#screw injection molding machine

Explore tagged Tumblr posts

Text

Injection molding machine principle and working overview

Applications: Injection molding machines can form plastic products with complex shapes, precise dimensions or dense textures with metal inserts in one go. Therefore, they are widely used in defense, electromechanics, automobiles, transportation, building materials, packaging, agriculture, culture, education, health and people’s daily lives. Working Principle: Injection molding machine uses…

View On WordPress

#Angle injection molding machine#horizontal injection molding machine#injection molding#Injection molding machine principle#plastic products#plunger injection molding machine#screw injection molding machine#vertical injection molding machine

0 notes

Text

#HiTech#HiTechMachinery#HiTechMachineryMIddleEast#HiTechMachineryME#Plastic Manufacturing Machinery#Injection Molding Machines#Extrusion Blow Molding Machines#Pipe & Profile Extrusion Lines#PET Blow Molding Machines#Injection Blow Molding Machines#One-Stop Manufacturing Solutions#Technical Support#Customized Solutions#Screw Barrels#Chillers#Robots and Automation#Mold Temperature Controllers#Vacuum Loaders#Water Treatment Systems#Hot Runners#Mold Clamps#Dehumidifiers#Molding Machine#Plastic Injection Molding Machine#After sales service#Pipe Profile Machinery#Auxillary#Machines

1 note

·

View note

Text

this box just gave me f---ing flashbacks

Netstal 110.240.9593 // Operator Panel for Injection Molder Synergy 600/110 (Switzerland, 1997)

#work suuuuucks#If I have to retract one more screw I swear to God#I'll purge you#Stupid injection molding machine#factory workers

122 notes

·

View notes

Text

Plastic Injection Molding Shapes Tomorrow

Plastic material is melted and then injected into a mold cavity using the industrial process of plastic injection molding to produce a solid, three-dimensional item. This method enables the constant mass manufacture of intricate and accurate plastic components.

Important Elements in Plastic Injection Molding

Melting and injecting the plastic material into the mold consists of a hopper for loading plastic pellets, a barrel for heating the material, and a screw or plunger for forcing the molten plastic into the mold.

Mold: Molds can be created with one or more cavities and are commonly constructed of steel or aluminum depending on the needs of the production process.

Clamping Unit: During the injection process by the injection moulding manufacturer, the clamping unit guarantees that the mold stays tightly closed. The two mold parts are held together by a clamping mechanism, and the necessary force is applied by a hydraulic system.

Ejector System: The ejector system forces the final item out of the mold once the plastic has cooled and set inside the mold. The removal of the molded pieces is made simple and effective by this element.

The Technique of Plastic Injection Molding:

Mold Setup: The injection molding machine is ready for use after the mold has been put inside of it.

Pellets of plastic are fed into the machine's hopper during material loading.

Plastic pellets are heated and melted in the barrel of the injection machine before being injected. The molten plastic is then forcefully pumped into the mold cavity.

Cooling: The plastic inside the mold is solidified by cooling the mold. The thickness of the component and the material has an impact on the cooling time.

Ejection: The ejector mechanism forces the final object out of the mold once the plastic has hardened.

Plastic injection molding advantages:

Precision and Consistency: Plastic injection molding yields components with precise tolerances and reliable quality, making it the perfect process for high-precision goods.

Wide Material Variety: The technique is flexible in that it can handle a variety of thermoplastic and thermosetting materials.

Complex Geometries: Using alternative manufacturing processes would be difficult or impossible for the fabrication of elaborate and complex forms. Injection moulding is the best fit for this.

#Injection Moulding#Plastic Injection Molding#Injection Moulding manufacturer#Injection Moulding supplier#Injection Moulding China

2 notes

·

View notes

Text

PCB Housing Design: A Comprehensive Guide

Printed Circuit Board (PCB) housing design is a critical aspect of electronic product development. It ensures that PCBs are well-protected, securely mounted, and function efficiently within their intended environment. A well-designed PCB housing not only enhances performance but also improves durability, manufacturability, and aesthetic appeal. In this guide, we will explore the key considerations and best practices for designing effective PCB housings.

Importance of PCB Housing Design

PCB housing serves multiple functions, including:

Protection: Shields the PCB from environmental factors such as dust, moisture, heat, and mechanical stress.

Heat Dissipation: Ensures proper thermal management to prevent overheating.

Structural Support: Secures the PCB in place to avoid movement and mechanical failures.

EMI Shielding: Reduces electromagnetic interference for stable operation.

User Safety: Prevents exposure to electrical hazards.

Key Considerations in PCB Housing Design

1. Material Selection

Choosing the right material is essential for durability and performance. Common materials include:

Plastic (ABS, Polycarbonate, Nylon): Lightweight, cost-effective, and customizable.

Metal (Aluminum, Stainless Steel): Provides superior strength, heat dissipation, and EMI shielding.

Composite Materials: A combination of plastic and metal for enhanced properties.

2. Form Factor and Size

The housing must accommodate the PCB’s dimensions while allowing for:

Proper clearances for connectors, buttons, and displays.

Adequate airflow for cooling.

Space for additional components such as batteries or sensors.

3. Thermal Management

Electronics generate heat, making cooling strategies vital. Effective solutions include:

Heat Sinks: Absorb and dissipate heat away from components.

Ventilation: Airflow channels or perforations to enhance cooling.

Thermal Pads or Insulators: Improve heat transfer while maintaining insulation.

4. Mounting and Assembly

Securely mounting the PCB within the housing is crucial to avoid movement or damage. Common methods include:

Screw Mounting: Provides strong and secure fixation.

Snap-Fit Designs: Quick and tool-free assembly.

Adhesives and Epoxy: For permanent fixation.

5. Environmental Protection

For applications in harsh conditions, additional protection may be necessary:

Sealed Enclosures (IP-Rated): Protect against water and dust.

Conformal Coatings: Shield against moisture and contaminants.

Shock and Vibration Resistance: Foam padding or rubber gaskets for impact absorption.

6. Accessibility and Maintenance

A good housing design allows for easy access to internal components for repairs and upgrades. Features to consider include:

Removable Panels or Covers

Modular Design for Component Replacement

Service Ports for Debugging and Testing

7. Aesthetic and Branding Considerations

The housing also plays a role in the product’s visual appeal and brand identity. Customization options include:

Color and Finish

Company Logo and Labels

Ergonomic Design for User Comfort

Best Practices for PCB Housing Design

Prototype Early: Use 3D printing or CNC machining to test the housing before mass production.

Collaborate with Manufacturers: Ensure feasibility and cost-effectiveness in the design phase.

Consider Regulatory Compliance: Follow industry standards like UL, RoHS, and IP ratings.

Optimize for Mass Production: Design for injection molding, die-casting, or sheet metal fabrication.

Future-Proof the Design: Allow room for component upgrades and modifications.

1 note

·

View note

Text

Screw Barrel Manufacturer in China | BJ Machinery

BJ Machinery is a leading screw barrel manufacturer in China, offering high-quality products for various industries. With years of experience and advanced manufacturing technology, we specialize in producing precision-engineered screw barrels for plastic extruders, injection molding machines, and more.

0 notes

Text

Innovative Molding Solutions: PEEK Mold, 2K Mold, and Machined Insert by Yakon

In the rapidly evolving world of precision molding, manufacturers seek cutting-edge solutions to enhance product performance and durability. Yakon Mold, a leading mold-making specialist, offers state-of-the-art molding solutions, including PEEK Mold, 2K Mold, and Machined Inserts. These advanced techniques cater to diverse industries, ensuring high precision, strength, and longevity in molded components.

PEEK Mold: High-Performance Polymer Molding

Polyether ether ketone (PEEK) is a high-performance thermoplastic known for its exceptional mechanical strength, chemical resistance, and thermal stability. PEEK molding is widely used in aerospace, medical, automotive, and industrial applications where high-temperature resistance and durability are critical.

Advantages of PEEK Molding:

High-Temperature Resistance: Withstands temperatures up to 260°C, making it ideal for extreme environments.

Excellent Chemical Resistance: Resistant to aggressive chemicals, acids, and solvents.

Superior Mechanical Strength: Offers excellent wear resistance and durability.

Biocompatibility: Perfect for medical applications, including surgical instruments and implants.

Yakon Mold specializes in precision PEEK molding, ensuring tight tolerances and flawless surface finishes to meet industry standards.

2K Mold: Advanced Two-Shot Molding Technology

2K molding (Two-Shot Injection Molding) is an innovative technique that enables the production of complex, multi-material, and multi-color components in a single process. This method is widely used in automotive, medical, and consumer electronics industries.

Key Benefits of 2K Molding:

Enhanced Product Functionality: Combines hard and soft materials for superior performance.

Improved Aesthetic Appeal: Allows seamless integration of colors and textures.

Reduced Assembly Costs: Eliminates the need for secondary assembly, reducing manufacturing time and costs.

Stronger Bonding: Ensures high adhesion between different materials, enhancing durability.

At Yakon Mold, we employ advanced machinery and expert engineering to deliver high-precision 2K molds, ensuring superior quality and efficiency.

Machined Insert: Reinforced Molding for Durability

Machined Inserts play a crucial role in strengthening molded components, providing structural integrity and enhanced performance. These inserts are commonly used in industries requiring high-strength parts, such as automotive, electronics, and aerospace.

Advantages of Machined Inserts:

Increased Strength and Longevity: Improves component durability and load-bearing capacity.

Enhanced Threading Capabilities: Ideal for applications requiring secure fasteners and screws.

Precision Engineering: Ensures accurate fit and superior performance.

Versatile Material Options: Available in brass, stainless steel, aluminum, and other metals.

Yakon Mold offers high-precision machined inserts tailored to specific application needs, guaranteeing optimal performance and reliability.

Why Choose Yakon Mold?

With years of expertise in mold manufacturing, Yakon Mold stands out as a trusted partner for industries requiring high-precision molding solutions. Our commitment to innovation, quality, and customer satisfaction ensures that clients receive the best-in-class molds tailored to their specific needs.

For more information on PEEK Mold, 2K Mold, and Machined Insert solutions, visit www.yakon-mold.com and explore our cutting-edge molding technologies today.

0 notes

Text

Reynold India: Leading Water Chillers Manufacturer

Reynold India has established itself as a premier manufacturer of water chillers, catering to diverse industrial applications across the globe. Renowned for its innovative solutions, superior quality, and commitment to excellence, Reynold India is a trusted name in the cooling technology industry. With a deep understanding of customer needs and a focus on energy-efficient technologies, the company has redefined the standards for water chillers.

Why Choose Reynold India?

Innovative Technology: Reynold India incorporates cutting-edge technologies in its water chillers. The company continually invests in research and development to offer advanced cooling solutions that meet the ever-evolving demands of industries.

Energy Efficiency: One of the standout features of Reynold India’s water chillers is their energy efficiency. Designed to minimize power consumption, these chillers help industries reduce operational costs while promoting sustainability.

Customization Options: Understanding that different industries have unique cooling requirements, Reynold India provides tailor-made solutions. Customers can choose from a wide range of models and configurations to suit their specific needs.

Durability and Reliability: Reynold India’s water chillers are built to last. With robust construction and high-quality components, these chillers deliver consistent performance even under demanding conditions.

Global Reach: Reynold India has a strong presence not just in India but also internationally. The company’s water chillers are trusted by clients in various sectors, including pharmaceuticals, food and beverage, chemicals, and more.

Product Range

Reynold India offers a comprehensive range of water chillers, ensuring that every client finds a suitable solution. The product lineup includes:

Air-Cooled Water Chillers: These chillers are ideal for installations where water availability is limited. Air-cooled chillers from Reynold India are known for their compact design, easy installation, and low maintenance requirements.

Water-Cooled Water Chillers: Designed for enhanced cooling efficiency, water-cooled chillers are perfect for industries requiring high-capacity cooling. They are equipped with advanced heat exchangers and compressors for optimal performance.

Scroll Chillers: Reynold India’s scroll chillers are compact, efficient, and perfect for applications with moderate cooling needs. These chillers are widely used in industries such as plastic, printing, and medical equipment.

Screw Chillers: For heavy-duty cooling requirements, Reynold India’s screw chillers offer unparalleled reliability and efficiency. These chillers are suitable for industries like petrochemicals, HVAC, and large-scale manufacturing.

Process Chillers: Tailored for specific industrial processes, Reynold India’s process chillers ensure precise temperature control, making them ideal for applications in pharmaceuticals, chemicals, and food processing.

Industries Served

Reynold India’s water chillers are versatile and serve a wide range of industries, including:

Pharmaceuticals: Ensuring consistent temperature control for manufacturing and storage processes.

Food and Beverage: Maintaining optimal cooling for food preservation, beverages, and processing.

Plastics: Providing cooling for injection molding, blow molding, and extrusion processes.

Chemicals: Ensuring safety and efficiency in chemical manufacturing and storage.

HVAC: Offering reliable cooling for large-scale air conditioning systems in commercial and industrial buildings.

Medical Equipment: Supporting critical applications like MRI machines, laser equipment, and laboratory processes.

Commitment to Quality

Reynold India’s dedication to quality is evident in every aspect of its operations. The company adheres to stringent quality control measures at every stage of production. From sourcing raw materials to final assembly, each water chiller undergoes rigorous testing to ensure it meets the highest standards.

Sustainability and Environmental Responsibility

As a responsible manufacturer, Reynold India prioritizes sustainability in its products and processes. The company’s water chillers are designed to minimize environmental impact by reducing energy consumption and using eco-friendly refrigerants. Reynold India also complies with international environmental regulations, demonstrating its commitment to a greener future.

Customer Support and After-Sales Service

Reynold India’s relationship with its customers goes beyond the sale. The company offers comprehensive after-sales support to ensure that its water chillers perform optimally throughout their lifespan. Services include installation assistance, preventive maintenance, troubleshooting, and spare parts availability. A dedicated team of experts is always ready to address customer queries and provide prompt solutions.

Innovation for the Future

Looking ahead, Reynold India continues to push the boundaries of innovation in cooling technology. The company is exploring advancements such as IoT-enabled chillers for remote monitoring and control, further enhancing efficiency and convenience for its clients. Reynold India’s vision is to remain a leader in the industry by embracing new technologies and delivering unparalleled value to its customers.

Conclusion

Reynold India’s reputation as a leading water chiller manufacturer is well-deserved. With a focus on quality, innovation, and customer satisfaction, the company has become a preferred choice for industries worldwide. Whether you need a standard solution or a customized cooling system, Reynold India’s expertise and dedication make it the ideal partner for your cooling needs. Trust Reynold India to keep your processes running smoothly and efficiently, no matter the challenge.

0 notes

Text

Introduction to Open-flame rock and roll rotational molding machine

The following is an introduction to the open-flame rock and roll rotational molding machine:

Working Principle

Heating Principle: The machine heats the mold directly by generating an open flame through the burner. The mold is usually made of high-temperature-resistant materials and can withstand the high temperature of the open flame. The burner can adjust the size and position of the flame as needed to ensure uniform heating of the mold.

Rocking Principle: The rocking motion of the mold is achieved through the coordinated action of the main drive motor, crank, connecting rod, and swinging base. The main drive motor drives the crank to rotate, and the crank is connected to the swinging base through the connecting rod. Thus, the swinging base swings up and down with the high bracket as the fulcrum, and then drives the rotational molding mold installed on the swinging base to rock synchronously.

Structure Composition

Power System: It includes a main drive motor and an auxiliary drive motor. The main drive motor is responsible for driving the mold to perform the up-and-down rocking motion, while the auxiliary drive motor drives the mold to rotate axially, enabling the plastic raw materials in the mold to be heated and distributed evenly.

Heating System: It mainly consists of a burner nozzle, an automatic igniter, and a solenoid valve. The burner nozzle faces the side wall of the rotational molding mold and is used to inject an open flame to heat the mold. The automatic igniter can realize the automatic ignition function of the burner nozzle, and the solenoid valve controls the on-off of the gas, thereby controlling the opening and closing of the burner nozzle.

Mold Mounting System: One end of the auxiliary machine's rotating shaft is connected to a flange plate, and one end of the rotational molding mold is provided with a connecting plate. The flange plate and the connecting plate are fixed by screws to achieve the installation and disassembly of the mold, which is convenient for replacing different molds to produce various shapes and specifications of plastic products.

Control System: Generally, a PLC control system is adopted, which can precisely control the rotation speeds of the main drive motor and the auxiliary drive motor to adjust the rocking amplitude and rotation speed of the mold. At the same time, it can also control the ignition time of the burner nozzle, the gas flow rate, etc., ensuring the stability of the rotational molding process and the product quality.

Characteristics

Advantages: The equipment cost is low. Compared with other types of rotational molding machines, such as oven-type rotational molding machines and electric heating rotational molding machines, the open-flame rock and roll rotational molding machine does not require a complex heating chamber or electric heating elements, reducing the manufacturing cost and procurement cost of the equipment. It has a small footprint and a relatively simple structure with a small overall volume, which can save production site space. It is suitable for large and simple hollow products and can produce large plastic products such as large water tanks, storage buckets, and chemical containers. For products with relatively regular and simple shapes, the production efficiency is relatively high. The operation is simple, and the control system is relatively intuitive. Operators can master the operation method of the equipment proficiently after simple training, making it an ideal equipment for beginners in rotational molding.

Limitations: The temperature control accuracy is relatively low. The open-flame heating method is difficult to achieve the same precise temperature control as electric heating, which may cause the local temperature of the mold to be too high or too low, affecting the stability of product quality. The energy consumption is relatively large. The burner uses gas as energy, and the energy cost is relatively high in the long run. It causes a certain amount of pollution to the environment. During the combustion process, a certain amount of exhaust gas and noise will be generated, and corresponding environmental protection equipment is required for treatment. It is not suitable for high-precision products. For some plastic products with high dimensional accuracy requirements and strict surface quality requirements, the open-flame rock and roll rotational molding machine is difficult to meet the production requirements.

Application Areas

Container Products: It can produce various specifications of water tanks, buckets, chemical raw material storage containers, etc. These containers have the characteristics of seamless, uniform wall thickness, smooth inner and outer walls, and no leakage, which can meet the needs of different industries for liquid storage and transportation.

Traffic Facilities: It is used to manufacture traffic anti-collision facilities such as crash barrels and isolation piers. The traffic facilities formed by rotational molding have good toughness and impact resistance and can play an effective cushioning role in traffic accidents.

Water Products: It can produce water floats, buoys, small boats, and other water products. Due to the good water resistance and corrosion resistance of rotational molding products, they can be used in water for a long time without damage.

0 notes

Text

Hard Chrome Plating: A Reliable Solution for Durability and Wear Resistance

Hard chrome plating is a specialized electroplating process that deposits a thick layer of chromium onto a metal surface to enhance its durability, wear resistance, and corrosion resistance. This process, which involves the use of a chromic acid solution, has become a go-to solution in various industries where component longevity is essential. WWG Engineering offers top-notch hard chrome plating services, with state-of-the-art facilities and plating tanks capable of accommodating both small and large components. Their advanced setup ensures that every part, regardless of size or complexity, receives a high-quality chrome coating to meet specific operational needs.

The Hard Chrome Plating Process

Hard chrome plating is distinct from decorative chrome plating. While decorative chrome is typically applied in thinner layers and is primarily used for aesthetic purposes, hard chrome is applied for functional reasons—mainly to increase the lifespan and performance of machine parts exposed to harsh environments. The thickness of hard chrome plating can range from 25 to 1,000 microns, making it a highly versatile solution for numerous industrial applications.

The process starts by immersing the metal component into a chromic acid solution, where chromium is electro-deposited onto the surface. Electro-deposited chrome is known for its incredible hardness, with typical values ranging between 850 and 1050 HV (63 to 70 HRc). These hardness levels make hard chrome one of the toughest and most durable coatings available, hence the term "hard" chrome.

Key Benefits of Hard Chrome Plating

The advantages of hard chrome plating go beyond its impressive hardness. Here are several key benefits that make it ideal for various industries:

Increased Wear Resistance: Hard chrome is exceptionally resistant to abrasive and erosive wear due to its high hardness and low coefficient of friction. The coating is capable of withstanding repeated contact and movement, making it perfect for components exposed to friction-heavy environments.

Enhanced Corrosion Resistance: Hard chrome offers excellent resistance to atmospheric oxidation, preventing the metal underneath from corroding. Its ability to withstand both oxidizing and reducing agents makes it a top choice for components that operate in corrosive environments.

Self-Lubricating Properties: One of the lesser-known features of hard chrome is its self-lubricating properties. This characteristic reduces the need for external lubrication in some applications, improving efficiency and reducing maintenance costs.

Thermal Stability: Hard chrome is considered a "cold" plating process because it operates at temperatures between 50 and 60°C. This ensures that the physical and mechanical properties of the base material are not affected during the plating process, making it suitable for a wide range of materials and applications.

Repair and Salvage Capabilities: In addition to improving the performance of new components, hard chrome plating is commonly used for salvaging and repairing worn, damaged, or mis-machined parts. Thicker deposits of chrome can restore these components to their original dimensions, allowing them to be reused and extending their operational life.

Common Applications of Hard Chrome Plating

Given its excellent wear resistance, corrosion protection, and other beneficial properties, hard chrome plating is widely used across a broad spectrum of industries. Among the most frequent applications are:

Hydraulic and Pneumatic Piston Rods and Cylinders: Hard chrome plating helps reduce friction and prevent wear on moving parts, extending the life of these critical components.

Molds, Dies, and Screws: In industries like plastic injection molding and die-casting, hard chrome improves wear resistance, helping molds and dies maintain their accuracy and prolonging their service life.

Print Cylinders and Plates: The smooth, hard surface of chrome-coated print cylinders ensures high-quality printing while resisting the wear and tear associated with high-speed printing operations.

Valves, Gates, and Bodies: The corrosion-resistant and wear-resistant properties of hard chrome make it a reliable solution for valves and gate bodies that operate in challenging environments, such as the oil and gas industry.

Mining Equipment: Hard chrome plating is commonly used to extend the operational life of mining equipment exposed to harsh conditions, including abrasive materials and corrosive environments.

Pump Shafts and Rotors: In the pump industry, hard chrome plating ensures that shafts and rotors maintain their dimensional integrity and resist wear, even in environments with high friction and pressure.

Textile Components: The self-lubricating properties of hard chrome make it an ideal material for textile components, reducing maintenance requirements and ensuring smooth operation.

Why Choose WWG Engineering for Hard Chrome Plating Services

WWG Engineering is a leader in providing hard chrome plating services for industries requiring superior durability and reliability in their components. Their facilities include plating tanks capable of accepting a wide range of component sizes, from small intricate parts to large, complex items. WWG Engineering’s commitment to quality ensures that every component receives a uniform, high-quality chrome coating that meets stringent industry standards.

Whether your goal is to increase the wear resistance of new components or restore worn or damaged parts to their original specifications, WWG Engineering’s hard chrome plating services can provide the solution. Their team of experts utilizes the latest technology to ensure precise, reliable results, helping your equipment perform better and last longer.

Conclusion

Hard chrome plating is an indispensable process for industries where durability, wear resistance, and corrosion protection are critical. With its numerous benefits—including its exceptional hardness, self-lubricating properties, and ability to restore damaged components—hard chrome is the ideal choice for extending the life of vital equipment. WWG Engineering’s expertise in hard chrome plating, combined with their top-tier facilities and experienced team ensures that your components receive the highest quality treatment, enhancing their performance and longevity across various applications.

#Surface Engineering Technology#Engineering Service Company#Engineering Service Provider#Engineering Solutions#Epoxy Composite Coating#Hard chrome plating

0 notes

Text

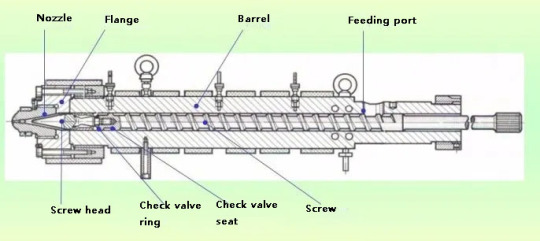

The most comprehensive introduction to injection molding screws

Screw Introduction Structure of injection screw and barrel: 1. Universal screw Demag Universal Screw Dimensions Screw diameter 60 mmScrew length 1200 mmL:D ratio 20:1SymbolFeeding section length LECompression section length LKMetering section length LMLength of each sectionL10D6D4DTooth depthh8.4mm8.4 to 3.5 mm3.5mmCompression ratioK2.4Tooth spacingt1D1D1D 2. Introduction to each section of…

View On WordPress

#amorphous plastics#Heat-sensitive plastics#How to improve service life of injection molding machine screw#injection molding#injection molding screws#Injection screw#non-crystalline plastics#plasticization#Surface treatment

0 notes

Text

We specialize in Plastic Injection Molding Machines, Screw Air Compressors, PET Blow Molding Machines, Extrusion Lines, Extrusion Blow Molding Machines, and all other Auxiliary Machineries.

With over 1,000 satisfied customers both locally and internationally, we are renowned for our quality products, reasonably priced industrial solutions and reliable services.

#HiTechMachineryME#HITechMachinery#Middleast#HiTechmachineryMiddleeast#HiTechPlasticMachinery#IndustrialEquipment#ManufacturingSolutions#MachineryDistributor#PlasticManufacturing#PlasticMolding#InjectionMolding#ExtrusionBlowMolding#PETBlowMolding#AuxiliaryMachinery#Screwaircompressor#aircompressor#Blowmolding#Industrialequipment#plastic-machinery#injectionmoldingmachine#plasticinjection#business#industrial#technology#plastic injection moulding

0 notes

Text

Caps, closures, HDPE containers & corrugation from Om Tech Containers

Based in Haridwar's Sidcul industrial area, Om Tech Containers began as a corrugation firm named Om Packaging in 2003. In 2016, the company entered the plastic packaging segment by forming Om Tech Containers – operating in plastic molding and blow molding.

Om Tech Containers supplies customized caps and closures to Patanjali, GNC, Bella Vita perfumes, ITC, RSPL, and Toyo Inks and others. Usually not many changes are needed in caps and closures, but when they happen, they can be capital intensive, Khurana, a first-generation entrepreneur, told Packaging South Asia during our recent visit to Haridwar.

The company uses five Milacron machines for injection molding of 150-200 tons as the production cost depends hugely on the tonnage of the machine, he said. For smaller products, they use smaller machines while the heavier machines are for large products and bigger lots.

In caps and closures, the company manufactures flip-top, regular, CTC, screw and lock break caps, he said. The caps are designed according to the usage of the product.

Om Tech containers manufactures HDPE containers through blow molding on five CMP machines manufactured in India. Its HDPE bottles are recyclable.

“The plastic molding industry is creative. Though the basic product is the same, you can change the design according to requirement. Everyone wants a good design to attract customers,” he said.

“We source our raw material from Reliance, HPCL, GAIL, and Indian Oil. The prices of raw material in the plastic industry mostly depend on the price of crude oil and the demand-supply ratio,” he added.

Corrugation plants for loyal customers

Om Packaging has one manual and one automatic plant for corrugation in Haridwar, where it makes 1500 tons of corrugated cartons per month, Khurana said.

Its corrugation customers include Patanjali, ITC, Prince Pipes and Fittings, Bella Vita perfumes, Fena and Ghadi detergent powders and Panasonic. “Most of our customers are from the FMCG or chemicals segments and a few from pharma. We have a loyal customer base,” Khurana said.

The company sends corrugated boxes to Delhi-NCR, Baddi in Himachal Pradesh and Uttarakhand. “We don't supply corrugated cartons beyond 400-500 kms because the freight cost gets higher as it is a volumetric product,” he said.

“We have a good turnover and adding more customers. India's packaging industry is competitive. We are looking to grow in the segments where we are already working. Service and on-time delivery are of prime importance in the packaging industry,” Khurana said.

The company plans to make PET bottles as there is a huge demand in pharma units, he said. By the end of this year, it plans to add one blow molding and one injection molding machine, he concluded.

0 notes

Text

Injection Mold Checklist

Excellence in manufacturing depends on injection frisbee quality. Our injection Mold Checklist simplifies this procedure, walking you through the necessary stages to uphold high standards. This checklist is an essential tool for any injection molding expert, as it includes all the necessary steps to optimize injection molding solutions, reduce errors, and increase productivity from original design to final inspection.

Mold appearance and dimension

Is the kind of water connector correct? Is there sufficient clearance in the hole for the water connector? The hole's outside border must be consistent and chamfered.

Indicate the water lines with "IN," "OUT," and neatly and legibly number them. For instance, INT1, OUT1.

Pneumatic or oil connection numbers must begin with the prefix "O" or "G," for example, G IN1, O IN1.

The gas, oil, and water plugs' screw threads all match the Tooling datasheet.

Are the KO pattern and size up to par?

The Locating ring's diameter and fastening type comply with the Tooling specification.

The tooling datasheet's sprue bushing sphere radius must be met.

The total size of the mold must satisfy the customer's press (tie bar space), and the clamping technique must satisfy the customer's demand.

When installing a mold that requires installation instruction, the cavity or core plate should be etched with an arrow that reads "UP."

Each part must have a unique number. Moreover, the standard mold datum needs to be etched.

It is not permitted to make any of the components within the home.

Using the right steel is important, and the molding injection company must submit the steel certification.

All connection screw threads, including K.O. and eyebolt holes, must be precise.

Wear plates should employ oil grooves whose designs adhere to client specifications.

The shut-off pieces must fulfill customer requirements and have a disparity in hardness.

Does Slide Gib require a dowel pin?

Are side locks properly purchased and installed?

Cycle Installing a counter as per the mold design sketch.

Make a vent opening for the guide bush.

Is a dustproof sheet required?

Are the slides assembled and properly fit the molding injection company?

The PL vent needs to be planned and cut. Is it directly cut to the part location and appropriate for parting?

Clearance space should be designed and created in the region beyond the portion wall. There is no need to invest in a grinding machine.

Sprue bushing should be OK and should not break.

Ejection, Return, Pull system and Removing

Smoothly ejecting, No unique sound, no get stick.

Lifter surfaces must be polished, lubricant slots must be made, and heat or nitride treatment must be applied (depending on the client's needs).

A & B plate guide pins, guide bushings, and ejector plate guide pins must satisfy client requirements.

Uneven ejector pins need to be placed in the molding injection company.

The ejecting plate ought to fully retract.

A flat-surfaced space block must be utilized for the ejecting stroke.

A return spring must be a normal part; it cannot be split or polished.

Does the material for the lifter, wedge block, and gib match the requirements of the customer? It must be heat-treated or nitride-treated.

Install a restricted switch on a hydraulic cylinder or slide.

The lifter stroke or slide must be sufficient to satisfy the requirements.

Both the ejector pin and the ejector plate must have the ejector number stamped on them.

Return pin top surfaces must be level and free of welding; bottom surfaces cannot have pillows or welding. The required hole clearance is 0.07 mm.

Unless otherwise noted, there should be 0.05mm of space between the B plate and the ejector guide pin (Conform to the molding injection company design specification).

With a sufficient stroke, the runner stripper plate moves smoothly.

The steel dimensions must be examined, and a steel check report must be submitted.

Cooling System

Water line seals must be leak-free, and utilize Teflon sealing tape.

Is the flow appropriate for cooling? To determine this, a flow metre must be used and the flow value recorded.

Cooling manifold installation must be done accurately and by client specifications.

The water baffle needs to fit the molding injection company specifications

Cold Runner System

Sprue bushing inside surface must be polished to design specifications.

It is necessary to polish the runner channel to the drawing standard.

For multi-molding injection company, the short-shot has to be tesmolding injection company.

Hot Runner System

Specifying the desired kind and size of sockets and installing safety settings is necessary.

Is there mold protection equipment placed on the outside of the connection box? The wiring must match the shop's given design.

To prevent breakage, wires must be bundled and covered with a plate.

When both connector sizes are the same, they must be carefully marked to prevent incorrect assembly.

Wires that are visible outside of the mold surface are prohibited.

The transition slot that allows the wire to pass through the plate and manifold must be rounded to prevent damage.

Does a mold-insulating plate exist? If not, has the consumer given their approval?

Mold Packing

The steel type, certification, and heat treatment must satisfy the client's needs.

Safety locks (at least two pieces) ought to fulfill the design specification, and a rest hole must be created.

The CD's files are full?

Are there any particular requirements for the outside surface of mold?

Are all the spare components filled up? And it must be supplied with a thorough list.

Mold must be wrapped in a plastic membrane.

After marking the positioning direction, spread mold # with lacquer.

Everything on the packing list must be packed.

Conclusion

In conclusion, obtaining consistent quality and operational efficiency requires the use of an injection mold checklist. You may drastically lower mistakes, raise the caliber of your output, and increase productivity by using this thorough guidance. By putting this checklist into practice, you can revolutionize your cheap injection molding process and make sure every project surpasses customer expectations and industry standards.

#plastic injection mold design#injection molding solutions#best injection molding company#injection frisbee#injection molding maker

0 notes

Text

In the exploration of sustainable agriculture and resource recycling, bagasse, which was once regarded as a waste material, is gradually showing its great potential as a raw material for organic fertilizer. Through the careful treatment of organic fertilizer production line, bagas can not only realize waste utilization, but also be converted into nutrient rich organic fertilizer, injecting new vitality into farmland.

The production and processing process of organic fertilizer revolves around the three core links of ripening, dehydration and granulation, and the addition of Sugarcaneadds new vitality to this process. On the Organic fertilizer production line, all kinds of advanced equipment work together to complete this green transformation.

Ripening stage: bagars are first mixed with appropriate amount of water, and regularly turned and aerated by organic fertilizer fermentation equipment -- Windrow Compost Turning Machine. This process promoted the activity of microorganisms, accelerated the decomposition and decay of organic matter in bagasse, and laid a good foundation for subsequent treatment.

Crushing and stirring: The decomposed Sugarcaneraw materials should be treated by a crusher. According to the humidity and characteristics of the raw materials, appropriate vertical or horizontal crusher should be selected for crushing. Subsequently, the Sugarcanewas thoroughly mixed with other organic materials using a blender (vertical or horizontal, uniaxial or biaxial) to ensure an even distribution of nutrients.

Screening and transportation: after crushing and stirring materials, through the roller screen or vibration grading screen for screening, remove impurities, improve product quality. Subsequently, the large Angle belt conveyor or screw conveyor will be screened after the material to the next process.

Pelleting and molding: In the pelleting process, Fertilizer Granules Compaction Machine with its unique double-roll extrusion technology, the Sugarcaneis mixed with other organic materials and extrudated into pellets. This step not only enhances the appearance and market value of the product, but also facilitates subsequent storage, transportation, and use. Of course, according to the market demand, some manufacturers will also choose to make the material directly into powder or extrusion into columns.

Drying and cooling: The organic fertilizer after granulation needs to be dried by a roller dryer to reduce moisture content and improve stability. A drum cooling machine is then responsible for cooling the dried particles to the appropriate temperature to avoid nutrient damage from overheating.

Packaging and sale: Finally, with the cooperation of automatic batching machine, conveyor and quantitative packaging scale and other equipment, the dried and cooled organic fertilizer is accurately measured and packaged into bags, ready to be sold to farmers or agricultural enterprises.

The green value of bagasse

The application of Sugarcaneas raw material of organic fertilizer not only realizes the resource utilization of agricultural waste, reduces environmental pollution, but also promotes the improvement of soil structure and the increase of crop yield. It is rich in cellulose, hemicellulose and mineral elements, which can release nutrients slowly in the soil and provide lasting and comprehensive nutritional support for plants.

The application of Sugarcanein organic fertilizer production is a vivid practice of agricultural circular economy. Through advanced organic fertilizer production lines and supporting equipment, we can convert this waste into valuable agricultural resources and contribute to the realization of sustainable agricultural development.

#Organic fertilizer production line#Windrow Compost Turning Machine,Fertilizer Granules Compaction Machine

0 notes

Text

In the exploration of sustainable agriculture and resource recycling, bagasse, which was once regarded as a waste material, is gradually showing its great potential as a raw material for organic fertilizer. Through the careful treatment of organic fertilizer production line, bagas can not only realize waste utilization, but also be converted into nutrient rich organic fertilizer, injecting new vitality into farmland.

The production and processing process of organic fertilizer revolves around the three core links of ripening, dehydration and granulation, and the addition of Sugarcaneadds new vitality to this process. On the Organic fertilizer production line, all kinds of advanced equipment work together to complete this green transformation.

Ripening stage: bagars are first mixed with appropriate amount of water, and regularly turned and aerated by organic fertilizer fermentation equipment -- Windrow Compost Turning Machine. This process promoted the activity of microorganisms, accelerated the decomposition and decay of organic matter in bagasse, and laid a good foundation for subsequent treatment.

Crushing and stirring: The decomposed Sugarcaneraw materials should be treated by a crusher. According to the humidity and characteristics of the raw materials, appropriate vertical or horizontal crusher should be selected for crushing. Subsequently, the Sugarcanewas thoroughly mixed with other organic materials using a blender (vertical or horizontal, uniaxial or biaxial) to ensure an even distribution of nutrients.

Screening and transportation: after crushing and stirring materials, through the roller screen or vibration grading screen for screening, remove impurities, improve product quality. Subsequently, the large Angle belt conveyor or screw conveyor will be screened after the material to the next process.

Pelleting and molding: In the pelleting process, Fertilizer Granules Compaction Machine with its unique double-roll extrusion technology, the Sugarcaneis mixed with other organic materials and extrudated into pellets. This step not only enhances the appearance and market value of the product, but also facilitates subsequent storage, transportation, and use. Of course, according to the market demand, some manufacturers will also choose to make the material directly into powder or extrusion into columns.

Drying and cooling: The organic fertilizer after granulation needs to be dried by a roller dryer to reduce moisture content and improve stability. A drum cooling machine is then responsible for cooling the dried particles to the appropriate temperature to avoid nutrient damage from overheating.

Packaging and sale: Finally, with the cooperation of automatic batching machine, conveyor and quantitative packaging scale and other equipment, the dried and cooled organic fertilizer is accurately measured and packaged into bags, ready to be sold to farmers or agricultural enterprises.

The green value of bagasse

The application of Sugarcaneas raw material of organic fertilizer not only realizes the resource utilization of agricultural waste, reduces environmental pollution, but also promotes the improvement of soil structure and the increase of crop yield. It is rich in cellulose, hemicellulose and mineral elements, which can release nutrients slowly in the soil and provide lasting and comprehensive nutritional support for plants.

The application of Sugarcanein organic fertilizer production is a vivid practice of agricultural circular economy. Through advanced organic fertilizer production lines and supporting equipment, we can convert this waste into valuable agricultural resources and contribute to the realization of sustainable agricultural development.

#Organic fertilizer production line#Windrow Compost Turning Machine,#Fertilizer Granules Compaction Machine

0 notes