#magnetic proximity sensor

Explore tagged Tumblr posts

Text

Proximity Sensors: Enhancing Efficiency and Safety Across Industries

What are Proximity Sensors

Proximity sensors identify an object's presence even in the absence of physical touch. Without coming into direct touch with the item, they are made to recognize when it enters the sensor field. In a variety of manufacturing applications, proximity sensors are used to identify the proximity of metallic and non-metallic items.

How Do Proximity Sensors Function?

In the least complex terms, proximity sensors work by communicating information about the presence or movement of an item into an electrical sign. They yield an ON signal when the article enters their reach. There are a few critical contrasts in the manner that different closeness sensors work, as made sense below:

Capacitive Nearness Sensor Working Guideline Capacitive

Proximity sensors work by identifying changes in capacitance between the sensor and an item. Factors, for example, distance and the size of the article will influence how much capacitance. The sensor just recognizes any progressions in the limit produced between the two.

Inductive Nearness Sensor Working Standard

Inductive sensors work by recognizing vortex flows causing attractive misfortune, created by outer attractive fields on a conductive surface. The discovery curl produces an air conditioner attractive field, and impedance changes are distinguished because of the created whirlpool flows.

Attractive Vicinity Switches Working Rule Attractive

Proximity switches are similarly basic and clear. The reed end of the switch is worked by a magnet. At the point when the reed switch is enacted and ON, the sensor additionally turns ON.

It is additionally significant that proximity sensors are not impacted by the surface shade of the article identified. They depend simply on actual development and the movement of an item, so its tone doesn't assume a part in that frame of mind of the sensor.

The Role of Proximity Sensors in Modern Industries

Sensors have become indispensable in today's automated world, serving important functions such as tracking and positioning control. In this field, location and proximity sensors are reshaping several industries. By detecting nearby vehicles in the automotive industry and accurately tracking the location of delivered packages in production, these sensors show their versatility and potential in several fields.

Robotics

Both position and proximity sensors are used in many applications in the field of robotics. For example, linear position sensors are commonly used in robotics and industrial settings for object detection, part fixation, and machine control. These sensors play an essential role in detecting the location, distance, and proximity of moving objects and provide important information for robot navigation and manipulation.

Industrial Automation

Today many manufacturers use these sensors to improve work productivity and efficiency. Integrating position and proximity sensors into production systems enables accurate detection and tracking of objects on conveyor belts, robotic arms, and assembly lines. This combination enables precise object positioning and motion control in industrial processes.

Security systems

Combining proximity and location sensors, security systems can be used to track and control the movement of objects in a certain area. It is useful in surveillance, burglar alarms, and access control systems.

Automotive Applications

The combination of these position and proximity sensors can be used in parking systems to detect open spaces and nearby cars in a parking lot, and accurately track the location of a vehicle for parking assistance. These sensors are also used to improve the safety and performance of Advanced Driver Assistance Systems (ADAS) vehicles.

Smart Healthcare

Location and proximity sensors play a vital role in healthcare, facilitating the monitoring and management of various aspects of medical facilities. Wearable proximity sensors play an important role in both acute and chronic health conditions, as they allow non-contact detection and monitoring of physical movements and interactions.

Food and Beverage Industry

A proximity sensor for food is a type of sensor that is designed specifically for use in the food industry. It is used to detect the presence or absence of food items during various stages of food processing, packaging, and handling.

As technology advances, the integration of location and proximity sensors is expected to increase security, automation, and sensor innovation. based systems in various industries.

#proximity sensors#inductive proximity sensor#proximity sensor types#inductive sensor#what is proximity sensor#proximity sensor price#proximity sensor working#working of proximity sensor#omron proximity sensor#sensors working principle#magnetic proximity sensor#optical proximity sensor#proximity switch sensor#inductive sensor working principle#an inductive proximity sensor comprises#autonics proximity sensor#features of sensors#proximity sensor definition#proximity switch function#capacitive sensor#capacitive proximity sensor#capacitive level sensor#capacitive sensor working

0 notes

Text

Magnet reed switch magnet proximity sensor is widely used in household appliance, anti-theft system of windowsand doors,running machine, bicycle and car counters as well as thecar door induction system,coffee machine, humidifier, computer, scanner etc…

1 note

·

View note

Text

Deku Beyond

I like to imagen that whilst the new suit has the lot of OFA abilities in it each one had a different amount of time allotted to it.

Smoke, Day 1 it was easy as, done on lock down.

Float, yeah flight controls were down boosters in the boots, cape acts as stabilizer.

Those three were easy, the rest had some crazy stuff behind the scene.

Black Whip, genuine advancements in chemical engineering had to be made there to even get it to work, had to call in the MHA equivalent of ol'Peter Parker to get that job done.

Fa Jin, How the hell do you even make that, that's converting kinetic energy to more power, simple the suit adsorbs that shit like a sponge, Black Panther style, imagen punching him the impact spreads out glowing red and you get punted with double what you just hit him with.

Danger Sense, a suite of electronics to even get it that close, proximity sensors, heat identification, lidar and radar, they had to pack so much in to even equate to that quirk.

Gear Shift, How how would they even get it to be able to alter the speed of objects, no it's just a hyped up magnet system powered by the Fa Jin kinetic set up, can be used like the railgun, maybe like the force, doesn't work on none magnetic items yet.

Oh and super strength, that's basically just Izuku's, just has the Neuron Amplifiers like the Batman Beyond suit, only due to his absolutely ridiculous physical abilities he's got a cruise missile in his hands now not a 50.cal.

So when combing through the training footage it becomes rather difficult to gauge what the suits effectiveness, you have this film of him demolishing a building with a blow, and it turns out they didn't have the NA's on, Izuku one tapped that building with his pure strength, the only difference the armor was making was it acted as boxing glove.

Still think that suit is less Iron Man more Beyond Batman.

8 notes

·

View notes

Text

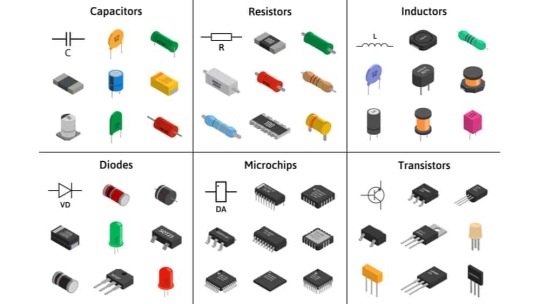

Electronics Components and Uses:

Here is a list of common electronics components and their uses:

Resistor:

Use: Limits or controls the flow of electric current in a circuit.

Capacitor:

Use: Stores and releases electrical energy; used for filtering, timing, and coupling in circuits.

Inductor:

Use: Stores energy in a magnetic field when current flows through it; used in filters, transformers, and oscillators.

Diode:

Use: Allows current to flow in one direction only; used for rectification, signal demodulation, and protection.

Transistor:

Use: Amplifies and switches electronic signals; fundamental building block of electronic circuits.

Integrated Circuit (IC):

Use: Contains multiple electronic components (transistors, resistors, capacitors) on a single chip; used for various functions like amplification, processing, and control.

Resistor Network:

Use: A combination of resistors in a single package; used in applications where multiple resistors are needed.

Potentiometer:

Use: Variable resistor that can be adjusted to control voltage in a circuit; used for volume controls, dimmer switches, etc.

Varistor:

Use: Protects electronic circuits from excessive voltage by acting as a voltage-dependent resistor.

Light-Emitting Diode (LED):

Use: Emits light when current flows through it; used for indicator lights, displays, and lighting.

Photodiode:

Use: Converts light into an electric current; used in light sensors and communication systems.

Zener Diode:

Use: Acts as a voltage regulator by maintaining a constant voltage across its terminals.

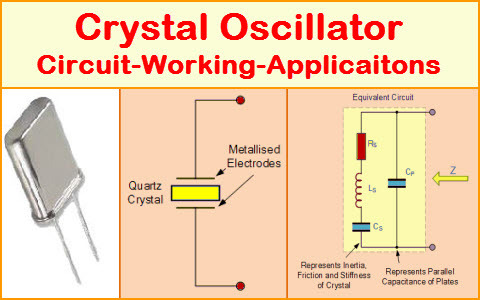

Crystal Oscillator:

Use: Generates a stable and precise frequency; used in clocks, microcontrollers, and communication devices.

Transformer:

Use: Transfers electrical energy between two or more coils through electromagnetic induction; used for voltage regulation and power distribution.

Capacitive Touch Sensor:

Use: Detects touch or proximity by changes in capacitance; used in touchscreens and proximity sensing applications.

Voltage Regulator:

Use: Maintains a constant output voltage regardless of changes in input voltage or load; used for stable power supply.

Relay:

Use: Electromagnetic switch that controls the flow of current in a circuit; used for remote switching and automation.

Fuse:

Use: Protects electronic circuits by breaking the circuit when current exceeds a certain value; prevents damage from overcurrent.

Thermistor:

Use: Resistor whose resistance changes with temperature; used for temperature sensing and compensation.

Microcontroller/Microprocessor:

Use: Processes and controls electronic signals; the brain of many electronic devices and systems.

fig:google-electronics

fig:google-electronics

fig:Crystal-Oscillator

This list covers some of the basic electronic components, and there are many more specialized components used for specific applications within the field of electronics.

#electronic#electricity#electric vehicles#electric cars#engineering#semiconductors#wireless#cables#electronics#smartphone#hardware

4 notes

·

View notes

Text

How Inductive Proximity Sensors Support Smart Factory Automation

In today’s rapidly advancing industrial world, smart factory automation has shifted from a futuristic vision to a critical requirement for staying competitive. At the core of this transformation are advanced sensing technologies that deliver precision, efficiency, and reliability. Among these technologies, inductive proximity sensors are essential for enabling precise and intelligent operations on the factory floor.

What Are Inductive Proximity Sensors?

Inductive proximity sensors are non-contact devices designed to detect the presence of metallic objects without any physical touch. They work on the principle of electromagnetic induction, generating an oscillating magnetic field and monitoring changes when a conductive object enters the detection zone.

Their ability to sense without wear and tear, combined with resistance to dirt, oil, and vibration, makes them ideal for demanding industrial environments.

Key Ways Inductive Sensors Enhance Smart Factory Automation

1. Enabling Real-Time Monitoring

Smart factories depend on real-time data to streamline and optimize their operations. Inductive sensors feed accurate information about machine status, object presence, and part positioning directly into PLCs and control systems. This real-time feedback loop enables predictive maintenance, improved throughput, and immediate fault detection.

2. Boosting Operational Efficiency

Automation thrives on precision and speed. Inductive sensors detect metal targets quickly and consistently, which helps prevent bottlenecks on assembly lines, packaging systems, and robotic arms. Their high switching frequency supports rapid detection in high-speed manufacturing environments.

3. Reducing Equipment Downtime

Since inductive sensors are non-contact and solid-state devices, they experience minimal mechanical wear, resulting in fewer failures and longer operational life. This durability reduces unplanned downtime and maintenance costs key goals in smart factory initiatives.

4. Supporting Condition-Based Maintenance

In smart factories, maintenance is shifting from reactive to condition-based strategies. Inductive sensors can monitor critical parameters such as movement frequency or object alignment. By integrating them into the asset management system, factories can schedule maintenance only when needed, minimizing unnecessary interruptions.

5. Integrating Seamlessly with IIoT Platforms

Modern inductive proximity sensors are compatible with Industry 4.0 technologies. Some models feature IO-Link communication capabilities, allowing enhanced diagnostics, remote configuration, and digital integration with Industrial Internet of Things (IIoT) platforms.

6. Enhancing Workplace Safety

Safety is non-negotiable in any factory. Inductive sensors contribute by ensuring that machinery does not operate unless metallic guards, covers, or components are correctly positioned. They can also identify unauthorized movements and help prevent potential safety hazards.

Applications in Smart Factory Environments

Robotic Systems: Detect arm positioning and part alignment.

Conveyor Belts: Monitor object flow and jam conditions.

Packaging Lines: Trigger quality checks or rejection mechanisms.

CNC Machines: Sense tool presence or part loading.

Automated Assembly: Verify metallic components at each stage.

❓ Frequently Asked Questions (FAQs)

Q1. What is the typical sensing range of an inductive sensor? Sensing ranges vary based on size and target material but generally range from 1 mm to 40 mm. Larger sensors or specialized designs can detect objects at greater distances.

Q2. How are these sensors integrated into automation systems? They can be connected directly to PLCs, control relays, or smart controllers. For Industry 4.0 setups, IO-Link-enabled sensors provide digital communication and advanced diagnostics.

Q3. Do inductive sensors require regular maintenance? They are generally maintenance-free. However, periodic visual checks for physical damage or debris accumulation are recommended for optimal performance.

Conclusion Inductive proximity sensors are silent enablers of smart factory automation. Their precision, durability, and compatibility with IIoT systems make them indispensable tools for enhancing productivity, ensuring safety, and driving digital transformation on the modern factory floor.

#inductive proximity sensors#inductive proximity sensor#inductive sensors#proximity sensors#inductive proximity sensors in lexington

0 notes

Text

How New Development in Garner, NC Is Driving Demand for Smart AC Repairs

Garner, NC, once a quiet suburban town just south of Raleigh, is now experiencing a boom in residential and commercial development. With new neighborhoods, mixed-use spaces, and businesses rapidly emerging, local infrastructure and home systems are being put to the test. One area seeing significant pressure? Air conditioning systems—specifically, smart AC units.

As homes and businesses upgrade to modern HVAC technology, the need for smart AC repairs in Garner is on the rise. At AC Today Heating and Air Conditioning, we’ve seen firsthand how these changes are reshaping our service calls and driving demand for fast, reliable, and tech-savvy AC repair solutions.

The Growth of Garner: What’s Happening?

Over the past few years, Garner has become a magnet for families, professionals, and developers alike. Proximity to Raleigh, access to top-tier schools, and a strong sense of community have fueled new housing developments and revitalization projects. With the construction of energy-efficient homes and the integration of smart home technologies, most new properties are now equipped with advanced HVAC systems.

These systems are designed to offer better energy efficiency, remote control access, and enhanced climate control. However, with new technology comes a new level of complexity when things go wrong.

Why Smart AC Systems Require Specialized Repairs

Smart air conditioning systems differ significantly from traditional units. They’re equipped with IoT (Internet of Things) components, smart thermostats, and mobile integration features that allow homeowners to control temperature, humidity, and airflow from their smartphones.

But these benefits can quickly become frustrations when:

Software glitches interfere with thermostat connections

Sensors malfunction or become miscalibrated

Wi-Fi connectivity issues disable remote access

Complex system updates disrupt performance

For many homeowners, a quick fix isn't always possible without the right expertise. That’s where AC Today Heating and Air Conditioning steps in.

How We’re Supporting Garner’s Growth

At AC Today Heating and Air Conditioning, we’ve invested in ongoing training and tools that allow our technicians to diagnose and repair both legacy HVAC systems and cutting-edge smart AC units. We’re proud to be one of the few locally owned HVAC providers in Garner equipped to handle these types of advanced repairs.

Whether you live in a new development like Oak Park, Clifford Grove, or a modernized home in Downtown Garner, our team has the experience and technical know-how to keep your smart HVAC systems running smoothly. We provide:

Smart thermostat troubleshooting (Nest, Ecobee, Honeywell, etc.)

Wi-Fi and connectivity issue resolution

Sensor calibration and replacement

Software and firmware updates

Routine maintenance and emergency repairs

As new developments continue to shape the town’s landscape, having a trusted HVAC partner who understands smart technology is more essential than ever.

Local Insight, Tech Expertise

Unlike national HVAC chains, we live and work right here in the Garner, North Carolina community. We understand the unique challenges that come with new construction, seasonal humidity, and rapidly growing demand on HVAC systems. Our commitment is to provide fast, honest, and expert-level service with every call—no matter how advanced the system.

We’ve already helped hundreds of homeowners across Garner adapt to the demands of smart living, and we’re ready to help you too.

Don’t Let a Smart AC Become a Smart Headache

If your smart AC system is acting up, running inefficiently, or failing to respond to remote controls, it’s time to bring in the experts. Let AC Today Heating and Air Conditioning handle the problem before it turns into a costly repair—or a sweaty summer.

AC Today Heating and Air Conditioning

187 Donmoor Ct, Garner, NC 27529

(919) 335-9030

0 notes

Text

Hall-Effect Sensors Market Growth Analysis, Market Dynamics, Key Players and Innovations, Outlook and Forecast 2025-2032

The global Hall-Effect Sensors market size was valued at USD 1,664 million in 2024. The market is projected to grow from USD 1,728 million in 2025 to USD 2,226 million by 2032, exhibiting a CAGR of 3.9% during the forecast period.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/1881/hall-effect-sensors-2025-2032-257

Hall-effect sensors are transducers that detect magnetic fields by measuring the Hall voltage generated across a conductor when current flows through it. These sensors enable contactless measurement of position, speed, and current while offering high reliability and durability. Key variants include Hall position sensors, speed sensors, switches, and current sensors, which find extensive applications across automotive, consumer electronics, and industrial automation sectors.

The global Hall-Effect sensors market is gaining strong momentum as industries increasingly adopt magnetic field sensing technologies for precision, reliability, and non-contact measurement. These sensors, which detect the presence, strength, and direction of magnetic fields, are integral to a wide range of applications from automotive electronics and industrial automation to consumer electronics and medical devices. With the growing shift toward electrification, smart devices, and safety-critical systems, Hall-Effect sensors are being embedded into electric vehicles (EVs), robotics, and IoT-enabled platforms to enable accurate position, speed, and current sensing. As demand for energy-efficient and miniaturized sensor solutions accelerates, Hall-Effect technologies are emerging as a foundational element in next-generation electronics and automation ecosystems.

MARKET DYNAMICS

MARKET DRIVERS

Widespread Adoption in Electric Vehicles to Accelerate Hall-Effect Sensor Demand

The automotive industry's rapid transition toward electric vehicles (EVs) represents a pivotal growth driver for Hall-effect sensors. Modern EVs utilize between 50-100 position and speed sensors per vehicle for critical functions including motor control, pedal position sensing, and battery management. Electric car sales neared 14 million in 2023, 95% of which were in China, Europe and the United States, this creates substantial demand for reliable magnetic sensing solutions. Hall-effect technology is particularly favored in automotive applications due to its contactless operation, immunity to environmental contaminants, and ability to function in harsh conditions. Leading manufacturers are responding with specialized automotive-grade sensors featuring reinforced packaging and extended temperature ranges up to 150°C.

Industry 4.0 Advancements Fueling Industrial Automation Sensor Deployment

The rise of Industry 4.0 is transforming manufacturing landscapes by embedding intelligence, connectivity, and automation deep into production systems and Hall-Effect sensors are playing a vital role in this transformation. These sensors are increasingly deployed in industrial machinery to enable precise, real-time monitoring of motor rotation, conveyor belt movement, robotic joint positions, and current flow in automated lines.

One notable example is Siemens’ Digital Industries division, which integrates Hall-Effect sensors in its advanced motor control units and servo drives to enhance predictive maintenance and reduce downtime. Similarly, ABB and Fanuc utilize Hall-based position and proximity sensors in robotic arms to improve movement accuracy and operational safety.

Hall-Effect sensors are especially valued in industrial automation because they work without physical contact. This means there’s less mechanical wear and tear, which helps them last longer. Plus, they perform reliably even in tough factory conditions like dust, moisture, or constant vibration where traditional sensors might struggle.Moreover, the convergence of Industrial Internet of Things (IIoT) and digital twins is boosting demand for sensors that can feed continuous, real-time data into cloud-based monitoring systems. Hall-Effect sensors, when combined with edge computing and wireless protocols, are enabling smart machines to self-monitor, optimize energy consumption, and predict failures key pillars of a modern Industry 4.0 ecosystem.

For instance, in 2024, Rockwell Automation deployed Hall-Effect-based linear position sensors in its iTRAK intelligent track system, allowing manufacturers in the packaging and pharmaceutical sectors to achieve high-speed, precise product handling with minimal mechanical wear and real-time system diagnostics.

Miniaturization Trend in Consumer Electronics Creating New Application Frontiers

Consumer electronics manufacturers increasingly adopt Hall-effect sensors for novel applications requiring ultra-compact form factors. The global smartphone market alone consumes over 4 billion sensors annually, with Hall-effect ICs enabling key functions like flip cover detection, camera positioning, and button replacement. New generations of miniature sensors measuring below 1mm² combined with ultra-low power consumption (under 1μA) are enabling innovative designs in wearable devices and IoT products. The push for thinner devices and waterproof constructions favors Hall-effect technology over mechanical alternatives. Emerging applications such as contactless user interfaces and precision movement tracking in AR/VR devices present significant growth opportunities.

MARKET RESTRAINTS

Magnetic Interference Issues Limiting Adoption in Critical Applications

While Hall-effect sensors offer numerous benefits, their fundamental operating principle makes them susceptible to external magnetic interference. Stray magnetic fields from nearby electric motors or power lines can cause measurement errors exceeding 10% in some industrial environments. This limitation restricts their adoption in precision medical equipment and aerospace applications where measurement accuracy is critical. Development teams must incorporate shielding solutions or complex compensation algorithms, increasing system cost and complexity. The problem becomes particularly acute in compact electronics where physical separation from interference sources is impractical.

MARKET CHALLENGES

Intense Pricing Pressure from Alternative Technologies

The Hall-effect sensor market faces growing competition from emerging sensing technologies including anisotropic magnetoresistance (AMR) and giant magnetoresistance (GMR) solutions. While Hall-effect maintains advantages in cost-effectiveness for many applications, competing technologies increasingly offer higher sensitivity and better noise immunity. Manufacturers must balance performance improvements with aggressive cost reduction targets, particularly in price-sensitive consumer markets where sensor pricing has fallen 28% over the past five years. This environment creates significant profitability challenges, especially for smaller players lacking economies of scale.

MARKET OPPORTUNITIES

Emerging IoT and Smart Infrastructure Applications Present Growth Potential

The rapid expansion of IoT networks and smart city infrastructure creates substantial opportunities for innovative Hall-effect sensor implementations. Smart utility meters, building automation systems, and predictive maintenance solutions collectively represent a potential market of $820 million for magnetic sensing technologies. Emerging applications include tamper detection in smart meters, position monitoring in automated HVAC systems, and vibration sensing in structural health monitoring. The combination of ultra-low power Hall-effect ICs with energy harvesting techniques enables completely wireless installations, a critical requirement for many IoT deployments. Market leaders are developing specialized sensor nodes with integrated wireless connectivity to address these growing segments.

September, 2023, Melexis launched the MLX91230, a 3rd-generation open‑loop Hall-effect DC current sensor offering ±0.5 % accuracy over temperature and lifetime. It features integrated voltage and temperature sensing (IVT), embedded microcontroller, galvanic isolation, AEC‑Q100 Grade 1 and ASIL-D safety compliance ideal for EV battery systems and industrial control.

HALL-EFFECT SENSORS MARKET TRENDS

Adoption in Automotive Electrification to Drive Market Growth

The automotive sector is experiencing a seismic shift toward electrification and automation, significantly boosting demand for Hall-effect sensors. With electric vehicle production projected to reach over 26 million units annually by 2030, these sensors have become indispensable for critical functions like motor control, battery management, and throttle positioning. Modern EVs utilize an average of 15-20 Hall-effect sensors per vehicle, compared to just 5-8 in traditional combustion engines. Advanced driver-assistance systems (ADAS) further amplify this demand, requiring high-precision position and speed detection for features like automatic braking and lane keeping.

For example, Tesla, BYD, and Volkswagen integrate Hall-based current and position sensors into their battery management systems (BMS) and electric drivetrain components to optimize performance and ensure safe operation. Additionally, Tier-1 suppliers such as Bosch and Denso are actively developing automotive-grade Hall-Effect sensors for applications including torque sensing, steering angle detection, and inverter current monitoring.

Other Trends

Miniaturization in Consumer Electronics

The relentless push for smaller, smarter devices continues to reshape the industry. Smartphone manufacturers now integrate multiple Hall-effect sensors for features like flip-to-sleep functionality, while wearables leverage them for ultra-low-power position detection. Industry leaders are developing MEMS-based Hall sensors measuring under 0.5mm², enabling breakthrough applications in hearables and IoT devices. This trend aligns with the broader industry movement toward sensor fusion, where Hall-effect components increasingly combine with accelerometers and gyroscopes to deliver richer contextual awareness.

Industrial IoT and Smart Manufacturing Evolution

Industry 4.0 initiatives are driving widespread sensor deployment across factory automation systems. Hall-effect sensors play pivotal roles in condition monitoring, with predictive maintenance algorithms analyzing magnetic field patterns to forecast equipment failures. The industrial segment now accounts for over 35% of sensor deployments, particularly in motor-driven applications where contactless operation prevents mechanical wear. Recent advancements include self-calibrating sensors with ±0.1° angular accuracy for robotic arms, alongside high-temperature variants capable of withstanding 150°C environments in heavy machinery.

COMPETITIVE LANDSCAPE

Key Industry Players

Leading Companies Focus on Technological Advancements to Gain Competitive Edge

The global Hall-Effect Sensors market features a moderately consolidated competitive landscape, dominated by major semiconductor manufacturers and specialized sensor providers. Allegro MicroSystems currently leads the market with an estimated 22% revenue share in 2024, attributed to its comprehensive product portfolio covering automotive and industrial applications. The company's strong position stems from continuous innovation in high-performance current sensor ICs and position sensors.

Infineon Technologies and Texas Instruments follow closely, collectively accounting for approximately 30% of the market share. These companies benefit from their vertically integrated manufacturing capabilities and strong R&D investments in next-generation Hall-Effect solutions. Their ability to provide customized sensor solutions across multiple industries gives them a distinct competitive advantage.

Meanwhile, Melexis and NXP Semiconductors are focusing on miniaturization and energy efficiency to capture the growing demand from consumer electronics and IoT applications. Both companies have recently introduced ultra-low-power Hall-Effect sensors with integrated signal conditioning, addressing the need for battery-powered devices.

The market also features emerging players from Asia-Pacific such as Suzhou Novosense Microelectronics and Shanghai Orient-Chip Technology who are gaining traction through cost-effective solutions for domestic automotive and industrial automation markets. These companies are particularly strong in the mid-range sensor segment, competing through competitive pricing and localized support networks.

April, 2025, Diodes Incorporated launched the AH4930Q, a 3D linear Hall‑effect sensor delivering ultra‑low power (13 µA) operation, I²C interface, and triple‑axis sensing (X, Y, Z). AEC‑Q100 Grade‑1 qualified and equipped with on‑chip temperature compensation, it’s ideal for automotive interior controls like knobs, stalks, and selectors.

February, 2024, Allegro MicroSystems unveiled its new high-bandwidth Hall‑Effect current sensors (ACS37030/ACS37032) tailored for automotive and industrial power systems. These core‑less solutions offer ≈1 % accuracy, ultra-low noise, rapid response, and compact, AEC‑Q100-qualified packages, optimized for GaN/SiC inverters, EV drives, and clean-energy applications.

October, 2023, Allegro MicroSystems completed its acquisition of Crocus Technology for $420 million in cash, integrating high-performance TMR (Tunnel Magnetoresistance) sensor IP including 200+ patents into its automotive and industrial sensing portfolio, reinforcing its leadership in precision magnetic sensing.

List of Key Hall-Effect Sensor Companies Profiled

· Allegro MicroSystems (U.S.)

· Melexis (Belgium)

· Infineon Technologies (Germany)

· TDK Corporation (Japan)

· Asahi Kasei Microdevices (Japan)

· NXP Semiconductors (Netherlands)

· ams OSRAM (Austria)

· Texas Instruments (U.S.)

· Diodes Incorporated (U.S.)

· Suzhou Novosense Microelectronics (China)

· Honeywell (U.S.)

· TE Connectivity (Switzerland)

· Shanghai Orient-Chip Technology (China)

· MEMSIC Semiconductor (U.S.)

· Analog Devices (U.S.)

Segment Analysis:

By Type

The market is segmented based on type into:

· Linear Hall-Effect Sensor

· Threshold (Digital) Hall-Effect Sensor

· Bipolar Hall Sensors

· Unipolar Hall Sensors

· Omnipolar Hall Sensors

By OIutput Type

The market is segmented based on output type into:

· Analog Output

· Digital Output

· PWM (Pulse Width Modulation) Output

By Technology

The market is segmented based on Technology into:

· Bipolar Technology

· CMOS Technology

· BiCMOS Technology

· Microsystem (MEMS)-based Hall Sensors

By Application

Automotive and Transportation Segment Dominates Due to Increasing Vehicle Electrification

The market is segmented based on application into:

· Automotive and Transportation

· Industrial Automation

· Consumer Electronics

· Aerospace & Defense

· Medical Devices

· Others

Regional Analysis: Hall-Effect Sensors Market

North America North America is a mature yet high-growth region for Hall-effect sensors, driven by advanced automotive electrification and industrial automation initiatives. The U.S. contributes over 60% of regional demand, with major automakers integrating these sensors for applications like position sensing in EV motors and gearbox controls. Stringent safety regulations, such as NHTSA mandates, further propel adoption in automotive systems. The region also benefits from strong R&D investments in IoT and Industry 4.0, particularly in MEMS-based Hall sensors with lower power consumption. However, supply chain disruptions and reliance on Asian semiconductor fabs pose intermittent challenges to market stability.

Europe Europe’s market thrives on green energy transitions and automotive electrification, with the EU’s “Fit for 55” package accelerating demand for Hall-effect sensors in renewable energy systems and EV drivetrains. Germany leads in industrial applications, where sensor-enabled smart manufacturing aligns with Industry 4.0 standards. A notable trend is the shift toward integrated Hall ICs combining sensing and signal conditioning, reducing system complexity. While growth is steady, high production costs and competition from Asian suppliers pressure local manufacturers to prioritize innovation in ruggedized sensors for harsh environments like wind turbines and railway systems.

Asia-Pacific Asia-Pacific dominates global volume, accounting for over 45% of shipments, fueled by China’s EV boom and Japan’s precision electronics sector. China’s focus on domestic semiconductor self-sufficiency has led to rising investments in Hall-sensor production, with firms like Shanghai Orient-Chip expanding capacity. India’s automotive and appliance sectors are emerging demand hotspots, though price sensitivity favors conventional sensor types. The region also sees rapid adoption in consumer electronics, particularly for smartphone compasses and flip-cover detection. Challenges include inconsistent quality in mid-tier products and intellectual property disputes, but the sheer scale of manufacturing activity ensures long-term growth.

South America South America shows niche potential, with Brazil and Argentina driving demand through automotive OEM partnerships and industrial equipment modernization. The region’s reliance on imported sensors, however, makes it vulnerable to currency fluctuations and supply chain delays. Local production is minimal, but initiatives like Argentina’s semiconductor incentives aim to reduce dependency. Key applications include current sensing in renewable energy inverters and position detection in agricultural machinery. While growth is slower compared to other regions, rising FDI in manufacturing could unlock future opportunities.

Middle East & Africa The MEA market is nascent but evolving, with the UAE and Saudi Arabia investing in smart infrastructure and industrial digitization. Hall sensors are increasingly used in HVAC systems, oil & gas flow meters, and automotive safety features. Africa’s growth is hindered by limited local expertise and fragmented supply chains, though demand for aftermarket automotive sensors is rising. The region’s focus on renewable energy projects, such as solar farms, could drive demand for current sensors in power management systems. While regulatory frameworks are underdeveloped, partnerships with global suppliers are gradually improving market access.

Report Scope

This market research report offers a holistic overview of global and regional markets for the forecast period 2025–2032. It presents accurate and actionable insights based on a blend of primary and secondary research.

Key Coverage Areas:

· ✅ Market Overview

o Global and regional market size (historical & forecast)

o Growth trends and value/volume projections

· ✅ Segmentation Analysis

o By product type or category

o By application or usage area

o By end-user industry

o By distribution channel (if applicable)

· ✅ Regional Insights

o North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

o Country-level data for key markets

· ✅ Competitive Landscape

o Company profiles and market share analysis

o Key strategies: M&A, partnerships, expansions

o Product portfolio and pricing strategies

· ✅ Technology & Innovation

o Emerging technologies and R&D trends

o Automation, digitalization, sustainability initiatives

o Impact of AI, IoT, or other disruptors (where applicable)

· ✅ Market Dynamics

o Key drivers supporting market growth

o Restraints and potential risk factors

o Supply chain trends and challenges

· ✅ Opportunities & Recommendations

o High-growth segments

o Investment hotspots

o Strategic suggestions for stakeholders

· ✅ Stakeholder Insights

o Target audience includes manufacturers, suppliers, distributors, investors, regulators, and policymakers

FREQUENTLY ASKED QUESTIONS:

▶ What is the current market size of Global Hall-Effect Sensors Market?

The Global Hall-Effect Sensors market was valued at USD 1,664 million in 2024 and is projected to reach USD 2,226 million by 2032, growing at a CAGR of 3.9% during the forecast period.

▶ Which key companies operate in Global Hall-Effect Sensors Market?

Key players include Allegro MicroSystem, Melexis, Infineon, TDK, Asahi Kasei Microdevices, NXP, ams OSRAM, Texas Instruments, and Honeywell, among others.

▶ What are the key growth drivers?

Key growth drivers include rising demand in automotive applications (especially electric vehicles), increasing adoption in consumer electronics, and industrial automation trends under Industry 4.0.

▶ Which region dominates the market?

Asia-Pacific leads the market share (over 40% in 2024), driven by China's manufacturing dominance, while North America shows strong growth in automotive and industrial applications.

▶ What are the emerging trends?

Emerging trends include integration with IoT systems, development of MEMS-based Hall sensors, and increasing demand for energy-efficient sensor solutions across industries.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/1881/hall-effect-sensors-2025-2032-257

https://www.rumorcircle.com/blogs/128058/Pressure-Swing-Adsorption-PSA-Technology-Market-2025https://hasster.com/blogs/153979/AR-Optical-Waveguide-Module-Market-Growth-Analysis-2025https://hasster.com/blogs/153983/Auto-Catalysts-Market-Growth-Analysis-2025https://hasster.com/blogs/153984/Automotive-Air-Conditioning-Electric-Compressors-Market-Growth-Analysis-2025https://hasster.com/blogs/153988/Corporate-E-learning-Market-Growth-Analysis-Market-Dynamics-2025https://hasster.com/blogs/153992/Cyber-Security-Training-Market-Growth-Analysis-Market-Dynamics-2025https://hasster.com/blogs/153993/Copper-Plating-Solutions-for-Semiconductor-Manufacturing-2025

0 notes

Text

Magnetic Sensor Market Driven by Emerging Technologies in Automotive and Industrial Applications

The magnetic sensor market is witnessing significant growth, driven by advancements in automotive, consumer electronics, and industrial automation sectors. These sensors, which detect changes and disturbances in magnetic fields, play a crucial role in modern applications—from navigation systems and smart phones to industrial equipment and electric vehicles. As industries shift toward automation, smart systems, and green mobility, the demand for highly sensitive and reliable magnetic sensors continues to surge globally.

Market Overview

Magnetic sensors are used for measuring parameters such as speed, proximity, position, and direction. These sensors fall into different categories—primarily Hall Effect sensors, magneto-resistive sensors, and SQUID (superconducting quantum interference devices)—each tailored to specific needs. The global magnetic sensor market has been expanding steadily and is projected to continue its upward trend over the next decade.

One of the key growth drivers is the automotive industry, especially with the rise in demand for electric and hybrid vehicles. Magnetic sensors are extensively used in automotive applications for ignition timing, throttle position, gear shifting, anti-lock braking systems (ABS), and motor control. With global regulations pushing for cleaner transport solutions, electric vehicles (EVs) are becoming mainstream, thereby boosting sensor integration.

Technological Advancements

Magnetic sensor technologies have significantly improved in recent years, resulting in smaller, more energy-efficient, and more accurate devices. The integration of MEMS (Micro-Electro-Mechanical Systems) has further accelerated the development of compact, low-power, and high-performance magnetic sensors. Additionally, the rise in IoT (Internet of Things) and AI-based devices has led to a higher need for precise sensor feedback, pushing manufacturers to innovate and enhance product quality.

Tunneling Magnetoresistance (TMR) and Giant Magnetoresistance (GMR) are examples of sensor types gaining traction for their sensitivity and ability to operate in harsh environments. These are widely used in industrial applications, particularly in robotics and automation systems, where reliability is critical.

Regional Insights

North America and Europe are mature markets with a strong presence of leading sensor manufacturers and extensive R&D infrastructure. The Asia-Pacific region, however, is emerging as the fastest-growing market, led by countries like China, Japan, and South Korea. These nations have rapidly developing electronics industries and are aggressively adopting electric vehicles and smart manufacturing technologies.

China, for instance, is not only a major producer of electronic components but also a top EV market, which significantly boosts the domestic demand for magnetic sensors. Japan’s expertise in automotive and robotics further strengthens its position in this sector.

Market Challenges

Despite growth prospects, the magnetic sensor market faces challenges. Price competition among key players, especially in cost-sensitive regions, can limit profitability. Additionally, supply chain disruptions for rare earth materials—often used in sensor production—can hinder manufacturing.

There’s also a constant need for miniaturization without compromising performance, particularly for consumer electronics. This puts pressure on R&D teams and increases product development costs. Companies that fail to innovate risk losing their market share to agile competitors who prioritize advanced technologies.

Key Players and Competitive Landscape

Major companies in the magnetic sensor market include TDK Corporation, Honeywell International Inc., Infineon Technologies AG, STMicroelectronics, and Allegro MicroSystems. These players focus on innovation, mergers, and acquisitions to strengthen their product portfolio and expand geographically.

For instance, STMicroelectronics continues to develop state-of-the-art Hall effect sensors for automotive and industrial uses, while Honeywell's sensors are known for their robustness in aerospace and defense applications.

Startups and SMEs are also contributing to market dynamism, often targeting niche applications or offering customized sensor solutions for emerging industries like wearable tech, drone navigation, and renewable energy.

Future Outlook

The future of the magnetic sensor market appears promising. As the world leans more toward automation, digitalization, and sustainability, the role of precise sensing technology becomes increasingly important. From smart cities and Industry 4.0 to autonomous vehicles and advanced healthcare diagnostics, magnetic sensors are poised to play a pivotal role in enabling intelligent, responsive, and efficient systems.

The integration of AI and machine learning in sensor platforms could open new opportunities, especially in predictive maintenance and real-time decision-making. The trend toward sensor fusion—combining data from multiple sensor types—will also boost performance and open new application avenues.

In conclusion, the magnetic sensor market is on a robust growth trajectory, supported by technological innovation and increasing demand across multiple sectors. As industry challenges are addressed through strategic investments and R&D, the market is expected to expand steadily, transforming how machines, vehicles, and systems interact with their environment.

0 notes

Text

Magnetic Sensor Market Forecast to Reach USD 8–9 Billion by 2032

Magnetic Sensors Market to Exceed USD 8 Billion by 2033, Driven by EV, Automation, and Smart Tech Demand

The Magnetic Sensors Market, valued at approximately USD 4.5 billion in 2024, is expected to grow steadily and reach USD 8–9 billion by 2033. This expansion reflects a compound annual growth rate (CAGR) of 6–8%, fueled by the rapid proliferation of electric vehicles, advancements in industrial automation, rising demand in consumer electronics, and growing Internet of Things (IoT) applications.

To Get Free Sample Report : https://www.datamintelligence.com/download-sample/magnetic-sensors-market

Key Market Drivers

1. Automotive Industry Electrification As the shift toward electric and hybrid vehicles continues, magnetic sensors play a central role in applications like anti-lock braking systems (ABS), steering angle detection, throttle position sensing, and battery management. The integration of advanced driver assistance systems (ADAS) is also driving demand for highly accurate Hall-effect and magnetoresistive sensors.

2. Rise in Consumer Electronics and Wearables Miniaturized magnetic sensors are now standard in mobile phones, tablets, and wearable devices for functions like electronic compassing, gesture control, and spatial navigation. The trend toward compact, multifunctional smart devices is accelerating demand across OEMs and component suppliers.

3. Industry 4.0 and Smart Manufacturing Magnetic sensors support real-time monitoring in industrial automation environments. They provide position, proximity, and rotational speed feedback in CNC machinery, robotic arms, elevators, and conveyor systems ensuring accurate performance in dynamic manufacturing conditions.

4. Growth in Renewable and Clean Energy Applications Magnetic sensors are used in wind turbine pitch systems, solar panel tracking, and electric grid condition monitoring. As global investment in renewable energy infrastructure rises, these sensors are increasingly vital to system control and energy efficiency.

Technology Segmentation & Market Trends

Hall-Effect Sensors Dominate Hall-effect sensors accounted for more than 50% of global revenue in 2023. They are valued for their reliability, compact design, and broad applicability in automotive and consumer electronics.

Magnetoresistive Sensors Gaining Ground Giant magnetoresistive (GMR) and tunneling magnetoresistive (TMR) sensors are being adopted for high-precision, low-power applications in robotics, medical devices, and automation control systems.

MEMS-Based Magnetic Sensors and 3D Integration Microelectromechanical systems (MEMS) magnetic sensors are enabling ultra-compact, low-cost 3D field sensing in smartphones and wearables. Their rise is central to the IoT movement and portable device innovation.

Regional Market Insights

Asia-Pacific Leads Global Demand Asia-Pacific dominates with over 45% market share, led by China, Japan, and South Korea. The region’s strong consumer electronics production base and leadership in electric vehicle manufacturing have solidified its position. Japan, in particular, has advanced high-end magnetic sensor design and exports globally.

United States Market Outlook The U.S. magnetic sensors market is driven by continued growth in ADAS development, aerospace and defense technologies, and industrial digitalization. Strong R&D investments and manufacturing automation have boosted adoption in both the public and private sectors.

European Innovation and Regulation Europe’s automotive innovation and renewable energy initiatives fuel magnetic sensor use. Germany, in particular, drives demand through automotive mechatronics, factory robotics, and wind energy monitoring systems.

Emerging Growth Opportunities

Automated Guided Vehicles (AGVs) and Drones Magnetic sensors are essential for orientation and obstacle navigation. Growth in smart logistics, drone surveillance, and delivery services is enhancing their role in autonomous guidance.

Healthcare & Medical Imaging In MRI systems and wearable diagnostic devices, magnetic sensors are crucial for position tracking and motion compensation. Sensor miniaturization is expanding opportunities in health monitoring devices.

High-Precision Robotics Sensors enabling feedback-controlled movement in robotics and cobots (collaborative robots) are opening high-value industrial and defense applications.

Smart Infrastructure and Building Automation In smart buildings, magnetic sensors are used for security (door/window detection), elevator systems, and HVAC control offering energy-saving advantages and enhanced monitoring.

Get the Demo Full Report : https://www.datamintelligence.com/enquiry/magnetic-sensors-market

Challenges in the Market

Price Pressure and Commoditization: Low-cost alternatives in saturated markets can hinder profit margins and innovation incentives.

Magnetic Interference Issues: High electromagnetic noise environments can disrupt performance unless proper shielding and design optimization are applied.

Raw Material Supply Risks: The availability of rare earth materials impacts sensor magnet production, making the industry vulnerable to geopolitical shifts.

Stringent Automotive and Industrial Certification: Reliability and safety standards for automotive-grade sensors require long testing cycles, increasing time to market for new products.

Conclusion

The global magnetic sensors market is evolving rapidly, supported by strong demand from automotive systems, consumer electronics, industrial automation, and renewable energy technologies. With a projected valuation surpassing USD 8–9 billion by 2033, the sector offers promising opportunities for sensor manufacturers, OEMs, and system integrators.

As technology continues to evolve, innovations in magnetoresistive and MEMS-based sensor designs will unlock new capabilities, while advanced signal processing and integration techniques will further elevate sensor precision and versatility. Key players investing in scalable manufacturing, regional expansion, and application-specific R&D will lead the next era of magnetic sensing solutions.

0 notes

Text

0 notes

Text

Magnetic Sensitive Transistor Market 2025-2032

The global Magnetic Sensitive Transistor Market size was valued at US$ 124 million in 2024 and is projected to reach US$ 178 million by 2032, at a CAGR of 5.2% during the forecast period 2025-2032

Magnetic Sensitive Transistor Market Overview

The U.S. market size for Magnetic Sensitive Transistors is estimated at USD 120 million in 2024, while China’s market is projected to reach USD 210 million in the same year.

The Germanium Magnetotransistor segment is expected to reach USD 350 million by 2032, growing at a CAGR of 7.2% during the forecast period 2026–2032.

We have surveyed the Magnetic Sensitive Transistor manufacturers, suppliers, distributors, and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks This report aims to provide a comprehensive presentation of the global market for Magnetic Sensitive Transistor, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Magnetic Sensitive Transistor. This report contains market size and forecasts of Magnetic Sensitive Transistor in global, including the following market information:

Global Magnetic Sensitive Transistor market revenue, 2020-2025, 2026-2032, ($ millions)

Global Magnetic Sensitive Transistor market sales, 2020-2025, 2026-2032, (Units)

Global top five Magnetic Sensitive Transistor companies in 2024 (%)

Receive Your Sample Report at No Cost-https://semiconductorinsight.com/download-sample-report/?product_id=97783

Magnetic Sensitive Transistor Key Market Trends :

Rising Demand in Automotive and Consumer Electronics: Increasing use of magnetic sensitive transistors in automotive sensors and consumer devices is driving market growth.

Shift Towards Silicon Magneto-Transistors: Silicon-based magnetotransistors are gaining popularity due to their cost-effectiveness and better integration with existing semiconductor technologies.

Growth in Contactless and Proximity Switch Applications: The expanding applications in contactless switching and proximity sensing boost the adoption of these transistors.

Advancements in Miniaturization and Sensitivity: Ongoing innovations improve transistor sensitivity while reducing size, enabling use in more compact electronic devices.

Expansion in Asia-Pacific Region: Rapid industrialization and growing electronics manufacturing in Asia-Pacific, especially China and India, contribute significantly to market growth.

Magnetic Sensitive Transistor Market Segmentation :

Global Magnetic Sensitive Transistor market, by Type, 2020-2025, 2026-2032 ($ millions) & (Units) Global Magnetic Sensitive Transistor market segment percentages, by Type, 2024 (%)

Germanium Magnetotransistor

Silicon Magneto-Transistor

Global Magnetic Sensitive Transistor market, by Application, 2020-2025, 2026-2032 ($ Millions) & (Units) Global Magnetic Sensitive Transistor market segment percentages, by Application, 2024 (%)

Magnetic Detection

Contactless Switch

Proximity Switch

Competitor Analysis The report also provides analysis of leading market participants including:

Key companies Magnetic Sensitive Transistor revenues in global market, 2020-2025 (estimated), ($ millions)

Key companies Magnetic Sensitive Transistor revenues share in global market, 2024 (%)

Key companies Magnetic Sensitive Transistor sales in global market, 2020-2025 (estimated), (Units)

Key companies Magnetic Sensitive Transistor sales share in global market, 2024 (%)

Further, the report presents profiles of competitors in the market, key players include:

NXP

DIODES

ON Semiconductor

WINGTEC

Vishay

Honeywell

Fairchild Semiconductor

JIEJEI MICROELECTRONICS

EVERLIGHT

Shenzhen Otis Electronics Co., Ltd.

Dongguan Pengzhixiang Electronics Co., Ltd.

Request Your Free Sample Report-https://semiconductorinsight.com/download-sample-report/?product_id=97783

FAQs

Q: What are the key driving factors and opportunities in the Magnetic Sensitive Transistor market? A: Key drivers include rising demand in automotive sensors, industrial automation, and technological advances. Opportunities lie in medical applications and smart consumer electronics.

Q: Which region is projected to have the largest market share? A: The Asia-Pacific region, especially China and India, is expected to hold the largest market share due to rapid industrialization and electronics manufacturing growth.

Q: Who are the top players in the global Magnetic Sensitive Transistor market? A: Leading companies include NXP, DIODES, ON Semiconductor, WINGTEC, Vishay, Honeywell, and Fairchild Semiconductor.

Q: What are the latest technological advancements in the industry? A: Innovations focus on miniaturization, improving sensitivity, and integration with silicon semiconductor technologies for cost-effective solutions.

Q: What is the current size of the global Magnetic Sensitive Transistor market? A: The market size was valued at US$ 124 million in 2024 and is projected to reach US$ 178 million by 2032, growing at a CAGR of 5.2%.

Related URL https://komal29singh.blogspot.com/2025/06/optical-spacer-market-2025-2032.html https://komal29singh.blogspot.com/2025/06/voice-coil-motor-driver-chips-market.html https://komal29singh.blogspot.com/2025/06/wet-cleaning-equipment-market-2025-2032.html https://komal29singh.blogspot.com/2025/06/lock-in-amplifier-module-market-2025.html https://komal29singh.blogspot.com/2025/06/phototube-market-2025-2032.html https://komal29singh.blogspot.com/2025/06/sequential-logic-circuit-market-2025.html https://komal29singh.blogspot.com/2025/06/gaas-low-noise-amplifier-market-2025.html https://komal29singh.blogspot.com/2025/06/glass-sealed-diode-thermistor-market.html https://komal29singh.blogspot.com/2025/06/smart-surge-protector-market-2025-2032.html https://komal29singh.blogspot.com/2025/06/surface-mount-technology-smt-sockets.html

0 notes

Text

part2 to 'stella re JMB two kiosks printing down billing upon receipts received on paper at POS line, where payment received, cash or electronic transaction. billing as legal entities, happening 20 meters away, at front-desk, using LCD screens, so if damaged, used by PAX, should be regarded as attacking the Treasury and the money, because everyone these days has a smartphone and a tablet, and punching force onto LCD screens is not justified as accident, so it be a deliberately use of excessive force onto computers of JUMBO. thus a real event security should be mentioning down in written, and NEVER does. and all be CCTV recorded, and available 45 days under law, then servers gradually erased, and gradually new CCTV streaming on. but paper registries at SECURITY holding all those DATA at least EIGHT years on, and inspecting policemen might be at some point reading all that, randomly. and all due to WAR in Ukraine which made Internal Affairs re-introduce paper-based tracking of Security activity. ignoring CCTV whatsoever, and electronic payslip proximity cards for shifts and labor purposes, too. another event 3rd kind, and more interesting, should be PERIMETER doors left unlocked and bypass-ed onto main-board of 40 doors armed for the night at shop premises locally, the fire-brigade also interested into that one, also. PERIMETER iron doors from ITALY, the three-ways of locking and arming redundancy, might be 20 of the 40 of JMB shop. applying paper seals, and sealing of such temporarily locked by iron chain and padlock, when battery failings noticed. that be EVENTS security registry and NEVER noted down, again. only when preservation of premises, conservation of premises such as MILKA Suchard sweets plant was during 2011, when Poiana and M&M moved into Bulgaria, and RAP (raptronic) bought warehouse and new spaces on Aeroportului ave at Ghimbav, leaving the Avram Iancu Cibo plant into preservation. only then applying paper seals onto buildings perimeter doors was tracked by SECURITY. and written down into the EVENTS registry the range of seals used during that shift. there were RANGE of SEALS and had to be written down, so at least ten minutes to write down doors and seals applied. and doors were indeed locked by way of padlocks, and magnetic door-trapping sensors ignored. and at night still melting chocolate entering a window, not using doors, and using electricity for melting oven, on a failsafe line, failover invoice pattern, w security chief signature, and sold under RAP and raptronic credencies, not MILKA Suchard, HORECA not shelf retail to PAX. JMB used such practice door 13, and had to bypass on the fire-board of sensors, where all 40 doors red LED if anything, and I WANTED LENEL ONGUARD software for 1,000 USD one year ago 2023, CARRIER Group. because they believed security was going to begin writing down PERIMETER battery failed events on magnetic sensors, inside the Events security registry. ten minutes of calligraphy. and 4-digit PIN issued for the exercise, and 20 minutes overtime on a Monday last week, and i had to go BANK ATM to check cash balance into my account, no BANK app onto my smartphone, just the ATM network at UniCredit Bank. and Bank showed 19.57 RON, and i was aware i should be 8 RON only, so ATM screen was showing 11 RON more cash!! and on tuesday next day i went shopping at end of shift at S2 night and above 8 RON, and chief cashier called for cancelling receipt over insufficient funds available 11 RON smth, less than 19.57 RON showed by ATM at Banking network 20h before. and chief cashiers made aware i was checking the BANKING ATMs and stop playing jokes on bypassing magnetic sensors on door 13 perimeter JMB, because timestamps onto my daily routes be ATM level and credencies, because am not using smartphone app. thus Vodafone GSM for 3rd party pooper. RANGE of SEALS to be written down by security would trigger SELGROS ARGO Ltd security too, so we be pampering them, we on a CAMPUS and that E60 level Airport road labeling, or E60 component, sort of Interstate I95, and campus. m

0 notes

Text

Global Magnetic Sensitive Transistor Market: Growth Outlook 2025–2032

Magnetic Sensitive Transistor Market Analysis:

The global Magnetic Sensitive Transistor Market size was valued at US$ 124 million in 2024 and is projected to reach US$ 178 million by 2032, at a CAGR of 5.2% during the forecast period 2025-2032

Magnetic Sensitive Transistor Market Overview

The U.S. market size for Magnetic Sensitive Transistors is estimated at USD 120 million in 2024, while China’s market is projected to reach USD 210 million in the same year.

The Germanium Magnetotransistor segment is expected to reach USD 350 million by 2032, growing at a CAGR of 7.2% during the forecast period 2026–2032.

We have surveyed the Magnetic Sensitive Transistor manufacturers, suppliers, distributors, and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks This report aims to provide a comprehensive presentation of the global market for Magnetic Sensitive Transistor, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Magnetic Sensitive Transistor. This report contains market size and forecasts of Magnetic Sensitive Transistor in global, including the following market information:

Global Magnetic Sensitive Transistor market revenue, 2020-2025, 2026-2032, ($ millions)

Global Magnetic Sensitive Transistor market sales, 2020-2025, 2026-2032, (Units)

Global top five Magnetic Sensitive Transistor companies in 2024 (%)

Magnetic Sensitive Transistor Key Market Trends :

Rising Demand in Automotive and Consumer Electronics: Increasing use of magnetic sensitive transistors in automotive sensors and consumer devices is driving market growth.

Shift Towards Silicon Magneto-Transistors: Silicon-based magnetotransistors are gaining popularity due to their cost-effectiveness and better integration with existing semiconductor technologies.

Growth in Contactless and Proximity Switch Applications: The expanding applications in contactless switching and proximity sensing boost the adoption of these transistors.

Advancements in Miniaturization and Sensitivity: Ongoing innovations improve transistor sensitivity while reducing size, enabling use in more compact electronic devices.

Expansion in Asia-Pacific Region: Rapid industrialization and growing electronics manufacturing in Asia-Pacific, especially China and India, contribute significantly to market growth.

Magnetic Sensitive Transistor Market Regional Analysis :

https://semiconductorinsight.com/wp-content/uploads/2025/01/download-34_11zon-1.png

North America:Strong demand driven by EVs, 5G infrastructure, and renewable energy, with the U.S. leading the market.

Europe:Growth fueled by automotive electrification, renewable energy, and strong regulatory support, with Germany as a key player.

Asia-Pacific:Dominates the market due to large-scale manufacturing in China and Japan, with growing demand from EVs, 5G, and semiconductors.

South America:Emerging market, driven by renewable energy and EV adoption, with Brazil leading growth.

Middle East & Africa:Gradual growth, mainly due to investments in renewable energy and EV infrastructure, with Saudi Arabia and UAE as key contributors.

Magnetic Sensitive Transistor Market Segmentation :

Global Magnetic Sensitive Transistor market, by Type, 2020-2025, 2026-2032 ($ millions) & (Units) Global Magnetic Sensitive Transistor market segment percentages, by Type, 2024 (%)

Germanium Magnetotransistor

Silicon Magneto-Transistor

Global Magnetic Sensitive Transistor market, by Application, 2020-2025, 2026-2032 ($ Millions) & (Units) Global Magnetic Sensitive Transistor market segment percentages, by Application, 2024 (%)

Magnetic Detection

Contactless Switch

Proximity Switch

Competitor Analysis The report also provides analysis of leading market participants including:

Key companies Magnetic Sensitive Transistor revenues in global market, 2020-2025 (estimated), ($ millions)

Key companies Magnetic Sensitive Transistor revenues share in global market, 2024 (%)

Key companies Magnetic Sensitive Transistor sales in global market, 2020-2025 (estimated), (Units)

Key companies Magnetic Sensitive Transistor sales share in global market, 2024 (%)

Further, the report presents profiles of competitors in the market, key players include:

NXP

DIODES

ON Semiconductor

WINGTEC

Vishay

Honeywell

Fairchild Semiconductor

JIEJEI MICROELECTRONICS

EVERLIGHT

Shenzhen Otis Electronics Co., Ltd.

Dongguan Pengzhixiang Electronics Co., Ltd.

Market Drivers

Increased Use in Automotive Safety Systems: Magnetic sensitive transistors are critical components in automotive sensors for safety, enhancing demand.

Rising Adoption in Industrial Automation: Growing industrial automation requires precise magnetic sensing, fueling market expansion.

Technological Improvements in Semiconductor Manufacturing: Enhanced production techniques reduce costs and improve performance, attracting wider usage.

Market Restraints

High Manufacturing Costs: Production of high-precision magnetic sensitive transistors can be costly, limiting adoption in price-sensitive markets.

Complexity in Integration: Integration of magnetic transistors with other systems poses design and compatibility challenges.

Competition from Alternative Technologies: Emerging sensor technologies like Hall-effect sensors may reduce market share for magnetic sensitive transistors.

Market Opportunities

Expansion in Medical and Healthcare Applications: Magnetic transistors can be utilized in non-invasive medical devices, opening new growth avenues.

Development of Smart Consumer Electronics: Increasing demand for smart gadgets with enhanced magnetic sensing capabilities offers opportunities.

Growth in Emerging Markets: Rapid urbanization and industrial growth in regions like Southeast Asia and Latin America provide new markets.

Market Challenges

Technological Barriers in Miniaturization: Achieving ultra-small sizes without compromising performance remains challenging.

Fluctuating Raw Material Prices: Variations in prices of semiconductor materials affect production costs and profitability.

Regulatory and Compliance Issues: Strict safety and environmental regulations may slow down product development and launch.

0 notes

Text

Birla Sector 71 Gurgaon | newly Launched Project

Birla Estates’ upcoming project in Sector 71, Gurugram unfolds as a refined expression of modern luxury, blending the trusted legacy of the Birla Group with contemporary design, green living, and best-in-class amenities. Spanning approximately five acres, this thoughtfully planned development offers spacious 2, 3, and 4 BHK apartments tailored for urban families and discerning investors alike, swiftly placing Sector 71 on Gurugram’s real estate map .

Strategically positioned along the Southern Peripheral Road, Birla Sector 71 Gurgaon provides seamless access to NH‑48, Dwarka Expressway, and Sohna Road, while linking directly to the future Delhi–Mumbai Expressway. The location affords effortless connectivity to Delhi, IGI Airport, and Cyber City, making it an attractive choice for professionals . A new 350 m connector between Sector 71 and 73 along SPR promises enhanced mobility within the area .

The neighbourhood is bolstered by proximity to top-tier schools like Ryan International and DPS, renowned hospitals including Medanta, Artemis, and Fortis, as well as shopping and lifestyle hubs such as Sapphire Mall, Raheja Mall, and Ambience Mall—offering everyday convenience and elevating the quality of life .

Architecturally, the project mirrors Birla Sector 71 dedication to precision and aesthetic finesse. Each home features cross-ventilation and abundant natural light enhanced by premium finishes like vitrified-tile living spaces, marble kitchen countertops, stainless-steel sinks, branded sanitary ware, and anti-skid bathroom tiles. Energy-efficient lighting and HVAC systems ensure comfort with a conscious eye on sustainability . The exterior displays a modern facade complemented by landscaped green pockets and open areas that invite both daily relaxation and social moments .

This project is enriched with a suite of amenities designed for wholesome living. A clubhouse featuring a gym, multipurpose hall, and yoga/spa zones caters to health and leisure, while a swimming pool with a children’s section and courts for tennis, badminton, and basketball serve fitness needs. Jogging and cycling tracks, children’s play zones, senior citizen decks, amphitheatre, and serene landscaped gardens foster strong community bonds .

Each apartment is equipped with smart-home features including app-controlled lighting, HVAC systems, smart locks, video door phones, and motion sensors—an integrated approach to comfort, convenience, and security . The project also promises robust safety with a gated entry, 24/7 CCTV surveillance, trained personnel, vehicle barriers, smart keycards, and fire safety systems in place .

Environmental responsibility is embedded in the design with rainwater harvesting, solar-powered street lighting, eco-friendly waste management, and energy-efficient fixtures. Lush green landscaping and public gardens reinforce the community’s eco-centric ethos .

Sector 71 is rapidly witnessing infrastructural growth and escalating property values, backed by rising demand for quality living and improved infrastructure. This makes Birla Sector 71 Gurgaon a magnetic option for capital appreciation and rental yield, especially with early-buyer pricing and RERA visibility . Flexible payment options tied to construction milestones, special early-bird offers, and financing support make premium living accessible to more families .

Guided by Birla Estates’ LifeDesigned® philosophy, this project reflects a holistic integration of location, layout, lifestyle, technology, and sustainability—all underpinned by the Birla Group’s reputation for transparent governance, quality construction, and timely delivery . Birla Sector 71 Gurgaon stands out not merely as a residential project but as a benchmark for sophisticated, smart, and sustainable living in Gurugram, offering residents an elevated urban lifestyle coupled with enduring investment potential.

0 notes

Text

Magnetic Field Sensors Market Size, Share, Trends, Growth and Competitive Outlook

Global Magnetic Field Sensors Market - Size, Share, Demand, Industry Trends and Opportunities

Global Magnetic Field Sensors Market, By Type (Hall Effect Sensors, Magneto Resistive Sensors, SQUID Sensors, Fluxgate Sensors, Others), Rnage (<1 Micro Gauss (Low-Field Sensors), 1 Micro Gauss–10 Gauss (Earth Field Sensors), >10 Gauss (BIAS Magnetic Field Sensors) Consoles), Application (Speed Sensing, Flow Rate Sensing, Detection, Position Sensing, Navigation And Electronic Compass, Others), End Users (Transportation, Consumer Electronics, BFSI, Healthcare, Aerospace and Defense, Industrial, Others Sectors), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends

Access Full 350 Pages PDF Report @

**Segments**

- **Technology**: The magnetic field sensors market can be segmented based on technology into Hall Effect, Giant Magnetoresistance (GMR), Tunnel Magnetoresistance (TMR), and others. Hall Effect sensors are commonly used for measuring magnetic fields and are utilized in applications like automotive, consumer electronics, and industrial automation. GMR sensors offer high sensitivity and accuracy, making them suitable for demanding applications such as medical equipment and aerospace. TMR sensors provide even greater sensitivity and are adopted in advanced applications where precision is critical.

- **Range**: Another key segmentation of the magnetic field sensors market is based on range, including low-range sensors, medium-range sensors, and high-range sensors. Low-range sensors are typically used for proximity sensing and object detection in smartphones, wearables, and IoT devices. Medium-range sensors find applications in navigation systems, robotics, and industrial control systems. High-range sensors are utilized in geophysical surveys, military applications, and scientific research where detecting extremely weak magnetic fields is essential.

- **Application**: The market for magnetic field sensors can also be segmented by application, with key areas including automotive, consumer electronics, industrial, healthcare, aerospace, and defense. In the automotive sector, these sensors are utilized for position sensing, torque sensing, and speed sensing in components such as steering systems and transmission systems. In consumer electronics, magnetic field sensors enable features like compasses in smartphones and tablets. The industrial sector relies on these sensors for motor control, flow meters, and security systems. In healthcare, magnetic field sensors are used in MRI machines and medical imaging equipment. Aerospace and defense applications include use in navigation systems, missile guidance systems, and satellite positioning.

**Market Players**

- **Allegro MicroSystems, LLC**: A leading player in the magnetic field sensors market, Allegro offers a wide range of Hall Effect sensors known for their high performance and reliability. The company serves various industries such as automotive, industrial, and consumer electronics.