#Disc Granulator

Explore tagged Tumblr posts

Text

youtube

Extrusion Granulator: Efficient and Eco-Friendly Solution for Fertilizer and Feed Production

#rotary drum granulator#disc granulator#organic fertilizer granulator#double roller press granulator#fertilizer granulator price#Youtube

2 notes

·

View notes

Text

Adjusting disc granulator parameters for different crop needs

Disc granulators are key equipment in modern agriculture. How you set their parameters directly impacts fertilizer granule quality and how well crops absorb nutrients. Different crops need specific granule sizes, densities, and compositions. Tweaking these settings scientifically boosts fertilizer efficiency and supports healthier crop growth.

Key Parameters and What They Do

1.Disc Granulator Tilt Angle: Controls how long material stays in the disc, affecting granule size.

2.Rotation Speed: Determines how dense and well-formed the granules are.

3.Spray Volume: Adjusts moisture and stickiness for binding.

4. Feed Rate: Affects output speed and how evenly sized the granules are.

Suggested Settings for Different Crops

1.Field Crops (Wheat, Corn, etc.)

Granule Size: 2–4 mm (medium)

Settings: Medium tilt angle (45–50°), Speed: 25–30 rpm

Benefits: Ensures slow nutrient release and works well with large-scale mechanized spreading.

2.Vegetable Crops

Granule Size: 1–2 mm (small)

Settings: Steeper tilt angle (55–60°), Speed: 30–35 rpm

Benefits: Speeds up fertilizer breakdown to match vegetables’ fast growth.

3.Fruit Trees

Granule Size: 4–6 mm (large)

Settings: Shallower tilt angle (40–45°), Speed: 20–25 rpm

Benefits: Extends fertilizer effect, reduces how often you need to apply it, and suits deep root systems.

By adjusting disc granulator settings for specific crops, you get fertilizer granules that fit their needs perfectly. This means smarter fertilizing, better yields, and higher-quality harvests.

0 notes

Text

Key considerations for granulator selection in NPK fertilizer production lines

In NPK fertilizer production lines, choosing the right granulator directly affects product quality, production efficiency, and operating costs. The right machine ensures uniform granules, meets strength requirements, and significantly lowers energy use and maintenance expenses.

1.Raw Material Properties

Different NPK blends (like 15-15-15 or 20-10-10) require different granulation methods. High-nitrogen formulas usually need a rotary drum granulator, while high-phosphorus blends are better suited for disc granulators. Material moisture content and stickiness also influence the choice. Wet granulation works well with higher moisture materials, while dry granulation is better for low-moisture feeds.

2.Production Capacity Needs

Small lines (10,000-50,000 tons/year) might consider compact disc granulators. Medium-sized plants (50,000-200,000 tons/year) often suit rotary drum granulation systems. Large producers (200,000+ tons/year) should look at high-efficiency double roller extrusion granulation.

3.Granule Specifications

Different crops need specific NPK fertilizer particle sizes (typically 1-4mm). Granule strength is also crucial, as it affects breakage during transport and application.

4.Energy Efficiency

New high-efficiency granulators typically use 20-30% less energy than older models. Heat source utilization is key. For wet granulation needing drying, choose equipment with waste heat recovery systems – this can cut fuel costs by over 15%.

5.Environmental Compliance

Modern NPK production must meet exhaust emission and wastewater treatment rules. When selecting equipment, check if it includes proper dedusting systems and exhaust gas scrubbers.

By fully considering these factors, NPK fertilizer producers can choose the most suitable granulation equipment. This ensures product quality while achieving efficient, energy-saving, and environmentally friendly production goals.

0 notes

Text

How to optimize the equipment parameters of the organic fertilizer granulator to improve the pelletizing rate

To optimize the equipment parameters of the organic fertilizer granulator to increase the pelletizing rate, the following aspects can be considered:

1. Strictly control the quality of powder materials: Carefully control the quality of various raw materials in accordance with the formula of organic fertilizer, ensuring that there are no iron blocks, overly large wood blocks or stones in the feed and discharge, and control the particle size distribution of raw materials.

2. Optimize the nozzle and spray parameters: Select the appropriate nozzle. According to the principles of fluid mechanics, the greater the nozzle pressure and the smaller the spray holes, the larger the droplet diffusion surface and the smaller the droplet density, which is conducive to improving the balling rate.

3. Adjust the speed and inclination Angle of the disc granulator: Adjust the speed and inclination Angle of the disc granulator according to the characteristics of the material. For materials with good fluidity and weak adhesiveness, the rotational speed can be appropriately increased. For materials with strong adhesiveness, the rotational speed should be reduced. The movement of materials is monitored in real time through the automatic control system to ensure that the disc Angle of the disc granulator adopts an integral arc structure, reducing the phenomenon of material sticking to the wall.

4. Control the amount of return material: During the granulation process of organic fertilizer, the size of the return material directly affects the output and quality. Controlling the return material volume between 30% and 35% can effectively control the generation of large particles.

5. Operator training: Provide pre-job training for operators to enhance their operational skills and technical proficiency, ensuring the efficient operation of the equipment.

Through the above measures, the parameters of organic fertilizer equipment can be effectively optimized, the pelletizing rate can be increased, and thereby the production efficiency and product quality can be enhanced.

0 notes

Text

How to evaluate the pelletizing rate of a disc granulator

The pelletizing rate of a disc granulator can be evaluated from the following aspects:

Definition and calculation method: The pelletizing rate refers to the proportion of qualified particles formed during the granulation process of organic fertilizer equipment to the total material volume. It is usually calculated by the following method: Manual screening method: Take samples from the discharge area of the granulator, separate the qualified particles from the unqualified ones using sieves of different specifications, weigh the weight of the qualified particles and the total weight, and calculate the pelletizing rate. Real-time detection method: By installing particle size detection devices in the discharge area, the particle size and quantity of raw pellets are detected in real time, and the pellet formation rate is calculated.

2. Influencing factors: The fineness and particle size uniformity of raw materials have a significant impact on the pelletizing rate. Raw materials with uniform particle size are more likely to form balls. The parameters such as the diameter, inclination Angle and rotational speed of the disc granulator have a significant impact on the pelletizing rate. For instance, an appropriate inclination Angle and rotational speed can enhance the efficiency of pelletizing. The feeding amount, the spraying position and method of the binder, the moisture content of the material and other operating conditions will also affect the pelletizing rate.

3. Optimization suggestions: Adjust equipment parameters: According to the actual production situation, adjust parameters such as the inclination Angle and rotational speed of the disc to increase the pelletizing rate. Maintain a stable feeding amount, ensure that the binder is sprayed in a mist form, and control the moisture content of the materials. By using the real-time detection system, the equipment parameters are adjusted in a timely manner according to the changes in the pelletizing rate.

Through the above methods, the pelletizing rate of the disc granulator can be effectively evaluated and optimized, improving production efficiency and product quality.

0 notes

Text

How to choose the right bio-organic fertilizer production line based on farm size?

When turning livestock manure into a resource, picking the right bio-organic fertilizer production line needs to perfectly match the farm’s scale. Farms with different herd sizes have very different manure handling needs, budgets, and ways of operating.

1.Small Farms

Recommended Setup: Simple trough fermentation line (Investment: ¥150,000 – ¥250,000)

Capacity: 3-5 tons/day

Key Equipment: Small windrow compost turning machine (1.5m wide), combined crusher and screener, manual packaging station.

Benefits: Needs only about 300 sqm of space, can flexibly handle mixtures like pig or chicken manure.

2.Medium Farms

Recommended Setup: Semi-automatic fermentation line (Investment: ¥500,000 – ¥800,000)

Capacity: 10-20 tons/day

Upgrades: Intelligent turner (with temperature sensors), automatic batching system, disc granulator set, mobile packaging machine.

Cost-Effectiveness: Processing cost per ton is 40% lower than small lines. Can also handle manure from nearby farms.

3.Large Farming Groups

Recommended Setup: Smart factory-style production line (Investment: ¥2 million+)

Capacity: 50-100 tons/day

Advanced Features: Fully enclosed fermentation workshop (with bio-deodorization), computer-controlled turner, extrusion granulator + coating machine, automated palletizing and storage system.

Always choose a production line with slightly more capacity than your current manure output, leaving about 20% room for growth. Getting the right equipment can turn manure handling from a cost center into a profit center.

0 notes

Text

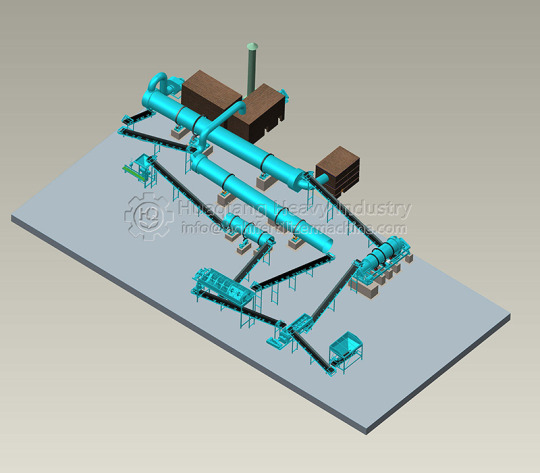

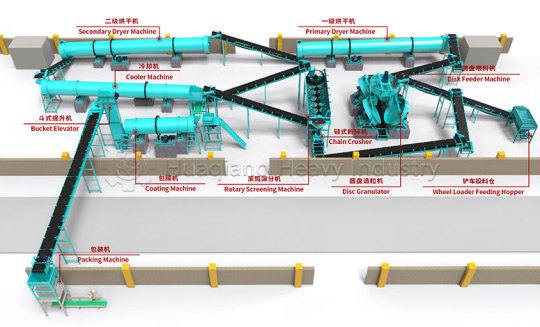

Disc Granulation: The Intelligent Choice for Organic Fertilizer Production

Core Advantages of Disc Granulation Production Line

The Organic Fertilizer Disc Granulation Production Line holds a prominent position in organic fertilizer manufacturing due to its unique granulation method. Its most notable advantage is the gentle granulation process, particularly suitable for organic materials containing live microorganisms. With adjustable inclination (45-60°) and rotational speed (30-50rpm), it can handle various organic materials from powdery to viscous while preserving microbial activity.

Standard disc granulation lines typically process 1-10 tons/hour with granulation rates reaching 85-92%, producing more spherical granules than other methods.

Key Efficiency Improvement Measures

Enhancing production line efficiency requires focus on: raw material pretreatment (25-35% moisture content), dynamic adjustment of disc speed/angle, regular cleaning (every 8 hours), and automated control systems. Adding 5-10% binders (like bentonite) significantly improves pelletization, while variable frequency drives adapt to different materials.

Unique Characteristics of the Production Line

Disc granulation produces organic fertilizer with uniform particle size (2-5mm), smooth surfaces, and moderate strength (10-20N/granule). This open granulation method allows real-time process observation and adjustment, with 30-40% lower energy consumption than extrusion granulation. Crucially, it perfectly preserves active components in organic matter - essential for premium bio-organic fertilizers.

With organic agriculture's rapid growth, disc granulation technology is evolving toward intelligent systems. Integrated sensors and AI controls now automatically adjust parameters for varying materials, elevating the efficiency of converting organic waste into high-value fertilizers to unprecedented levels.

0 notes

Text

How to increase the pelletizing rate of the disc granulator

To increase the granulation rate of the disc granulator, the following aspects can be considered:

1. Optimize equipment parameters: The inclination Angle and rotational speed of the disc are key factors affecting the granulation rate. By adjusting these parameters, the movement trajectory and residence time of the materials within the disc can be controlled, thereby increasing the granulation rate.

2. Control the characteristics of raw materials: The moisture content of raw materials has a significant impact on the granulation rate. It is generally recommended to control the moisture content of raw materials between 10% and 15% to ensure that the materials have good adhesion properties. Ensure that the particle size of the materials entering the disc granulator is uniform to avoid uneven granulation due to excessive differences in particle size.

3. Process flow optimization: Before entering the disc granulator, the raw materials are pre-treated to enhance the uniformity of the materials and the granulation rate. Maintain a stable feeding speed to avoid fluctuations in granulation rate caused by uneven feeding.

4. Equipment maintenance and Inspection: Regularly inspect and maintain the key components of the disc granulator, such as the spray device, discs, and scrapers, to ensure that the equipment is in good condition. Regularly clean the interior of the disc granulator to prevent material residue and caking, which may affect the granulation effect.

5. Operation and Monitoring: Install an organic fertilizer equipment monitoring system to monitor the equipment's operating parameters in real time, such as disc speed and water spray volume, and make timely adjustments to ensure the best granulation effect. Regularly analyze production data, optimize process parameters, and increase granulation rate.

6. Use of additives: Adding an appropriate amount of binders, such as bentonite or humic acid, to the raw materials can enhance the viscosity and granulation rate of the materials.

Through the above measures, the granulation rate of the disc granulator can be effectively increased, and the production efficiency and product quality of the organic fertilizer production line can be improved.

0 notes

Text

youtube

0 notes

Text

Why can our conveying machine reduce material loss?

In the field of fertilizer production, material loss is not only related to cost control, but also affects production efficiency and product quality. As a professional manufacturer of fertilizer production machine, we know the importance of reducing material loss, especially in key production links such as organic fertilizer production lines and fertilizer production lines. And our fertilizer transport aircraft is the right assistant to achieve this goal.

Our fertilizer conveyors use advanced design concepts and manufacturing processes to ensure minimal loss of materials during transportation. Our fertilizer conveyors offer higher accuracy and stability than conventional conveyors. Through the precise control system, it can automatically adjust the conveying speed and flow rate according to the characteristics of the material and the production needs, avoiding the overflow and accumulation of the material caused by the speed is too fast or too slow, thus effectively reducing the waste of the material.

In the organic fertilizer production line, our fertilizer conveyors show their unique advantages. Because organic fertilizers usually contain high moisture and fragility, traditional conveying machine is often prone to damage and scattering of materials during conveying. Our fertilizer conveyor adopts a soft transportation method, with a special conveyor belt or pipeline, to ensure the integrity of the material in the transportation process, which greatly improves the utilization rate of organic fertilizer.

In addition, our fertilizer conveyors also have excellent sealing performance, which effectively prevents dust and volatilization of materials during transportation. This not only protects the production environment, but also reduces the loss caused by volatilization of materials. In the fertilizer production line, this is particularly important, because it is directly related to the quality and yield of fertilizer products.

To sum up, our fertilizer conveyors successfully reduce the loss of materials during transportation with their advanced design, precise control, gentle delivery and excellent sealing performance. This not only saves costs for customers, improves production efficiency, but also contributes to the sustainable development of the fertilizer production industry. When you choose our fertilizer conveyor, you choose an efficient, environmentally friendly and intelligent fertilizer production solution.

#organic fertilizer production line#fertilizer granules compaction machine#disc granulator#flat-die pellet machine

0 notes

Text

Why in the production process of fertilizer humidity exceeded?

During the operation of fertilizer production line, the quality and storage stability of the final product are directly affected by the standard of fertilizer humidity. However, many enterprises will encounter the problem of excessive fertilizer humidity in the production process, which will not only lead to easy caking and mold of the finished product, but also may affect the normal operation of the fertilizer granulator. So why is this happening?

1. The moisture content of raw materials is too high

Some organic raw materials, such as livestock manure, biogas residue, straw, etc., have high moisture, and if they enter the production process directly without pretreatment, it is easy to lead to the difficulty of running the granulator or blender in the NPK fertilizer production line, and eventually cause the humidity of the finished fertilizer to exceed the standard.

2. Excessive spray during granulation

In the granulation process of the fertilizer granulator, in order to improve the particle forming rate, it is usually necessary to add a certain proportion of water or adhesive. However, if the amount of spray is not properly controlled, the excess liquid will make the internal water content of the fertilizer particles too high, resulting in increased drying difficulty, and eventually the humidity of the finished product exceeds the standard.

3. Insufficient treatment of drying link

Drying machine plays a key role in the fertilizer production line. If the drying temperature is too low, the drying time is insufficient, or the operating efficiency of the machine is reduced, the water in the fertilizer cannot be fully evaporated, which is easy to lead to high humidity of the finished product. In addition, excessive load or improper operation of the dryer may also affect the drying effect.

4. The production environment humidity is high

If the production environment is humid, especially in the rainy season or high humidity areas, the fertilizer may absorb moisture in the air during storage and cooling, resulting in an increase in the humidity of the finished fertilizer. Therefore, in the production process, good ventilation and dehumidification measures should be maintained to reduce the impact of air humidity on the quality of fertilizer.

0 notes

Text

Innovative practice of chicken manure organic fertilizer production line

The innovation practice of chicken manure organic fertilizer production line has made remarkable progress in recent years, through technological innovation and process optimization, the efficient treatment and resource utilization of chicken manure has been realized, and new vitality has been injected into the development of agricultural recycling. The following are the main innovative practices of the current chicken manure organic fertilizer production line:

1. Intelligent and automatic control: Through the Internet of Things technology, the chicken manure organic fertilizer production line realizes the real-time monitoring and remote operation of the fermentation process.

2. Automated production line: Modern chicken manure organic fertilizer production line adopts automated equipment, such as belt conveyor, disc granulator, dryer, etc., which reduces manual intervention and improves production efficiency.

3. Process optimization and product innovation: Secondary fermentation process is adopted, with a variety of strains undergoing primary fermentation first, and then adding strains that fix nitrogen, dissolving phosphorus and activating potassium for secondary fermentation, which significantly improves the nutrient content and fertilizer efficiency of organic fertilizer.

4. Economic and social benefits cost reduction and income improvement: The application of new fermentation technology and automation equipment has significantly reduced production costs and improved production efficiency.

5. Environmental protection and sustainable development of agriculture: organic fertilizer production line of chicken manure not only solves the environmental problems of chicken manure treatment, but also provides high-quality fertilizer for agricultural production and promotes the development of agricultural circular economy.

Through these innovative practices, the chicken manure organic fertilizer production line not only improves production efficiency and product quality, but also provides new solutions for the resource utilization of agricultural waste, and promotes the development of green agriculture.

0 notes

Text

Core process differences between dry and wet granulation

In fertilizer and chemical production, granulation techniques directly impact product quality and efficiency. Dry and wet granulation, as two mainstream methods, have fundamental differences in process flow, equipment needs, and product characteristics.

1.Process Principles

Dry granulation: Uses mechanical pressure (roller press) to press dry powder directly into shape—no liquid binder added. Typical equipment includes double roller press granulators. Wet granulation: Requires adding liquid binders (water or solvents). Powder particles clump together through mixing or tumbling. Common equipment: disc granulators, rotary drum granulators.

2.Material Suitability

Dry granulation: Best for heat-sensitive materials (avoids decomposition). Handles dry powders with < 8% moisture.

Wet granulation: Works for non-sticky powders that are hard to press. Handles moist materials with 15–30% moisture.

3.Key Process Flow Differences

Dry process:

Raw material prep→Mechanical pressing→Crushing and Screening→Packaging

Wet process:

Mixing→Binder addition→Granule forming→Drying→Cooling→Screening→Packaging

The wet method needs an extra drying step, increasing energy use by ~30%.

4.Cost Comparison

Dry granulation: Higher upfront cost (20–30% more equipment), lower energy use (no drying), reduced maintenance.

Wet granulation: More flexible equipment options. Binder cost is extra. Better for small-batch, multi-product production.

0 notes

Text

How disc granulators help cut costs and boost efficiency in organic fertilizer production?

In organic fertilizer production, disc granulators stand out as key equipment for lowering costs and boosting profits, thanks to their unique process advantages. Compared to other granulation methods, they excel in investment cost, energy use, and material flexibility.

1.Lower Equipment Investment Cost

Disc granulators have a simple structure – mainly an inclined rotating disc, drive system, and frame. They don’t need complex pressing or drying systems. The purchase cost is 40%-50% lower than extrusion granulators, making them ideal for small to medium-sized organic fertilizer plants.

2.Lower Energy Use, Saves Operating Costs

They only need a standard motor to run, using just 3-5 kWh per ton of material – over 60% less than extrusion granulation.

No extra heating or drying is needed (relying on natural ball formation), cutting out fuel or hot air system costs.

3.Wide Material Flexibility, Less Pre-Treatment Cost

Can directly handle fermented materials with 20%-35% moisture, eliminating the drying process.

Less strict on raw material particle size – standard crushing is enough, reducing crusher energy use.

4.High Pelletizing Rate, Less Recycle Loss

The unique rolling action achieves 85%-95% pelletizing success. Unformed powder automatically recycles for re-granulation.

Significantly reduces material waste compared to flat die granulators (which have 15%-20% recycle rates).

5.Easy Maintenance, Lower Labor Costs

No precision molds or high-pressure parts. The only wear part is the scraper blade, with yearly maintenance under 2000 yuan.

Simple operation – one person can manage 2-3 machines at once, cutting labor input by 50%.

In short, for organic fertilizer made from manure, straw, etc., disc granulators are the top choice for lowering overall production costs. Their strengths lie in low investment, low energy use, and high pelletizing rates.

0 notes

Text

New development trend of disc granulator

Disc granulator as the core equipment of fertilizer production line, the new development trend of disc granulator is mainly reflected in the following aspects:

1. Intelligence and automation: Intelligence and automation is an important development direction of the disc pelletizer industry. With the continuous progress of the Internet of Things, big data, artificial intelligence and other technologies, the disc granulator will achieve intelligent upgrading and improve production efficiency and product quality.

2. Environmental protection and green: With the enhancement of global environmental awareness, the disc granulator industry will pay more attention to environmental protection and sustainable development. The equipment will use more environmentally friendly materials and technologies to reduce energy consumption and pollutant emissions in the production process.

3. Market demand growth: The market demand for disc granulators continues to grow, mainly due to the modernization of global agricultural production, the improvement of fertilizer quality demand and the promotion of environmental protection policies.

4. Technological innovation and upgrading: technological innovation will be the core driving force to promote the development of the disc pelletizer industry, including the improvement of intelligence and automation level, as well as the research and development of green organic fertilizer equipment with energy saving, low noise and less waste emissions.

In summary, the disc granulator industry in the next few years will show the development trend of intelligence, automation, environmental protection and customization. Enterprises need to pay close attention to market demand and technological progress, increase investment in research and development, and improve product performance to meet the market demand for efficient, environmentally friendly and intelligent granulation equipment.

0 notes

Text

The unique advantages of organic fertilizer equipment disc granulator

Disc granulator has unique advantages in the organic fertilizer production line, the following are some key points:

1. High granulation rate: The disc granulator adopts the overall arc structure, and the granulation rate can reach more than 93%.

2. Easy operation: the granulation plate is equipped with three discharge ports, which is convenient for intermittent production, greatly reducing labor intensity and improving labor efficiency.

3. Strong durability: the reducer and motor are driven by flexible belt, which can start smoothly, slow down the impact force and improve the service life of the equipment.

4. Stable structure: The bottom of the granulation plate is strengthened by a number of radiation steel plates, which is durable and never deformed.

5. Reasonable design: thickened, weighted, solid base design, does not need anchor bolts fixed, stable operation.

6. Strong adaptability: disc granulator is suitable for granulation of various materials, such as pulverized coal, cement, clinker, fertilizer and so on.

7. Environmental protection and energy saving: small power and reliable operation, no three wastes emissions, stable operation, easy maintenance, reasonable process layout, advanced technology, low production cost.

8. Wide adaptability of raw materials: can be used for compound fertilizer, medicine, chemical, feed, coal, metallurgy and other raw materials granulation, and can produce various concentrations, various types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc.) compound fertilizer.

9. Advanced technology: Especially rare earth, ammonium carbide, ammonium sulfate compound fertilizer granulation, is a national environmental protection applicable technology promotion project.

These advantages make the disc granulator an indispensable organic fertilizer equipment, helping to improve production efficiency and product quality, while reducing production costs and environmental impact.

0 notes