#quality butterfly valves

Explore tagged Tumblr posts

Text

Butterfly Valves Suppliers in UAE - TradersFind

Find butterfly valves suppliers & manufacturers in UAE. Connect with top companies that offers the best-quality butterfly valves. Contact us!

0 notes

Text

Industrial dampers manufacturer in Pune

Pune, a bustling hub of industrial activity in India, is home to numerous manufacturing companies, including Parth Valve & Hoses Pvt. Ltd, a leading high-quality Industrial Dampers manufacturer. With a strong commitment to innovation, quality, and customer satisfaction, Parth Valve is the go-to choice for businesses seeking reliable and efficient solutions for their industrial needs

A Legacy of Excellence

Founded with a vision to deliver top-notch industrial solutions, Parth Valve has grown to become a prominent name in the manufacturing sector. Their extensive experience and expertise have earned them a reputation for producing some of the best Industrial Dampers manufacturer in Pune market. The company’s dedication to maintaining high standards is evident in every product they manufacture.

Industrial Dampers

Cutting-Edge Technology and Innovation

Parth Valve is at the forefront of technological innovation and is also the leading Industrial Dampers manufacturer in Pune. They utilize state-of-the-art machinery and employ advanced manufacturing techniques to ensure their products meet the highest quality standards. By continuously investing in research and development, Parth Valve stays ahead of the curve, delivering innovative solutions that cater to the evolving needs of their clients.

Industrial Dampers

Comprehensive Product Range

Parth Valve, the Industrial Dampers manufacturer in Pune, offers a wide range of Industrial Dampers designed to meet diverse industrial requirements. Their product line-up includes:

Butterfly Dampers: Known for their compact design and efficient operation, butterfly dampers are ideal for applications requiring tight shut-off and precise flow control.

Guillotine Dampers: These dampers are perfect for isolating sections of ductwork or equipment, providing a reliable seal even in high-temperature environments.

Louver Dampers: Designed for precise airflow regulation, louver dampers are used in various industrial applications to control ventilation and exhaust systems.

Multi-Louver Dampers: These dampers offer superior control over airflow, making them suitable for complex ventilation systems in industrial settings.

Quality Assurance

Quality is at the core of Parth Valve’s manufacturing process. Each product undergoes rigorous testing and quality checks to ensure it meets the stringent industry standards. The company is ISO certified, which reflects its commitment to delivering products that are not only reliable but also durable and efficient.

Customer-Centric Approach

Parth Valve’s success can be attributed to their customer-centric approach. They work closely with clients to understand their specific needs and provide customized solutions that best fit their requirements. Their dedicated customer support team ensures that clients receive prompt assistance and support throughout their engagement with the company.

Sustainability and Environmental Responsibility

In addition to their focus on quality and innovation, Parth Valve is committed to sustainability and environmental responsibility. They implement eco-friendly manufacturing practices and strive to minimize their environmental footprint. By doing so, they contribute to a greener future while maintaining their competitive edge in the industry.

Conclusion

Parth Valve & Manufacturing Co. is the best choice for Industrial Dampers manufacturer in Pune. Their unwavering commitment to quality, innovation, and customer satisfaction has earned them a stellar reputation. As industries continue to evolve, Parth Valve is well-equipped to meet the challenges of the future, providing top-tier solutions that drive efficiency and reliability in industrial operations.

For more information on Parth Valve’s products and services, visit their website or contact their customer support team. With Parth Valve, you can be assured of the best in Industrial Dampers technology and unparalleled service.

#Industrial Dampers in Pune#Industrial Dampers#Importance of industrial dampers#Pune#a bustling hub of industrial activity in India#is home to numerous manufacturing companies#including Parth Valve & Hoses Pvt. Ltd#a leading high-quality Industrial Dampers manufacturer. With a strong commitment to innovation#quality#and customer satisfaction#Parth Valve is the go-to choice for businesses seeking reliable and efficient solutions for their industrial needs#A Legacy of Excellence#Founded with a vision to deliver top-notch industrial solutions#Parth Valve has grown to become a prominent name in the manufacturing sector. Their extensive experience and expertise have earned them a r#Cutting-Edge Technology and Innovation#Parth Valve is at the forefront of technological innovation and is also the leading Industrial Dampers manufacturer in Pune. They utilize s#Parth Valve stays ahead of the curve#delivering innovative solutions that cater to the evolving needs of their clients.#Comprehensive Product Range#Parth Valve#the Industrial Dampers manufacturer in Pune#offers a wide range of Industrial Dampers designed to meet diverse industrial requirements. Their product line-up includes:#Butterfly Dampers:#Known for their compact design and efficient operation#butterfly dampers are ideal for applications requiring tight shut-off and precise flow control.#Guillotine Dampers: These dampers are perfect for isolating sections of ductwork or equipment#providing a reliable seal even in high-temperature environments.#Louver Dampers: Designed for precise airflow regulation#louver dampers are used in various industrial applications to control ventilation and exhaust systems.#Multi-Louver Dampers: These dampers offer superior control over airflow

0 notes

Text

OCs ˏˋ°•*⁀➷

Liz

Yeah, it’s basically me :D

Lesbian and genderfluid

Kind of cardiophile/medical fetish

All pronouns (but they/them and she/her preferred)

Just a simple Russian girl (not living there actually)

19

ENFJ

Trying to study medicine (Liz is the doctor person of my OCs)

Liz will not be in the patient role in animations and pictures, because they’re the “doctor” in these scenarios and will do the examinations on the other characters. So information about their heart is not included!

Nabi

Lesbian cardiophile

She/Her

South Korean - American girl living in Europe 🫶🏼

21

INFP

Currently interning in a dance school

Nabi is more of a patient in the scenarios, listening to the heart of another person and examining them kind of overwhelms her because she gets too nervous, so she stays in the patient position.

Her heart rate is quite fast, even at rest and it’s an easy task to make it speed up. When she rests, it beats at around 80 bpm and sounds veeeeery thumpy.

She doesn’t have a real heart condition but has quite low blood pressure, which sometimes causes her to feel weak. Also, especially when standing up, her blood pressure often drops down to around 90/55.

Nabi’s biggest turn-on are blood pressure measurements on herself.

Funfact: her name means butterfly in Korean

Shana

Bisexual medical fetish person

She/They

Russian - Indian mixed girl living in Europe

20

ESTJ

Working in a bar

Shana likes to be in the patient and doctor position at the same time. She loves examining herself, not only her heart but generally exploring her body in a medical way, especially with ultrasound.

Because of her job at the bar, she rarely sleeps more than 5 hours at night, smokes from time to time and that definitely has an impact on her heart and lungs. It is hard for her to take deep breaths and her heart sometimes stumbles. Also, when her heart rate gets beyong 120 bpm, there is a light murmur caused by a small valve leak due do her stress and smoking.

Shanas biggest turn-on are ultrasounds, especially of her arteries and her heart itself.

Hua

Asexual/biromantic cardiophile

She/Her

Chinese woman living in Europe

45

ENFP

Working as a psychologist

Hua explores the more softer and cuter sides of cardiophilia and other kinks. She is quite new to it and discovered it recently, when she bought a stethoscope just for fun and couldn’t stop listening to her heart because it made her feel warm and fuzzy. Sometimes, Hua is kind of stressedand that causes her heart to have a slight S3 sound, also her heart already beats since 45 years, so it tends to feel a little tired and heavy sometimes. But most of the time, she has a healthy, steady heart rate of around 65 bpm at rest.

Hua rarely feels sexually turned on but she is fascinated and excited by long stething sessions.

Funfact: her name means flower in Chinese

Also, she has vitiligo and heterochromia (green and hazel)

⁺˚⋆。°✩₊✩°。⋆˚⁺⁺˚⋆。°✩₊✩°。⋆˚⁺⁺˚⋆。°✩₊✩°。⋆˚⁺⁺˚⋆。°✩₊✩°。⋆˚⁺

DO NOT STEAL MY ART OR CLAIM IT AS YOUR OWN!

The quality is only that bad because it makes it harder and more unattractive for people to steal it… Since it has happened to me before….

ˏˋ°•*⁀➷

#art#artists on tumblr#digital art#cardiophile#cardiophile ocs#lesbian#bisexual#asexual#medfet#cardiophilia

9 notes

·

View notes

Text

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

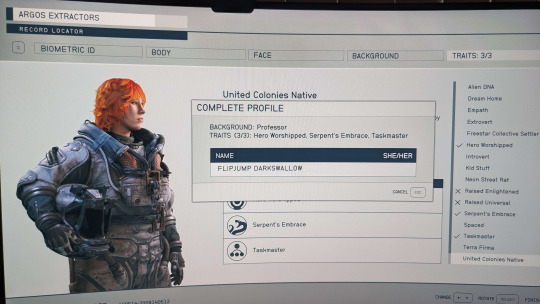

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

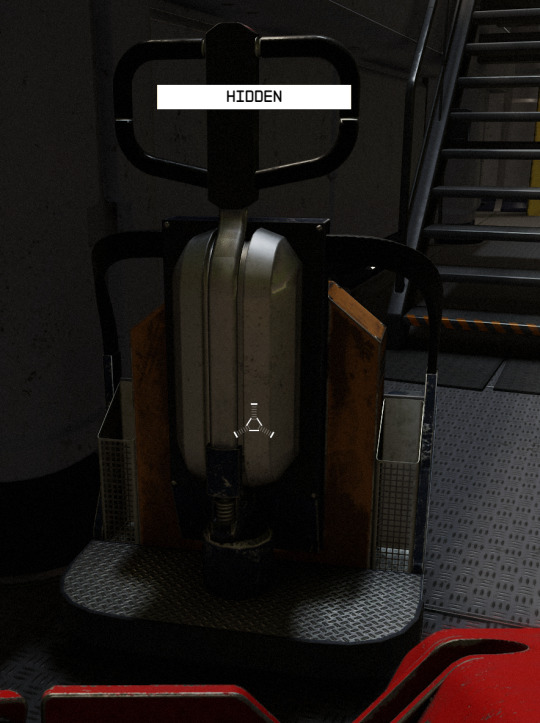

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

47 notes

·

View notes

Text

Buy Jamco CI Butterfly Valve at the Lowest Price

If you're searching for a reliable and durable Jamco CI Butterfly Valve, Udhhyog has got you covered with the best prices in the market. These Cast Iron (CI) Butterfly Valves from Jamco are designed for efficient flow control across various industrial applications.

Why Choose Jamco CI Butterfly Valves?

High Durability: Made from premium cast iron, these valves are built to withstand tough conditions, providing long-lasting service in high-pressure environments.

Corrosion Resistance: The Jamco CI Butterfly Valve is resistant to rust and corrosion, ensuring performance in water, chemical, and oil & gas applications.

Cost-Effective Solution: Udhhyog offers Jamco CI Butterfly Valves at the lowest price, providing you with a cost-effective solution for your flow control needs.

Effortless Installation: These valves are easy to install and require minimal maintenance, making them an ideal choice for industrial systems.

Applications of Jamco CI Butterfly Valves

Water treatment and distribution

Chemical processing

Oil and gas systems

HVAC systems

Industrial piping and flow control

Why Buy from Udhhyog?

Best Prices: We ensure that our customers get the lowest price on all Jamco CI Butterfly Valves, without compromising on quality.

Fast and Reliable Delivery: We prioritize fast delivery to keep your projects running smoothly and on time.

Top Quality Products: Each Jamco CI Butterfly Valve is quality-tested to meet industry standards and perform reliably in demanding environments.

How to Order

Simply visit Udhhyog’s website or contact us directly to place your order for Jamco CI Butterfly Valves. Enjoy a seamless purchasing experience with the best deals and exceptional customer support.

#JamcoButterflyValve#CIButterflyValve#ButterflyValve#IndustrialValves#LowestPrice#Udhhyog#CastIronValve#FlowControl#ValveSupplier#HVACValves

4 notes

·

View notes

Text

Gate Valves in the Petrochemical Industry: Key Applications

In the complex and demanding environment of the petrochemical industry, the selection of appropriate valves is critical to ensuring the efficiency and safety of operations. Among the various types of valves used, gate valves play a crucial role due to their unique characteristics and versatility. This article explores the key applications of gate valves in the petrochemical industry and highlights their importance, especially for those seeking reliable suppliers such as a Valve Stockist in the Dubai or renowned Valve Manufacturers globally.

Understanding Gate Valves

Gate valves are primarily used to either completely stop or allow the flow of a fluid through a pipeline. Unlike other valve types, gate valves operate by lifting a gate out of the path of the fluid. This mechanism is ideal for applications that require the valve to be either fully open or fully closed, making them unsuitable for flow regulation but perfect for on-off control.

Key Applications in the Petrochemical Industry

Isolation of Flow:

Gate valves are extensively used for isolating sections of pipelines during maintenance or emergencies. Their ability to provide a tight seal ensures that no leakage occurs, which is vital in handling hazardous fluids. This makes them indispensable in petrochemical plants where safety is paramount.

Handling High-Pressure Fluids:

The petrochemical industry often deals with high-pressure fluids, and gate valves are well-suited to handle such conditions. Their robust design and capability to withstand high pressures make them a preferred choice for critical applications. Valve Manufacturers in Spain are known for producing high-quality gate valves that can operate efficiently under extreme conditions.

Controlling Corrosive Media:

Petrochemical processes frequently involve corrosive media. Gate valves made from specialized materials, such as stainless steel or alloy, are used to resist corrosion and prolong the valve’s service life. For industries looking for specialized valves, engaging with a reputable Gate Valves Supplier is crucial to ensure durability and reliability.

Steam and Heat Transfer Systems:

In petrochemical plants, steam and heat transfer systems are integral to various processes. Gate valves are employed in these systems to manage the flow of steam and other high-temperature fluids. These valves can handle the thermal expansion and contraction that occur in such systems, making them a vital component of heat management.

Shutdown Systems:

In emergency shutdown systems, gate valves are often used due to their ability to quickly and completely stop the flow of hazardous fluids. This quick response capability is critical in preventing accidents and ensuring the safety of the plant and its personnel.

Sourcing the Right Gate Valves

For businesses in the petrochemical industry, sourcing the right gate valves from reliable suppliers is essential. A Valve Stockist offers a wide range of options, ensuring that industries can find the exact specifications they need. Moreover, working with a Ball valves Supplier, Globe Valves Supplier, or Butterfly valve supplier can provide comprehensive valve solutions for various applications.

Additionally, many industries are turning to international markets for their valve needs. Valve Manufacturers in Spain have earned a reputation for their quality and innovation, providing robust solutions for petrochemical applications. Engaging with such manufacturers ensures access to advanced technology and high-quality products.

Conclusion

Gate valves are indispensable in the petrochemical industry, serving critical functions across various applications. Whether isolating sections of a pipeline, handling high-pressure fluids, or managing corrosive media, these valves provide the reliability and safety that petrochemical plants demand. To ensure optimal performance and safety, it is crucial to source these valves from reputable suppliers, such as a Valve Stockist in UAE or leading Valve Manufacturers globally. Additionally, working with specialized suppliers like a Control valves supplier or Water Valves Supplier can further enhance the efficiency and safety of petrochemical operations

2 notes

·

View notes

Text

Valves Market is Estimated to Witness High Growth

Valves Market is Estimated to Witness High Growth Owing to Rising Constructional and Infrastructure Development Activities The valves market comprises products such as gate valves, globe valves, check valves, butterfly valves, ball valves and pressure regulating valves which are used to control the flow, pressure and direction of fluids. Valves are extensively used in power plants, refineries, oil & gas, water & wastewater and construction activities. These products play a key role in fluid transportation and management which makes them an integral component across various industrial sectors. Rising infrastructure development projects across both developed and developing nations are augmenting the demand for valves. Moreover, growing pipeline networks for oil & gas transportation is also favoring market growth. The Global valves market is estimated to be valued at US$ 83 Mn in 2024 and is expected to exhibit a CAGR of 3.5% over the forecast period 2024 To 2031. Key Takeaways Key players operating in the valves market are Tyson Foods, Inc., JBS S.A., Pilgrim's Pride Corporation, Wens Foodstuff Group Co. Ltd., BRF S.A., Perdue Farms, Sanderson Farms, Baiada Poultry, Bates Turkey Farm, and Amrit Group. The major players are focusing on capacity expansion plans and mergers & acquisitions to gain market share. Rising population and changing diets are expected to fuel the growth of the poultry sector which presents significant opportunities for valve manufacturers. With the growing poultry industry, demand for processing equipment including valves is also projected to rise substantially over the forecast period. The global valves market is estimated to witness growth across key regions such as North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. This can be attributed to surging investments in oil & gas, water & wastewater infrastructure, and industrial development projects worldwide. Emerging economies with high urbanization rates like China and India also offer lucrative prospects for market expansion. Market Drivers The key driver behind the Valves Market Demand is the increasing constructional and infrastructure development activities worldwide. There is huge government focus as well as private investments toward projects such as roadways, railways, metro stations, power generation, water supply, etc. which involves extensive use of valves in various process applications. Further, the rising need for energy and growing focus on rural electrification has boosted investments in power transmission and distribution sector augmenting valves demand.

PEST Analysis

Political: The valves market is regulated by laws pertaining to safety, environmental protection and quality standards. New regulations regarding emissions could impact demand patterns. Economic: Changes in the global and regional economic conditions directly impact spending on industries like oil & gas, energy & power, and water & wastewater management which influences Valves demand. Social: Growing population and urbanization is increasing requirements for water, energy and other infrastructure development which boost the usage of valves. Technological: Advancements in materials and designs of valves are improving efficiency, lowering costs and enabling usage in newer applications. Digitalization is also aiding remote monitoring of industrial valves. The regions concentrating maximum valves market share in terms of Valves Market Size and Trends include North America, Europe and Asia Pacific. North America accounts for a major portion owing to strong presence of end-use industries like oil & gas and significant infrastructure spending. Europe and Asia Pacific are also sizable markets led by Germany, China, India respectively. The fastest growing regional market for valves is expected to be Asia Pacific led by increasing investments in water & wastewater management, power projects and industrial activities in China and India. Rising standards of living and initiatives to improve urban infrastructure will further drive the demand across developing nations in the region.

Get more insights Valves Market

Discover the Report for More Insights, Tailored to Your Language.

French German Italian Russian Japanese Chinese Korean Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Valves Market#Control Valves#Globe Valves#Plug Valves#Gate Valves#Ball Valves#Butterfly Valves

2 notes

·

View notes

Text

AL ASAS Valves Trading LLC

AL ASAS Valves Trading LLC leading wholesale & retail distributor of high-quality Flow Control Equipments has now joined TradersFind. Discover our wide range of products, including Butterfly Valves, Petrochemical Valves, Ball Valves, Pipe Fittings, Y Strainers, and more. Discover our catalog today for all your valves and fittings needs. Check out the catalog here: https://www.tradersfind.com/seller/al-asas-valves-trading-llc

#ALASAS#FlowControlEquipment#ValveSupplier#ButterflyValves#PetrochemicalValves#BallValves#PipeFittings#YStrainers#Actuators#GRPProducts#ValveDistributor#TradingHub#B2BPortal#UAEMarket#IndustrialSupplies#MRO#ProcessEquipment#FluidControl#ValveTechnology#IndustryLeader#QualityProducts#OneStopSolution#TradersFindUAE#BuyerSellerConnect#IndustrialSupplyChain#ValveApplications#CommercialValves

2 notes

·

View notes

Text

Cooking Without Limits: Butterfly's 10L Pressure Cooker Unleashed

The Butterfly Aluminium Standard Plus Pressure Cooker (10 L) stands as a testament to Butterfly's commitment to quality and innovation in kitchen appliances. With a generous 10-liter capacity, this pressure cooker is designed to cater to the needs of larger households or occasions where cooking in large quantities is essential.

Crafted from high-quality aluminium, the Butterfly Aluminium Standard Plus Pressure Cooker ensures efficient heat distribution, promoting even cooking and reducing cooking times. The use of aluminium not only enhances the cooker's thermal conductivity but also makes it lightweight and easy to handle. This combination of durability and user-friendly design sets the stage for a reliable and efficient cooking experience.

The 10-liter capacity of this pressure cooker makes it a standout choice for families or gatherings where preparing substantial meals is a regular occurrence. The ample space within the cooker allows for versatile cooking, accommodating a variety of dishes, from soups and stews to large cuts of meat. This capacity proves especially beneficial for those who like to cook in batches, saving time and effort in the kitchen.

Safety is a top priority in the design of the Butterfly Aluminium Standard Plus Pressure Cooker. The cooker features a secure locking lid mechanism that ensures a tight seal during the cooking process. This prevents any accidental spills or leaks, offering peace of mind to the user. The pressure release valve and gasket further contribute to a controlled cooking environment, preventing excessive pressure build-up. The ergonomically designed handles remain cool to the touch, allowing for safe and comfortable handling even when the cooker is in use.

Versatility is another key feature of this pressure cooker. Compatible with various cooktops, including gas stoves, electric cookers, and induction hobs, it adapts seamlessly to different kitchen setups. This versatility expands the cooker's user base, making it an ideal choice for those with diverse cooking preferences and equipment.

Cleaning and maintenance are made convenient with the Butterfly Aluminium Standard Plus Pressure Cooker. The interior is coated with a non-stick material, preventing food from sticking and easing the cleaning process. The durable construction ensures longevity, and the cooker is built to withstand regular use, providing a reliable cooking solution for years.

In summary, the Butterfly Aluminium Standard Plus Pressure Cooker (10 L) is a standout kitchen appliance that combines functionality, safety, and durability. Its 10-liter capacity makes it an excellent choice for families or anyone who frequently cooks in larger quantities. The use of high-quality aluminium, coupled with thoughtful safety features, ensures a cooking experience that is not only efficient but also secure. With its versatility and user-friendly design, the Butterfly Aluminium Standard Plus Pressure Cooker proves to be a valuable addition to any kitchen, making cooking a breeze and allowing users to create delicious meals with ease.

Buy the Latest Butterfly Aluminium Standard Plus Pressure Cooker 10 L Online @ Best Offers from Poorvika!

Click here: https://www.poorvika.com/butterfly-aluminium-standard-plus-pressure-cooker-10-litre/p

2 notes

·

View notes

Text

Explore The Benefits of Using a Butterfly Valve with Pneumatic Actuator

In fluid control systems, the combination of butterfly valves and pneumatic actuators has become increasingly popular due to their efficiency, reliability, and ease of use. These components play a critical role in various industries, including water treatment, chemical processing, and HVAC systems. Understanding their benefits can help you make informed decisions about integrating them into your operations.

Efficient Flow Control

A butterfly valve is designed to regulate the flow of liquids, gases, and slurries. Its simple yet effective mechanism involves a disc that rotates around its axis to open or close the valve, allowing precise control of flow rates. When paired with a pneumatic actuator, the operation becomes even more efficient. The actuator uses compressed air to automate the valve's movement, enabling rapid and accurate adjustments.

Cost-Effective Solution

Butterfly valves are known for their cost-effectiveness. They require less material to manufacture compared to other types of valves, such as gate or ball valves, resulting in lower costs. Additionally, the integration of a pneumatic actuator further enhances cost savings by reducing manual labor and minimizing the risk of human error.

Durability and Longevity

PVC butterfly valves, in particular, offer excellent resistance to corrosion and chemical damage, making them ideal for harsh environments. This durability ensures a longer service life, reducing the frequency of replacements and maintenance. PVC valves are highly valued in industries where exposure to chemicals is common. The pneumatic actuator, known for its robust construction, also contributes to the longevity of the system by providing consistent performance under varying conditions.

Easy Installation and Maintenance

The design of butterfly valves allows for easy installation, especially in systems with limited space. Their lightweight and compact structure simplify handling and setup. When paired with pneumatic actuators, the system becomes even more user-friendly. Pneumatic actuators are low-maintenance and offer a straightforward operational mechanism, which further simplifies the overall maintenance process.

Improved Safety and Reliability

Automation provided by pneumatic actuators enhances the safety and reliability of fluid control systems. The actuator valve can be programmed to respond to system changes in real-time, reducing the likelihood of operational failures. This level of automation also minimizes the need for manual intervention, reducing the risk of accidents and ensuring a safer working environment.

Versatility Across Applications

Butterfly valves with pneumatic actuators are highly versatile, making them suitable for a wide range of applications. From handling potable water to controlling the flow of aggressive chemicals, these valves can adapt to various needs. Their ability to operate effectively in different temperatures and pressures further broadens their applicability.

Energy Efficiency

Pneumatic actuators are known for their energy efficiency. They require compressed air, which can be generated using renewable energy sources, making them an eco-friendly option. This efficiency translates to lower energy consumption, reducing operational costs and environmental impact.

Enhanced Control and Precision

The combination of a butterfly valve and a pneumatic actuator provides superior control and precision in fluid management. The actuator allows for fine-tuned adjustments to the valve's position, enabling precise flow control. This precision is crucial in processes that require exact flow rates to maintain product quality and system efficiency.

Conclusion

Integrating a butterfly valve with a pneumatic actuator offers numerous benefits, including cost savings, durability, easy maintenance, and enhanced safety. Whether you are managing a small-scale operation or a large industrial system, this combination provides an efficient and reliable solution for fluid control. By leveraging the strengths of both components, you can optimize your system's performance and ensure long-term success in your operations.

0 notes

Text

8 Tips for Troubleshooting Butterfly Valves

Butterfly valves are essential components in many industries for regulating the flow of liquids and gases. However, even the best butterfly valves may encounter issues over time. Here are eight troubleshooting tips to ensure your butterfly valves function optimally.

1. Inspect for External Damage

Regularly examine the valve body and disc for cracks, dents, or other visible damage. Butterfly valves manufacturers and suppliers in Saint Chair recommend addressing any damage immediately to prevent further operational issues.

2. Check for Misalignment

Misalignment of the valve can hinder its ability to open or close properly. Ensure that the valve is installed in a straight line with the piping to avoid unnecessary wear and tear. Butterfly valves suppliers emphasize proper alignment during installation for optimal performance.

3. Examine the Seals and Gaskets

Leaks around butterfly valves are often caused by worn-out seals or gaskets. Replace damaged components to maintain a tight seal and prevent fluid leakage. Butterfly valves manufacturers suggest using high-quality replacement parts for longer durability.

4. Address Corrosion Issues

Corrosion can compromise the valve's structural integrity and performance. Regular maintenance, including cleaning and applying anti-corrosion treatments, can extend the lifespan of butterfly valves. This is especially crucial for valves in humid or chemical-heavy environments.

5. Lubricate Moving Parts

Butterfly valves rely on moving components like shafts and actuators. Proper lubrication ensures smooth operation and prevents friction-related damage. Butterfly valves manufacturers and suppliers recommend using compatible lubricants to avoid material degradation.

6. Test for Proper Functioning

Conduct regular tests to confirm the valve opens and closes fully without resistance. Partial movement or stalling can indicate mechanical or alignment issues. Butterfly valves suppliers suggest testing after any repairs or adjustments.

7. Monitor Operating Pressure

Excessive pressure can damage the valve and reduce its efficiency. Butterfly valves manufacturers stress the importance of adhering to the recommended pressure range specified by the manufacturer. Over-pressurization can also lead to sudden failure.

8. Consult Experts When Needed

If troubleshooting efforts fail, consult professionals. Butterfly valves manufacturers and suppliers in Missouri and Saint Chair often provide technical support and repair services to address complex issues.

By following these tips, you can minimize downtime and maintain the reliability of your butterfly valves. Whether sourcing new valves or seeking expert advice, reach out to reputable butterfly valves manufacturers and suppliers to ensure you get high-quality products and support. For industries in Missouri or Saint Chair, reliable suppliers are invaluable for maintaining efficient operations.

#butterfly valves#butterfly valves manufacturers suppliers in saint chair#butterfly valves manufacturers suppliers#butterfly valves manufacturers#butterfly valves suppliers in missouri#missouri#usa

0 notes

Text

Explore Udhhyog’s comprehensive valve category, featuring a diverse range of high-quality valves such as gate valves, ball valves, butterfly valves, and more. Designed for optimal flow control and durability, our valves are ideal for various industrial and commercial applications. Whether it's for water supply, oil and gas, or chemical processing, Udhhyog provides reliable solutions to meet your specific requirements. Discover the perfect valve for your system and ensure smooth and efficient operations.

#UdhhyogValves#IndustrialValves#FlowControl#GateValve#BallValve#ButterflyValve#ValveSolutions#ValveSupplies#FluidControl#ValvesIndia

4 notes

·

View notes

Text

Premium Actuated Butterfly Valves for Precision Flow Control

Discover top-quality actuated butterfly valves for precise flow control in industrial and commercial systems, FlowCon IVC PN16 and PN25 lugged electric actuated butterfly valves produce precise regulation of flow, enhancing efficiency and reliability in industrial applications.. Engineered for efficiency, these valves are ideal for automated operations in water, gas, and chemical applications. Durable, cost-effective, and easy to integrate, they ensure reliable performance. Upgrade your system with our advanced actuated butterfly valves. Contact us today for expert guidance and custom solutions. For More Details :- https://www.flocontrol.ltd.uk/, Contact Us :- +44 1282 564425

#PICV Valve function#PICVs#PICV Valve#PICV Valves#PICV#PICV Valve Package#PICV Valve for AHU#PICV Installation#PICV Valve for FCU

0 notes

Text

Industrial Valve Manufacturers in India

Speciality Valve is the largest Industrial valve manufacturers in India produces a wide range of valves used in various sectors like oil and gas, chemical, water treatment, power generation, and more. Valves are crucial components in controlling the flow of liquids, gases, and slurries within pipelines, tanks, and other systems. Manufacturers design and produce valves according to specific industry needs, ensuring they meet high-quality standards for durability, efficiency, and safety.

How it Works:

Valves control the flow and pressure of fluids through pipes by opening, closing, or regulating the flow based on the desired output. Depending on the design, they can be operated manually or automatically through electric, pneumatic, or hydraulic actuators. The basic operation involves a valve body, an inlet, an outlet, and a closure mechanism (such as a ball, gate, or globe). The valve’s internal components, such as seals, stem, and actuator, work together to ensure precise control.

Types of Industrial Valve

Gate Valve

Globe Valve

Ball Valve

Check Valve

Butterfly Valve

Pressure Relief Valve

Benefits:

Flow Control: Valves are integral to maintaining optimal flow in industrial systems, ensuring processes run efficiently.

Safety: Valves can help prevent overpressure, leaks, or contamination, offering safety in hazardous environments.

Energy Efficiency: Proper flow regulation reduces energy consumption and operating costs.

Customization: Manufacturers in India offer valves tailored to specific needs, allowing for versatility across industries.

Types of Industries

1. Oil and Gas Industries

2. Water and Wastewater Industries

3. Chemical Processing Industries

4. HVAC

5. Power Generation Industries

6. Marine and Shipbuilding Industries

7. Pulp and Paper Industries

8. Metallurgy and Mining industries

9. Automotive industries

Main Components:

Valve Body: The main structure that houses all internal components.

Bonnet: Covers the valve’s body and houses the stem and actuator.

Stem: Connects the actuator to the valve plug or disc, controlling the opening or closing of the valve.

Seat: The surface that seals against the valve plug to prevent leaks.

Actuator: Mechanism that operates the valve (manual, pneumatic, hydraulic, or electric).

so whenever you want connect with us as Industrial valve manufacturers in India making products that are essential in a variety of industrial applications

visit now - https://www.specialityvalve.com/

1 note

·

View note

Text

Shop Premium Valve Lockout Devices for Ultimate Safety in Australia

Protect your workforce and machinery with high-quality valve lockout devices available in Australia. These essential safety tools prevent accidental or unauthorized operation during maintenance, ensuring a safe working environment.

Why Choose Our Valve Lockout Devices?

Durability: Constructed from robust materials to endure harsh industrial conditions.

Versatility: Suitable for various valve types, including gate valves, ball valves, and butterfly valves.

Ease of Use: Simple installation and operation for efficient safety management.

Regulatory Compliance: Adheres to Australian safety standards and regulations.

Key Benefits:

Our premium valve lockout devices can fit various valve sizes. These are made from high visible colors for easy identification in the working area. Check out more benefits:

Enhanced Safety: Mitigates the risk of workplace accidents.

Reliable Protection: Secures machinery during maintenance activities.

Long-Lasting: Built to withstand wear and tear in demanding environments.

Wide Selection: Available in different sizes and configurations to meet your specific needs.

Invest in premium valve lockout devices to ensure the safety of your team and compliance with Australian regulations. Shop now and safeguard your workplace with the best safety solutions available in Australia. Check the product range - https://www.safetylock.net/lockout-tagout-devices/valve-lockouts/

#Valve Lockout Devices#Lockout Tagout#Valve LOTO Devices#Valve Lockouts#Gate Valve Lockout#Ball Valve Lockouts#Lockout Tagout Devices#Lockout Tagout Manufacturer#LOTO Supplier#E-Square Alliance

0 notes

Text

High Quality, High-Performance Industrial Valves Manufacturer and Supplier

🔧 Prime Industrial Valves is your trusted manufacturer and supplier of high-performance valves designed to meet global industrial standards. Our range includes: ✅ Gate Valves ✅ Globe Valves ✅ Check Valves ✅ Ball Valves ✅ Butterfly Valves ✅ Strainers & More

💡 Why Choose Us? ✔️ Precision Engineering ✔️ Durable & Reliable Products ✔️ Extensive Industry Expertise ✔️ Global Shipping & Support

🔗 Explore our full range of products here: www.primevalvesindia.com

#IndustrialValves#GateValves#ButterflyValves#BallValves#CheckValves#GlobeValves#HighPerformanceValves#ValveManufacturer#PrimeValves

0 notes