#precast engineering design

Explore tagged Tumblr posts

Text

Structural Engineering Projects with BIM-Integrated Precast Concrete Design

Discover the future of construction with BIM-Integrated Precast Concrete Design! This innovative approach revolutionizes how we plan and execute structural engineering projects. By integrating Building Information Modeling (BIM) with precast concrete, we achieve unparalleled precision, efficiency, and sustainability. Say goodbye to traditional methods and embrace a smarter, more streamlined process that saves time and reduces costs.

Join the movement towards modern construction excellence! BIM-Integrated Precast Concrete Design not only enhances collaboration among project stakeholders but also ensures higher quality and consistency in every build. From concept to completion, experience the benefits of cutting-edge technology in your structural engineering projects. Let's build the future together! 🏗️✨

#precast CAD drawings#precast concrete design#precast concrete design workflow#precast constructions using BIM software#precast engineering design

0 notes

Text

#precastconcrete#concrete#precast#construction#architecture#building#design#concreteconstruction#architect#civilengineering#beton#concretedesign#exteriordesign#engineering#manufacturing#prefabbricati#formwork#bahrain#uditch#edilizia#archilovers#prefabricados#crane#architectualprecast#selectprecast#concreteproducts#steelconstruction#betonpracetak#wikabeton#konstruksibaja

0 notes

Text

Centre Point photographed here in 1966, occupies 101–103 New Oxford Street and 5–24 St Giles High Street WC1, with a frontage also to Charing Cross Road close to St Giles Circus and almost directly above Tottenham Court Road tube Station.

The building was designed by George Marsh with engineer Pell Frischmann and was constructed by Wimpey Construction from 1963 to 1966, for a cost of £5.5 million. The precast segments were formed of fine concrete utilising crushed Portland Stone and were made by Portcrete Limited at Portland Dorset. They were transported to London by lorry. It is said the site was once occupied by a gallows which was situated on St Giles Street as the tower sits directly over the former route of St Giles High Street, which had to be re-routed for the construction. On completion, the building remained vacant for many years, leading to its being referred to as "London's Empty Skyscraper".

55 notes

·

View notes

Text

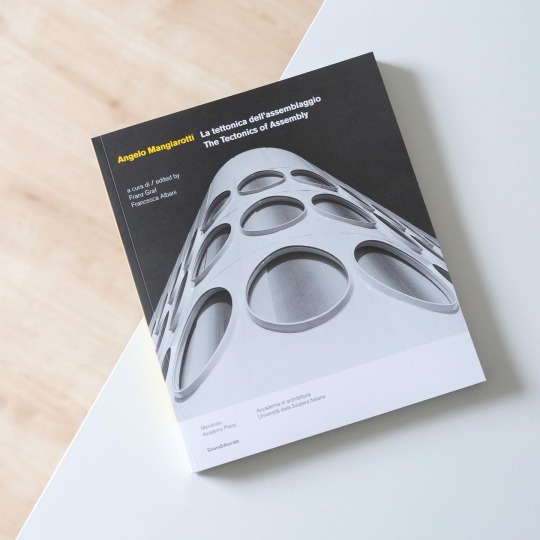

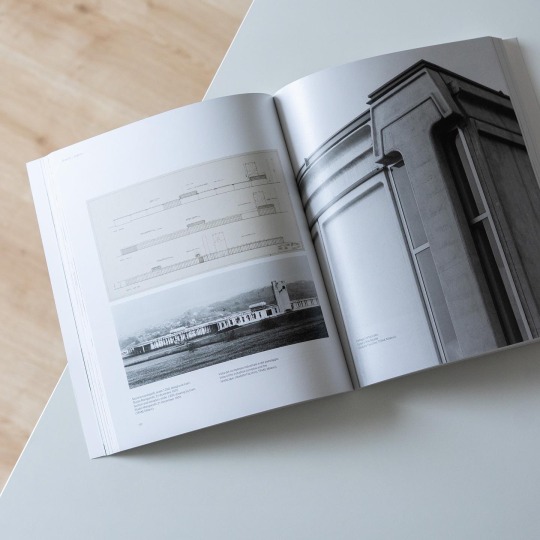

The ingenious work of Italian architect and designer Angelo Mangiarotti still remains somewhat under-appreciated outside of Italy which indeed is a shame in view of the sophisticated oeuvre he left. The latter is characterized by a poetic engineering that combines logical form and structural beauty that sets Mangiarotti’s buildings way apart from pure works of engineering. Throughout his career he worked on an architectural language of the assemblage consisting of vocabulary and grammar aligned with three key concepts: experimentation, gravity and module as Franz Graf and Francesca Albani explain in the introduction to the present volume they edited: „Angelo Mangiarotti - The Tectonics of Assembly“, published by Silvana Editoriale in 2015. These concepts, which relate to Mangiarotti’s sounding out of material capabilities and limitations, the main force in the trilithic system of simply supported precast concrete elements and the modular use of his structural inventions, can be explored further in the select but extensively documented catalogue of ten representative projects: structured along the aforementioned three concepts projects like the Elmag Factory in Lissone (1963-69) or Snaidero premises (1971-78) in Majano are presented in a brief explanatory text, design drawings, technical drawings, plans, models and photographs that provide an unusually comprehensive overview of the genesis of each project.

The two lengthy essays by the editors situate these works and Mangiarotti’s oeuvre in general within the postwar building culture of Northern Italy, his unique contribution to it and how it is perceived today. A more personal, close-up view on Mangiarotti’s practical work and design ethics is in turn provided by Kinue Horikawa who was one of the many Japanese architects and designers passing through the Milan office.

„Angelo Mangiarotti - The Tectonics of Assembly“ is a beautifully illustrated, concise and comprehensive introduction to the Italian master’s work and thinking and as such highly recommended!

29 notes

·

View notes

Text

Precast Panel Detailing CAD Services Provider in USA

Silicon Engineering Consultant Pvt. Ltd. gives good services of Precast Panel Detailing CAD Services. Our Precast Panel Detailing involves creating drawings and plans that show the dimensions, specifications, and placement of each precast panel. precast panel detailing, some companies also offer Precast Panel Engineering Services. This involves analyzing the structural requirements of the panels and designing them to meet those requirements. If you have to require any Precast Panel Detailing Design and Drafting project work then Connected with US.

Precast Panel Detailing Engineering Services include:

- Precast Shop Drawings

- Wall Panel Detailing

- BIM Coordination

- Beam and Column Detailing

- Bar Bending Schedule Visit Website: https://www.siliconec.com/structural-detailing-services/precast-panel-detailing.html

We provide Precast Panel Detailing Services in USA major cities like New York, Los Angeles, Chicago, Houston, San Diego, Dallas, San Jose, San Antonio, San Francisco, Boston, Dallas, Seattle, Washington

We provide Precast Panel Detailing Services in major UK cities like London, Liverpool, Newcastle, Bristol, Manchester, Sheffield, York, Cambridge, Norwich, Cardiff

We provide Precast Panel Detailing Services in New Zealand's major cities like Auckland, Christchurch, Dunedin, Rotorua, Whangarei, New Plymouth, Wellington, Dunedin, Rotorua, Tauranga

We provide Precast Panel Detailing Services in Australia's major cities like Sydney, Brisbane, Hobart, Newcastle, Canberra, Melbourne, Perth, Cairns, Gold Coast, Darwin, Brisbane

#precastpaneldetailing#precastdetailing#precastdetailingservices#precastpaneldetailingservices#precastengineeringservices#precastconsultantsServices#precastshopdrawings#precastpanelengineeringservices#CADServices#CADD#SiliconEC#USA

1 note

·

View note

Text

What is the process of precast erection and how does it work?

Precast construction is revolutionising the building industry in India, providing a solution that is not only efficient but also sustainable. One essential step in the precast process is precast erection—the method of installing precast components at the construction site. This technique ensures efficiency, safety, and speed while maintaining high quality and durability. In this blog, we’ll explore what precast erection is, how it works, and why it is essential for modern construction projects.

The Process of Precast Erection

Precast erection refers to the process of lifting, positioning, and installing precast elements, such as hollow core slabs, beams, wall panels, staircases and columns with corbel, onto a construction site. These components are manufactured in a controlled factory environment and then transported to the site for assembly. The erection process requires skilled labor, specialized equipment, and careful planning to ensure precise installation.

Unlike traditional construction methods, where concrete is poured and cured on-site, precast erection reduces the time and resources required. It combines off-site manufacturing efficiency with on-site assembly precision, resulting in faster project completion.

Also Read: [Is Precast Sustainable?]

How Does Precast Erection Work?

1. Design and Engineering The process begins in the pre-design phase where engineers plan the precast elements tailored to meet specific architectural demands. This stage is crucial as it lays the groundwork for what will be manufactured.

2. Manufacturing Once the design is finalized, manufacturing of precast elements begins in the controlled environment of a precast plant. This setting ensures quality and uniformity in the production of precast elements. Top manufacturers like Urbanaac use advanced technologies to produce a wide range of components, including the widely used precast hollow core slabs.

Site Preparation and Planning Before precast erection begins, the construction site is thoroughly prepared. This includes creating a level surface, ensuring proper foundation alignment, and planning logistics for crane placement and component delivery. Detailed plans and schedules are developed to streamline the installation process.

2. Transportation of Precast Elements Precast elements are transported from the manufacturing facility to the construction site using specialized vehicles. To prevent damage during transit, elements are securely loaded and carefully handled.

3. Lifting and Positioning Cranes or lifting machinery are used to lift precast elements into place. Skilled technicians and engineers coordinate this step to ensure accurate positioning and alignment. Each component is placed according to the site plan with respect to the element ID, ensuring structural stability.

4. Assembly and Connections Once in place, the precast components are securely connected using techniques such as bolting, welding, or grouting. These connections are critical to maintaining the structural integrity of the entire building or infrastructure.

5. Final Inspection and Safety Checks After all components are installed, engineers perform thorough inspections to ensure the structure meets safety standards and design specifications. Any adjustments required are addressed immediately to guarantee the building’s durability and performance.

Key Manufacturers and Innovator

Among the top precast manufacturers in India, Urbanaac stands out as a leader, known for its innovative approach and comprehensive solutions in precast construction. As one of the trailblazers in India’s precast industry, Urbanaac’s journey began with a vision to transform an unorganised construction industry into an organised one. Today Urbanaac has emerged as the leading and most trusted precast solutions provider in the western region of India.

Also Read:[Advantages of using precast elements by Urbanaac in construction]

Benefits of Precast Erection

Faster Construction: Precast erection significantly reduces construction time compared to traditional methods.

Quality Assurance: Factory-made precast components ensure consistency and durability.

Faster timelines- Faster timelines lead to quicker returns on investment (ROI), boosting overall project profitability.

Safer Sites: Less on-site labour minimises risks associated with traditional construction.

Why Choose Urbanaac for Precast Erection Services?

Urbanaac, a trusted precast manufacturer in India, specializes in providing high-quality precast components and seamless erection services. With advanced technologies, skilled professionals, and a commitment to excellence, Urbanaac ensures precision, safety, and efficiency in every project. Whether for residential, commercial, or industrial projects, Urbanaac’s expertise guarantees superior results.

Conclusion

Precast erection is an essential part of modern construction, combining off-site manufacturing with efficient on-site assembly. It offers numerous advantages, including faster project completion, quality assurance, and reduced costs. Partnering with Urbanaac ensures expert handling and installation of precast components, making your project efficient, durable, and sustainable.

0 notes

Text

Enhance your construction process with Moldtech’s top-tier precast concrete molds for sale. Our molds are built for precision, durability, and efficiency, ensuring high-quality results in every project. Whether you need molds for beams, columns, walls, or slabs, our cutting-edge designs meet diverse precast requirements. With advanced engineering and high-strength materials, our molds provide long-lasting performance and easy handling. Upgrade to superior precast technology and boost your production efficiency with Moldtech—your trusted partner for innovative concrete solutions! Please click on the link here https://moldtechsl.es/en/present/precast-concrete-molds-for-sale/

0 notes

Text

What are the business opportunities for a Civil Engineer?

A Civil Engineer has numerous business opportunities, leveraging their expertise in construction, infrastructure, and project management. Here are some of the top business ideas:

1. Construction Company

Start a general contracting or specialized construction business for residential, commercial, or infrastructure projects.

Services: Building construction, roads, bridges, real estate development.

2. Structural Consultancy

Provide structural design, analysis, and consultancy for buildings and infrastructure.

Clients: Architects, builders, government projects.

3. Interior & Renovation Services

Offer renovation, remodeling, and interior design solutions for homes and offices.

Focus on sustainable and smart home solutions.

4. Precast Concrete Products Business

Manufacture precast concrete slabs, blocks, pipes, fencing, or ready-mix concrete for the construction industry.

5. Surveying & Land Development Services

Provide land surveying, plot demarcation, GIS mapping, and site development consulting.

6. Waterproofing & Insulation Services

Specialize in waterproofing buildings, basements, and terraces using modern techniques.

7. Green Building & Sustainable Construction

Offer eco-friendly, energy-efficient construction using sustainable materials.

Work with companies focusing on LEED certification and green buildings.

8. Real Estate Development & Investment

Build or invest in residential/commercial real estate projects.

Develop townships, gated communities, or industrial parks.

9. Road Construction & Infrastructure Development

Take up government or private contracts for roads, highways, drainage, and bridges.

10. Civil Engineering Software & Training

Provide AutoCAD, Revit, STAAD Pro, and project management training for students and professionals.

Develop or sell construction ERP & project management software.

11. Modular Construction & Prefabricated Homes

Start a business in modular housing solutions, offering fast and affordable construction alternatives.

12. Construction Equipment Rental

Rent out heavy machinery like cranes, JCBs, and concrete mixers to builders and contractors.

13. Smart City & Infrastructure Solutions

Work on urban development projects, smart city infrastructure, and waste management systems.

14. Demolition & Excavation Services

Offer services for building demolition, excavation, and site preparation.

15. Testing & Quality Control Lab

Set up a materials testing lab for soil, concrete, and steel quality assessment.

Why Civil Engineers Should Start a Business?

✅ Growing construction industry with high demand for specialized services. ✅ Government infrastructure projects, smart cities, and real estate boom. ✅ Opportunities in sustainable and tech-driven construction.

Sagar Institute of Research & Technology (SIRT) offers a B.Tech in Civil Engineering, providing students with the skills and knowledge needed to excel in the construction and infrastructure industry.

Why Choose B.Tech in Civil Engineering at SIRT?

✅ Comprehensive Curriculum – Covers structural engineering, construction technology, geotechnical engineering, and environmental engineering. ✅ State-of-the-Art Labs – Advanced labs for material testing, surveying, hydraulics, and CAD designing. ✅ Industry-Oriented Training – Exposure to real-world projects, site visits, and internships. ✅ Placement Assistance – Career opportunities in top construction firms, government sectors, and private industries. ✅ Entrepreneurship Support – Guidance for students interested in starting their own civil engineering business.

#civil engineering#civil engineer#b.tech in civil engineering#Construction Company#sirt bhopal#Career opportunities#business opportunities#engineering college bhopal

0 notes

Text

5 Carr Place, Myaree, WA 6154 TEK1 recently completed the project Audi Centre Myaree a Audi Car showroom in Western Australia. This impressive structure is a 100-tonne steel building, featuring two floors and a main roof, exemplifying modern design and engineering precision. Scope of Work: Steel and Precast Panels Our scope for this project included detailing both steel and precast panels. Managing these two critical elements simultaneously required meticulous coordination and attention to detail. The integration of steel and precast detailing enabled us to ensure accurate connections between the two systems, delivering a seamless result. Overcoming Challenges with Precision Handling both steel and precast in a single project can often lead to coordination challenges. However, thanks to TEK1’s skilled team and advanced detailing processes, we completed the project without any hitches. Our approach ensured that all connections were detailed precisely, aligning perfectly with the design and site requirements. Precast Model Conclusion: A Milestone in Steel Detailing The Audi Centre Myaree stands as a testament to TEK1’s ability to manage complex projects involving multiple structural elements. By combining expertise, coordination, and a commitment to excellence, we delivered a showroom that reflects the high standards of the Audi brand. At TEK1, we continue to set benchmarks in steel and precast detailing, ensuring that every project we undertake is marked by efficiency, accuracy, and success. Read the full article

0 notes

Text

How to Choose the ideal PEB Structure Manufacturer

The pre-engineered building construction has led to a substantial shift in the construction model in the past few years. The demand for prefabricated structures has surged. They offer various advantages, including fast construction, high durability, recyclability and flexible designs.

There are various PEB structure manufacturers in India that also provide container site offices and other prefab structures. Therefore it is important to select the ideal one that can assure to deliver great quality in a given budget. Getting the ideal PEB manufacturer not just speeds up the construction process but make sure the smooth working of the construction process.

Checklist to find a PEB structure manufacturer

Before giving an agreement to a PEB manufacturer, one should do the required checks. One should run the following checks.

Material specifications

It is the most vital and required step to check while evaluating any PEB structure manufacturer. These specifications include MPA, sheet density, precast walls, sheet purlin, and various other details. While checking purlin, one should check if it is galvanized purlin or wood purlin.

If the manufacturer is providing wooden purlin, then one should request for the galvanized purlin. The galvanizd purlin is more accurate, straight and lightweight.

Check for professionalism

Checking the worth ethics and professionalism of the fencing solution manufacturer is vital as one invests his time and money in the project. This work ethics and professionalism determine the after-sales service of the manufacturer. If there is some maintenance work in the building, the manufacturer should provide the vital support and after-sales services to the client.

Check out the construction projects done by the manufacturer

Visiting previous construction projects of the manufacturer assist in checking the quality of the material used in the projects. It includes quality of the frames of the metal windows, steel, purlin, insulating sheets, beams and much more.

0 notes

Text

BIM Courses in Mumbai: Elevate Your Construction Career with Matrix BIM Academy

BIM Courses in Mumbai: Elevate Your Construction Career with Matrix BIM Academy

BIM Courses in Mumbai , The construction industry is rapidly evolving, and Building Information Modeling (BIM) is at the forefront of this transformation. If you're looking to enhance your skills and gain a competitive edge in the Mumbai job market, investing in high-quality BIM training is essential.

Matrix BIM Academy is your premier destination for comprehensive and industry-relevant BIM courses in Mumbai. We offer a diverse range of programs tailored to meet the specific needs of professionals at all levels, from beginners to experienced practitioners.

Our Comprehensive Course Offerings:

BIM Prime: This foundational course provides a solid understanding of BIM principles, methodologies, and best practices. You'll learn about the core concepts of building information modeling, its applications across the construction lifecycle, and the benefits it offers in terms of efficiency, accuracy, and collaboration.

BIM Ultra: Designed for those seeking advanced expertise, BIM Ultra delves deeper into the intricacies of BIM implementation. You'll gain hands-on experience with industry-leading software like Revit, Navisworks, and other relevant tools. This course covers advanced modeling techniques, clash detection, 4D construction simulation, and quantity take-off.

BIM Prime Plus: This accelerated program combines the core knowledge of BIM Prime with practical, project-based learning. You'll work on real-world case studies, applying your skills to solve complex challenges and develop a portfolio that showcases your expertise.

BIM Architecture: This specialized course focuses on the architectural applications of BIM. You'll learn how to model architectural elements, create detailed drawings and visualizations, and integrate architectural design with other disciplines.

BIM Structure: This course is tailored for structural engineers and focuses on the structural aspects of BIM. You'll learn how to model structural systems, perform structural analysis, and design efficient and sustainable structures.

BIM Precast: This specialized course covers the unique challenges and opportunities of using precast concrete in construction projects. You'll learn how to model precast components, coordinate with other disciplines, and optimize precast construction processes.

BIM MEP: This course focuses on the mechanical, electrical, and plumbing (MEP) aspects of BIM. You'll learn how to model MEP systems, coordinate with other disciplines, and ensure the efficient design and installation of building services.

Why Choose Matrix BIM Academy?

Experienced Instructors: Our faculty comprises industry experts with extensive experience in BIM and construction. They bring real-world knowledge and practical insights to the classroom.

Industry-Relevant Curriculum: Our courses are designed to align with the latest industry standards and best practices. We stay abreast of the evolving BIM landscape to ensure our training remains relevant and valuable.

Hands-on Learning: We emphasize hands-on learning through practical exercises, real-world projects, and the use of industry-standard software.

Flexible Learning Options: We offer a variety of learning formats to suit your schedule and preferences, including classroom training, online courses, and blended learning options.

Career Support: We provide comprehensive career support services, including resume and portfolio building, interview preparation, and job placement assistance.

Invest in Your Future with BIM Training

In today's competitive job market, BIM skills are highly sought after. By enrolling in a Matrix BIM Academy course, you'll gain the knowledge and expertise you need to excel in your career and contribute to the success of your projects.

Enroll Now:

Visit the Matrix BIM Academy website: https://matrixbimacademy.com/bim-courses-in-mumbai/

Explore Course Offerings: Browse through the detailed course descriptions and choose the program that best aligns with your career goals.

Contact Us:

Phone: 91451 51694

Contact us today to learn more about our BIM courses in Mumbai and take the first step towards a brighter future.

0 notes

Text

Enhancing Construction Efficiency with Advanced Precast Solutions

In today’s fast-paced construction industry, efficiency and precision are crucial for delivering high-quality structures on time and within budget. Precast concrete, a widely used solution, offers unmatched versatility and durability for various construction projects. One key aspect of ensuring its effectiveness is the use of Precast Detailing Services, which play a pivotal role in optimizing project outcomes.

What Are Precast Detailing Services?

Precast Detailing Services involve the creation of detailed, accurate drawings and plans for precast concrete components. These services ensure every element is meticulously designed and coordinated to meet specific project requirements. From walls and beams to slabs and columns, precast detailing provides clarity on dimensions, connections, and reinforcements, facilitating smooth manufacturing and installation processes.

Benefits of Precast Detailing

Enhanced Precision: By using advanced software tools, precast detailing ensures all components are fabricated to exact specifications, minimizing errors and rework.

Cost and Time Efficiency: Accurate detailing accelerates the construction timeline, reducing material wastage and labor costs.

Improved Collaboration: Detailed plans streamline communication among architects, engineers, contractors, and manufacturers, ensuring everyone is on the same page.

Versatility: Whether for residential, commercial, or industrial projects, Precast Detailing Services cater to diverse design and structural needs.

Advanced Technology in Precast Detailing

Modern Precast Detailing Services leverage cutting-edge technology like Building Information Modeling (BIM) to provide 3D visualizations and simulations. These tools enable stakeholders to identify potential clashes and design flaws early in the project, ensuring a seamless execution process. Additionally, the integration of automation and digital workflows enhances efficiency and accuracy.

Applications of Precast Detailing

From parking structures and bridges to high-rise buildings and stadiums, precast detailing is integral to a wide range of construction projects. Its ability to accommodate complex designs and large-scale requirements makes it an indispensable service in the construction sector.

Conclusion

The demand for reliable and efficient construction methods continues to rise, and Precast Detailing Services are at the forefront of meeting this need. By ensuring accuracy, reducing costs, and enhancing collaboration, these services contribute significantly to project success. For top-notch precast detailing, consider Moldtekengineering, a trusted name in delivering quality and precision for construction projects. Their expertise ensures your projects are executed flawlessly, saving time and resources while maintaining exceptional standards.

0 notes

Text

What Are the Different Types of Walls in Construction?

Overview

With functional and aesthetic roles to play, the walls form an essential part of all constructions. They provide support, privacy, security, and insulation. There are different categories of walls in construction based on functions, materials, and design.

This article discusses types of walls, their different features, applications, and their importance in civil engineering.

Types of walls in construction and civil engineering:

1. Load-Bearing Walls

Load-bearing walls are critical structural components. These walls take the load from the roof, floors, and other roof parts from the superstructure to the foundation. Typically, materials include concrete, brick, or stone, which provide stability in a building.

In modern development, reinforced concrete walls are mainly being utilized due to strength and durability. Nonetheless, conventional brick walls remain popular in the residential sector because they are cheaper and easy to erect.

2. Non-Load-Bearing Walls

Different from load-bearing walls, non-load-bearing walls solely function as separating barriers and veil for spaces inside buildings. Non-load-bearing walls act as closers in order to give separating privacy to light-weight construction materials like plasterboard, gypsum, and wood.

Non-bearing partitions are very important modern-day interior partition walls. They allow for flexibility, thus popular in commercial and residential projects.

3. Partition Walls

Partition walls are ones used for dividing up interiors into small sections, they can also be described to be permanent or temporary, depending on whether or not the requirement necessitates them. Materials to make them common are glass, wood, aluminum, and drywall.

Movable walls, demountable partitions, and acoustic walls are types of partition walls quite common in today's construction. These walls often contain insulation for soundproofing or thermal control, increasing comfort in the internal spaces.

Also Read : Estimate Of Retaining Wall

4. Retaining Walls

Retaining walls are engineered means used to hold back soil or rock. Besides landscaping, they also are means of paving roads and anti-soil erosion.

There are different types of retaining walls: gravity walls, cantilever walls, anchored walls, and sheet pile walls. Each wall type is selected depending on the slope, soil conditions, and project requirements.

5. Concrete Walls

Concrete walls are one of the mainstays of modern construction because of their strength and durability and, particularly in the face of natural forces, versatility. They lend themselves to structural as well as decorative uses; with three common types being reinforced concrete walls, precast concrete panels, and tilt-up concrete walls.

Whether for insulation or resistance to fire and weather, these layers are still another factor in their choice. Hence, they are increasingly becoming material of choice in residential, commercial, and industrial buildings.

6. Masonry Walls

Masonry walls are made of different materials, such as bricks, stones, or concrete blocks. This gives it the advantage of a beautiful look and durability. The wall could be load-bearing and non-load-bearing, depending on the design and the way it has been constructed.

Brick masonry walls are commonly used in residential houses, while stone walls are usually used in heritage and ornamental structures. The use of mortar in masonry renders the structure strong and stable.

Also Read : Parapet Roof Detail

7. Drywall and Plasterboard Walls

Drywall and plasterboard walls provide lightweight, flexible options for interior partitions. These walls have ease of assembly and can be painted or wallpapered from a smooth surface. They are used mostly for interior walls in offices, homes, and commercial buildings.

The drywall has also become an essential component of wall systems, which include insulation and soundproofing materials. They pave the way for the creation of energy-efficient and comfortable living environments.

8. Timber Walls

Timber walls are able to bring warmth and the aesthetic beauty of nature to the structure. They are commonly used for residential construction and aesthetic detailing. Timber can be used in structural walls and in non-structural walls depending on the design.

Most modern wall materials would use engineered wood products, such as plywood or laminated veneer lumber. These materials provide enhanced strength and do not warp or shrink.

9. Glass Walls

Glass walls are hallmarks of modernist architecture and minimalist design. They provide an open, airy experience, permitting natural light to filter into internal spaces.

Glass walls find their applications in various forms like frameless glass partitions, curtain-wall systems, and structural-glass wall systems. They often find use in commercial buildings, hotels, and exclusive residences.

10. Insulated Walls

Insulated walls are designed for energy efficiency against heat conduction. They include multiple layers in which insulation material obliquely goes in between the structural material.

These walls best constitute the green architectural wall systems. To maintain their health within a desired temperature range, these wall systems cut down energy costs while conserving resources to protect environmental quality.

11. Shear Walls

Shear walls offer specialized structural walls that resist lateral forces, forces arising, for instance, from wind or seismic activity. Normally, these are either reinforced concrete or steel, and they play a crucial role in the stability of high-rise buildings.

Anticlimactically, shear walls become part of wall construction in order to save the day and sustain structured residential and other buildings since these areas are prone to seismic activities and heavy winds.

12. Precast Walls

Precast walls are manufactured away from the site and moved to the construction site for construction and assembly. They are preferred for commercial and industrial works for their speed and precision.

In modern construction, precast walls include precast concrete panels and hollow-core slabs. With less construction time and labor cost, it causes high-quality finishes.

13. Stone Walls

Stone walls have timeless appeal and are mostly associated with historical or rustic architecture. They are durable, low maintenance, and eco-friendly.

In modern construction, stone walls are used structurally and decoratively. An example of this is dry-stone walls, which are common in landscaping and demarcating property boundaries.

14. Hybrid Walls

Hybrid walls combine a multiplicity of materials together to meet given performance standards. For instance, a wall might comprise a steel frame with glass panels or a timber structure sandwiched between layers of insulation.

These walls leverage the strengths of different materials, thus making them quite versatile, giving rise to many variations of wall applications in construction.

15. Curtain Walls

Curtain walls typically lightweight in material e.g., aluminum and glass mostly, curtain walls are used predominantly in high-rise buildings, imparting an elegant, modern look to the building.

The wall will be attached to the main skeleton of the building and basically take care of all the environmental forces concerning insulation, aesthetics, and beauty.

16. Green Walls

Green walls, just like living walls or vertical gardens, are organic, sustainable, and innovative in modern architecture. They consist of plants with integrated irrigation systems.

Such walls not only elevate the style of a structure but also contribute to air quality and guarantee natural insulation that is now found mostly in urban surroundings for getting ecological returns.

Wall Systems:

Wall systems are all-inclusive assemblages made from a variety of components that would enable a building to affect certain performance criteria in functional, efficient walls. Such are operative in the context of load across walls and finishing requirements as insulation, vapor barriers, or finish materials.

Some more examples are insulated panel systems, curtain wall systems, and composite wall systems. These kinds of advanced wall systems have been all the rage in building recently, as they improve building performance and sustainability. Commonly incorporated to earn building green certification and contribute to the comfort within a building.

Wall Construction:

Wall construction is a process that combines the act of planning, designing, and erecting walls featuring durability and aesthetics. There are numerous processes depending on the type of wall, building materials employed, and scope of the projects.

Masonry, framing, and precast assembly are typical methods in wall construction. Details of materials and craftsmanship during construction ensure longevity, safety, and code compliance.

Conclusion:

Just as diverse as other construction and civil engineering structures, so are various types of walls. Different wall purposes include load-bearing walls, partition walls, retaining walls, and green walls. Knowledge of these various options gives architects, engineers, and builders the ability to select for their projects the wall systems that they want.

With advances in technology and materials, wall construction continues to improve in performance, sustainability, and design opportunities. The choice you make, as part of your architectural expression in designing a home, office, or public space, ensures its final functionality, aesthetics, and longevity.

0 notes

Text

HVM BLOCKS / Hostile Vehicle Mitigation blocks and barriers rush delivered and installed! Sales and rentals.

INTRODUCING JACK BLOCKS!

2 x 2 x 4 FEET 2000 LBS. Premium fresh concrete blocks 32 MPA air-entrained, chamfered edges.

(600 MM X 600 MM X 1200 MM). High strength structural premium fresh concrete.

This product is proprietary and designed and engineered in house.

Exclusive to Budget Blocks, it can be lifted by forklift and also with any size manual pallet jack truck, pump truck. The clean and elegant design doubles as seating. The removable pull hook options can be used to string steel cable or chain to create a gate discreetly.

Jack Blocks can be moved by hand by any style hand truck used for moving skids. Jack Blocks can be used as high security barriers for cars with easy movement by hand dolly to allow authorized cars / trucks entry.

Hostile Vehicle Mitigation

Temporary and permanent installations

Anti-terrorism barriers

High security blockers

HVM Stoppers

K-Rated or crash rated certified OPSD barriers available

Emergency installations available 24 hours, evenings, weekends, holidays.

Special events, charity events, corporate / private / public events and spaces. Based in downtown Toronto. Will deliver all over Canada and the USA. Supplier to NYPD-approved installation at the Apple Event in Brooklyn, New York in 2018.

Experienced, professional, punctual team fully licensed and Ministry-compliant. Please check our Google reviews and inquire about our current PDF email catalog. We can custom make any style barrier, block, planter, bench etc. for all your precast requirements.

Thank you,

Sam 416 550 7373

BudgetBlocks.ca

View our products on display at:

25 Polson Street

Toronto, Canada

M5A1A4

Clients include:

APPLE INC. (BROOKLYN, NYC EVENT) / BILLY BISHOP AIRPORT / CASA LOMA / CENTENNIAL COLLEGE / CN RAIL / DEPARTMENT OF NATIONAL DEFENCE / DUNPAR / FEDEX / HYDE PARK HOMES / HYDRO ONE / PEARSON INTERNATIONAL AIRPORT / PUROLATOR / REGIONAL MUNICIPALITY OF DURHAM / STUDIO CITY

#HOSTILE VEHICLE MITIGATION #CONCRETE BLOCKS #JERSEY BARRIERS #ANTI-TERRORISM #HVM BLOCKS #HVMBLOCKS #HVM BARRIERS #HOSTILEVEHICLEMITIGATION #BOLLARDS #CONCRETE BARRIERS #CEMENT BARRIERS #CONCRETE PLANTERS #SECURITY FENCING #TORONTO #ONTARIO #CANADA #USA #SPECIAL EVENTS #EVENT PLANNING #ONTARIO TRAFFIC #TRAFFIC CONTROL #HVM #HVM TORONTO #HVM ONTARIO

0 notes

Text

Precast Plunge Pools: Build Your Concrete Plunge Pool in Brisbane

Plunge Pools Brisbane has partnered with Queensland Plunge Pools to bring you the very best in precast concrete plunge pools. Engineered to perfection and designed with Australian backyards in mind, these pools offer the ultimate combination of luxury and affordability.

Why Choose Our Precast Plunge Pools?

Fast Installation: Quick and hassle-free setup.

Cost-Effective: Quality pools at competitive prices.

Customizable Designs: Choose from above-ground, semi-inground, or fully inground options.

Durable & Stylish: Built to last with finishes that complement any backyard.

Popular Pool Options

Round Pools: From compact 2.5m (5,200L) to spacious 3.5m (14,000L). Perfect for relaxing or entertaining.

Square Pools: 2.48m x 2.48m (7,000L) for modern, space-saving designs.

Rectangle Pools: Up to 3m x 6m (24,000L) for families or serious swimmers.

Visit the website to learn more: https://plungepoolsbrisbane.net.au/concrete-precast-plunge-pool/

0 notes

Text

Steel Detailing for "Emu in the Sky - Sydney Airport" - Client Chess Engineering Click on image to view 3d model Tek1 have modeled the main structure and all the architectural elements with Tekla Strutures. The structural steel shop drawings and the whole steel detailing process was in collaboration with Engineers and fabrication shop supervisors at Chess Engineering. Tek1 has provided numerous suggestions in design, procurement of appropriate equipment, advise on design of jigs saving hundreds of thousands of dollars in the fabrication of the item. As of 11/08/2024 the work is still in progress About Us Steel Detailing and Drafting Services We've been providing detailing services and associated solutions for the past 16 years: Our Stack - We own 23 Tekla licences ( 2 Global + 21 India) - 8 Revit AEC licenses. - 8 Intellicad based dwg licenses Consisting of 7 Teams under very experienced team leads, we provide detailing services for Our Services: - Structural Steel Shop drawings(Tekla / Advance Steel) - Precast Panel drafting and detailing services (Revit, Tekla, Autocad) - Light Gauge Steel Frame Modeling(Scottsdale/Frame CAD/Vertex) - Vertex and FrameCAD you might have to provide your Lic. - Material Take off for Structural steel - As Built Drawings for plumbing services - Estimation services for Precast and Steel - We site measure with point cloud scan. - General Drafting Service Why Choose Us - Huge Industry experience - Repeat Customers who rate us highly. - Excellent documentation, with in house built Apps (Prolox, Quote App) when you don't have Aconex or Procore with ability easily track changes delays - Team of over 40 detailers who are highly experienced. - Zero error or low error rates. - Based in Melbourne. - We own / hire / train / fire staff in our back offices in Chennai and Pondicherry. No flipping. - Comparing quotes / detailers? How do you assess one detailer vs another? Check out our guide. Show Me Proof Judge for yourself: - Look at our large pool of repeat and satisfied clients: - Check our google reviews. - Check out: 100s of Past Projects - Check out our blogs: - Steel Detailing (Tekla, Standards, Detailing Tips) - Staff Memos - Check our tooling and programming capabilities for detailing Precast panels and Structural Steel: - Tekla API. - AutoCAD .net API. - It's no accident that our turn-around for precast and bubble deck projects are lightning fast: our tools help us deliver quickly, while also eliminating errors. - Training: - Online Testing across key Australian Standards - AS1657 and AS1428 which are relevant for producing good steel shop drawings. Training (we made course). We're good with stairs: maintenance and public access. - Recruitment process and training: is rigorous for young aspiring steel detailers. Checkout our training website https://www.training.tek1.com.au - Checkout our training videos on Youtube. - Long standing and highly skilled staff. - We're been in business for +18 years. That's a long time: surely, we must be doing something right? - Strictly no piracy: We do not pirate licenses. Licenses are expensive. This means we have a basic level of integrity in our operations (and to our clients), and we have sufficient quality (in order to recoup our investment), and stay in business over a long period of time. Can the pirates in XYZ location say the same? - Melbourne based, back-offices we own and manage in South India. - We are insured. But remember, insurance is a fallacy. - Still got questions? Call Koshy on +61 0425 791 837. Read the full article

0 notes