#plastic molds

Explore tagged Tumblr posts

Text

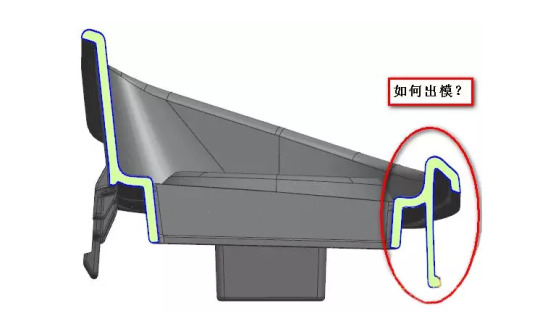

N93 mobile phone bottom case injection mold design key points

N93 mobile phone bottom case product is shown in Figure 1. Maximum outer dimensions of product are 90.97 mm * 43.62 mm * 14.50 mm; average thickness of plastic parts is 1.00 mm, plastic part material is PC+ABS, shrinkage rate is 1.004, and plastic part weight is 16.50 grams. Technical requirements for plastic parts are that there must be no defects such as peaks, underfilling, flow lines, pores,…

View On WordPress

#injection mold design#mobile phone bottom case injection mold design#mobile phone molds#mold design#Mold design drawing#N93 mobile phone bottom case injection mold design#plastic molds#plastic part#plastic parts#precise mobile phone molds

0 notes

Text

Driving Automotive Innovation Forward with Advanced Rapid Injection Molding Techniques

In the ever-evolving landscape of automotive manufacturing, staying ahead of the curve is paramount. With the demand for lightweight, durable, and cost-effective components, plastic injection molding has emerged as a cornerstone technology in the industry. As pioneers in the field, RPWORLD is leading the charge in driving automotive innovation forward through advanced rapid injection molding techniques.

Plastic Injection Molders play a pivotal role in the automotive supply chain, producing a diverse array of components ranging from interior trims to exterior panels. With the relentless pursuit of efficiency and precision, manufacturers are continually seeking ways to enhance their processes. This is where advanced rapid injection molding techniques come into play, revolutionizing the way automotive parts are produced.

At RPWORLD, we leverage cutting-edge technologies and extensive expertise to deliver unparalleled solutions to our clients. Our state-of-the-art facilities are equipped with advanced machinery and automated systems, allowing for high-speed production without compromising on quality. Through meticulous process optimization and stringent quality control measures, we ensure that each component meets the exacting standards of the automotive industry.

Plastic Molding is not just about producing parts; it's about pushing the boundaries of what's possible. With innovative materials and design concepts, we empower automotive manufacturers to unlock new possibilities in vehicle design and performance. From lightweight thermoplastics to high-strength composites, our comprehensive range of materials caters to diverse applications, providing the flexibility and versatility needed to realize ambitious design visions.

Innovation is at the heart of everything we do at RPWORLD. Our dedicated team of engineers and designers work closely with clients to develop customized solutions tailored to their specific requirements. Through collaborative partnerships and a relentless commitment to excellence, we strive to push the boundaries of what's possible in automotive manufacturing.

One of the key advantages of rapid injection molding is its ability to accelerate the product development cycle. With traditional manufacturing methods, prototyping and tooling can be time-consuming and cost-prohibitive. However, with rapid injection molding, we can quickly iterate designs and produce functional prototypes in a fraction of the time, enabling faster time-to-market and greater agility in response to changing market demands.

Furthermore, rapid injection molding offers cost efficiencies that are unparalleled in the industry. By streamlining the production process and minimizing material waste, we help automotive manufacturers optimize their manufacturing costs without compromising on quality or performance. This cost-effectiveness is particularly crucial in today's competitive market environment, where margins are constantly under pressure.

In conclusion, advanced rapid injection molding techniques are driving automotive innovation forward, empowering manufacturers to push the boundaries of design, performance, and efficiency. As a leading provider of plastic injection molding solutions, RPWORLD is committed to pushing the envelope of what's possible, helping our clients stay ahead of the curve in the fast-paced world of automotive manufacturing. With our cutting-edge technologies, unrivaled expertise, and unwavering dedication to excellence, we are shaping the future of mobility, one injection at a time.

#Plastic Injection Molders#Plastic Molding#Plastic Molds#Injection Molding Near Me#Injection Molding Spin Bar

0 notes

Text

Some product parts produced by injection molds

If you're looking for help with your plastic injection mould, this is a great place to start.

We welcome any of your new project for which we will be pleased to provide you our competitive offers.

Email:[email protected]

0 notes

Text

Advantages of Plastic Injection Molding

Polymer injection molding is a high-precision technology for the production of parts & solid products. With the help of special equipment, the polymer blanks become viscous & are subsequently injected into the mold under high pressure, where they acquire the required shape. The plastic material in the forming tool is evenly distributed over its entire inner surface, after which the cooling stage begins. According to the experts at injection molding service China, the molding of products due to high pressure requires preliminary preparation of the material. High-quality equipment, exposure to proper heating & the experience of the operator ensure the production of polymer products with high mechanical and external properties.

Advantages of injection molding

Each manufacturer tries to minimize its costs for the manufacture of goods. But, often we have to deal with the fact that the reduction in price negatively affects the quality of the goods supplied, and in the future, the demand for it. For this reason, many manufacturers incur losses.

Why is it recommended to resort to the high-pressure casting method for the manufacture of large quantities of polymer products?

Unlimited circulation. Metal molds made to order for a certain type of product can be used for a long time because they are designed for a large number of work cycles.

Due to injection molding technology, it is possible to produce objects of the most complex design, which other equipment is not capable of performing. If necessary, the part can have very thin walls. For the production of such parts, it is recommended to use metal molds, the properties and design of which allow you to accurately recreate the smallest elements of the future product. It is an excellent option for the manufacture of both the simplest products & elements with complex design solutions with the presence of patterns, various recesses, and a large number of slots.

High-precision & cost-effective production: The thermoplastic is injected into the mold under high pressure, which allows the material to be evenly distributed over the entire inner surface of the forming tool. When casting, the material completely repeats even the smallest patterns and recesses of the prototype.

Products produced by the injection molding method do not need further labor-intensive modifications. Exceptions include only very complex products that require minimal mechanical intervention.

Low price for the product: Under the condition of a large circulation, the cost of plastic goods is reduced, which ensures quick sales. The main costs occur at the stage of preparing the equipment for operation, more precisely during initial launches.

In addition to these advantages, the high-pressure casting method has some disadvantages. The cost of preliminary work is considerable, and the payback in the manufacture of products in small batches or single copies is low.

If you are looking for quality products, then visit hsmolds.net, aninjection molding service in China. They are proud to showcase their high-quality products, all made with precision & care in China using the latest plastic injection molding technology. Our state-of-the-art facilities and experienced team allow us to produce various plastic parts for different industries. Browse through their collection & see for yourself the level of craftsmanship and attention to detail that goes into every piece.

Source: Advantages of Plastic Injection Molding

0 notes

Text

Safety Relief Valve Manufacturer in China

Shanghai Wuyue Pump & Valve Group is a professional breather valve, pressure reducing valve as well as Safety relief valve manufacturer in china. It is a high-tech enterprise specializing in technology development; product development and after-sales service in the field of pump and valve fluids. Visit our website to know more about safety relief valve supplier in china.

#safety relief valve manufacturer in china#Suppliers#Plastic Molds#Mold Parts#Manufacturers#Machining#Injection Mold

0 notes

Text

Given that Belobog is so full of snow, I'm kinda sad we never get to see any snowmen anywhere. Like that would have made for such a cute bg decoration!

And I think it would be especially funny for Sampo to make them, not out of pure, innocent whimsy and joy, but like specifically to be a menace smzhnsjd

Like Gepard keeps finding little snowmen out around the frontlines. And normally he would just turn a blind eye to this like he does with other things (like the shitty amateur distillery no one thinks he knows about); war sucks, their own damn leader is trying to kill them and Gepard is treading water just trying to keep Cocolia from using his guards as cannon fodder. If his soldiers want to make some snowmen in their downtime, then they should be allowed that. God knows they've earned it.

BUT SOMEONE IS MAKING SNOWMEN THAT LOOK LIKE HIM, DAMMIT!!!

Gepard keeps finding them down the back alleys and more hidden parts of the frontlines! And they all have the same grumpy little face, with blue-painted rocks for eyes and sometimes even gold-colored bullet casings for hair! And he knows who it is the second he finds another little blue haired, green eyed snowman next to it! Fuckin' Koski is sneaking in here, and easily enough that he has the time to taunt him!

Gepard once found a little Snow Geppie with angry eyebrows and red roses stuck in its blushing cheeks that was handcuffed to a weapons rack, which was when he realized someone had pickpocketed his handcuffs. He punches the head clean off the little Snow Sampo nearby, only to discover that it is also holding his wallet, minus all the shield he'd had in it that morning. Gepard kicks it for good measure.

One time he found a little Snow Sampo offering roses to a little Snow Geppie, and he quickly knocked those over too before anyone else could see them or his red face. He swears he can feel Sampo snickering and mocking him nearby.

Sometimes, Gepard finds little Snow Sampos with tiny sacks thrown over their shoulders, all filled with items that are SUPPOSED to be in the depths of the guarded Silvermane storehouses. Sampo technically isn't even stealing anything, he's just showing Gepard that he could if he wanted to, and poor Gepard is going to pop an aneurysm.

Pela: Good morning, Captain. Have you been outside of your tent yet?

Gepard: No. ....Why.

Pela: No reason. Say, have you heard of any break ins recently?

Gepard: No, why.

And Pela holds open the tent flap and there's a ton of tiny little Silvermane Guards snowmen in tight neat rows, all with their little stick arms up in salute, and each one with an actual, stolen official helmet-mask.

Pela: You run a real tight ship out here, huh.

Gepard: (looooong weary muffled sigh as he drags a hand down his face)

#gepo#sampard#hsr gepard#hsr sampo#sampo koski#gepard landau#pelageya sergeyevna#hsr#honkai star rail#I love Sampo being petty as shit just to rile Geppie up fkdsajflasdj#like he is absolutely watching from somewhere hidden nearby and snickering to himself#of a related note I think Caelus and March 7th should be given those little plastic mold thingies that make rubber ducky-shapes in the snow#they go through the restricted zone and just leave them in random places#Gepard trying to conduct serious military business and up on the wall behind him are a row of rubber duckies judging the Guards fjklasjfkld

286 notes

·

View notes

Text

Happy Fakie Friday! Here's a brand new fakie line: Wild Manes from Jakks Pacific!

#fakie friday#Jakks Pacific#Wild Manes#if you are about to type 'they aren't fakie! they're good quality and inventive and creative!'#well fakies can be those things too#80s Remco fakies had great quality plastic#(people just forget b/c other companies bootlegged Remco's molds so much)#Enchanted Kingdom horses were very creative#and also they were fakies

80 notes

·

View notes

Text

no I lied im posting it now. here are some fullbodies of the characters that need it least, because one of them I've already posted a fullbody of and the other is a shameless rip of an official design

#puyo puyo#puyo puyo school au#my stuff#arle nadja#doppelganger arle#a teeny cameo of#carbuncle#though technically its not him its plastic molded badly in his image#i gave doppel a little carbuncle keychain and had to think about where she would have gotten one#and if so if arle would also have one#so those little dudes are from a gachapon machine they saw once and never again.#anyway youve seen doppel's keychain its in the allysol installment#arle's strap hasnt made a debut but it is in the next one.

33 notes

·

View notes

Text

Adam takes a very specific stance over his fallen foes: boot on their chest, weapon in his hand, and a smirk on his face

You think that's the last thing he ever saw with two eyes?

#rwde#me when characters use their abusers tactics to feel and be seen as powerful as they unwittingly continue the cycle of violence: 😍😍😍#its probs significant that he never does this w blake even when he does have her pinned down#to me it means he never saw her as lesser. as a beast to be tamed or a minion to conquer#even when he wanted to remove her head he never wanted to pin her down like he had been#granted we never actually see him fight any other faunus so who knows if that's true#the ones we see him boot are all human so it could be that specific reversal he wants rather than the general sense of power over another#i just think he's neat#also maya era is ugly as sin. who is this plastic mold and what happened to my scrappy boy w the scuffed mask

15 notes

·

View notes

Text

Illustration detail from a Bakelite Plastics promotional postcard - 1938.

#vintage illustration#vintage advertising#bakelite#bakelite plastics#plastics#plastic products#chemistry#bakelite company#molded plastics#resins#polymers#chemical companies#plastic manufacturers#union carbide#vinyl#union carbide and carbon corporation#deco design#art deco#vintage postcards#industry#science#product design#industrial design

15 notes

·

View notes

Text

The world's top ten mold types ranking-Plastic mold

For previous reading, please refer to Stamping die.A mold that allows molten plastic raw materials to fill cavity under pressure and solidify into products and parts, including injection molds, compression molds, extrusion molds, blow molding molds, thermoforming molds, foaming molds, etc. Overview of principle of plastic molds Plastic molds are important tools in plastic processing industry.…

View On WordPress

#hot runner mold#injection molding#injection molding process#injection molds#mold design#mold manufacturing#Mold manufacturing and processing#mold structure#molded product#molding parts#molding process#part design#plastic mold#plastic mold design#Plastic mold manufacturing process#plastic mold shrinkage ratio#plastic molds#plastic parts#plastic processing#plastic product#plastic products#plastic shrinkage#precision injection molding#precision molds

0 notes

Text

How Customized Injection Molding Solutions Save Your Biotech Device Development by 80%

Introduction:

In the rapidly evolving landscape of biotechnology, the development of cutting-edge devices demands innovative solutions that not only meet stringent industry standards but also ensure efficiency and cost-effectiveness. One key aspect that plays a pivotal role in the biotech device development process is injection molding. This article delves into the significant impact of customized injection molding solutions on saving up to 80% of the development costs for biotech devices.

Precision Engineering for Complex Designs:

Customized injection molding allows for the precise replication of intricate and complex designs, a crucial requirement in the biotech industry where devices often have intricate geometries and tight tolerances. This level of precision ensures that the final product meets the specific needs of the biotech application, eliminating the need for costly revisions and adjustments in the later stages of development.

Material Selection for Enhanced Performance:

Biotech devices often require specialized materials to meet the stringent regulatory and performance criteria. Customized injection molding solutions enable the selection of materials that are not only compliant with industry standards but also enhance the overall performance of the device. This targeted material selection ensures durability, biocompatibility, and resistance to harsh environmental conditions, reducing the likelihood of failures and the need for redesigns.

Rapid Prototyping for Iterative Development:

The iterative nature of biotech device development demands quick turnaround times for prototypes and design modifications. Customized injection molding facilitates Rapid Prototyping, allowing developers to assess and refine their designs swiftly. This agility in the development process not only accelerates time-to-market but also significantly reduces costs associated with prolonged development cycles.

Cost-Efficient Production:

Traditional manufacturing methods often involve high tooling costs and lengthy lead times. Customized injection molding solutions, on the other hand, offer a more cost-efficient approach by minimizing

tooling expenses and allowing for large-scale production with shorter cycle times. This results in substantial cost savings, contributing to an overall reduction in the financial burden of biotech device development.

Streamlined Quality Control:

Ensuring the quality and consistency of biotech devices is paramount. Customized injection molding solutions enable the implementation of rigorous quality control measures throughout the manufacturing process. By maintaining tight control over key parameters, such as temperature, pressure, and material flow, manufacturers can produce high-quality components consistently, reducing the need for post-production inspections and rejections.

In conclusion, the utilization of customized injection molding solutions in biotech device development presents a transformative opportunity for companies to achieve substantial cost savings of up to 80%. From precision engineering and material selection to rapid Prototyping and cost-efficient production, these solutions empower developers to navigate the complexities of biotech innovation with greater flexibility and efficiency.

As you embark on your biotech device development journey, consider partnering with RPWORLD, a leading provider of customized injection molding solutions. With our expertise and commitment to excellence, we can help you realize significant cost savings while ensuring the precision and quality your project demands. Embracing customized injection molding is not just a strategic choice; it's a crucial step towards optimizing the development process and driving advancements in the biotech industry. Contact RPWORLD today and let's shape the future of biotechnology together.

0 notes

Text

Eastcom Technology provides Plastic Injection molds service. We are a supplier of precision molds, if you have interests, I will be very appreciate.

0 notes

Text

Mold Inserts in CNC Machining: A Key Component in Precision Manufacturing

CNC machining is a precise and efficient method used in various industries to create custom-machined parts and components with high accuracy. One essential element that contributes significantly to the precision of CNC machining is mold inserts. In this article, we will explore the significance of mold inserts in CNC machining and how they play a crucial role in achieving precision in manufacturing processes.

Understanding Mold Inserts

Mold inserts are specialized components used in CNC machining to create specific features or details within a larger part. These inserts are designed to fit precisely into a mold or cavity, allowing for the creation of intricate shapes, patterns, and fine details that would be challenging to achieve through traditional machining methods.

The Role of Mold Inserts

Precision and Detail: Mold inserts enable CNC machines to produce custom-machined parts with exceptional precision and intricate details. They are particularly useful when manufacturing parts with complex geometries or tight tolerances.

Cost Efficiency: By using mold inserts, CNC machined components manufacturers can avoid the need to machine an entire part from solid material. This results in significant cost savings in terms of material and machining time.

Versatility: Mold inserts are versatile and can be easily replaced or modified to accommodate design changes. This flexibility is especially valuable in industries where product iterations are common.

Consistency: Mold inserts help maintain consistency across multiple parts or batches. The precision of the inserts ensures that each part produced is identical in quality and accuracy.

Reduced Waste: Using mold inserts minimizes material wastage because only the necessary areas are machined, reducing the amount of scrap material generated.

In CNC machining, precision is paramount, and mold inserts are an integral part of achieving that precision. They enable custom machined parts & aluminum CNC turning parts manufacturers to create intricate and accurate parts efficiently, ultimately contributing to cost savings and high-quality end products. Mold inserts are a testament to the versatility and adaptability of CNC machining, allowing manufacturers to meet the demands of various industries with precision and efficiency.

Resource: Mold Inserts in CNC Machining: A Key Component in Precision Manufacturing

0 notes

Text

the way that landlords are negligent about water damage in my city completely drives me up the wall. what's worse, laying down a tarp for the damp season until you can conduct repairs, or having to pay to completely replace the roof and replaster the ceilings, and rebuild walls that experienced intrusion? make it make sense!!!!

#and then do mold remediation and replace/fix floors that experienced water damage#fuck dude dispense the big piece of plastic and schedule some shit for april#surely between insurance and months of accrued rent they'll have $ for the repairs#ffs

8 notes

·

View notes