#proximity sensors

Explore tagged Tumblr posts

Text

Forced Proximity Prompts

Locked in a classroom together by the teacher on accident after serving detention

Hiding in a cramped space when they’re almost caught somewhere they’re not meant to be- end up getting stuck

locked in a room or a closet by their friends.

Door gets jammed

one of them gets their foot/ clothes stuck

There’s only one bed

only one horse/ other small methods of transport

forced to take a carriage together

forced to work on a group/ paired project together

A is forced to tutor/teach something to B

prisoners in the same cell/ something along that concept

arranged marriage

servant/master dynamic (NOT SLAVERY, *SERVANTS* e.g., maid attending to the prince)

they end up in an unfamiliar land and are forced to stick together

A is B’s bodygaurd

Forced to be dorm mates at an academy/school/institute

A is a wanted criminal, B is the knight/gaurd/mercenary/officer/ ect. Who captures them

#HEAVENLYRAIN’S WRITING PROMPTS#writing ideas#writing prompt#writing community#writing inspiration#writing advice#creative writing#on writing#writer#writerscommunity#writer stuff#romance prompts#romantic#romance#forced proximity#close proximity#proximity sensors#story prompt#dialogue prompt#writer problems#prompt#prose#fic prompt#whump prompt#writers on tumblr#writeblr#writers and poets#writing#scene pack#scene prompt

308 notes

·

View notes

Text

The Advantages of Using Capacitive Proximity Sensors in Automation

Capacitive proximity sensors are invaluable components in modern automation systems, offering distinct advantages that make them a preferred choice for various industrial and technological applications. These sensors operate on the principle of detecting changes in capacitance when an object approaches their sensing field, allowing them to identify materials regardless of conductivity. Below are the key advantages of using capacitive proximity sensors in automation.

Versatile Detection Capabilities

One of the primary advantages of capacitive proximity sensors is their ability to detect a wide range of materials. Unlike inductive sensors, which are limited to metallic objects, capacitive sensors can detect both conductive and non-conductive materials, including wood, glass, plastics, and liquids. This versatility makes them suitable for diverse applications, from monitoring fluid levels in containers to detecting products on a conveyor belt.

Non-Contact Sensing

Capacitive proximity sensors operate without physical contact with the object they detect. This non-contact feature minimizes wear and tear, leading to longer sensor life and reduced maintenance costs. In automation, where continuous and efficient operation is critical, the durability of these sensors contributes to system reliability and reduced downtime.

High Sensitivity and Precision

Capacitive sensors offer high sensitivity and precise detection capabilities. They can be configured to detect small changes in position or the presence of objects with high accuracy. This level of precision is essential in applications where detecting minor variances is crucial, such as quality control and automated inspection processes.

Compact and Easy Integration

Capacitive proximity sensors are often compact and lightweight, making them easy to integrate into existing automation systems. Their small size allows for flexible installation in tight spaces or complex machinery setups. Additionally, modern capacitive sensors often come with user-friendly interfaces and programmable settings, further simplifying integration and operation.

Adaptability to Harsh Environments

Many capacitive sensors are designed to withstand harsh industrial environments, including extreme temperatures, high humidity, and exposure to dust or chemicals. This robust construction ensures consistent performance in challenging conditions, making them suitable for industries such as manufacturing, food processing, and material handling where environmental factors could otherwise compromise sensor function.

Energy Efficiency

Capacitive proximity sensors generally have low power consumption, contributing to the overall energy efficiency of automated systems. This feature is particularly beneficial in large-scale operations where reducing energy costs is a priority. The lower energy requirement also makes these sensors suitable for battery-operated and portable automated equipment.

Fast Response Time

In automation, speed is often just as critical as accuracy. Capacitive sensors offer fast response times, ensuring that they can keep up with high-speed processes. This rapid detection capability enables real-time monitoring and control, which is essential for optimizing production lines and ensuring safety protocols.

Customizability and Advanced Features

Capacitive proximity sensors are available with various customizable features, such as adjustable sensing ranges and different housing materials to match specific application needs. Advanced models may include digital outputs and connectivity options compatible with modern automation protocols, facilitating integration into smart systems and Industry 4.0 initiatives.

Conclusion

The advantages of capacitive proximity sensors make them a reliable and efficient choice for automation applications. Their versatility in detecting various materials, non-contact operation, high sensitivity, and adaptability to demanding conditions are just a few of the factors that contribute to their widespread use. By integrating these sensors into automated systems, industries can achieve enhanced performance, reliability, and cost savings, driving more streamlined and effective operations.

#capacitive proximity sensors#capacitive proximity sensor#proximity sensors#capacitive sensors#capacitive proximity sensors in lexington

0 notes

Text

Big Andon Displays, Manufacturer, Supplier, India

We are Manufacturer, Supplier, Exporter of Big Andon Displays, from Pune, Maharashtra, India.

Proximity Sensor, Proximity Sensors, Proximity Switch, Proximity Switches, AC Proximity Switch, AC Proximity Switches, Addressable Pull Cord Switch, Addressable Pull Cord Switches, Belt Loading Monitor, Belt Loading Monitors, Belt Monitoring Switch, Belt Monitoring Switches, Belt Rupture Switch, Belt Rupture Switches, Belt Sway Switch, Belt Sway Switches, Belt Tear Switch, Belt Tear Switches, Capacitive Proximity Sensor, Capacitive Proximity Sensors, Capacitive Proximity Switch, Capacitive Proximity Switches, Chute Jam Switch, Chute Jam Switches, Compact Pull Cord, Compact Pull Cords, DC Proximity Switch, DC Proximity Switches, Digital Frequency Controller, Digital Frequency Controllers, Electromagnetic Vibrator Controller, Electromagnetic Vibrator Controllers, Electronic Speed Monitoring Switch, Electronic Speed Monitoring Switches, Electronic Speed Switch, Electronic Speed Switches, Electronic Zero Speed Switch, Electronic Zero Speed Switches, Frequency Controllers For Bowl Feeder, Heavy Duty Limit Switch, Heavy Duty Limit Switches, Heavy Duty Pull Cord Switch, Heavy Duty Pull Cord Switches, Inductive Proximity Sensor, Inductive Proximity Sensors, Inductive Proximity Switch, Inductive Proximity Switches, Infrared Sensors Light Carton, Infrared Sensors Light Cartons, Level Switch, Level Switches, Magnetic Proximity Sensor, Magnetic Proximity Sensors, Magnetic Proximity Switch, Magnetic Proximity Switches, Optical Proximity Sensor, Optical Proximity Sensors, Optical Proximity Switch, Optical Proximity Switches, Position Sensor, Position Sensors, Position Switch, Position Switches, Pull Cord Switch, Pull Cord Switches, RF Admittance Level Sensor, RF Admittance Level Sensors, RF Admittance Type Level Switch, RF Admittance Type Level Switches, Rotary Paddle Type Switch, Rotary Paddle Type Switches, Rupture Switch, Rupture Switches, Safety Switch, Safety Switches, Safety Switches For Conveyor, Special Pull Cord Switch, Special Pull Cord Switches, Tilt Switch, Tilt Switches, Trip Indication System, Trip Indication Systems, Vibrating Fork Type Level Switch, Vibrating Fork Type Level Switches, Vibrator Controller, Vibrator Controllers, Vibratory Feeder Controller, Vibratory Feeder Controllers, Voltage Regulators For Vibratory Feeder, Manufacturer, Supplier, Exporter, Pune, Maharashtra, India.

#Proximity Sensor#Proximity Sensors#Proximity Switch#Proximity Switches#AC Proximity Switch#AC Proximity Switches#Addressable Pull Cord Switch#Addressable Pull Cord Switches#Belt Loading Monitor#Belt Loading Monitors

0 notes

Text

Proximity Sensors: Enhancing Efficiency and Safety Across Industries

What are Proximity Sensors

Proximity sensors identify an object's presence even in the absence of physical touch. Without coming into direct touch with the item, they are made to recognize when it enters the sensor field. In a variety of manufacturing applications, proximity sensors are used to identify the proximity of metallic and non-metallic items.

How Do Proximity Sensors Function?

In the least complex terms, proximity sensors work by communicating information about the presence or movement of an item into an electrical sign. They yield an ON signal when the article enters their reach. There are a few critical contrasts in the manner that different closeness sensors work, as made sense below:

Capacitive Nearness Sensor Working Guideline Capacitive

Proximity sensors work by identifying changes in capacitance between the sensor and an item. Factors, for example, distance and the size of the article will influence how much capacitance. The sensor just recognizes any progressions in the limit produced between the two.

Inductive Nearness Sensor Working Standard

Inductive sensors work by recognizing vortex flows causing attractive misfortune, created by outer attractive fields on a conductive surface. The discovery curl produces an air conditioner attractive field, and impedance changes are distinguished because of the created whirlpool flows.

Attractive Vicinity Switches Working Rule Attractive

Proximity switches are similarly basic and clear. The reed end of the switch is worked by a magnet. At the point when the reed switch is enacted and ON, the sensor additionally turns ON.

It is additionally significant that proximity sensors are not impacted by the surface shade of the article identified. They depend simply on actual development and the movement of an item, so its tone doesn't assume a part in that frame of mind of the sensor.

The Role of Proximity Sensors in Modern Industries

Sensors have become indispensable in today's automated world, serving important functions such as tracking and positioning control. In this field, location and proximity sensors are reshaping several industries. By detecting nearby vehicles in the automotive industry and accurately tracking the location of delivered packages in production, these sensors show their versatility and potential in several fields.

Robotics

Both position and proximity sensors are used in many applications in the field of robotics. For example, linear position sensors are commonly used in robotics and industrial settings for object detection, part fixation, and machine control. These sensors play an essential role in detecting the location, distance, and proximity of moving objects and provide important information for robot navigation and manipulation.

Industrial Automation

Today many manufacturers use these sensors to improve work productivity and efficiency. Integrating position and proximity sensors into production systems enables accurate detection and tracking of objects on conveyor belts, robotic arms, and assembly lines. This combination enables precise object positioning and motion control in industrial processes.

Security systems

Combining proximity and location sensors, security systems can be used to track and control the movement of objects in a certain area. It is useful in surveillance, burglar alarms, and access control systems.

Automotive Applications

The combination of these position and proximity sensors can be used in parking systems to detect open spaces and nearby cars in a parking lot, and accurately track the location of a vehicle for parking assistance. These sensors are also used to improve the safety and performance of Advanced Driver Assistance Systems (ADAS) vehicles.

Smart Healthcare

Location and proximity sensors play a vital role in healthcare, facilitating the monitoring and management of various aspects of medical facilities. Wearable proximity sensors play an important role in both acute and chronic health conditions, as they allow non-contact detection and monitoring of physical movements and interactions.

Food and Beverage Industry

A proximity sensor for food is a type of sensor that is designed specifically for use in the food industry. It is used to detect the presence or absence of food items during various stages of food processing, packaging, and handling.

As technology advances, the integration of location and proximity sensors is expected to increase security, automation, and sensor innovation. based systems in various industries.

#proximity sensors#inductive proximity sensor#proximity sensor types#inductive sensor#what is proximity sensor#proximity sensor price#proximity sensor working#working of proximity sensor#omron proximity sensor#sensors working principle#magnetic proximity sensor#optical proximity sensor#proximity switch sensor#inductive sensor working principle#an inductive proximity sensor comprises#autonics proximity sensor#features of sensors#proximity sensor definition#proximity switch function#capacitive sensor#capacitive proximity sensor#capacitive level sensor#capacitive sensor working

0 notes

Text

0 notes

Note

see what i said about you being there the second adam is mentioned. five minutes it took u. im impressed and also kind of in awe. how do u do it

i'm just chronically online tbf i shouldnt even be online rn i have so many songs i need to learn skskksksk

2 notes

·

View notes

Text

PCB of the Day! The VCNL4200 has long-ranging vision 🔍🤖🛠️

The VCNL4200 proximity sensor https://www.digikey.com/en/products/detail/vishay-semiconductor-opto-division/VCNL4200/7394601 , which we found on last weeks The Great Search ---

youtube

can detect motion up to 1.5 meters away, and has an I2C interface that makes it an excellent match for a Stemma QT board prototype. Which is what we've got here! Note the IR LED requires an external P FET to drive it!

#adafruit#electronics#pcb#opensource#opensourcehardware#pcboftheday#VCNL4200#proximity#sensor#vision#techdiscovery#motiondetection#i2cinterface#stemmaqt#boardprototype#innovation#irled#pfetdrive#hardwarelove#engineeringdesign#Youtube

8 notes

·

View notes

Text

Honestly agree. I don't give a hot fuck about the thickness of my phone; I bought a really slim phone for the specs and promptly doubled the thickness of it with a case, and it feels great to hold anyway.

#plus i had to get rid of my last phone because the screen broke#and the local phone repair guy fucked up the proximity sensor placement when trying to replace it#not to mention#the lack of a user-replaceable battery has vexed me terribly since its inception

34K notes

·

View notes

Text

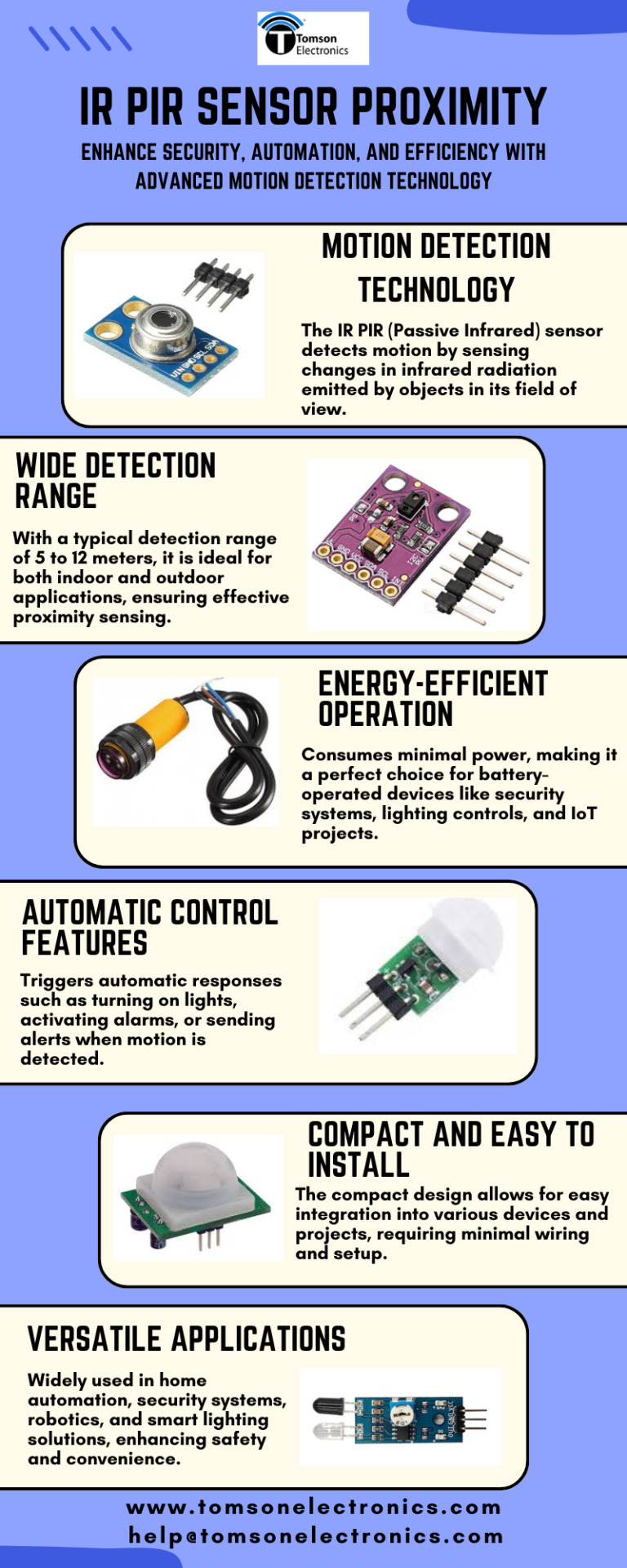

Buy IR PIR Sensor Proximity | Buy Online In India

Enhance security and automation with IR PIR Sensor Proximity at Tomson Electronic Shop. Detect motion with precision and simplify your projects. Shop now for advanced sensor solutions! Buy Now!

0 notes

Text

The Baumer IFRM 18N1701/S14L Inductive Proximity Sensor is a reliable and efficient solution for industrial automation. Designed to detect metal objects without physical contact, this sensor offers high precision and durability. Its robust design ensures consistent performance in harsh environments, making it ideal for manufacturing, assembly lines, and machine monitoring. With a sensing range tailored for versatile applications, it enhances operational efficiency and reduces downtime. The Baumer IFRM 18N1701/S14L combines advanced technology with dependable functionality, making it a preferred choice for industries requiring precise and non-contact object detection. Visit Auto2mation for quality automation solutions.

#industrial equipment#auto2mation#marine spare parts#industrial automation#industrial spare parts#industrial and marine automation#automation#industrial and marine automation equipment#marine automation#industrial automation equipment#industrial parts supplier#sensor#proximity sensor#baumer

0 notes

Text

Position and Proximity Sensors Market is expected to grow at a CAGR of 1.6% during the forecast period and it is expected to reach US$ 3041.9 Mn. by 2029.

0 notes

Text

Get The Best Proximity Sensor Wire for Sale at Reasonable Prices.

Twittlebit is always your best bet when it comes to high temperature proximity sensor wire because they are the greatest option for detecting metal objects in high temperature situations.

0 notes

Text

Electromagnetic Vibrator Controllers For Vibratory Feeder, Manufacturer

We are Manufacturer, Supplier, Exporter of Electromagnetic Vibrator Controllers, Vibrator Controller For Vibratory Feeder, Electronic Zero Speed Switches from Pune, Maharashtra, India.

Proximity Sensor, Proximity Sensors, Proximity Switch, Proximity Switches, AC Proximity Switch, AC Proximity Switches, Addressable Pull Cord Switch, Addressable Pull Cord Switches, Belt Loading Monitor, Belt Loading Monitors, Belt Monitoring Switch, Belt Monitoring Switches, Belt Rupture Switch, Belt Rupture Switches, Belt Sway Switch, Belt Sway Switches, Belt Tear Switch, Belt Tear Switches, Capacitive Proximity Sensor, Capacitive Proximity Sensors, Capacitive Proximity Switch, Capacitive Proximity Switches, Chute Jam Switch, Chute Jam Switches, Compact Pull Cord, Compact Pull Cords, DC Proximity Switch, DC Proximity Switches, Digital Frequency Controller, Digital Frequency Controllers, Electromagnetic Vibrator Controller, Electromagnetic Vibrator Controllers, Electronic Speed Monitoring Switch, Electronic Speed Monitoring Switches, Electronic Speed Switch, Electronic Speed Switches, Electronic Zero Speed Switch, Electronic Zero Speed Switches, Frequency Controllers For Bowl Feeder, Heavy Duty Limit Switch, Heavy Duty Limit Switches, Heavy Duty Pull Cord Switch, Heavy Duty Pull Cord Switches, Inductive Proximity Sensor, Inductive Proximity Sensors, Inductive Proximity Switch, Inductive Proximity Switches, Infrared Sensors Light Carton, Infrared Sensors Light Cartons, Level Switch, Level Switches, Magnetic Proximity Sensor, Magnetic Proximity Sensors, Magnetic Proximity Switch, Magnetic Proximity Switches, Optical Proximity Sensor, Optical Proximity Sensors, Optical Proximity Switch, Optical Proximity Switches, Position Sensor, Position Sensors, Position Switch, Position Switches, Pull Cord Switch, Pull Cord Switches, RF Admittance Level Sensor, RF Admittance Level Sensors, RF Admittance Type Level Switch, RF Admittance Type Level Switches, Rotary Paddle Type Switch, Rotary Paddle Type Switches, Rupture Switch, Rupture Switches, Safety Switch, Safety Switches, Safety Switches For Conveyor, Special Pull Cord Switch, Special Pull Cord Switches, Tilt Switch, Tilt Switches, Trip Indication System, Trip Indication Systems, Vibrating Fork Type Level Switch, Vibrating Fork Type Level Switches, Vibrator Controller, Vibrator Controllers, Vibratory Feeder Controller, Vibratory Feeder Controllers, Voltage Regulators For Vibratory Feeder, Manufacturer, Supplier, Exporter, Pune, Maharashtra, India.

#Proximity Sensor#Proximity Sensors#Proximity Switch#Proximity Switches#AC Proximity Switch#AC Proximity Switches#Addressable Pull Cord Switch#Addressable Pull Cord Switches#Belt Loading Monitor#Belt Loading Monitors#Belt Monitoring Switch

0 notes

Text

Omron Proximity Sensor FAQs: Answers to Your Most Common Questions

In today’s fast-paced industrial and automation sectors, proximity sensors play a crucial role in ensuring seamless operations, precision, and safety. Amongst multiple brands available in the market, Omron Proximity Sensors have emerged as a preferred choice for their reliability, versatility, and cutting-edge technology. At Balaji Switchgears, we pride ourselves on offering top-notch solutions, including a wide range of Omron products.

This blog answers some of the most frequently asked questions about Omron Proximity Sensors, providing valuable insights to help you make informed decisions.

What is a Proximity Sensor and Why Choose Omron?

A proximity sensor detects the presence or absence of an object without requiring physical contact. These sensors are widely used in industries like manufacturing, robotics, and automotive, where precision and reliability are paramount.

Omron Proximity Sensors stand out because of their:

Advanced Technology: High sensitivity and quick response times.

Durability: Designed to function in harsh environments.

Wide Variety: A range of models to suit diverse industrial needs.

What Are the Different Types of Omron Proximity Sensors?

Omron offers a diverse portfolio of proximity sensors tailored for various applications. Here are the main types:

Inductive Proximity Sensors

Detect metallic objects.

Ideal for automation and assembly lines.

Capacitive Proximity Sensors

Detect both metallic and non-metallic objects, such as liquids or plastics.

Commonly used in packaging and material handling.

Photoelectric Proximity Sensors

Use light to detect objects.

Suitable for long-range applications.

Ultrasonic Proximity Sensors

Use sound waves to detect objects.

Best for detecting transparent or reflective materials.

What Applications Are Omron Proximity Sensors Best Suited For?

Omron Proximity Sensors are versatile and can be used in:

Manufacturing: Detecting components on conveyor belts.

Robotics: Assisting in automation tasks.

Automotive: Monitoring assembly processes.

Packaging: Ensuring accurate placement of materials.

Material Handling: Managing inventory systems.

At Balaji Switchgears, we help you select the right sensor for your specific application to maximize efficiency and productivity. read more.........

0 notes

Text

Proximity and Displacement Sensor Market: Precision Solutions for Smart Systems

"Proximity and Displacement Sensor Market Size And Forecast by 2031

The revenue analysis and revenue forecast for the Proximity and Displacement Sensor Market reveal a promising upward trajectory, driven by innovative product offerings, strategic collaborations, and expanding applications. With leaders in the industry focusing on enhanced customer experiences and operational efficiency, the market continues to present lucrative opportunities for growth. The report provides a detailed overview of these trends and their implications for the market’s future.

The proximity and displacement sensor market is expected to witness market growth at a rate of 9.1% in the forecast period of 2021 to 2028 and is expected to reach by the value of USD 8,297.93 million by 2028. Data Bridge Market Research report on proximity and displacement sensor market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market’s growth. Rapid urbanization globally is escalating the growth of proximity and displacement sensor marke

The global size of the Proximity and Displacement Sensor Market has witnessed substantial growth in recent years, supported by increasing adoption across industries and regions. Market share dynamics highlight the dominance of key players while showcasing the emergence of new entrants. The market’s scope extends across multiple applications, making it a pivotal area of focus for stakeholders looking to capitalize on emerging trends and opportunities.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-proximity-and-displacement-sensor-market

Which are the top companies operating in the Proximity and Displacement Sensor Market?

The Top 10 Companies in Proximity and Displacement Sensor Marketinclude well-established names that lead the industry with their innovative products and strong market presence. These companies are recognized for their quality, reliability, and ability to meet the evolving needs of consumers. each known for their significant contributions and competitive strategies that drive growth and maintain their leadership in the industry.

**Segments**

- **By Type:** The proximity and displacement sensor market can be segmented based on type into inductive, capacitive, photoelectric, ultrasonic, and others. Inductive sensors are widely used in industrial applications due to their robustness and non-contact operation. Capacitive sensors are suitable for detecting non-metal objects and liquids. Photoelectric sensors offer flexibility in detection range and are often used in packaging and material handling industries. Ultrasonic sensors are ideal for distance measurement in harsh environments.

- **By End-Use Industry:** The market can also be segmented by end-use industry, including automotive, food and beverage, pharmaceuticals, manufacturing, and others. In the automotive sector, proximity and displacement sensors are essential for advanced driver-assistance systems (ADAS) and autonomous vehicles. The food and beverage industry utilizes these sensors for packaging and quality control processes. In pharmaceuticals, sensors are crucial for maintaining sanitary conditions and automating production lines.

- **By Application:** Another key segmentation is based on application, with segments such as object detection, distance measurement, level measurement, and others. Object detection applications include presence sensing, position control, and counting of objects on a conveyor belt. Distance measurement finds applications in robotics, machinery, and industrial automation. Level measurement is critical in tanks, silos, and other storage systems.

**Market Players**

- **Key Market Players:** Some of the prominent players in the proximity and displacement sensor market include Honeywell International Inc., Omron Corporation, Panasonic Corporation, Keyence Corporation, Rockwell Automation Inc., Schneider Electric, Sick AG, STMicroelectronics, Texas Instruments Incorporated, and Turck Holding GmbH. These market players focus on technological advancements, product innovation, strategic partnerships, and acquisitions to maintain their competitive positions in the market.

- **Emerging Companies:** There are also emerging players making significant contributions to the market, such as Balluff GmbH, Hans Turck GmbH & Co. KG, IFM Electronic GmbH, Lion Precision, Micro-Epsilon,The proximity and displacement sensor market is witnessing significant segmentation based on various factors such as type, end-use industry, and application. By type, the market is divided into inductive, capacitive, photoelectric, ultrasonic, and other sensors. Inductive sensors are popular in industrial settings for their durability and non-contact operation, while capacitive sensors are preferred for detecting non-metal objects and liquids. Photoelectric sensors offer versatility in detection range, making them suitable for applications in packaging and material handling industries. Ultrasonic sensors excel in distance measurement, particularly in challenging environments where other sensors may struggle.

Furthermore, the market segmentation based on end-use industries reveals key sectors where proximity and displacement sensors play a crucial role. In the automotive industry, these sensors are essential for advanced driver-assistance systems and autonomous vehicles' operations. The food and beverage sector relies on these sensors for packaging and quality control purposes. In the pharmaceutical industry, proximity and displacement sensors help maintain cleanliness and streamline production processes through automation.

Another vital segmentation criterion is based on applications, with segments like object detection, distance measurement, and level measurement. Object detection applications involve tasks such as presence sensing, position control, and object counting on conveyor belts. Distance measurement applications are prevalent in robotics, machinery, and industrial automation for accurate positioning. Level measurement is critical in monitoring liquid levels in tanks, granular materials in silos, and other storage systems to ensure operational efficiency and safety.

Moving on to the market players in the proximity and displacement sensor industry, key market players like Honeywell International Inc., Omron Corporation, and Panasonic Corporation dominate the market with their focus on technological advancements and strategic initiatives. These companies invest in research and development to introduce innovative sensor solutions and forge partnerships to expand their market presence. Additionally, emerging players such as Balluff GmbH, IFM Electronic GmbH, and Lion Precision are making noteworthy contributions to the market by introducing unique sensor technologies and catering to niche market segments. These emerging companies add vibrancy to the market landscape and drive further innovation**Market Players:**

- Delta Electronics, Inc. - Datalogic S.p.A. - STMicroelectronics - OMRON Corporation - Rockwell Automation, Inc. - Schneider Electric - Pepperl+Fuchs SE - Honeywell International Inc. - Panasonic Corporation - SICK AG - Baumer Holding AG - Contrinex AG - Autonics Corporation - Broadcom - Semtech Corporation - Infineon Technologies AG - Balluff Automation India Pvt. Ltd. - Hans Turck GmbH & Co. KG - Fargo Controls Inc. - Eaton

The major players covered in the proximity and displacement sensor market report are engaged in fierce competition to maintain their market positions and drive innovation. Companies such as Honeywell International Inc., Omron Corporation, and Panasonic Corporation are leading the market through continuous technological advancements and strategic collaborations. These key players are focused on enhancing their product portfolios to cater to the evolving demands in various industries.

Emerging companies like Balluff GmbH, IFM Electronic GmbH, and Lion Precision are also playing a significant role in shaping the proximity and displacement sensor market with their innovative solutions and niche market approaches. These players are introducing unique sensor technologies to address specific industry requirements and are contributing to the overall growth and competitiveness of the market.

The proximity and displacement sensor market is witnessing substantial growth due to the increasing demand for automation and efficiency across industries. The adoption of these sensors in automotive, food and beverage, pharmaceuticals, and manufacturing sectors

Explore Further Details about This Research Proximity and Displacement Sensor Market Report https://www.databridgemarketresearch.com/reports/global-proximity-and-displacement-sensor-market

Key Insights from the Global Proximity and Displacement Sensor Market :

Comprehensive Market Overview: The Proximity and Displacement Sensor Market is expanding rapidly, driven by innovation and growing global demand across key regions.

Industry Trends and Projections: Automation, sustainability, and digital transformation are key trends, with strong growth projected over the next few years.

Emerging Opportunities: New growth opportunities are emerging in eco-friendly technologies and untapped regional markets.

Focus on R&D: Companies are heavily investing in R&D to develop next-gen technologies like AI, IoT, and sustainable solutions.

Leading Player Profiles: Market leaders, such as Company A and Company B, dominate due to strong portfolios and global distribution.

Market Composition: The market is fragmented, with both large corporations and emerging startups driving innovation.

Revenue Growth: The market is experiencing steady revenue growth, driven by both consumer demand and industrial applications.

Commercial Opportunities: Key commercial opportunities lie in expanding into emerging markets and forming strategic partnerships.

Get More Reports:

https://webcraftx.wordpress.com/market-research-trends-and-dynamics-in-the-fmcg-industry/https://dbmrmarkettrends.wordpress.com/food-and-beverages-market-research-trends-challenges-and-opportunities/https://dbmrbusinessinsights.wordpress.com/fast-moving-consumer-goods-fmcg-market-trends-growth-drivers-and-future-outlook/https://dbmrgrowthtrends.wordpress.com/market-research-report-fmcg-fast-moving-consumer-goods-industry/https://dbmrbusinessinsightscom.wordpress.com/fmcg-market-research-unlocking-insights-for-business-growth/https://panaseaditya69.wordpress.com/market-research-report-chemical-and-materials-industry/https://researchword.wordpress.com/fast-moving-consumer-goods/https://dbmrmarketresearchcom.wordpress.com/evolving-dynamics-of-the-fmcg-market-trends-challenges-and-growth-strategies-in-a-consumer-driven-era/https://myfree5093.wordpress.com/market-research-on-the-healthcare-industry-trends-drivers-challenges-and-future-outlook/https://dbmrmarkettrendsdotcom.wordpress.com/exploring-market-trends-and-consumer-behavior-in-the-fmcg-sector/https://dbmrmarkettrendscom.wordpress.com/fmcg-fast-moving-consumer-goods-market-research/

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

#Proximity and Displacement Sensor Market#Proximity and Displacement Sensor Market Size#Proximity and Displacement Sensor Market Share#Proximity and Displacement Sensor Market Trends#Proximity and Displacement Sensor Market Growth#Proximity and Displacement Sensor Market Analysis#Proximity and Displacement Sensor Market Forecast#Proximity and Displacement Sensor Market Report#Proximity and Displacement Sensor Market Industry Report

0 notes

Text

Omron Products | Relays, Sensors, Vision Systems, Robotics & More - Lubi Electronics

Explore Omron's range of innovative automation products at Lubi Electronics, including relays, proximity sensors, photoelectric sensors, temperature controllers, timers, phase sequence relays, safety products, vision systems, code readers, and robotics. Enhance your industrial processes with reliable Omron solutions.

#Relay#Omron relays#Omron proximity sensors#photoelectric sensors#temperature controllers#phase sequence relays#safety products

0 notes