#permanent magnet synchronous motor

Explore tagged Tumblr posts

Text

MG ZS EV Executive: A Comprehensive Review

₹18.98 Lakh General Overview The MG ZS EV Executive is a modern electric vehicle (EV) that offers a balance of style, practicality, and cutting-edge features. It is available in three colors: Starry Black, Aurora Silver, and Candy White, and is backed by a 3-year warranty with unlimited kilometers, ensuring long-term reliability for owners. This SUV targets individuals seeking an eco-conscious…

#50.3 kWh battery#6 Airbags#ADAS#Android Auto#Apple CarPlay#Automatic Transmission#CCS 2#driver assistance#Eco-Friendly Vehicle#electric car#Electric SUV#Electric vehicle#EV Technology#Fast charging#FWD#i-Smart connected technology#LED headlights#MG ZS EV Executive#MG ZS EV review#permanent magnet synchronous motor#PM 2.5 filter#range 461 km#regenerative braking#reverse camera#safety features#SUV#SUV review#Urban Driving

0 notes

Text

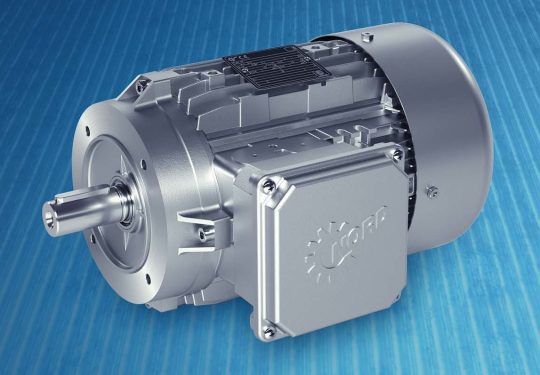

Unlocking Growth: Exploring the IE4 Permanent Magnet Synchronous Motor Market

The global economy is undergoing a significant shift towards sustainability and energy efficiency, driven by environmental concerns and regulatory mandates. In this transformative landscape, the IE4 Permanent Magnet Synchronous Motor (PMSM) market has emerged as a critical enabler of progress. According to a study by Next Move Strategy Consulting, the global IE4 Permanent Magnet Synchronous Motor Market size is predicted to reach USD 308.6 million with a CAGR of 8.97% by 2030. This underscores the growing importance of these advanced electric motors in various industries worldwide.

Request for a sample, here: https://www.nextmsc.com/ie4-permanent-magnet/request-sample

Understanding IE4 Permanent Magnet Synchronous Motors:

IE4 Permanent Magnet Synchronous Motors represent a paradigm shift in electric motor technology. Unlike conventional motors that rely on electromagnetic induction, PMSMs utilize permanent magnets to generate magnetic fields, resulting in higher efficiency, precision control, and reduced energy consumption. These motors are characterized by their synchronous operation, where the rotor rotates at the same speed as the magnetic field produced by the stator, enabling precise speed control and torque regulation.

Key Drivers of Market Growth:

The growth of the IE4 Permanent Magnet Synchronous Motor market is driven by several key factors. Firstly, stringent environmental regulations aimed at reducing carbon emissions and improving energy efficiency have prompted industries to adopt eco-friendly technologies, including high-efficiency electric motors. IE4 PMSMs offer significant energy savings compared to traditional motors, making them an attractive choice for applications where energy efficiency is paramount.

Moreover, the rapid expansion of industrial automation and the adoption of smart manufacturing technologies have fueled the demand for high-performance motors capable of delivering optimal efficiency and reliability. IE4 PMSMs are well-suited for use in robotics, CNC machines, conveyor systems, and other automated processes, where precision control and high torque density are essential.

Furthermore, the growing adoption of electric vehicles (EVs) and hybrid vehicles is driving demand for IE4 PMSMs in the automotive sector. These motors play a crucial role in powering electric propulsion systems, offering superior efficiency, power density, and torque characteristics compared to traditional internal combustion engines. As governments worldwide implement policies to reduce vehicle emissions and promote electric mobility, the demand for IE4 PMSMs in the automotive industry is expected to surge in the coming years.

Challenges and Opportunities:

Despite the promising growth prospects, the IE4 Permanent Magnet Synchronous Motor market faces several challenges. One of the primary challenges is the high initial cost associated with these motors, primarily due to the use of rare-earth magnets such as neodymium and dysprosium. The limited availability of these materials and their fluctuating prices pose a significant risk to manufacturers and end-users alike. However, ongoing research and development efforts aimed at alternative magnet materials, such as ferrite and samarium cobalt, are expected to mitigate this challenge in the long term.

Additionally, the complexity of motor design and integration presents challenges in terms of manufacturing, installation, and maintenance. IE4 PMSMs require sophisticated control systems and advanced manufacturing techniques to achieve optimal performance and efficiency. Moreover, the customization requirements for different applications and industries add further complexity to the production process, potentially increasing lead times and costs.

Despite these challenges, the IE4 Permanent Magnet Synchronous Motor market presents significant opportunities for growth and innovation. The emergence of new applications and industries, such as renewable energy, robotics, and IoT, is driving demand for high-performance motors with enhanced efficiency, reliability, and durability. For instance, the rise of wind and solar power generation has created a growing need for IE4 PMSMs in wind turbines, solar tracking systems, and grid stabilization solutions. Similarly, the integration of robotics and IoT technologies in manufacturing, logistics, and healthcare sectors is driving demand for IE4 PMSMs in robotic arms, automated guided vehicles (AGVs), and medical devices.

Adoption Challenges in Traditional Industries: Despite the advantages of IE4 Permanent Magnet Synchronous Motors, the adoption rate in traditional industries such as HVAC, pumping systems, and material handling equipment has been relatively slow. This can be attributed to factors such as entrenched reliance on conventional motor technologies, lack of awareness about the benefits of PMSMs, and concerns about compatibility with existing infrastructure. Overcoming these adoption challenges will require targeted education and awareness campaigns, along with incentivization programs to encourage businesses to transition to more energy-efficient motor solutions.

Regulatory Compliance and Standards: Compliance with industry standards and regulations poses another challenge for the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must ensure that their products meet stringent performance, safety, and efficiency standards set forth by regulatory bodies and industry associations. Failure to comply with these standards can result in costly recalls, penalties, and damage to brand reputation. Therefore, investing in research and development to develop motors that not only meet but exceed regulatory requirements will be essential for gaining a competitive edge in the market.

Inquire before buying, here: https://www.nextmsc.com/ie4-permanent-magnet/inquire-before-buying

Supply Chain Vulnerabilities: The IE4 Permanent Magnet Synchronous Motor market is susceptible to supply chain disruptions, particularly concerning the procurement of rare-earth magnets and other critical components. Dependence on a limited number of suppliers, geopolitical tensions, and trade restrictions can lead to shortages, price fluctuations, and delays in production. To mitigate supply chain vulnerabilities, manufacturers must diversify their supplier base, invest in vertical integration, and explore alternative sourcing options to ensure a reliable and resilient supply chain.

Technological Innovation and Advancements: Continuous technological innovation is imperative for driving growth and differentiation in the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must invest in research and development to enhance motor efficiency, reliability, and performance while reducing costs and environmental impact. Advancements in materials science, motor design, power electronics, and digital control systems offer opportunities to develop next-generation PMSMs that meet the evolving needs of industries and consumers alike.

Lifecycle Sustainability and End-of-Life Management: Ensuring the sustainability of IE4 Permanent Magnet Synchronous Motors throughout their lifecycle presents both challenges and opportunities for manufacturers. From raw material extraction to manufacturing, use, and end-of-life disposal, minimizing environmental impact and maximizing resource efficiency are paramount. Implementing circular economy principles, such as remanufacturing, recycling, and responsible disposal, can help reduce waste and extend the lifespan of PMSMs, thereby contributing to a more sustainable and circular economy.

Market Fragmentation and Competition: The IE4 Permanent Magnet Synchronous Motor market is characterized by intense competition and market fragmentation, with numerous players vying for market share across different regions and industry verticals. As a result, manufacturers must differentiate their products through innovation, quality, and value-added services to stand out in the crowded marketplace. Strategic partnerships, mergers and acquisitions, and market consolidation may also be necessary to strengthen market position and achieve economies of scale.

Skills Gap and Talent Shortage: Addressing the skills gap and talent shortage in the IE4 Permanent Magnet Synchronous Motor industry is essential for driving innovation and sustaining market growth. As technology advances and the demand for specialized skills increases, manufacturers must invest in workforce development, training programs, and knowledge transfer initiatives to cultivate a skilled workforce capable of designing, manufacturing, and servicing advanced PMSM systems. Collaboration with educational institutions, vocational training centers, and industry associations can help bridge the skills gap and ensure a steady supply of talent for the future.

Conclusion:

In conclusion, the IE4 Permanent Magnet Synchronous Motor market is poised for substantial growth and innovation in the coming years. With increasing emphasis on energy efficiency, sustainability, and technological advancement, IE4 PMSMs are expected to play a pivotal role in powering the industries of the future. By leveraging their superior efficiency, reliability, and performance, these advanced electric motors are unlocking new opportunities for growth and transformation across various sectors. However, addressing the challenges associated with cost, materials, and complexity will be crucial for realizing the full potential of IE4 PMSMs and driving widespread adoption. As manufacturers, researchers, and policymakers collaborate to overcome these challenges, the IE4 Permanent Magnet Synchronous Motor market will continue to evolve and thrive, shaping a more sustainable and efficient future for generations to come.

#IE4 Permanent Magnet Synchronous Motor#construction and manufacturing#market research#market trends#business insights

0 notes

Link

vIE4 & IE5 Permanent Magnet Synchronous Motors Market Trends Analysis Report 2023-2029: The IE4 & IE5 Permanent Magnet Synchronous Motors Market report provides information about the Global industry, including valuable facts and figures. This research study explores the Global M

0 notes

Text

Even BMW—a company that literally has "motor" for a middle name—only deigns to reveal on its i3 product page that the motor is “AC synchronous.” Meanwhile, the engine in the base-model 3 Series a few clicks over is described as a “2.0-liter BMW TwinPower Turbo inline 4-cylinder, 16-valve 180-hp engine that combines a twin-scroll turbocharger with variable valve control (Double-VANOS and Valvetronic) and high-precision direct injection.” That's before the site goes on to describe the engine’s electronic throttle control, auto start-stop function, direct ignition system with knock control, electronically controlled engine cooling (map cooling), brake energy regeneration, and driving dynamics control with Eco Pro, Comfort, and Sport settings.

But then, it's hard to blame people for not giving a damn. Most consumers—hell, even car geeks—don’t possess the knowledge or vocabulary to authoritatively converse about electric motors, and on the surface, there would seem to be precious little indication that there’s even anything meaningful to discuss about them. It’s a lot harder to get excited about, say, the difference between permanent magnets and AC induction than it is between V8s and twin-turbo sixes. The fact that carmakers and the media don’t billboard motor innovation naturally leads the public to assume that there’s nothing much going on there.

interesting the way marketing focuses on the battery, which obviously has been the major development in the tech overall

33 notes

·

View notes

Text

How does an engine contribute to a car's powertrain?

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

3 notes

·

View notes

Text

China: Alstom Demonstrates New Propulsion System on Chengdu Line 7

Alstom’s Chinese joint venture, Alstom NUG Propulsion System Co. (ANP) has successfully applied its silicon carbide (SIC) and permanent magnet motor propulsion system (PMM) on a demo train on Chengdu Line 7. This was the first time that this type of traction system has been introduced in China, combining a complete silicon carbide traction converter and a permanent magnet synchronous…

View On WordPress

3 notes

·

View notes

Text

How Permanent Magnet Machines Improve Energy Efficiency in Industrial Applications

Energy efficiency has become a key focus for industries looking to reduce operational costs, minimize energy waste, and meet sustainability goals. One of the most effective ways to enhance energy efficiency in industrial applications is through the use of permanent magnet machines. These machines, including Permanent Magnet Synchronous Machines (PMSMs) and Brushless DC Motors (BLDCs), offer superior performance, higher efficiency, and reduced energy consumption compared to traditional induction motors.

In this article, we will explore how permanent magnet machines contribute to energy efficiency in industrial applications and why they are becoming the preferred choice in modern manufacturing and automation systems.

1. Higher Efficiency Compared to Induction Motors

Why It Matters

Traditional induction motors are widely used in industrial settings, but they lose energy through electrical resistance and rotor slip. This inefficiency increases energy consumption and operational costs.

How Permanent Magnet Machines Help

Elimination of Rotor Losses – Permanent magnet machines do not require electrical current to excite the rotor, reducing energy losses.

Higher Power Density – They provide more power output for the same size compared to induction motors.

Improved Load Efficiency – These machines maintain efficiency even at partial loads, making them ideal for variable-speed applications.

The improved energy efficiency of permanent magnet motors results in lower electricity bills, reduced heat generation, and longer operational life of industrial equipment.

2. Reduced Power Consumption in High-Torque Applications

Why It Matters

Many industrial processes require high torque at low speeds, such as conveyor belts, extruders, and material handling equipment. Induction motors often consume excess energy in these conditions due to their dependency on high currents.

How Permanent Magnet Machines Help

Higher Torque Density – These machines generate higher torque per unit of electric power.

Lower Current Requirements – They require less electrical current to achieve the same torque output.

No Need for Gearbox Systems – Direct-drive permanent magnet motors eliminate mechanical inefficiencies in transmission systems.

By optimizing power consumption in high-torque applications, permanent magnet machines enable industries to reduce energy waste and increase overall productivity.

3. Enhanced Performance in Variable-Speed Operations

Why It Matters

Many industrial processes require variable-speed operations to optimize performance and energy consumption. Traditional motors suffer from efficiency losses when operated at varying speeds.

How Permanent Magnet Machines Help

Precise Speed Control – With advanced motor control technology, these machines adjust speed efficiently without excess energy loss.

Smooth Acceleration and Deceleration – Unlike traditional motors that require additional control mechanisms, permanent magnet motors respond quickly and smoothly.

Integration with Smart Drives – These machines work seamlessly with variable frequency drives (VFDs) and intelligent motor controllers for optimized energy usage.

Industries using variable-speed systems such as pumps, compressors, and HVAC systems benefit greatly from permanent magnet machines due to their dynamic efficiency and adaptive energy consumption.

4. Lower Maintenance and Longer Lifespan

Why It Matters

Frequent maintenance of industrial machinery increases downtime, reduces productivity, and adds to operational costs. Traditional motors with brushes, slip rings, and bearings require regular servicing and replacements.

How Permanent Magnet Machines Help

Brushless Design – BLDC motors and PMSMs eliminate brushes, reducing wear and tear.

Minimal Heat Generation – Lower energy losses mean cooler operating temperatures, which extends motor lifespan.

Less Mechanical Wear – Fewer moving parts lead to less friction and lower maintenance costs.

Industries relying on continuous operations, such as manufacturing, packaging, and assembly lines, can reduce maintenance costs and extend machine life by switching to permanent magnet machines.

5. Energy Savings in Renewable and Sustainable Applications

Why It Matters

Industries are shifting towards energy-efficient and sustainable solutions to meet global carbon reduction targets. Traditional motors often consume more energy than necessary, leading to excess CO₂ emissions.

How Permanent Magnet Machines Help

Higher Efficiency in Wind and Hydro Power Systems – These motors are widely used in renewable energy systems for power generation.

Integration with Smart Grids – Permanent magnet motors work efficiently with energy storage and grid balancing systems.

Reduction in CO₂ Emissions – Lower energy consumption directly translates to reduced environmental impact.

By adopting permanent magnet machines, industries contribute to sustainability efforts while improving their own operational efficiency.

6. Compact and Lightweight Design for Space Efficiency

Why It Matters

Industrial spaces are often limited, and bulky machines can create inefficiencies in factory layouts. Traditional motors require large cooling systems and additional space for auxiliary components.

How Permanent Magnet Machines Help

Smaller Footprint – Higher power density means compact motor designs, freeing up valuable floor space.

Lighter Weight – Reducing weight allows for easier installation and mobility.

Flexibility in Industrial Layouts – Compact machines enable optimized factory and plant layouts.

Industries with limited space, such as robotics, automation, and electric vehicle (EV) manufacturing, benefit significantly from compact and efficient motor solutions.

Conclusion

Permanent magnet machines are revolutionizing industrial applications by providing higher efficiency, lower energy consumption, reduced maintenance, and superior performance. Industries adopting these motors benefit from cost savings, better productivity, and sustainability.

As businesses focus on energy efficiency and long-term savings, transitioning to permanent magnet machines is an investment that delivers both economic and environmental benefits.

0 notes

Text

Powering The Future: Understanding EV Motor Technologies by Belrise Industries

Electric vehicles (EVs) are gaining popularity worldwide, and as the demand for these vehicles increases, there is a greater need for efficient and reliable electric motors. When it comes to EV motors, the below three main types are widely used: Permanent Magnet Synchronous Motors (PMSMs), Induction Motors, and Brushless DC Motors.

Each type has its own advantages and disadvantages, making it important for an Automobile company to choose the right motor for their EV vehicles.

EV Motors & Their Types

Let’s start by understanding the basic functionality of these motor types and how they drive the EV industry. Essentially, an electric motor is a device that converts electrical energy into mechanical energy, propelling the vehicle forward. All motors consist of a rotor, a stator, and a set of windings. As electric current flows through the windings, a magnetic field is created. This magnetic field interacts with the magnetic field of the stator, resulting in the rotation of the rotor, which powers the electric vehicle.

Let’s delve into the different types of EV motors:

Ev Motor Types and Their Usages

Permanent Magnet Synchronous Motors (PMSMs):

PMSMs are the most commonly used motors in EVs. They are known for their efficiency, reliability, and long lifespan. PMSMs generate a rotating magnetic field using a permanent magnet, which interacts with the stator coils to produce the electric current that powers the motor. PMSMs strike an optimal balance between efficiency, reliability, and cost-effectiveness. They are also relatively easy to manufacture, contributing to lower overall costs.

Induction Motors:

Induction motors are a more budget-friendly option compared to PMSMs, but they tend to be less efficient and have a shorter lifespan. These motors create a rotating magnetic field through the stator coils, inducing a current in the rotor. The resulting current generates a magnetic field that interacts with the stator field to produce torque. Induction motors are suitable for budget-conscious EV buyers as they offer adequate performance for most driving conditions, though they may not be as efficient as PMSMs.

Brushless DC Motors:

Brushless DC motors are the most efficient type of motor available but also the most expensive. They utilise a DC motor with a controller to generate a rotating magnetic field that interacts with the stator coils, producing the electric current needed to power the motor. These motors are primarily used in high-performance EVs such as Tesla’s Model S Plaid. Despite being more costly, brushless DC motors offer superior efficiency compared to induction motors.

Key Factors in Choosing Motors for EV Segment Vehicles

Now, let’s explore the steps involved in the motor selection process, highlighting the key factors that automobile companies take into account.

The motor selection process involves a series of steps that enable automobile companies to make informed decisions. Let’s examine the factors, which contribute to achieving the desired outcomes for EVs.

Cost Considerations:

Cost is a significant factor in the motor selection process. Automobile companies aim to strike a balance between performance requirements and affordability to ensure their EVs are competitive in the market. Factors such as motor manufacturing costs, economies of scale, and potential long-term savings in maintenance and operating expenses are carefully considered. By selecting a cost-effective motor, automobile companies enhance the overall viability and market competitiveness of their EVs.

Battery Compatibility:

Selecting a motor that is compatible with the EV’s battery system is crucial for seamless integration and efficient power transfer. Factors such as voltage, current, and charging capabilities are taken into account to ensure proper alignment between the motor and battery. Compatibility ensures optimal performance, longevity, and efficient utilization of the battery’s capabilities.

Power Rating:

Determine the power requirements of your application to select a motor that can handle the workload effectively. Consider factors such as load demands, duty cycle, and potential future expansions or changes that may impact power requirements.

Torque Rating:

Assess the torque requirements of your application to ensure the motor can provide sufficient force to move the load. Consider factors such as load characteristics, starting torque requirements, and potential variations in torque during operation.

Efficiency:

Choose a motor with higher efficiency to minimise energy consumption and reduce operating costs. Look for motors that adhere to recognized efficiency standards such as NEMA Premium or IE3.

Performance:

Evaluate various performance factors such as speed, acceleration capabilities, precision control requirements, and noise level. Tailor your motor selection to meet the specific demands of your application effectively.

Warranty and Customer Support:

Opt for a motor from a reputable manufacturer that offers a warranty and good customer support. A longer warranty period provides peace of mind and protects your investment.

By considering these factors, Automobile companies select electric motors, ensuring optimal performance, longevity, and a successful outcome for your motor-driven EV.

The Future of EV Motor Manufacturing

As the demand for EVs continues to rise, the development of more efficient and reliable electric motors becomes paramount. The EV motor manufacturing industry is experiencing rapid growth, with numerous companies striving to develop innovative motor technologies.

Some key trends in EV motor manufacturing include:

Embracing Lighter and Stronger Materials: Enhancing Efficiency and Reducing Vehicle Weight

One of the prominent trends in EV motor manufacturing is the adoption of lighter and stronger materials. By incorporating advanced materials such as high-strength alloys, carbon fibre composites, and lightweight polymers, manufacturers can significantly reduce the overall weight of EV motors. This reduction in weight has a twofold benefit: it enhances the efficiency of the motor and contributes to the overall weight reduction of the vehicle.

Lighter EV motors require less energy to propel the vehicle, resulting in improved energy efficiency and extended driving range. Additionally, reduced vehicle weight translates to lower energy consumption, allowing EVs to maximise their battery capacity and minimise charging frequency. By embracing lighter and stronger materials, manufacturers are pushing the boundaries of efficiency and redefining the possibilities of electric mobility.

Adopting More Efficient Manufacturing Processes: Driving Down Costs and Enhancing Production Efficiency

In the quest for more affordable and accessible EV motors, manufacturers are investing in the development and implementation of more efficient manufacturing processes. Advanced automation technologies, such as robotics and machine learning, are revolutionising the production lines, streamlining operations, and reducing manufacturing costs.

By automating repetitive tasks and optimising production workflows, manufacturers can achieve higher levels of precision, consistency, and productivity. This, in turn, contributes to cost reduction, making EV motors more affordable for consumers. Furthermore, efficient manufacturing processes allow for greater scalability and faster production, enabling manufacturers to meet the growing demand for EV motors in a timely manner.

Developing New Motor Designs: Enhancing Performance and Efficiency

The pursuit of better performance and efficiency is at the core of EV motor development. Manufacturers are continuously exploring new motor designs and configurations to unlock the full potential of electric propulsion. These innovative designs focus on maximising power output, improving torque characteristics, and minimising energy losses during operation.

For instance, some manufacturers are exploring advanced magnet technologies, such as rare-earth magnets and magnetised laminated cores, to enhance the magnetic field strength and overall motor efficiency. Others are integrating advanced control systems and algorithms to optimise motor performance in real-time, allowing for dynamic adjustments based on driving conditions.

Additionally, the development of compact and integrated motor designs is gaining traction. By integrating multiple components and subsystems into a single unit, manufacturers can reduce the size, weight, and complexity of EV motors while maintaining or even enhancing their performance and efficiency.

These developments in motor design hold tremendous potential for the future of electric vehicles. As EV motors become more sophisticated, we can expect increased power, improved acceleration, and enhanced overall driving experience, all while maximising energy efficiency and range.

Conclusion

In conclusion, the evolution of electric vehicle motor technologies is shaped by the adoption of lighter and stronger materials, the implementation of more efficient manufacturing processes, and the development of new motor designs.

These trends not only enhance the efficiency and performance of EV motors but also contribute to the affordability and accessibility of electric vehicles for a wider audience. As the electric revolution accelerates, we can look forward to even more groundbreaking innovations that will propel us towards a cleaner, greener, and more sustainable future of transportation.

0 notes

Text

Motor Stator And Rotor: Characteristics And Functions

The motor, a ubiquitous device in modern technology, is responsible for converting electrical energy into mechanical energy. Within its intricate design, two key components play pivotal roles: the stator and the rotor. Both have unique characteristics and functions that contribute to the motor's overall performance and efficiency.

The Stator: The Stationary Backbone

The stator, as the name suggests, is the stationary part of the motor. It serves as the backbone of the motor, providing a stable structure for the rotating parts to interact with. Constructed typically from laminated steel or aluminum, the stator's primary function is to generate a rotating magnetic field.

One of the stator's defining characteristics is its windings, which are coils of wire wrapped around the stator core. When an electrical current flows through these windings, they create a magnetic field. This field is designed to rotate, thanks to the strategic placement and activation of the windings in a sequence.

The stator also acts as a support system for other motor components, such as bearings, which help to reduce friction and support the rotor's rotation. Its robust construction ensures that it can withstand the mechanical stresses and vibrations inherent in motor operation.

The Rotor: The Dynamic Converter

The rotor, on the other hand, is the moving part of the motor. It is mounted on the motor's shaft and rotates within the stator. The rotor's primary function is to convert the rotating magnetic field generated by the stator into mechanical torque.

Rotors can be classified based on their construction and operation principle. For instance, squirrel-cage rotors, common in induction motors, consist of a cylindrical core with aluminum or copper conductors embedded within its slots. When the stator's rotating magnetic field interacts with this rotor, currents are induced in the rotor conductors, generating a secondary magnetic field that opposes the stator's field, causing the rotor to rotate.

In contrast, permanent magnet rotors, used in synchronous motors, employ magnets mounted on the rotor surface or embedded within it. These magnets create a constant magnetic field that aligns with the stator's rotating magnetic field, enabling the rotor to rotate in synchrony with the stator field.

Functional Harmony and Motor Performance

The stator and rotor work in harmony to ensure the motor's efficient operation. The stator generates the necessary magnetic field, while the rotor converts this magnetic energy into mechanical rotation. This interplay enables electric motors to perform diverse tasks, from powering industrial machinery to driving everyday appliances.

Understanding the characteristics and functions of the stator and rotor is crucial for designing, maintaining, and optimizing electric motor systems for various applications. By fine-tuning the stator windings, rotor construction, and their interaction, engineers can create motors that are more efficient, reliable, and suited to specific tasks. This understanding also facilitates effective maintenance and repair, ensuring that motors continue to operate at their best throughout their lifespan.

0 notes

Text

Vehicle Motors Market: Trends, Growth, and Future Opportunities

The Vehicle Motors market is expected to grow from USD 46.39 Billion in 2024 to USD 75.27 Billion by 2030, at a CAGR of 8.40% during the forecast period.

The vehicle motors market has emerged as a pivotal segment of the global automotive industry, fueled by advancements in electrification, stringent emission regulations, and the growing adoption of electric vehicles (EVs). Vehicle motors play a crucial role in converting electrical energy into mechanical energy, ensuring optimal performance and energy efficiency. This market encompasses motors used in various types of vehicles, including electric, hybrid, and conventional internal combustion engine (ICE) vehicles.

Top Key Market Players are

Nidec, Mabuchi, Johnson Electric, Mitsuba, Buhler, Denso, Bosch, ASMO, Brose, Shilin Electric, Remy International, Valeo

For More Insights into the Market, Request a Sample of this Report: https://www.reportprime.com/enquiry/sample-report/19870

Key Market Drivers

Rise of Electric Vehicles (EVs): The accelerating shift toward EVs is one of the primary drivers of the vehicle motors market. Governments worldwide are implementing policies to promote EV adoption, such as subsidies, tax rebates, and infrastructure development. Electric motors, which form the core of EV propulsion systems, are experiencing unprecedented demand. This trend is expected to grow further as automakers expand their EV portfolios to meet sustainability goals.

Stringent Emission Standards: With global efforts to reduce carbon emissions, regulatory bodies are enforcing stricter fuel efficiency and emission norms. This has prompted automakers to adopt advanced motor technologies, such as brushless DC motors and permanent magnet synchronous motors, to enhance vehicle efficiency.

Technological Advancements: Innovations in motor technology, such as high-efficiency motors and lightweight designs, are propelling market growth. Emerging trends, including integrated motor and inverter systems, are reducing the overall weight and complexity of propulsion systems, thereby improving vehicle performance.

Market Segmentation

By Motor Type:

DC Brushed Motors: Common in ICE vehicles for auxiliary applications like power windows and wipers.

Brushless DC Motors (BLDC): Preferred for EVs due to their high efficiency, reliability, and low maintenance.

Induction Motors: Widely used in hybrid vehicles for traction purposes.

Permanent Magnet Synchronous Motors (PMSM): Dominant in high-performance EVs due to their superior efficiency and power density.

By Vehicle Type:

Passenger Cars: The largest market segment, driven by the rapid adoption of EVs and hybrids.

Commercial Vehicles: Growing investments in electric buses and trucks are boosting demand in this segment.

Two-Wheelers: Rising urbanization and e-mobility trends are fueling the use of electric motors in scooters and motorcycles.

By Geography:

North America: Robust EV adoption and government incentives are key growth factors.

Europe: A leader in EV innovation, with stringent emission norms driving market demand.

Asia-Pacific: Rapid industrialization, urbanization, and the dominance of automotive giants like China and Japan make this region a growth hub.

Challenges in the Market

Despite its promising growth, the vehicle motors market faces several challenges. One major obstacle is the high cost associated with advanced motor technologies, which can hinder adoption in cost-sensitive markets. Additionally, the scarcity of raw materials like rare earth metals used in permanent magnet motors poses a supply chain risk. Overcoming these challenges will require a focus on alternative materials, improved recycling technologies, and government policies supporting sustainable practices.

Future Trends and Opportunities

Integration of AI and IoT: The integration of artificial intelligence (AI) and the Internet of Things (IoT) in vehicle motors is revolutionizing their functionality. Smart motors equipped with predictive maintenance capabilities and energy management systems are likely to dominate future markets.

Focus on Sustainability: As sustainability becomes a core focus, the development of recyclable motor components and energy-efficient designs will be pivotal. Research into bio-based materials for motor construction is also gaining traction.

Expansion of EV Infrastructure: The growth of EV charging networks and advancements in battery technology will further enhance the adoption of electric motors.

0 notes

Text

Mahindra XUV400 EV EL Pro Review: Performance & Features

₹16.94 Lakh Performance and Driving Experience Powertrain and Motor The XUV400 EV EL Pro 34.5 kWh DT is powered by a Permanent Magnet Synchronous Motor that produces a maximum power output of 147.51 bhp and 310 Nm of torque. This setup offers quick acceleration and robust low-end torque, making it suitable for city driving and highway overtaking. The “L” mode for Single Pedal Drive enhances the…

#10.25-inch touchscreen#147.51 bhp#150 km/h top speed#310 Nm torque#34.5 kWh battery#375 km range#5-Star NCAP Rating#8.3 seconds 0-100 km/h#Advanced Safety#Android Auto#Apple CarPlay#Connected Car#Connected Car Technology#DC Fast Charging#drive modes#Dual-Tone Design#Eco-Friendly Vehicle#Electric SUV#front-wheel drive#Infotainment System#IP67 Battery#Leatherette upholstery#Mahindra EV#Mahindra XUV400 EV#Mahindra XUV400 EV EL Pro 34.5 kWh DT#permanent magnet synchronous motor#regenerative braking#safety features#SUV features#Wireless charging

0 notes

Text

0 notes

Text

Towards Zero Emission: AEAUTO New Power Steering Solution for Commercial Vehicle

AEAUTO presented the latest electric drive technology to help the commercial vehicle industry move towards a more sustainable future.

Meet the needs of electrification and autonomous driving; Meet the high torque requirements of commercial vehicle steering

Advanced new electric power steering pumb systems for trucks, coaches and city buses provide a solid foundation for electrification and autonomous driving.

AEAUTO new Electric Power Steering system lays the foundation for the electrification transition in the commercial vehicle industry. Suitable for a wide range of medium and heavy duty trucks, coaches and city buses, the EPS system is also one of the key elements in the realisation of the next generation of Advanced Driver Assistance Systems (ADAS), which will drive the vision of autonomous driving in the commercial vehicle industry.

The use of an integrated electric motor instead of a hydraulic pump removes the electric power steering system from the vehicle driveline and eliminates the need for hydraulic fluid assistance. Seamlessly adapted to electric vehicle architectures, the system optimises the driving experience through quiet and smooth electric handling while achieving zero local emissions for pure electric and fuel cell vehicles.The EPS system is available in all powertrain concepts to seamlessly match the architectural requirements of electric vehicles. The modular EPS system, adapted to 24V battery packs, supports power outputs of up to 8,000Nm and has a scalable design to meet the requirements of diverse packages.AEAUTO EPS system is currently available for steer-by-wire, and, thanks to its highly reliable and redundant architecture, as an active electric power steering system, the EPS can be integrated with ADAS to enable safety functions such as Continuous Lane Keeping.

AEAUTO Core Technology of EPS

Heavy commercial vehicles with heavy loads require a steering output torque of 8000Nm, which is achieved through double-winding motor and high-precision variable large transmission ratio deceleration mechanism.

AEAUTO EPS achieves high torque output through dual-winding motors and high-precision variable ratio gearboxes for heavy commercial vehicles with heavy loads and a required steering output torque of 8,000Nm.

24V High power motor: double winding low slot torque, low moment of inertia permanent magnet synchronous motor, output torque of 8000Nm after deceleration.

Patented deceleration mechanism: through high-precision ball screw, planetary wheel and planar secondary enveloping torus worm to achieve a variable transmission ratio of 15~23.

Double winding motor for heavy commercial vehicles + Double MCU+ Double control chip based on functional safety redundant architecture, leading in China.

The steering system is a functional safety component, and the high reliability and safety of electric steering are just necessary.

Highly reliable redundancy design: dual power source + double winding + double MCU+ double control chip based on functional safety redundancy design to ensure high reliability and safety.

Based on the dynamic tracking and feedback control strategy in the loop of the booster value, the response time of angle control is ≤50ms, leading at home and abroad.

The response time of the steering system is very critical for heavy commercial vehicles in high-speed scenarios. With the same steering wheel angle control precision, the shorter the response time, the higher the maximum speed allowed to be reached.

Adopting low rotational inertia permanent magnet synchronous motor with high mechanical sensibility and matching precision, the steering system makes judgment on the control mode through different sensor signals, uses the control algorithm to track the target parameters accurately, and controls the motor to output the ideal assisting torque according to the optimized assisting curve to realize the fast response of EPS assisting.

Advantages Of Electric Power Steering Over Electric Hydraulic Steering

System Efficiency Increased by 30%

No hydraulic link energy consumption loss, high efficiency;

Electric + wire control to meet the needs of heavy commercial vehicles such as electric vehicles and autonomous heavy trucks.

35% Reduction in System Weight

Light weight and small size: Compared with traditional hydraulic or electro-hydraulic steering, electric drive-by-wire steering eliminates 5 components such as hydraulic pump and hydraulic steering device, and is completely driven by motor to achieve steering.

Total System Cost Reduced by 20%

After the cancellation of five components such as hydraulic pump and hydraulic electric power steering gear, the overall cost of parts was greatly reduced after the allocation of R&D investment and mold costs.

AEAUTO EPS has been used in Europe (Norway, Finland) and the Middle East to help achieve low energy consumption and zero emissions in transport, providing an indispensable support for the creation of environmentally friendly societies and the promotion of sustainable development of various industries, as well as providing valuable examples for the development of related fields in other regions of the world.

#aeauto#electric power steering pumb#advantage of electric power steering#electric power steering system

0 notes

Text

#ABB ACS580 VFD DRIVES

The ACS580-01 is a drive for controlling asynchronous AC induction motors, permanent magnet motors and synchronous reluctance motors.

ACS580 drives include all the essential components for typical light industry applications, with a scalable offering from 0.75 kW to 500 kW.

The drive is ready to control compressors, conveyors, mixers, pumps and fans, as well as many other variable and constant torque applications.

The all-compatible drives family ensures that you will always find the best drive for your needs. These drives share a similar user interface and PC tools, making using and learning them fast and easy.

Video Link:

Various types of Low-Voltage VFD drives in ABB.

If you find this post valuable, please follow our page.

Please like and share our page so that we can develop more useful posts and content. Thank you.

0 notes

Text

0 notes