#process water solutions

Explore tagged Tumblr posts

Text

Process Water Tanks in Australia

Efficient water management is essential for industrial operations, and process water tanks play a vital role in ensuring seamless functionality. COEP Enviro specializes in providing top-quality process water storage tanks in Australia, designed to meet the diverse needs of various industries. Our tanks are renowned for their durability, reliability, and customizability, making them the perfect choice for industrial applications.

Why Choose Process Water Tanks?

Our COEP Enviro tanks are engineered to deliver exceptional performance in demanding environments. Key benefits include:

Durability: Manufactured from premium materials to ensure longevity and withstand tough industrial conditions.

Customizability: Tailored designs to suit specific operational needs, including size, capacity, and layout.

Efficiency: Designed to optimize water storage and streamline processes for maximum productivity.

Applications of Process Water Tanks

Our process water storage tanks in Australia cater to a variety of industrial applications, such as:

Manufacturing: Supporting production lines, cooling systems, and cleaning processes.

Energy and Power: Providing water for boiler operations and cooling systems in power plants.

Mining: Assisting in ore processing, dust suppression, and equipment cleaning.

Agriculture: Supplying water for irrigation, livestock, and processing facilities.

Commercial Operations: Offering reliable water storage for large-scale commercial facilities.

Features of COEP Enviro Process Water Tanks

Our industrial water tanks Australia are built to meet the highest standards of quality and performance. Features include:

Corrosion Resistance: Protecting tanks against wear and ensuring long-term usability.

Scalable Solutions: Accommodating both small-scale and large-scale water storage needs.

Eco-Friendly Design: Supporting sustainable water usage practices.

Customizable Water Tanks for Specific Needs

At COEP Enviro, we understand that every industry has unique requirements. That’s why we offer customizable water tanks designed to address specific challenges. From capacity adjustments to specialized features, our tanks provide tailored solutions for your process water storage needs.

Why Partner with COEP Enviro?

COEP Enviro is a trusted provider of industrial process tanks in Australia. Our commitment to quality, innovation, and customer satisfaction sets us apart. By choosing our process water solutions, you invest in efficient and reliable storage systems that drive operational success.

Contact Us Today

Explore our range of process water tanks and discover how COEP Enviro can meet your industrial water storage needs. Contact us to learn more about our durable water tanks and customizable solutions in Australia.

#Process water tanks#process water storage tanks in Australia#COEP Enviro tanks#industrial water tanks Australia#process water solutions#durable water tanks#customizable water tanks#industrial process tanks Australia

0 notes

Text

We are being poisoned. No one should lead a debilitated life for lack of this vital information.

#Fasting Firepower By Marjan#Detox And Heal Naturally#Stop Being Poisoned Today#MarjanBooks.com#Detox#Water Fasting#Detox Guide#Natural Healing Tips#Detoxification Methods#Fasting Firepower Book#Marjan Fasting Book#Heal Naturally Fast#Avoid Processed Foods#Reduce Pharmaceutical Use#Improve Mental Health Naturally#Cancer Prevention Tips#Beat Heart Disease#Fight Diabetes Naturally#Overcome Mystery Illnesses#Environmental Toxins Effects#Organic Living Tips#Natural Detox Solutions#Health and Wellness Guide

3 notes

·

View notes

Text

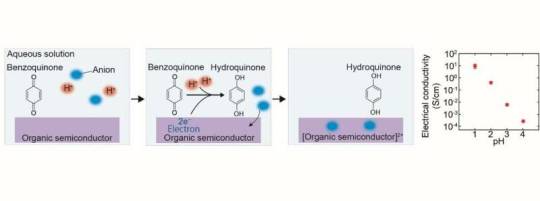

Precise chemical doping of organic semiconductors in an aqueous solution

A research team consisting of NIMS, the University of Tokyo and the Tokyo University of Science has developed the world's first technique capable of precisely doping an organic semiconductor in an aqueous solution without requiring a vacuum or a nitrogen atmosphere using special equipment. This technique—which uses water, previously unexploited for this purpose—could bring about a breakthrough or even a paradigm shift. The study is published in the journal Nature. Chemical doping is a crucial process in semiconductor device production. Doping organic semiconductors involves the use of redox agents. Because effective redox agents are prone to react with water and/or oxygen, they need to be handled in a vacuum or a nitrogen atmosphere created using special equipment. In addition, these doping methods do not allow precise, consistent adjustment of doping levels.

Read more.

12 notes

·

View notes

Text

How to Paint a Stained Glass Window on Canvas.

Ft. Princess Peach

I took a college class on Scene Painting once, and as our final project, we had to apply everything we learned and make a stained glass window out of canvas and paint.

We could copy any design we wanted, and I chose to do the Princess Peach stained glass window from the games.

Since I had a lot of fun making it, let me show you the process.

First, we divided the canvas into squares that are all the same size. 6 vertical squares and 4 horizontal squares. Do the same thing with the reference photo and then copy the lines using charcoal.

Next, you lightly brush off the charcoal, enough to still see the lines lightly and trace over them with Sharpie.

For this art piece, we needed to have a curtain as a part of the piece. What you want to do first is pick the base color you want to use. Then you get it in a shade that is lighter and darker than the original (mixing in white and black, respectively). You want to mimic the texture of curtains through your brush strokes and the shades of colors you use. The only advice I have for this is to follow the lines of the fabric and keep working on it until it feels right. Try alternating between the dark, original, and light paint. That's what I did.

Next is the color for the glass. This part is basically like a paint-by-number but with a twist. Since this is supposed to be a stained glass window, we want to be able to see through the canvas when there is light behind it. So, the paint has to be diluted with water. Also, we are not allowed to use the color white since it will block out the light. So, if you want a lighter color, you need to add a lot more water that paint. And if you want it darker, more paint than water. It is basically watercolors at this stage.

And let me tell you, it is super hard to get the right shade of pink from plain red paint and water. But, I did it.

After painting in color, you will want to go over the sharpie lines with black paint to make them stand out better.

Then, the final thing is to get some heavily diluted dark purple paint to create a shadow between the curtain and the stained glass window. Also, it is a good idea to make some thin shadow lines on the curtains and some gold tassles for decor.

And here is the final product:

This took me weeks of hard work, but it was so much fun and very therapeutic. I am still very proud of the final product.

If someone gave the materials and money for it, I would definitely want to do this again.

Now you can try this at home! Good luck!

#princess peach#stained glass window#art lesson#princess peach stained glass window#super mario#super mario princess peach#btw if you couldnt tell from the pictures#the painting is 6 ft tall and 4 ft wide#i have it hanging up#and it takes up a whole wall#this process should still work regardless of the size of your canvas#though i do recommend getting a canvas that is see through#we used a fabric called muslin that we stiffened with some sort of cornstarch liquid solution#i think we mixed cornstarch in warm water#then we used paint brushes to spread it on the canvas#and used push brooms to stiffen the fabric so we could paint on it#enjoy!#painting#painting art#painting lesson#video game art#princess peach art#sorry if this is too wordy#i get excited talking about these kinds of things

3 notes

·

View notes

Text

Water Reuse Revolution: How India Tackles Liquid Waste Management Dive into India’s water reuse revolution! Discover how the nation is adapting to new liquid waste management regulations with innovative approaches to sustainability.

#water treatment#water treatment solutions#water plant treatment process#water treatment systems#zld

1 note

·

View note

Text

['CAUSE I DON'T GET TO SAY "GURGLING MONSTROSITY" ENOUGH-- THIS IS OUR ICEMAKER. WE CAN’T ALWAYS TELL THE WHOLE STORY ABOUT OURSELVES. WHAT'S THIS SOLUTION INSIDE OF HERE? THIS IS WATER MIXED WITH GLYCOL, WHICH IS AN ACCELERATION PROCESS TO FREEZE THE ICE.]

#s08e03 stacked stuffed and loaded#guy fieri#guyfieri#diners drive-ins and dives#gurgling monstrosity#whole story#acceleration process#enough#icemaker#solution#water#glycol

6 notes

·

View notes

Text

Water for Injection A Critical Component in Pharmaceutical Processes

Water for Injection (WFI) holds a pivotal role in pharmaceutical and healthcare industries. As a highly purified form of water, WFI is indispensable for producing injectables, parenteral solutions, and other critical formulations. Its stringent quality requirements ensure that it remains free from pyrogens, microbes, and contaminants, making it safe for direct introduction into the human body. The meticulous production and storage of WFI system are essential to maintain its integrity and suitability for use in sensitive applications.

Understanding Water for Injection

It is governed by strict standards set by pharmacopeias such as the United States Pharmacopeia (USP), European Pharmacopeia (EP), and Indian Pharmacopeia (IP). These standards outline precise requirements for conductivity, microbial load, and endotoxin levels. WFI must exhibit high purity with conductivity less than 1.3 µS/cm at 25°C and endotoxin levels not exceeding 0.25 EU/mL.

The primary applications of WFI include:

Parenteral Drug Manufacturing: Used as a solvent for drug formulations administered via injection.

Sterile Product Preparation: Serves as a base ingredient in sterile solutions and suspensions.

Cleaning Processes: Used for sterilizing equipment, containers, and closures in aseptic environments.

Methods of WFI Production

Producing Water for Injection involves advanced purification techniques to meet the required standards. Key methods include:

Distillation: Considered the most reliable method, distillation effectively removes impurities, pyrogens, and bacteria. Multi-effect distillation (MED) and vapor compression distillation (VCD) are commonly used systems.

Reverse Osmosis (RO) with Electrodeionization (EDI): An efficient alternative combining RO and EDI to achieve high purity. This method is often complemented with ultrafiltration to ensure endotoxin removal.

Ultrafiltration: Typically employed in conjunction with other methods, ultrafiltration ensures the elimination of pyrogens and endotoxins from water.

The choice of method depends on the scale of production, energy efficiency requirements, and compliance with regulatory norms.

Storage and Distribution of WFI

Maintaining the quality of Water for Injection post-production is as critical as its generation. Specially designed storage and distribution systems are employed to prevent microbial contamination and ensure consistent quality. Key features include:

Sanitary Design: Stainless steel tanks and piping with smooth, polished surfaces minimize microbial growth.

Temperature Control: Storage systems are often maintained at high temperatures (typically 80°C) to inhibit bacterial proliferation.

Circulating Loops: Continuous circulation prevents water stagnation and maintains consistent quality.

Advanced Monitoring: Real-time sensors and automated controls ensure compliance with quality standards.

Regulatory Compliance and Validation

Regulatory bodies mandate rigorous validation of WFI systems to ensure consistent performance. Validation includes:

Design Qualification (DQ): Verification of system design against user requirements.

Installation Qualification (IQ): Confirmation that the system is installed correctly.

Operational Qualification (OQ): Testing to ensure the system operates within specified parameters.

Performance Qualification (PQ): Evaluation of the system’s ability to produce WFI consistently over time.

Routine maintenance, monitoring, and periodic re-validation are also essential to ensure ongoing compliance.

Significance of WFI in Pharmaceutical Manufacturing

The importance of Water for Injection in pharmaceutical manufacturing cannot be overstated. Its purity and sterility are fundamental to ensuring patient safety and product efficacy. Without adherence to stringent standards, the risks of contamination and adverse reactions increase significantly, compromising the quality and safety of pharmaceutical products.

Pharmaceutical manufacturers must invest in advanced WFI systems that deliver consistent quality while optimizing operational efficiency. The integration of automation and real-time monitoring has further enhanced the reliability and traceability of WFI systems.

Future Trends in WFI Production

As the pharmaceutical industry evolves, innovations in WFI production and management are becoming increasingly critical. Emerging trends include:

Energy-Efficient Systems: New technologies are reducing energy consumption in WFI generation, making processes more sustainable.

Enhanced Automation: Advanced monitoring and control systems improve operational efficiency and regulatory compliance.

Integrated Solutions: Combining WFI production with other water treatment processes for seamless integration and cost efficiency.

The industry’s focus on innovation ensures that WFI production continues to meet the growing demands of pharmaceutical manufacturing.

It remains a cornerstone of pharmaceutical processes, ensuring the highest standards of purity and safety. Its production, storage, and distribution require precision, adherence to stringent norms, and continuous innovation.

Swjal Process Pvt. Ltd. is a leading Water for Injection Plant manufacturer in India, delivering state-of-the-art solutions that align with global standards and support the pharmaceutical industry’s mission of safeguarding health and well-being.

#wfi system#wfi plant#water for injection#pharmacutical industry#high purity water solution#Swjal Process#India

0 notes

Text

A Seamless Solution for Hot Water Needs in the North Shore and Northwest Suburbs.

At Emergency Plumbing, we pride ourselves on delivering high-quality solutions for all your plumbing needs. Recently, we had the privilege of assisting a homeowner in Northbrook with an urgent water heater issue. Their 75-gallon Bradford White water heater had stopped producing hot water and had begun leaking, causing concern and inconvenience. Thanks to a recommendation from their neighbor—another happy client of Emergency Plumbing—the homeowner reached out to us for help.

Expert Installation of a Bradford White Water Heater.

The homeowner decided on a 75-gallon Bradford White water heater, a reliable and energy-efficient choice. Our team also installed a recirculating pump to ensure consistent hot water delivery throughout the home. This upgrade not only addressed the immediate issue but also enhanced the overall efficiency and convenience of the plumbing system. From the removal of the old unit to the installation of the new one, the process was smooth and efficient. Our team worked meticulously to ensure everything was up to code, providing a seamless experience for the client.

Competitive Pricing and Guaranteed Workmanship.

Contact us today for expert assistance and see why your neighbors recommend us time and time again!

Building Trust Across Communities.

Phone 224-754-1984

#A Seamless Solution for Hot Water Needs in the North Shore and Northwest Suburbs.#At Emergency Plumbing#we pride ourselves on delivering high-quality solutions for all your plumbing needs. Recently#we had the privilege of assisting a homeowner in Northbrook with an urgent water heater issue. Their 75-gallon Bradford White water heater#causing concern and inconvenience. Thanks to a recommendation from their neighbor—another happy client of Emergency Plumbing—the homeowner#Expert Installation of a Bradford White Water Heater.#The homeowner decided on a 75-gallon Bradford White water heater#a reliable and energy-efficient choice. Our team also installed a recirculating pump to ensure consistent hot water delivery throughout the#the process was smooth and efficient. Our team worked meticulously to ensure everything was up to code#providing a seamless experience for the client.#Competitive Pricing and Guaranteed Workmanship.#Contact us today for expert assistance and see why your neighbors recommend us time and time again!#Building Trust Across Communities.#Phone#224-754-1984

1 note

·

View note

Text

#Sewage Treatment Plants#wastewater treatment#public health protection#environmental conservation#resource recovery#sewage treatment process#types of STPs#sustainable water management#urban wastewater solutions

1 note

·

View note

Text

Durable and Corrosion-Resistant Stainless Steel 304 Pipe Fittings for Reliable and Efficient Fluid Handling in Diverse Industrial Applications

Our Stainless Steel 304 Pipe Fittings provide reliable and corrosion-resistant connections for various piping systems. Suitable for applications such as food processing, chemical processing, and water treatment, these fittings ensure a precise fit and long-lasting service. Available in multiple sizes and configurations, they meet the demands of projects requiring efficient fluid handling solutions.

#Stainless Steel 304#Pipe Fittings#Corrosion Resistance#Piping Systems#Food Processing#Chemical Processing#Water Treatment#Precise Fit#Long-Lasting Service#Fluid Handling Solutions

0 notes

Text

Process Water Tanks in Australia

Efficient water storage is essential for various industrial operations, and process water tanks provide a reliable solution to meet these demands. At Prefab Tanks, we specialize in offering high-quality industrial water tanks in Australia designed to cater to diverse needs. Whether you require process water storage for manufacturing, cooling, or other industrial applications, our tanks are the perfect choice.

Why Choose Process Water Tanks?

Process water tanks are critical for industries that rely on a consistent water supply for their operations. Our tanks are engineered to deliver:

Durability: Made from premium materials, they withstand harsh industrial environments.

Customizability: Tailored to suit specific storage requirements, ensuring optimal performance.

Efficiency: Designed to facilitate seamless water storage and usage for various processes.

Applications of Process Water Tanks

Our process water storage tanks in Australia are versatile and suitable for numerous applications, including:

Manufacturing Plants: Supporting water needs for production lines, cooling systems, and cleaning processes.

Power Plants: Storing water for boiler feed, cooling, and other operations.

Agricultural Use: Providing water storage solutions for irrigation and livestock needs.

Commercial Facilities: Ideal for facilities requiring substantial water supply for daily operations.

Benefits of Prefab Tanks’ Water Storage Solutions

At Prefab Tanks, we pride ourselves on delivering top-tier water storage solutions tailored to your needs. Our tanks offer:

Longevity: Designed for long-term use with minimal maintenance.

Quick Installation: Modular construction ensures a hassle-free setup process.

Eco-Friendly Features: Promoting sustainable water management practices.

Customizable Water Tanks for Every Requirement

We understand that every industry has unique requirements. That’s why our customizable water tanks can be adapted to meet your specific needs, from capacity adjustments to site-specific designs. Whether you need a compact solution or a large-scale storage system, we have the expertise to deliver.

Why Prefab Tanks?

Prefab Tanks is a trusted name in providing industrial water tanks in Australia. Our commitment to quality, innovation, and customer satisfaction ensures that you receive the best process water storage solutions available.

Contact Us Today

Explore our range of process water tanks and discover how we can meet your industrial water storage needs. Contact Prefab Tanks to learn more about our customizable and efficient water storage solutions in Australia.

#“”“Process water tanks#industrial water tanks Australia#process water storage#Prefab tanks#water storage solutions#customizable water tanks#process water storage Australia#industrial tanks“”

0 notes

Text

This 6-minute video could save your health or the health of your loved ones, and quite possibly save your lives.

#Fasting Firepower By Marjan#Detox And Heal Naturally#Stop Being Poisoned Today#MarjanBooks.com#Detox#Water Fasting#Detox Guide#Natural Healing Tips#Detoxification Methods#Fasting Firepower Book#Marjan Fasting Book#Heal Naturally Fast#Avoid Processed Foods#Reduce Pharmaceutical Use#Improve Mental Health Naturally#Cancer Prevention Tips#Beat Heart Disease#Fight Diabetes Naturally#Overcome Mystery Illnesses#Environmental Toxins Effects#Organic Living Tips#Natural Detox Solutions#Health and Wellness Guide

0 notes

Text

DM Water Plant: Process, Principles, and Industrial Uses

Explore the fascinating world of DM Water Plants and learn about the demineralized water process, its principles, and key industrial applications.

DM Water Plant Process

Demineralized (DM) water, also known as deionized water, is crucial in industries where water purity is paramount. The DM water plant process removes mineral salts and impurities, producing highly purified water essential for various industrial operations.

0 notes

Text

Eco-Friendly Innovations by Water Treatment Plant Manufacturers

In an era where environmental sustainability is paramount, water treatment plant manufacturers are leading the charge with innovative and eco-friendly solutions. Their advancements are not only ensuring access to clean water but are also significantly reducing the environmental footprint of water treatment processes. This article explores the latest eco-friendly innovations by water treatment plant manufacturers and their impact on the environment.

The Importance of Eco-Friendly Water Treatment

Water treatment is essential for providing safe and clean water for various uses, including drinking, agriculture, and industrial processes. However, traditional water treatment methods can be resource-intensive and environmentally damaging. Eco-friendly innovations aim to address these issues by making water treatment more sustainable.

Reducing Energy Consumption

One of the primary goals of eco-friendly water treatment is to reduce energy consumption. Traditional water treatment plants often rely on energy-intensive processes. By incorporating energy-efficient technologies, manufacturers can significantly lower the energy requirements of these plants.

Minimizing Chemical Use

Many conventional water treatment processes use chemicals that can be harmful to the environment. Eco-friendly innovations focus on reducing the use of chemicals or finding non-toxic alternatives, thereby minimizing environmental impact.

Innovations in Water Treatment Technologies

Water treatment plant manufacturers are continually developing new technologies to enhance the sustainability of their operations. Here are some of the most notable eco-friendly innovations:

Membrane Filtration

Membrane filtration is a process that uses semi-permeable membranes to remove impurities from water. This method is highly efficient and requires less energy compared to traditional filtration techniques. It also reduces the need for chemical coagulants, making it an environmentally friendly option.

Biological Treatment

Biological treatment utilizes microorganisms to break down organic matter in water. This natural process is effective in treating wastewater and is less harmful to the environment compared to chemical treatments. Innovations in biological treatment are making it more efficient and scalable for various applications.

Solar-Powered Water Treatment

Harnessing solar energy for water treatment is a game-changer in the industry. Solar-powered water treatment plants can operate independently of traditional energy sources, reducing their carbon footprint and making clean water accessible in remote areas.

Advanced Oxidation Processes (AOPs)

Advanced oxidation processes (AOPs) involve the use of powerful oxidants to break down pollutants in water. These processes are highly effective in removing contaminants and are being optimized to reduce energy consumption and chemical use.

Benefits of Eco-Friendly Water Treatment

The shift towards eco-friendly water treatment technologies offers numerous benefits for both the environment and society:

Environmental Protection

By reducing energy consumption and minimizing chemical use, eco-friendly water treatment technologies help protect natural ecosystems. This is crucial for maintaining biodiversity and ensuring the health of our planet.

Cost Savings

Eco-friendly innovations can lead to significant cost savings over time. Energy-efficient processes lower operational costs, and the reduced need for chemicals and maintenance further contributes to financial savings.

Improved Public Health

Access to clean water is vital for public health. Eco-friendly water treatment technologies ensure that water is free from harmful contaminants, reducing the incidence of waterborne diseases and promoting overall well-being.

Sustainability

Sustainable water treatment practices are essential for meeting the needs of the present without compromising the ability of future generations to meet their own needs. Eco-friendly innovations support long-term sustainability and resource conservation.

Challenges and Future Directions

While eco-friendly water treatment technologies offer significant advantages, they also face challenges:

High Initial Costs

The initial investment for implementing eco-friendly technologies can be high. Manufacturers need to balance the upfront costs with long-term benefits to make these solutions viable for widespread adoption.

Technological Advancements

Continuous research and development are necessary to improve the efficiency and effectiveness of eco-friendly water treatment technologies. Staying ahead of technological advancements is crucial for manufacturers to remain competitive.

Regulatory Compliance

Water treatment plants must comply with stringent environmental regulations. Ensuring that eco-friendly technologies meet these standards can be complex and requires ongoing monitoring and adaptation.

Conclusion

Water treatment plant manufacturers are at the forefront of developing and implementing eco-friendly innovations that are transforming the industry. By focusing on reducing energy consumption, minimizing chemical use, and harnessing renewable energy sources, they are making significant strides in ensuring sustainable and clean water for all. As these technologies continue to evolve, they will play a vital role in protecting the environment and promoting public health, ultimately contributing to a more sustainable future.

If You Want To Explore More About Water Treatment Plant Manufacturers then Visit the Site: Jasmino

#technology#manufacturing#manufacturing industry#safe drinking water#water treatment technology#water treatment plant#water treatment solutions#water management#water treatment process#water filtration#water treatment

0 notes

Text

Understanding Wastewater Treatment: Biological vs. Chemical Methods in ZLD Processes

Dive into our latest blog post, where we conduct a thorough comparative analysis of biological and chemical wastewater treatment methods used in Zero Liquid Discharge (ZLD) processes. Discover the unique benefits and challenges of each approach to help you choose the best solution for your wastewater management needs. Stay informed and make sustainable choices for your business—read the full article now!

#water treatment#water treatment plant#water treatment process#water treatment system#water treatment systems#water plant treatment process#water treatment chemicals#water treatment solutions#water treatment and desalination

1 note

·

View note

Text

#Arsenic treatment methods#Arsenic filtration techniques#Arsenic detoxification processes#Arsenic purification methods#Water decontamination from arsenic#Arsenic elimination techniques#Arsenic mitigation strategies#Arsenic water remediation#Arsenic reduction methods#Arsenic removal technologies#Arsenic decontamination procedures#Arsenic extraction processes#Arsenic separation methods#Arsenic detox methods#Arsenic cleansing procedures#Arsenic treatment systems#Arsenic removal solutions#Arsenic decontamination techniques#Arsenic water purification#Arsenic filtration systems#Arsenic removal equipment#Arsenic removal plants#Arsenic detoxification systems#Arsenic removal filters#Arsenic water treatment methods

0 notes