#rotatingequipment

Explore tagged Tumblr posts

Text

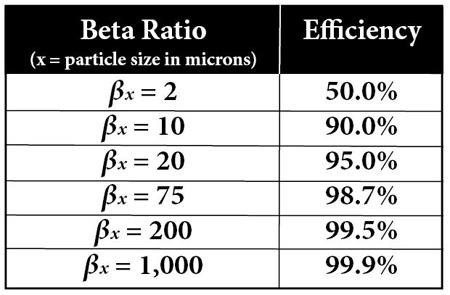

Understanding of the BETA factor

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

This rigid strander delivery to competitors in Hefei. they bought main cage from me. then equipped pay-off and take-up, send to their customers.

#rigidstrander #framestrandingmachine #copper #aluminum #rotatingequipment #cablemanufacturer #cablemakingmachine

0 notes

Text

"Reliability Redefined: The Role of Static and Rotating Machinery"

Static and rotating equipment form the backbone of industrial facilities, encompassing a diverse range of machinery essential for various processes across industries such as oil and gas, power generation, petrochemicals, and manufacturing. Static equipment, including pressure vessels, heat exchangers, tanks, and pipelines, play a crucial role in storing, transferring, and processing fluids and gases under different conditions of pressure and temperature. These robust structures provide the foundation for safe and efficient operations, ensuring the integrity and reliability of process systems. On the other hand, rotating equipment, such as pumps, compressors, turbines, and motors, are responsible for generating mechanical energy, fluid movement, and power transmission. These dynamic components are vital for maintaining fluid flow, driving machinery, and generating electricity, making them indispensable in industrial processes. With the increasing demand for energy efficiency, reliability, and safety, the optimization and maintenance of static and rotating equipment have become paramount. Predictive maintenance techniques, condition monitoring systems, and digital twins are revolutionizing asset management practices, allowing for proactive identification of potential failures and performance optimization. Additionally, advancements in materials, design, and manufacturing techniques are enhancing the performance, durability, and sustainability of static and rotating equipment, contributing to operational excellence and environmental stewardship. As industries embrace digitalization and automation, static and rotating equipment remain at the forefront of innovation, driving efficiency, productivity, and competitiveness in the global market.

#StaticEquipment #RotatingEquipment #IndustrialProcesses #AssetManagement #PredictiveMaintenance #ConditionMonitoring #DigitalTwin #EnergyEfficiency #OperationalExcellence #EnvironmentalStewardship #SmartManufacturing #IndustrialAutomation #ProcessOptimization #ReliabilityEngineering #InnovationInIndustry

0 notes

Text

KZ Bearings play a crucial role in industrial blowers as they support rotating components, reduce friction, and enable smooth operation.

👉Email your inquiry – [email protected]

👉KZ Bearings – https://kgbearing.com/products/

👉Follow us for wide range of bearings at - https://linktr.ee/kgbearingindia

industrialblowers #industrialbearings #blowerbearings #industrialmachinery #engineeringsolutions #industrialequipment #manufacturingtechnology #industrialmaintenance #mechanicalengineering #industrialtechnology #bearingsolution #blowerperformance #MechanicalDesign #industrialengineering #heavydutybearings #rotatingequipment #industrialautomation #maintenancetips #reliabilityengineering #powertransmission #bearing #kgbearingindia #kzbrand #engineering #manufacturer #rolamentos #rodamientos #lager #rulman #cuscinetti #подшипник

0 notes

Photo

Informasi Training Turbin dan Generator. Jadwal Pelatihan Generator dan Turbine 2023 di Bandung dan kota lainnya. Seminar Teknik. Topik training Turbine and Generator: 1. Pump Operation, Maintenance And Troubleshooting 2. Pump Selection, Design And Operation For Oil And Gas Surface Production Facilities 3. Rotating Equipment 4. Rotating Equipments 5. Rotating Equipments 6. Steam Generator And Turbine Operation And Maintenance 7. Steam Turbine Operation, Maintenance And Troubleshooting 8. Sucker Rod Pump Design, Operation And Troubleshooting 9. Turbin & Generator Operation 10. Turbin Gas 11. Turbin Uap Info seminar training lengkap: WA: 0851-0197-2488 Jadwal training lengkap: https://www.informasi-seminar.com #rotatingequipment #steamgenerator #turbineoperation #pumpdesign #turbingas #turbin uap #informasiseminar #informasitraining #training #pelatihan #seminar | Jadwal Training Turbin Gas | Jadwal Pelatihan Turbin Uap | Training Generator Operation | Pelatihan Pump Operation | Info Seminar Training Engineering | https://www.instagram.com/p/CngM8lKJAGG/?igshid=NGJjMDIxMWI=

#rotatingequipment#steamgenerator#turbineoperation#pumpdesign#turbingas#turbin#informasiseminar#informasitraining#training#pelatihan#seminar

0 notes

Photo

#TimesSqureGrand Fire Fighting Pumps End Suction Pumps Vertical And Horizontal, Multistage Centrifugal Pumps We supplied Fire Fighting pump set at Times Squre Grand Neptune Technology is authorized Dealer #wilo For more information +91 82380 07357 | +91 83200 86504 or message us m.me/neptunetechnology.india

#distributors#contractors#environmentallyconscious#waterpumps#pump#boosters#watertreatment#sewagetreatmentworks#sewagepump#powertransmission#engineering#environmental#rotatingequipment#teamwork#gearboxes#water#wastewater#mechanicalengineering#electricalengineering#cleanwater#mechanicalengineer#boostingwater#powerboost#commercialwaterboosting#pumping#motors#pumps#inverters#bearings

0 notes

Photo

slip ring rotary joibt,we start to working today🧐🧐#sliprings #JARCH #rotatingequipment https://www.instagram.com/p/CLgmw4_FcGc/?igshid=1m9xbasinw1qs

0 notes

Photo

#MasterClassSeries2021 Webinar Alert Register Here: https://lnkd.in/g6ixNu-k LIVE Webinar : How To Optimize The Performance Of Rotating Machinery? REGISTER Here: https://lnkd.in/g6ixNu-k Date: 26th August 2021 | Time: 2:30 PM IST Speaker: Rushikesh Bhedasgaonka

0 notes

Video

instagram

Thanks @thunderclap_newton for this gem! Albeit it looks tempting and looks like fun but it could probably end with a bad ER visit. #oshaisthissafe #oshaoffender #construction #constructionhyjinx #rotatingequipment #equipment #holedigger https://www.instagram.com/p/B4c2pOMnt_r/?igshid=wq0ohjiybsga

0 notes

Text

Saved the plant from a major breakdown

The Minimac team successfully completed a critical flushing project in a big fertilizer company with a capacity of 4000 tonnes in Jharkhand.

Synopsis

An installation project was ongoing at the fertilizer plant’s premises. Newly built lube pipelines and tanks were to be flushed to remove the welding debris and other components left inside while fabricating the pipelines. The entire project was delayed due to a very slow flushing process. Minimac Operations and Maintenance Service (MOMS) team evaluated the situation and came out with a solution to expedite the flushing process. The project required flushing their two main compressors, i.e., PSE processed air compressor and carbon dioxide compressor

Problems

Proper flushing had to be done as the pipeline was newly fabricated; otherwise, it would have led to a major breakdown of the compressor, as the impurities would choke the blades and erode/damage the compressor. Other issues were to ensure proper calculation for variable pipe diameters, and if the oil goes to the rundown tank and overflows, 60-65 degree oil will fall, causing a huge mishap.

Client’s Requirement

Fast completion of the job to meet the project timeline.

Solutions

Minimac Systems examined the pipeline, which consisted of a low-pressure pipeline, high-pressure pipeline, and run-down tank.

A proper calculation was done as the work was a bit critical; any negligence could become a mishap

All parameters must be considered, including segment-wise flushing, hammering, thermal showering, etc.

At the end of the flushing, a mesh was installed to check if any impurities were present

Completing the flushing project was ensured as per ISO 18/15/12

Cost Saving

This plant managed to save:

Cost of import caused due to deficit of fertilizer.

CO2 e Saving

Benefits

The reliable operation of the system and trouble-free operation of machines.

Sustainable performance of manufacturing process.

Elimination of new compressor cost.

Avoiding the risk of fire and explosion.

Reduction in the possibility of product degradation due to lack of proper flushing

Timely execution.

Feedback

As a result of Minimac's excellent work, another assignment of a similar nature was assigned to them. Minimac achieved the OEM's request for no debris in the mesh.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#hydraulic oil#oil & gas#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#hydraulic oil flushing#chemical cleaning flushing#oil filtration#oil filtration systems#oil contamination#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#gas turbine market trends#steam turbine#wind turbines#coalescer separator#transformer oil#transformation oil purification#transformer oil cleaning#transformer oil filtration#oil dehydration systems#frf condition systems#electrostatics lube cleaner

0 notes

Text

Reclamation of FRF

A 1200 MW coal-fired thermal power plant using Indo-Chinese Turbine EHC System in Southern India

Synopsis

Problems

Failure of Moog valve: This was the main reason for the trip of the turbine and breakdown in the power plant.

Poor Oil Analysis Program: An oil analysis is supposed to be done monthly for Particle count & TAN (weekly if the trend is negative) and weekly test for water content but the customer has scheduled these indefinitely.

Inadequate Operation Practices: The solenoid valve of the LVDH (oil purification machine) vacuum line was only 20% closed which failed to generate vacuum.

Solutions

Benefits

1) Extended oil life 2) Reduced TAN value 3) Elimination of oil Replacement cost 4) Protection of Turbine against hunting 5) Increased Turbine reliability.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil filtration machine#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil filtration systems#oil testing#oil analysis#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical#turbinemaintenance#gas turbine market trends#power industry#metal#mining#oil purification system#oil purification machine#oil filtration system#transformer oil#transformer oil cleaning#transformation oil purification#transformer oil filtration

0 notes

Text

Reconditioning of EH oil

A 1200 MW coal-fired thermal power plant using Indo-Chinese turbine EHC system in southern India.

Synopsis

The plant was struggling with the rapid increase in TAN values in the EH oil of the governing system of the turbine. Also, the moisture content was more than permissible limits. Degradation of the oil was due to contamination ingression into the system resulting in by-product formation.

Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20” proved to be the savior and an unexpected shutdown of the turbine worth ₹1.05 Cr per day was saved.

Problems

A rapid increase in the Total Acid Number (TAN) could degrade the EH oil and lead to the possibilities of failure of servo valve, hunting, power generation loss, unplanned shutdown, etc

Solutions

Installation of Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20” comprehensively designed with 4 major technologies to:

Remove solid contamination from oil by Superfine filtration

Remove moisture from oil by vacuum Dehydration technology

Reduce Total Acid Number (TAN) by Ion exchange technique.

EHC system tank moisture removal and ingress prevention by Inert Gas blanketing technique.

Along with equipment installation, our service engineer trained the customer’s team on the functions of the EH oil re-conditioner, FRF maintenance, contamination control, and importance of the oil analysis program.

Cost Saving

This plant managed to save:

Cost of oil replacement: ₹60 Lakh approx.

Cost of downtime: ₹4.2 Cr approx

CO2 e Saving

14,400 kg of CO2 e / 0.0144 gigagrams of CO2 e

Benefits

Extending oil life.

Eliminate oil Replacement cost.

Protect Turbine against hunting.

Increased Turbine reliability.

Total Consumable Details

Filter - 01 qty of 10 - microns

Filter - 01 qty of 3 - microns to achieve NAS 5 cleanliness

Total resin - 60 liters

Subscribe to our What's App Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil purification system#oil filter systems#oil contamination#oil dehyration#oil filters#oil industry#industrial oil#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical#electrostatics lube cleaner#transformation oil purification#chemical cleaning#flushing systems#flushing machine#oil condition monitoring#oil analysis#coalescer separator#FRF

0 notes

Text

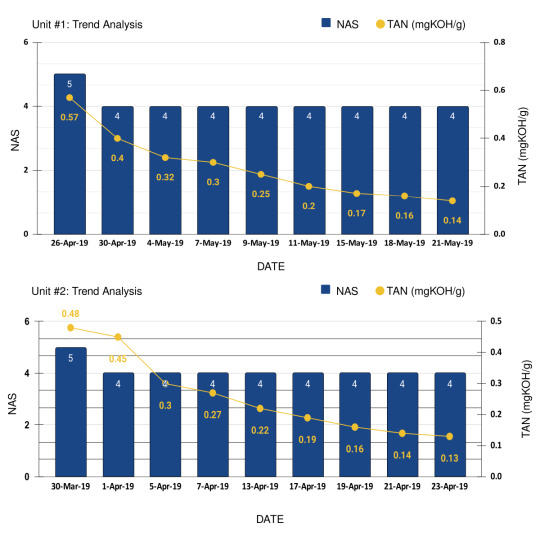

PE fluid reconditioning in turbine EHC system

A 1,320 MW (2 x 660 MW), one of the first and largest supercritical coal-fired power plants using Indo-Chinese turbine EHC system in northern India

Synopsis

The plant was struggling with the rapid increase in TAN values in the EH oil of the governing system of the turbine. Moisture content was also more than permissible limits. Degradation of the oil was due to contamination ingression into the system resulting in by-product formation.

Problems

Degradation of EH oil properties at both the units of the plant.

The installed regeneration system for each EHGC tank of unit #1 and #2 was failing to control neutralization number (TAN value) and showing a rapid increase in the same

The company was unaware of the consequences of increased TAN values like possibilities of failure of servo valve, hunting, power generation loss, unplanned shutdown, etc

Solutions

Installation of Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20” comprehensively designed with 4 major technologies to:

Remove solid contamination from oil by Superfine filtration

Remove moisture from oil by vacuum Dehydration technology

Reduce Total Acid Number (TAN) by Ion exchange technique.

EHC system tank moisture removal and ingress prevention by Inert Gas blanketing technique.

Along with equipment installation, our service engineer trained the customer’s team on the functions of the EH oil re-conditioner, FRF maintenance, contamination control, and importance of the oil analysis program.

Cost Saving

This plant managed to save:

Cost of oil replacement: ₹78 Lakh approx.

Cost of downtime: ₹5.6 Cr approx

CO2 e Saving

14,400 kg of CO2 e / 0.0144 gigagrams of CO2 e.

Benefits

Extending oil life.

Eliminate oil Replacement cost.

Protect Turbine against hunting.

Increased Turbine reliability.

Subscribe to our Whats App Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#coalescer separator#oil dehydration systems#lvdh full form#mlc lvdh#transformer oil filtration#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#oil filtration#oil filtration system#oil filteration#oil filtration machine#oil filtration systems#oil contamination#frf condition systems#diesel oil purification#hydraulic oil cleaning#chemical cleaning

0 notes

Text

Success Story: A small change can bring a Big Difference

Do you agree that the little things, if done consistently, add to the big things? The same applies to every field of life, whether it is personal or professional. The very recent example recites it very true. The whole story begins with an opportunity to supply and commission 8 numbers of Oil Quality Testing Equipment for a sector that is crucial regarding the nation's safety. It was a great experience to work with the best brains and brave hearts.

We started our journey from Pune to a remote location in Odisha, Koraput. When we landed at the nearest airport, we knew it was more than a 5-hour journey by road, crossing many hills, valleys, forests, and ghats. During our travel, we encountered many wild animals and, surprisingly, snakes like pythons crossing the road. Probably, high wind and rain were making it more scary and adventurous. We arrived at our stay very late at night. After such a long day, we were excited to hit the bull’s eye the next day.

We couldn’t resist the enthusiasm and reached the plant before the time the next morning. We were very happy to see the grand welcome following intense security protocols. The industry can be classified as Defense & Space. A division regularly conducted workshops for the customers to better understand and utilize the products.

We showed our advanced Oil Testing Equipment, LPA3, but a few officers were not confident enough about the deliverables. The technology they used then was outdated and failed to meet the latest standard. We had to install, commission, and demonstrate 8 particle counters at different locations and in different machines. We did it within 10 working hours, which was an achievement in every sense. Along with the demonstration, we made them understand the minimum human intervention and the impossibility of tampering with our oil quality testing equipment results. As they were following traditional practices, this technological advancement was much needed in their plant, and it was about to bring a big difference. We did our best in the least time. The company officials were really happy & fulfilled and so were we. It was a great experience, and a perfect example of a small change can bring a big difference.

Subscribe to our YouTube Channel and be a part of our Journey - Cick Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil#lube oil flushing#oil testing#oil filters#oil industry#oil and gas#oil#gas turbine market trends#gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#power generation#metal#heavy metal#mining#oil dehyration#oil dehydration systems#oil purification system#hydraulic oil flushing#oil flushing systems

0 notes

Text

Best practices for maintenance of FRF in turbine EHC system

What is a Turbine EH System?

Due to high steam pressure & temperature in the vicinity of a steam turbine, as safety compliance, it is a mandate to use Fire Resistant Fluids (FRF) for hydraulic control of the EHC system. A specially designed synthetic fluid called tri-xylenyl phosphate ester demonstrates best fire resistant properties for the application.

Phosphate esters are polar fluids with excellent lubricating properties that can operate under extreme conditions. However, phosphate esters require strict control in order to extend their useful lifespan.

Water and Acids de-grade FRF

Phosphate esters (which are being used as FRF in EHC systems) are manufactured under controlled environment through the esterification of phosphoric acid, where water is a by-product.

Phosphoric Acid + Alcohol → Phosphate Ester + Water

Unfortunately, phosphate esters are highly hygroscopic (tendency to absorb water) in nature and the esterification process is reversible when phosphate esters come in contact with water. This is referred to as hydrolysis. The higher the water content and temperature, the faster the ester will break down by hydrolysis.

Phosphate Ester + Water → Phosphoric Acid or Acid Phosphates + Alcohol

Thereby it is recommended to control the water level, temperature, and acidity in FRF of the EHC systems. If uncontrolled, the acidity accelerates rapidly.

TAN value or Total Acid Number (measured in unit mgKOH/gm) is a parameter to denote acid content accumulation in FRF. A high TAN value degrades the fluid rapidly, decreases its viscosity and resistivity. Thereby causing acid corrosion of sensitive servo-valves and other system components of an EH System.

FRF de-gradation due to particles

Water and acid are not the only contaminants which can degrade the FRF.

Since the dynamic oil film and fine clearances in servo-valves are less than 5 micron, even the finest silt particles and sludge/varnish deposits from fluid degradation can hinder proper operation. Fine particles get trapped in clearances between the valve plunger and housing. This abrasive wear is known as seizing or grinding. This can result in wear rates that are a thousand times greater than anticipated by the valve manufacturer. Therefore, it only makes sense to use very fine filtration (3-5 micron) for maintaining the EHC fluid. For any Technical Consultancy Call - +91 89751 50700

Consequences of FRF de-gradation

Acid, gel and sludge/varnish formation

Valve sticking or blocking

Reduced lubricity and film strength

Corrosion, erosion and abrasion wear

Reduced fluid resistivity

Soot generation (entrained air)

Short fluid life

The result is poor EHC system reliability and reduced turbine availability.

Condition based monitoring of FRF

It is highly recommended to carry out regular fluid analysis of FRF and identify any abnormalities in the trend for further preventive actions. Recommended parameter values for FRF: Parameter unit value Appearance ASTM colour code clear, < 3 Water content ppm 500 Kinematic Viscosity (@40 0C) cSt 41-45 Acidity (TAN) mgKOH/gm < 0.15 Particle contamination code ISO 4406 15/12 Cleanliness code (NAS-1638) NAS 1638 5

To learn more follow https://www.linkedin.com/company/minimacsystemsprivatetlimited

The Minimac® FRF Re-conditioning System comprises 4 major steps, all packaged carefully in 1 single skid.

Solid contamination Super-fine Filtration

Moisture in oil separation by Vacuum Dehydration technology

TAN reduction by Ion Exchange technique

EHC system tank moisture removal by Inert Gas Blanketing technique

Would love to have your feedback, experience, query.. Got any question? Ask away!!

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#chemical cleaning#electrostatics lube cleaner#frf condition systems#electrostatic discharge protection#transformation oil purification#TOFS#coalescer separator#condition monitioring#oil condition#mechanical maintance#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbine oil#hydraulic oil machine#wind turbines#oil analysis#oil filter#hydraulic oil flushing#industry oil#industriallubricants

0 notes