#shelf life testing of food products

Explore tagged Tumblr posts

Text

How Accelerated Shelf Life Testing Supports Dubai’s Food Exporters in Meeting Global Standards? | +971 554747210

Dubai has emerged as a major hub for food exports, connecting global markets with high-quality food products. However, to maintain this status, food exporters must comply with international food safety and quality standards. Accelerated Shelf Life Testing of Food Products plays a crucial role in ensuring that Dubai’s food exports meet the required regulatory and safety standards of different markets worldwide.

What is Accelerated Shelf Life Testing of Food Products?

Accelerated Shelf Life Testing (ASLT) is a scientific method that helps food manufacturers and exporters determine the shelf life of their products in a shorter time frame. By simulating aging conditions, such as increased temperature and humidity, food testing labs can predict how long a product will remain safe and retain its quality under normal storage conditions.

The process involves:

Controlled environmental exposure to heat, light, and humidity

Microbiological and chemical analysis to detect spoilage factors

Sensory evaluations to assess taste, texture, and aroma stability

Predictive modeling to estimate actual shelf life under normal conditions

Why is Accelerated Shelf Life Testing Essential for Dubai’s Food Exporters?

1. Compliance with International Regulations

Global markets impose strict food safety and labeling requirements. Countries such as the United States, the European Union, and China have stringent shelf-life regulations that exporters must meet. Accelerated Shelf Life Testing ensures that food products comply with HACCP, ISO 22000, FDA, and Codex Alimentarius standards, allowing seamless entry into these markets.

2. Reduces Risks of Product Recalls

Food recalls due to incorrect shelf-life labeling can result in financial losses, brand damage, and regulatory penalties. By conducting Accelerated Shelf Life Testing, Dubai’s food exporters can ensure accurate expiration date labeling, minimizing the risk of recalls and legal disputes.

3. Enhances Product Quality and Customer Satisfaction

Global consumers demand high-quality food products with extended freshness and safety. Accelerated Shelf Life Testing helps exporters optimize formulations, preservatives, and packaging to enhance product longevity, ensuring better customer satisfaction.

4. Supports Supply Chain Efficiency

Dubai’s food export industry relies on efficient logistics and distribution channels. Proper shelf-life determination allows businesses to optimize storage, reduce food waste, and ensure that products reach international markets in peak condition.

5. Facilitates Entry into New Markets

Each country has unique regulatory standards for food products. Accelerated Shelf Life Testing helps Dubai’s exporters meet these diverse requirements, opening doors to new markets and business expansion opportunities.

How Dubai’s Food Testing Labs Conduct Accelerated Shelf Life Testing

Dubai is home to ISO 17025-accredited food testing laboratories that specialize in shelf-life studies. These labs follow a scientific approach to determine shelf life accurately:

Step 1: Sample Selection and Preparation

Food samples are carefully chosen to represent the product’s typical composition and packaging conditions.

Step 2: Exposure to Simulated Storage Conditions

Temperature: Increased temperature accelerates chemical and microbial reactions.

Humidity: High humidity levels assess moisture-related spoilage.

Light Exposure: Determines the impact of light on color, flavor, and texture stability.

Step 3: Microbial and Chemical Analysis

Microbial testing: Identifies bacteria, yeast, and mold growth over time.

Chemical stability analysis: Assesses oxidation, pH changes, and nutrient degradation.

Packaging interaction testing: Determines whether packaging materials influence food quality.

Step 4: Sensory Evaluation

Trained experts conduct sensory testing to examine changes in taste, aroma, color, and texture under accelerated aging conditions.

Step 5: Data Interpretation and Shelf Life Estimation

Scientific models are used to extrapolate real-world shelf life based on accelerated testing results. This data is used to determine the ideal expiration date and packaging requirements.

Choosing the Right Lab for Accelerated Shelf Life Testing in Dubai

Selecting the right food testing lab is crucial for obtaining accurate and reliable shelf-life test results. Consider the following factors:

ISO 17025 Accreditation: Ensures credibility and compliance with global food safety standards.

Advanced Testing Equipment: Look for labs with cutting-edge facilities for microbiological, chemical, and sensory analysis.

Expertise in Global Compliance: The lab should have experience in meeting the export standards of different countries.

Comprehensive Reporting: The lab should provide detailed scientific reports and recommendations for improving product shelf life.

Conclusion

Accelerated Shelf Life Testing is an essential tool for Dubai’s food exporters aiming to maintain international compliance, minimize risks, and improve product quality. By leveraging advanced testing methods, food businesses can ensure global market acceptance, reduce food waste, and enhance brand reputation.

#accelerated shelf life testing of food products#shelf life testing of food products#shelf life testing#testing lab near me#testing lab uae

0 notes

Text

Why Food Businesses in Abu Dhabi Need Accelerated Shelf Life Testing for Regulatory Compliance? | +971 554747210

In Abu Dhabi’s fast-growing food industry, ensuring product safety, quality, and longevity is essential for regulatory compliance and consumer trust. Accelerated shelf life testing of food products is a critical process that helps food manufacturers meet stringent safety standards set by local and international regulatory bodies. This scientific method estimates the shelf life of food products in a shorter time frame, allowing businesses to comply with food safety regulations, optimize packaging, and prevent product recalls.

In this blog, we explore why food businesses in Abu Dhabi rely on accelerated shelf life testing (ASLT) to achieve regulatory compliance and maintain product integrity.

Understanding Accelerated Shelf Life Testing

Accelerated shelf life testing is a laboratory process that simulates aging conditions for food products under controlled environmental factors such as temperature, humidity, and oxygen exposure. By doing so, it predicts the product’s longevity and stability under normal storage conditions.

Key Components of Accelerated Shelf Life Testing:

Microbiological Testing: Identifies microbial growth that may cause food spoilage.

Chemical Analysis: Evaluates oxidation, pH balance, and moisture retention.

Sensory Evaluation: Assesses changes in taste, texture, aroma, and appearance.

Packaging Assessment: Determines the effectiveness of packaging materials in preserving product freshness.

Regulatory Compliance in Abu Dhabi’s Food Industry

Food businesses in Abu Dhabi must adhere to strict food safety regulations established by the Abu Dhabi Agriculture and Food Safety Authority (ADAFSA) and international bodies like HACCP, ISO 22000, and Codex Alimentarius.

1. Ensuring Compliance with UAE Food Safety Standards

The UAE Food Code mandates food businesses to conduct stability testing to determine accurate expiration dates. ASLT helps ensure compliance with these regulations by providing scientific validation of product shelf life.

2. Meeting International Export Requirements

Food exporters in Abu Dhabi must comply with global food safety standards, such as the FDA (U.S.), EFSA (Europe), and GSO (Gulf Standards Organization). Accelerated shelf life testing ensures that food products meet these requirements, facilitating smooth entry into international markets.

3. Preventing Product Recalls and Legal Issues

Inaccurate shelf life claims can lead to costly product recalls and legal liabilities. ASLT provides scientific data to back up shelf life claims, reducing the risk of regulatory violations.

4. Ensuring Consumer Safety and Trust

Proper shelf life testing prevents foodborne illnesses and contamination, enhancing consumer confidence in food products.

How Accelerated Shelf Life Testing Helps Abu Dhabi’s Food Businesses

1. Optimizing Packaging and Storage Conditions

ASLT helps determine the best packaging materials and storage conditions to extend product longevity and maintain food freshness.

2. Reducing Food Waste and Economic Losses

Accurate shelf life testing prevents premature food spoilage, reducing waste and saving costs for food businesses.

3. Supporting Product Development and Innovation

New food formulations require ASLT to ensure stability and safety before entering the market.

4. Improving Supply Chain Management

Food manufacturers and distributors can plan inventory management effectively by understanding product shelf life under different environmental conditions.

Choosing the Right Testing Lab in Abu Dhabi

Factors to Consider:

ISO 17025 Accreditation: Ensure the lab is certified for food testing.

Advanced Testing Equipment: Look for labs with cutting-edge technology such as HPLC and GC-MS.

Comprehensive Testing Services: The lab should offer microbiological, chemical, and sensory testing.

Fast Turnaround Time: Ensure the lab delivers results efficiently to support business operations.

Conclusion

For food businesses in Abu Dhabi, accelerated shelf life testing of food products is an essential tool for regulatory compliance, product safety, and market competitiveness. By working with accredited food testing labs, businesses can ensure their products meet UAE and international food safety standards, prevent costly recalls, and build consumer trust. Investing in ASLT helps businesses achieve long-term success in the competitive food industry of Abu Dhabi.

#accelerated shelf life testing of food products#shelf life testing#testing lab near me#testing lab uae#shelf life testing of food products

0 notes

Text

NASA continues BioNutrients space-fermented food research

NASA's BioNutrients series of experiments is testing ways to use microorganisms to make nutrients that will be needed for human health during future long-duration deep space exploration missions.

Some vital nutrients lack the shelf-life needed to span multi-year human missions, such as a mission to Mars, and may need to be produced in space to support astronaut health. To meet this need, the BioNutrients project uses a biomanufacturing approach similar to making familiar fermented foods, such as yogurt. But these foods will also include specific types and amounts of nutrients that crews will be able to consume in the future.

The first experiment in the series, BioNutrients-1, set out to assess the five-year stability and performance of a hand-held system—called a production pack—that uses an engineered microorganism, yeast, to manufacture fresh vitamins on-demand and in space.

The BioNutrients-1 experiments began after multiple sets of production packs launched to the station in 2019. This collection included spare production packs as backups to be used in case an experiment needs to be re-run during the five-year study.

The planned experiments concluded in January 2024 spare production packs still remaining aboard the orbiting lab and in the BioNutrients lab at NASA's Ames Research Center in California's Silicon Valley, where the ground team runs experiments in parallel to the crew operations.

Leaders at NASA's International Space Station and Game Changing Development programs worked to coordinate the crew time needed to perform an additional BioNutrients-2 experiment using the spare packs. This extended the study's timeline to almost six years in orbit, allowing valuable crew observations and data from the additional experiment run to be applied to a follow-on experiment, BioNutrients-3, which completed its analog astronaut experiment in April 2024, and is planned to launch to the station this year.

Astronauts on the space station will freeze the sample and eventually it will be returned to Earth for analysis to see how much yeast grew and how much nutrient the experiment produced. This will help us understand the shelf stability of the packets.

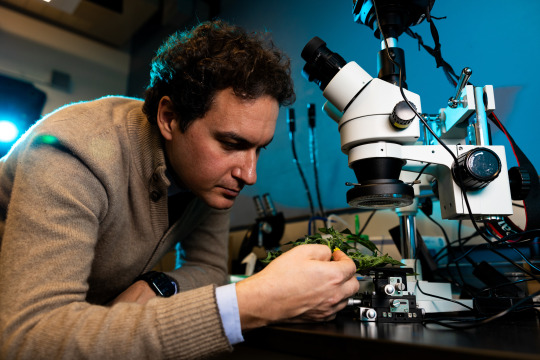

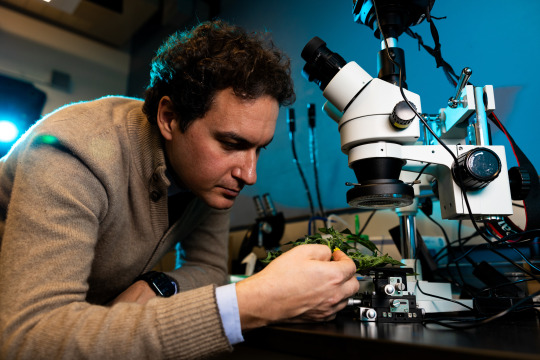

IMAGE: NASA astronaut and Expedition 72 Commander Suni Williams displays a set of BioNutrients production packs during an experiment aboard the International Space Station. The experiment uses engineered yeast to produce nutrients and vitamins to support future astronaut health. Credit: NASA

8 notes

·

View notes

Text

Learn About the Best Tomato Paste Production Factory

In the case of tomato paste, the only thing that matters is the quality—taste, texture, shelf life, and safety all hinge on its production. It is therefore important to deal with the top tomato paste factory or the new company that manufactures tomato paste for food business companies. These businesses are not just about tomato processing; they merge technology, capability, and quality standards in an effort to come up with a product that satisfies business as well as consumer demands. Are you someone who wants to gather more facts about the Best tomato paste production factory, modern tomato paste manufacturing company? If Yes. This is the best place where people can gather more facts about the Best tomato paste production factory, modern tomato paste manufacturing company.

Factories now are equipped to manufacture in an economic and clean manner with modern machinery to wash, peel, crush, and concentrate tomatoes. In temperature-controlled rooms and accurate temperature control, the companies maintain the natural color, taste, and nutrients of the fresh tomatoes. The outcome is a dense, rich paste with uniform texture and taste—ideal for soups, sauces, and processed food.

The modern tomato paste manufacturing company

Another differentiating factor is the quality control system. International manufacturers possess international food safety standards like ISO, HACCP, and BRC. Each batch of tomato paste is subjected to exhaustive testing for acidity, Brix, color, and microbial safety. This is to ensure reliability and consistency, particularly critical to export customers and high-volume food processors.

Best Tomato Paste Production Factory

In addition to quality products, a contemporary Best tomato paste production factory provides convenient packaging facilities from retail-pack sachets and cans to drums and bulk aseptic bags. As a food processor, distributor, or restaurateur, a good factory will provide several options that are appropriate for your supply chain requirements.

Sustainability is also a top area of interest. The vast majority of high-grade factories lead with green projects like water reclamation, conservation power systems, and waste recovery programs. Besides reducing environment deterioration, these are also very good for the brand's commitment to manufacturing with a focus on sustainability.

Selecting a quality, new factory guarantees your tomato paste is made with care, precision, and integrity. To companies who desire to develop or expand globally, employing the best factory to make tomato paste is an investment in quality, safety, and profitability in the long run.

#Best Tomato Paste Production Factory#Best tomato paste manufacturer China#Tomato Paste Manufacturer#Tomato Paste China

3 notes

·

View notes

Text

How to Choose the Best Quality Garlic Paste for Your Kitchen

Garlic paste is a staple in kitchens around the world, cherished for its rich aroma and bold flavour that adds depth to countless dishes. From curries and marinades to soups and sauces, a spoonful of garlic paste can elevate any recipe. However, with the growing number of garlic paste brands in the market, it can be overwhelming to choose the best one for your kitchen. In this blog, we shall guide you through the key factors to consider when selecting top-quality garlic paste and explain why sourcing from reputed manufacturers and exporters matters.

Whether you are a home cook or a commercial buyer, making an informed choice ensures that your dishes retain authentic flavour, freshness, and hygiene. Let us dive into the essentials of choosing the best garlic paste and take a closer look at the companies making waves in the food product industry in Vadodara and across India.

1. Check the Ingredient List

When choosing garlic paste, simplicity is key. High-quality garlic paste should contain minimal ingredients—ideally just fresh garlic and a natural preservative like vinegar or citric acid. Avoid products with artificial colours, flavour, or thickening agents.

As a reputed garlic paste manufacturer in India, MFP Food Products ensures all its condiments, including garlic paste, are made with fresh, locally sourced ingredients and processed using hygienic, state-of-the-art methods.

2. Look for Authentic flavour and Aroma

The hallmark of good garlic paste is its pungent, sharp aroma and taste. Poor-quality products often lose flavour due to over-processing or the use of low-grade garlic. Choose garlic paste from a condiments manufacturer in India that prioritizes flavor preservation through cold processing and careful packaging.

Our products retain the raw intensity of fresh garlic, making them a preferred choice among chefs and food lovers alike.

3. Evaluate the Texture and Consistency

Good garlic paste should be smooth and uniform, without lumps or fibrous residues. It should blend easily into recipes without leaving behind gritty particles. Consistency also impacts shelf life—homogeneous paste lasts longer and stores better.

As one of the private label food manufacturers in Vadodara, MFP Food Products produces garlic paste in customizable textures to suit diverse culinary applications—from thick pastes ideal for pickles to smooth versions perfect for sauces.

4. Choose Trusted Manufacturers and Exporters

When purchasing garlic paste, especially in bulk, it is essential to buy from a reputed garlic paste exporter or food exporter company in Vadodara. Export-quality garlic paste undergoes rigorous testing and adheres to international food safety standards.

At MFP Food Products, we serve clients across the globe with premium-quality food items. As a trusted food exporter company in Vadodara, we ensure our garlic paste meets global standards while retaining traditional flavours.

5. Certifications and Compliance

Always check if the garlic paste is produced by certified food processing companies in India. Certifications like FSSAI, ISO, and HACCP ensure the product meets hygiene and safety regulations. Compliance also shows that the company maintains transparency in production and packaging.

We are proud to be among the top food manufacturing companies with industry certifications, ensuring our customers get nothing but the best.

6. Private Labelling Opportunities

If you are a business owner or a retailer looking to create your own brand, partnering with companies offering private labelling services in India or private labelling services in Gujarat can be a smart move. Private label garlic paste allows you to customize packaging, branding, and product variants to cater to your audience.

MFP Food Products offers flexible private labelling options for clients worldwide. As leading private label food manufacturers in Vadodara, we help businesses create custom garlic paste brands that resonate with their target market.

7. Packaging and Shelf Life

Proper packaging plays a vital role in retaining the freshness of garlic paste. Opt for brands that use vacuum-sealed pouches, glass jars, or food-grade plastic containers with air-tight seals. Always check the expiration date to ensure longer usability.

As part of the food product industry in Vadodara, MFP Food Products utilizes advanced packaging technology that extends shelf life without compromising flavour or quality.

8. Sourcing and Sustainability

Modern consumers are becoming more conscious of the sourcing and sustainability of food products. Opt for a food product company in India that sources garlic from responsible farmers and follows sustainable practices in manufacturing.

At MFP, we work closely with local farmers to procure high-grade garlic while supporting eco-friendly and ethical production processes.

9. Complementary Products for Culinary Use

While garlic paste is a kitchen essential, it pairs well with other condiments like ginger paste, green chilli paste, and white vinegar. Buying from a multi-product food companies in Gujarat can help you get all your cooking essentials under one roof.

Did you know MFP Food Products is also a reputed white vinegar manufacturer in India? Our complementary range of condiments is crafted to meet diverse culinary requirements—from home kitchens to commercial food outlets.

10. Reputation in the Food Industry

When selecting a garlic paste brand, the company’s market reputation speaks volumes. Choose a supplier that is known within the list of food industries in Vadodara for consistent quality, innovation, and customer satisfaction.

Being recognized as one of the best food product company in Vadodara, MFP Food Products is trusted by households and food businesses across India and abroad. Our commitment to excellence sets us apart in the competitive landscape of food companies in Gujarat.

Why MFP Food Products?

At MFP Food Products, our garlic paste is more than just a condiment—it is a promise of purity, taste, and trust. Here is why you should choose us:

Exporter Quality: We are a certified garlic paste exporter, delivering quality products to international markets.

Private Label Solutions: As one of the top private label food manufacturers in Vadodara, we help businesses launch custom garlic paste brands.

Advanced Manufacturing: We are a leading garlic paste manufacturer in India with modern production facilities and a skilled workforce.

Certified and Compliant: As a part of the reputed food processing companies in India, our processes meet all safety and hygiene norms.

Complete Product Range: From garlic paste to vinegar and sauces, we are a one-stop food product company in India catering to a wide clientele.

Final Thoughts

Garlic paste is a must-have in every kitchen, and choosing the right product makes all the difference in your cooking experience. Whether you are shopping for home use, stocking a restaurant, or planning to launch a private label, ensure you source from a reputable manufacturer known for quality and authenticity.

With MFP Food Products, you are choosing more than just garlic paste—you are choosing a legacy of flavour, consistency, and trust built over years of experience in the food product industry in Vadodara.

Explore our range, taste the difference, and bring the essence of authentic Indian flavours to your table.

For bulk inquiries, export orders, or private labelling collaborations, reach out to MFP Food Products—your trusted partner in flavour.

#Garlic paste exporter#Garlic paste manufacturer in India#Food exporter company in Vadodara#List of food industries in Vadodara#Private labelling services in Gujarat#Private label food manufacturers in Vadodara#Condiments manufacturer in India#Food manufacturing companies#Food processing companies in India#Food companies in Gujarat#Private labelling services in India#Best food product company in Vadodara#Food product company in India#Food product industry in Vadodara#Oman#Kuwait#United Arab Emirates#India

4 notes

·

View notes

Text

What Makes a Reliable Non-Basmati Rice Manufacturer?

Non-basmati rice is a staple food in many countries due to its affordable price, versatility, and varying grain sizes. From long-grain to short-grain varieties, it serves as the backbone of countless meals. But what’s the difference between an ordinary supplier and a reliable manufacturer when it comes to non-basmati rice? For wholesalers, retailers, and even consumers, choosing the right rice manufacturer can make a huge difference in quality, consistency, and long-term relationships. This blog will explore the key factors that ensure you’re sourcing from a trustworthy non-basmati rice manufacturer.

Quality Control Practices and Certifications

The foundation of any reliable rice manufacturer is its commitment to quality. Manufacturers with strict quality control processes ensure that each batch of rice meets specific standards for purity, grain length, moisture content, and taste. Look for manufacturers that adhere to international certifications such as ISO 9001 for quality management and HACCP (Hazard Analysis and Critical Control Points) for food safety. These certifications ensure that the rice is produced under clean conditions and undergoes rigorous testing to remove impurities.

Additionally, quality manufacturers often employ state-of-the-art testing laboratories that analyze rice for contaminants such as pesticides, aflatoxins, and heavy metals. This commitment to food safety ensures that you are getting a premium product that meets global standards.

Consistent Supply and Scalability

A reliable non-basmati rice manufacturer must be able to meet consistent demand, whether you are a small retailer or a large-scale distributor. This means maintaining adequate stock, having capacity for large orders, and increasing production as needed. Manufacturers with extensive farming networks or partnerships with multiple farmers can better guarantee stable supply throughout the year, regardless of seasonal fluctuations.

Scalability is especially important for businesses looking to expand into new markets. A trustworthy manufacturer will have the flexibility to adjust production volumes to align with your growth, ensuring a smooth supply chain even during peak seasons.

Technological advancements in milling and packaging

Modern rice milling and packaging technology plays a key role in maintaining the quality and shelf life of non-basmati rice. Reliable manufacturers invest in advanced milling machinery that reduces broken grains and preserves the natural texture and flavor of rice. Look for manufacturers that use automated sorting technologies to remove discolored or damaged grains, ensuring a more consistent product.

Packaging also matters. Vacuum-sealed or air-tight packaging helps preserve freshness and prevent moisture ingress, which can lead to spoilage or insect infestation. Manufacturers that adopt innovative packaging solutions help ensure that their rice reaches consumers in optimal condition.

Sustainable and ethical sourcing

As consumers and businesses are becoming more aware of sustainability, it is important to work with a manufacturer that values ethical sourcing. Reliable manufacturers prioritize environmentally friendly farming practices, such as minimizing the use of chemical pesticides and adopting water conservation methods. Some manufacturers also support small-scale farmers by offering fair trade agreements, ensuring that local communities benefit from their involvement.

Sustainably sourced rice also tends to be higher in quality, as the plants are grown in healthy soil, without an excessive reliance on synthetic chemicals. Look for manufacturers that openly share their sustainability initiatives or hold certifications such as Fairtrade or Organic to further validate their commitment to ethical practices.

Customer Support and Global Reach

Strong customer support is the hallmark of any reliable non-basmati rice manufacturer. A good manufacturer should provide clear communication channels, timely responses to inquiries, and efficient problem-solving when issues arise. This level of support fosters trust and ensures a seamless business relationship over time.

Additionally, manufacturers with a global reach and experience exporting rice to multiple countries are better equipped to handle the complexities of international shipping, customs regulations, and regional preferences. A manufacturer with a proven export track record can provide invaluable guidance, especially for businesses looking to expand internationally.

Choosing the right non-basmati rice manufacturer isn’t just about considering price. Quality control, supply continuity, technological advancements, consistency and customer support all play a vital role in ensuring you get a great product. By partnering with a reliable manufacturer, you can guarantee that your business will thrive and your customers will be happy.

2 notes

·

View notes

Text

Behind the Scenes: A Day in the Life of a Hot Sauce Producer

Morning: Sourcing the Best Ingredients

The day starts early at Modern Food Products with the sourcing of fresh ingredients. As a leading hot sauce supplier in KSA, the company emphasizes quality and consistency. The procurement team works closely with local farmers to ensure a steady supply of high-quality peppers, garlic, and other essential ingredients. The team conducts thorough inspections to ensure that only the best produce makes it into their sauces.

Farm Inspections and Quality Control

Farm Visits: Regular visits to farms are essential to maintain strong relationships with farmers and to ensure sustainable farming practices.

Quality Checks: Each batch of peppers is inspected for color, size, and heat level. Only the peppers that meet the strict standards are approved for processing.

Late Morning: Production Begins

Once the ingredients arrive at the production facility, the real magic begins. The production process at Modern Food Products is a well-oiled machine, designed to maximize efficiency while maintaining the highest standards of quality.

Washing and Preparing Ingredients

Cleaning: All ingredients undergo a rigorous cleaning process to remove any dirt, pesticides, or contaminants. This step is crucial for maintaining the purity and safety of the hot sauce.

Preparation: Peppers are sorted, and stems are removed. Garlic is peeled, and other ingredients are prepped according to the recipe specifications.

Mixing and Cooking

Recipe Formulation: Modern Food Products prides itself on its proprietary recipes, which are carefully guarded secrets. Each recipe is a precise blend of ingredients designed to deliver a unique flavor profile.

Cooking: The ingredients are then cooked in large vats. The cooking process is closely monitored to ensure that the flavors meld perfectly and that the sauce achieves the desired consistency. Temperature control is critical, as overheating can alter the flavor and texture of the sauce.

Afternoon: Bottling and Packaging

After cooking, the hot sauce is ready to be bottled. This stage is as crucial as the preparation and cooking stages, involving stringent hygiene and quality control measures.

Bottling Process

Sterilization: Bottles are sterilized to prevent any contamination. This is a key step in ensuring the shelf stability of the hot sauce.

Filling: The hot sauce is poured into bottles using automated machines that ensure uniformity and prevent spillage. Each bottle is filled to the exact level to maintain consistency across batches.

Labeling and Packaging

Labeling: Bottles are labeled with the brand’s distinctive design. For clients interested in hot sauce private labelling in Saudi Arabia, Modern Food Products offers customization options to create unique labels that reflect their brand identity.

Packaging: The labeled bottles are packed into boxes for distribution. Packaging is designed to protect the bottles during transit and storage, ensuring that the product reaches consumers in perfect condition.

Late Afternoon: Quality Assurance and Testing

Quality assurance is a cornerstone of Modern Food Products' operations. Throughout the day, samples from each batch are tested to ensure they meet the company’s high standards.

Sensory Evaluation

Taste Testing: A team of experienced tasters evaluates the flavor, heat level, and consistency of the hot sauce. This step ensures that every batch delivers the expected taste experience.

Visual Inspection: The color and texture of the sauce are inspected to ensure they align with the product specifications.

Laboratory Testing

Microbial Testing: Samples are tested for microbial contamination to ensure the hot sauce is safe for consumption.

Chemical Analysis: The pH levels and other chemical properties are analyzed to ensure the sauce’s stability and shelf life.

Evening: Logistics and Distribution

As the day winds down, the focus shifts to logistics and distribution. Modern Food Products, being a prominent hot sauce producer in the Kingdom of Saudi Arabia, has a well-established distribution network that ensures timely delivery to retailers and customers.

Inventory Management

Stock Monitoring: Inventory levels are monitored in real-time to ensure there is always enough stock to meet demand.

Order Fulfillment: Orders from retailers and private label clients are processed and prepared for shipping.

Shipping and Delivery

Distribution: The packed hot sauce bottles are loaded onto trucks for delivery to various locations across KSA. The logistics team ensures that the products are delivered on time and in perfect condition.

Export: For international clients, including those looking for a hot sauce supplier in KSA, the export team handles all the necessary documentation and logistics to ensure smooth international shipping.

Conclusion: The Passion Behind the Spice

The journey of hot sauce from farm to bottle is a testament to the dedication and passion of the team at Modern Food Products. As a leading hot sauce producer in the Kingdom of Saudi Arabia, the company’s commitment to quality, innovation, and customer satisfaction is evident in every bottle they produce. Whether you are enjoying their signature hot sauce or benefiting from their hot sauce private labelling in Saudi Arabia, you can be sure that each drop is crafted with care and expertise.

So, the next time you reach for that bottle of hot sauce, remember the intricate process and the hardworking individuals behind it. From the early morning farm inspections to the late evening logistics operations, every step is a crucial part of bringing that fiery flavor to your table.

#Hot sauce supplier in KSA#Hot sauce private labelling in Saudi Arabia#Hot Sauce producer in Kingdom of Saudi Arabia#Condiments manufacturer#Condiments exporter#Private Labelling services#Food processing company#Food distributors company#Food manufacturing companies#Food product company in India#India#UAE#KSA#Oman

4 notes

·

View notes

Text

Researchers turn potato chip bags into energy-saving cooling films

Films made of aluminum-plastic laminates (APL) have long been used extensively to extend the shelf life of chips, roasted and powdered coffee, milk, fruit juices and other foods. During the COVID-19 pandemic, they were used to package FFP2 masks and rapid tests. The films consist of several polymer layers and an aluminum layer, which protects the products from damaging factors—especially from sunlight and heat, but also from moisture and oxygen. However, recycling such composite films is difficult as a result of this combination of different materials. The upcycling process of chips bags now developed in Bayreuth shows a way to improve the recycling of APL waste and, at the same time, reduce global energy consumption. Cooling systems already account for around 15 % of global energy consumption, and in view of climate change and the occurrence of heat waves, this share threatens to continue to rise.

Read more.

#Materials Science#Science#Aluminum#Plastics#Composites#Packaging#Recycling#Passive cooling#Bayreuth University

12 notes

·

View notes

Text

The World of Pink: Unveiling the Magic Behind Your Favorite Food Colors

Pink food coloring takes center stage in countless treats, from bubblegum frosting to rosy macarons. But have you ever wondered how this vibrant hue transforms your favorite dishes? Delving deeper, we'll explore the fascinating world of pink food colour manufacturer, uncovering the science and creativity behind these delightful pigments.

Natural vs. Synthetic: A Spectrum of Pinks Helvetica Neue

Pink food colour manufacturer offer a spectrum of options, catering to both health-conscious consumers and those seeking bold hues. Here's a breakdown of the two main categories:

Natural Pink Colors: Derived from fruits, vegetables, and minerals, these colorings offer a subtler, softer pink. Beetroot juice, hibiscus extract, and anthocyanins (found in berries) are some popular natural sources.

Synthetic Pink Colors: Manufacturers create these vibrant pinks through a controlled chemical process. They are often more cost-effective and produce a wider range of intense shades. However, some consumers prefer natural options due to potential concerns about artificial ingredients.

The Art and Science of Pink Perfection

Creating the perfect pink shade requires a delicate balance of science and artistry. Manufacturers employ sophisticated equipment and expertise to ensure consistent color, stability, and safety for consumption. Here's a peek behind the curtain:

Selection of Raw Materials: Whether natural or synthetic, the starting materials undergo rigorous testing to ensure purity and suitability for food applications.

Color Formulation: Food scientists meticulously blend different colorants to achieve the desired pink shade. Factors like lightfastness (resistance to fading) and shelf life are crucial considerations.

Quality Control: Throughout the production process, stringent quality checks guarantee consistent color and adherence to food safety regulations.

Beyond the Bakery: A World of Pink Applications

Pink food coloring isn't limited to frosting and candy. It plays a vital role in various food applications, including:

Dairy Products: Yogurt, ice cream, and pink-hued milkshakes often incorporate pink food coloring.

Meats and Seafood: Some processed meats and seafood may utilize pink colorings to enhance their appearance.

Beverages: Pink drinks like fruit punches and sports drinks often rely on food coloring for a visually appealing hue.

The Future of Pink: Innovation and Sustainability

As consumer preferences evolve, Pink food colour manufacturer are constantly innovating. are some exciting trends to watch:

Natural Color Focus: The demand for natural colorings is on the rise. Manufacturers are exploring new and sustainable ways to extract vibrant pinks from natural sources.

Clean Label Movement: Consumers are increasingly interested in products with recognizable ingredients. Manufacturers are responding by developing "clean label" pink colorings with simpler formulations.

A Touch of Pink: Adding Vibrancy to Your Plate

Pink food colour manufacturer plays a significant role in creating visually appealing and delightful food experiences. From the vibrant hues in candies to the subtle blush in yogurt, these colorings add a touch of magic to our plates. As the industry continues to evolve, we can expect even more innovative and sustainable ways to bring the world of pink to life!

2 notes

·

View notes

Text

Unlocking the secrets of natural materials

New Post has been published on https://thedigitalinsider.com/unlocking-the-secrets-of-natural-materials/

Unlocking the secrets of natural materials

Growing up in Milan, Benedetto Marelli liked figuring out how things worked. He repaired broken devices simply to have the opportunity to take them apart and put them together again. Also, from a young age, he had a strong desire to make a positive impact on the world. Enrolling at the Polytechnic University of Milan, he chose to study engineering.

“Engineering seemed like the right fit to fulfill my passions at the intersection of discovering how the world works, together with understanding the rules of nature and harnessing this knowledge to create something new that could positively impact our society,” says Marelli, MIT’s Paul M. Cook Career Development Associate Professor of Civil and Environmental Engineering.

Marelli decided to focus on biomedical engineering, which at the time was the closest thing available to biological engineering. “I liked the idea of pursuing studies that provided me a background to engineer life,” in order to improve human health and agriculture, he says.

Marelli went on to earn a PhD in materials science and engineering at McGill University and then worked in Tufts University’s biomaterials Silklab as a postdoc. After his postdoc, Marelli was drawn to MIT’s Department of Civil and Environmental in large part because of the work of Markus Buehler, MIT’s McAfee Professor of Engineering, who studies how to design new materials by understanding the architecture of natural ones.

“This resonated with my training and idea of using nature’s building blocks to build a more sustainable society,” Marelli says. “It was a big leap forward for me to go from biomedical engineering to civil and environmental engineering. It meant completely changing my community, understanding what I could teach and how to mentor students in a new engineering branch. As Markus is working with silk to study how to engineer better materials, this made me see a clear connection with what I was doing and what I could be doing. I consider him one of my mentors here at MIT and was fortunate to end up collaborating with him.”

Marelli’s research is aimed at mitigating several pressing global problems, he says.

“Boosting food production to provide food security to an ever-increasing population, soil restoration, decreasing the environmental impact of fertilizers, and addressing stressors coming from climate change are societal challenges that need the development of rapidly scalable and deployable technologies,” he says.

Marelli and his fellow researchers have developed coatings derived from natural silk that extend the shelf life of food, deliver biofertilizers to seeds planted in salty, unproductive soils, and allow seeds to establish healthier plants and increase crop yield in drought-stricken lands. The technologies have performed well in field tests being conducted in Morocco in collaboration with the Mohammed VI Polytechnic University in Ben Guerir, according to Marelli, and offer much potential.

“I believe that with this technology, together with the common efforts shared by the MIT PIs participating in the Climate Grand Challenge on Revolutionizing Agriculture, we have a real opportunity to positively impact planetary health and find new solutions that work in both rural settings and highly modernized agricultural fields,” says Marelli, who recently earned tenure.

As a researcher and entrepreneur with about 20 patents to his name and awards including a National Science Foundation CAREER award, the Presidential Early Career Award for Scientists and Engineers award, and the Ole Madsen Mentoring Award, Marelli says that in general his insights into structural proteins — and how to use that understanding to manufacture advanced materials at multiple scales — are among his proudest achievements.

More specifically, Marelli cites one of his breakthroughs involving a strawberry. Having dipped the berry in an odorless, tasteless edible silk suspension as part of a cooking contest held in his postdoctoral lab, he accidentally left it on his bench, only to find a week or so later that it had been well-preserved.

“The coating of the strawberry to increase its shelf life is difficult to beat when it comes to inspiring people that natural polymers can serve as technical materials that can positively impact our society” by lessening food waste and the need for energy-intensive refrigerated shipping, Marelli says.

When Marelli won the BioInnovation Institute and Science Prize for Innovation in 2022, he told the journal Science that he thinks students should be encouraged to choose an entrepreneurial path. He acknowledged the steepness of the learning curve of being an entrepreneur but also pointed out how the impact of research can be exponentially increased.

He expanded on this idea more recently.

“I believe an increasing number of academics and graduate students should try to get their hands ‘dirty’ with entrepreneurial efforts. We live in a time where academics are called to have a tangible impact on our society, and translating what we study in our labs is clearly a good way to employ our students and enhance the global effort to develop new technology that can make our society more sustainable and equitable,” Marelli says.

Referring to a spinoff company, Mori, that grew out of the coated strawberry discovery and that develops silk-based products to preserve a wide range of perishable foods, Marelli says he finds it very satisfying to know that Mori has a product on the market that came out of his research efforts — and that 80 people are working to translate the discovery from “lab to fork.”

“Knowing that the technology can move the needle in crises such as food waste and food-related environmental impact is the highest reward of all,” he says.

Marelli says he tells students who are seeking solutions to extremely complicated problems to come up with one solution, “however crazy it might be,” and then do an extensive literature review to see what other researchers have done and whether “there is any hint that points toward developing their solution.”

“Once we understand the feasibility, I typically work with them to simplify it as much as we can, and then to break down the problem in small parts that are addressable in series and/or in parallel,” Marelli says.

That process of discovery is ongoing. Asked which of his technologies will have the greatest impact on the world, Marelli says, “I’d like to think it’s the ones that still need to be discovered.”

#2022#advanced materials#agriculture#architecture#background#Bioinspiration#Biological engineering#Building#career#career development#challenge#Civil and environmental engineering#climate#climate change#coatings#Collaboration#Community#cooking#Design#development#devices#energy#Engineer#engineering#engineers#Environmental#environmental impact#Faculty#Food#food production

2 notes

·

View notes

Text

Career Opportunity in Food Science & Technology

Food science and technology is an exciting and rapidly growing field that offers numerous career opportunities. It combines scientific principles with the application of technology to ensure the safety, quality, and nutritional value of food products.

As a food science and technology professional, you can work in various sectors of the food industry, including food processing, product development, quality assurance, research and development, food safety and regulatory compliance. Here are some potential career paths in this field:

Food Technologist: As a food technologist, you would be involved in developing and improving food products, from concept to commercialization. You would work on formulating new recipes, conducting sensory evaluations, and ensuring that the products meet quality and safety standards.

Food Safety Specialist: Food safety is a critical aspect of the food industry. As a food safety specialist, you would develop and implement food safety protocols, conduct inspections, and ensure that food processing facilities adhere to regulatory guidelines and standards.

Quality Assurance Manager: Quality assurance managers are responsible for maintaining and improving the quality of food products in Food industry. They develop and implement quality control systems, conduct product testing, and oversee compliance with food safety regulations.

Research and Development Scientist: In research and development, you would work on innovative food products, ingredients, and processes. This role involves conducting experiments, analyzing data, and developing new technologies to enhance food quality, nutrition, and functionality.

Food Packaging Technologist: Food packaging plays a crucial role in preserving food quality and safety. As a packaging technologist, you would work on developing packaging materials and techniques that ensure product freshness, extend shelf life, and meet sustainability goals.

Regulatory Affairs Specialist: Regulatory affairs professionals ensure that food products comply with local and international regulations. They stay updated with food labeling requirements, ingredient approvals, and other regulatory aspects to ensure compliance and facilitate market access.

Food Consultant: Food consultants provide expertise and guidance to businesses in various aspects of the food industry, such as product development, quality management, food safety, and regulatory compliance.

To pursue a career in food science and technology, a degree in food science, food technology, or a related field is typically required. Additionally, gaining practical experience through internships or research projects can be beneficial.

Continuous learning and staying updated with the latest advancements in food science and technology are crucial for career growth in this field. Professional organizations and certifications, such as the Institute of Food Technologists (IFT), can provide valuable networking opportunities and resources.

Overall, a career in food science and technology offers a dynamic and rewarding path where you can contribute to the development of safe, nutritious, and innovative food products that impact people's lives.

4 notes

·

View notes

Text

Vitamin E Acetate: Properties, Benefits, and Uses

In this article, we will explore the properties, benefits, and uses of Vitamin E Acetate: Properties, Benefits, and Uses, a valuable compound. Join us as we delve into the world of vitamin E acetate and its significance in various industries.

Vitamin E Acetate Properties:

Vitamin E acetate, also known as tocopheryl acetate, is a stable form of vitamin E. It is a clear, viscous liquid or solid with a pale yellow color. Vitamin E acetate is derived from natural sources such as vegetable oils, and it is commonly used in dietary supplements, personal care products, and various industrial applications. Some key properties of vitamin E acetate include:

Stability: Vitamin E acetate is highly stable and has a long shelf life. It can withstand exposure to heat, light, and air, making it suitable for a wide range of applications.

Solubility: Vitamin E acetate is soluble in various organic solvents such as ethanol, oils, and fats. It has limited solubility in water, but it can be dispersed in water-based formulations with the help of emulsifiers or surfactants.

Antioxidant Properties: Vitamin E acetate is a potent antioxidant, meaning it helps protect cells from damage caused by free radicals. It prevents oxidative stress and supports overall cellular health.

Benefits and Uses:

Dietary Supplements: Vitamin E acetate is commonly used in dietary supplements due to its antioxidant properties. It plays a crucial role in maintaining the health of cells, tissues, and organs. It supports immune function, helps protect against oxidative damage, and promotes overall well-being.

Skincare and Cosmetics: Vitamin E acetate is a popular ingredient in skincare and cosmetic products. It is known for its moisturizing and nourishing properties, promoting skin hydration and reducing the appearance of fine lines and wrinkles. It also helps protect the skin from environmental stressors and can assist in soothing skin irritation.

Hair Care: Vitamin E acetate is utilized in hair care products for its conditioning and moisturizing benefits. It helps improve the health and appearance of hair, making it smoother, shinier, and more manageable.

Pharmaceutical Formulations: Vitamin E acetate is incorporated into various pharmaceutical formulations, including creams, ointments, and gels. It can enhance the stability and effectiveness of active ingredients and contribute to the overall therapeutic properties of the product.

Industrial Applications: Vitamin E acetate is also utilized in industrial applications such as food fortification and animal feed supplements. It helps enrich food products with essential nutrients and acts as a natural preservative to extend the shelf life of certain food items.

Safety Considerations:

Recommended Dosages: When used as a dietary supplement or in personal care products, it is important to follow recommended dosage guidelines provided by manufacturers or healthcare professionals.

Allergies and Sensitivities: Some individuals may have allergies or sensitivities to vitamin E acetate. It is advisable to perform a patch test before using any skincare or cosmetic product containing this ingredient.

Regulatory Compliance: Manufacturers and users of vitamin E acetate should comply with applicable regulations and guidelines, ensuring product quality, labeling accuracy, and adherence to safety standards.

Conclusion:

Vitamin E acetate is a valuable compound known for its antioxidant properties and various benefits in dietary supplements, skincare, cosmetics, and industrial applications. Its stability, solubility, and health-promoting properties make it a versatile ingredient in a wide range of products. However, it is important to use vitamin E acetate responsibly, follow recommended dosages, and adhere to safety guidelines to ensure its effective and safe utilization.

#Vitamin E acetate#chemicals#chemical industries#my chemical reunion#my chemical frank#chemistry#chemical products#alpha chemical

3 notes

·

View notes

Text

Choosing the Right Testing Lab for Accelerated Shelf Life Testing of Food Products in the UAE | +971 554747210

In the highly regulated food industry of the United Arab Emirates (UAE), ensuring product safety, quality, and compliance is paramount. One critical aspect of food safety and market readiness is Accelerated Shelf Life Testing (ASLT), a scientific method that determines a product’s longevity under simulated conditions. Choosing the right testing laboratory for ASLT is essential to obtaining accurate, reliable, and regulatory-compliant results.

This guide will help food manufacturers, exporters, and retailers identify the best food testing lab in the UAE for Accelerated Shelf Life Testing of Food Products, ensuring their products meet local and international standards.

Understanding Accelerated Shelf Life Testing

Accelerated Shelf Life Testing (ASLT) is a process used to estimate the shelf life of food products by exposing them to controlled environmental conditions, such as:

Increased temperature to simulate long-term storage effects.

Controlled humidity to assess moisture-related deterioration.

Oxygen exposure to evaluate oxidative spoilage.

Microbial analysis to monitor bacterial and fungal growth.

By applying these stress factors, food testing labs can predict how a product will age over time, helping manufacturers establish accurate "best before" or "expiry dates."

Why Choosing the Right Lab Matters

Not all food testing laboratories offer the same level of expertise, technology, or regulatory compliance. Selecting an accredited lab ensures:

Reliable results backed by scientific methods.

Regulatory compliance with UAE’s Emirates Authority for Standardization and Metrology (ESMA) and global bodies like the FDA, EFSA, and Codex Alimentarius.

Faster market access for local and international distribution.

Protection against product recalls due to incorrect labeling or safety concerns.

Key Factors to Consider When Choosing a Testing Lab in the UAE

1. ISO Accreditation and Compliance

A credible ASLT laboratory must be ISO/IEC 17025 accredited, which guarantees:

Accuracy in test results and data validation.

Standardized testing methodologies approved by regulatory agencies.

Competence in shelf life determination using internationally accepted techniques.

In the UAE, regulatory bodies like ESMA and Dubai Municipality require food manufacturers to work with accredited labs for compliance.

2. Expertise in Food Shelf Life Testing

Shelf life testing is a specialized field that requires expertise in:

Microbiology (bacteria, yeast, and mold analysis).

Chemical stability testing (pH levels, oxidation, and nutrient degradation).

Sensory evaluation (taste, texture, and aroma changes over time).

Choose a food testing lab with a proven track record in Accelerated Shelf Life Testing of Food Products and case studies demonstrating successful results for similar food categories.

3. Advanced Testing Equipment and Facilities

State-of-the-art facilities ensure the most accurate and reproducible ASLT results. The right lab should have:

High-precision environmental chambers to simulate real-world storage conditions.

Microbiological testing labs for pathogen detection.

Gas chromatography and spectroscopy for oxidation and chemical stability analysis.

Texture analyzers and colorimeters for sensory evaluation.

4. Customization of Testing Parameters

Different food products have unique stability challenges. The best food testing lab will customize ASLT conditions based on:

Product composition (dairy, meat, bakery, etc.).

Packaging materials (oxygen barrier, vacuum-sealed, etc.).

Intended storage conditions (ambient, refrigerated, frozen).

Labs offering tailored ASLT protocols help manufacturers optimize packaging and formulations for longer shelf life.

5. Regulatory and Market Compliance Support

Beyond testing, a good ASLT lab helps UAE food manufacturers navigate:

UAE Food Code and ESMA labeling regulations.

GCC food import/export requirements.

International food safety standards for exports to Europe, the US, and Asia.

A lab with regulatory expertise ensures products meet the necessary compliance requirements for local and global market approval.

6. Turnaround Time and Cost-Effectiveness

Speed matters in food production. Select a lab that offers:

Fast turnaround times for ASLT reports.

Affordable pricing for testing packages.

Comprehensive service options (including real-time shelf life studies if needed).

The best labs balance efficiency, affordability, and accuracy to support food businesses effectively.

7. Reputation and Client Feedback

Research the lab’s industry reputation by:

Checking online reviews and testimonials from food manufacturers.

Requesting references from previous clients.

Assessing the lab’s experience with major UAE food brands.

A well-established lab with positive client feedback is more likely to provide dependable ASLT services.

Benefits of Working with a Certified ASLT Lab in the UAE

Partnering with an accredited Accelerated Shelf Life Testing lab in the UAE offers numerous advantages:

✅ Regulatory Compliance: Ensures food products meet ESMA, GSO, and international safety standards.

✅ Market Expansion: Helps food businesses export with confidence, meeting global shelf life labeling laws.

✅ Cost Savings: Prevents unnecessary product recalls, rejections, and food waste.

✅ Product Improvement: Identifies packaging and formulation optimizations to extend shelf life.

✅ Consumer Safety: Confirms food safety by detecting microbial risks, chemical changes, and sensory degradation.

How to Get Started with ASLT in the UAE

If you’re a food manufacturer, distributor, or exporter looking for Accelerated Shelf Life Testing of Food Products, follow these steps:

Identify your product requirements (target shelf life, storage conditions, packaging type).

Shortlist ISO-accredited labs in the UAE with expertise in ASLT.

Request a consultation to discuss customized testing solutions.

Submit food samples for testing based on agreed ASLT parameters.

Review results and recommendations to ensure regulatory compliance and market readiness.

Conclusion

Choosing the right food testing lab for Accelerated Shelf Life Testing in the UAE is crucial for product safety, compliance, and market success. By selecting an ISO-accredited lab with expertise in ASLT, UAE food businesses can ensure their products meet shelf life regulations, minimize waste, and maintain high consumer trust.

#accelerated shelf life testing of food products#shelf life testing#shelf life testing of food products#testing lab near me#testing lab uae

0 notes

Text

who was Kazutora?

Baji’s best friend. The first one, at least. Some guy with a tiger tattoo. At the end of the day though, Toman was Toman. Chifuyu would bleed that belief — that message — to the day he died. And he was forced to endure that belief. Kazutora tested it as the person who led Chifuyu to endure Baji’s ‘betrayal.’ Many memories carved into his mind, and none of them pleasant.

But Kazutora is Baji’s best friend. The person for whom Baji wanted to learn to write letters. The same letters Chifuyu helped him author. The reason they met at all. The kanji was ‘tora’ after all. To think Chifuyu owed that to Kazutora. In some respect, Kazutora was the person who shaped his entire future. For the better — at first.

However, good things often ended. That was why they were meant to be cherished. Chifuyu stood at the grave with palms pressed together, and he bowed deeply to the name. Baji Keisuke. The image was fresh in his mind. Kazutora stabbed Baji. Even if Kazutora wasn’t the one to kill him, he provided the means. Fists clenched at his sides, and he sighed them open. Rolling his head back, Chifuyu’s eyes searched the sky as if looking for guidance. “ Baji-san, you want me to forgive him, right? ” Chifuyu voiced the question, but he already knew the answer. Resentment would help no one, and holding a grudge was sure to anger Baji’s spirit.

With that, he rocked on his heels and stared at the soba that lay there. It would go cold soon...

-x-

This was the first time they’d seen each other since that day. The day titled ‘Bloody Halloween.’ Truthfully, Chifuyu didn’t hate Kazutora. He had every right to do so, and a part of him wanted it. A demanding part of him that was still very angry. Why was it that Kazutora got to live and Baji had to die? But Baji died for Kazutora to live; that was Baji’s choice. That was his love for Kazutora. To hate someone who meant so much to Baji was wrong, and so Chifuyu was here facing the alleged ‘villain’ of the story who was trapped behind a plastic wall between them.

Kazutora would never change if no one let him. There was no sense in leaving him to fight his own battles alone. Chifuyu would never ever let someone go through that again.

“ I’m planning to visit Baji-san again tomorrow. Is there any message you want me to pass along to him? ”

who is Kazutora?

Bag of cat food in hand, Chifuyu heaved the load and set it on the shelf with a notable thud. “ I think that just about finishes up stocking tonight. ” He declared, flashing a grin Kazutora’s way. The day had been a productive one. Several customers, one cat adoption, and a restock of inventory between the two of them. To think, twelve years ago Chifuyu’s dream was to become a pilot. Now, he was running a pet shop. So much could change in the span of a decade. The influence of one soul could overturn an entire person’s life trajectory.

Was he proud? Surely, he had to be.

“ You’ve really come into your own, Kazutora. ” Time had healed a rigid heart, broken and serrated at its edges. It wasn’t perfect and it never would be, but time was a buffer and smoothed out those edges with its sand. Things were better; things were good. Only one piece was missing.

“ If Baji-san was here, I’m sure he’d pat you on the back and tell you to keep it up with your second chance. ” Chifuyu’s lips fell then, and his attention turned to Kazutora. The way his eyes dulled expressed the importance of what he said next. “ You're still looking into Mikey-kun, aren’t you? ” The question didn’t sound accusing but hollow. Sad.

Toman was gone, and they were supposed to move beyond it. Perhaps, Kazutora never had that opportunity... He was, after all, still in juvie when Toman disbanded. “ Please don’t. ” Chifuyu almost pleaded despite the smile along his expression. “ We have a good life here now, and I can’t risk the shop getting involved in gang affairs. ” And I don’t want to lose someone else who’s important to me. Mikey’s bad news. We can’t delve into this; just let it go.

“ I think it’s time we find our own path. ”

3 notes

·

View notes

Text

Food Grade Sodium Lactate CAS NO. 867-56-1 Wholesale

The CAS number of sodium lactate is 867-56-1, also known as sodium lactate and sodium lactate salts. It is a liquid with a food grade sodium lactate color of<150, a light yellow color, tasteless, and slightly salty. It is a natural product extracted from lactic acid and a key ingredient in the food industry, used as a preservative, emulsifier, and stabilizer. It is also used in the cosmetics and pharmaceutical industries as an antioxidant and preservative.

Specification of Food Grade Sodium Lactate CAS NO. 867-56-1

Ldentification

Of sodium salt and lactate

Color fresh

Colorless to light yellow

Smell

No irriation,no odor

Content

≥60%

Stereochemical purity (L-isomer)

≥95%

Color fresh

≤150APHA

PH(lmo/L solution

6.5-7.5

Chloride

≤0.05%

Sulfate

≤0.005%

Citric,oxalic,phosphoric and tartaric acid

Passes test

Reducing sugar

Passes test

Lead

≤2mg/kg

Arsenic

≤1mg/kg

Heavy metal(calculated as Pb)

≤20mg/kg

Cyanide

≤1mg/kg

Food Grade Sodium Lactate Application

1. Food Grade Sodium Lactate is used as a preservative and flavoring agent in food.

2. It can be used as an emulsion stabilizer in emulsions and as an acidity regulator, flavor enhancer and preservative in sauces, dressings, canned food, and jams.

3. It is also used as a humectant in bakery products, ice cream, and other dairy products.

4. Food Grade Sodium Lactate is used to increase the shelf life of food products.5. It can also be used as a buffering agent, thickening agent and flavoring agent in beverages.

2 notes

·

View notes

Text

There were floods near where I live two weeks ago so I'm also adding a few

6: If you're told to evacuate, do that. The flood comes quickly and the current can get so strong no one will be able to reach you if you stay in your house.

7: It doesn't matter that you/ your parents/grandparents can't remember there ever being a flood where you live. There are floods that only happen like once in 100 years and also the land changes so water might go where it wasn't before. Listen to official warnings and prepare accordingly.

8: don't go near the water because you are curious. it's deeper than it looks and the current is very strong. if you fall in, the chance you will survive is very low.

9: if you live in area that might be flooded, keep bag with the most important things packed so you can leave quickly. Everything should be packed in one bag, backpack is ideal becuase you'll have free hands. The backpack should have your name and contact information on it. It should include: -long shelf life food (ideally high protein), water in refilablebottle - any medication you need to take, basic pain meds and fever reducers - bandages and bandaids, turniquet, disinfection, sterile gloves - soap, toothbrush and toothpaste, towel, toiled paper, menstruation products if you use them - phone with a charging cable, radio with spare battery (if you have one), flashlight, matches, small sewing kit, knife - spare clothes, a raincoat or an umbrella - sleeping bag and a sleeping pad (if you don't have one of these, take a blanket) - ID, birth certificate, passport, health insurance card -important documents - money, payment card, gold etc.

10: If you need to evacuate, turn off all electrical appliances and water and gass in your house. Close windows and doors. If you have small children give them a card with their name, your name, your phone number and your home adress in case you get separated. If you have time seal any opening through which water could get inside, move valuable objects you can't take with you and any dangerous chemicals (like cleaning products) to higher floor, secure objects outside the house.

11:avoid travel as much as you can. The fact that things are fine where you live doens't mean they are fine everywhere. roads and railways will be flooded and covered in fallen trees and debris.

12:power outage is likely, so keep your phone charged.

13: if your house was flooded and you have flood insurance, make sure to document everything.

14: after the flood ends, make sure your house is safe to be in before you return. Get rid of food that was flooded as it will be contaminated (unless it was sealed and water didn't get to it but even than be careful and wash the container well). If you drink water from a well it has to be cleaned and the water has to be tested. When cleaning out debris, use protective equipment and treat every wound thoroughly to reduce the chance of becoming ill.

15: In general, listen to the instructions and advice of professionals

My friends who have never experienced flooding, and who are about to deal with it from this storm, please remember:

1. NO. YOU CANNOT MAKE IT THROUGH THAT WATER ON THE ROAD. I DON'T CARE WHAT YOU'RE DRIVING. TURN. AROUND.

2. DO NOT GO WADING THROUGH THE WATER. EVEN IF YOU JUST WANT TO SEE HOW DEEP IT IS. THAT. WATER. IS. CONTAMINATED.

3. IT IS CALLED FLASH FLOODING FOR A REASON. THE WATER RISES AND SURGES IN A FLASH. STAY. HOME.

4. If you're at risk of flooding, raise up any of your belongings now. Put the legs of tall things in buckets. Know where your important documents are.

5. Stay safe.

53K notes

·

View notes