware?" or "how could you recommend HP when they come loaded with bloatware?"

You know how I said at the beginning that this is literally my job?

Yeah I have bad news for you about literally every brand of computer. They all come with some kind of bloatware these days. They all come with hardware bullshit, though some hardware bullshit is worse than others and some hardware bullshit impacts some populations more than others (for example: gamers and heavy users care a lot about Dell's processor throttling with third-party chargers. People who just use the browser and an office suite don't care because the don't notice. We sell third party chargers to dell users all the fucking time and none of them have noticed because as it turns out most people use their computers for email and watching cat videos and those don't actually require a shitload of processing power).

Fuck. As to bloatware, Windows 10 installed like eight candy crush games on my last laptop as well as a new disney game I had to uninstall with every major update. That's not a manufacturer problem, that's a "the entire ecosystem is fucked and the only way to fix it is linux" problem but this is a post for people who want to spend < $500 on a laptop and who don't know what RAM is so this is not the post where I'm making actual suggestions for how to fix things (keep every computer you own for as long as possible, upgrading the hardware yourself every 3-5 years, and install linux on every machine that doesn't 100% have to be windows for software/professional/etc. reasons)

But yeah. With every single computer you get there's going to be about a 1-in-20 chance *at least* that it's going to fail in the first year. This is because computers are complicated machines assembled by other complicated machines out of components that want to explode at the slightest provocation and hate humidity almost as much as they hate power fluctuations and almost as much as they love randomly springing bugs that take dozens of hours to chase down. For as cheap and as complicated as computers are, these are actually pretty good numbers.

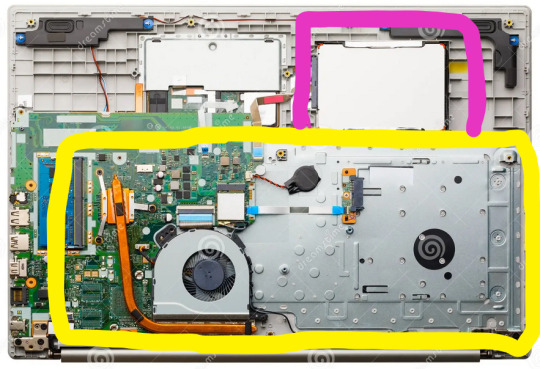

But also it's not terribly unusual for your laptop to have the keyboard directly over the drive if for no reason other than the fact that the keyboard is a huge part of the footprint of your laptop. Often drives are along the sides of the touchpad, but not always, and if there's room for a secondary drive it will likely be under the keyboard. But also nothing should have been able to fall through the bottom of the keyboard into any other components because the keyboard on laptops looks like this from underneath (outlined in yellow):

there's an impenetrable membrane of metal where all the wires and sensors and junk are so that the keyboard will actually read the key presses. (The pink outline is the drive in this computer but in newer laptops that's MUCH more likely to be where you'd find the battery because most laptops don't have external batteries anymore, they're totally enclosed within the case)

So I'm not sure who diagnosed your drive errors, but also hard drives inside computers look like this:

There's nowhere for dust to fall *into* either. These things are pretty well sealed specifically because dust can fuck with them, which is why it's not a big deal to shove them just any old where inside a computer case as long as you protect them from drop damage.

However a lot of laptops do have issues with dust and stuff clogging them up inside. The primary causes of this tend to be: eating with your computer in your lap, using your computer on soft surfaces (i know they're called laptops but your computer is going to operate MUCH MUCH better if you only use it on hard surfaces), owning pets, and smoking around your computer. This often manifests as overheating and is pretty simple to resolve by just opening the case and blowing out the dust.

If I was looking at a computer that had had 4 drive failures after replacing the drive I'd be looking at either the OS (windows 10 had a lot of massive write error issues that could be persistent and difficult to resolve) or a motherboard problem (wiring is funky for some reason and you just have to write it off), but I'm not sure what kind of drive failures you were having and obviously I can't diagnose this after the fact, I'm just saying that it probably wasn't a design flaw that let dust fall through the keyboard into the drive that was causing your problem.

(the laggy-from-the-start alienware, well, I'd want to know what specs you got the device with and what you were trying to run on it - avoiding lagginess from the start for basic users is the point of this post but those standards are different when you start talking about gaming machines, which are NOT my wheelhouse).

(also everybody uses the cheapest hardware they can get, dell just does that and then sticks their own logo on it - it's all the same guts, which is pretty easy to tell because there are a vanishingly small number of plants that make the components; you open up 80% of computers with an HDD in the last ten years and you're going to find a SeaGate or a Western Digital drive no matter whose name is on the case)

Like. I just want to go through the notes and take everyone's hand and look deeply into their eyes and tell them the truth: ALL COMPUTERS ARE BAD. (POSSIBLY and RECENTLY excepting FrameWork).

Everyone buys shit parts. The assembly is all done in the cheapest way possible. Everyone cares about volume over quality. None of these companies care about you or customer service and all of them want to do whatever they can to bump up sales numbers or upsell people on upgrades. The fact that you were able to send the computer into the manufacturer for repairs four times and get it back three times with some work ostensibly done indicates that you had an unusually good service plan and were getting unusually good service (a lot of manufacturers will do like two repairs to the same part and then just swap out the motherboard as a 'nuke it from orbit' solution so the fact that you still had anyone troubleshooting with you on round 4 was remarkable). (Though I do hope they paid you out in some way for your mislabeled computer and if anyone wants tips on how to yell about support cases let me know, that is ALSO literally my job).

Anyway. Yeah. Computers bad. The reason I named the big three is because they're the ones who usually have decent service plans available and have more easily findable parts because they make so fucking many of them. I can find you a bezel for a 3-year-old Dell XPS. If you ask me to find a bezel for a 3-year-old acer there's a decent chance that I'll have to buy a whole actual computer on Ebay to salvage the bezel. (a common problem that we have with the acer/asus computers is that they tend to be made of shittier plastic and the hinges break and then people come in thinking that it's a hinge, how much can it be michael, ten dollars? and then find out that in order to fix their shitty hinge we have to buy an entire second laptop used for $200 and hope that the hinges on that hunk of shit don't have similar wear, which they almost certainly do, which is why I'm fucking begging people to buy the $500 piece of junk with the aluminum case instead of the $300 heap of shit in the plastic case)

ANYWAY. YEAH. COMPUTERS BAD (sorry i just finished a final project and am avoiding my final exam and I am TIRED).

Generally speaking, computers bad.

But the only computer that has shit hardware that's not worth the cost 100% of the time and that is actively and intentionally hostile to user repairs in a way that Dell and HP could only dream of is Apple.

So You Need To Buy A Computer But You Don't Know What Specs Are Good These Days

Hi.

This is literally my job.

Lots of people are buying computers for school right now or are replacing computers as their five-year-old college laptop craps out so here's the standard specs you should be looking for in a (windows) computer purchase in August 2023.

PROCESSOR

Intel i5 (no older than 10th Gen)

Ryzen 7

You can get away with a Ryzen 5 but an intel i3 should be an absolute last resort. You want at least an intel i5 or a Ryzen 7 processor. The current generation of intel processors is 13, but anything 10 or newer is perfectly fine. DO NOT get a higher performance line with an older generation; a 13th gen i5 is better than an 8th gen i7. (Unfortunately I don't know enough about ryzens to tell you which generation is the earliest you should get, but staying within 3 generations is a good rule of thumb)

RAM

8GB absolute minimum

If you don't have at least 8GB RAM on a modern computer it's going to be very, very slow. Ideally you want a computer with at least 16GB, and it's a good idea to get a computer that will let you add or swap RAM down the line (nearly all desktops will let you do this, for laptops you need to check the specs for Memory and see how many slots there are and how many slots are available; laptops with soldered RAM cannot have the memory upgraded - this is common in very slim laptops)

STORAGE

256GB SSD

Computers mostly come with SSDs these days; SSDs are faster than HDDs but typically have lower storage for the same price. That being said: SSDs are coming down in price and if you're installing your own drive you can easily upgrade the size for a low cost. Unfortunately that doesn't do anything for you for the initial purchase.

A lot of cheaper laptops will have a 128GB SSD and, because a lot of stuff is stored in the cloud these days, that can be functional. I still recommend getting a bit more storage than that because it's nice if you can store your music and documents and photos on your device instead of on the cloud. You want to be able to access your files even if you don't have internet access.

But don't get a computer with a big HDD instead of getting a computer with a small SSD. The difference in speed is noticeable.

SCREEN (laptop specific)

Personally I find that touchscreens have a negative impact on battery life and are easier to fuck up than standard screens. They are also harder to replace if they get broken. I do not recommend getting a touch screen unless you absolutely have to.

A lot of college students especially tend to look for the biggest laptop screen possible; don't do that. It's a pain in the ass to carry a 17" laptop around campus and with the way that everything is so thin these days it's easier to damage a 17" screen than a 14" screen.

On the other end of that: laptops with 13" screens tend to be very slim devices that are glued shut and impossible to work on or upgrade.

Your best bet (for both functionality and price) is either a 14" or a 15.6" screen. If you absolutely positively need to have a 10-key keyboard on your laptop, get the 15.6". If you need something portable more than you need 10-key, get a 14"

FORM FACTOR (desktop specific)

If you purchase an all-in-one desktop computer I will begin manifesting in your house physically. All-in-ones take away every advantage desktops have in terms of upgradeability and maintenance; they are expensive and difficult to repair and usually not worth the cost of disassembling to upgrade.

There are about four standard sizes of desktop PC: All-in-One (the size of a monitor with no other footprint), Tower (Big! probably at least two feet long in two directions), Small Form Factor Tower (Very moderate - about the size of a large shoebox), and Mini/Micro/Tiny (Small! about the size of a small hardcover book).

If you are concerned about space you are much better off getting a MicroPC and a bracket to put it on your monitor than you are getting an all-in-one. This will be about a million percent easier to work on than an all-in-one and this way if your monitor dies your computer is still functional.

Small form factor towers and towers are the easiest to work on and upgrade; if you need a burly graphics card you need to get a full size tower, but for everything else a small form factor tower will be fine. Most of our business sales are SFF towers and MicroPCs, the only time we get something larger is if we have to put a $700 graphics card in it. SFF towers will accept small graphics cards and can handle upgrades to the power supply; MicroPCs can only have the RAM and SSD upgraded and don't have room for any other components or their own internal power supply.

WARRANTY

Most desktops come with either a 1 or 3 year warranty; either of these is fine and if you want to upgrade a 1 year to a 3 year that is also fine. I've generally found that if something is going to do a warranty failure on desktop it's going to do it the first year, so you don't get a hell of a lot of added mileage out of an extended warranty but it doesn't hurt and sometimes pays off to do a 3-year.

Laptops are a different story. Laptops mostly come with a 1-year warranty and what I recommend everyone does for every laptop that will allow it is to upgrade that to the longest warranty you can get with added drop/damage protection. The most common question our customers have about laptops is if we can replace a screen and the answer is usually "yes, but it's going to be expensive." If you're purchasing a low-end laptop, the parts and labor for replacing a screen can easily cost more than half the price of a new laptop. HOWEVER, the way that most screens get broken is by getting dropped. So if you have a warranty with drop protection, you just send that sucker back to the factory and they fix it for you.

So, if it is at all possible, check if the manufacturer of a laptop you're looking at has a warranty option with drop protection. Then, within 30 days (though ideally on the first day you get it) of owning your laptop, go to the manufacturer site, register your serial number, and upgrade the warranty. If you can't afford a 3-year upgrade at once set a reminder for yourself to annually renew. But get that drop protection, especially if you are a college student or if you've got kids.

And never, ever put pens or pencils on your laptop keyboard. I've seen people ruin thousand dollar, brand-new laptops that they can't afford to fix because they closed the screen on a ten cent pencil. Keep liquids away from them too.

LIFESPAN

There's a reasonable chance that any computer you buy today will still be able to turn on and run a program or two in ten years. That does not mean that it is "functional."

At my office we estimate that the functional lifespan of desktops is 5-7 years and the functional lifespan of laptops is 3-5 years. Laptops get more wear and tear than desktops and desktops are easier to upgrade to keep them running. At 5 years for desktops and 3 years for laptops you should look at upgrading the RAM in the device and possibly consider replacing the SSD with a new (possibly larger) model, because SSDs and HDDs don't last forever.

COST

This means that you should think of your computers as an annual investment rather than as a one-time purchase. It is more worthwhile to pay $700 for a laptop that will work well for five years than it is to pay $300 for a laptop that will be outdated and slow in one year (which is what will happen if you get an 8th gen i3 with 8GB RAM). If you are going to get a $300 laptop try to get specs as close as possible to the minimums I've laid out here.

If you have to compromise on these specs, the one that is least fixable is the processor. If you get a laptop with an i3 processor you aren't going to be able to upgrade it even if you can add more RAM or a bigger SSD. If you have to get lower specs in order to afford the device put your money into the processor and make sure that the computer has available slots for upgrade and that neither the RAM nor the SSD is soldered to the motherboard. (one easy way to check this is to search "[computer model] RAM upgrade" on youtube and see if anyone has made a video showing what the inside of the laptop looks like and how much effort it takes to replace parts)

Computers are expensive right now. This is frustrating, because historically consumer computer prices have been on a downward trend but since 2020 that trend has been all over the place. Desktop computers are quite expensive at the moment (August 2023) and decent laptops are extremely variably priced.

If you are looking for a decent, upgradeable laptop that will last you a few years, here are a couple of options that you can purchase in August 2023 that have good prices for their specs:

14" Lenovo - $670 - 11th-gen i5, 16GB RAM, and 512GB SSD

15.6" HP - $540 - 11th-gen i5, 16GB RAM, and 256GB SSD

14" Dell - $710 - 12th-gen i5, 16GB RAM, and 256GB SSD

If you are looking for a decent, affordable desktop that will last you a few years, here are a couple of options that you can purchase in August 2023 that have good prices for their specs:

SFF HP - $620 - 10th-gen i5, 16GB RAM, 1TB SSD

SFF Lenovo - $560 - Ryzen 7 5000 series, 16GB RAM, 512GB SSD

Dell Tower - $800 - 10th-gen i7, 16GB RAM, 512GB SSD

If I were going to buy any of these I'd probably get the HP laptop or the Dell Tower. The HP Laptop is actually a really good price for what it is.

Anyway happy computering.

50K notes

·

View notes

Text

SBJ Nirmal Products: Your Trusted Partner for High-Quality Rotavator Spare Parts

Agriculture is the backbone of the economy, and efficient farming equipment plays a critical role in ensuring high productivity. Among the essential farming tools, the rotavator is widely used for soil preparation, helping farmers achieve optimal soil conditions. The performance of a rotavator largely depends on the quality of its spare parts. This is where SBJ Nirmal Products stands out as a trusted manufacturer and supplier of durable and high-performance rotavator parts.

Introduction to SBJ Nirmal Products

SBJ Nirmal Products is a leading rotavator parts manufacturer in Ludhiana, Punjab, specializing in producing robust, affordable, and precision-engineered spare parts. With a commitment to excellence, the company serves farmers and agricultural dealers across India, Bangladesh, Nepal, Sri Lanka, and other global markets.

SBJ Nirmal Products is known for delivering cost-effective solutions, ensuring that farmers get the best quality rotavator components that enhance the lifespan and efficiency of their machinery.

Why SBJ Nirmal Products Stands Out?

1. Unmatched Quality Standards

SBJ Nirmal Products adheres to stringent quality control measures, ensuring that every rotavator spare part meets international standards. The company uses high-grade materials, advanced heat treatment processes, and cutting-edge CNC technology to manufacture parts that offer longevity and reliability.

2. Extensive Range of Rotavator Spare Parts

SBJ Nirmal Products offers a diverse collection of rotavator spare parts catering to various agricultural machinery brands. The product range includes:

Rotavator Blades (L-type, C-type, J-type)

Crown Pinions

Stub Axles

Side Gears

Gearbox Assemblies

Bearings and Oil Seals

Flanges and Shafts

3. Affordable and Durable Solutions

Understanding the financial constraints of farmers, SBJ Nirmal Products provides cost-effective rotavator parts that last longer, reducing the need for frequent replacements. The company's dedication to durability ensures that farmers experience maximum efficiency with minimal maintenance.

4. Expansive Market Reach

SBJ Nirmal Products has a robust distribution network across India, Bangladesh, Nepal, and Sri Lanka, ensuring that high-quality rotavator spare parts reach farmers and dealers promptly.

Exploring SBJ Nirmal Products’ Rotavator Spare Parts

1. Rotavator Blades

Rotavator blades play a critical role in soil preparation. SBJ Nirmal Products manufactures blades from hardened steel, ensuring superior strength and sharpness.

Key Features:

Available in L-type, C-type, and J-type.

Heat-treated for maximum durability.

Compatible with various rotavator brands.

2. Crown Pinions

Crown pinions are crucial for power transmission in rotavators, ensuring smooth and efficient operation.

Key Features:

Constructed from hardened alloy steel.

Ensures optimal torque transmission.

Minimizes friction for enhanced machine efficiency.

3. Stub Axles

Stub axles are essential for supporting the weight and movement of rotavators.

Key Features:

High load-bearing capacity.

Manufactured from high-strength steel.

Corrosion-resistant coating for extended lifespan.

4. Gearbox Assemblies

A high-quality gearbox ensures smooth functioning of the rotavator. SBJ Nirmal Products provides precision-engineered gearbox components that deliver high performance and longevity.

Key Features:

Manufactured using hardened steel.

Designed for minimal friction and maximum efficiency.

Enhances rotavator lifespan.

5. Bearings and Oil Seals

Bearings and oil seals play a vital role in reducing friction and ensuring smooth movement of the rotavator parts.

Key Features:

High load capacity for smooth operation.

Corrosion-resistant for extended durability.

Reduces wear and tear of rotavator components.

Commitment to Farmers and Dealers

SBJ Nirmal Products prioritizes farmers' needs, offering user-friendly, durable, and easy-to-install rotavator spare parts that enhance efficiency and productivity.

Customer-Centric Approach

Tailor-Made Solutions: SBJ Nirmal Products provides customized rotavator spare parts based on farmers’ requirements.

24/7 Customer Support: Dedicated support team to assist customers in selecting the right spare parts.

On-Time Delivery: Extensive logistics network ensuring timely supply of products.

Competitive Pricing Strategy

Best value for money without compromising on quality.

Special bulk purchase offers for dealers and distributors.

Reliable Logistics & Supply Chain

Nationwide and international distribution network.

Ensuring timely and secure deliveries across India, Bangladesh, Nepal, and Sri Lanka.

Why Choose SBJ Nirmal Products for Rotavator Parts?

✅ Years of Industry Experience – Trusted name in rotavator spare parts manufacturing. ✅ Global Recognition – Exporting to Bangladesh, Nepal, and Sri Lanka. ✅ Advanced Engineering – Precision-crafted components using state-of-the-art technology. ✅ Superior Performance – Heat-treated, corrosion-resistant, and high-strength parts. ✅ Affordable Solutions – Cost-effective spare parts for farmers and dealers. ✅ Sustainable Manufacturing – Eco-friendly and waste-minimized production practices.

Future Expansion Plans of SBJ Nirmal Products

SBJ Nirmal Products continues to innovate and expand its product range. Upcoming plans include:

Smart rotavator parts with digital monitoring features.

Eco-friendly coatings for extended durability.

Increased automation in manufacturing for improved precision and efficiency.

Conclusion

SBJ Nirmal Products is the go-to manufacturer for premium-quality rotavator spare parts. With a commitment to affordability, durability, and efficiency, SBJ Nirmal Products ensures that farmers and dealers receive the best-in-class rotavator components to enhance agricultural productivity.

For top-quality rotavator blades, crown pinions, stub axles, gearbox components, and more, trust SBJ Nirmal Products. Experience unparalleled quality and superior performance!

#sbj nirmal#agriculture#rotavator parts manufacturer#farming#agricultural machinery parts#rotavator#sbj#sbj nirmal products#high-quality rotavator parts#agricultural equipment

0 notes

Text

The Ultimate Guide to Hydraulic Seals manufacturer by Crown Rubber Works premium quality Industrial

In the world of mechanical engineering, hydraulic seals play a crucial role in ensuring the smooth operation of various hydraulic systems. From piston seals to rod seals, wiper seals to guide rings, each type of hydraulic seal has its own unique function and importance. Let's dive deeper into the world of hydraulic seals and explore the different types and applications of these essential components.

What are Hydraulic Seals? Hydraulic seals are designed to prevent leakage of fluid in hydraulic systems. They are used to seal the openings between various components in a hydraulic system, such as pistons, rods, and cylinders. By effectively sealing these gaps, hydraulic seals help to maintain the pressure and integrity of the system, ensuring its efficient operation.

Piston Seals Piston seals are used in hydraulic cylinders to prevent fluid from leaking past the piston as it moves back and forth. These seals are typically made of rubber or polyurethane and are designed to withstand high pressures and temperatures. Piston seals play a critical role in maintaining the efficiency and performance of hydraulic systems.

Rod Seals Rod seals are used to prevent leakage along the rod in a hydraulic cylinder. They are typically installed on the outer diameter of the rod and create a barrier between the rod and the cylinder wall. Rod seals help to maintain the integrity of the system and prevent contamination of the hydraulic fluid.

Wiper Seals Wiper seals, also known as scraper seals, are used to clean contaminants from the rod as it retracts into the cylinder. These seals help to prevent dirt, dust, and other particles from entering the system and damaging the components. Wiper seals are essential for ensuring the longevity and reliability of hydraulic systems.

Applications of Hydraulic Seals Hydraulic seals are used in a wide range of applications across various industries. From large diameter seals used in heavy machinery to TBM seals used in tunnel boring machines, these seals are essential components in hydraulic systems. Whether it's in construction equipment, agricultural machinery, or automotive vehicles, hydraulic seals play a vital role in ensuring the efficiency and reliability of hydraulic systems.

Guide Rings Guide rings are used to guide the piston or rod in a hydraulic cylinder, preventing side movement and ensuring smooth operation. These rings are typically made of nylon or PTFE and are designed to withstand high pressures and temperatures. Guide rings help to enhance the performance and longevity of hydraulic systems.

O-Rings and Backup Rings O-rings and backup rings are used in hydraulic systems to provide additional sealing and support. O-rings are typically made of rubber or elastomers and are used to seal static and dynamic joints in hydraulic systems. Backup rings are used in conjunction with O-rings to provide additional support and prevent extrusion under high pressure.

Conclusion In conclusion, hydraulic seals are essential components in hydraulic systems, playing a crucial role in preventing leakage and maintaining the integrity of the system. From piston seals to rod seals, wiper seals to guide rings, each type of hydraulic seal has its own unique function and importance. By understanding the different types and applications of hydraulic seals, engineers can ensure the efficient operation and reliability of hydraulic systems across various industries. Choose hydraulic seals wisely to ensure smooth operations without any leakage or contamination.

Meta Description:

Learn all about the different types and applications of hydraulic seals in this comprehensive guide. Explore the world of piston seals, rod seals, wiper seals, and more!

Remember, when it comes to hydraulic systems, choosing the right hydraulic seals is key to ensuring optimal performance and efficiency. So, next time you're working on a hydraulic system, make sure to consider the importance of hydraulic seals and their role in keeping everything running smoothly.

1 note

·

View note

Text

The Evolution of Khakhra Making Machines: From Traditional to Automated

Khakhra, a popular Indian snack made from whole wheat flour, is loved for its crispiness and flavor. Traditionally, khakhra making was a labor-intensive process, requiring a significant amount of manual effort. However, the introduction of the khakhra-making machine has revolutionized this process, making it more efficient and less time-consuming. This article explores the evolution of the khakhra-making machine, from traditional methods to fully automated solutions.

1. Customary Khakhra-making machine

Making khakhra the old-fashioned way required a number of physical procedures. Water, spices, and whole wheat flour were combined to make the dough. The dough was then manually rolled out into thin discs in small pieces. On a heated griddle, these discs were roasted, necessitating continual supervision and hand labor to guarantee uniform cooking and avoid burning. Producing a tiny batch of khakhra was a time-consuming and arduous procedure that frequently took hours.

2. Semi-Automatic Machines' Introduction

The introduction of the semi-automatic khakhra-making machine marked the first notable development in khakhra manufacture. While some steps of the process, including rolling and kneading the dough, were mechanized by these machines, roasting still required human interaction. Machines that khakhra making machines semi-automatically greatly decreased the amount of work required and enhanced output. They enabled small-scale firms to expand their operations and offered a more uniform product quality.

3. Fully Automated Khakhra-making machine

The creation of a completely automated khakhra-making machine marked the next advancement in khakhra production technology. Everything is automated by these machines, including the making of the dough, roasting, and packing. The following are essential components of a fully automated khakhra-making machine:

Dough Kneading: To guarantee consistent quality, the machine automatically kneads the dough to the ideal consistency.

Dough Rolling: The machine rolls out the dough into uniformly thin discs, removing the need for manual rolling.

Roasting: To guarantee uniform cooking and crispiness, the machine roasts the khakhra discs equally on both sides.

Packaging: To maintain freshness, some machines additionally include an automatic packaging function that seals the khakhra in airtight containers.

Benefits of Fully Automatic Khakhra Making Machines

The introduction of the fully automatic khakhra-making machine has brought numerous benefits to the industry:

Increased Efficiency: Fully automatic machines can produce large quantities of khakhra in a fraction of the time required by traditional methods. This allows manufacturers to meet higher demand and increase their market reach.

Consistent Quality: Automation ensures that each khakhra is rolled and roasted to the same standard, resulting in a uniform product that meets quality expectations.

Reduced Labor Costs: With the entire process automated, the need for manual labor is significantly reduced. This lowers production costs and increases profitability for manufacturers.

Hygiene and Safety: Fully automatic khakhra-making machines operate in a controlled environment, minimizing the risk of contamination and ensuring higher hygiene standards.

Scalability: These machines enable small and medium-sized enterprises to scale up their production without a proportional increase in labor costs, making it easier to grow their business.

Technological Innovations

The evolution of the khakhra-making machine continues with ongoing technological innovations. Modern machines are equipped with advanced features such as:

Touchscreen Controls: For easy operation and precise control over the production process.

Energy Efficiency: Machines are designed to consume less energy, reducing operational costs and environmental impact.

Customization: Machines can be customized to produce different types of khakhra, catering to diverse consumer preferences.

The snack industry is undergoing a notable change due to the introduction of fully automatic khakhra-making machines. These machines have transformed the production process, enhancing efficiency, consistency, and scalability to unprecedented heights.

The foremost benefit of utilizing a fully automatic khakhra-making machine is the significant enhancement in production efficiency. These machines streamline the entire operation, encompassing dough preparation, roasting, and packaging. By automating these processes, the reliance on manual labor is diminished, leading to a reduction in production time and an increase in output. Consequently, manufacturers are now able to generate substantial quantities of khakhra in a considerably shorter timeframe compared to conventional methods.

The Khakhra-making machine fully automatic guarantees uniform product quality. By automating the production process, these machines ensure consistency in dough thickness, roasting duration, and overall texture. Such uniformity is essential for upholding a brand reputation and satisfying customer demands. Each batch of khakhra produced by a fully automatic machine adheres to the same elevated standards, providing a dependable product consistently.

The khakhra-making machine fully automatic is transforming the snack production sector by improving efficiency, uniformity, and scalability. These machines provide a variety of advantages, such as heightened production efficiency, consistent quality of products, lower labor expenses, improved hygiene standards, scalability, energy efficiency, and advancements in technology. With the increasing demand for premium khakhra, investing in a khakhra-making machine fully automatic enables manufacturers to maintain a competitive edge and address the changing requirements of their clientele.

0 notes

Text

Flexure Print N Pack to commission new blown film extrusion line in 2024-25

Ahmedabad-based flexible packaging converter Flexure Print N Pack is set to expand its capabilities with significant new investments. The company plans to commission a multilayer blown film extrusion line within the financial year 2024-25, aiming to strengthen its vertical integration. Flexure Print N Pack is also gearing up to install converting machinery for both monolayer and multilayer packaging in the next few months, according to Jainam Shah, managing partner at Flexure Print N Pack.

“We are also exploring collaborations with industry suppliers to add value to our wide-web flexographic printed products through offline processes,” Shah said in an exclusive interview with Packaging South Asia.

Current capabilities and machinery

Flexure at present operates four flexographic printing presses, including one central impression press and three stack-type configured presses. The facility is equipped with an advanced photopolymer plate mounting machine along with anilox sleeves and photopolymer plate cleaning machines to ensure quality and durability. In the lamination department, the company utilizes both solvent-free and solvent-based lamination machines.

The slitting department boasts drum-type and cantilever differential slitting machines. For conversion, Flexure Print N Pack runs a variety of machines, including bottom seal bag-making machines, side seal bag-making machines, slit-seal plus gusset machines, and multiple pouch-making machines.

A milestone year in 2024

Reflecting on 2024, Shah described the year as "busy, challenging, and eventful," marked by significant achievements. Flexure Print N Pack reached a notable milestone by successfully printing 208 LPI print resolution jobs on its flexographic press. The company also conducted trials with hybrid screening, water-based inks, and extended color gamut, which are set to transition into full-scale production in the coming months.

Established in 2001, the Asian Packaging Excellence Awards recognize outstanding achievements, innovation, and contributions to packaging production across the Asia region, celebrating the pinnacle of excellence in the Asian packaging industry.

“These awards underscore our commitment to excellence in packaging production,” Shah said.

Production capacity and solutions

Flexure Print N Pack currently converts between 175 and 200 metric tonnes of material per month. The company’s product portfolio spans a range of exclusive flexographic-printed solutions, including LDPE, CPP, TQPP, BOPP, PET, coated paper, and compostable films as substrates. These materials are supplied in monolayer and multilayer roll forms, as well as in converted pouch formats.

Flexure Print N Pack specializes in manufacturing a variety of packaging solutions, including bakery bags, shopping bags, hygiene application pouches, vacuum pouches, zipper pouches, quad seal pouches, and stand-up pouches, among others.

A vision for the future

With its new investments and a focus on innovation, Flexure Print N Pack is poised to strengthen its position in the flexible packaging industry, Shah said. The addition of the blown film line and enhanced converting capabilities will enable the company to meet evolving market demands and reinforce its reputation for quality and innovation.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Dubblin Refersh Mug is made from 304 stainless steel. This double-walled non vacuum mug is designed for no sweat exterior and keeps your favorite drinks hot/cold. The lid has a slider cap console for easy sipping and silicon seal for spill proof. The taste and nutritive value of the drinks remain intact for a long time making the mug a very appropriate choice for serving beverages. Mug is 304-grade stainless steel that is rust-free and its plastic Lid is made of food-grade material and is BPA free. This mug is convenient to use, has a handle and is compatible with most single serve coffee machines. Amazing for Gifting. Dubblin as a Brand in the industry has flourished as a manufacturer of household products. Over the years since its inception in 2008, the company has focused its activities on the manufacturing of household goods and has entered the market with a range of world-class products that includes Stainless Steel Vacuum kettles, Sport kettles, Flasks, Sippers, Food containers, Lunch Boxes, Double Wall Mugs, Coffee Mugs, Steel Fridge kettles, Borosilicate Glass kettles and many more products. With its motto “Survival by Quality and Development by innovation” company served to anticipate and provide consumers with high eminence and resilient products that can enhance individuals day to day life. Material type: 304 Stainless Steel; No. of pieces: 1; Capacity: 350 ml Insulation type: Double wall; Temperature retention: Yes ; No sweat Exterior (Keeps liquid hot/cold); Leak proof: No; Wide Mouth for easy cleaning Inner and Outer side of mug is made from 304 Grade Steel which is Rust Free and 100% Food Grade. Curved handle for easy grip. Flip lid is easy to use with a straw or drink directly and silicon seal for spill proof Best Usage: Great for all kinds of hot and cold beverages, designed for coffee, tea, juice etc. [ad_2]

0 notes

Text

Slip-On Flange

Slip-on flange is a popular type of pipe flange designed to accept pipe into the bore/center of the flange for welding around both the Outer Diameter (OD) of the pipe and on the interior side of the connection. You may recognize them:

The slip-on flange is a simple and excellent alternative to a weld neck as it does not have a weld bevel, and therefore allows the pipe to be adjusted in length relative to its position of the flange.

The bore of the slip on will give ample amount of space for the matching pipe. This allows for enough working space for the welder and fabricator to make the connection.

This flange type is extremely common in lower pressure applications. Most slip on style flanges will have a hub, which will often appear similar dimensionally to a raised face. It can be furnished without a hub if space is limited and the application allows for a “ring style” slip on.

Although the hub style is more common when referring to a slip on, a ring style slip on without a hub still falls under the category of a slip on flange, and can be called out as you desire.

Slip ons in higher pressure classes are often made with the height of a lap joint for a better connection. If the hub height is not a concern and a lap joint is not readily available, customers will sometimes opt for a slip on made to a lap joint style with a machined hub.

Slip on flanges are more commonly found in lower pressure assemblies and become less utilized when a higher stress service calls for a superior connection to the piping assembly.

This is because a slip on style flange will accept a pipe with a fillet weld connection, whereas a weld neck flange will have a reinforced hub at the base and form a weld bevel connection directly to the butt weld end of a pipe. This tapered hub allows for stronger service in a mechanical stress environment.

Slip-on Flanges

Types of Slip-On Flange Welding

Slip-on (SO) flanges come in two main types: SO welding plate flanges and SO welding hubbed steel pipe flanges.

These flanges balance integral and lap joint flanges with a straightforward design and easy processing. Consequently, slip-on flange welding finds extensive applications in various fluid pipelines.

Raised Face Slip-On Flange

The raised face slip-on flange features a small protrusion on its bottom face. This raised face serves as a designated area for gasket placement during installation, enhancing the overall sealing performance.

RTJ Slip-On Flange

In the case of RTJ slip-on flanges, a small groove is precision-machined on the raised face section. This unique RTJ design is intended explicitly for high-pressure applications, providing a compelling groove for gasket ring placement and ensuring superior sealing compared to the RF type.

What is a slip-on flange?

A slip-on flange is a type of pipe flange that slides over the pipe's end and is secured with bolts that align with pre-drilled holes.

It is designed with a slightly larger bore than the pipe to allow it to "slip on" easily before fastening. It is commonly used in low to medium-pressure systems.

What are the advantages of slip-on flanges?

The design allows for quick assembly without the need for complex welding or alignment, making them ideal for projects where time is a factor.

Slip-on flanges are typically less expensive than other flanges, such as weld-neck or blind flanges, due to their simpler design and manufacturing process.

When should I use a slip-on flange?

These flanges are not designed to handle high-pressure or high-temperature systems, so they are ideal for standard applications where pressure is not a concern.

When budget is a critical factor and the application does not require the strength and durability of more expensive flanges, slip-on flanges are a cost-effective option.

When should I not use a slip-on flange?

Slip-on flanges are not designed for high-pressure systems and may fail or leak under extreme pressure.

The design of the slip-on flange does not provide the same resistance to vibration as other flange types, like welded or socket weld flanges, which can lead to connection failure over time.

How do I install a slip-on flange?

Ensure the end of the pipe and the inside of the slip-on flange are free of debris. Slide the slip-on flange over the pipe end. The flange should fit snugly but not require force.

Rotate the flange as necessary until the bolt holes of the flange align with the matching holes on the pipe or pipe fitting. Insert the appropriate bolts through the aligned holes.

Tighten the bolts in a criss-cross pattern to evenly distribute pressure and achieve a proper seal.

0 notes

Text

Tanishka Packaging Machines: Pouch Packing Machine Manufacturers in Jaipur | Packaging Machine Manufacturers in India

When it comes to efficient and reliable packaging solutions, Tanishka Packaging Machines stands out as one of the leading names in the industry. Based in Jaipur, Rajasthan, Tanishka Packaging Machines is recognized as a top-tier manufacturer of pouch packing machines, providing state-of-the-art technology to businesses across India. Whether you’re looking for automatic or semi-automatic machines, Tanishka delivers innovative solutions tailored to meet diverse packaging needs.

The Role of Tanishka Packaging Machines in the Packaging Industry

Products Offered by Tanishka Packaging Machines

1. Pouch Packing Machines

One of the flagship offerings of Tanishka Packaging Machines is its range of pouch packing machines. These machines are designed to handle a variety of products and industries, including food, pharmaceuticals, chemicals, and more. From powder filling to liquid packing, these machines offer versatility and high precision.

The machines are capable of packing products in different types of pouches such as:

Stand-up pouches

Zip-lock pouches

Spout pouches

Side gusset pouches

With customizable features like multi-track systems, automated weighing, and sealing systems, Tanishka ensures that each machine can be adapted to meet specific business needs.

2. Strapping Machines

As strapping machine manufacturers in Rajasthan, Tanishka Packaging Machines also specializes in manufacturing strapping machines that are an essential component of packaging and logistics. These machines ensure that your products are securely strapped, making them safe for transportation and storage. Whether it’s for light or heavy-duty applications, Tanishka’s strapping machines offer high performance and reliability.

Strapping machines by Tanishka are designed for various industries, ensuring the tight and secure bundling of products. With features like adjustable tension control, automatic strap feeding, and user-friendly interfaces, these machines are easy to use and maintain.

3. Other Packaging Solutions

Tanishka Packaging Machines also offers a wide range of other packaging solutions like:

Liquid filling machines

Carton sealing machines

Shrink wrapping machines

Auger fillers and volumetric fillers

Each of these machines is crafted with precision engineering and cutting-edge technology to ensure that businesses get the most out of their packaging process.

Why Choose Tanishka Packaging Machines?

Quality and Durability

At Tanishka, every machine is built with top-quality materials and undergoes strict quality checks to ensure durability and longevity. The machines are designed to withstand heavy-duty operations, ensuring that businesses get the best value for their investment.

Innovation and Customization

Tanishka Packaging Machines believes in the power of innovation. With the latest technology integrated into their machines, they guarantee that each product meets the evolving needs of the packaging industry. Whether it’s a new feature or a completely customized machine, Tanishka works closely with clients to deliver bespoke packaging solutions.

Cost-Effective Solutions

Despite offering advanced technology and high-end features, Tanishka Packaging Machines ensures that its solutions remain affordable. The company understands the importance of cost-effectiveness for businesses, especially startups and small enterprises, and offers machines that deliver value without compromising on quality.

After-Sales Support

One of the key advantages of choosing Tanishka Packaging Machines is their reliable after-sales support. From installation to maintenance, Tanishka ensures that their clients have access to prompt assistance when needed. This commitment to customer satisfaction has earned them a loyal customer base across India.

The Significance of Tanishka Packaging Machines in Rajasthan and India

Tanishka Packaging Machines has carved a niche for itself not just in Rajasthan but throughout India. The company’s products are used by businesses in various sectors such as food processing, pharmaceuticals, chemicals, and e-commerce. As pouch packing machine manufacturers in Jaipur and strapping machine manufacturers in Rajasthan, Tanishka has become a go-to name for reliable packaging machinery.

Rajasthan, known for its thriving industrial landscape, has seen an increasing demand for quality packaging machines, and Tanishka has been at the forefront of meeting this demand. The company’s strategic location in Jaipur also allows it to serve customers across the country with ease.

Conclusion

If you’re looking for high-quality pouch packing machines, strapping machines, or any other packaging solutions, Tanishka Packaging Machines is the name you can trust. Their commitment to innovation, quality, and customer satisfaction makes them a top choice for businesses in India. As packaging machine manufacturers in India, they continue to set new industry standards with their reliable and advanced packaging technologies.

Investing in Tanishka Packaging Machines ensures that your business remains at the forefront of the packaging industry, with machinery that enhances productivity, efficiency, and profitability.

0 notes

Text

New Branch in Kerala - Filling Line Solutions

For sales and services in Kerala and Tamilnadu Region. Shiv Shakti Machtech Manufacturer Unit is in Ahmedabad, Gujarat, India. Shiv Shakti Machtech is proud to announce the opening of new branches in Kerala and Tamil Nadu, marking a significant milestone in our growth and enhancing our ability to provide exceptional sales and service across South India. We specialize in a comprehensive range of machinery solutions designed to improve efficiency, precision, and productivity in manufacturing processes. Our product offerings include Bottle Washing/ Cleaning Machines, Liquid Filling Machines, Capping Machines, Induction Cap Sealing Machines, Sticker Labeling Machines, Shrink Sleeve Label Applicators, Double Side Labeling Machines, Semi-Automatic Machines, Powder Filling Machines, and other packaging equipment. Why Choose Shiv Shakti Machtech? Reputation for Excellence: Shiv Shakti Machtech has established a strong reputation for delivering high-quality machinery solutions across multiple industries, from packaging to manufacturing. Strategic Expansion: The new branches in Kerala and Tamil Nadu are strategically located to meet the growing demand for advanced machinery and reliable after-sales support in South India. Commitment to Quality: We remain focused on quality, reliability, and customer satisfaction, ensuring that our clients receive exceptional products and services. Our Services in Kerala and Tamil Nadu: Industrial Equipment Sales: A wide selection of industrial machinery and tools offered at competitive prices. Machine Installation: Professional installation of equipment to ensure seamless integration and optimal performance. Preventive Maintenance: Customized servicing and maintenance packages to ensure your machinery remains in top working condition. Emergency Repair Services: Fast and efficient repair services to minimize downtime and keep your operations running smoothly. Spare Parts Supply: Access to high-quality, genuine spare parts, ensuring the longevity and reliability of your machinery. Shiv Shakti Machtech provides sales and services across key locations in Kerala and Tamil Nadu, Including Alappuzha, Kottayam, Palakkad, Manjeri, Thalassery, Thrippunithura, Ponnani, Vatakara, Kanhangad, Payyanur, Koyilandy, Parappanangadi, Kalamassery, Kodungallur, Neyyattinkara, Tanur, Kayamkulam, Malappuram, Guruvayur, Thrikkakkara, Wadakkancherry, Nedumangad, Kondotty, Tirurangadi, Tirur, Panoor, Kasaragod, Feroke, Kunnamkulam, Ottappalam, Tiruvalla, Thodupuzha, Perinthalmanna, Chalakudy, Payyoli, Koduvally, Mananthavady, Changanassery, Mattanur, Punalur, Nilambur, Cherthala, Sultan Bathery, Maradu, Kottakkal, Taliparamba, Shornur, Pandalam, Kattappana, Cherpulassery, Mukkam, Iritty, Valanchery, Varkala, Nileshwaram, Chavakkad, Kothamangalam, Pathanamthitta, Attingal, Paravur, Ramanattukara, Mannarkkad, Erattupetta, Sreekandapuram, Angamaly, Chittur-Thathamangalam, Kalpetta, North Paravur, Haripad, Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Alappuzha#andotherpackagingequipment#Angamaly#Arcot#Ariyalur#Attingal#BottleWashing/CleaningMachines#CappingMachines#Chalakudy#Changanassery#Chavakkad#Chengalpattu#Chennai#Cherpulassery#Cherthala#Chidambaram#Chittur-Thathamangalam#Coimbatore#Cuddalore#Dharmapuri#Dindigul#DoubleSideLabelingMachines#Erattupetta#Erode#Exporter#Feroke#Gujarat#Guruvayur#Haripad

1 note

·

View note

Text

Quick and Efficient Appliance Repair Solutions for Minneapolis and St. Paul Homes

Home appliances play a crucial role in modern living, making our lives easier and more efficient. However, when these appliances break down, it can throw our daily routines into disarray. For residents of Minneapolis and St. Paul, finding quick and efficient appliance repair solutions is essential to restore normalcy and keep your home running smoothly. At Central Minnesota Appliance Repair, we pride ourselves on offering expert services tailored to meet the unique needs of Twin Cities residents.

Why Choose Professional Appliance Repair Services?

Whether it’s a malfunctioning refrigerator or a washing machine that won’t spin, appliance issues are frustrating and inconvenient. Attempting DIY repairs might seem tempting, but they often lead to more significant problems or even permanent damage. Here’s why professional appliance repair in Minneapolis and St. Paul is the better choice:

Expert Knowledge and Skills: Certified technicians have the expertise to diagnose and fix problems efficiently, saving you time and money.

Access to Proper Tools and Parts: Professionals use specialized tools and genuine replacement parts to ensure lasting repairs.

Safety Assurance: Appliances involve electrical components and complex mechanisms. Professional repairs minimize risks and ensure your appliances are safe to use.

Warranty Protection: Hiring certified technicians can help maintain manufacturer warranties on your appliances.

Common Appliance Issues Faced by Minneapolis and St. Paul Residents

From freezing winters to humid summers, the climate in the Twin Cities puts unique demands on household appliances. Here are some common problems we encounter:

Refrigerator Problems

Cooling Issues: A refrigerator that doesn’t cool properly can lead to food spoilage. This issue is often caused by faulty thermostats, compressors, or clogged vents.

Leaking Water: Water leakage might result from a clogged defrost drain or damaged water inlet valve.

Unusual Noises: Loud or unusual sounds may indicate issues with the motor or evaporator fan.

Washing Machine Malfunctions

Failure to Spin: This can result from a broken belt, faulty motor, or imbalance in the drum.

Water Leakage: Leaks are often caused by loose hoses, damaged seals, or faulty water pumps.

Excessive Vibrations: Improper leveling or worn-out shock absorbers can cause your machine to shake excessively.

Dryer Inefficiencies

Not Heating: A malfunctioning heating element, thermal fuse, or thermostat can prevent your dryer from generating heat.

Long Drying Times: Restricted airflow due to clogged vents or lint filters often leads to extended drying times.

Drum Not Turning: This issue is typically caused by a broken belt or faulty motor.