#Windrow Compost Turning Machine,

Explore tagged Tumblr posts

Text

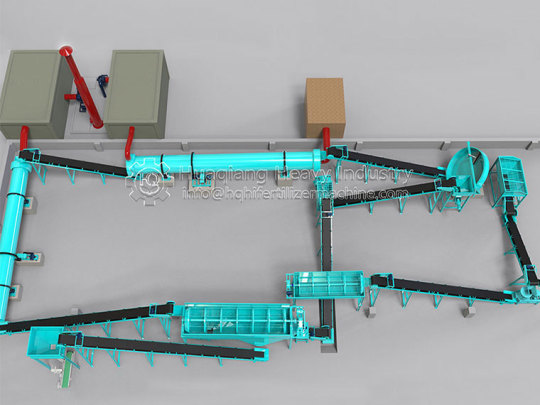

In the exploration of sustainable agriculture and resource recycling, bagasse, which was once regarded as a waste material, is gradually showing its great potential as a raw material for organic fertilizer. Through the careful treatment of organic fertilizer production line, bagas can not only realize waste utilization, but also be converted into nutrient rich organic fertilizer, injecting new vitality into farmland.

The production and processing process of organic fertilizer revolves around the three core links of ripening, dehydration and granulation, and the addition of Sugarcaneadds new vitality to this process. On the Organic fertilizer production line, all kinds of advanced equipment work together to complete this green transformation.

Ripening stage: bagars are first mixed with appropriate amount of water, and regularly turned and aerated by organic fertilizer fermentation equipment -- Windrow Compost Turning Machine. This process promoted the activity of microorganisms, accelerated the decomposition and decay of organic matter in bagasse, and laid a good foundation for subsequent treatment.

Crushing and stirring: The decomposed Sugarcaneraw materials should be treated by a crusher. According to the humidity and characteristics of the raw materials, appropriate vertical or horizontal crusher should be selected for crushing. Subsequently, the Sugarcanewas thoroughly mixed with other organic materials using a blender (vertical or horizontal, uniaxial or biaxial) to ensure an even distribution of nutrients.

Screening and transportation: after crushing and stirring materials, through the roller screen or vibration grading screen for screening, remove impurities, improve product quality. Subsequently, the large Angle belt conveyor or screw conveyor will be screened after the material to the next process.

Pelleting and molding: In the pelleting process, Fertilizer Granules Compaction Machine with its unique double-roll extrusion technology, the Sugarcaneis mixed with other organic materials and extrudated into pellets. This step not only enhances the appearance and market value of the product, but also facilitates subsequent storage, transportation, and use. Of course, according to the market demand, some manufacturers will also choose to make the material directly into powder or extrusion into columns.

Drying and cooling: The organic fertilizer after granulation needs to be dried by a roller dryer to reduce moisture content and improve stability. A drum cooling machine is then responsible for cooling the dried particles to the appropriate temperature to avoid nutrient damage from overheating.

Packaging and sale: Finally, with the cooperation of automatic batching machine, conveyor and quantitative packaging scale and other equipment, the dried and cooled organic fertilizer is accurately measured and packaged into bags, ready to be sold to farmers or agricultural enterprises.

The green value of bagasse

The application of Sugarcaneas raw material of organic fertilizer not only realizes the resource utilization of agricultural waste, reduces environmental pollution, but also promotes the improvement of soil structure and the increase of crop yield. It is rich in cellulose, hemicellulose and mineral elements, which can release nutrients slowly in the soil and provide lasting and comprehensive nutritional support for plants.

The application of Sugarcanein organic fertilizer production is a vivid practice of agricultural circular economy. Through advanced organic fertilizer production lines and supporting equipment, we can convert this waste into valuable agricultural resources and contribute to the realization of sustainable agricultural development.

#Organic fertilizer production line#Windrow Compost Turning Machine,#Fertilizer Granules Compaction Machine

0 notes

Text

Comparison between self-propelled compost turning machine and trough compost turning machine

In the field of organic fertilizer production, compost turning machines are the core tools of compost fermentation. Self-propelled compost turning machine and trough compost turning machine are two types of equipment widely used in the composting process. After years of development, Huaqiang Heavy Industry has researched and produced various types of compost turning machine, such as self-propelled compost turning machine (Windrow Compost Turning Machine) and trough compost turning machine (Hydraulic Compost Turning Machine).

1.Working principle and structure

Trough type: It usually needs a fixed track or trough structure. When working, it runs along the established track and uses the stirring mechanism to turn the material. This structure enables the compost turning machine to maintain stable operation during large-scale and continuous production.

Self-propelled: It has the function of walking, and uses wheels as the moving method. This makes its structure more flexible and can freely shuttle between different material piles.

2.Work efficiency

Trough type: Because of its stable structure and highly automated operation mode, it can handle a large amount of materials each time. In large organic fertilizer production plants, it can efficiently turn a large amount of materials, greatly shortening the fermentation cycle.

Self-propelled: Although it is highly flexible, the single processing volume is relatively small. However, in small organic fertilizer production sites or when processing different small piles of materials, it can quickly switch between different piles.

3.Applicable scenarios

Trough type: Suitable for large organic fertilizer plants with relatively fixed sites, large production scales, and precise control of fermentation processes.

Self-propelled: More suitable for small farms or farmers with relatively small sites, scattered material stacking, or seasonal production of organic fertilizers.

4.Selection recommendations

Trough type: If the annual output exceeds 5,000 tons, the site is fixed, and the fermentation quality is stable, the trough compost turning machine is recommended.

Self-propelled: If you handle scattered materials (such as straw, mushroom residue), have a limited budget, or need to take into account multiple agricultural scenarios, the self-propelled compost turning machine is more cost-effective.

The core difference between trough compost turning machines and self-propelled compost tuning machines lie in the balance between scale and flexibility. When choosing a compost turning machine, you should consider the production scale, site conditions, and capital budget.

0 notes

Text

Many pig farms, chicken farms, cattle farms have a lot of pig manure, chicken manure, cow manure need to be dealt with. And these livestock manure for fermentation compost can be made into organic fertilizer, increase income. Among them, the windrow compost turning machine is a commonly used fermentation compost dumper in fertilizer factories, which has many advantages and has won the favor of customers at home and abroad. 1. The windrow compost turning machine adopts four-wheel walking design, which can move forward, backward and turn. It is controlled by one person, and the whole vehicle is driven on a long pile of pre-stacked piles. A rotating knife shaft suspended under the rack turns, fluffs and moves the stacked material, turning it into a new strip pile after the vehicle passes by.

2.Windrow compost turning machine is suitable for open air or shed operation, the whole machine structure is reasonable, good rigidity, force balance, simple, firm, safe and stable performance, easy to operate, strong adaptability to the site, easy to use and maintain. 3.The windrow compost turning machine is designed according to the principle of aerobic fermentation, so that the fermentation bacteria have the space to give full play to its function. Its machinery and equipment has the advantages of less investment, low energy consumption, fast fertilization, large output, saving civil engineering and a lot of manpower and material resources. Because of the above advantages of the windrow compost turning machine, many farms will give priority to it when choosing the fermentation compost turning machine. Huaqiang Heavy Industry specializes in the production and sale of a variety of fermentation compost turning machines, including windrow compost turning machine, simple compost turning machine, hydraulic compost turning machine, etc.

0 notes

Text

As an important auxiliary material in agricultural production, the quality and safety of organic fertilizer directly affect the growth of crops and the health of soil. In the production process of organic fertilizer, the effective control of microbial activity is the key link to ensure the quality of organic fertilizer. Here are a few key points for effective control of microbial activity:

1. Raw material pretreatment: The raw materials of organic fertilizer usually come from agricultural waste and livestock and poultry manure, which are rich in microorganisms. Turning through a Compost turning Machine (such as the Windrow Compost Turning Machine) can effectively control the activity of microorganisms, promote the growth of beneficial microorganisms, and inhibit the reproduction of harmful microorganisms.

2. Fermentation process management: In the organic fertilizer production line, fermentation is a key step, which directly affects the control of microbial activity. By adjusting the moisture, temperature and ventilation conditions in the fermentation process, the living environment of microorganisms can be optimized and the reproduction of beneficial microorganisms can be promoted. For example, maintaining the right humidity can promote microbial metabolism, while proper ventilation helps aerobic microorganisms grow.

3. Microbial inoculation: In the production process of organic fertilizer, beneficial microorganisms can be inoculated to improve the control of microbial activity. These microorganisms can be azotobacter, phosphorus solubilizer or other microorganisms that can improve soil structure and improve soil fertility. Mixing evenly through a Horizontal Ribbon Mixer ensures an even distribution of microorganisms throughout the organic fertilizer, thus enhancing its effectiveness.

4. Microbial control in the pelleting process: In the organic fertilizer pelleting process, the fertilizer pelleting Machine series (such as Flat-Die Pellet Machine) can form uniform particles, which contributes to the stable existence of microorganisms in the fertilizer. At the same time, the temperature and pressure during the granulation process also affect the activity of the microorganisms, and precise control is required to maintain the activity of the microorganisms.

5. Quality testing and monitoring: In the entire organic fertilizer production process, regular quality testing is essential. By detecting the type and number of microorganisms, the quality and safety of organic fertilizers can be assessed. In addition, the Rotary Screening Machine is used to screen the finished product, which can remove unqualified particles and ensure the uniformity of the final product and the stability of the microbial activity.

Through the above measures, we can effectively control the microbial activity in the production of organic fertilizer, produce high-quality organic fertilizer, and promote the sustainable development of agriculture.

#Windrow Compost Turning Machine#Horizontal Ribbon Mixer#Flat-Die Pellet Machine#Rotary Screening Machine

0 notes

Text

In agricultural production, the fermentation process of organic fertilizer plays a crucial role, which is not only related to the quality of fertilizer, but also directly affects the improvement effect of soil. Today, we will discuss the positive effect of organic fertilizer fermentation process on soil improvement, and introduce relevant keywords in this process.

First of all, in the process of organic fertilizer fermentation, the decomposition of microorganisms converts the organic matter in the raw material into humus, which requires the help of Windrow Compost Turning Machine and other equipment to turn the pile to ensure uniform fermentation. After fermentation, organic fertilizer is rich in organic matter and microbial flora, which can significantly improve the soil aggregate structure, improve the soil permeability and water retention ability.

Secondly, the fermentation process of organic fertilizer can also effectively reduce pathogens and pests in the soil. The high temperatures generated during the fermentation process can kill most pests, thus reducing the occurrence of soil diseases and pests. At the same time, the beneficial microorganisms rich in the fermented organic fertilizer can also compete with pathogenic bacteria for nutrition and space, further inhibiting their growth.

The Fertilizer Granulating Production Line also plays an important role in the production of organic fertilizers. By means of equipment such as Disc Granulator or Rotary Drum Granulator, the fermented organic fertilizer is granulated for easy storage, transportation, and use. This not only improves the utilization rate of fertilizer, but also facilitates the fertilization operation of farmer friends.

Finally, the fermentation process of organic fertilizer can also promote the recycling of soil nutrients. Various nutrients produced during the fermentation process, such as nitrogen (N), phosphorus (P), potassium (K), etc., are necessary for plant growth. Through the application of organic fertilizers, these nutrients are returned to the soil to provide a continuous supply of nutrients for crops. At the same time, the organic matter in the organic fertilizer can also combine with the inorganic nutrients in the soil to form a more stable nutrient form and reduce the loss and waste of nutrients.

In summary, the fermentation process of organic fertilizer has a significant positive effect on soil improvement. Through scientific fermentation process and advanced production equipment, we can produce high-quality organic fertilizer, which provides strong support for agricultural production.

0 notes

Text

What are the positive effects of using a wheel type compost turning machine on the soil

The positive effects of using wheel type windrow compost turning machine on soil are mainly reflected in the following aspects:

1. Improve soil fertility: Organic fertilizer treated by organic fertilizer equipment can increase the content of organic matter in the soil, thereby improving soil fertility and providing continuous nutrient supply for crops.

2. Improve soil structure: Organic fertilizer helps to improve the physical structure of the soil, increase the porosity and permeability of the soil, and is conducive to the growth of crop roots and water retention.

3. Promote microbial activity: Microorganisms in organic fertilizers can promote the propagation and activity of beneficial microorganisms in the soil, which contribute to the circulation of nutrients in the soil and the suppression of crop diseases.

4. Improve crop yield and quality: Organic fertilizer can provide comprehensive nutrition needed for crop growth, help to increase crop yield and improve the quality of agricultural products.

5. Enhance soil water retention capacity: Organic fertilizers can improve soil water retention capacity, reduce water evaporation, and improve soil resistance to drought.

6. Reduce soil erosion: Organic fertilizers help to enhance soil erosion resistance, reduce soil erosion, and protect soil resources.

7. To promote the ecological balance, the use of organic fertilizers help maintain and restore the balance of soil ecosystem, promote the sustainable development of the agricultural ecosystem.

In summary, the application of wheeled composting machine in agricultural production not only improves the quality of soil and crop yield, but also helps to achieve sustainable development of agriculture and environmental protection.

0 notes

Text

Wheel type windrow compost turning machine has played a great role in the development of agriculture

Wheel type windrow compost turning machine plays an important role in the development of agriculture, and its credit is mainly reflected in the following aspects:

1. Improve composting efficiency: By turning compost materials, the push machine increases the contact between materials and air, thereby improving the aerobic metabolism rate in the composting process, shortening the composting cycle, and improving the composting efficiency.

2. Improve the quality of compost: the turning machine can evenly turn the compost material, making the water and temperature distribution in the material more uniform, which helps to improve the quality of compost products.

3. Reduce environmental pollution: Through effective turning and ventilation, the odor and harmful gas emissions generated during the composting process are reduced, and the impact on the surrounding environment is reduced.

4. Resource utilization: The push machine helps to convert agricultural waste into organic fertilizer, which realizes the resource utilization of agricultural waste and promotes the sustainable development of agriculture.

5. Improve agricultural economic efficiency: The use of organic fertilizers produced by the rollover can improve crop yield and quality, thereby improving the economic efficiency of agriculture.

6. Policy support: With the state's attention to the utilization of agricultural waste resources, the push machine as an important agricultural machinery has been supported and promoted on the policy.

7. Advances in technology: the technology progress of organic fertilizer equipment, such as automatic control, such as highly efficient drive, make the equipment more efficient, energy saving and environmental protection.

Article 8. Above all, wheeled stamping compost turns pushing role in agricultural development to be reckoned with, it not only improves the efficiency and quality of agricultural production, also contribute to environmental protection and sustainable utilization of resources.

0 notes

Text

The fermentation process of organic fertilizer is the key link to produce high quality organic fertilizer. Judging whether the fermentation is normal can not only ensure the quality of the fertilizer, but also improve the production efficiency. The following are some methods and key factors to determine whether the fermentation of organic fertilizer equipment is normal.

1. Temperature change

Temperature is the most direct and sensitive index to judge whether the fermentation of organic fertilizer is normal. In the Organic Fertilizer Production Line, the fermentation process is usually divided into three stages: early, middle and late. The temperature in the early stage should rise rapidly but not too fast, the temperature in the middle stage should be maintained at 50~60℃, and the temperature in the later stage should gradually decrease. If the temperature fluctuates abnormally during fermentation, it may mean that the fermentation is not normal.

2. Smell changes

Smell is also an important indicator to judge whether the fermentation of organic fertilizer is normal. Normal fermentation of organic fertilizer will gradually lose the original odor, and instead emit a scent similar to soil. If there is still a strong odor of ammonia or hydrogen sulfide during the fermentation process, it indicates that the fermentation is incomplete or anaerobic fermentation has occurred.

3. Color change

During the fermentation process, the color of the organic fertilizer will gradually change from light to dark. Fully fermented organic fertilizers usually appear dark brown or black. If the color change is not obvious, it may be a sign of insufficient fermentation.

4. pH value

pH value is another important indicator to judge whether organic fertilizer fermentation is normal. During the fermentation process, the pH value will go through a process of first falling and then rising, and eventually stabilize at about 7. If the pH value is too high or too low, it may affect the activity of microorganisms, resulting in abnormal fermentation.

5. Microbial activity

Microbial activity is the core index to judge whether organic fertilizer fermentation is normal. By measuring the number and types of microorganisms in the compost, you can get an idea of how fermentation is progressing. In normal fermentation of organic fertilizer, microbial activity should be maintained at a high level, and beneficial microorganisms dominate.

6. Use a compost tumbler

Compost Turning Machine plays a key role in the fermentation process of organic fertilizer. By turning the pile regularly, the uniformity and ventilation of the compost can be ensured and the occurrence of anaerobic fermentation can be prevented. Windrow Compost Turning Machine and and Wheel Type Windrow Compost Turning Machine is a common device choice.

7. Degree of automation of equipment

Modern organic Fertilizer Production lines are often equipped with highly automated equipment, such as the NPK Fertilizer Production Line, which monitors the temperature, humidity and gas composition of the fermentation process in real time to ensure that the fermentation process is stable and efficient.

In summary, to determine whether the fermentation of organic fertilizer equipment is normal, multiple factors such as temperature, odor, color, pH value, and microbial activity need to be comprehensively considered. Through scientific methods and advanced equipment, the fermentation quality of organic fertilizer can be effectively improved to ensure the production of efficient and environmentally friendly organic fertilizer.

#Organic Fertilizer Production Line#Windrow Compost Turning Machine#Wheel Type Windrow Compost Turning Machine#NPK Fertilizer Production Line

0 notes

Text

The important role of windrow compost turning machine in the agricultural field

The important role of crawler dumper in the agricultural field is mainly reflected in the following aspects:

1. Improve production efficiency: The windrow compost turning machine, through automated operation, speeds up the stacking and mixing process of agricultural waste, improves the preparation efficiency of organic fertilizer, and thus improves the overall efficiency of agricultural production.

2. Resource recycling: The organic fertilizer equipment can effectively transform agricultural waste such as livestock manure and crop straw into organic fertilizer, realizing the resource utilization of agricultural waste and promoting the sustainable development of agriculture.

3. Reduce environmental pollution: By converting agricultural waste into organic fertilizer, the pollution of these wastes to the environment is reduced, and the use of fertilizers is also reduced, reducing the negative impact of agricultural production on the environment.

4. Improve crop quality: The use of organic fertilizers helps to improve the quality and nutritional value of crops, produce healthier and safer food, and meet the market demand for high-quality agricultural products.

5. Strong adaptability: The crawler design enables the tiller to operate flexibly in a variety of complex farmland environments, such as wetlands, slopes, etc., expanding the scope of application of the equipment.

6. Promote technological progress: With the development of science and technology, crawler tipping machine is also constantly carrying out technological innovation and upgrading, such as more efficient tipping mechanism, more environmentally friendly material use, etc., to promote the continuous progress of agricultural technology.

Through the above role, the caterpillar stacking machine not only improves the efficiency and quality of agricultural production, but also helps to realize the resource utilization of agricultural waste and environmental protection, which is of great significance for the sustainable development of agriculture.

0 notes

Text

Rollover advantage of windrow compost turning machine

As an important equipment in the construction site of organic fertilizer production line, the windrow compost turning machine has been widely used in many fields. It can easily turn and toss materials, and has significant advantages in improving material mixing, improving work efficiency and reducing waste.

The windrow compost turning machine has high working efficiency. Due to its large working space and flexible mobility, it can quickly complete a large area of material flipping operations. This not only reduces manual labor intensity, but also greatly improves work efficiency, saving valuable time and human resources for enterprises.

Secondly, the rollover effect of the windrow compost turning machine is remarkable. Through reasonable design and operation, the dump truck can evenly distribute the material in the working area to ensure the uniformity and quality of the material mix. This not only helps to improve production efficiency, but also effectively avoids material waste and saves costs for enterprises.

In addition, the operation of the windrow compost turning machine is simple and convenient. Due to its advanced control system and intelligent technology, the operator only needs simple training to master the operation skills. At the same time, the dump truck also has high safety and reliability, which can greatly reduce the operation risk and improve the work efficiency and safety.

Finally, the windrow compost turning machine has a wide range of applications. It is suitable for various types of construction sites, such as construction sites, landfills, agricultural land, etc. Through the dumping operation, the dumping truck can effectively improve soil structure, improve soil fertility, reduce environmental pollution, and bring significant benefits to enterprises and society.

To sum up, the advantages of the windrow compost turning machine are obvious, with high working efficiency, remarkable flipping effect, simple operation, a wide range of applications and so on. These advantages make the crawler dumper one of the indispensable equipment in the construction site.

0 notes

Text

The maintenance method of the equipment of the windrow compost turning machine

Windrow compost turning machine is a kind of equipment for stacking bulk materials, its main role is to stack the material in the designated position, in order to facilitate subsequent transportation and use. The following is an introduction to the maintenance of the caterpillar tilting machine:

1. Regularly check whether all nut connectors of organic fertilizer equipment are loose;

2. Regularly check the wear of the roller blade blade and whether the screws are loose;

3. Regularly check the tension of the belt inside the wheel cover;

4. Add lubricating oil to the bearing regularly;

5. Check the diesel engine regularly;

6. After 200 hours of operation of the hydraulic system, all the hydraulic oil should be emptied, the impurities in the hydraulic system filter should be removed, and the filter element should be replaced. According to the degree of cleanliness of the discharged hydraulic oil, whether to reuse after filtration. When discharging hydraulic oil, the cylinder rod should first be retracted into the cylinder; Every 800h, the hydraulic system should be cleaned.

In general, the maintenance of the windrow compost turning machine needs to be adjusted and improved according to the actual situation of the equipment, in strict accordance with the operating specifications and maintenance principles of operation, in order to ensure the normal operation of the organic fertilizer production line and extend the service life.

0 notes

Text

Organic fertilizer is an indispensable part of agricultural production, and every link of its production process is crucial. The correct use of organic fertilizer fermentation equipment can not only improve the quality and efficiency of fertilizers, but also ensure the safety and environmental protection of the production process. Here are a few key points to pay attention to when using organic fertilizer fermentation equipment:

Use of Uniform Feeder: In the production process of organic fertilizer, uniform feeding is an important link to ensure the quality of fermentation. By using a uniform feeder, the material can be ensured to enter the fermentation equipment continuously and evenly, avoiding the problem of incomplete or excessive fermentation caused by uneven feeding.

Selection and use of fertilizer mixer: mixer plays a role in the production of organic fertilizer. Horizontal Ribbon Mixer and Double Shafts Paddles Mixer are two common types of mixers that ensure an even mix of ingredients and improve fermentation efficiency. When using, pay attention to the mixing speed and time to avoid destroying the microbial activity in organic fertilizer.

Application of fertilizer Screening Machine: Organic fertilizer will produce materials of different particle sizes during fermentation. The Rotary Screening Machine or Vibration Screening Machine can effectively separate the fertilizer particles that meet the standard and improve the uniformity and quality of the final product.

Maintenance of Organic Fertilizer Production Line: Organic Fertilizer Production Line includes multiple links, such as raw material treatment, fermentation, drying, screening and packaging. Regular maintenance and inspection of all aspects of the equipment, such as Fertilizer Granules Compaction Machine, Flat-Die Pellet Machine, Rotary Drum Granulator, etc., can ensure the continuous and stable operation of the production line. Reduce the risk of failure.

Operation of Compost Turning Machine: compost turning machine, such as Windrow Compost Turning Machine, is the key equipment to improve the efficiency of compost fermentation. Proper operation can ensure the air permeability and temperature control inside the compost, promote the activity of microorganisms, and accelerate the decomposition of organic matter.

The rational use of fertilizer crusher: In the production process of organic fertilizer, the crushing of materials is an important step to improve the fermentation efficiency. Equipment such as Cage Crusher can crush large pieces of material into a suitable size for fermentation, but the crushing size should be adjusted to avoid excessive fine materials affecting the fermentation effect.

Environmental control: During the use of organic fertilizer fermentation equipment, the temperature, humidity and pH value of the fermentation environment need to be strictly controlled to ensure the activity of microorganisms and fermentation efficiency. At the same time, it is also necessary to pay attention to ventilation and stacking to avoid the accumulation of harmful gases.

Safe operation: When operating organic fertilizer fermentation equipment, the relevant safety procedures must be followed to ensure the safety of the operator. This includes properly wearing protective equipment, following instructions in the operating manual, and conducting regular safety training.

Through the strict implementation of these precautions, you can ensure the efficient, safe and environmentally friendly operation of organic fertilizer fermentation equipment, so as to produce high-quality organic fertilizer to meet the needs of modern agriculture.

0 notes

Text

How to choose an organic fertilizer compost turning machine that suits you?

In the process of making organic fertilizer, compost turning machines play a vital role. But facing the many types of compost turning machines on the market, how to choose the one that suits you? We can consider the following aspects:

1.Production scale

Small production scenario: If it is a small farm or organic fertilizer workshop, the processing volume of raw materials such as chicken manure is relatively small, and a small compost turning machine, such as a windrow compost turning machine, can be selected.

Large production scenario: For large organic fertilizer plants, hundreds of cubic meters of raw materials need to be processed every day. In this case, it is necessary to consider a large track compost turning machine, which has high production efficiency and can process a large amount of materials in a short time to ensure production progress.

2.Site conditions

Regular site: If the fermentation site is relatively regular, there are fixed fermentation tanks, and the site space allows the laying of tracks, then the track compost turning machine is a good choice. It runs along the track, has high compost turning accuracy, and can effectively use space.

Irregular site: If the site is irregular or there is no fixed fermentation tank, then a self-propelled compost turning machine may be more suitable. It is flexible to operate, does not require laying tracks, and can be moved freely to different sites for operation.

3.Material characteristics

This is also a key factor. If the material is loose, like some dry straw materials, most compost turning machine can do the job. But if the material is wet and sticky, you need to choose a compost turning machine with a special structure, such as equipment with stronger mixing ability and anti-adhesion design.

4.Budget

The prices of compost turning machines of different types, functions and brands vary greatly. On the premise of meeting your own production needs, you should choose according to your budget.

5.After-sales service

Choose a manufacturer with good after-sales service, so that when the equipment fails or requires daily maintenance, you can get timely technical support and spare parts supply to ensure the normal use of the compost turning machine and reduce production delays caused by equipment problems.

In short, when choosing a compost turning machine, you should comprehensively consider factors such as production scale, site, materials and budget, and finally choose the most cost-effective compost turning machine.

0 notes

Text

In modern agricultural production, organic fertilizers are favored for their environmental protection and soil improvement properties. However, the quality and safety of raw materials in organic fertilizer production lines are directly related to the effect of fertilizers and the safety of agricultural products. Here are some key steps to take to ensure the quality and safety of Organic Fertilizer Production Line materials:

Raw material selection and pretreatment: First of all, the raw materials of organic fertilizer need to be strictly selected and pretreatment. Livestock manure, crop straw and other raw materials should be crushed before fermentation to increase the surface area and promote the decomposition of microorganisms. For example, the use of Cage Crusher can effectively crush materials such as urea, thereby improving fermentation efficiency.

Fermentation process control: the fermentation link in the organic fertilizer production line is crucial. Turning raw materials through a Compost turning Machine, such as the Windrow Compost Turning Machine, ensures that the fermentation process is uniform and adequate, helping to kill pathogens and weed seeds while releasing heat and promoting the breakdown of organic matter.

Mixing uniformity: The use of Double Shafts Paddles Mixer can ensure that the NPK Fertilizer and other additives in the organic fertilizer are evenly mixed to avoid the difference in fertilizer effect caused by uneven mixing.

Granulation quality: The granulation link in the organic fertilizer production line is equally important. Through the fertilizer Granulator series, such as the Flat-Die Pellet Machine or Rotary Drum Granulator, uniform fertilizer particles can be formed to improve the efficiency and effectiveness of fertilizer application.

Screening and dust removal: After granulation, use fertilizer screening Machine (such as Rotary Screening Machine) to screen fertilizer particles, remove unqualified particles, and ensure the uniformity of the finished product. At the same time, it is equipped with efficient dust removal equipment to reduce dust emissions in the production process and protect the environment and workers' health.

Drying and cooling: organic fertilizer particles need to be dried and cooled before packaging. The use of Rotary Dryer Machine and Rotary Cooler Machine can effectively remove the moisture in the particles, extend the shelf life of the fertilizer, and reduce the risk of mildew caused by excessive moisture.

Quality testing: In the whole process of Organic Fertilizer Production Line, the quality of raw materials and finished products are regularly tested to ensure that they meet national and industry standards. This includes the detection of organic matter content, nutrient composition, heavy metal content and other indicators to ensure the safety and effectiveness of organic fertilizers.

Through the above measures, we can effectively ensure the quality and safety of raw materials in the organic fertilizer production line, produce efficient and environmentally friendly organic fertilizer products, and promote the sustainable development of agriculture.

#Organic Fertilizer Production Line#Cage Crusher#Windrow Compost Turning Machine#Double Shafts Paddles Mixer#Rotary Screening Machine

0 notes

Text

In modern agriculture, large-scale composting production has become an important means to improve soil fertility and promote sustainable agricultural development. In this green revolution, the compost turning machine has become an indispensable equipment in the compost fermentation process with its unique advantages. So, why do we use a flip machine for large-scale composting? Let's unravel the mystery of it.

First, the Turning Machine, especially the Windrow Compost Turning Machine, ensures an even distribution of oxygen during the composting process through its powerful turning capacity. In large-scale composting production, the volume of the material pile is huge, and if the lack of effective turning, the internal anaerobic environment is easy to form, affecting the microbial activity and reducing the fermentation efficiency.

The use of flipping machine not only solves this problem, but also promotes the uniform propagation of microorganisms, accelerates the decomposition and transformation of organic matter, and lays a solid foundation for the production of high-quality organic fertilizer. Naturally, this is closely related to the Organic Fertilizer Production Line, because high-quality compost is a prerequisite for subsequent granulation, screening and other processes.

Secondly, the turning machine also helps to regulate the humidity and temperature of the compost. In the early stage of compost fermentation, the material humidity is high and the temperature rises rapidly. Regular operation of the tilting machine can effectively reduce the temperature of the pile, prevent excessive evaporation of water, and maintain a suitable fermentation environment. With the deepening of the fermentation process, the tilting machine can also mix the partially decomposed material in the outer layer with the insufficiently fermented material inside to further improve the uniformity of fermentation. This process, echoing the working principle of the Disc Granulator or Rotary Drum Granulator in the Fertilizer Granulating Production Line, both emphasize the importance of material uniformity to the quality of the finished product.

Moreover, the use of the turning machine has greatly improved the efficiency and automation level of composting production. Compared with the traditional manual turning method, the turning machine not only saves the labor cost, but also reduces the influence of human factors on the quality of compost. Especially when dealing with a large amount of organic waste, such as urban sludge, agricultural straw, etc., the application of the rollover machine is indispensable. It not only speeds up the conversion of waste to Fertilizer, but also provides a reliable guarantee for the production of Organic-Inorganic Fertilizer Compound Fertilizer.

Finally, it is worth noting that the selection and operation of the rollover machine also need to be adjusted according to the characteristics of the compost raw materials, production scale and expected objectives. Whether it is a bar type, wheel type or large wheel disk overturning machine, it has its applicable scenes and advantages. The correct selection and rational use of turning machine will bring greater economic and ecological benefits for large-scale composting production.

In summary, the use of large-scale composting machine is not only an inevitable choice to improve fermentation efficiency and ensure fertilizer quality, but also an important measure to promote the green transformation of agriculture and achieve sustainable development. In the future development of agriculture, the turning machine will continue to play its irreplaceable role, leading the composting production to a more efficient and environmentally friendly new chapter.

#Windrow Compost Turning Machine#Organic Fertilizer Production Line#Disc Granulator#Rotary Drum Granulator

0 notes

Text

New Zealand, an island country located in the southern hemisphere, with its unique natural environment and advanced agricultural technology, has become an important producer and exporter of global dairy products. In New Zealand, the dairy industry is not only an important pillar of the economy, but also part of the national image. Today, we explore how the New Zealand dairy industry is harnessing leading technology to maintain its leading position in the global market by ensuring quality through efficient feed granulation.

1. Innovative application of Organic Fertilizer Production Line

New Zealand dairy farmers know that good feed is the foundation for producing high quality milk. Therefore, they use the Organic Fertilizer Production Line to improve the quality and yield of pasture. Through this production line, organic waste from the farm can be converted into efficient organic fertilizers that improve the soil structure and increase the nutrient content of pasture, thereby providing better quality food for cows.

2. NPK Fertilizer Production Line precision nutrition

In addition to organic fertilisers, NPK Fertilizer Production Line is widely used on New Zealand dairy farms. This production line can accurately adjust the ratio of nitrogen, phosphorus and potassium according to the growth needs of different grasses to ensure that the grasses get balanced nutrition. This precise nutrient supply not only improves the yield and quality of forage, but also helps to improve the nutritional content of milk, meeting the needs of consumers for healthy food.

3. Efficient transformation of Fertilizer Granules Series

4. the application of Windrow Compost Turning Machine in feed fermentation

New Zealand dairy farmers also make use of the Windrow Compost Turning Machine to process feed. This equipment can evenly turn the material during the feed fermentation process to ensure the oxygen supply and temperature control during the fermentation process, thus accelerating the decomposition and conversion of organic matter. The fermented feed not only has high nutritional value, but also can enhance the immunity of dairy cows and improve the quality and safety of dairy products.

Conclusion

The success of the New Zealand dairy industry is due to its continuous pursuit and application of scientific and technological innovation. Through the use of advanced equipment such as the Organic Fertilizer Production Line, NPK Fertilizer Production Line, fertilizer pelletizer series and compost turners, New Zealand dairy farmers are able to provide their cows with customized and efficient feed. To ensure the quality and safety of dairy products. This innovative approach not only brings economic benefits to the New Zealand dairy industry, but also provides valuable experience for the sustainable development of the global dairy industry.

#Organic Fertilizer Production Line#NPK Fertilizer Production Line#Fertilizer Granules Compaction Machine#Windrow Compost Turning Machine

0 notes