#rollingmills

Explore tagged Tumblr posts

Text

youtube

vertical lathe tooling,Double Helical Gear,rolling mill,3.5 ton Double Helical Gear, british vertical lathe, DoubleHelicalGear, helical gear manufacturing,double helical gear design,Lathe technique,metal turning,how to turn,3 ton complete process,Manufacturing process of Double Helical Gear,Metal turning / how to turn 3Ton Double Helical Gear smarter than others,craftsmanship,150yrs,manufacturing process,cutting edge engineering australia, how to make

Lathe technique making gear with a lathe Metal Turning /how to turn How to turn 3.5 ton double helical gear smarter than others Manufacturing process of Double Helical Gear 150yrs old British vertical lathe tooling - 3.5 ton Double Helical Gear for rolling mill how to make 150yrs old British vertical lathe tooling Complete Process of Machining & Tempering Double Helical Gear 3.5 ton Double Helical Gear for rolling mill 150yrs old British Workmanship vertical lathe tooling 3.5 ton Double Helical Gear for rolling mill Vintage Lathe Double Helical Gear Engineering Heritage Craftsmanship Industrial History restoration British Lathe precision machining helical gear manufacturing double helical gear design old school hack manufacturing process

#mechanical engineering#auto repairs#mechanical#monster engines#engines#manufacturingprocess#3.5tondoublehelicalgear#double helical gear design#double helical gear#rollingmill#Britishverticallathe#150yrs#doublehelicalgear#manufacturing process of double helical gear#Youtube

2 notes

·

View notes

Text

1 note

·

View note

Text

A Brief Guide On Billet Ejectors!

We are excited to provide the latest quality Billet Ejectors that are user-friendly design ensures easy operation and maintenance, while their robust construction guarantees long years of trouble-free service. We are one of the ideal Billet Ejectors Manufacturers and Suppliers in India. For more queries, visit our website!

0 notes

Text

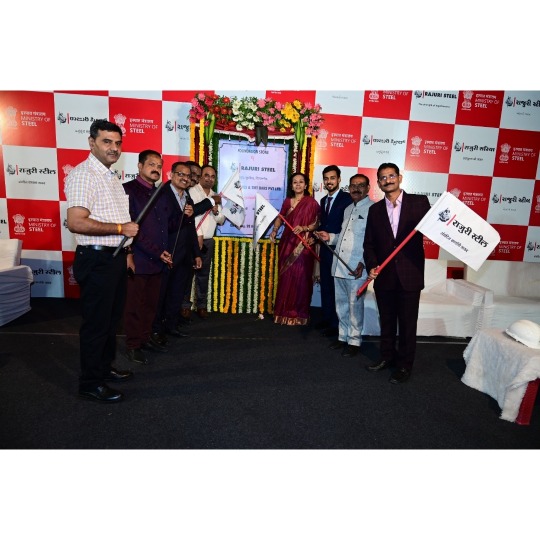

We are incredibly pleased, excited, humbled, and honored to share that our facility was inaugurated on 28th April 2023 at Jalna, Maharashtra by Smt. Ruchika Chaudhry Govil, Additional Secretary, Ministry of Steel and Hon’ble MP Raosaheb Patil Danve, Union Minister of State for Railways, Coal and Mines. We were also graced by the presence of Mr. Subhash Kumar (Joint Secretary, Ministry of Steel), Mr. R. P. Gupta (Director, Ministry of Mines), Dr. Anupam Agnihotri and Mr. R. N. Chouhan (JNARDDC), and many other prominent personalities.

Here are some glimpses of the inauguration of India's leading TMT Bar Manufacturer Rajuri Steel's state-of-the-art MeltingShop and Rolling Mill facility.

We are extremely grateful for all the support we have received from all our stakeholders and partners. Our ascertained quality, customer relationship, and trust which you all relayed to us over three decades helped us to achieve this milestone.

We thank everyone who supported us in making this world -class facility a reality and look forward to growing together.

#inauguration #steelplant #plantinauguration #rollingmill #openingceremony #growth #jalna #jalnaindustry #MinistryOfSteel #steelindustry #steel #RajuriSteel #TMTsteel #TMTbars #RCC #construction #architecture #building #BindingWire #RingerStirrups #Nails #TMTBar #TMT #Steelbar #TMTSariya #qualitysteel #TMTBarManufacturer #StrengthofTogetherness #InternationalQuality #GermanTechnology #33StrengtheningYears #Rajuri500 #Rajuri500DPlus #Rajuri550 #Rajuri500TMX #Rajuri550✓actual #Rajuri550DPlus #Rajuri550CRS #RajuriRingerStirrups #RajuriBindingWire #RajuriNails

4 notes

·

View notes

Text

"Precision in Every Drop: Cold Rolling Lubricants Market Outlook 📊"

Cold rolling lubricants are critical to the efficiency and quality of modern metal processing. These specialized lubricants play a vital role in reducing friction, minimizing wear, and enhancing the surface finish of metal sheets during the cold rolling process.

By creating a thin, protective layer between the metal and the rolling equipment, these lubricants not only ensure smooth operation but also prevent damage to the metal surface, leading to a higher quality end product. In an industry where precision and durability are paramount, the use of high-performance cold rolling lubricants can significantly improve production rates, extend the lifespan of machinery, and reduce operational costs. As the demand for finer, more resilient metal products increases across sectors like automotive, construction, and electronics, cold rolling lubricants are becoming an indispensable part of the manufacturing landscape, driving both innovation and sustainability.

#MetalProcessing #ColdRolling #IndustrialLubricants #SurfaceFinish #MetalForming #ManufacturingInnovation #FrictionReduction #MachineryProtection #MetalIndustry #RollingMill #PrecisionEngineering #HighPerformanceLubricants #ProductionEfficiency #SustainableManufacturing #WearResistance #MetalQuality #IndustrialSolutions #EngineeringExcellence #MachineryMaintenance #InnovativeManufacturing

0 notes

Video

tumblr

The cyclone dust cover absorbs smoke and dust better. When using a cyclone dust hood, when the furnace body tips forward and backward, the hood and flue pipe will also tip over, ensuring full dust removal, greatly increasing the effect and better meeting the requirements. #rollingmill #Closedcoolingtower #Crossflowcoolingtower #electricarcfurnace Email : [email protected] whatsapp: +8613007564317

0 notes

Text

NIEL FOR STEEL MILLS (DC Motors) part -3

Part 3

If your Steel factory has a capacity of fewer than 5 Million tons/year and is located near an Industrial hub then AC Motors with AC drives would be a good choice.

However, if you are located away from an industrial hub in a remote location then i would recommend choosing DC Motors & DC drives.

Here thinking of serviceability in event of a breakdown. Steel manufacturing is a continuous operation. Cannot afford long delays in serviceability.

DC motors have been in use in Steel making actively for more than 40 years. Finding service engineers for them is easier.

So if am staying in a remote town, I would prefer to buy a Maruti car over a new 5/6-year-old brand. My car can be serviced more easily & economically if it's a Maruti.

I rest my case

#engineers#MotorsforSteel#MillDutyDCMotors#SteelManufacturing#SteelMills#RollingMills#ReRollingMills#SteelMaking#NIELforSTEEL

0 notes

Text

Composite wire rod & rebar production line

Composite wire rod & rebar production line is mainly customized for small and medium plants, because their required annual capacity is about 300, 000 tons – 500, 000 tons, fully in consideration of the investment capacity of the steel company, the size of the plant scale, and other conditions.

0 notes

Photo

12 MT Output Steel Billet Reheating FURNACE GAS fired By UNITED INDUSTRIES. #reheatingfurnace #gasfiredfurnaces #indianexporter #furnaceexporter #rollingmills #steelmills #billet #hotprocess #tmtbars https://www.instagram.com/p/B7RE9sPh3SR/?igshid=u1wfgc4maomu

#reheatingfurnace#gasfiredfurnaces#indianexporter#furnaceexporter#rollingmills#steelmills#billet#hotprocess#tmtbars

0 notes

Link

CASE Mono Block Mills for Rolling Industry

0 notes

Photo

I really need a rolling mill for my workshop to be able to more precisely modify the silver to my specifications. So if you’d like to help go see if you can find anything you like in my shop!! Follow link in bio!! Use code MILL. #jewellerysale #jewelrysale #sale #handmadejewellery #handmadejewelry #silver #silversmith #jewellerylover #jewelrylover #opthandmade #helpme #rollingmill #handmade #handmadesale #silversale #silverjewellery #silverjewelry https://www.instagram.com/p/CTcuZIJoweA/?utm_medium=tumblr

#jewellerysale#jewelrysale#sale#handmadejewellery#handmadejewelry#silver#silversmith#jewellerylover#jewelrylover#opthandmade#helpme#rollingmill#handmade#handmadesale#silversale#silverjewellery#silverjewelry

1 note

·

View note

Text

India's Metal Masters: Hot Rolling Mill Manufacturers

When it comes to Hot Rolling Mill Manufacturers in India, Akshi Engineers Pvt. Ltd. stands out as a trusted and reliable name in the industry. With their commitment to excellence, cutting-edge technology, and a customer-centric approach, we have earned a strong reputation as a preferred choice for steel manufacturers. In this article, we will delve into the key factors that make Akshi Engineers Pvt. Ltd. an excellent option for your rolling mill requirements.

Expertise and Experience:

With years of experience in the industry, we bring a wealth of expertise to the table. They possess in-depth knowledge of hot rolling mill technology, enabling them to understand and cater to the specific needs and challenges faced by steel manufacturers. Their team of skilled engineers and technicians is well-versed in the intricacies of rolling mill design, installation, and maintenance, ensuring that you receive the highest level of service and support.

Cutting-Edge Technology:

We are committed to staying at the forefront of technological advancements in the rolling mill industry. They continuously invest in research and development to develop and implement the latest innovations and solutions. By incorporating state-of-the-art technology into their products and services, we ensure that you benefit from enhanced efficiency, productivity, and quality in your rolling mill operations.

Customized Solutions:

Recognizing that each steel manufacturer has unique requirements, we offer tailored solutions to meet your specific needs. They take a collaborative approach, working closely with you to understand your goals, challenges, and operational constraints. Whether you require a complete turnkey rolling mill plant or specific equipment upgrades, we will design and deliver a mill stand solution that aligns perfectly with your requirements.

Quality and Reliability:

We place a strong emphasis on delivering products and services of the highest quality. They adhere to stringent quality control processes at every stage, from design and manufacturing to installation and commissioning. By utilizing top-grade materials, robust construction techniques, and thorough testing procedures, Akshi Engineers ensures that their rolling mills are durable, reliable, and capable of delivering consistent performance over the long term.

Customer Support and Service:

We believe in establishing long-term relationships with our customers. They provide comprehensive after-sales support, including maintenance services, spare parts availability, and technical assistance. Their dedicated support team is always ready to address any queries or concerns promptly, ensuring uninterrupted operations and maximum customer satisfaction.

Commitment to Safety and Sustainability:

We understand the importance of safety and sustainability in today's industrial landscape. They design their rolling mill solutions with a strong focus on safety features and environmental considerations. By incorporating energy-efficient technologies and sustainable practices, Akshi Engineers helps you achieve your production goals while minimizing your carbon footprint.

Conclusion:

Choosing Akshi Engineers Pvt. Ltd. as your rolling mill partner means gaining access to industry-leading expertise, cutting-edge technology, customized solutions, exceptional quality, and comprehensive customer support. With their commitment to excellence and a track record of delivering successful projects, We have earned the trust of steel manufacturers across India. When it comes to meeting your hot rolling mill requirements, Akshi Engineers Pvt. Ltd. is a name you can rely on.

source url: https://www.pearltrees.com/raganitiwari/item518232569

#hotrollingmill#hotrollingmillmanufacturers#rollingmill#rollingmillmanufacturers#millstand#akshiengineers#steelproducts

0 notes

Text

Leading Coal Pulverizer Machine Suppliers in India!

We provide premium quality Coal Pulverizer Machine. This cutting-edge equipment is engineered to deliver exceptional pulverizing efficiency, providing finely ground coal for various applications.

#CoalPulverizerMachine#PulverizerMachine#rollingmill#tmt#tmtbar#machine#heavyequipment#equipment#industrial#machines

0 notes

Text

We are extremely pleased to announce the grand opening of our new state-of-the-art Meltingshop and Rolling Mill facility at Jalna, Maharashtra on 28th April 2023 which has brought us one step closer to fulfilling our vision of expanding our horizons to meet the ever growing demand and be the market leader while delivering quality TMT Rebars and focusing on customer satisfaction.

The inauguration of our new facility would be done by Smt. Ruchika Chaudhry Govil, Additional Secretary, Ministry of Steel and Hon’ble MP Raosaheb Patil Danve, Union Minister of State for Railways, Coal and Mines.

We are commited to serving our customers better by developing leading edge solutions in the technology, processes and products.

With our customer-first approach, innovative products, and continuous nurturing of our distribution channel, Rajuri Steel has emerged as a market leader in the Steel Rebar Industry with an evergrowing and strong PAN India dealer network.

We owe our success to all our dealers, customers, associates, and employees.

Thank you for your support and confidence in us and we assure you that Rajuri Steel is poised to achieve a lot of milestones in the future.

The Real Strength Of Togetherness!

#inauguration #steelplant #plantinauguration #rollingmill #openingceremony #growth #jalna #jalnaindustry #ministryofsteel #steelindustry #steel #RajuriSteel #TMTsteel #TMTbars #RCC #construction #architecture #building #TMTBar #TMT #Steelbar #TMTSariya #qualitysteel #TMTBarManufacturer #StrengthofTogetherness #InternationalQuality #GermanTechnology #33StrengtheningYears #Rajuri500 #Rajuri500DPlus #Rajuri550

3 notes

·

View notes

Text

NIEL FOR STEEL MILLS (DC Motors) part -1

PART -1

One of the oldest and most pertinent questions that Mill owners and Engineers ask me is, should we choose AC motors or DC Motors to run our plant ?

The answer is different for different applications, and different installations in different conditions.

Typical Possibilities:

New plant - Small

2. New Plant - Large

3. Integrated Steel Plant

4. Old plant upgrade

5. New Plant remote location

6. Technical strategies are different for different types as above.

Another set of criteria can be:

Cost of Power

2. Quality of Power Supply

3. Availability of Skilled Labour

4. Availability of Capex and so on...

Each of the above calls for a deeper study.

Over the last 50 years, we have been one of the largest suppliers of Motors to the Steel Sector across 45 countries. This experience has given me a rather rich insight into this industry and its many challenges.

In one sentence, if you are setting up a large capacity STEEL unit higher than 5 Million Tons Per Year (5 MT/Y), with a good quality power supply, located near an industrial hub then go for AC Motor & AC controls, else choose DC Motors and DC Controls. Over the next few weeks I shall try to explain myself in more detail.

Will be Happy to take any questions to answer to the Best of my knowledge.

#engineers#MotorsforSteel#MillDutyDCMotors#SteelManufacturing#SteelMills#RollingMills#ReRollingMills#SteelMaking#NIELforSTEEL

1 note

·

View note

Text

Hot Rolling Mill in production.

#rollingmills#machinery#steelindustry#steelfabrication#steelconstruction#steelmaking#steel#manufacturing#sustainability#energy#recycling#construction#renewableenergy

0 notes