#injection molding screws

Explore tagged Tumblr posts

Text

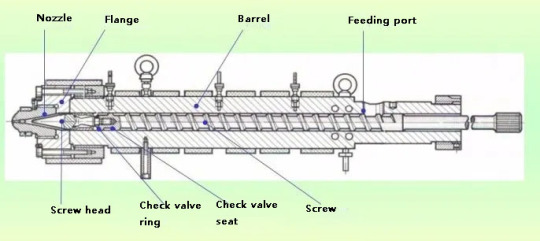

The most comprehensive introduction to injection molding screws

Screw Introduction Structure of injection screw and barrel: 1. Universal screw Demag Universal Screw Dimensions Screw diameter 60 mmScrew length 1200 mmL:D ratio 20:1SymbolFeeding section length LECompression section length LKMetering section length LMLength of each sectionL10D6D4DTooth depthh8.4mm8.4 to 3.5 mm3.5mmCompression ratioK2.4Tooth spacingt1D1D1D 2. Introduction to each section of…

View On WordPress

#amorphous plastics#Heat-sensitive plastics#How to improve service life of injection molding machine screw#injection molding#injection molding screws#Injection screw#non-crystalline plastics#plasticization#Surface treatment

0 notes

Text

this box just gave me f---ing flashbacks

Netstal 110.240.9593 // Operator Panel for Injection Molder Synergy 600/110 (Switzerland, 1997)

#work suuuuucks#If I have to retract one more screw I swear to God#I'll purge you#Stupid injection molding machine#factory workers

122 notes

·

View notes

Text

Wait, Zhao Yunlan's gun is actually a...?!

(I've never claimed production meta for @guardianbingo before, but after the amount of time and research I put in on this, I feel like I've earned the "Zhao Yunlan's Gun or Whip" square, haha)

SO. GUYS.

Maybe this is something fandom as a whole figured out back in 2018, but I, who didn't hear of Guardian until 2020, did not realize until now and I need to share the knowledge because when I finally noticed, I made an unholy sound.

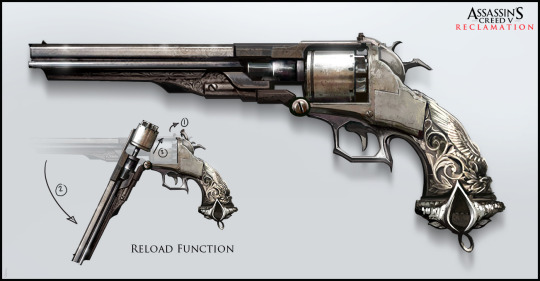

I've tracked down where Zhao Yunlan's gun came from -- or at least, what it most likely started as. Not the in-universe dark-energy-maybe-uses-bullets-maybe-doesn't-device-that's-best-not-thought-about-too-long, but rather the actual fake-steampunk-revolver-that-is-best-not-looked-at-too-long-because-it's-awful prop.

Y'know, this disaster:

I was actually working on a different Guardian Bingo fill and needed to look something up for continuity, so I'd flipped through a couple of episodes at super high speed trying to find a scene. As luck would have it, one of my skips forward happened to land on the scene I screencapped above, when ZYL confronts Zhang Shi.

Normally we don't get this clear (or this stationary) a shot of the godawful gun prop. I'd assumed all along they had just taken a plastic gun, glued some extra bits and bobs on it to make it look fancy, and hit it with some dry brushing (fun fact: you can watch the paint flake throughout the series; check out the top of the barrel and the side of the cylinder in the above screenshot!) to make it look #steampunk like the abandoned aesthetic of 25% of the show (as I've said before, I have theories about what happened in preproduction, but that's another post). This sort of thing is exactly what I've done for cheap cosplay weapons or background props for film work that aren't going to be seen at HD detail range.

Anyway, since the detail showed up better here than in other shots, I paused the video to look at the random screws and hex bolts (why??) they'd glued on it, since I recalled that I had the aforementioned gun/whip bingo square to fill.

That's when I noticed a detail that had eluded me before: An inverted V shape at the bottom of the grip.

Only looking more closely, that's not an inverted V. It's a symbol that I've seen a whole series of variations of over the past 15+ years... every time there's a new installment of the Assassin's Creed video game series:

So I started hunting. The principal weapons in each game turned up no matches, but eventually I found a gun that looks almost exactly like ZYL's:

It's not a perfect replica, but the details are certainly all there: The stylized logo; the leaves and swirls on the grip; the feathers up the back; even the Victorian scrollwork beneath the barrel.

Now, what's really interesting is that this gun isn't actually from the AC game series. It's part of an elaborate fan project by artist David Paget that started as a class assignment back in 2014. Even though it gathered a bit of steam in the AC fandom and generated a couple of forum role-play groups, OCs and the like, nothing about this artwork was ever connected to a real Assassin's Creed title. So why would there be a physical version of a gun that was only someone's fanart?

This is where the smoking gun (*rimshot*) goes missing, because I can't prove any of this, and it's been long enough that digging through the archives of the internet to find answers is going to take way more time than I can afford to spend on a project I'm not getting paid for. But there are two likely possibilities:

Scenario A: Some employee in a toy factory somewhere in China got told, "This Assassin's Creed franchise is really big, so we need to be producing replicas from those games to sell. Work up some designs." So the employee Googles "assassin's creed gun," finds David Paget's very professional-looking art, and whips up a replica to mass-injection-mold without realizing it's not actually from a game. Later, someone on the cash-strapped Guardian production team needs a gun to mod, and finds a cheap toy revolver on clearance after several years of sitting in storage because there was little demand for a replica of a gun that was never in a game. They buy several, glue hex bolts on the cylinder for reasons unknown, and poof! Instant pseudo-steampunk!

Scenario B: Other fans were involved in the design. Someone did build a 3D model of David Paget's design that's still available on Sketchfab (screenshot below), and it's not unreasonable to assume that other fans could have thought it looked cool and built 3D printable models. Later, someone on the cash-strapped Guardian production team needs a gun to mod, and acquires the 3D print file of one of those models from the interwebs. They mod the file a bit, print some, glue hex bolts on the cylinder for reasons unknown, and poof! Instant pseudo-steampunk!

Personally, I find Scenario A far more likely than Scenario B, for two reasons: First, the hero prop looks more injection molded than 3D printed, especially given the technical state of 3D printing back in 2017-8. And second... Budget-challenged dramas do have a history of picking up bulk video game replicas and using them as cheap props. I made a post back in 2019 about the WoW Horde shields we spotted in a different drama...

Anyway, no firm answers about the source of the hero prop -- the world may never know! -- but we have now confirmed that in some alternate universe (possibly one of the first eighty?), Zhao Yunlan and/or Zhao Xinci is an Assassin.

Wait, wait, wait... *recalls mechanics of how the whole Assassin's Creed frame story is supposed to work* Uh... so... who wants to write a genetic memory explanation for the whole Kunlun -> [lots of lifetimes] -> Zhao Yunlan thing?

.

(I did actually check the catalogue of a friend of mine who makes replicas of props from various media franchises to see if he'd done a commission of the David Paget design, since a surprising number of his custom pieces actually do end up on film and television, but while he has a gorgeous replica of a revolver that actually appears in an AC game, it appears he has not done the Zhao Yunlan gun. I didn't really think it likely, since he's in the U.S., but you never know.)

#guardian#zhen hun#c-drama#guardian bingo#assassin's creed#tv props#it's always fun when my various hats end up stacked on top of one another

142 notes

·

View notes

Text

Sneak peek at a rough draft of the Winterserra wedding + a little bit of the "honeymoon" for Father's Day (mostly happy but one bittersweet scene) :3

The first few days after Rosa's birth are slow and quiet. All Luis really does is sleep and gaze at Rosa with misty eyes, still absolutely baffled that a screw up like him made something so flawless.

While Ethan doesn't get any one on one time with her, due to her preferring Luis and him being obsessed and wanting her laying on his chest whenever he's awake, Ethan still keeps all the lofty promises he made about how Luis wouldn't have to lift a finger because he'd go all out taking care of them. Luis gets at least three meals a day brought to him in bed and a steady supply of any and all snacks he asks for. Ethan helps Luis get up and to the bathroom. Luis insists on being the one to bottle feed her whenever he's awake, but Ethan is the one to go downstairs to get the formula bottles ready.

Ethan also takes a lot of pictures, somewhat because of Luis. Every time Ethan wanted to take a picture of Luis while he was pregnant, he let him, but also playfully rolled his eyes and poked fun at how silly it was that Americans always wanted to take pictures of everything all the time, not just special occasions. But now that Rosa is here, he gets it. He wants every tiny little moment with her preserved forever. Every yawn, hiccup, all her adorable little mushroom pajama sets and princess dresses, Luis wants it all documented forever. Ethan is all too happy to indulge, snapping dozens of pictures of her everyday.

Once Luis is recovered enough to be up on his feet again by himself, activity in the household picks back up. Ethan takes up wedding planning and logistics of them relocating to Valdelobos for a few months. Luis is just too occupied with other things to contribute much. He was itching to get back down into the lab and back at work finding a cure for Ethan, and Rosa too. So far he's found no evidence she's infected, but since he was dosing himself with the mold growth suppressant during pregnancy and giving her the suppressant directly since birth, he's concerned that she is still infected and the suppressant has just done a good job keeping it at an undetectable level. Curing her is still as important as curing Ethan, because he doesn't want her to spend the rest of her life dependent on the injections.

And on top of that, Luis ends up being the primary caregiver. While she does start to warm up to Ethan more, she definitely still has a favorite and has days where she's fussy and only wants Luis, crying until Ethan hands her to Luis. When he's downstairs working, she's either strapped to his chest or in a little bassinet right by his chair. (Ethan still gets plenty of time with her, taking her for a little bit when he brings Luis lunch, doing some of her feedings, sometimes reading to her at bedtime.)

The “wedding planning” isn't exactly hard. It's just a small backyard ceremony, they're not even going to make any of it legal/official for a long while yet. The existence of Rosa María Winters will remain a closely guarded secret until both her and her father are completely cured of the mold, and no longer valuable targets to unsavory scientists. So it's truly a tiny wedding, the only guests being Claire, Sherry, Chris, Rebecca, and, of course, Rosa as the guest of honor, strapped to Luis's chest in her carrier with a pink rose headband. It's the first time Sherry and Chris meet her in person, so Luis and Ethan were excited about showing her off, especially now that she was getting even cuter, features she inherited from Luis beginning to show. Her hair was still dark like his, and her complexion was starting to get tanner too. Her facial features weren't as obvious yet, but the fact she definitely got his coloring is enough to make him happy.

What came after the wedding was harder to figure out– the logistics of moving to Valdelobos with a tiny baby. (Who can't be taken on a normal plane because she doesn't legally exist.) But Ethan figured it out. Chris has a private plane ready for them after the wedding, and Ethan had packed all the essentials they needed to take with them, mostly sentimental things. Once in Spain they buy a truck to load everything into before shopping for everything they'd need that Ethan didn't feel was worth bringing on a plane.

“Just tell me when you start getting tired at all,” Ethan says while they walk from the truck to the village square. Luis has Rosa in her carrier and a small backpack with her light necessities, the standard diaper bag supplies, plus some extra clothing and her favorite toy. Ethan has a heavier weight on his back, Rosa's folded up pack and play. He'll have to go back and make multiple trips to get everything from the truck, but wants to focus on getting Luis and Rosa settled first. “I know you think you're fully recovered, and you have come a long way, but you're still not 100%, I don't want you pushing yourself too hard.”

“I'm fine!” Luis insists. “But I do think it's hot when you pick me up and carry me around like I weigh nothing, so I won't object if you decide to carry me part of the way…”

Ethan grins and doesn't wait, immediately scooping Luis up bridal style, Rosa still safe on his chest. The movement does wake her up and startles her into crying, but settles back down with some soft comforting words from Luis. Once they reach the renovated house, she's hungry and fussy so Luis gets comfortable on the couch and gives her a ready bottle from an insulated lunch box with an ice pack, while Ethan goes back to the truck to get more of their stuff. The rest of the day is just spent getting settled in.

Luis is so paranoid about Rosa getting snatched in the night that he boards up the bedroom window. But after that he has no problem falling asleep. He is safe here. No one looking for Ethan Winters is going to start looking in a ghost town in Spain. And even if they did… Ethan came well armed and, after how attentive to all of Luis's emotions and needs, Luis has no doubts that Ethan would kill anyone that tried to fuck with their little family. Rosa sleeps well too, in her bassinet by the bed, right next to Luis.

“How are your arms doing from all the carrying you did yesterday?” Luis asks while they have breakfast the next morning. “I want to show you the cabin I grew up in, but a rowboat stored near here is the best way to get to it. The foot paths to it obviously haven't been maintained, and have become too overgrown to use easily, but you can get there quick taking a boat across the lake. But I understand if you need time to recover, you did all of the work yesterday, after all.”

“We can go soon. Don't forget I have magic mold,” Ethan smiles while he talks. He never would have smiled so casually about it before, but becoming a father has helped him embrace his infection. “But I'm guessing it'll be a long outing? I'll have to pack everything Rosa might need before we go, and some food for us too. I bet she'll love it. There was one night you fell asleep early and I was watching TV with her. I put on some nature documentary because I didn't want to rot her brain, I think she liked when it was showing the ocean. She seemed like she was watching it.”

“We got a little nature lover? She will love it here. Not a whole lot to do except stare at nature,” Luis sighs. “I really wouldn't want to stay here for so long, if it weren't for the safety aspect. I spent my whole childhood desperately wanting to get the fuck out of here, then the first time I came back I also spent the whole time wanting out, albeit for different reasons, so willingly coming back feels so strange.”

“We won't be here forever, just until we have some better safety plans. We'll figure it out. And it's not going to be as boring, now that you have someone that's never been here. Giving me a tour of everything might make the same old, same old feel a bit more exciting to you. I want to see everything.”

“Everything?”

“Everything,” Ethan confirms. “It's interesting, learning more about you.”

“I was planning to visit where I buried Leon today. I was going to alone, but– Do you..?”

“If you want to go alone, that's okay. But I was serious when I said everything. If you want me to come with you, I will. I'm not going to get jealous. He was important to you, so he's important to me.”

“I would like that. We go there before the boat, it's only a few minutes away from here.”

It's close enough that he doesn't bother getting Rosa into the carrier, opting to just carry her in his arms after getting her into one of her warmest outfits. They walk in silence. There's no tombstone, just a regular flat rock Luis had found and moved after burying Leon, and later carved his initials into. Luis hands Rosa to Ethan when they get to the clearing, then kneels down by the rock.

“Hey, Leon,” Luis looks up at Ethan, expecting to see a judgemental look for talking out loud to a dead man, but he only sees a small, supportive smile. It gives him the encouragement to really pour his heart out. “I really did it. I moved on, kept my promise to you. I'm married now. That fun guy I was telling you about last time. He's not you, but I love him with all my heart, and he does remind me of you. He's as forgiving as you. I thought I was going to get dumped for hiding the pregnancy for so long and generally being a shitty boyfriend, but he forgave me as fast as you did… By the way, the baby is okay. Better than okay. You should see her, she's perfect,” Taking that as a cue, Ethan gets closer and passes Rosa to Luis. Pleased to be back with her favorite person, she starts smiling and Luis can almost pretend it's because she knows he's talking about her. “Perfect. I don't deserve her, honestly. I love her so much, I love being a father. I still feel like I'm a shitty person, but the guilt doesn't cripple me like it used to. There was nothing right about you trading your life for mine, but trading your life for mine and Rosa María's? That's more fair.”

Luis continues to ramble to Leon. A little bit about the wedding and Ethan, but mostly about Rosa. When he's finally done he turns his head back expecting to see Ethan, and instead realizes he's gone, it's just him and Rosa. After a couple minutes of Luis doing his best to not have a panic attack, Ethan returns with a fistful of wildflowers he sets on the stone, before taking Rosa with one arm and letting Luis use the other to pull himself back up to a standing position.

“Thank you for coming with me,” Luis whispers to Ethan, pecking him on the cheek and taking Rosa back. He holds her out and raises her up above his head before shifting to an overly excited tone. “Ready to go for a fun boat ride, maybe see some fishies in the lake?!”

She smiles, waves her tiny arms around a bit, and starts making some of her happy little baby cooing noises that never fail to make Luis's heart explode.

#winterserra#luis serra#ethan winters#if rheres anything that doesn't make sense it's bc i was moderately blazed writing it#btw this is very ROUGH DRAFT. there will be more focusbon the wedding in the final version

8 notes

·

View notes

Text

what makes it worse for me is how abysmal the fo4 pip boy replicas were, those things stopped working if you even breathed on them. they were like The major preorder perk but they were built with saltine crackers and hatred. don’t even get me started on the 76 pip boy building kits either, that shit drove me to a legitimate meltdown more than once. if id melted down the amount of stripped or snapped screws i got out of that gotdamn pip boy i could have made a tire iron to beat todd howard over the head with

and now gods most blighted TV adaptation gets die cast metal! injection molding!! a timepiece with alarm clock function!!!!!!

the nerve of it all!!!!!

#did fo3/nv even get pip boy replica releases#like official ones by bethesda#i wasn’t In The Know at the time those games got released (was 10 years old) so i wouldn’t know#not art#i’m cranky because i’m extremely hungry and my baby daughter (cat) is laying on my legs

10 notes

·

View notes

Text

Plastic Injection Molding Shapes Tomorrow

Plastic material is melted and then injected into a mold cavity using the industrial process of plastic injection molding to produce a solid, three-dimensional item. This method enables the constant mass manufacture of intricate and accurate plastic components.

Important Elements in Plastic Injection Molding

Melting and injecting the plastic material into the mold consists of a hopper for loading plastic pellets, a barrel for heating the material, and a screw or plunger for forcing the molten plastic into the mold.

Mold: Molds can be created with one or more cavities and are commonly constructed of steel or aluminum depending on the needs of the production process.

Clamping Unit: During the injection process by the injection moulding manufacturer, the clamping unit guarantees that the mold stays tightly closed. The two mold parts are held together by a clamping mechanism, and the necessary force is applied by a hydraulic system.

Ejector System: The ejector system forces the final item out of the mold once the plastic has cooled and set inside the mold. The removal of the molded pieces is made simple and effective by this element.

The Technique of Plastic Injection Molding:

Mold Setup: The injection molding machine is ready for use after the mold has been put inside of it.

Pellets of plastic are fed into the machine's hopper during material loading.

Plastic pellets are heated and melted in the barrel of the injection machine before being injected. The molten plastic is then forcefully pumped into the mold cavity.

Cooling: The plastic inside the mold is solidified by cooling the mold. The thickness of the component and the material has an impact on the cooling time.

Ejection: The ejector mechanism forces the final object out of the mold once the plastic has hardened.

Plastic injection molding advantages:

Precision and Consistency: Plastic injection molding yields components with precise tolerances and reliable quality, making it the perfect process for high-precision goods.

Wide Material Variety: The technique is flexible in that it can handle a variety of thermoplastic and thermosetting materials.

Complex Geometries: Using alternative manufacturing processes would be difficult or impossible for the fabrication of elaborate and complex forms. Injection moulding is the best fit for this.

#Injection Moulding#Plastic Injection Molding#Injection Moulding manufacturer#Injection Moulding supplier#Injection Moulding China

2 notes

·

View notes

Text

extruder screw barrel

There are plenty of enterprises these days creating plastic derivatives. Yet, every firm or manufacturing corporation requires a plastic type of tool. one essential part of plastic processing tools is a screw barrel, which has a threaded design for melting, mixing, and shaping plastic materials. This unique barrel, which is used in conjunction with a screw to efficiently melt, compress, and inject molten plastic into molds, is essential to the manufacturing processes that produce plastic goods. Without an Extruder Screw Barrel technique, any plastic derivative department can't achieve the final stage. Also, with the service of these Screw Barrels, the derivative unit can effortlessly achieve the crucial quantity of creation.

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#ScrewBarrel#PlasticProcessing#IndustrialTools#ManufacturingComponents#MachineryParts#commercial#marketing#ecommerce#branding#sales

1 note

·

View note

Text

Looking for precision-engineered molds for your projects? Aeromould specializes in plastic injection molds for household products and engineering parts, including expansion screw molds. Our advanced designs ensure durability, strength, and reliability, making your products stand out in the market.

💡 Ideal for construction, hardware, and industrial applications where performance matters most!

📩 Email: [email protected] 📱 Phone/WeChat: +86 13989656287

Aeromould – Innovating mold solutions for your engineering needs!

#PlasticInjectionMolds#HouseholdProductMolds#EngineeringPartsMolds#ExpansionScrewMolds#PrecisionMolds#IndustrialMolds#DurablePlasticMolds#ConstructionHardwareMolds#CustomMoldDesigns#ReliableMoldSolutions

0 notes

Text

What is Plastic Injection Molding and How Does It Work?

Plastic injection molding is a widely used manufacturing process that allows for the mass production of plastic parts with high precision and efficiency. This method is versatile, cost-effective, and capable of producing components for industries ranging from automotive to consumer goods and medical devices. Below, we delve into the basics of plastic injection molding and explain how the process works.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing technique used to create plastic parts by injecting molten plastic into a mold. The mold is typically made from metal and consists of two halves—a cavity and a core—that shape the final product. Once the plastic solidifies within the mold, the finished part is ejected and the cycle begins again.

This process is ideal for creating large quantities of identical parts with high accuracy, making it a popular choice for mass production.

How Does Plastic Injection Molding Work?

The plastic injection molding process involves several key steps:

1. Material Preparation

The process begins with the selection of a suitable plastic material, often in the form of pellets or granules. These materials can be thermoplastics (e.g., polypropylene, ABS, or nylon) or thermosetting plastics, depending on the desired properties of the final product.

2. Melting the Material

The plastic pellets are fed into a heated barrel, where they are melted by high temperatures and the friction generated by a rotating screw. The molten plastic is then ready for injection.

3. Injection

The molten plastic is injected into the mold cavity under high pressure. The mold is securely clamped to withstand the pressure and maintain its shape during this step. The pressure ensures that the molten plastic fills every corner of the mold.

4. Cooling

Once the mold is filled, the plastic begins to cool and solidify into the desired shape. Cooling times vary depending on the material and the complexity of the design. Some molds may feature cooling channels to expedite this process.

5. Ejection

After the plastic has fully solidified, the mold opens, and ejector pins push the finished part out of the mold. The part is then inspected for quality and any excess material, such as sprues or flash, is trimmed away.

6. Repeat

The mold is closed again, and the cycle repeats. Modern injection molding machines can complete this process in a matter of seconds, allowing for rapid production.

Advantages of Plastic Injection Molding

High Efficiency: Once set up, the process is highly efficient, enabling the production of large volumes of parts in a short time.

Design Flexibility: Intricate designs with complex geometries can be achieved.

Material Versatility: A wide range of materials can be used, each offering unique properties.

Consistency: Parts produced are uniform, ensuring high precision and quality.

Cost-Effectiveness: While initial mold creation may be expensive, the cost per part decreases significantly with large production runs.

Applications of Plastic Injection Molding

Plastic injection molding is used in various industries, including:

Automotive: Components such as dashboards, bumpers, and interior panels.

Consumer Goods: Toys, household items, and packaging.

Medical Devices: Syringes, surgical instruments, and casings for medical equipment.

Electronics: Enclosures, connectors, and switches.

Why Choose Yakon Mold for Plastic Injection Molding?

At Yakon Mold, we specialize in delivering high-quality plastic injection molding solutions tailored to meet your specific needs. With advanced technology and a commitment to precision, we ensure that your products are manufactured to the highest standards.

Ready to bring your ideas to life? Visit us at www.yakon-mold.com to learn more or contact our team for a consultation.

Conclusion Plastic injection molding is an essential manufacturing process that combines efficiency, precision, and versatility. From its ability to produce complex designs to its applications across diverse industries, this technique continues to revolutionize modern manufacturing. Choose Yakon Mold for all your plastic injection molding needs and experience unmatched quality and service.

0 notes

Text

Composites Market Business Analysis, Share, Revenue & Sales Till 2030

The global composites market size is expected to reach USD 163.97 billion by 2030, registering a CAGR of 7.2% over the forecast period, according to a new report by Grand View Research, Inc. The demand for composites is expected to witness significant growth owing to the rising fuel prices and stringent government regulations have shifted automobile manufacturers focus on light-weighted components which would further propel the market demand over the forecast period.

Composite products play an essential role in the manufacturing of automotive and aircraft parts. The growing concerns regarding fuel consumption and CO2 emission levels have prompted the manufacturers to use carbon fiber composite materials as substitutes for metal components. Technological innovations to minimize the manufacturing cycle time is expected to propel the usage of composites in the automotive sector.

The high cost of composites has limited their application scope to premium segment cars. However, key players are conducting extensive R&D activities to develop low-cost composite grades with similar mechanical properties as that of the high-cost variants. This is expected to spur the demand for the product in the automotive industry over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Global Composites Market

Composites Market Report Highlights

The glass fiber segment accounted for the largest market share in 2022 and is further expected to grow at a CAGR of 6.4% on account of increased penetration in pipe manufacturing applications owing to the strength and durability of these composites. Additionally, glass fiber comprises several thin that find application in building & construction, automotive, industrial, energy, and consumer goods

The layup process segment is forecasted to grow at a CAGR of 9.0% by 2030. The market is again forecast to grow due to easier technology applications and the requirement of less expensive machinery. The process involves placing multiple layers of composite fiber in a sequence by using a matrix of resin and hardener

The automotive & transportation segment dominated the composites market with a revenue share of USD 19.70 billion in 2022. This is attributed to its advantages such as fuel saving to the transportation sector as the components are significantly lighter in weight that allows ascending fuel efficiency

The demand for composites in Asia Pacific was the largest in the global market due to the increase in air passenger traffic, rise in automotive vehicle production, and ambitious electrical & electronics production capacity addition targets set by various governments in the Asia Pacific including China, India, Japan, and South Korea

Various initiatives such as technology innovations, research & development, partnerships, and merger & acquisitions to manufacture cost-effective and lightweight composite products have been undertaken by the key market players. Prominent players have patented technologies used for composites manufacturing

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

Aluminum Composite Panels Market: The global aluminum composite panel market size was estimated at USD 6.47 billion in 2024 and is expected to grow at a CAGR of 7.0% from 2025 to 2030.

Centrifugal Pump Market: The global centrifugal pump market size was estimated at USD 39.80 billion in 2024 and is projected to grow at a CAGR of 4.2% from 2025 to 2030.

Composites Market Segmentation

Grand View Research has segmented the collated screws market on the basis of product, manufacturing process, end-use, and region:

Composites Product Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Carbon Fiber

Glass Fiber

Others

Composites Manufacturing Process Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Layup Process

Filament Winding Process

Injection Molding Process

Pultrusion Process

Compression Molding Process

Resin Transfer Molding Process

Others

Composites End-Use Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

Automotive & Transportation

Wind Energy

Electrical & Electronics

Construction and Infrastructure

Pipes & Tanks

Marine

Others

Composites Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

UK

Spain

Asia Pacific

China

India

Japan

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

Order a free sample PDF of the Composites Market Intelligence Study, published by Grand View Research.

0 notes

Text

Injection molding process parameters

Injection pressure 1. Pressure distribution during injection2. Factors affecting injection pressure3. Relationship between injection pressure and position, number of injection ports4. Relationship between injection pressure and product thickness5. Relationship between injection pressure and material6. Relationship between injection pressure and injection time7. Relationship between injection…

View On WordPress

#barrel temperature#clamping force#Gate design#holding pressure#injection molding#injection molding pressure#injection molding process#injection molding process parameters#injection pressure#Mold temperature#molded parts#Molding temperature#plastic part#plastic part design#Screw back pressure

0 notes

Text

Composites Market 2030 Overview, Regional Outlook, Growth Report

The global composites market size is expected to reach USD 163.97 billion by 2030, registering a CAGR of 7.2% over the forecast period, according to a new report by Grand View Research, Inc. The demand for composites is expected to witness significant growth owing to the rising fuel prices and stringent government regulations have shifted automobile manufacturers focus on light-weighted components which would further propel the market demand over the forecast period.

Composite products play an essential role in the manufacturing of automotive and aircraft parts. The growing concerns regarding fuel consumption and CO2 emission levels have prompted the manufacturers to use carbon fiber composite materials as substitutes for metal components. Technological innovations to minimize the manufacturing cycle time is expected to propel the usage of composites in the automotive sector.

The high cost of composites has limited their application scope to premium segment cars. However, key players are conducting extensive R&D activities to develop low-cost composite grades with similar mechanical properties as that of the high-cost variants. This is expected to spur the demand for the product in the automotive industry over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Global Composites Market

Composites Market Report Highlights

The glass fiber segment accounted for the largest market share in 2022 and is further expected to grow at a CAGR of 6.4% on account of increased penetration in pipe manufacturing applications owing to the strength and durability of these composites. Additionally, glass fiber comprises several thin that find application in building & construction, automotive, industrial, energy, and consumer goods

The layup process segment is forecasted to grow at a CAGR of 9.0% by 2030. The market is again forecast to grow due to easier technology applications and the requirement of less expensive machinery. The process involves placing multiple layers of composite fiber in a sequence by using a matrix of resin and hardener

The automotive & transportation segment dominated the composites market with a revenue share of USD 19.70 billion in 2022. This is attributed to its advantages such as fuel saving to the transportation sector as the components are significantly lighter in weight that allows ascending fuel efficiency

The demand for composites in Asia Pacific was the largest in the global market due to the increase in air passenger traffic, rise in automotive vehicle production, and ambitious electrical & electronics production capacity addition targets set by various governments in the Asia Pacific including China, India, Japan, and South Korea

Various initiatives such as technology innovations, research & development, partnerships, and merger & acquisitions to manufacture cost-effective and lightweight composite products have been undertaken by the key market players. Prominent players have patented technologies used for composites manufacturing

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

Aluminum Composite Panels Market: The global aluminum composite panel market size was estimated at USD 6.47 billion in 2024 and is expected to grow at a CAGR of 7.0% from 2025 to 2030.

Centrifugal Pump Market: The global centrifugal pump market size was estimated at USD 39.80 billion in 2024 and is projected to grow at a CAGR of 4.2% from 2025 to 2030.

Composites Market Segmentation

Grand View Research has segmented the collated screws market on the basis of product, manufacturing process, end-use, and region:

Composites Product Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Carbon Fiber

Glass Fiber

Others

Composites Manufacturing Process Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Layup Process

Filament Winding Process

Injection Molding Process

Pultrusion Process

Compression Molding Process

Resin Transfer Molding Process

Others

Composites End-Use Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

Automotive & Transportation

Wind Energy

Electrical & Electronics

Construction and Infrastructure

Pipes & Tanks

Marine

Others

Composites Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

UK

Spain

Asia Pacific

China

India

Japan

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

Order a free sample PDF of the Composites Market Intelligence Study, published by Grand View Research.

0 notes

Text

Hard Chrome Plating: A Reliable Solution for Durability and Wear Resistance

Hard chrome plating is a specialized electroplating process that deposits a thick layer of chromium onto a metal surface to enhance its durability, wear resistance, and corrosion resistance. This process, which involves the use of a chromic acid solution, has become a go-to solution in various industries where component longevity is essential. WWG Engineering offers top-notch hard chrome plating services, with state-of-the-art facilities and plating tanks capable of accommodating both small and large components. Their advanced setup ensures that every part, regardless of size or complexity, receives a high-quality chrome coating to meet specific operational needs.

The Hard Chrome Plating Process

Hard chrome plating is distinct from decorative chrome plating. While decorative chrome is typically applied in thinner layers and is primarily used for aesthetic purposes, hard chrome is applied for functional reasons—mainly to increase the lifespan and performance of machine parts exposed to harsh environments. The thickness of hard chrome plating can range from 25 to 1,000 microns, making it a highly versatile solution for numerous industrial applications.

The process starts by immersing the metal component into a chromic acid solution, where chromium is electro-deposited onto the surface. Electro-deposited chrome is known for its incredible hardness, with typical values ranging between 850 and 1050 HV (63 to 70 HRc). These hardness levels make hard chrome one of the toughest and most durable coatings available, hence the term "hard" chrome.

Key Benefits of Hard Chrome Plating

The advantages of hard chrome plating go beyond its impressive hardness. Here are several key benefits that make it ideal for various industries:

Increased Wear Resistance: Hard chrome is exceptionally resistant to abrasive and erosive wear due to its high hardness and low coefficient of friction. The coating is capable of withstanding repeated contact and movement, making it perfect for components exposed to friction-heavy environments.

Enhanced Corrosion Resistance: Hard chrome offers excellent resistance to atmospheric oxidation, preventing the metal underneath from corroding. Its ability to withstand both oxidizing and reducing agents makes it a top choice for components that operate in corrosive environments.

Self-Lubricating Properties: One of the lesser-known features of hard chrome is its self-lubricating properties. This characteristic reduces the need for external lubrication in some applications, improving efficiency and reducing maintenance costs.

Thermal Stability: Hard chrome is considered a "cold" plating process because it operates at temperatures between 50 and 60°C. This ensures that the physical and mechanical properties of the base material are not affected during the plating process, making it suitable for a wide range of materials and applications.

Repair and Salvage Capabilities: In addition to improving the performance of new components, hard chrome plating is commonly used for salvaging and repairing worn, damaged, or mis-machined parts. Thicker deposits of chrome can restore these components to their original dimensions, allowing them to be reused and extending their operational life.

Common Applications of Hard Chrome Plating

Given its excellent wear resistance, corrosion protection, and other beneficial properties, hard chrome plating is widely used across a broad spectrum of industries. Among the most frequent applications are:

Hydraulic and Pneumatic Piston Rods and Cylinders: Hard chrome plating helps reduce friction and prevent wear on moving parts, extending the life of these critical components.

Molds, Dies, and Screws: In industries like plastic injection molding and die-casting, hard chrome improves wear resistance, helping molds and dies maintain their accuracy and prolonging their service life.

Print Cylinders and Plates: The smooth, hard surface of chrome-coated print cylinders ensures high-quality printing while resisting the wear and tear associated with high-speed printing operations.

Valves, Gates, and Bodies: The corrosion-resistant and wear-resistant properties of hard chrome make it a reliable solution for valves and gate bodies that operate in challenging environments, such as the oil and gas industry.

Mining Equipment: Hard chrome plating is commonly used to extend the operational life of mining equipment exposed to harsh conditions, including abrasive materials and corrosive environments.

Pump Shafts and Rotors: In the pump industry, hard chrome plating ensures that shafts and rotors maintain their dimensional integrity and resist wear, even in environments with high friction and pressure.

Textile Components: The self-lubricating properties of hard chrome make it an ideal material for textile components, reducing maintenance requirements and ensuring smooth operation.

Why Choose WWG Engineering for Hard Chrome Plating Services

WWG Engineering is a leader in providing hard chrome plating services for industries requiring superior durability and reliability in their components. Their facilities include plating tanks capable of accepting a wide range of component sizes, from small intricate parts to large, complex items. WWG Engineering’s commitment to quality ensures that every component receives a uniform, high-quality chrome coating that meets stringent industry standards.

Whether your goal is to increase the wear resistance of new components or restore worn or damaged parts to their original specifications, WWG Engineering’s hard chrome plating services can provide the solution. Their team of experts utilizes the latest technology to ensure precise, reliable results, helping your equipment perform better and last longer.

Conclusion

Hard chrome plating is an indispensable process for industries where durability, wear resistance, and corrosion protection are critical. With its numerous benefits—including its exceptional hardness, self-lubricating properties, and ability to restore damaged components—hard chrome is the ideal choice for extending the life of vital equipment. WWG Engineering’s expertise in hard chrome plating, combined with their top-tier facilities and experienced team ensures that your components receive the highest quality treatment, enhancing their performance and longevity across various applications.

#Surface Engineering Technology#Engineering Service Company#Engineering Service Provider#Engineering Solutions#Epoxy Composite Coating#Hard chrome plating

0 notes

Text

-Upgraded GPS Autopilot System.Supports 40 GPS waypoints across multiple lakes.Set 8 GPS positions per lake, covering up to 5 lakes.The boat remembers your set waypoints, allowing for precise autopilot navigation on future visits. -Super High Speed: Equipped with 12V brushless dual motors, this high-speed fishing boat reaches speeds of 4-5 meters per second, effortlessly gliding over ocean waves. -Waterproof Design: With an IP66 rating, this waterproof RC fishing boat is fully protected against rust and water damage. The hull is made using injection molding, ensuring every gap is sealed, while all screws and propellers are crafted from durable 304 stainless steel. -Long-lasting Battery: A 22,000mAh high-capacity 12V rechargeable lithium battery powers your adventures, ensuring longer fishing trips without interruptions. The boat’s striking green and white hull not only looks fantastic but is also easy to spot on the water. Buy our product please visit www.fishingbaitboat.com or our Amazon store in US https://www.amazon.com/dp/B0DKFHGDH9

1 note

·

View note

Text

The Evolution of HDPE Liquid Detergent Bottles: From Functionality to Customization

Introduction

The HDPE bottles have also experienced changes in their design after they were first adopted into the market. What was once a product with only the objective of functionality, these bottles are today both functional improvements and uniquely designed products. In this blog post, we will discuss how HDPE Liquid Detergent Bottles have transformed from mere containers to individualistic packaging materials.

The Basics of HDPE Bottles: Organization from Scratch

What is HDPE?

High-density polyethene (HDPE) is one of the most preferred plastic materials due to its high mechanical strength, high impact, and chemical-resistant properties. Such characteristics make the use of HDPE suitable for packaging products such as liquid detergents. Originally, the use of HDPE bottles was more functionary, with little or no thought given to their beauty.

Early Designs: Plain and Useful

When HDPE bottles first appeared, they were straightforward and functional. Here’s what characterised their early designs:

Standard Shapes:

The majority of bottles had a cylindrical or rectangular shape, which was appropriate for piling up and shifting.

Basic Colours:

Early bottles were normally clear or white; changes in colour were rare and only slightly different.

Simple Closures:

Lids were mostly simple screws or snap-ons that were intended at minimizing spills and leakages.

The first objective was to develop a package that would keep the detergent and dispense it in a manner that does not worry about the aesthetics or the design of the package.

Advancements in Design

This aspect comprises the ergonomics and aesthetics of the products designed and manufactured.

Improving User Experience

In the subsequent phase, as the market expanded, all manufacturers turned their attention towards making the bottles more convenient to use. Several ergonomic features were introduced: Several ergonomic features were introduced:

Contoured Shapes:

Grips and curves are notably introduced on the bottles so that they can be handled perfectly and poured with ease.

Handles:

Some of the designs had handles to enable easy carriage and handling of the containers, particularly the big ones.

Spouts and Triggers:

New functions such as pouring spouts and trigger sprays were incorporated in order to create a more controlled and less messy way of dispensing the product.

These changes further enhanced the user interface, making the bottles functional and, at the same time, easier to use.

Aesthetic Enhancements

When competition was introduced into the market, things such as aesthetics turned out to be crucial. HDPE bottles started to evolve in design

HDPE bottles started to evolve in design:

Color Variations:

This led to manufacturers adopting the use of different colors in order to make their products easily identifiable on the shelf.

Unique Shapes:

That meant that bottles were shaped in every way to grab the viewers’ attention and make brands distinct from each other.

The reason for these enhancements was to ensure that brands capture the consumers’ attention and create a recognizable position in the market.

The Era of Customization: Innovative and Personalized

Advanced Manufacturing Techniques:

Technological advancements have revolutionized the production of HDPE bottles. Technological advancements have revolutionized the production of HDPE bottles.

Blow molding and injection molding:

Such techniques enable the creation of more complex shapes and designs, such as custom patterns and even embossed logos.

Custom Labels:

As any label can be created with the goal of best fitting certain brands’ parameters, they can be equipped with customised graphics and text.

These innovations help brands to develop packaging that not only serves the purpose but also can have aesthetic and communication value.

Sustainability and Eco-Friendly Practices Environmental concerns have driven significant changes in HDPE bottle design.

Recycled Materials:

Most bottles use recycled HDPE, meaning that there is not much call for manufacturing new plastic.

Lightweighting:

The pressure brought by major consumers to cut down on the usage of plastics has meant the development of a lighter type of bottle that is equally strong.

Recyclability:

New designs also focus on recycling, giving a way to reduce the impacts on the environment.

Environmental concerns are alarming, and so consumers’ preference for sustainable packaging strategies has led to many organizations’ incorporation of such practices.

Smart Packaging Innovations

The latest trend in HDPE bottles includes integrating technology into packaging: The latest trend in HDPE bottles includes integrating technology into packaging:

QR Codes:

These codes give the consumers further information about the product when the barcode is read.

NFC Tags:

Interactivity includes product finding and promotion, such as near-field communication (NFC) technology.

These features are integrated to add to the value of packaging since they perform much more than just containing products.

READ MORE- https://regentplast.com/the-evolution-of-hdpe-liquid-detergent-bottles-from-functionality-to-customization/

0 notes

Text

Composites Market Poised for Steady Growth in the Future

Composites Market Size & Trends

The global composites market size was estimated at USD 93.69 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This growth is attributed to the rising demand for lightweight components in the automotive and transportation industry. Furthermore, increasing utilization of advanced lightweight components across the manufacturing industries is anticipated to support the market growth during the forecasted years.

Composites find application in the aerospace & defense sector owing to their ability to reduce the body weight of military aircraft and helicopters to a large extent. A reduction in weight is considered important in order to increase fuel efficiency and overall performance and is expected to emerge as the key driver propelling the industry’s growth.

Gather more insights about the market drivers, restrains and growth of the Composites Market

The COVID-19 outburst across the globe has significantly impacted the supply chains as major economies suspended trade operations. Moreover, demand for the product across various end-use industries such as aerospace, automotive, and construction has been reduced in 2020. However, with the ease of trade restrictions, the situation is expected to recover in 2021, which is expected to restore the growth trajectory of the market.

The U.S. composites market is expected to grow in aerospace & defense on account of the increasing penetration of the product coupled with the presence of the leading aircraft manufacturer in the country i.e. The Boeing Company. The rapid growth of the aerospace industry in the country and expected growth in the defense sector is likely to drive the demand over the forecast period.

The growing environmental concerns and stringent regulations regarding pollution control have forced automotive manufacturers to enhance their technologies and develop vehicles having low pollution. Moreover, the implication of environmental regulations primarily in Europe and the U.S. has forced automotive manufacturers to include composites in automotive production. This is expected to accelerate market growth progressively.

The high cost of raw materials for composites is likely to challenge procurement operations by the component manufacturers. Moreover, the growing demand for these raw materials by other manufacturing industries is likely to pose a challenge for composites manufacturers. However, key players are conducting extensive R&D activities to develop low-cost composite grades with similar mechanical properties as that of the high-cost variants. This is expected to spur the demand for composites during the forecast period.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The global field-erected cooling tower market size was estimated at USD 2.10 billion in 2023 and is projected to grow at a CAGR of 3.5% from 2024 to 2030.

The global shooting ranges market size was estimated at USD 1.84 billion in 2023 and is projected to grow at a CAGR of 7.8% from 2024 to 2030.

Composites Market Segmentation

Grand View Research has segmented the collated screws market on the basis of product, manufacturing process, end-use, and region:

Composites Product Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Carbon Fiber

Glass Fiber

Others

Composites Manufacturing Process Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Layup Process

Filament Winding Process

Injection Molding Process

Pultrusion Process

Compression Molding Process

Resin Transfer Molding Process

Others

Composites End-Use Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

Automotive & Transportation

Wind Energy

Electrical & Electronics

Construction and Infrastructure

Pipes & Tanks

Marine

Others

Composites Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

UK

Spain

Asia Pacific

China

India

Japan

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

Order a free sample PDF of the Composites Market Intelligence Study, published by Grand View Research.

Key Companies profiled:

Teijin Ltd.

Toray Industries, Inc.

Owens Corning

PPG Industries, Inc.

Huntsman Corporation LLC

SGL Group

Hexcel Corporation

DuPont

Compagnie de Saint-Gobain S.A.

Weyerhaeuser Company

Momentive Performance Materials, Inc.

Cytec Industries (Solvay, S.A.)

China Jushi Co., Ltd.

Kineco Limited

Veplas Group

0 notes