#pressure die casting

Explore tagged Tumblr posts

Text

2024/07/30 Die Casting is coming

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#machining parts#precision machining#die casting#die cast cars#casting#pressure die casting#cnc machining

1 note

·

View note

Text

Aluminium Actuator Housing, Manufacturer, Supplier, Sangli, India

We are Manufacturer, Supplier, Exporter of Aluminium Actuator Housing, Aluminium Casting For Electrical Products from Sangli, Maharashtra, India.

Aluminium Actuator Housing, Aluminium Casting For Electrical Products, Aluminium Gravity Die Castings, Machined Components, Gravity Die Casting, Aluminium Gravity Die Casting, Aluminium Casting, Pressure Die Casting, Aluminium Pressure Die Casting, Manufacturer, Supplier, Exporter, Sangli, Asia, Mumbai, Thane, Navi Mumbai, Pune, Nashik, Aurangabad, Ratnagiri, Nagpur, Ahmednagar, Akola, Amravati, Chandrapur, Dhule, Jalgaon, Raigad, Satara, Belgaum, Kolhapur, Belgaon, Maharashtra, India.

#Aluminium Actuator Housing#Aluminium Casting For Electrical Products#Aluminium Gravity Die Castings#Machined Components#Gravity Die Casting#Aluminium Gravity Die Casting#Aluminium Casting#Pressure Die Casting

0 notes

Text

The process of investment casting, also called wax casting, has been used in the metal casting process for several years, and this method has been improved as technology advances the casting process that makes use of one single shot moulds for creating the castings. This casting method is best for giving high-precision and complex shapes in structures.

#die casting#investment casting companies#zinc die casting#pressure die casting#die casting companies near me#stainless steel casting companies#die casting companies#investment casting companies near me#rapid die casting#die casting near me

0 notes

Text

0 notes

Text

Plastic Injection Molding in Pune India

Precious Enterprise is one of the most notable plastic injection molding companies in India that ensure highly durable products without causing our clients to spend unnecessarily. The quality and exactness of the mold significantly impact the strength, adequacy, and accuracy of the injection molding process. A decent quality mold base ensures easy creation, less downtime , and better mold life.

#Plastic Injection Molding Pune#Best Molding Companies India#Gun Drilling Machine Pune#Deep-Hole Drilling Machine India#Pressure Die-Casting Machines in Pune#Die-Casting mould in Pune#Injection molding machine manufacturers in Pune

0 notes

Text

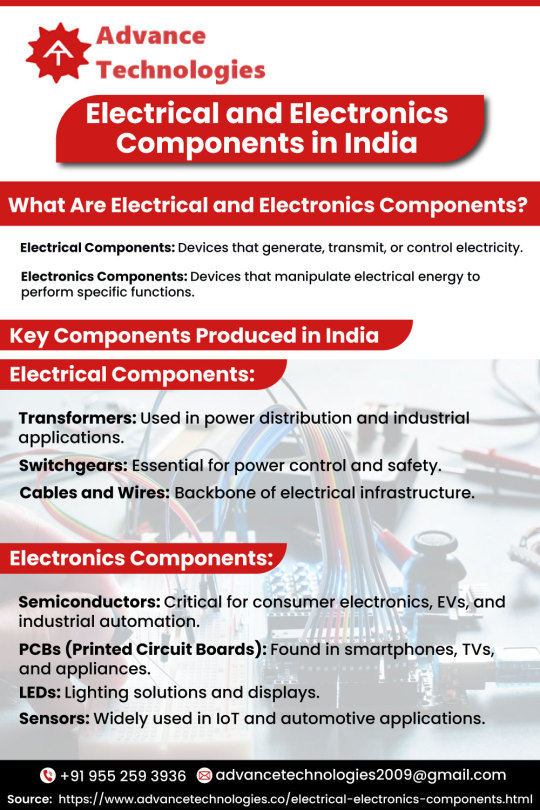

Electrical and Electronics Components in India

Quality is a fundamental matter when it comes the electrical components. The Electrical and Electronics Components in India is perfect in case of the quality and price. We are sure you can find only the best choices with our variations. Office address Plot No.9 & 10, WMDC, Ambethan Road, Kharabwadi, Chakan, Pune-410 504.

#Electrical Components Pune#Electronics Components India#Home Appliances Components in Pune#Household Appliances in India#Aluminium Other Components in India#Aluminium Pressure Die Casting in India#Shot Blasting of Components in Pune

1 note

·

View note

Text

Overview of the world's top ten casting processes 2

For previous article, please refer to Overview of the world’s top ten casting processe . 3. Die casting Die casting: It is to use high pressure to press molten metal into cavity of a precision metal mold at high speed. Molten metal cools and solidifies under pressure to form a casting.Process flow: Die casting machineDie casting process characteristicsAdvantages: 1. Metal liquid is under high…

View On WordPress

#casting process#Centrifugal casting#Continuous casting#die casting#die casting mold#Die Casting Mould#die casting process#gravity die casting#Lost foam casting#Low pressure casting#Metal mold casting#mold manufacturing#non-ferrous carbon alloy castings#sand castings#Squeezing die casting#Vacuum die casting

0 notes

Text

Discover the cutting-edge technology of Magnesium Aluminum Alloy Castings, the innovative material that is transforming industries with its exceptional strength-to-weight ratio. These castings are crafted from a blend of magnesium and aluminum, offering a unique combination of properties that make them ideal for a wide range of applications. From automotive to aerospace, Magnesium Aluminum Alloy Castings are setting new standards for performance and efficiency.

Our Magnesium Aluminum Alloy Castings are renowned for their high strength, excellent corrosion resistance, and outstanding thermal conductivity. These castings are lightweight, which is a significant advantage in industries where reducing weight is crucial for fuel efficiency and performance. The use of Magnesium Aluminum Alloy Castings can lead to a decrease in overall product weight without compromising on durability or safety. Manufactured through advanced casting techniques, our Magnesium Aluminum Alloy Castings are designed to meet the precise specifications of our clients.

They are perfect for components that require high structural integrity and are subjected to heavy loads. The castings are also favored for their ability to be easily machined and finished, which simplifies the manufacturing process and reduces production costs. In summary, Magnesium Aluminum Alloy Castings are the epitome of modern casting technology, offering a lightweight, strong, and versatile solution for various industrial needs.

Choose our Magnesium Aluminum Alloy Castings for your next project and experience the difference that advanced materials can make.

#Magnesium Aluminum Alloy Casting#magnesium alloy castings#aluminum die casting auto parts#aluminum die casting parts#across the spiderverse#aluminium pressure die cast motor body#aluminum die casting auto parts For Sale

0 notes

Text

Expert Aluminum High Pressure Die Casting Parts Manufacturer for Custom Solutions

G.M. Hi-Tech is an Expert Aluminum High Pressure Die Casting Parts Manufacturer for Custom Solutions, delivering precision-engineered components for diverse industries. With advanced technology and strict quality control, we ensure durability, accuracy, and efficiency in every part. Trust G.M. Hi-Tech for tailored die-casting solutions that meet your exact specifications with superior performance and reliability.

0 notes

Text

#High Pressure Die Casting Suppliers#HPDC Manufacturing Services#Custom HPDC Solution#precision HPDC Part#HPDC Parts Suppliers#HPDC Automotive Components Suppliers#High Pressure Die Casting parts Manufacturers in India#HPDC parts Manufacturers

0 notes

Text

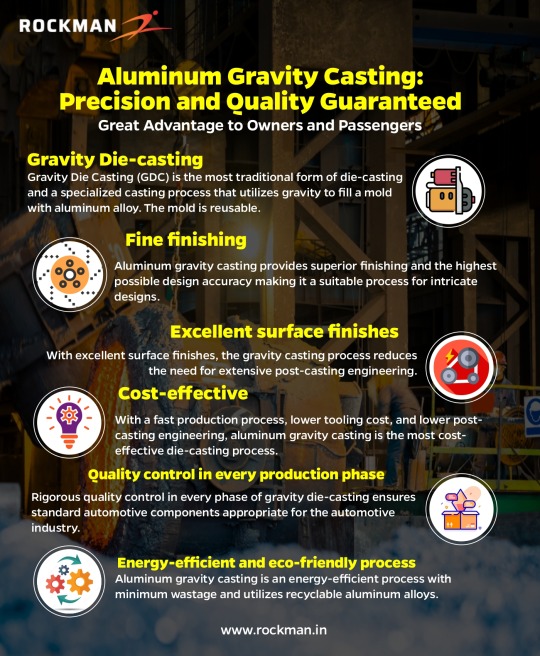

Aluminum Gravity Casting: Precision and Quality Guaranteed

Gravity Die-casting

Gravity Die Casting (GDC) is the most traditional form of die-casting and a specialized casting process that utilizes gravity to fill a mold with aluminum alloy. The mold is reusable.

Advantages of aluminum gravity casting

Fine finishing

Aluminum gravity casting provides superior finishing and the highest possible design accuracy making it a suitable process for intricate designs.

Excellent surface finishes

With excellent surface finishes, the gravity casting process reduces the need for extensive post-casting engineering.

Cost-effective

With a fast production process, lower tooling cost, and lower post-casting engineering, aluminum gravity casting is the most cost-effective die-casting process.

Quality control in every production phase

Rigorous quality control in every phase of gravity die-casting ensures standard automotive components appropriate for the automotive industry.

Energy-efficient and eco-friendly process

Aluminum gravity casting is an energy-efficient process with minimum wastage and utilizes recyclable aluminum alloys.

For more information on gravity casting and aluminum die-casting visit: https://www.rockman.in/

#Aluminum gravity casting#Alloy wheels for passenger cars#Aluminium die casting#die casting parts#High Pressure Die Casting suppliers in india#Aluminium casting#Aluminium Die cast#Aluminium die casting parts suppliers in india

0 notes

Text

Looking For a Trusted Manufacturer of Centrifugal Die Casting.

Get centrifugal die casting latest prices compared to other manufacturers in India. We have listed down a huge range of manufacturing products like centrifugal die casting. The world's biggest collection of new ideas.

#Centrifugal Die#centrifugal die casting#centrifugal die casting machine#centrifugal#centrifugal compressors#a centrifugal#centrifugal flow#centrifugal pressure

0 notes

Text

Precision CNC Machining: Using Precision to Create the Future

Uncover how precision CNC machining is shaping the future of manufacturing. In sectors including aerospace, medical, and automotive, cutting-edge technology and human skills are opening up new possibilities for components that are creative and high-performing.

#precision cnc machining#pressure die castings#low pressure die casting#plastic injection molding#aluminum die casting

0 notes

Text

girl help the bjds are calling to me again

#i cant i CANT i dont have MONEY but augh theres some i want So Bad#theyre so expensive & like I Get It but mannnn i cant afford them anymore & im crying abt it#i still wish i could make my own AUGH i have so many ideas#i mean i do want to like 3d print prototypes & then ??? idk probably get a more Final Print professionally done#with a better printer than i have & have them make it nice & polished & then i can make a mold & cast the pieces in resin.....#but i also still need the mold making stuff & the resin & probably also a pressure pot & vacuum chamber so the molds/casts come out good#its sososo expensive i die#its 8am i cant sleep help me lmao

0 notes

Text

Aluminum Die Casting Companies

It is important to know more about aluminum designer before getting hold of aluminum casting from his side. Metal Stamping Dies is one of the leading aluminum die casting companies, where you get help straight from experienced designers in town. So, choose us the next time you are looking for aluminum pressure die casting related help.

0 notes

Text

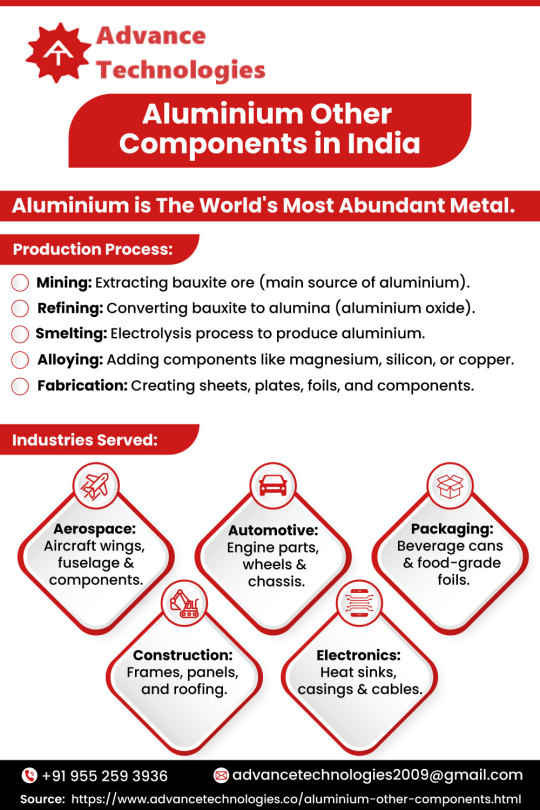

Aluminium Other Components in India unrivalled strength-to-weight ratio makes it ideal for use in transportation. Because of its reduced weight, the vehicle moves with less effort, which increases fuel economy. Although not the strongest metal, aluminium can be made stronger by alloying with other metals. Since it resists corrosion, there is no need for cumbersome anti-corrosion coatings, which are also expensive. Although steel is still largely used in the auto industry, aluminum is now widely used due to efforts to improve fuel efficiency and lower CO2 emissions. By 2025, the average amount of aluminium in cars is expected to rise by 60%, according to experts.

#Aluminium Other Components in Pune#Parts Manufacturer in India#Electrical Components Pune#Electronics Components India#Home Appliances Components in Pune#Household Appliances in India#Aluminium Pressure Die Casting in India

0 notes