#orbital welding

Explore tagged Tumblr posts

Text

The Benefits of Adapting Orbital Welding for Fabricating Semiconductors

Semiconductor fabrication is a highly sophisticated process that demands extreme precision, cleanliness, and consistency. The need for ultra-high purity (UHP) environments in semiconductor manufacturing facilities makes the selection of welding techniques crucial to ensuring product quality and process efficiency. Orbital welding, an automated welding process, has emerged as a preferred method for fabricating semiconductor components due to its ability to deliver high-quality, repeatable, and contamination-free welds. This article explores the various benefits of adapting orbital welding in semiconductor fabrication.

1. Enhanced Precision and Consistency

Orbital welding is a fully automated welding technique that ensures unparalleled precision and consistency. Unlike manual welding, which is susceptible to human error, orbital welding eliminates inconsistencies by employing computer-controlled parameters. The process guarantees uniform weld penetration, bead formation, and defect-free joints, which are essential in semiconductor applications where even minor defects can lead to contamination or operational failure.

2. Ultra-High Purity Welding

In semiconductor manufacturing, maintaining UHP conditions is imperative. Contaminants such as oxides, particles, and hydrocarbons can significantly impact the performance of semiconductor devices. Orbital welding is specifically designed to produce high-purity welds by controlling parameters such as gas flow, arc current, and heat input. The process minimizes oxidation and eliminates the need for filler materials, thereby reducing the risk of contamination and ensuring the integrity of the semiconductor manufacturing process.

3. Improved Productivity and Efficiency

Orbital welding enhances efficiency by automating the welding process, which significantly reduces production time and labor costs. Since the process does not rely on manual operators, welds can be completed with minimal supervision, allowing for higher throughput and faster turnaround times. Additionally, orbital welding reduces the need for extensive post-weld inspections and rework, further improving productivity in semiconductor fabrication.

4. Superior Weld Quality and Strength

The semiconductor industry requires exceptionally strong and defect-free welds to prevent leaks and failures in vacuum systems, gas delivery lines, and cooling assemblies. Orbital welding ensures superior weld quality by eliminating inconsistencies associated with manual welding techniques. The precise control of parameters results in uniform welds with optimal mechanical properties, reducing the likelihood of failures and enhancing the reliability of semiconductor components.

5. Reduced Heat-Affected Zone (HAZ)

Heat-affected zones (HAZ) in welded joints can alter the metallurgical properties of the base materials, leading to stress concentration and potential failures. Orbital welding minimizes the HAZ by carefully controlling heat input and maintaining consistent arc stability. This results in welds with minimal distortion, reduced residual stresses, and enhanced durability, which is essential for semiconductor applications that require high structural integrity.

6. Compliance with Stringent Industry Standards

Semiconductor manufacturing facilities must adhere to stringent industry standards such as SEMI F78, ASME BPE, and ASTM A270 S2 for high-purity piping systems. Orbital welding ensures compliance with these standards by producing consistent, repeatable, and validated welds that meet or exceed regulatory requirements. The ability to document and trace each weld provides further assurance of quality and adherence to industry best practices.

7. Reduction in Operator Skill Dependency

Traditional welding techniques require highly skilled operators with years of experience, making it challenging to maintain consistent weld quality across multiple operators. Orbital welding significantly reduces dependency on operator skill levels by utilizing pre-programmed welding parameters. Once set up, the system performs welds with minimal intervention, ensuring uniform results regardless of operator expertise. This allows manufacturers to maintain high production standards with less reliance on specialized labor.

8. Lower Maintenance and Operational Costs

By enhancing weld quality and minimizing defects, orbital welding reduces the need for frequent maintenance and repairs of semiconductor equipment. The elimination of rework, reduction in material wastage, and improved process efficiency translate into significant cost savings for semiconductor manufacturers. Additionally, the longevity of high-purity piping systems and components is enhanced, reducing downtime and operational disruptions.

9. Scalability for Large-Scale Production

Semiconductor fabrication facilities often require large-scale production with consistent quality across multiple batches. Orbital welding is highly scalable, making it ideal for high-volume manufacturing. The repeatability of the process ensures that all welds meet the same stringent quality standards, allowing for seamless integration into automated production lines.

Conclusion

The adoption of orbital welding in semiconductor fabrication offers numerous benefits, including enhanced precision, ultra-high purity welding, improved productivity, superior weld quality, and compliance with industry standards. By reducing human error, minimizing contamination, and ensuring consistency, orbital welding has become a critical technology for semiconductor manufacturers looking to optimize their processes and maintain a competitive edge. As the semiconductor industry continues to evolve, the reliance on advanced orbital welding training will be essential in meeting the increasing demand for high-performance, contamination-free semiconductor components.

#orbital welding#orbital welding program#welding technology#orbital welding technology#orbital welding courses#semiconductor#welding automation

0 notes

Text

How to Choose the Right Orbital Welder for Your Welding Projects |Arcellor controls

In the realm of welding, precision, efficiency, and reliability are paramount, especially in industries in which accuracy is non-negotiable. , which include orbital tube welding and welding fittings, has emerged as the favored method for reaching impeccable welds. Arcellor Controls India stands as a leading authority, providing a diverse range of orbital welders and orbital tube welders tailor-made to meet numerous venture necessities. With our information in orbital welding, we make sure the best great welds for all styles of fittings welding applications.

Orbital Welding

Orbital welding is a specialized welding method wherein the welding arc rotates 360 ranges round a set workpiece. This approach guarantees uniformity and consistency in weld exceptional, making it ideal for industries which include aerospace, prescribed drugs, and semiconductor manufacturing. With Arcellor Controls India’s widespread lineup of orbital welders, customers can pick out the device best proper to their precise packages.

Factors to Consider When Choosing an Orbital Welder:

Welding Application:

Before diving into the choice system, it’s essential to pick out the number one application of the ,orbital weld. Whether it is for joining small diameter tubing or big pipes, Arcellor Controls India gives a diverse array of orbital welders capable of managing numerous welding programs.

Welding Material and Thickness:

Different materials and thicknesses require precise welding parameters and system. Our variety of orbital welders caters to a extensive spectrum of substances, including stainless steel, carbon metal, Inconel, and titanium, ensuring compatibility with various venture requirements.

Welding Standards and Regulations:

Compliance with enterprise standards and rules is vital, specially in sectors like prescription drugs and meals processing. Arcellor Controls India’s orbital welders adhere to global standards, ensuring weld integrity and regulatory compliance.

Welding Automation and Control:

Automation capabilities play a pivotal role in enhancing welding performance and consistency. Our superior orbital welders are prepared with intuitive manipulate interfaces and automation competencies, empowering operators to gain precise welds with minimal attempt.

Portability and Versatility:

For initiatives that demand mobility and flexibility, portability will become a key attention. Arcellor Controls India offers compact and flexible orbital welders appropriate for on-web page installations and limited spaces, ensuring seamless workflow continuity.

Technical Support and Training:

Investing in an orbital welder entails a dedication to lengthy-term overall performance and reliability. Our dedicated technical guide group offers comprehensive schooling and assistance, empowering customers to maximise the capacity of their orbital welding gadget.

Final Words! Choosing the proper orbital welder, whether or not for orbital tube welding or welding fittings, is crucial to the achievement and performance of your welding duties. At Arcellor Controls India, we provide an extensive variety of orbital welders and orbital tube welders, making sure clients have get entry to to modern-day generation and unrivaled reliability. Our commitment to excellence extends to presenting unwavering assist to our customers. Explore our various lineup these days and take your welding talents, consisting of orbital welding and welding fittings, to new heights.

#orbital welder#orbital welding#orbital tube welding#orbital tube welder#fittings welding#orbital weld#welding fitting

0 notes

Text

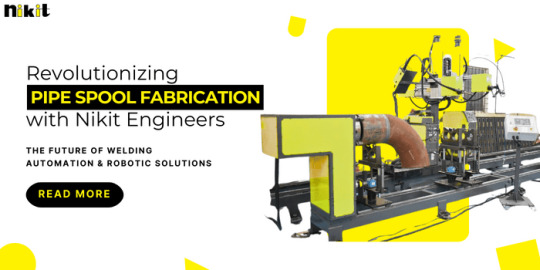

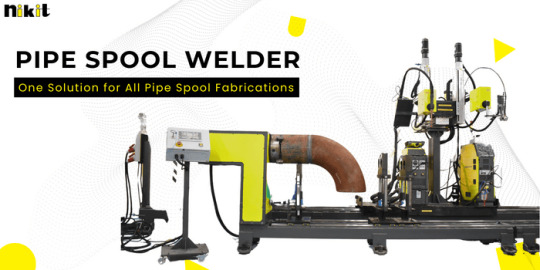

Revolutionizing Pipe Spool Fabrication with Nikit Engineers: The Future of Welding Automation and Robotic Solutions

In the dynamic landscape of industrial fabrication, the quest for efficiency, precision, and cost-effectiveness has led to significant advancements. Among these, pipe spool fabrication stands out as a vital process in industries ranging from oil and gas to pharmaceuticals and beyond. At the forefront of this evolution is Nikit Engineers Welding Automation and Robotic Solutions, pioneering innovative approaches to enhance the pipe spool fabrication process in India.

Key Takeaways about Pipe Spool Fabrication:

Off-Site Precision: Pipe spool fabrication entails the assembly of pre-cut pipe sections and fittings in a controlled off-site environment. This controlled setting allows for meticulous attention to detail, ensuring precise measurements and welds.

Reduced Construction Time: By fabricating pipe spools off-site, construction time at the installation site is significantly reduced. This streamlined process minimizes downtime, accelerating project completion timelines.

Enhanced Quality Control: Fabricating pipe spools in dedicated facilities enables easier quality management. Rigorous inspection protocols can be implemented, ensuring compliance with industry standards and specifications.

Mitigated Production Delays: Fabrication in specialized facilities mitigates the risk of production delays caused by adverse weather conditions or site-specific challenges. This resilience to external factors enhances project reliability and on-time delivery.

What Is Pipe Spool Fabrication?

Pipe spool fabrication involves the prefabrication of interconnected pipe sections, valves, and fittings into modular units known as spools. These spools are then transported to the installation site for final assembly, significantly simplifying on-site construction.

Pipe Spooling Application

The versatility of pipe spooling extends across various industrial sectors, including:

Oil and Gas: Pipeline networks for transportation and distribution.

Chemical Processing: Complex piping systems for chemical production.

Power Generation: Steam and water piping for thermal and nuclear power plants.

Pharmaceutical: Hygienic piping for pharmaceutical manufacturing facilities.

HVAC: Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Why Are Pipe Spools Prefabricated?

The prefabrication of pipe spools offers several advantages:

Precision Engineering: Off-site fabrication ensures consistent quality and adherence to design specifications.

Cost Efficiency: Reduced labor and material costs associated with on-site assembly.

Enhanced Safety: Controlled environments minimize the risk of accidents and injuries.

Flexibility: Modular spools allow for easy customization and adaptation to project requirements.

Cost Savings in Pre-Fabrication, Inspection, and Testing

Nikit Engineers leverages cutting-edge welding automation and robotic solutions to optimize the pipe spool fabrication process. By integrating advanced technologies, they deliver unparalleled efficiency, accuracy, and cost savings throughout the fabrication journey. From automated welding systems to robotic inspection and testing, Nikit Engineers ensures that every spool meets the highest standards of quality and performance.

Contact Nikit Engineers for Your Next Industrial Pipe Spool Fabrication Project

With a proven track record of excellence and innovation, Nikit Engineers is your trusted partner for all your industrial pipe fabrication needs. Whether you’re embarking on a new construction project or seeking to optimize existing processes, our team of experts is ready to deliver tailor-made solutions that exceed your expectations.

Experience the future of pipe spool fabrication with Nikit Engineers Welding Automation and Robotic Solutions. Contact us today to discuss your project requirements and discover how we can transform your vision into reality.

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

At Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

#robotics solutions#welding automation#orbital welding#circular welding#linear welding#Profile Wedling#Stainless Steel Welding

0 notes

Text

Why Renting an Orbital Welding Machine Is the Best Choice for Your Project

Orbital welding is a specialized and highly precise welding technique commonly used in industries such as aerospace, pharmaceutical, food processing, and petrochemicals. This process relies on orbital welding machines, which are designed to weld pipes and tubes with unparalleled accuracy and consistency. For businesses that require orbital welding, choosing to rent an orbital welding machine instead of purchasing one can often be the most practical and cost-effective solution. Below, we explore why renting is an excellent choice and discuss the key benefits in detail.

1. Cost-Effective Solution

One of the primary reasons businesses opt to rent orbital welding machines is the significant cost savings. High-quality orbital welding equipment can be expensive to purchase outright, especially for smaller companies or contractors. Renting allows businesses to access top-of-the-line machines without incurring the high upfront investment.

Reduced Initial Expenses: Instead of allocating substantial capital to buy a machine, renting allows you to redirect resources to other crucial areas of your business, such as hiring skilled labor or purchasing consumables.

No Depreciation Costs: Purchased equipment depreciates over time, reducing its resale value. When you rent, depreciation becomes irrelevant, saving you money in the long run.

2. Access to Advanced Technology

Orbital welding technology evolves rapidly, with newer models offering improved features, automation, and capabilities. Renting ensures that you have access to the latest and most efficient equipment.

Stay Updated: Rental companies frequently update their inventory to include the latest models, giving you a competitive edge in terms of performance and quality.

Enhanced Capabilities: Advanced features like programmable welding parameters, closed-loop control systems, and automatic alignment improve both productivity and the quality of your welds.

3. Flexibility and Scalability

Every project has unique requirements, and renting gives you the flexibility to choose the ideal machine for your specific needs. Whether you're handling small-diameter tubing or large-scale industrial piping, rental companies typically offer a variety of orbital welding machines.

Project-Based Rentals: Renting allows you to scale up or down depending on the scope and duration of your project. Once the project is complete, you can return the equipment without worrying about storage or maintenance.

Testing Different Models: If you are unsure which machine best suits your needs, renting provides the opportunity to test different models before making a long-term investment.

4. Reduced Maintenance and Repair Costs

Orbital welding machines, like all industrial equipment, require regular maintenance and occasional repairs. When you rent, the responsibility for maintaining the equipment typically falls on the rental company.

Hassle-Free Maintenance: Rental agreements often include routine maintenance, ensuring that the machine is always in peak working condition.

Quick Repairs and Replacements: In case of a malfunction, rental providers usually offer prompt repair services or replacement units, minimizing downtime.

5. Avoid Storage Challenges

When you own heavy equipment like orbital welding machines, you also need a secure and suitable space to store it when it's not in use. Storage can be a logistical and financial burden.

Eliminate Storage Costs: Renting means you only have the machine for the duration of your project, eliminating the need for long-term storage solutions.

Convenience: With rental equipment, you avoid concerns about environmental factors like humidity or temperature, which could affect machine performance during storage.

6. Ideal for Short-Term Projects

For businesses handling short-term projects or one-off jobs, renting is far more economical than purchasing.

Maximize Budget Efficiency: If your project requires orbital welding for a limited time, renting ensures you only pay for what you use.

Avoid Idle Equipment: When you own a machine, there’s always a risk it will sit idle between projects, tying up valuable capital. Renting avoids this issue entirely.

7. Expert Support and Training

Many rental companies offer additional services, such as technical support and operator training. This can be particularly valuable if your team is new to orbital welding or requires guidance with a specific machine.

On-Demand Assistance: Rental providers often have knowledgeable staff who can assist with setup, troubleshooting, and operation.

Training Programs: Some companies include training as part of the rental package, ensuring that your team is fully equipped to operate the machine safely and efficiently.

8. Environmental Benefits

Renting equipment can also contribute to sustainability efforts by promoting the reuse of high-quality machinery.

Lower Resource Consumption: By renting instead of purchasing, you reduce the need for additional manufacturing, which consumes resources and energy.

Efficient Use of Equipment: Rental companies ensure that their machines are continuously utilized, reducing waste and maximizing the lifespan of each unit.

9. Simplified Budgeting

Renting an orbital welding machine simplifies budgeting and financial planning, as you can predict costs more accurately.

Fixed Rental Costs: With a rental agreement, you know exactly what you’ll pay, making it easier to plan and allocate your budget.

Tax Benefits: In some regions, rental expenses can be written off as operational costs, offering potential tax advantages.

10. No Long-Term Commitment

Finally, renting gives you the freedom to complete your project without being tied down by long-term ownership.

Adaptability: As your business evolves, your equipment needs may change. Renting allows you to adapt without being burdened by outdated or underutilized machines.

No Resale Hassles: When it’s time to upgrade or change your approach, you can simply return the rented equipment, avoiding the complexities of selling used machinery.

Conclusion

Renting an orbital welding machine is a smart choice for businesses and contractors who value cost efficiency, flexibility, and access to the latest technology. It eliminates the challenges of high upfront costs, maintenance, and storage while providing the opportunity to scale operations seamlessly. Additionally, with the added benefits of expert support and the ability to test different models, renting ensures that your project is executed with precision and efficiency. For short-term projects, growing businesses, or companies exploring orbital welding for the first time, renting is the ideal solution.

0 notes

Link

Astronomy Daily - The Podcast: S03E198 Welcome to Astronomy Daily, your Daily source for the latest in space and Astronomy news. I'm your host, Anna, and today we have an exciting array of stories that will take you from the latest SpaceX mission to the International Space Station to groundbreaking discoveries about Mars and Venus. Highlights: - SpaceX Resupply Mission: SpaceX has successfully launched its 31st commercial resupply mission to the International Space Station. The Dragon spacecraft carried over 6,000 pounds of supplies and cutting-edge scientific experiments, including AstroBeat, a project exploring cold welding in microgravity for spacecraft repair. - Australia's Space Milestone: Gilmore Space Technologies has been granted Australia's first orbital launch permit, paving the way for the ERIS rocket's inaugural flight. This development highlights the burgeoning space industry in Australia and its potential economic impact. - Parker Solar Probe's Venus Maneuver: NASA's Parker Solar Probe is preparing for its final Venus gravity assist, setting the stage for an unprecedented approach to the Sun. This maneuver will bring the probe closer to the solar surface than any human-made object has ever ventured. - Mars's Crusty Surface Explained: New insights from NASA's InSight mission reveal the chemical processes behind Mars's distinctive crusty soil layer. This discovery has significant implications for future Mars exploration and potential human missions. - NEOWISE's Final Mission: After 15 years of service, NASA's NEOWISE spacecraft has completed its mission, leaving a legacy of over 3,000 near-Earth object discoveries. The upcoming NEO Surveyor, set to launch in 2027, will continue its crucial planetary defense mission. For more cosmic updates, visit our website at astronomydaily.io. Sign up for our free Daily newsletter to stay informed on all things space. Join our community on social media by searching for #AstroDailyPod on Facebook, X, YouTube, Tumblr, and TikTok. Share your thoughts and connect with fellow space enthusiasts. Thank you for tuning in. This is Anna signing off. Until next time, keep looking up and stay curious about the wonders of our universe. Sponsor Links: Check out great deals from our sponsors on our website and catch up on past episodes' NordVPN - www'bitesz.com/nordvpn Old Glory - www.bitesz.com/oldglory - Now with Official NASA Merch Proton Mail - www.bitesz.com/protonmail - Secure and private Email.

#antarctic-moss#astrobeat#bowen#cold-welding#coronagraph#eris-rocket#gilmore#gravity#international#orbital#parker#probe#solar#solar-wind#space#spaceport#spacex#station#technologies#venus

0 notes

Text

Superior Quality Tubes Manufacturer in India

Zion Tubes & Alloys is a leading Stainless Steel Orbital Welding Tubes Manufacturer in India. Our Stainless Steel Instrument Tubing we supply and export an extensive range of products, including stainless steel 304, 304L, and 316 orbital welding tubes. For the availability and ranging of products we are always at your service.We are Also Leading Stainless Steel 317L Seamless Tubes Manufacturer in India.

We provide market-leading rates to all of our clients on Stainless Steel Instrumentation Tubing & Stainless Steel Electropolished Tubes hOur exclusive range of products includes electropolished tubes made of stainless steel 304 and 304L, as well as stainless steel 316.

Our Products Lists:Stainless Steel coil tube , Bright Annealed Stainless Steel Tubing & Nickel Alloy Tubes are used in a wide range of sectors and are manufactured with

Product Source:SS Orbital WeldingTubes

0 notes

Text

since so many of you asked... 😳😅

Requirements:

-max. 25 words/day -must be cute (8/10 or higher) -must be <5'6" -must be <20% body fat -must have good bimax protrusion -must have visible supraorbital ridge but not too much -must have eye spacing of 1,5 ocular lengths or be willing to undergo orbital box osteotomy -must have black or dyed hair -must listen to incelcore -must be blackpilled -must share all my opinions -must fit Jungian archetype "the lover" -must know how to weld -must like me NO: -scleral show -recessed zygomata -pets -TikTok -nasal labial folds -small talk -spotify top-50 listening -skincare routines longer than 3 steps -enjoyment of pastel colors -sleeping with socks on -owning more than one scented candle -childhood pets mentioned unless taxidermied for display

19 notes

·

View notes

Text

Imperator Butterpants, my charge for the weekend, had treed a squirrel in the park. Normally, I would help out the dog - that’s what is humans are for - but there’s a complication. A nearby toddler birthday party would be ruined by the sight of my aunt’s Pomeranian ripping a domestic rodent in half for fun. That’s the tragedy of the commons, right there. Exactly what Plato was talking about.

As a result, I squat gently and prepare myself to pick up the dog in a caring embrace. This feels natural, comforting. I am communing with my ancestors who tamed his ancestors, and in a moment I will have experienced the sensation of another living thing obeying my demands. Nothing doing. Butterpants turns around, snaps at my face, and dislodges my 3M Tekk P100 respiratory-particulate-protection bayonet fitting mask slightly. We are going home, I declare to a dog that does not understand English.

Luckily for me, I have prepared a vessel for transporting the dog. It is a sidecar consisting of an old bumper car, hastily welded with leftover Home Depot fence strapping (don't worry, I ground off most of the galvanization) to the side of a Razor Pocket Mod child's electric scooter. Well, I say "child's," but we both know that's some bullshit that I trot out to make the cop think it's impossible that I break the speed limit on this pink piece of plastic. In actuality, I know that there is no way that the officer is tuned-in enough to electronic engineering to realize that the several hundred pounds of lithium ion phosphate pouch batteries ziptied together under the seat is easily enough stored energy to launch this thing into low earth orbit should I decide to whack the throttle bare open. Plus, it means I can ride in the bike lane, which is good. Have you seen what kind of maniacs drive cars?

Despite what I just told you, I pin the throttle nonetheless, knowing that the aggregate resistance of the battery cables momentarily turning to a liquid will act as a sort of dynamic throttle control. We are off, both figuratively and literally. You might have encountered in the past a dog wearing "doggles," which is a portmanteau of the word "dog" and "goggles." Eye protection for dogs is absolutely critical at these kinds of velocities, and it is for that reason that I have placed a welding mask on the muzzle of my aunt's dog, protecting him from impacts with bugs, gravel, and other multi-use-pathway users.

We get home in quite a hurry, so much so that I have to use my neighbour's garden hose to extinguish the foam-rubber tires bonded to the rear hub motor. Imperator Butterpants is dazed initially, having reached a land speed formerly only attempted by dogs named Laika, but soon recovers. And, hey! We got that squirrel after all, although I'm pretty sure I'll have to peel it off of the welding mask and run it through a strainer before I can put it in with his Ol' Roy.

224 notes

·

View notes

Note

I wondered what would Cron gift to Moon if he ever considered it and i think he would give crystals

Just imagine Unicron hijacking a crow and dropping crystals with (or without cuz crow brain will steal anything shiny) deep meanings. Moon may not know the crystal (or flower) language/symbolism/meaning but Earth does and vibrated inside whenever Cron gifted crystals to the Titan.. Btw amethysts look like dark energon but minus the sickness effect.. Cron absolutely would he can't give innermost energon so this is basically equivelent to it.. not like he will ever admit that the emotionally constipated old man he is (Wait what if he tried gifting to Primus his innermost but it backfired? )

Earth: Oh! It's Tiger eye!

Moon: ...Tiger eye is not literal eye is it??

Unicron:* crow laugh*

Neat concept! Personally I am of the belief that Unicron would rather die than give anyone except Earth anything. The way he offers affection to those around him differs from person to person. To Earth, he gives gifts and offers aid. It is the only thing he can truly do for his daughter who yet remains bound to him. To Mars he gives his time, often watching movies or conversing with the rusted Titan when there is a spare moment. They don't usually get along, at least on the surface, but the general familial care is there. Him and Pluto have screaming matches. They both have a fantastic time.

But Moon? Moon is difficult. Moon is old and wise and Unicron knows Moon probably as well as he knows Earth. And yet at the same time, there is so little he actually knows that it is hard for him to make a serious connection to the watchful Titan that orbits Earth like a guardian angel. They are bound by their shared adoration for Earth. So instead of giving Moon any gifts, I imagine he would instead help Moon to create gifts worthy of his precious daughter.

When Moon's drone is on the planet, they sometimes work together to gather crystals and precious stones to weld together into the shape of either a flower or some other plant. Unicron gathers the pieces with his creatures, Moon does the welding part. It is soothing for the both of them since neither could handle being around the other for long if not in the service of a higher goal.

Working with Moon reminds Unicron of the times he once spent with Primus. Long ago, he tried to offer his brother and other half a piece of himself as a gift. He thought a shard of his spark chamber would be a well received gift. Primus did take it with joy, but by taking the gift, Unicron watched his brother grow ill until the shard integrated into his systems.

Two pieces of the same, but so set apart that they hurt each other with the slightest touch. Unicron doesn't like to think about his rather similar relationship to Earth when he makes her gifts.

#transformers#maccadam#transformers prime#unicron and earth au#unicron#moon#earth#primus#alternate universe

37 notes

·

View notes

Text

So, I've been mulling it over, and I now have my considered thoughts on Tales of the Empire!

First Morgan and then the bit that matters.

I thought Morgan's segment was entertaining, and I liked learning about another Dathomiri clan. But for real, she's never beating the 'damn we shouldn't have killed Pryce' allegations XD. And that's the problem. The whole thing had a feeling of canon welding, as the airplane rattles apart at 30,000 feet. Perhaps most egregious is the explanation for how she met Thrawn. Apparently, she's behind his favoured TIE fighter design! Does she have any knoweldge of engineering, orbital mechanics, astrophysics or anything else that might enable her to look at a TIE fighter and say 'hey, I know how to improve that!' If she does, the show has no interest in telling us.

Then there's the whole wanting revenge thing. Why? Againts whom? For what purpose? The only thing she takes revenge on in the episodes is a forest, and what did that do to her?

Okay, now the main event: Barriss.

I set my expectations really low, so nearly anything would pass it. Acknowledging that, I'd say this was about the best I would have hoped for given the constraints of canon, Filoni and such. It was really nice getting to see Barriss being the idealist, sticking to her values and having the courage to say no when it became clear where the Inquisitorious was going. And she never fully bought into it, showing she has learned from her prior experience. As a friend pointed out, even when she choked Dante her eyes never turned yellow.

Seeing her as a Jedi Master at the conclusion also felt special, and not going ot lie, I did shed a small tear when I saw her free and at peace with herself after so long. And I love the fact that she defeats Lyn, not with badass lightsabre moves, but by being relentlessly kind and compassionate. Or, essentially, allows Lyn to defeat herself and so open the path back for her. It's a rare display, in Star Wars, of a character actually using the Force for knowledge and defence and not attack.

I loved the implication the reconciled with Ahsoka and made her peace with Luminara. And I don't mind those not being shown on screen; honestly I'd prefer they get time devoted to them in a novel or a comic, rather than 2-5 minutes in what are some already quite rushed episodes.

I'm 80% sure she's dead, and honestly I'm okay with that. She died to save a child and redeem a nobody (in meta-terms with Lyn), and there's something truly Jedi in that. There's something beautiful in that.

That said, there are two caveats.

The first is on Ahsoka. I'm getting increasingly frustrated with the way that Barriss' importance to Ahsoka is getting airbrushed out of the story. Because it is an important component. What sells Ahsoka on leaving the Order is not just the Council's lack of faith it's because she agrees with Barriss. Not in the method she chose, but in her critqiue yes. How can she not? She's just seen her good friend, a paragon Jedi in her eyes, fall to Darkness in fear of what the Order was becoming and she never suspected a thing.

And from Barriss' side the persistent question is why did she target Ahsoka and no one else? I'm starting to suspect that Filoni has worked out that only reasonable answer to this one is Barrisoka one and because he's allergic to writing relationships (a friend pointed out how much he seems to dislike physical displays of affection in his stories), but also specifically with reference to Ahsoka.

The second is on the bombing, and murder of Letta and clone troopers. Like, I'm happy that eleven years later it's been decided that having the Muslim-coded girl become a terrorist was a bad move. And I'm happy to take Barriss' gentle portrayal here as something of an apology note. But ultimately, Filoni made that decision so he doesn't get to employ fanfic rules to handwave it.

And the thing is, addressing it in the text would make the arc stronger. Because it's a fascinating flaw in Barriss' character that, for all her idealism, piety etc. when push came to shove she was too afraid to take the role of martyr and got someone else (willing or not) to do it. We need to see her grapple with that fear and work through it. We do see a strain of this (she does initially turn a blind eye to Lyn's massacre of the vilalge), but it's not really developed. Because it makes her triumph at the finish all the more important.

Barriss at the finish is not a Jedi Master because she can dance around lightsabre blades and spout wisdom laced in sarcasm (though those are cool!). She's a Jedi Master because she's transferring (so it's implied) her life energy to heal others. She's a Jedi Master because she allows herself to potentially be sacrificed to guide another back to the Light.

She's a Jedi Master because she's finally surpassed her fear and let go of her final attachment.

25 notes

·

View notes

Text

Asteroids

---

Leo is alive, and Jason is alive. Because this time it stuck

And it continued to stick, for years

And Leo tried his best not to take it for granted, he would take Jason in any way he could. He loved him, he knew he did, he loved him back to life over and over again in his fool's errand. Leo didn't question why Jason did it back, he didn't really care as long as this time it just continued to stick

It was like an orbit, for years. Two asteroids in space, flying through the darkness around each other, unwilling to let go of their shared gravitational field because they were finally there together. It didn't matter if Piper was going to disown him from the pining, as long as it continued to stick. If all he could have was the orbit then Leo would take what he could get

Leo's anxiety spiked when he didn't know where Jason was. He knew he felt the same by the look in his eyes when he arrived back home to the Way Station. They shared a room, but not a bed. Jason always wanted to be touching him in some way. It became natural, the everyday norm, but Leo was too scared to jinx it by confessing. To tempt this hair's breadth of an opportunity that maybe this time the fates would just let him have him

He knew it wasn't healthy, he couldn't help it

They orbited for ages, but gravity kept pulling them closer with each rotation. It took them three years for their flight paths to finally crash into each other

It was close in time to when Jason died for the first time, when Leo was gone warning Camp Jupiter and the other man was on his quest. Jason is at Camp Jupiter and Leo had held the stress of it in his jaw all week, trying to distract himself through the sleepless nights. When Jason finally made it back to him it was with a rough landing

Leo was the only one awake, sometime around four or five am. He heard Jason hit the roof, and the Way Station tumbled the blond into the main room without much fanfare. The larger man lies on the ground outside the workstation with a groan

“Jesus Christ dude you good?” Leo asks, pulling his welding mask up and turning off the torch. Jason just rolls over onto his back to starfish on the ground and groans again

Leo takes a moment to get off his welding gloves and shut down the station, the last thing they need is a fire. It also gives him a beat to collect himself, he knows he's been a sleepless wreck. By the time he's done and turns back around Jason is watching him with lightning focus

“What?” he asks, whipping welding grime and sweat off his arms and face. Jason licks his lips

“Come ‘mer” he calls, and makes a grabby hands at him

“Did you hit your head again” Leo teases, but he goes to him anyway “What the hell was that landing?”

“It's like five AM” Jason mumbles, reaching for Leo and pulling him down onto the floor with him “I've been up since six AM yesterday, cut me some slack”

[read more AO3]

“Why are you flying if you've been awake eleven hours?” Leo asks concerned as he kneels down next to the blond “That can't be safe”

“I didn't want you to be alone tomorrow,” he says, rolling towards Leo like a flower following the sun “I didn't want to be without you”

Tomorrow, the anniversary of Jason's first real death.

Leo feels his heart clench in his chest, the tension in his jaw makes it pop. The date he's been trying not to think about, that he was trying to overwork himself through. It's been six years and neither of them has ever handled it with much grace. And here Jason is, flying stupid from California to make sure they were together for it. To make sure Leo knows where he is

“Come on man,” Leo says instead of what he wants to say, pulling Jason into a sitting position by his arms “Let's get you to bed”

“Come with me,” Jason begs, he looks a bit loopy from fatigue

“Jase-”

“I was talking to Piper, about us,” Jason presses on, pulling Leo closer from where their arms are connected

“What about us?” Leo lets himself go to him, ever in orbit, even as the hot lump of dread settles in his gut

“It's been years,” Jason pulls him onto his lap on the floor, Leo’s scrawny legs on either side of Jason's muscular thighs “We’re not going anywhere”

“How do you know that?” Leo hisses, worried that even talking about it could set the cycle in motion again. Because he knows in his bones if the world decides they still have to play prophecy, if it goes back to storm or fire, Leo would do it all again. He would keep trying, chasing instead of running for the first time in his life

Jason trails his hands up from where they interlock, resting on Leo's upper arms cool and firm. He's studying Leo's face, that look of devotion back in his eyes. Because as much as Leo denies it, as much as he pretends it's not there; Jason speaks best through action, and his actions have been telling Leo that he loves him back for a long time.

It scares Leo, more than a little bit.

“I don't,” Jason confesses “I don't know that. But we're here now?”

“Is that what Piper was saying?”

“No,” he grins, that one that shows a single canine and makes his scar pull attractively “She's back to cussing us out in frustration”

“So same old?”

“Same old,” Jason licks his lips again “But she mentioned something, about three being the lucky number. It got me thinking”

“About us?”

“About us”

Six years since the first death, three years since the last one.

“What about us?” Leo presses, voice quiet like maybe this time something larger than them won't hear

“That it's been so long,” Jason's gaze is intense on his face “That we’re still here. That we can have, more”

“More?”

“Leo” his hands are on his shoulders, solid and sure, he's getting lost in the possibility of those blue eyes “I want more, more of us”

It's the first time they've spoken about it, out loud. It almost blows Leo over.

He can't help it, Leo kisses him. Two asteroids in the same gravitational field, slamming into each other and becoming something new. A planet, a moon or star, it didn't matter as long as they were together

Jason clutches at Leo like he can't believe he's real, like that time when Leo had just gotten him back for good. His grip was tight and rough, first clutching at his upper arms, then pulling him in impossibly tighter by the waist until one hand made it up to the nape of Leo's neck to hold on. Leo opens wider, his hold on the other man's jaw pulling him closer as Jason groans

When they reluctantly separate for oxygen, faces close and breathing the same air, Leo can feel himself trembling

“Leo” Jason breaths “Leo Leo Leo”

“M’ right here” he breaths back, voice soft like it would break the bubble there in, tell the fates they broke spades, and Jason brings him into the next kiss as desperate as the first

They kiss like that for a while, trying to merge the shattered remains of their collision into their new celestial body together. Bruising grips on each other, mouths only separating to grasp for air. Leo feels drunk on the other man, the feel of him and the smell of heat lightning, the pattern of his heartbeat against his own. Alive and whole, safe in his arms.

Leo eventually has to pull away as he overheats. He brings his face as far away as he can to pant out into the open air, the temperature of his breath is visible and fire licking up his face and into his hair. Jason isn't detoured, pressing his face into Leo's neck. He licks a long stripe against the femoral artery, nips under his jaw, and then presses his nose hard against his pulse point.

Leo’s being reeled back in my strong arms before he's done venting out the heat. He can feel how his internal temperature is scalding, but Jason acts like he's desperate to get broiled alive. He has one arm around Leo's waist and the other snaking up his shirt, hand splayed between his wing bones holding him as close as he can. Leo turns his face away to continue to try and pant out the heat, sucking the cooler night air into his lungs and letting his breath steam out of him. That just gives Jason more access to his neck, and Leo can't stifle the low moan that's forced out of him when the blond clamps his teeth around where his collarbone dips from his shoulder and sucks.

“Jace,” he pants out, he's going to catch fire at this point “Jace, Jason please”

Jason whines again, one of the feral noises he does high and desperate, and goes back to nipping. Leo has to grab the other man by the hair to pull him back so he can let his face catch fire again, the only part of his body not flush with him. Jason doesn't look afraid, pupils blown wide and expression filled with awe. A few sparks of static dance between the strands of his blond hair, one inside his open and panting mouth. As soon as Leo stops smoking Jason is back to kissing him

“I'm gonna burn you” Leo whines into his mouth

“No you won't,” Jason says back just as close, the blind trust and longing make Leo moan into him

“You won't” Jason continues, kissing back down Leo's neck and towards his chest. Leo takes the opportunity to throw his head back and try and vent more heat “You won't, I'm always safe with you”

“Fuck, Jace”

“Gods, you're here” Jason pleads, his forehead pushing hard above Leo's heart. He can probably feel his rabbiting pulse against his face, he's still trying to pull Leo closer “You're really here like this , I'm not dreaming “

Leos folds himself over the curl of Jason's body, hand moving over his hair and neck and back, energy trapped in their dwindling momentum

“I'm here” he pants “You're here too”

“I'm here,” Jason says back looking up to meet Leo's eyes but not taking his face off his heart. His cheek is pressed in against Leo's chest, eyes looking up and pleading. Leo smooths his hands through Jason's hair and then down the side of his jaw and back up again. The blond lets out a sigh and folds back into Leo's chest. His face pressed above his heart, breathing him in through his nose.

They stay like that for a while, curled and clutched close. Leo's hand in Jason's hair and Jason's face in Leo's chest, until Leo folds down to rest his forehead against the top of Jason's head, breathing him in in return

A single celestial body orbiting a gravitational pull. Together in the new planet of their own making

#valgrace#leo valdez#jason grace#getting together#good future au#fic#my fic#pjo#pjo hoo toa#percy jackson

41 notes

·

View notes

Text

🚀 𝗪𝗵𝘆 𝗝𝗼𝗶𝗻 𝗔𝘄𝗶𝗹𝗹𝗶 𝗚𝗿𝗼𝘂𝗽?🌟

👉 𝗚𝗿𝗼𝘄𝘁𝗵 𝗢𝗽𝗽𝗼𝗿𝘁𝘂𝗻𝗶𝘁𝗶𝗲𝘀: Your career, your growth. We invest in YOU with training, mentorship, and promotions.

💡 𝗜𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝘃𝗲 𝗪𝗼𝗿𝗸: Work on exciting projects that challenge you to think big and make an impact.

🌍 𝗜𝗻𝗰𝗹𝘂𝘀𝗶𝘃𝗲 𝗖𝘂𝗹𝘁𝘂𝗿𝗲: Join a team that values diversity, collaboration, and your unique voice.

💼 𝗖𝗼𝗺𝗽𝗲𝘁𝗶𝘁𝗶𝘃𝗲 𝗣𝗲𝗿𝗸𝘀: Market-leading pay, benefits, and recognition programs to celebrate your success.

🕊️ 𝗪𝗼𝗿𝗸-𝗟𝗶𝗳𝗲 𝗕𝗮𝗹𝗮𝗻𝗰𝗲: Flexible schedules and wellness support because your happiness matters.

✨ 𝗕𝗲 𝗣𝗮𝗿𝘁 𝗼𝗳 𝗦𝗼𝗺𝗲𝘁𝗵𝗶𝗻𝗴 𝗕𝗶𝗴𝗴𝗲𝗿: We’re shaping the future—and you can be part of it!

💬 Ready to grow, thrive, and make a difference? Join us today! 🔗 https://awilli-ag.ch/

0 notes

Text

Describe how orbital welding works and what it is - Arcellor Controls

In the realm of industrial manufacturing, achieving flawless welds is paramount to ensure the durability and integrity of pipeline systems. With advancements in technology, orbital welding has emerged as a game-changer, revolutionizing the way pipe connections are made.

At Arcellor Controls India, we take immense pride in being the leading Orbital Weld Fittings manufacturers, suppliers, stockists, and exporters in India. Our extensive range of fittings, including 90 Elbow, Equal Tee Orbital Fittings, and Reducing Tee Orbital Fittings, caters to diverse project requirements, and we offer a wide selection of materials, standards, sizes, and grades to meet our clients' specific needs.

In this blog post, we will delve into the world of orbital welding, exploring its workings, benefits, and the exceptional range of orbital weld fittings provided by Arcellor Controls India.

What is Orbital Welding

Orbital welding is an automated welding process that revolutionizes the way pipes and tubes are joined. It utilizes an orbital welder, a specialized machine capable of rotating an electrode around the workpiece with precise control. This orbital motion enables the electrode to travel along the circumference of the joint, creating a continuous and uniform weld.

The orbital welder operates by enclosing the welding area in a chamber, protecting it from external contaminants. This controlled environment, combined with the consistent motion of the electrode, ensures the production of high-quality welds with minimal defects. The result is superior strength, integrity, and longevity of the pipe connections.

How Orbital Welding Works!..

To understand how orbital welding works, let's explore its fundamental components and the welding process involved.

Orbital welding relies on specialized equipment, including a power supply, welding head, and control system. The power supply provides the necessary energy for the welding process, while the welding head carries out the actual welding operation. The control system ensures precise control over the welding parameters.

Before initiating the weld, proper joint preparation is crucial. This involves cleaning the joint surfaces thoroughly and aligning the components accurately. By ensuring optimal joint conditions, orbital welding can deliver superior results.

Once the joint is prepared, the welding head rotates around it, following a predefined path. Simultaneously, the welding head feeds the filler material, ensuring a continuous and uniform weld. The automated nature of orbital welding eliminates human error, leading to consistent weld quality.

Types of Orbital Weld Fittings

90 Elbow Orbital Fittings: These fittings enable smooth directional changes in pipeline systems. They offer excellent flow characteristics and are widely used in applications that require efficient fluid transportation.

Equal Tee Orbital Fittings: Equal tees allow the division of flow or the convergence of multiple pipelines. They maintain equal pressure and fluid distribution, ensuring optimal performance in complex piping systems.

Reducing Tee Orbital Fittings: Reducing tees provide a transition between different pipe sizes, allowing for seamless connections between pipes with varying diameters. They ensure smooth flow transitions without compromising the structural integrity of the system.

Benefits of Orbital Welding

Orbital welding offers a range of benefits that make it the preferred choice for critical pipe connections:

Accuracy and Repeatability: The automated nature of orbital welding eliminates human error, ensuring precise weld placement and consistent results across multiple welds. This accuracy is particularly vital in industries where even minor deviations can have significant consequences.

Reliability and Consistency: Orbital welding delivers consistent weld quality, regardless of the operator's skill level or fatigue. This reliability ensures uniformity throughout the project and minimizes the need for rework or repairs.

Defect Reduction: By providing a controlled welding environment, orbital welding reduces common weld defects such as porosity, undercutting, and uneven penetration. This results in stronger and more reliable pipe connections, reducing the risk of leaks or failures.

Orbital Welding Uses

Orbital welding finds extensive application in diverse industries. In aerospace engineering, this welding technique is employed to join components on aircraft and rockets to ensure safe flight operations. The food and beverage production industry benefits from orbital welding as it provides secure connections for pipes conveying water and beverages. The pharmaceutical manufacturing and chemical industries also rely on orbital welding for precision and stringent quality control requirements. Moreover, military defense contractors use it extensively for its ability to produce high-quality welds on sensitive parts like weapons systems components and armored vehicles.

Choose Arcellor Controls India for Orbital Weld Fittings!

When it comes to selecting reliable and high-quality orbital weld fittings, Arcellor Controls India is your trusted partner. As the leading orbital weld fittings manufacturer, supplier, stockist, and exporter in India, we offer a comprehensive range of products that cater to diverse project requirements.

Here's why you should choose us:

Extensive Range of Fittings: At Arcellor Controls India, we understand that each project has unique specifications. That's why we provide a wide selection of orbital weld fittings, including 90 Elbows, Equal Tee Orbital Fittings, and Reducing Tee Orbital Fittings. With various types, of materials like Stainless Steel, Alloy, Carbon Steel C.S., Duplex, Super Duplex, Hastelloy, Monel, and Inconel, standards, specifications, sizes, and grades available, you can find the perfect fit for your upcoming projects.

Uncompromising Quality: We take immense pride in delivering products of exceptional quality. Our orbital weld fittings are manufactured using top-grade materials and adhere to stringent industry standards. With our commitment to quality, you can trust that our fittings will provide reliable and durable pipe connections.

Precision through Orbital Welding: Our orbital weld fittings are specifically designed for use with orbital welding technology. By leveraging the precise and consistent welds achieved through orbital welding, we ensure that our fittings deliver robust and leak-proof connections. This advanced welding technique guarantees the integrity of your piping systems.

Customization Options: We understand that every project has unique requirements. That's why we offer customization options for our orbital weld fittings. Whether you need specific dimensions, materials, or finishes, our team is dedicated to meeting your exact specifications. We work closely with our clients to provide tailored solutions that perfectly fit their project needs.

Competitive Pricing: At Arcellor Controls India, we believe in providing the best value to our customers. Our orbital weld fittings are competitively priced without compromising on quality. We strive to offer cost-effective solutions, ensuring that you receive exceptional products at a competitive price point.

Global Export Expertise: Our reach extends beyond the borders of India. We are proud exporters of orbital weld fittings to various countries, including Oman, Qatar, USA, Germany, UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia. Our global export expertise ensures that our international clients receive the same level of quality and service that we provide domestically.

Applications of Orbital Welding Fittings

Orbital welding fittings have gained significant popularity and recognition across various industries due to their exceptional quality, reliability, and efficiency. These fittings, manufactured by Arcellor Controls India, find extensive applications in diverse sectors, offering reliable and robust pipe connections.

Let's explore some of the key industries where orbital welding fittings are widely used:

Pharmaceutical and Biotechnology

Food and Beverage

Petrochemical and Oil & Gas

Power Generation

Semiconductor Manufacturing

HVAC and Refrigeration

Automotive, Aerospace, and so on

Final Thoughts!..

Orbital welding stands as a game-changer in the field of pipe connections, delivering unmatched accuracy, reliability, and quality. Arcellor Controls India emerges as the leading orbital tube welding supplier, manufacturer, stockist, and exporter offering a comprehensive range of fittings to meet diverse project requirements. With a commitment to excellence and adherence to international standards, Arcellor Controls India is the go-to choice for perfect pipe connections.

Explore the exceptional range of orbital tube welding and elevate your projects to new heights of precision and performance!

0 notes

Text

Enhancing Industrial Efficiency: Welding Components on Nikit Engineers’ Mini Profile Welder

n the realm of industrial automation, precision and efficiency are paramount. Nikit Engineers Welding Automation and Robotics Solutions India have been at the forefront of revolutionizing industrial processes with their cutting-edge technologies. Among their impressive array of offerings, the Mini Profile Welder stands out as a versatile solution for welding various industrial components with utmost precision. Let’s delve into the diverse components welded on this remarkable machine and explore how they contribute to enhancing industrial efficiency.

Stellite Welding

Stellite, known for its exceptional wear resistance and durability, is a vital component in many industrial applications, particularly in high-temperature and corrosive environments. Welding Stellite requires precision and expertise to ensure a strong bond without compromising its properties. The Mini Profile Welder, equipped with advanced welding capabilities, ensures seamless welding of Stellite components, guaranteeing optimal performance and longevity in industrial settings.

youtube

Bellow with Flange

Bellow assemblies find widespread use in various industries for their ability to absorb thermal expansion, vibration, and misalignment. Welding bellows with flanges demands meticulous attention to detail to maintain structural integrity and sealing effectiveness. With its precise control and customizable welding parameters, the Mini Profile Welder ensures flawless welding of bellows with flanges, meeting the stringent quality standards required in industrial applications.

youtube

Spin Tube

Spin tubes play a crucial role in diverse industrial machinery, facilitating smooth rotational motion and power transmission. Welding spin tubes demands high precision to achieve uniformity and strength along the weld joints. The Mini Profile Welder’s advanced welding technology, coupled with its automated processes, enables consistent and reliable welding of spin tubes, contributing to the seamless operation of industrial equipment.

youtube

Copper Busbar

Copper busbars are essential components in electrical power distribution systems, requiring robust welding techniques to ensure efficient current flow and conductivity. Welding copper demands specialized expertise due to its high thermal conductivity and susceptibility to oxidation. The Mini Profile Welder’s advanced welding capabilities, including precise heat control and shielding gas management, facilitate accurate and reliable welding of copper busbars, ensuring optimal electrical performance in industrial applications.

youtube

Castor Wheel Brackets

Castor wheel brackets play a critical role in facilitating mobility and maneuverability in various industrial setups. Welding these brackets demands structural integrity and stability to withstand dynamic loads and harsh operating conditions. The Mini Profile Welder’s precision welding technology ensures strong and durable welds on castor wheel brackets, providing reliable support for equipment mobility in industrial environments.

youtube

Bellow Nut Assembly

Bellow nut assemblies are integral components in mechanical systems, providing adjustable support and sealing capabilities. Welding bellow nut assemblies requires precision to maintain dimensional accuracy and thread integrity. With its advanced welding features and customizable parameters, the Mini Profile Welder enables seamless welding of bellow nut assemblies, ensuring optimal functionality and performance in industrial applications.

youtube

In conclusion, the Mini Profile Welder by Nikit Engineers Welding Automation and Robotics Solutions India offers a comprehensive solution for welding a diverse range of industrial components with precision and efficiency. By seamlessly welding components such as Stellite, bellows, spin tubes, copper busbars, castor wheel brackets, and bellow nut assemblies, this innovative machine enhances industrial productivity and reliability, setting new standards in welding automation technology. With its advanced features and robust performance, the Mini Profile Welder continues to revolutionize industrial welding processes, driving progress and innovation across various sectors.

Why Choose Nikit Engineers for Mini Profile Welding Automation?

Tailored Solutions: At Nikit Engineers, we understand that every welding project is unique. Our automation solutions are customized to suit the specific needs and intricacies of profile welding applications. From simple profiles to complex geometries, our systems adapt to the nuances of each project.

Expertise that Matters: Backed by years of experience, our team of engineers is well-versed in the intricacies of profile welding. We provide comprehensive support from the initial consultation to the implementation phase, ensuring a seamless transition to automated welding processes.

Robust Training Programs: Transitioning to automation can be daunting, but not with Nikit Engineers. We offer robust training programs to empower your workforce with the skills needed to operate and maintain our automated welding systems. Our goal is to make the adoption of automation a smooth and positive experience for your team.

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

At Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

#robotics solutions#welding automation#orbital welding#circular welding#Stainless Steel Welding#Profile Wedling#Youtube

0 notes

Text

US space officials do not like to talk about the perils of flying astronauts on the aging International Space Station, elements of which are now more than a quarter of a century old.

However, a new report confirms that NASA managers responsible for operating the space station are seriously concerned about a small Russian part of the station, essentially a tunnel that connects a larger module to a docking port, which is leaking.

Russian and US officials have known that this small PrK module, which lies between a Progress spacecraft airlock and the Zvezda module, has been leaking since September 2019. A new report, published Thursday by NASA's inspector general, provides details not previously released by the space agency that underline the severity of the problem.

New Details About the Leak

For example, in February of this year NASA identified an increase in the leak rate from less than 1 pound of atmosphere a day to 2.4 pounds a day, and in April this rate increased to 3.7 pounds a day. Despite years of investigation, neither Russian nor US officials have identified the underlying cause of the leak.

"Although the root cause of the leak remains unknown, both agencies have narrowed their focus to internal and external welds," the report, signed by Deputy Inspector General George A. Scott, states.

The plan to mitigate the risk is to keep the hatch on the Zvezda module leading to the PrK tunnel closed. Eventually, if the leak worsens further, this hatch might need to be closed permanently, reducing the number of Russian docking ports on the space station from four to three.

Publicly, NASA has sought to minimize concerns about the cracking issue because it remains, to date, confined to the PrK tunnel and has not spread to other parts of the station. Nevertheless, Ars reported in June that the cracking issue has reached the highest level of concern on the space agency's 5x5 "risk matrix" to classify the likelihood and consequence of risks to spaceflight activities. The Russian leaks are now classified as a "5" both in terms of high likelihood and high consequence.

At the time, NASA would not comment on, or confirm, the space agency's concerns about the risk matrix rating. However, the new report confirms the agency's concerns.

"In May and June 2024, ISS Program and Roscosmos officials met to discuss heightened concerns with the increased leak rate," the inspector general's report states. "The ISS Program subsequently elevated the Service Module Transfer Tunnel leak risk to the highest level of risk in its risk management system. According to NASA, Roscosmos is confident they will be able to monitor and close the hatch to the Service Module prior to the leak rate reaching an untenable level. However, NASA and Roscosmos have not reached an agreement on the point at which the leak rate is untenable."

An Uncertain Future in Low Earth Orbit

The report comes as NASA is considering the future of the space station. The US space agency and Russia have an agreement to continue flying the station through 2028, and NASA would like to extend operations to 2030. NASA had anticipated that it would agree to this extension more than a year ago, but as of yet no agreement has been finalized.

Once the station reaches the end of its life, NASA intends to transition its activities in low Earth orbit onto private space stations, and it has funded initial development work by Axiom Space, Northrop Grumman, Blue Origin, and Voyager Space. Northrop has since dropped out of the competition—determining that it would not be a profitable business. There is general uncertainty as to whether any of the private space station operators will be ready in 2030.

NASA's other potential option is extending the life of the space station beyond 2030, but this would require a lot of work to ensure the space station's structure remains viable and yet another extension agreement with Russia. The US partnership with that nation has been severely strained by Russia's invasion of Ukraine.

"Extending the ISS past 2030 will require significant funding to operate and maintain the station, acceptance of increased risk stemming from its components and aging structures, and assurances of continued support from NASA’s international partners," the new report states. “Further complicating matters is the likelihood that NASA may continue to face a flat or reduced budget, inflation, and supply chain challenges.”

14 notes

·

View notes

Text

Is it fair to say Tiber Septim nuked Alinor? - The nature of Numidium as a weapon

Reposted from r/teslore. Yes. It's completely fair.

Lately, I’ve read and participated in a bunch of arguments over

whether it’s right to compare Numidium to a nuclear weapon,

whether it caused nuclear-weapon level destruction in Tiber Septim’s conquering of Summerset.

I’ve seen the argument that if you go by official Bethesda sources only, there is nothing to support 1 & 2. It’s alleged that only Michael Kirkbride’s unofficial writings support this. Specifically, this post:

Numidium's siege of Alinor: It's not the Brass God that wrecks everything so much as it is all the plane(t)s and timelines that orbit it, singing world-refusals. The Surrender of Alinor happened in one hour, but Numidium's siege lasted from the Mythic Era until long into the Fifth. Some Mirror Logicians of the Altmer fight it still in chrysalis shells that phase in and out of Tamrielic Prime, and their brethren know nothing of their purpose unless they stare too long and break their own possipoints.

That’s a reflection on how the Numidium worked in Alinor by one of the devs who wrote parts of this story about Tiber Septim and Numidium. I think it influences Bethesda official lore (as we’ll see when we get to ESO) and will continue to do so. However, we’re going to put unofficial lore aside for this post, and take a look at what the official lore says about Numidium and whether it supports the nuclear weapon comparison.

Numidium of course doesn't work like a nuclear bomb. That's not what anyone means when they're comparing it to a nuclear bomb. They're comparing it to a similarly feared horrible weapon of mass destruction. For us, the nuclear bomb represents the worst weapon imaginable, for Third Era Tamriel, it’s much the same way.

There are not many sources on Tiber Septim’s invasion of Summerset. The Pocket Guide to the Empire, First Edition, which is one of the main Tiber-era sources, is written before the Armistice with Morrowind and the invasion of Summerset. The anti-Imperialism game Redguard is also pre-Numidium, with Tiber Septim’s deputies searching Dwemer ruins for weapons. We never hear the story of the invasion from a Summerset source. We’re stuck with some very vague references. We know Tiber Septim used Numidium to conquer Summerset, but what happened there?

The Pocket Guide to the Empire, Third Edition says,

Thus, the Dominion thrived until the coming of Tiber Septim. The conquest and assimilation of Summerset into the Empire is remembered by many a living Altmer with horror only partially diminished by time. Certainly, the pride of the people has never recovered.

People argue over whether the “horror only partially diminished by time” refers to the horrific nature of the Conquest or to Altmer horror at humans conquering them. I believe that, from what we know of Numidium, it’s both, but the source here doesn’t say outright.

During the War of the Isle in 3E 110, the Maormer of Pyandonea were very nearly successful in conquering their ancient enemy, and the Altmer had to call upon the aid of the Psijics and the Empire to help defend themselves.

The Dominion’s ability to defend itself was still not restored 110 years after Numidium.

So, given how scant our sources are on the use of Numidium in Summerset, we have to look at the general cultural memory and opinion of Numidium in Tamriel, and at the one time we get a detailed canon look at its use: the Warp in the West.

Sotha Sil, quoted in the Truth in Sequence, calls it “the walking horror.”

But most profane is this: the walking horror that bears the Name, NM. The Brass Tower of Vanity. The mindless guardian of the Nirn-Prior. The Antipodal-God-Thing that reigns on the darkest pole of the sacred Nirn-Sphere. Of all the threats to Tamriel Final, NM is the greatest. Anuvanna'si. The Daedra can be banished in thought, but NM must be sundered on Nirn. It is the welded knot at the center of Anu that must be untied. The God-Puzzle. The Mainspring Ever-Wound remains silent on this point. And where there is silence, there is great wisdom.

In Where You When the Dragon Broke? the tender to the Mane speaks

You did it again with Big Walker, not once, but twice! Once at Rimmen, which we'll never learn to live with.

What happened at Rimmen with Big Walker that the Khajiit can never learn to live with? Well, there's an official Bethesda Q&A promoting Morrowind from 1999 that makes the nuclear comparison clear

Jodenjone! Don' let Marshee lie to you about Big Walker. The Blades took It from here, sure, but they din' take It back to Cyrodiil and rebuild the thing. Talos, he "annexed" a swath of our bounty-land in Ana'quinal and cleared the Khajiiti out by force. There's where he built the Hall of Colossus—a mighty name for a secret testing warehouse—and that's where Big Walker was born. And that's why that part of our Elsweyr is still poisoned glow-rock, where no cats go. Ach, for the lunacy of you Wayward Folk!

"Poisoned glow-rock". It’s not just the fans comparing Numidium to a nuclear weapon It's clear that was the devs' intention here.

The horror of the Numidium is also the foundation of the main quest of Daggerfall. Throughout the Agent’s quest, s/he receives letters from various random people and factions in game detailing the Numidium’s reputation.

The first letter the Agent gets reads

You have probably not heard the fairy tale of Numidium, but you need to. The legend dates back to the earliest parts of the third era [sic]. Numidium was supposed to be a giant so big his hands could knock the moons from the sky. I do not recall from the stories whether Numidium was supposed to be good or bad, but the legends used to scare me as a child.

Followed by another letter:

Numidium was Tiber Septim's secret weapon in his bid for supreme power: a thousand foot tall automaton, a golem or an atronach of sorts powered by a gem called the Mantella. The Mantella was infused with the life orce [sic] of Tiber Septim's Imperial Battlemage, and with it, Septim crushed all who stood in his way. After the complete and total defeat of all his opponents, Septim began using Numidium to crush the neutral royal families of Tamriel so that he could enthrone only persons he knew to be loyal. His Imperial Battlemage was furious at this use of his creation, and fought to reclaim the Mantella.

The letter writers aren’t certain how it worked or what it did exactly - which matches Tiber Septim’s secrecy, Numidium’s immediate destruction after its first big use, and the nature of a time-breaking machine that messes with people’s recollections of how things happened. But they are sure that Numidium was a horror, a weapon of mass destruction unlike anything else.

The people of the Iliac Bay would soon get a front row seat to that horror.

The Warp in the West is the only time in canon that we get extensive details on the aftermath of Numidium’s use. As could be expected from the general fear of the Numidium in the above sources, the picture isn’t pretty. We don’t know exactly how Numidium would have functioned in Summerset, but we do know that Numidium works by breaking time. The clash of many different narratives and timelines in the Iliac Bay brought about massive losses of life and property, and huge environmental damage.

The shorter account of the Warp in the West is in the Pocket Guide to the Empire, Third Edition. Bolding of phrases attesting to the destructive force of the events mine.

In the year 417, however, the province redefined itself in a most mysterious way. They call the event the Miracle of Peace. On the 10th of Frostfall, a strange force exploded over the Iliac Bay, displacing armies and decimating whole territories. Though its nature is still unknown, most Bretons believe it was the ancient Gods who had once made High Rock their home scouring the land, making it whole once again. Though it was a painful process for most - the Miracle is sometimes spoken of as the Warp in the West - the result of it is a province that is more unified than it has ever been in modern history. Where once there were a hundred small squabbling kingdoms, today, just two decades after the Miracle, there are five.

Even the ever-optimistic PGE3 admits it was a catastrophe for those who lived through it, but claims the resulting hegemonies and peace were worth it.

The Book, The Warp in the West, which is a private Blades’ report on the event is less circumspect about the details.

Speaking of the official “Miracle of Peace”:

The catastrophic destruction of landscape and property and the large loss of life attending upon this miracle is understood to have been 'tragic, and beyond mortal comprehension.'

And

The other remarkable features of these events -- mass disappearances, armies mysteriously transported hundreds of miles or completely annihilated, titanic storms and celestial phenomena, apparent local discontinuities of time -- fit comfortably into the notion that these events are part of a vast, mysterious divine intervention.

Mass disappearances of people, armies annihilated, titanic storms: all these are part of the catastrophe caused by Numidium. The Blades agents on the scene had more details. I’m quoting the bits that specifically attest to the destruction and harm caused by Numidium.

The Blades have on file few reports from agents dating from the "Warp in the West" period. Most of our agents were lost in the initial dislocations, and others were lost in the confusion after the event.

Most Blades agents in the area died or vanished in the Warp. Others fell to the after-effects.